Welded steel tube for carrier roller and manufacturing method thereof

A technology for welding steel pipes and steel pipes, applied in the field of welded steel pipes for idlers and their manufacturing, can solve the problems of insufficient control of forming accuracy, unable to meet the production requirements of idlers, etc., to increase the difficulty of rolling, inhibit the recovery of austenite, The effect of increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

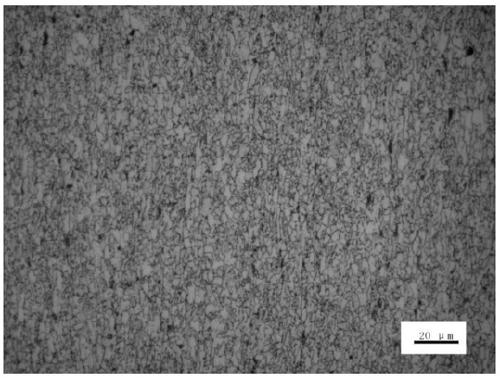

[0028] This embodiment provides a welded steel pipe for idlers, please refer to figure 1 , the composition mass percentage of the welded steel pipe is C: 0.050% to 0.150%, Si: 0.05% to 0.26%, Mn: 0.5% to 1.50%, P: ≤0.010%, S: ≤0.005%, Al: 0.02% ~0.05%, Cr: 0.1%~0.5%, Nb: 0.01%~0.05%, V: 0.01~0.05%, Ti: 0.01%~0.05%, the rest is Fe and unavoidable impurities, and the carbon equivalent Ceq≤0.4 %, cold crack sensitivity index Pcm≤0.2%.

[0029] Further, the mass percentage of Nb+V+Ti in the welded steel pipe is 0.05%-0.10%.

[0030] Specifically, the composition mass percentage of the steel strip is: the proportion of C is 0.050% to 0.150%, and C is one of the most economical strengthening elements in steel. If the C content is too high, the desired elongation cannot be ensured. value, the cold formability, low temperature toughness and weldability of strip steel are also reduced, if the carbon content is too low, the wear resistance of the matrix will be affected, therefore, co...

Embodiment 2

[0036] This embodiment provides a manufacturing method of welded steel pipes for idlers, please refer to Figure 2-4 , the method includes:

[0037] Step 10: Performing a hot rolling process on the steel billet raw material to obtain a hot-rolled steel strip as the steel pipe raw material, the composition mass percentage of the steel billet raw material is C: 0.050% to 0.150%, Si: 0.05% to 0.26%, and Mn: 0.5% to 1.50% %, P: ≤0.010%, S: ≤0.005%, Al: 0.02%~0.05%, Cr: 0.1%~0.5%, Nb: 0.01%~0.05%, V: 0.01~0.05%, Ti: 0.01%~ 0.05%, and Nb+V+Ti is 0.05%~0.10%, the rest is Fe and unavoidable impurities, wherein, the hot rolling process includes:

[0038] Step 101: heating and keeping warm the billet raw material, the heating temperature is 1180-1260°C, and the holding time is 160-200min;

[0039] Step 102: Roughly rolling the heated billet raw material to obtain an intermediate slab, the exit temperature of the rough rolling is 1020-1060°C;

[0040] Step 103: Hot rolling the interme...

Embodiment 3

[0058] In order to understand more clearly a kind of welded steel pipe for idlers provided by the embodiment of the present invention and its manufacturing method, please refer to figure 2 , the embodiments of the present invention will be described in detail below with specific examples.

[0059] In the embodiment of the present invention, the size of the pipe is selected to be 60*2.2mm, and the chemical ratio of each element of the billet raw material is C: 0.06%, Si: 0.15%, Mn: 1.5%, P: 0.008%, S: 0.003%. , Al: 0.035%, Cr: 0.3%, Nb: 0.05%, V: 0.02%, Ti: 0.03%, and the rest are Fe and unavoidable impurities. Wherein the mass percentage of Nb+V+Ti is 0.08%, ranging from 0.05% to 0.10%.

[0060] The billet raw material first undergoes hot rolling process: the thickness is 2.2mm, the furnace temperature is 1250°C, the furnace time is 195min, the rough rolling exit temperature is 1060°C, the intermediate billet thickness is 32mm, the final rolling temperature is 900°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com