Steel tube used for hollow stabilizer bar of automobile and manufacturing method of steel tube

A manufacturing method and technology for a stabilizer bar, which are applied in the field of steel pipes for hollow stabilizer bars for automobiles and the manufacturing field thereof, can solve the problems of high manufacturing cost and unsatisfactory torsional fatigue performance of products, and achieve low price, ensure anti-torsion fatigue performance, and ensure cooling The effect of bend formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

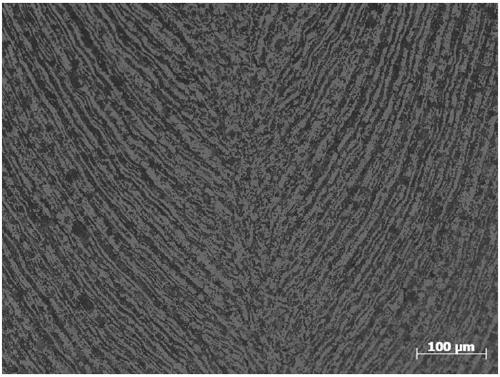

Image

Examples

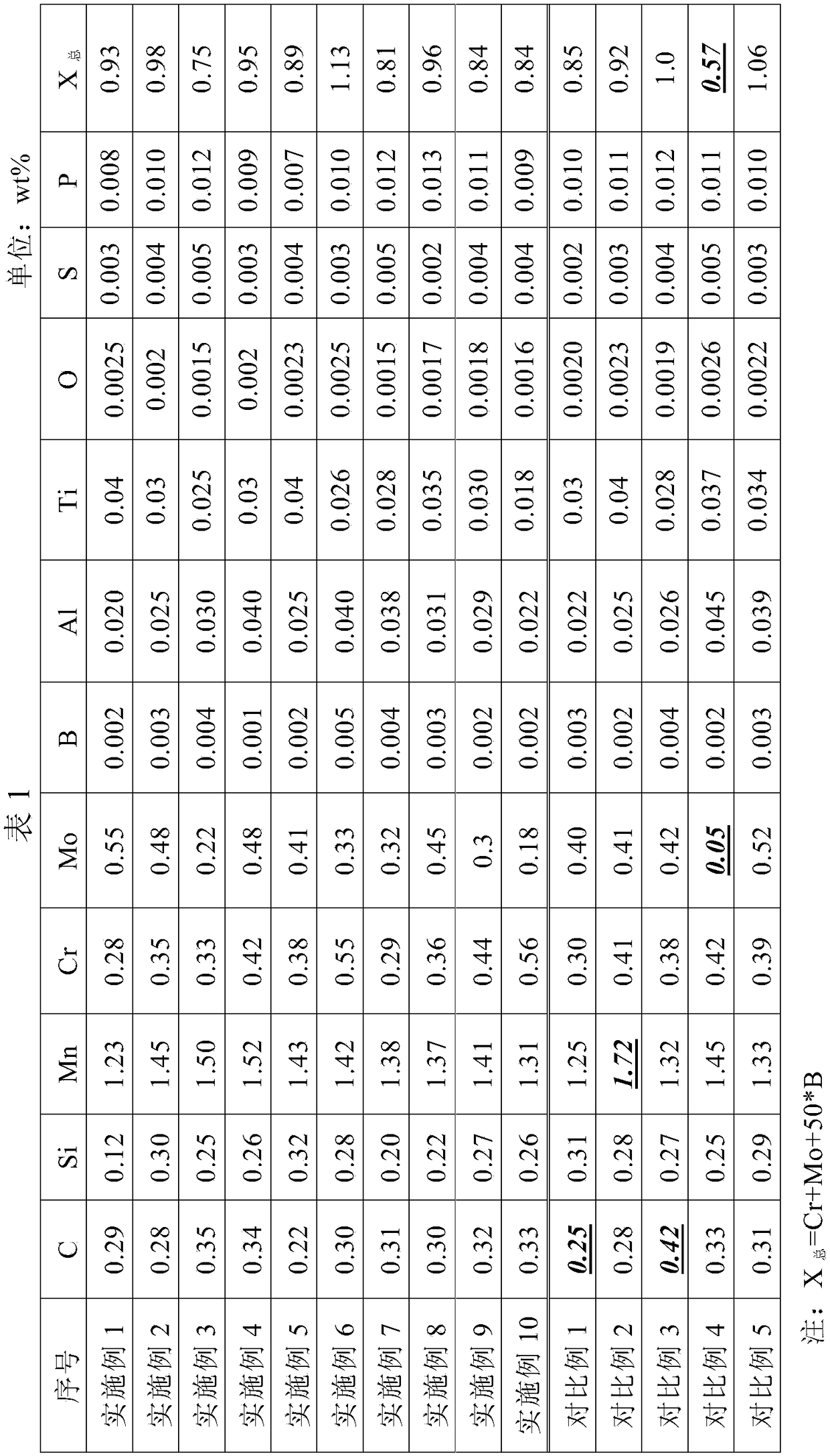

Embodiment 1-10 and comparative example 1-5

[0052] Manufacture steel pipe 1-10 for automobile hollow stabilizer bar of the present invention and comparative example 1-5 according to the following steps, and it comprises steps as follows:

[0053] (1) Carry out smelting, casting and rolling coils according to the mass percentage ratio of the chemical elements shown in Table 1, the coiling temperature of the coils is 780-900°C;

[0054] (2) Uncoiling and stripping the coil;

[0055] (3) The mother tube is obtained by welding by high-frequency resistance welding, the internal and external burrs are removed, and the temperature of the on-line induction heat treatment after welding is 550-800 °C;

[0056] (4) Carry out pickling, phosphating and saponification to the welded mother pipe;

[0057] (5) Use cold drawing or cold rolling to carry out cold processing to the finished product size. The elongation coefficient of each cold processing is 1.3-1.8. Between each cold processing, an intermediate heat treatment process of 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com