Automobile beam steel with tensile strength of 550MPa and preparation method for automobile beam steel

A technology of automobile girder steel and tensile strength, which is applied in the field of metallurgy, can solve the problems of high cost of microalloying, increase of coiler load, and reduced production efficiency, so as to improve mechanical properties, qualified cold bending performance, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

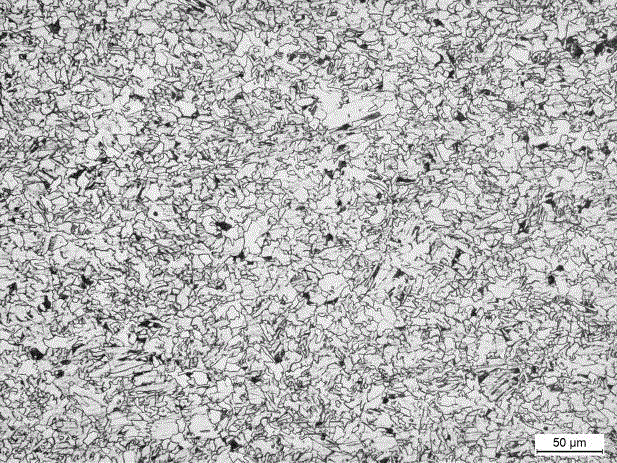

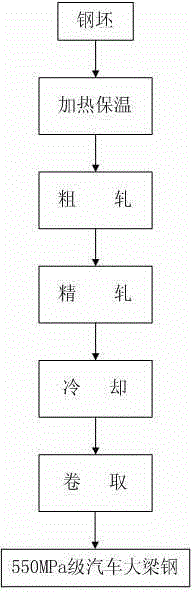

[0023] Preparation of automobile frame steel with a thickness of 3mm

[0024] (1) Heat a steel slab with a thickness of 150mm to 1200°C and hold it for 2.5 hours. The chemical composition of the steel slab is: C: 0.04%, Si: 0.05%, Mn: 1.2%, S: 0.01%, P: 0.02 %, Als: 0.02%, Ti: 0.02%, the balance is Fe and unavoidable impurities;

[0025] (2) Roughly rolling the heated slab, the rolling temperature is 1130°C, rolling 5 passes, the average reduction rate of each pass is 23.2%, and the intermediate billet with a thickness of 40mm is obtained;

[0026] (3) Carry out finish rolling on the intermediate slab, the starting rolling temperature is 1000°C, rolling 7 passes, the average reduction rate of each pass is 30.9%, and the final rolling temperature is 910°C to obtain a strip with a thickness of 3mm;

[0027] (4) Perform intensive front-stage cooling on the strip at a cooling rate of 40°C / s, and coil after cooling at a coiling temperature of 600°C to obtain automobile frame steel...

Embodiment 2

[0030] Preparation of automobile frame steel with a thickness of 5.75mm

[0031] (1) Heat a steel slab with a thickness of 150mm to 1250°C and hold it for 2 hours. The chemical composition of the steel slab is: C: 0.12%, Si: 0.35%, Mn: 0.5%, S: 0.006%, P: 0.012% , Als: 0.032%, Ti: 0.04%, the balance is Fe and unavoidable impurities;

[0032] (2) Roughly rolling the heated slab, the rolling start temperature is 1180°C, rolling 5 passes, the average reduction rate of each pass is 28.5%, and the intermediate billet with a thickness of 28mm is obtained;

[0033] (3) Carry out finish rolling on the intermediate slab, the starting rolling temperature is 960 ° C, rolling 7 passes, the average reduction rate of each pass is 20.2%, and the final rolling temperature is 860 ° C to obtain a strip with a thickness of 5.75 mm;

[0034] (4) Perform intensive front-stage cooling of the strip at a cooling rate of 30°C / s, and coil after cooling at a coiling temperature of 620°C to obtain autom...

Embodiment 3

[0037] Preparation of automobile frame steel with a thickness of 7.75mm

[0038] (1) Heat a billet with a thickness of 150mm to 1220°C and hold it for 2 hours. The chemical composition of the billet is: C: 0.1%, Si: 0.2%, Mn: 1%, S: 0.015%, P: 0.012% , Als: 0.05%, Ti: 0.03%, the balance is Fe and unavoidable impurities;

[0039] (2) Roughly rolling the heated slab, the rolling temperature is 1160°C, 5 passes, the average reduction rate of each pass is 24%, and the intermediate billet with a thickness of 38mm is obtained;

[0040] (3) Carry out finish rolling on the intermediate slab, the starting temperature is 960°C, rolling 7 passes, the average reduction rate of each pass is 20.3%, and the final rolling temperature is 870°C to obtain a strip with a thickness of 7.75mm;

[0041] (4) Perform intensive front-stage cooling on the strip at a cooling rate of 30°C / s, and coil after cooling at a coiling temperature of 720°C to obtain an automobile frame steel with a thickness of 7.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com