Three-axis real-time tracking welding device capable of conducting rotary symmetric welding

A technology of real-time tracking and rotational symmetry, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of no automatic adjustment of welding angle, difficulty in ensuring welding symmetry, high equipment cost, etc., to achieve adaptability and practicability Strong, improve welding quality, good welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

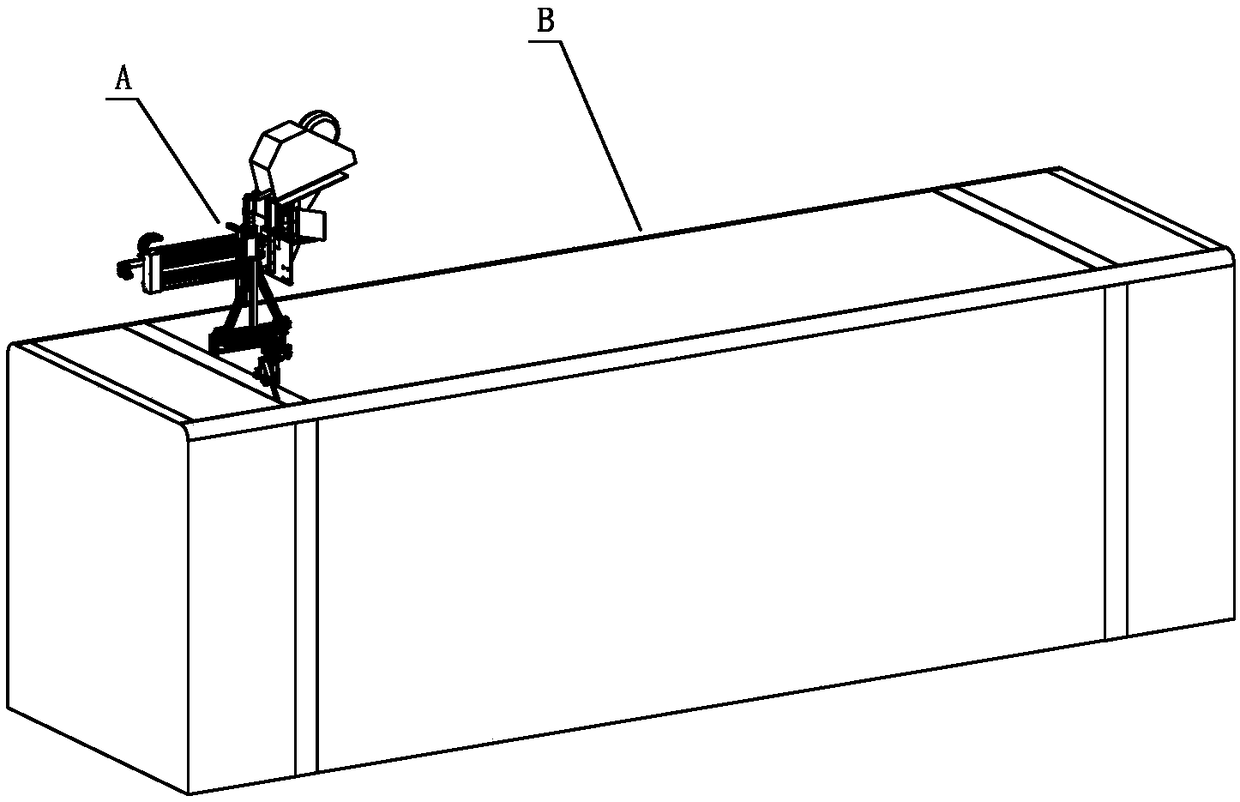

[0032] see Figure 1-Figure 3 , the product to be welded involved in the present invention is a special refrigerator B, and the three-axis real-time tracking welding device A is used to perform welding operations for the special refrigerator B;

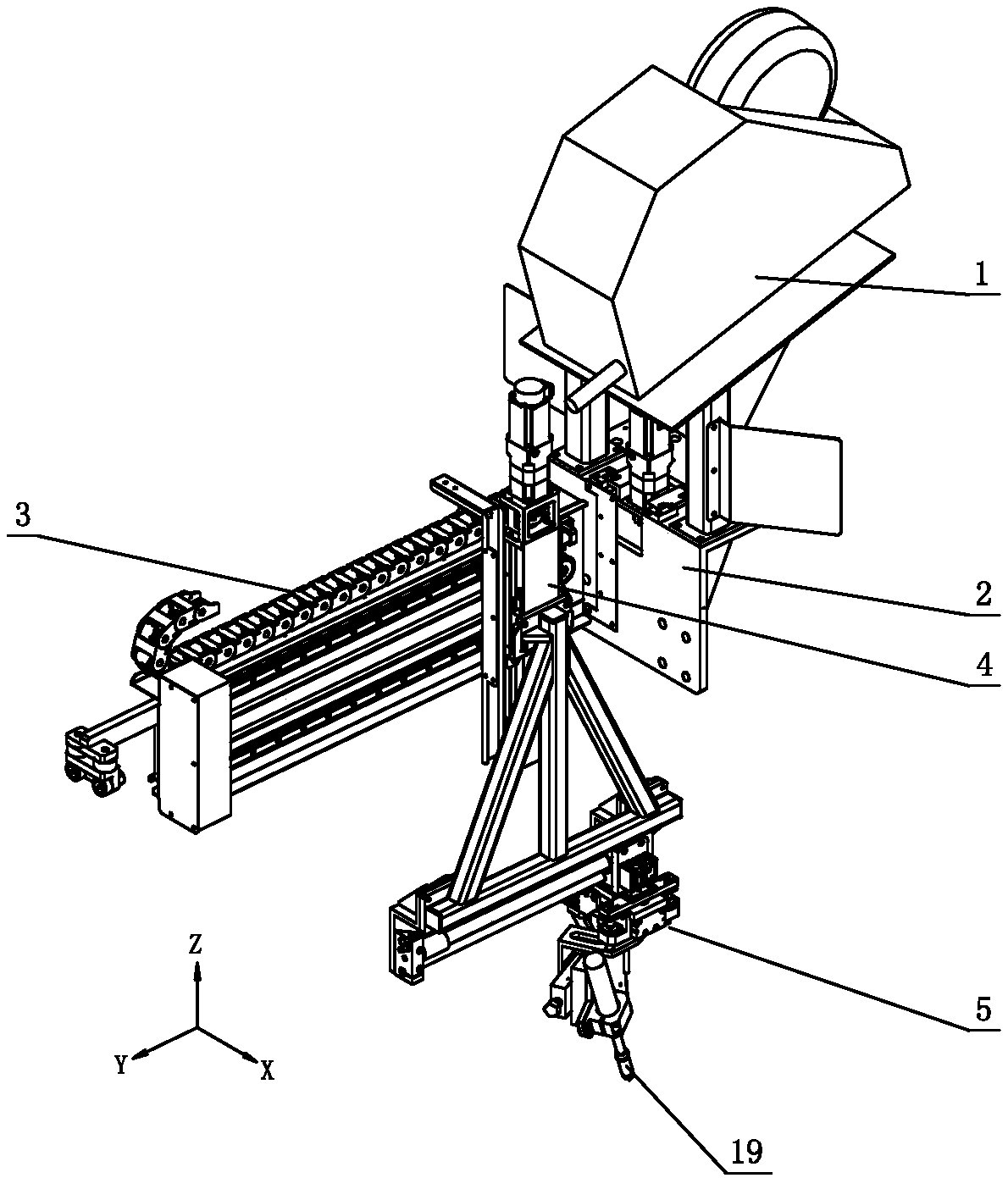

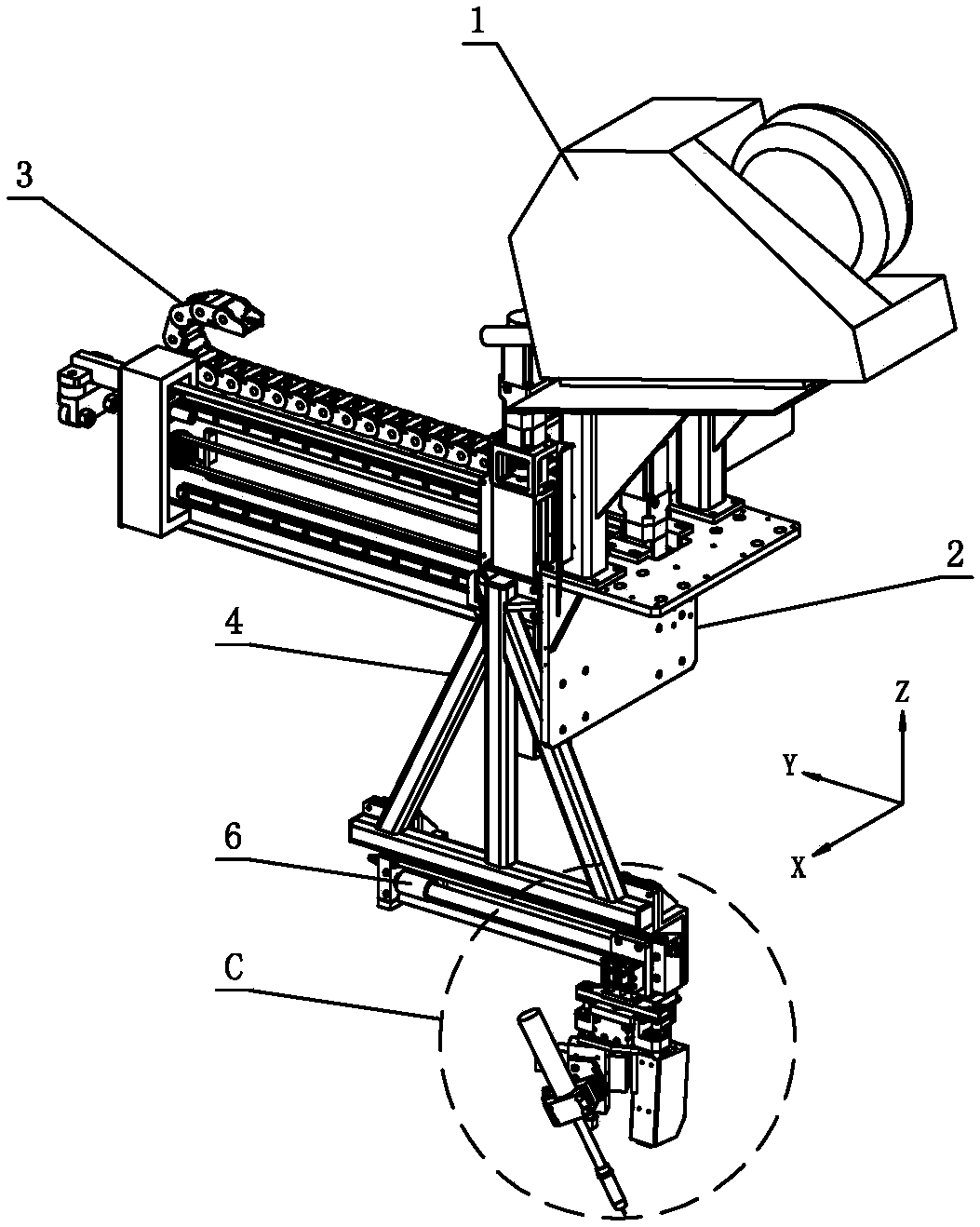

[0033] Among them, the three-axis real-time tracking welding device A capable of rotationally symmetrical welding includes

[0034] A wire feeder 1 for supplying welding wire for welding work;

[0035] Welding torch 12, the execution element of the welding process;

[0036] Laser tracking device 7, real-time scanning welding seam, to ensure welding accuracy;

[0037] Axial drive mechanism for driving the welding torch 12 and / or the laser tracking device 7 to move relative to the equipment body along the X-axis and / or Y-axis and / or Z-axis;

[0038]The rotating mechanism 5 is at least used to drive the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com