Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "No flow phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

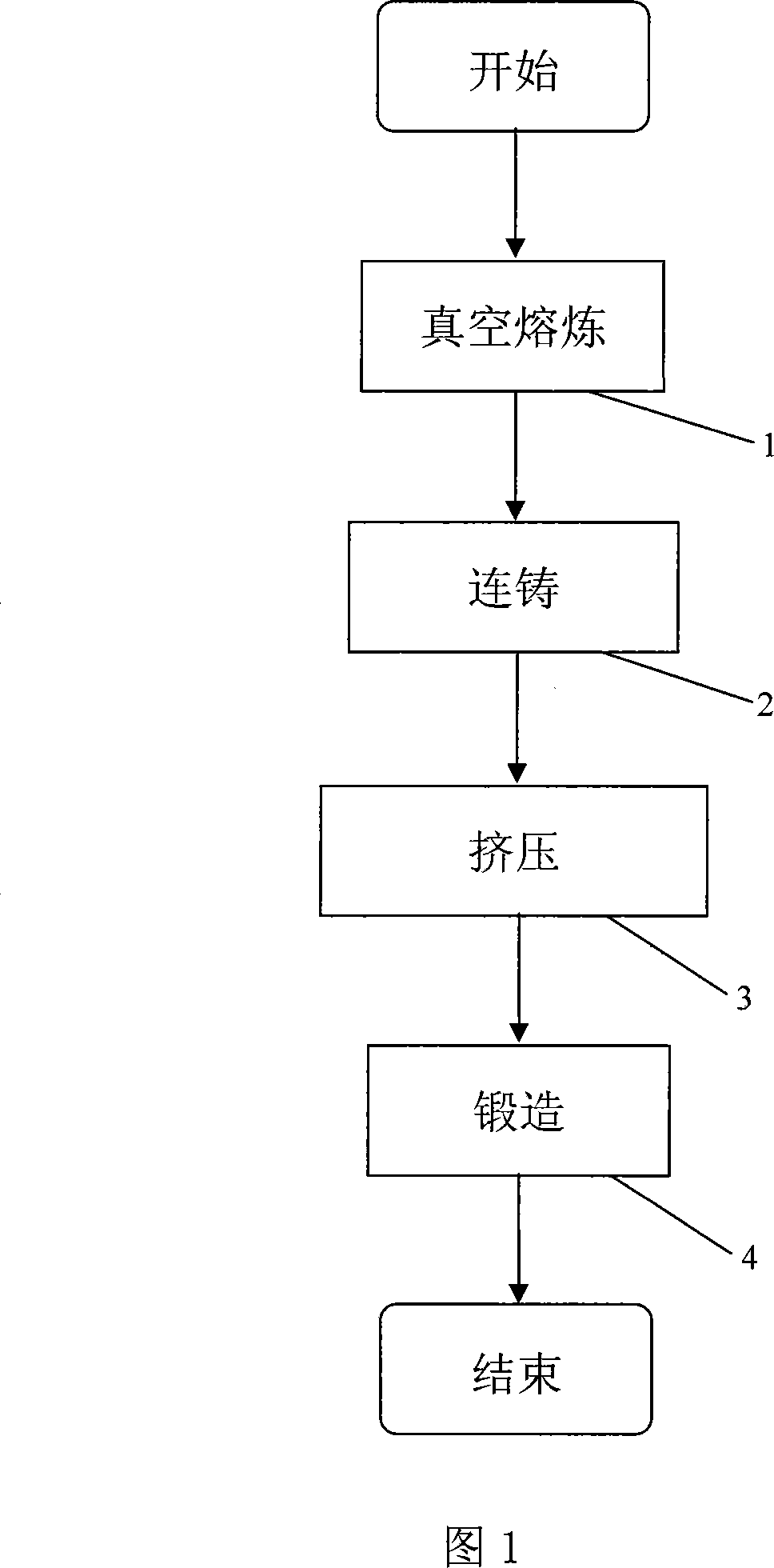

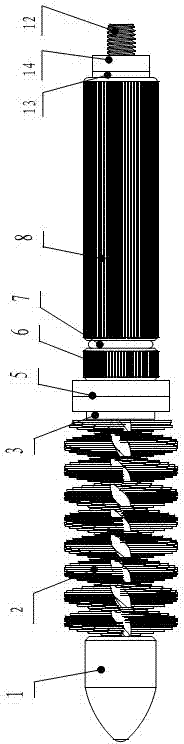

Technique for processing high-strength high-tractility magnesium alloy member

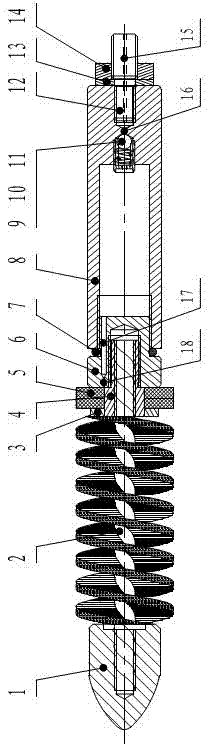

InactiveCN101121980AAvoid secondary oxidationGuarantee casting safetyExtrusion control devicesSteering controlElectromagnetic pump

The invention discloses a technology of processing a magnesium alloy with high intensity and flexibility, which subsequently includes vacuum melting, continuous casting, extrusion, forging and such procedures. The invention reasonably matches the solution body composition and the metamorphism liquid during casting process, and the grains are refined through the chilling action of a crystallizer at first; the magnesium alloy liquid is transmitted by an electromagnetic pump so as to prevent secondary oxidation and ensure safety in casting of the magnesium alloy; and then further refining the grains through electromagnetic mixing power, large ratio extrusion and heat treatment secondary crystallization, which effectively ensures tiny enough isometric crystals can be obtained from the alloy microstructure. The magnesium alloy elements of the automotive steering control arms, support elements of motorcycles and bicycles, can be obtained for the first time by the improvement, which are fully filled, good in surface quality, fine and even in grain size, reasonable in streamline distribution and without disordered streamline, vortexing and draining phenomena. The invention combines a plurality of technological processes into a production cycle, which reduces the turnover links, saves energy and reduces cost.

Owner:王仁辉

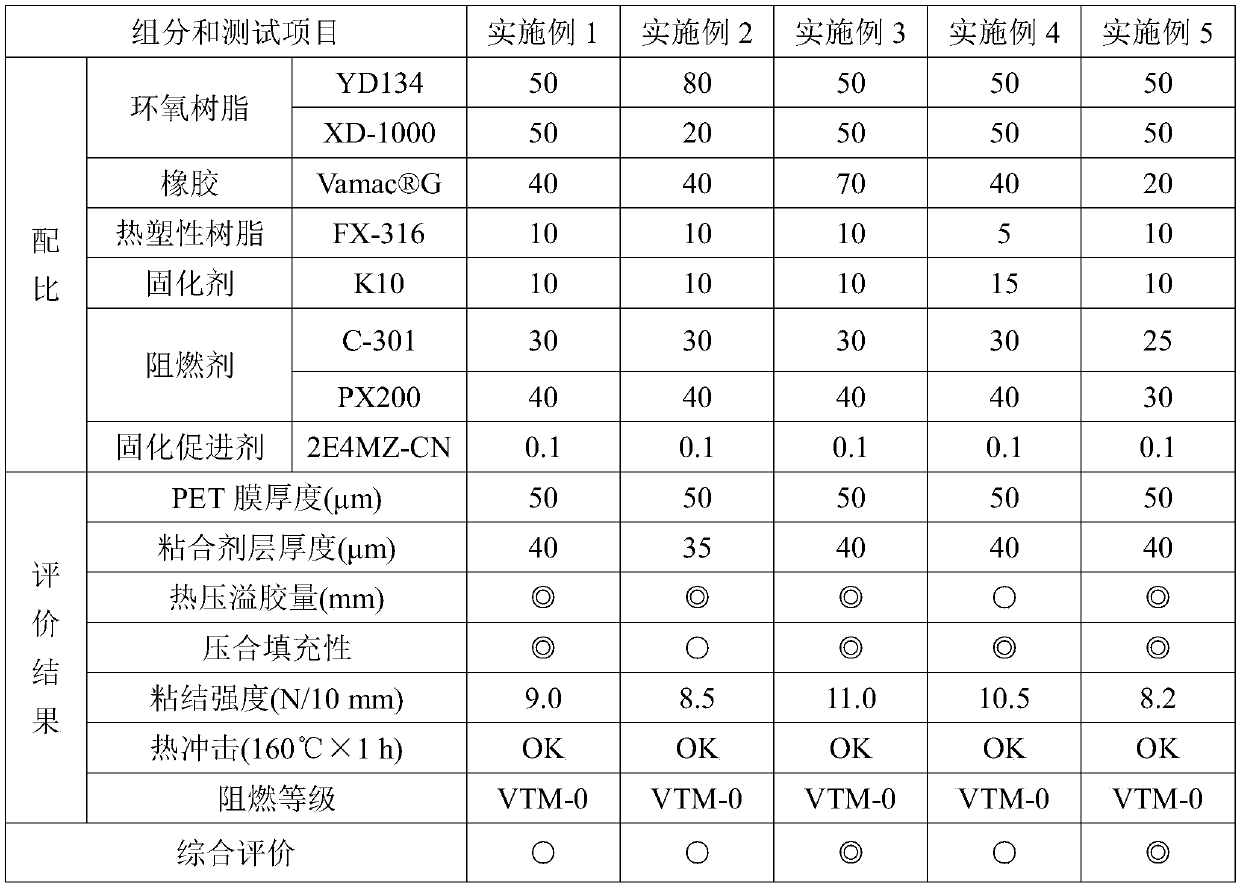

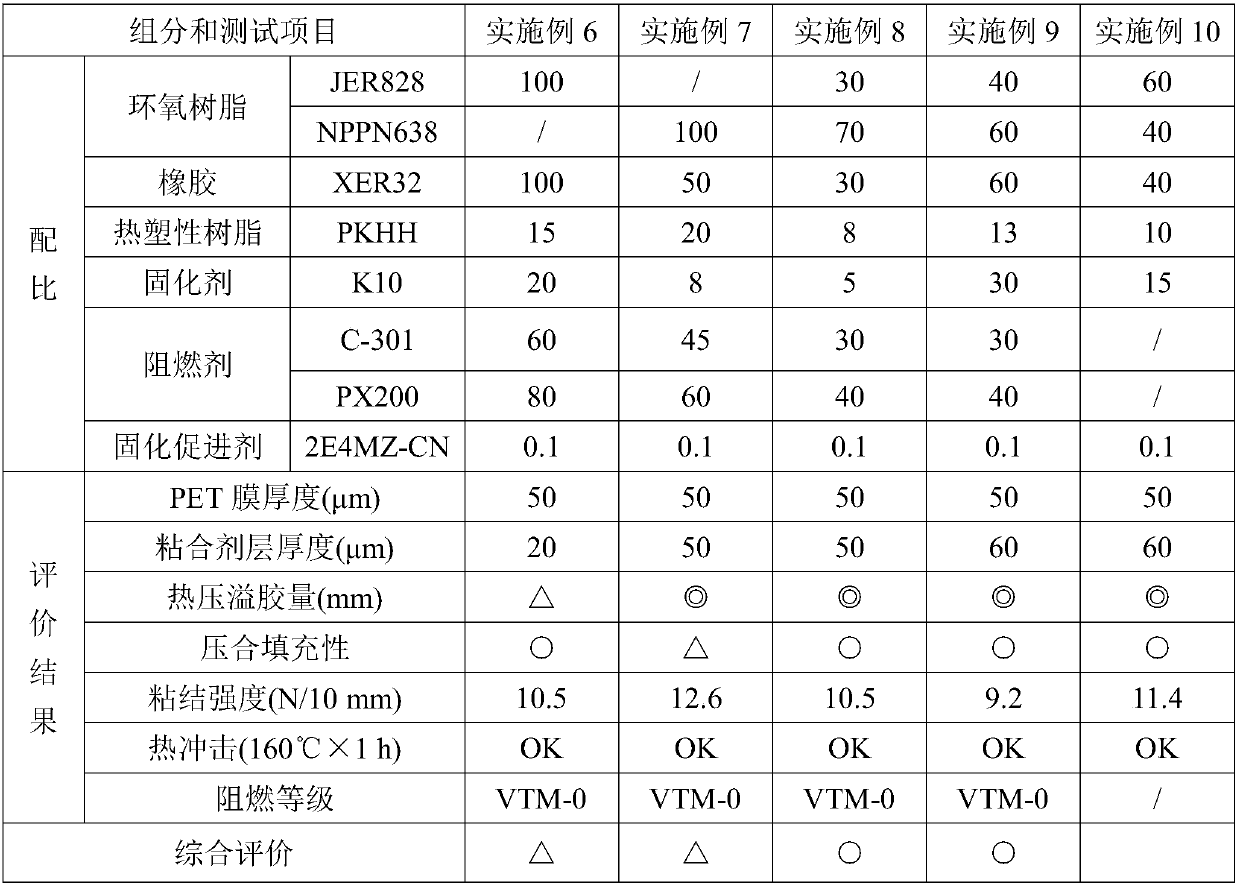

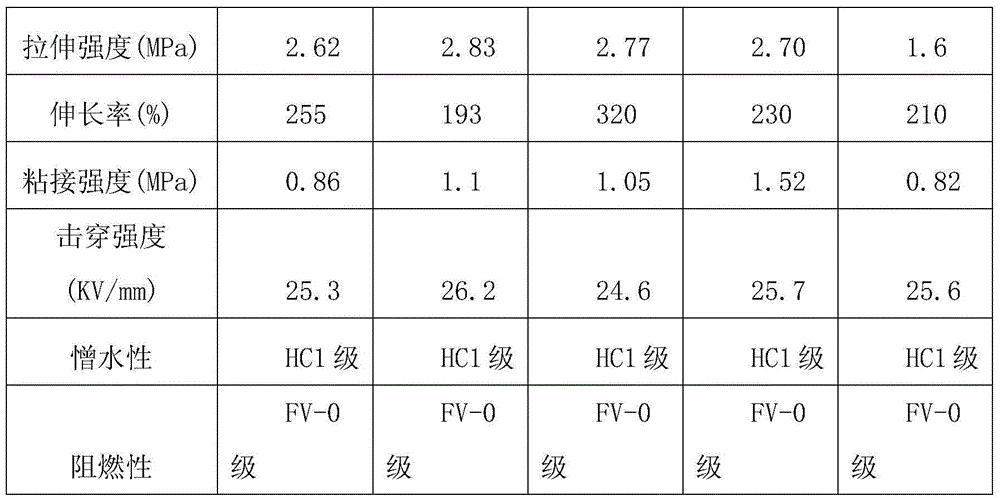

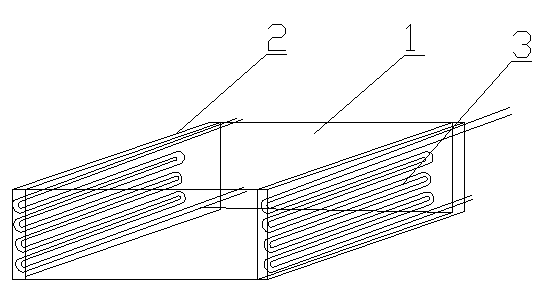

Adhesive and insulating reinforcing tape containing adhesive

InactiveCN109651988AImprove adhesionImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyFlexible circuits

The invention provides an adhesive and an insulating reinforcing tape including the adhesive. The adhesive includes the following components (by weight): 100 parts of epoxy resin, 5-20 parts of thermoplastic resin, 20-100 parts of rubber, and 5-30 parts of a curing agent. The insulating reinforcing tape includes an insulating substrate and an adhesive layer disposed on the insulating substrate, wherein the adhesive layer is formed of the above adhesive. The adhesive provided by the invention has high adhesive force, heat resistance and good fluidity, and the insulating reinforcing tape prepared by the invention has small amount of glue overflow during hot-pressing, good adhesive property, strong deformation plasticity and good pressure fillibility, is easy for hot-press forming, low-cost,can be used for reinforcement and insulation coating of flexible circuit boards.

Owner:CYBRID TECHNOLOGIES INC

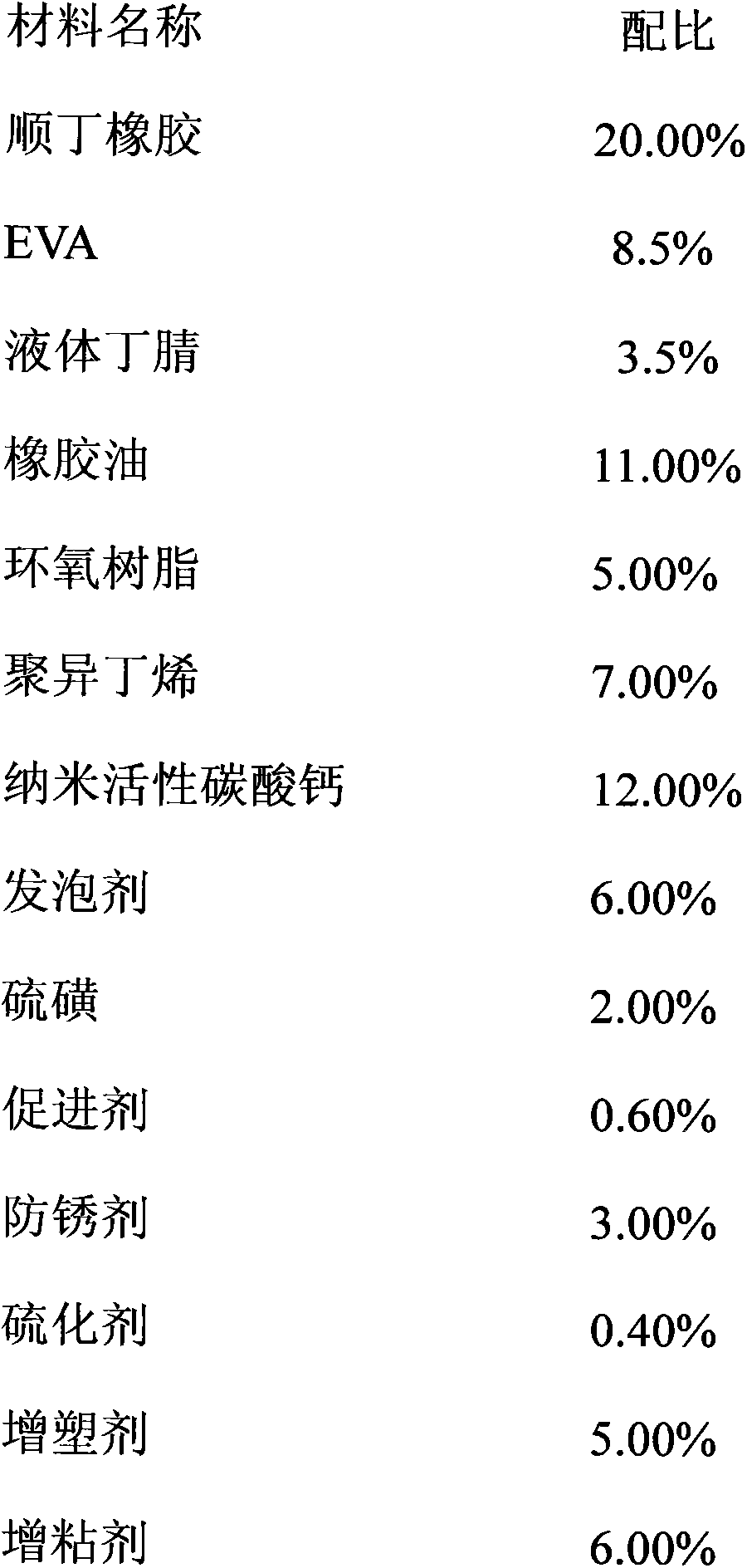

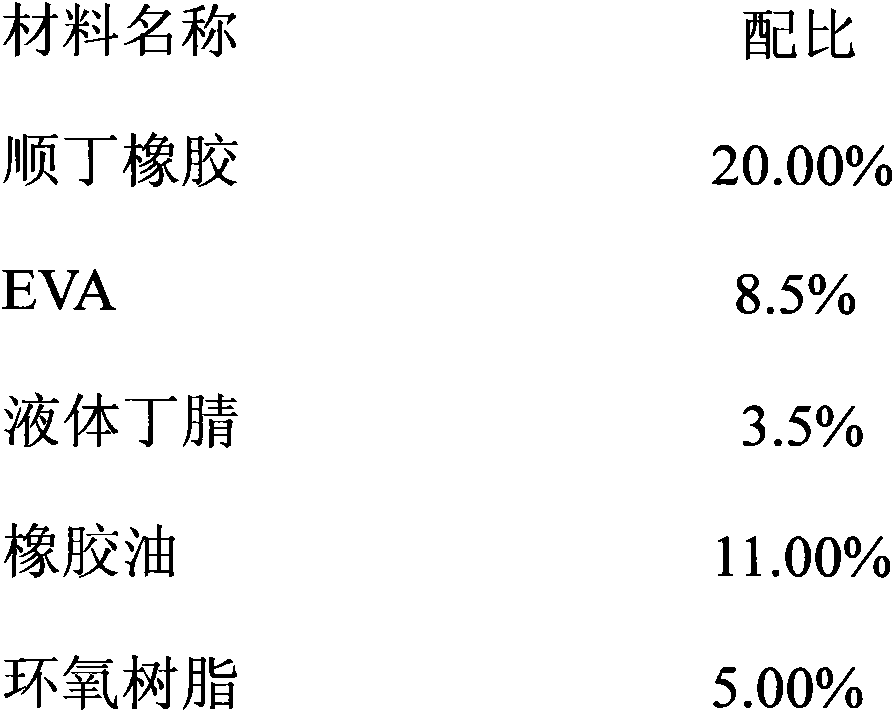

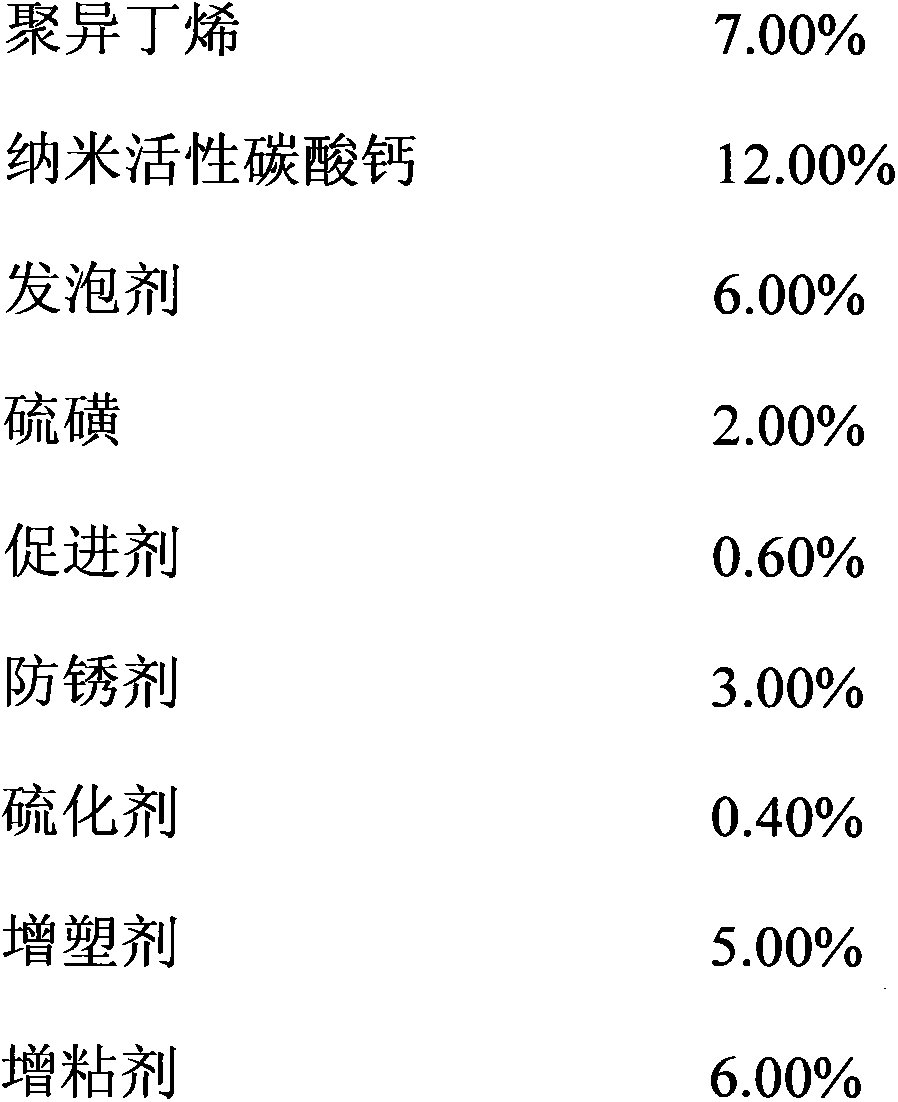

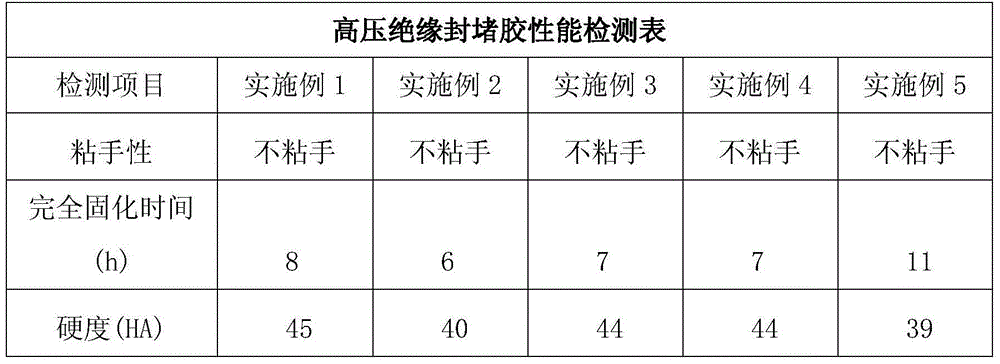

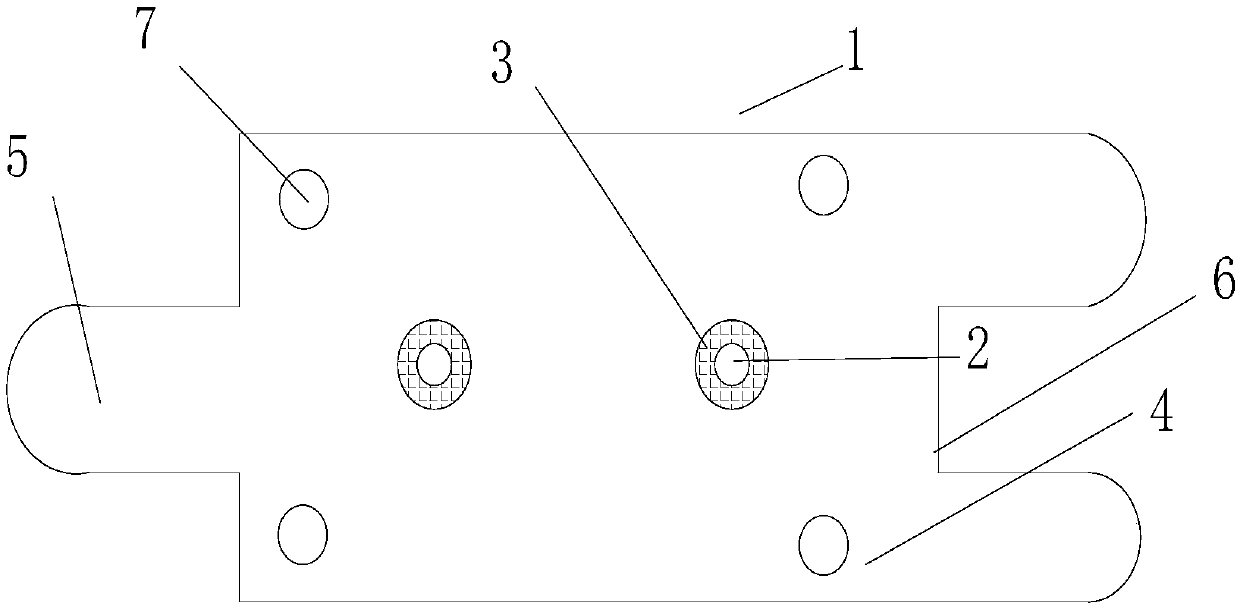

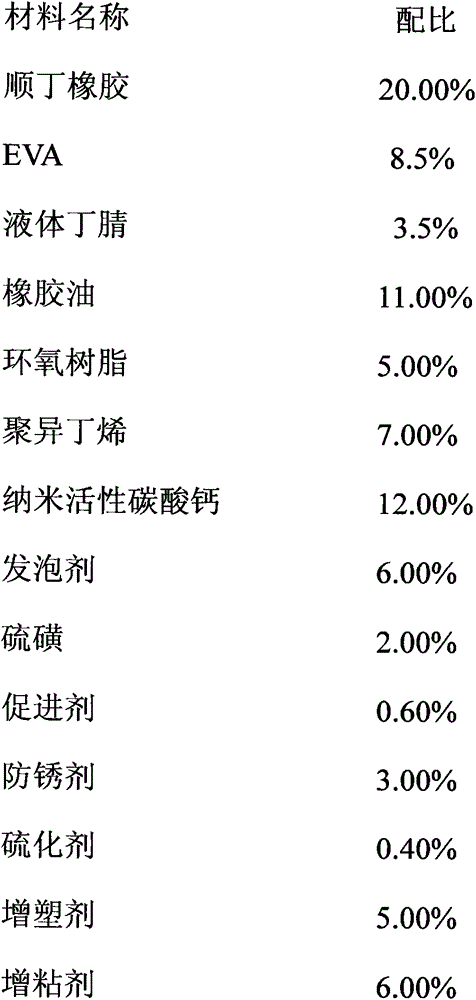

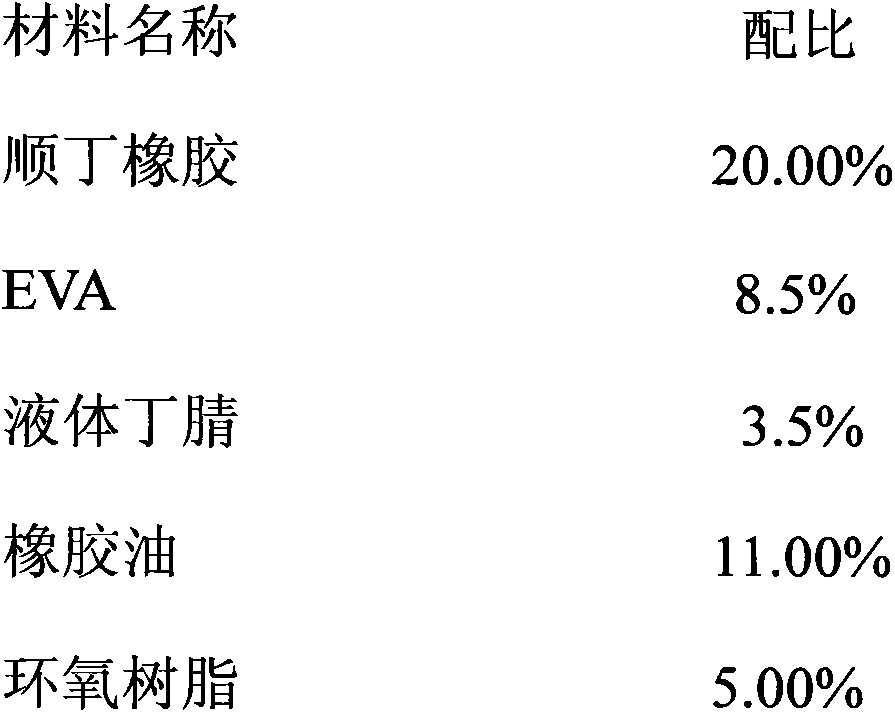

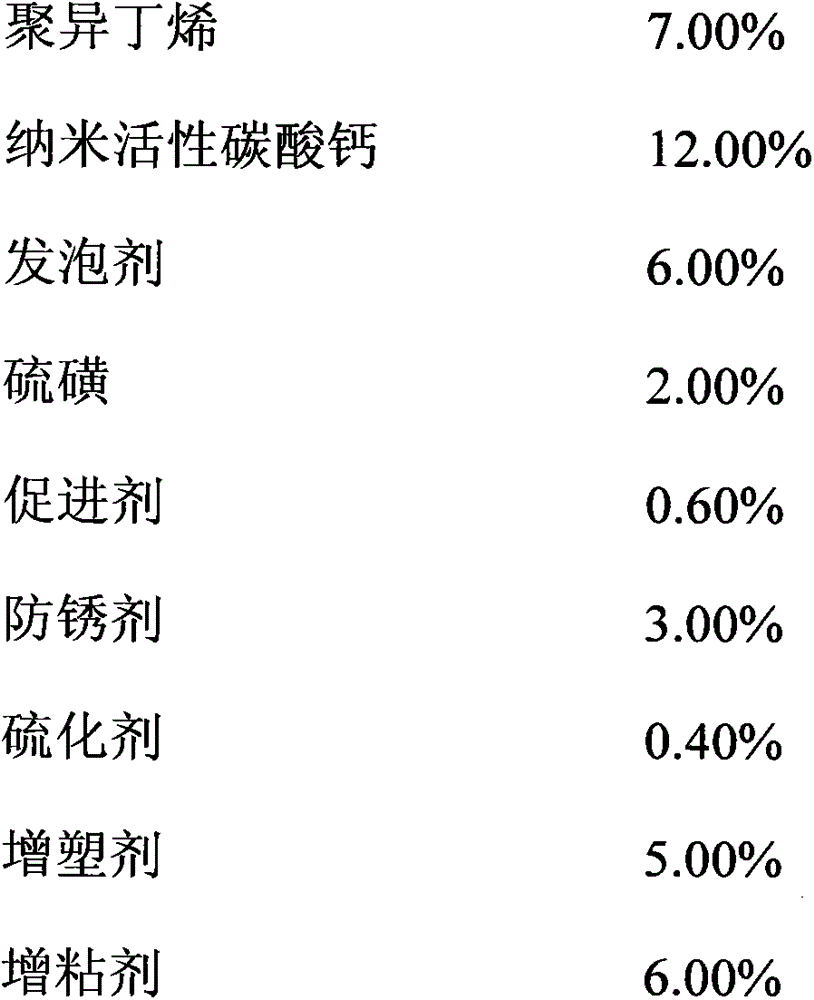

Automobile paste high-expansion vibration-reduction and sound-insulation rubber and manufacturing process thereof

The invention provides automobile paste high-expansion vibration-reduction and sound-insulation rubber and a manufacturing process thereof. Butadiene rubber, EVA, liquid butyronitrile, rubber oil, epoxy resin, polyisobutene, nano activated calcium carbonate, a foaming agent, sulfur, an accelerating agent, a rust inhibitor, a vulcanizing agent, a plasticizer and a tackifier are selected and used, and a pressure kneader is used for mixing the dispersed materials. The rubber is spread on corresponding parts of steel plates in an automobile body welding workshop by a glue spreading pump; the rubber passes through a painting shop after automobile body welding, is heated with an electrophoretic paint drying line to foam to fill up an entire cavity, and achieves the effects of vibration reduction, sound insulation, dust separation and dust prevention.

Owner:保光(天津)汽车零部件有限公司

Slide sand-slope deep sand-fixation method

InactiveCN1851153AChange the properties of the bulk structureTo achieve the purpose of deep sand consolidationExcavationsSoil preservationEngineeringHigh pressure

The invention is a quicksand slope depth-type sand fixing method, comprising the steps of: adopting the flower pipe-micro root pile depth-type sand fixing method to carry out quicksand slope depth-type sand fixing design, i.e. drilling vertically the ground to the sand slope depth on a sand slope necessary to fix sand, inserting micro flow pipe into the hole and injecting high pressure clay, soil powder / cement and fine sand pulp into the flower pipe, so that the pulp is ejected through pores around the flower pipe to form rootlike pulp veins, which tightly hold the sand by their bonding and absorbing actions, so as to achieve the sand fixing purpose. And it can effectively fix the quicksand slope.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

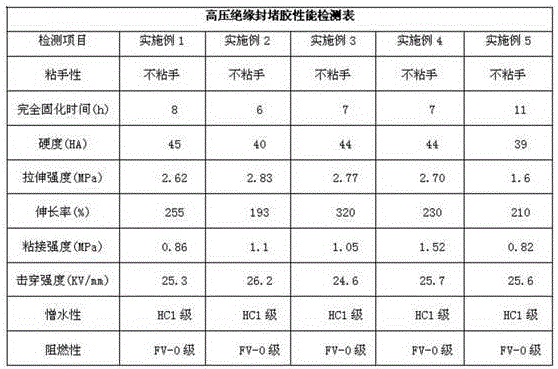

High-voltage-insulation sealing adhesive

ActiveCN104610905AStrong randomnessEasy to useNon-macromolecular adhesive additivesMacromolecular adhesive additivesElectricityCross-link

The invention relates to high-voltage-insulation sealing adhesive. The high-voltage-insulation sealing adhesive comprises a first composition and a second composition which are stored separately, wherein the first composition comprises the following components in parts by weight: 40-60 parts of hydroxy-terminated polysiloxane, 3-10 parts of silicon dioxide, 10-60 parts of a filler, 1-5 parts of a cross-linking agent and 0.2-1 part of a silane coupling agent; the second composition comprises the following components in parts by weight: 30-60 parts of hydroxy-terminated polysiloxane, 0-10 parts of polymethyl siloxane, 10-60 parts of a filler and 0.8-1.5 parts of a catalyst. The first composition and the second composition are stored separately, and during room-temperature mixing, sulfuration reaction is performed on the hydroxy-terminated polysiloxane, the cross-linking agent and the silane coupling agent under the action of the catalyst; after the sulfuration reaction, a product is excellent in flame retardance, electrical performance and bonding strength, and has shockproof and waterproof functions; the two compositions are shaped as blocks, and can be directly kneaded into any shapes by hands for sealing, so that the high-voltage-insulation sealing adhesive is easy and convenient to use.

Owner:FUJIAN RUISEN CHEM

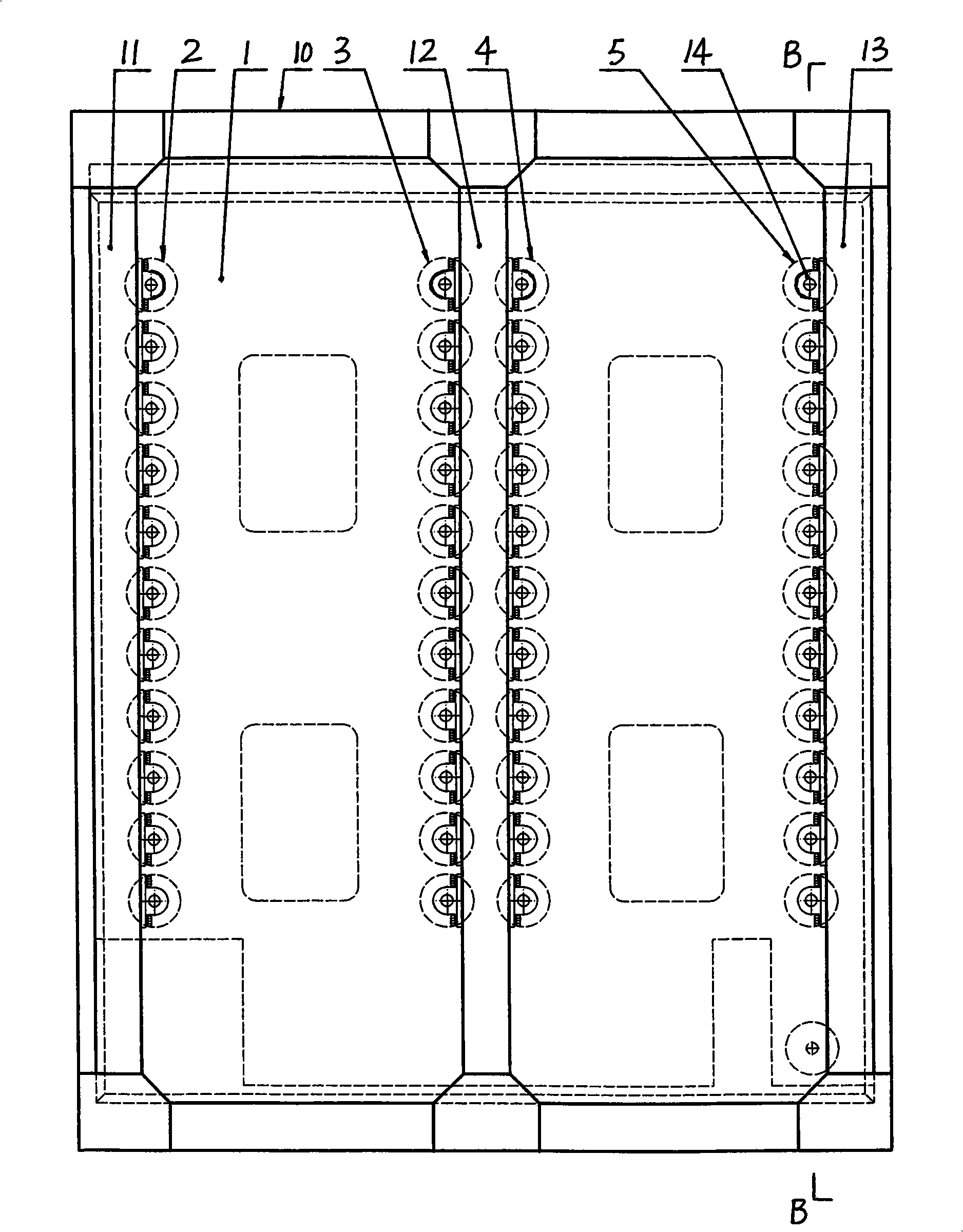

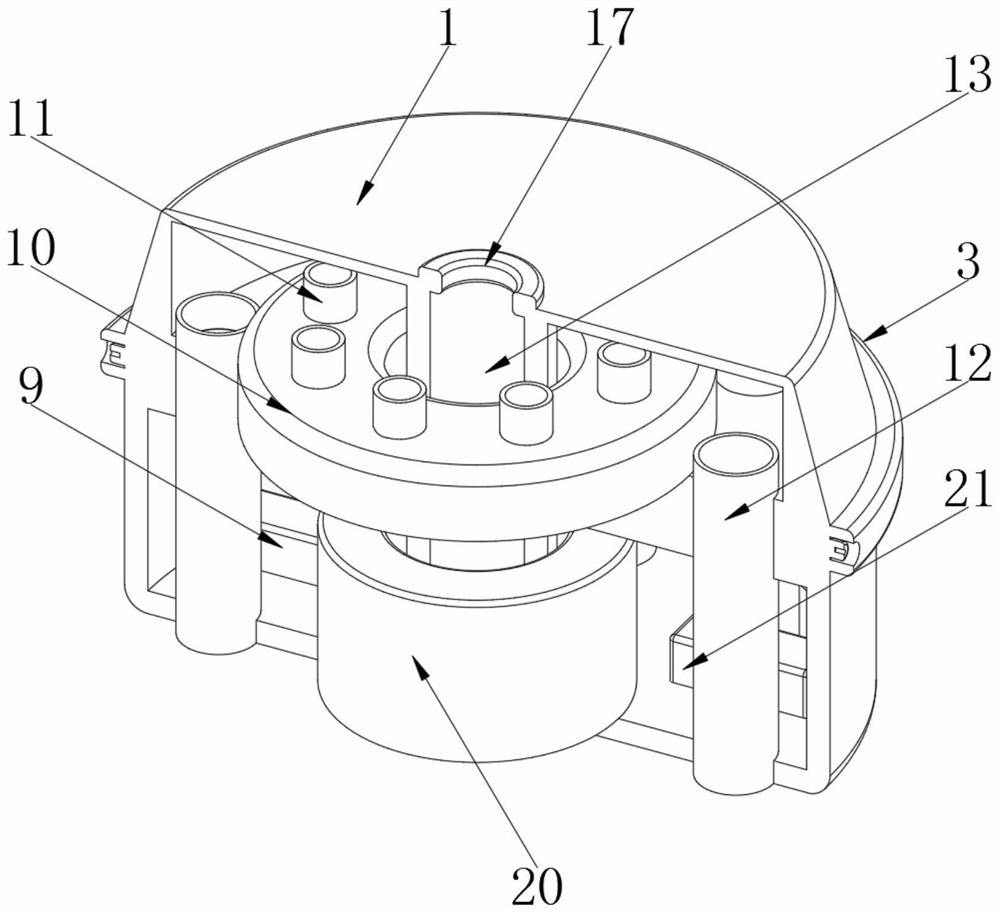

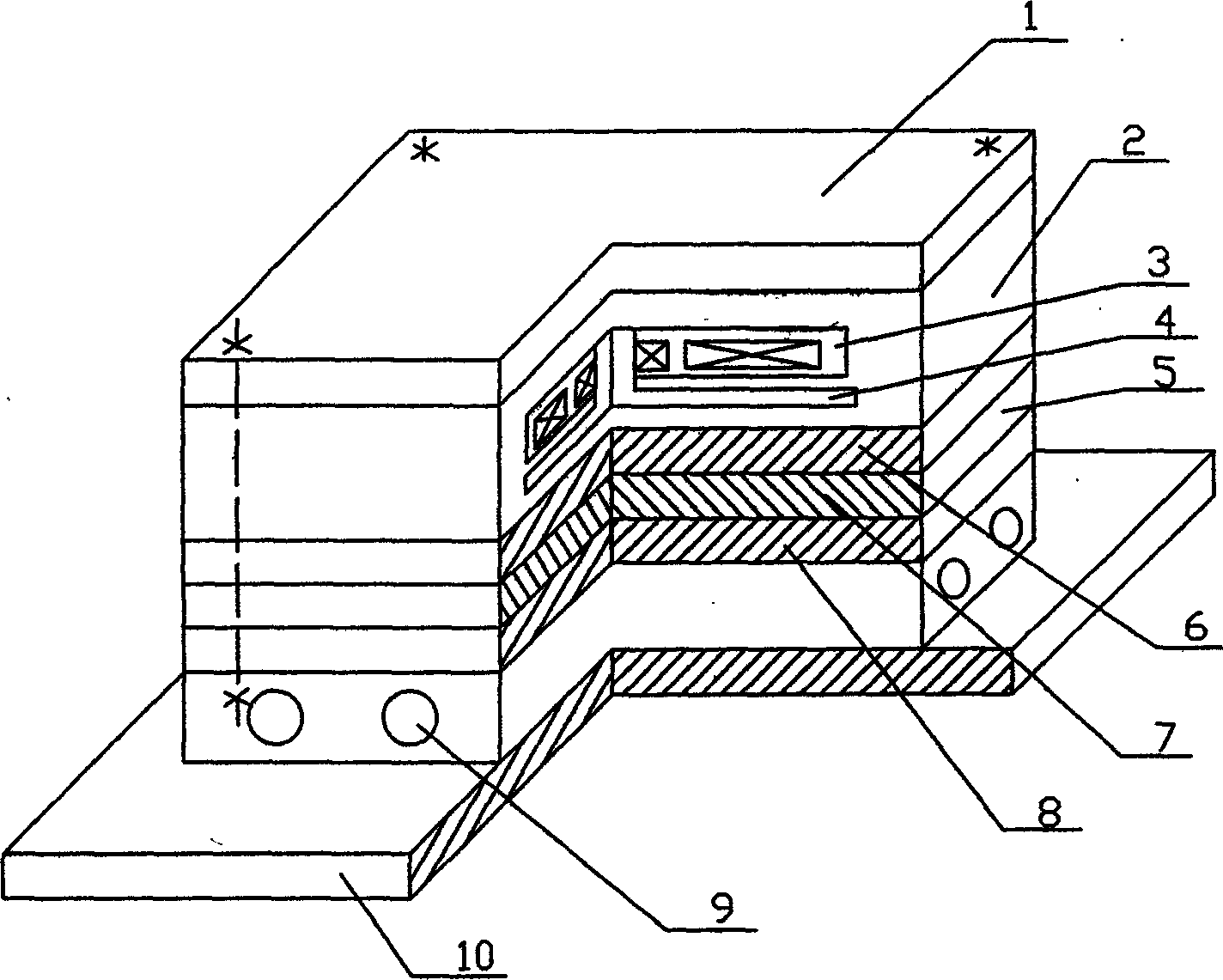

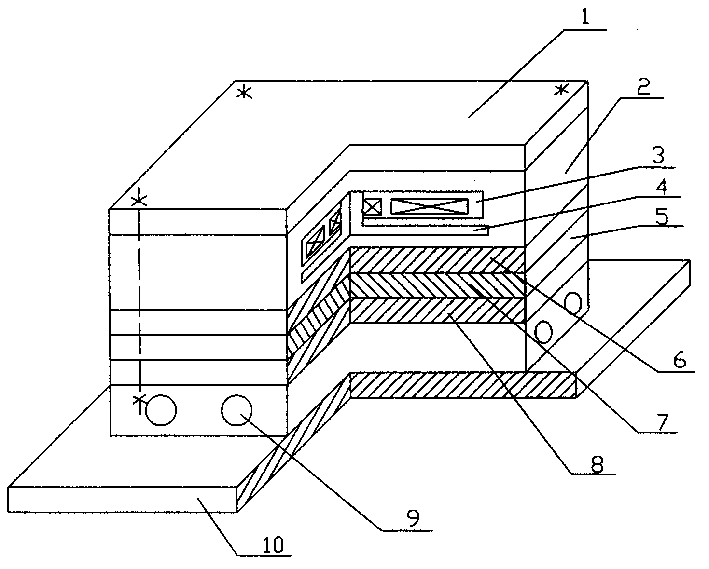

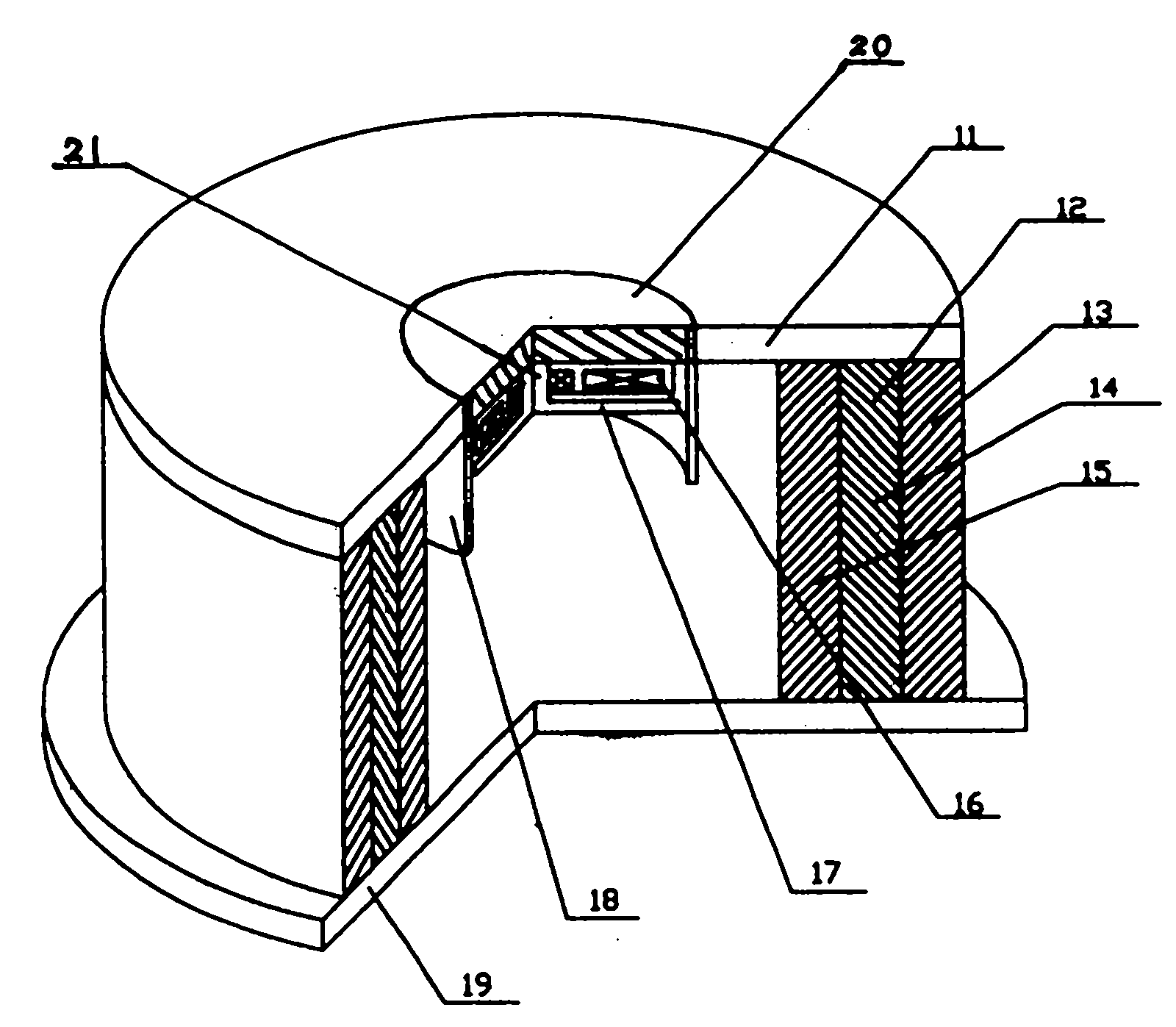

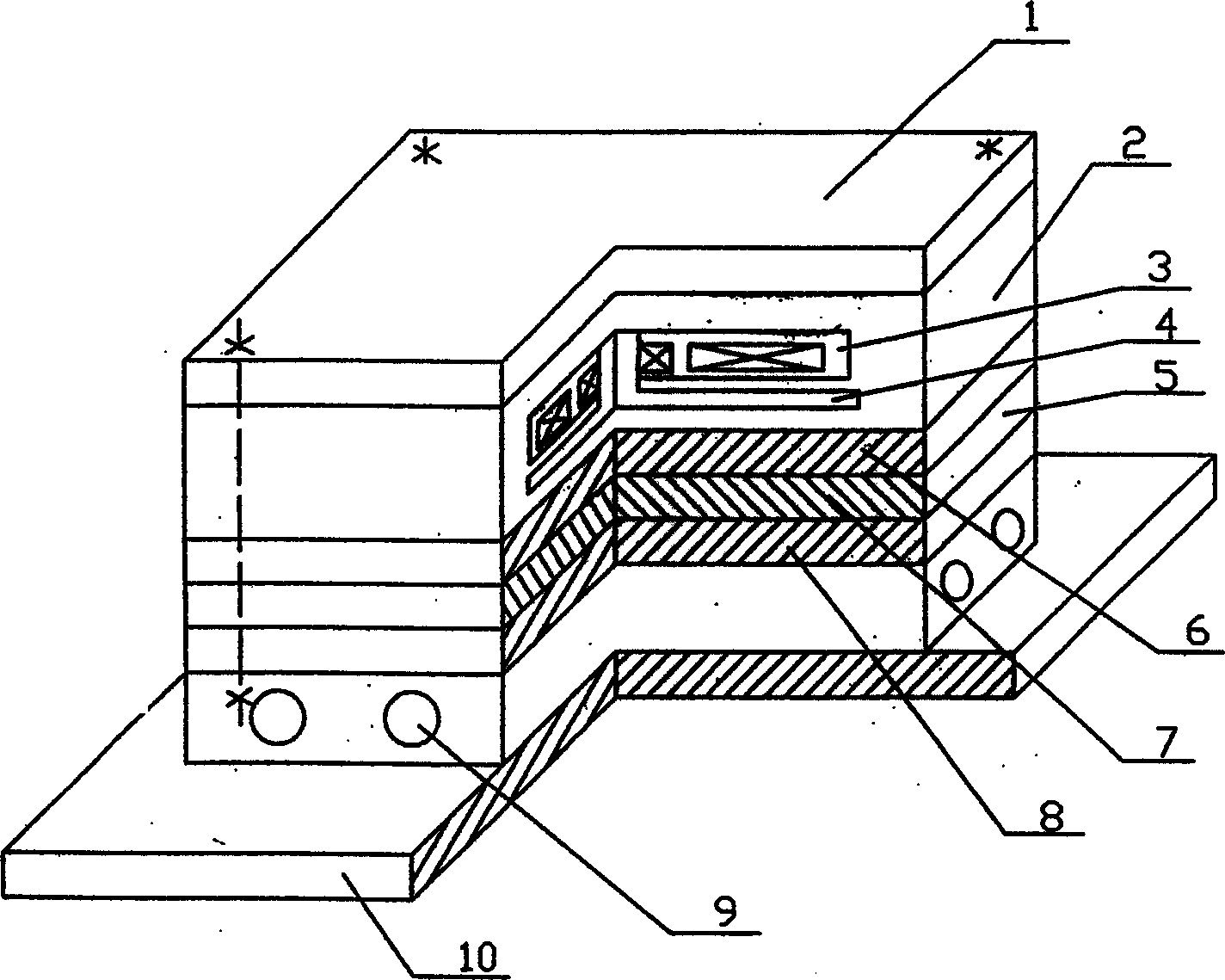

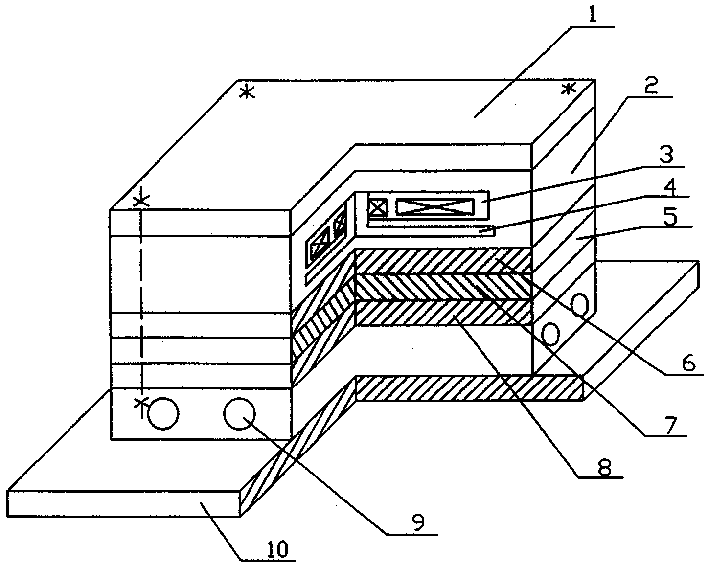

Water-cooled machine frame for power distribution cabinet

InactiveCN103346494AStable temperatureNo flow phenomenonSubstation/switching arrangement cooling/ventilationEngineeringPower equipment

The invention relates to a water-cooled machine frame for a power distribution cabinet, and belongs to the field of power equipment. The machine frame comprises a machine frame body, wherein the side walls of the two sides of the machine frame body are provided with cavities, and cooling tubes are disposed in the cavities. According to the water-cooled machine frame for the power distribution cabinet, water cooling is used in the machine frame for cooling, the phenomenon of air circulation does not exist in the cabinet, rising of dust is reduced, and accumulation of a return stroke is reduced. By means of water cooling, heat exchange efficiency is improved, and the temperature in the cabinet is stabilized.

Owner:万能亿工业科技发展(苏州)有限公司

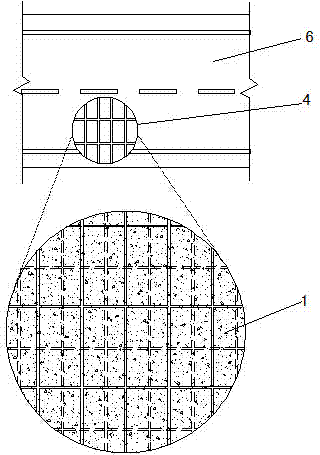

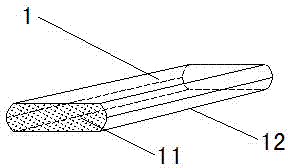

Substrate-free reactive fiber conductive hot melt adhesive tape, glue for melt adhesive tape as well as preparation methods of melt adhesive tape and glue

ActiveCN108300405AImprove conductivityNo flow phenomenonNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberPlasticizer

The invention discloses substrate-free reactive fiber conductive hot melt adhesive tape, glue for the melt adhesive tape as well as preparation methods of the melt adhesive tape and the glue. The preparation method of the glue comprises the steps of separately dissolving thermoplastic polyurethane, rosin glycerin ester and polyester resin into a solvent in advance, then evenly mixing the solutionsof thermoplastic polyurethane, rosin glycerin ester and polyester resin, adding conductive fibers, an enclosed type curing agent, a flatting agent, a dispersing agent, a thermal oxidation stabilizer,a defoaming agent and a plasticizer, and evenly stirring to obtain the substrate-free reactive fiber conductive hot melt glue; the preparation method of the substrate-free reactive fiber conductive hot melt adhesive tape comprises the steps of coating a substrate with the glue, heating for drying, and then rolling up to obtain the substrate-free reactive fiber conductive hot melt adhesive tape. The conductive hot melt glue solves the problem that the conventional hot melt glue can not conduct electricity, and has good adhesive property and electrical conductivity, thus being suitable for bonding the special parts of electronic products and conducting electricity.

Owner:苏州世诺新材料科技有限公司

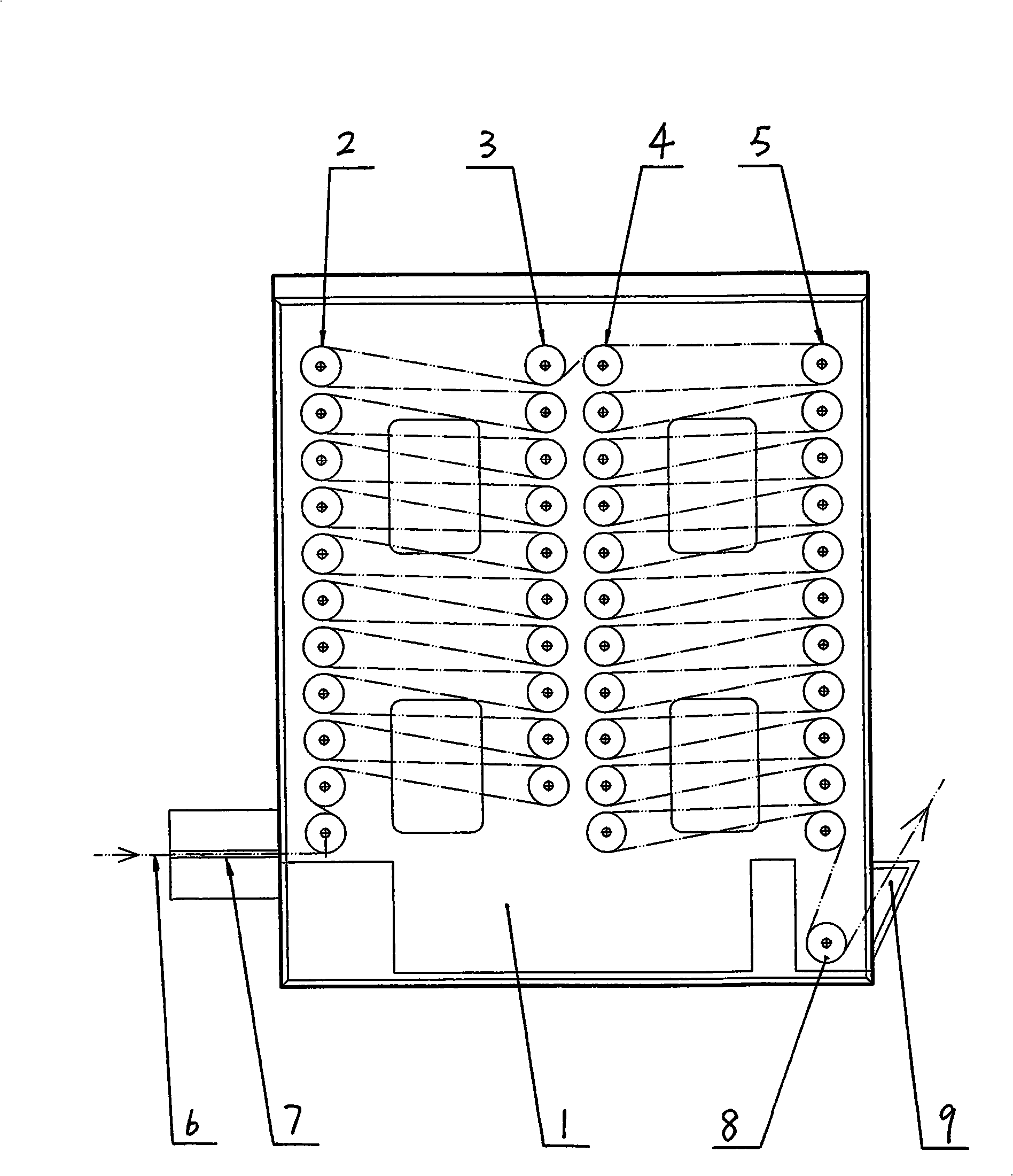

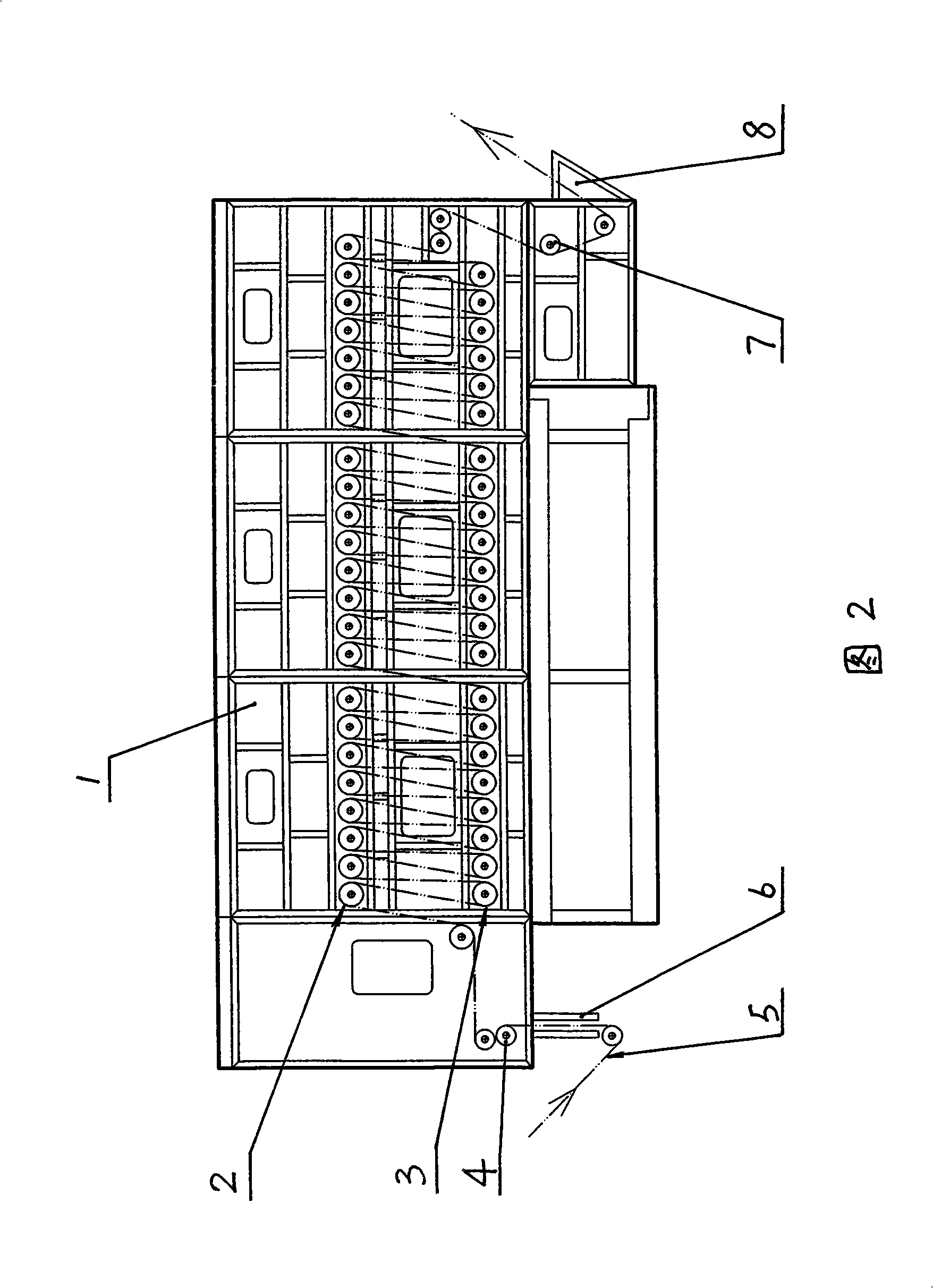

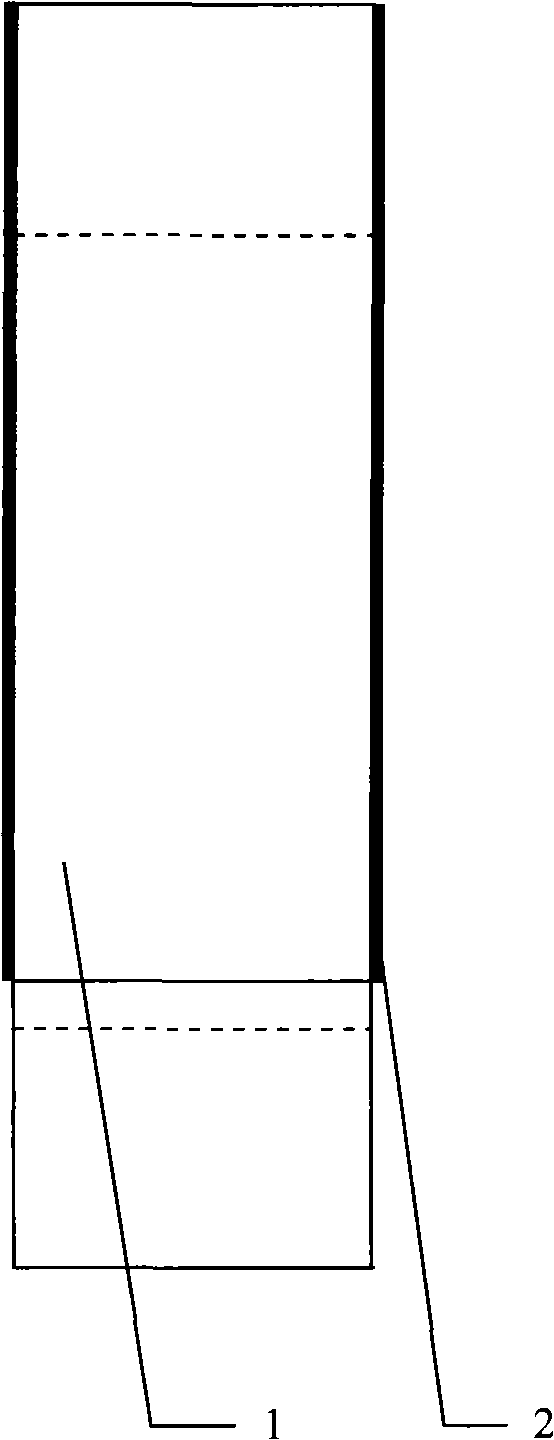

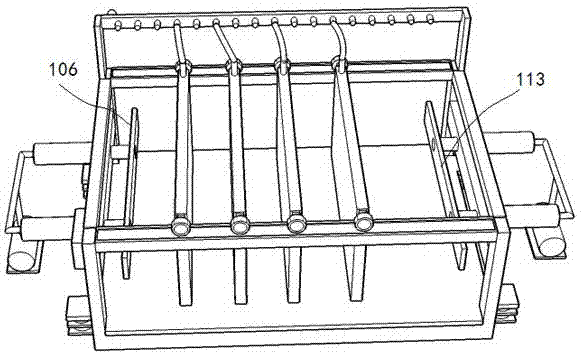

Dominant cloth roll group in fixation steaming box

InactiveCN101298727AWon't bendExtended service lifeTextile treatment carriersEngineeringMechanical engineering

The invention discloses a main cloth-guiding roller unit which is used for a color-fixation steaming box and can reduce the occupied area, conserve steam, bring convenience for cleaning and guarantee dyeing quality. The main cloth-guiding roller is characterized in that the main cloth-guiding roller is composed of four rows of main cloth-guiding rollers, and each row of main cloth-guiding rollers are vertically arranged in the box body of the color-fixation steaming box and are composed of a plurality of cloth-guiding rollers, and each neighboring two rows of main cloth-guiding rollers among the four rows of main cloth-guiding rollers form one group of matched main cloth-guiding rollers for the operation to fabrics.

Owner:JIANGSU JIANGHAI MASCH CO LTD

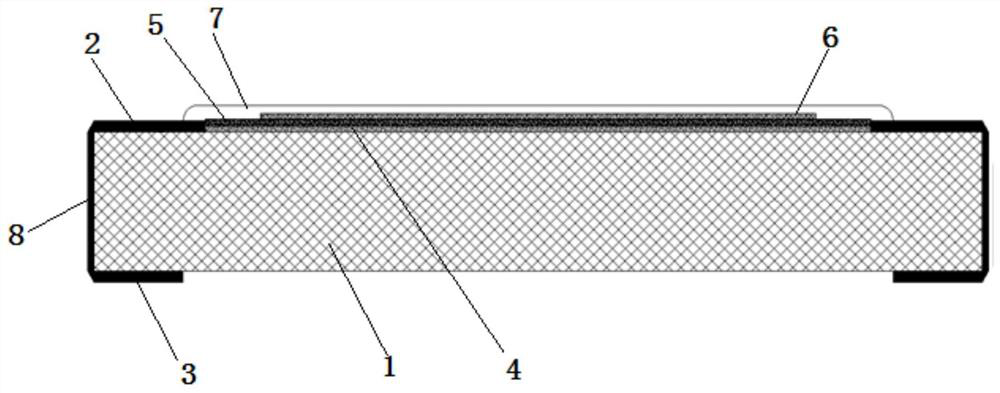

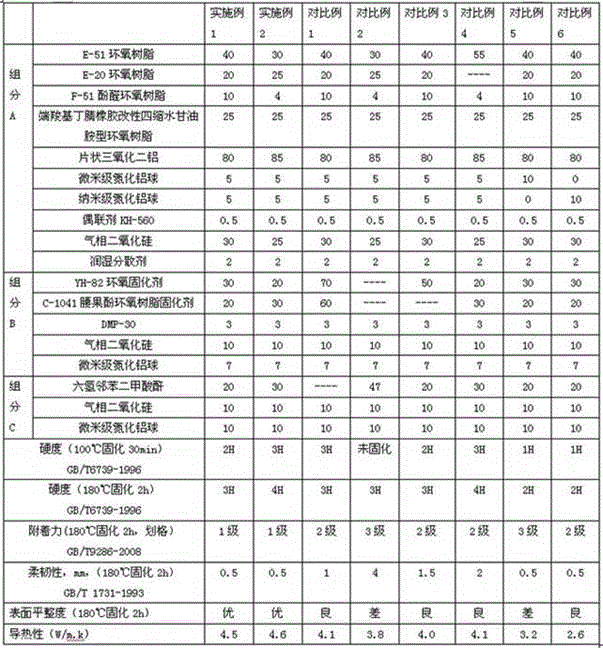

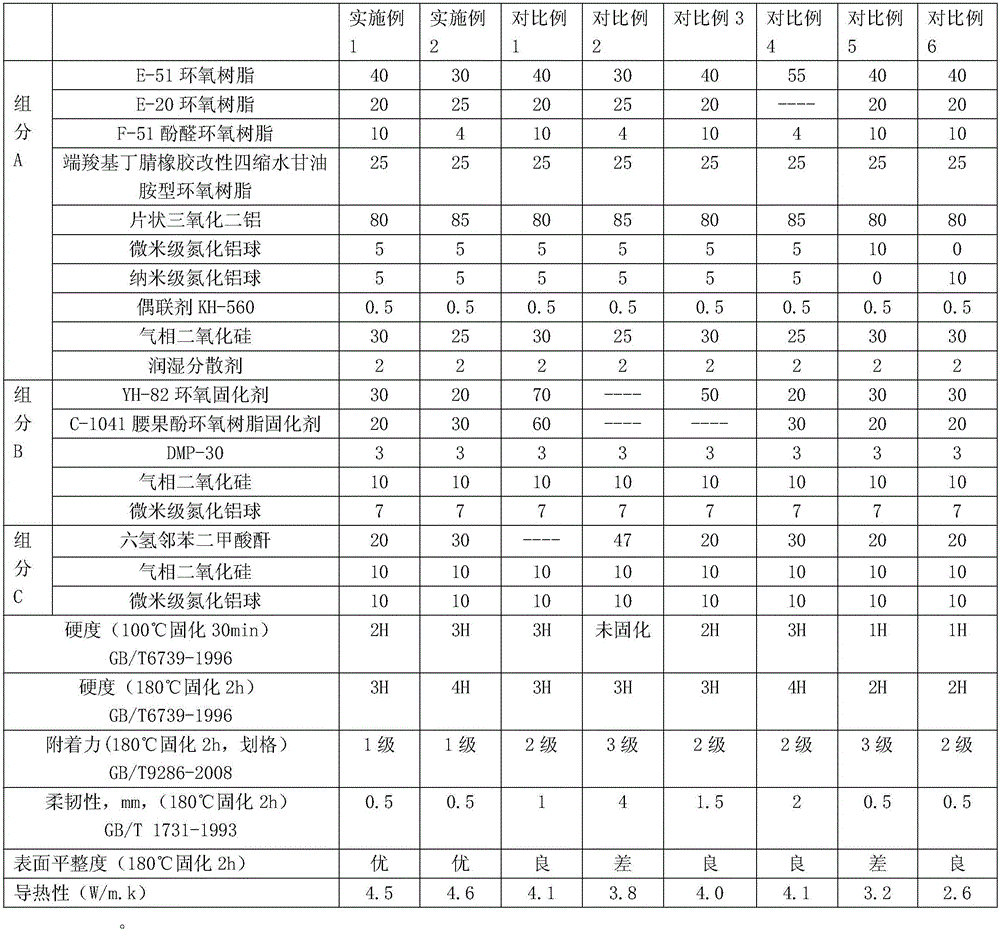

High temperature-resistant step-cured epoxy paint and application method thereof

ActiveCN103319984AImprove high temperature resistanceImprove interface adhesionEpoxy resin coatingsHexahydrophthalic anhydrideGas phase

The invention discloses a high temperature-resistant step-cured epoxy paint and an application method of the paint. The high temperature-resistant step-cured epoxy paint is obtained by mixing ingredient A, ingredient B and ingredient C in A certain proportion, wherein the ingredient A is an epoxy resin ingredient and comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic aldehyde epoxy resin, carboxylate-terminated nitrile butadiene rubber modified tetraglycidylamine type epoxy resin, aluminum oxide, aluminum nitride, fumed silica, a wetting dispersant, and a coupling agent; the ingredient B is a first curing agent ingredient and comprises an YH-82 epoxy curing agent, a C-1041 anacardol epoxy resin curing agent, DMP-30, fumed silica, and aluminum nitride; and the ingredient C is a second curing agent ingredient and comprises hexahydrophthalic anhydride, fumed silica, and aluminum nitride. The high temperature-resistant step-cured epoxy paint disclosed by the invention can be pre-cured at low temperature, does not form an unsmooth paint film, is cured at a high temperature, and remains the advantages of high strength and good adhesive force of the paint film which is cured at a high temperature.

Owner:广东顺召涂料有限公司

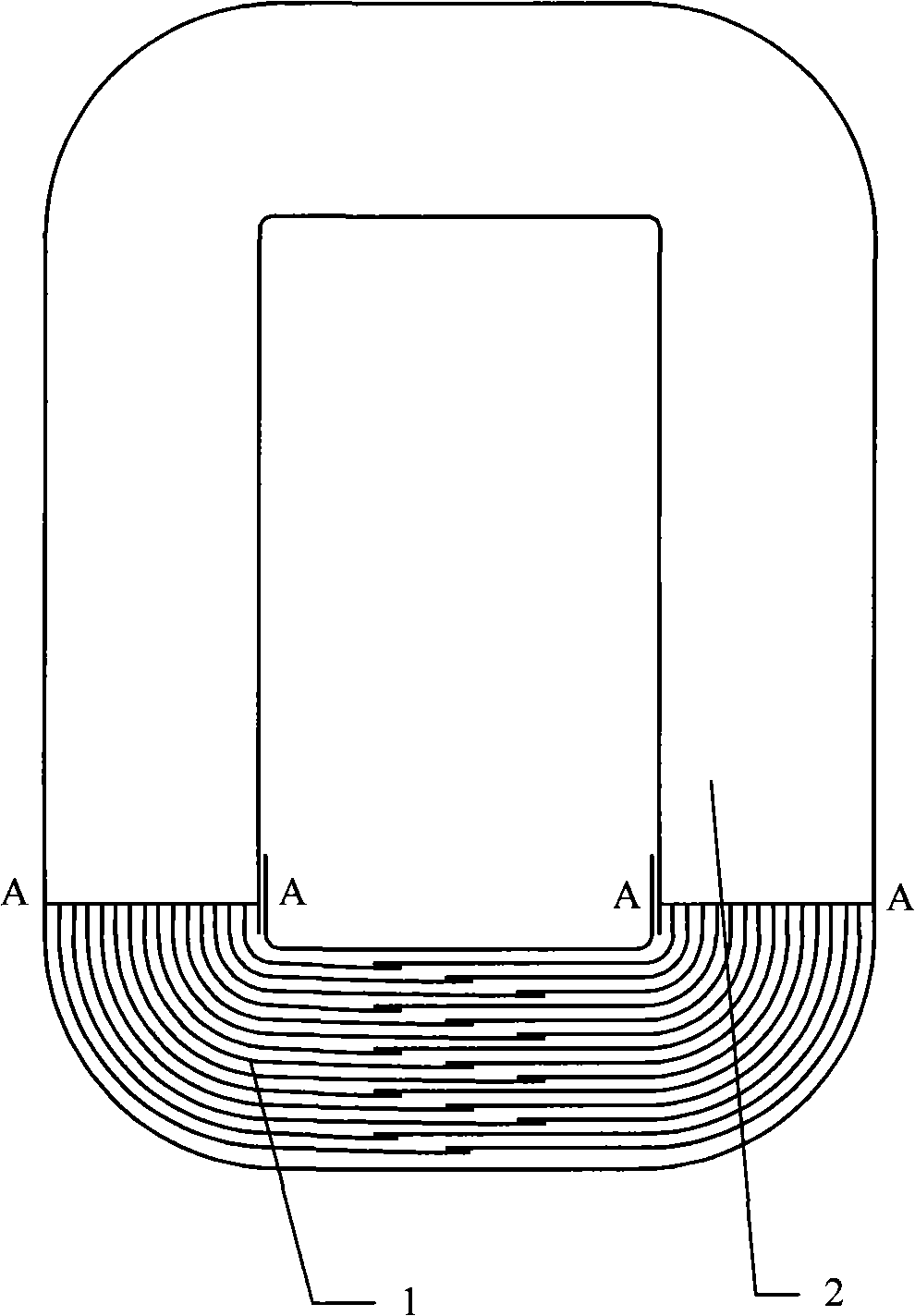

Method for coating thin epoxy resin of amorphous alloy iron core

InactiveCN101299388AReduce stressEasy curingInductances/transformers/magnets manufactureEpoxyResin coating

The invention relates to a method of the amorphous alloy core thin epoxy resin coating, characterized by using the brush coating. The method includes removing the surface dust of the amorphous alloy core through a brush; sticking the adhesive tape with the width 1 cm beside the coating along the line A-A on the amorphous alloy core 1, for preventing the epoxy resin extravasating; brushing the epoxy resin evenly on the core surface above the line A-A on the amorphous alloy core 1, wherein the thickness of the epoxy resin is lower than 1mm; putting the amorphous alloy core with the coating into the oven for roasting at the roasting temperature 100-150 DEG C for 10 minutes to 30 minutes. The invention has the advantages of lower no-load loss, smaller no-load current; the solidifying time of the epoxy resin is reduced for 60%, the whole height of the core is reduced for 2-3 minutes, thereby reducing the size of the transformer for saving.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

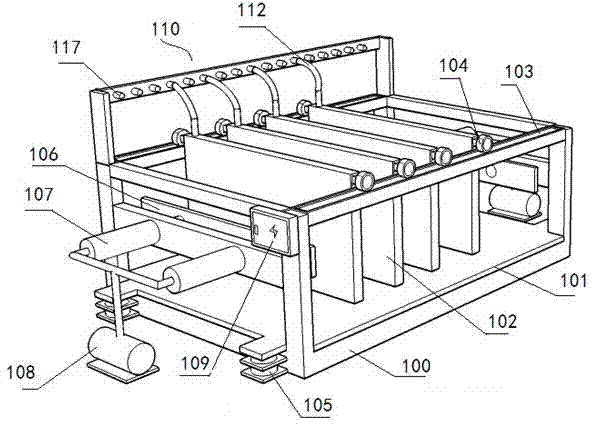

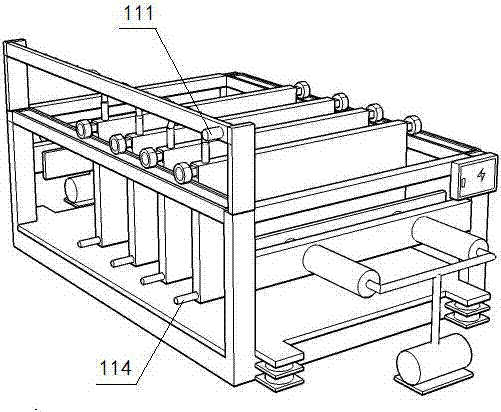

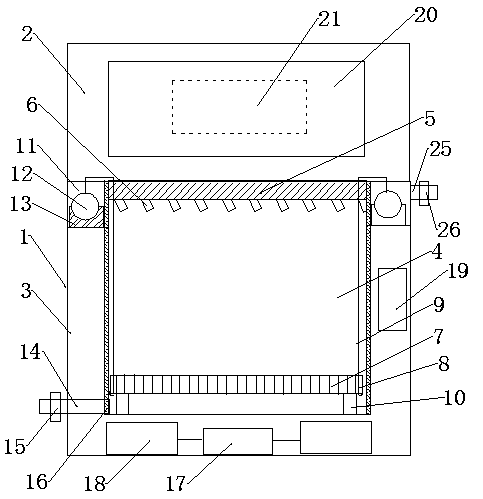

Processing equipment for fireproof cross-band veneer

InactiveCN104842436AEasy to pourNo flow phenomenonAuxillary shaping apparatusProcess equipmentBiochemical engineering

The invention relates to processing equipment for fireproof cross-band veneer. The processing equipment comprises a rack, a horizontal lifting workbench is arranged in the rack, at least two heating forming insulation boards capable of sliding on the rack are arranged on the horizontal lifting workbench, a heating forming area is formed between every two adjacent heating forming insulation boards, the heating forming insulation boards are perpendicular to the lifting workbench, and a hot water circulating pipe is arranged in each heating forming insulation board. A left ejector plate and a right ejector plate are arranged at the two ends of the rack, pushed by a tightening mechanism and used for compressing the heating forming insulation boards and workpieces to be processed to achieve forming. The processing equipment is arranged horizontally, so that the fireproof cross-band veneer is convenient to take and store, no complex lifting device is needed, fireproof mortar materials are poured conveniently, one-shot forming is achieved, mortar cannot flow everywhere, the surface of the fireproof cross-band veneer is smooth, and the processing equipment can be used for fireproof cross-band veneer of different sizes.

Owner:QINGDAO MUCHENG DOORS IND GRP

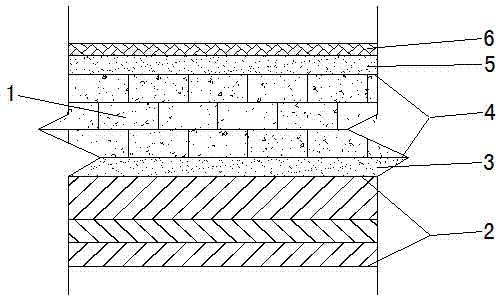

Lateral permeable road and construction method thereof

The invention provides a lateral permeable road and a construction method thereof. A subgrade is formed by paving a treated soil layer, a clay compacted layer and a permeable layer from bottom to top respectively, wherein the permeable layer is composed of permeable broken stone bags which are closely arranged in a staggered manner; a leveling layer and a pavement surface are paved on the permeable layer. The construction method comprises the following steps: performing filling earthwork construction on the bottom part of the subgrade, mixing lime treated soil in the excavated road cutting and then compacting to form the treated soil layer; paving a geomembrane, putting a clay layer on the geomembrane and compacting to form the clay compacted layer; putting broken stones in permeable woven bags and sealing to form the permeable broken stone bags; flatly laying the permeable woven bags in a layered manner and closely arranging the permeable woven bags above the clay compacted layer, closely arranging the permeable broken stone bags of every two adjacent broken stone permeable layers in a staggered way and filling the gap between the adjacent broken stone permeable layers with the broken stones, thereby forming the permeable layer; putting soil on the permeable layer and compacting to form the leveling layer; performing pavement construction on the leveling course.

Owner:NANJING COMM INST OF TECH +1

Sand wall texture coating material

InactiveCN105602365AIncrease viscosityDoes not affect the natureCoatingsSodium BentoniteCrack resistance

The invention provides a sand wall texture coating material, and relates to the field of coating materials, particularly to a sand wall texture coating material. The present invention provides a sand wall texture coating material with characteristics of water resistance, cracking resistance and uniform sand ensuring. The a sand wall texture coating material comprises, by mass, 10-20 parts of a pure acrylic acid emulsion, 0-3 parts of mesh stone powder, 1-5 parts of color sand, 0.1-0.2 part of hydroxyethyl cellulose, 0.1-0.5 part of a dispersing wetting agent, 0-1 part of a pigment filler, 1-2 part of a film forming auxiliary agent, 0.1-0.2 part of an anti-mould agent, 3-5 parts of a macromolecule water absorption resin, 4-10 parts of silicon-magnesium soil, 10-20 parts of kaolin or bentonite, and 20-40 parts of water.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

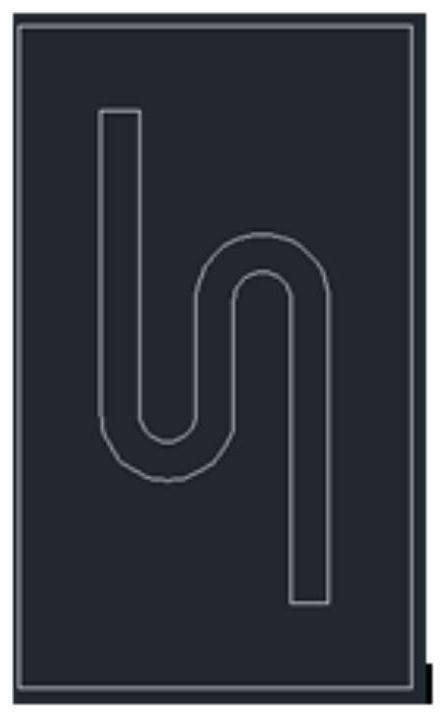

Surface-mounted fuse based on low-temperature co-fired ceramic technology and preparation method thereof

ActiveCN112266272AGood fusing performanceConcentration of fuse timeFuse device manufactureMetal/alloy conductorsCo-fired ceramicSi substrate

The invention discloses a surface-mounted fuse based on a low-temperature co-fired ceramic technology and a preparation method thereof. The preparation method comprises the following steps of sequentially preparing low-temperature co-fired ceramic powder, an organic carrier, low-temperature co-fired ceramic slurry, fuse electrode slurry, terminal electrode slurry, a positive electrode layer and aback electrode layer, then sequentially printing the low-temperature co-fired ceramic slurry, the fuse electrode slurry and the terminal electrode slurry on a ceramic substrate, and then co-firing each printing slurry layer to obtain a surface-mounted fuse semi-finished product, then, manufacturing a glass protection layer and identification characters on the surface-mounted fuse semi-finished product, and finally, acquiring a surface-mounted fuse finished product through a post-processing procedure. According to the preparation method, a low-temperature co-fired ceramic technology is utilized, so that the problems of diffusion and uneven surface during printing of the fuse electrode slurry are solved, and the pattern of the fuse is more complete, clearer and higher in controllability; thefusing process of the prepared surface-mounted fuse is rapid, and the phenomenon of arc discharge is avoided.

Owner:SEMITEL ELECTRONICS

High-temperature resistant sectional curing epoxy paint and use method thereof

ActiveCN106010127ANo crackDoes not reduce adhesionFireproof paintsEpoxy resin coatingsNitrile rubberHexahydrophthalic anhydride

The invention relates to high-temperature resistant sectional curing epoxy paint and a use method thereof. The high-temperature resistant sectional curing epoxy paint comprises a component A, a component B and a component C which are mixed in a certain ratio, wherein the component A is an epoxy resin component which comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic epoxy resin, carboxyl terminated nitrile rubber modified tetra-glycidyl amide type epoxy resin, aluminium oxide, micron-grade and nanometer-grade aluminum nitride balls, fumed silica, a wetting dispersant and a coupling agent; the component B is a first curing agent component which comprises a YH-82 epoxy curing agent, a C-1041 cardanol epoxy resin curing agent, DMP(Dimethylphthalate)-30, fumed silica and micron-grade aluminum nitride balls; the component C is a second curing agent component which comprises hexahydrophthalic anhydride, fumed silica and micron-grade aluminum nitride balls. The high-temperature resistant sectional curing epoxy paint prepared by the invention has the effects of low temperature pre-curing for avoiding uniform paint films, and high temperature curing, thereby keeping high strength and good adhesion of the paint films formed by low temperature curing.

Owner:中国森田企业集团有限公司

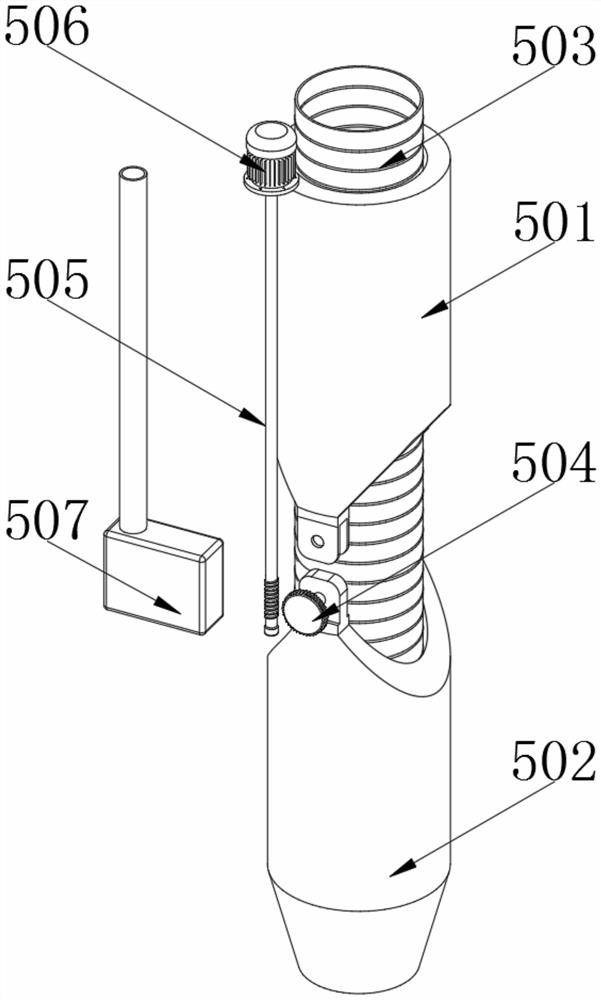

An outdoor water environment monitoring device for river governance

ActiveCN110987044BAchieve circumventionAchieve obstacle avoidanceWaterborne vesselsTesting waterEnvironmental engineeringBuoy

The invention belongs to the technical field of water environment monitoring, and specifically discloses an outdoor water environment monitoring device for river governance. The detection device includes a buoy, a detection ring and a power component. A detection ring is installed outside the middle of the buoy, and the buoy is located on the water surface. Several power components are installed at the bottom below. The present invention is scientific and reasonable, safe and convenient to use. The detection ring is used to detect and calculate the distance between the obstacle floating on the water surface and the monitoring equipment and the relative acceleration between the two. Adjust the position of the adjustment tube so that the power provided by the power source can realize the reverse thrust on the monitoring equipment, so that obstacles can be avoided, and the monitoring equipment can effectively avoid obstacles floating on the water surface. Preventing collisions between obstacles and monitoring equipment from causing damage to the monitoring equipment can effectively prolong the service life of the monitoring equipment and reduce the number of maintenance of the monitoring equipment.

Owner:青海赛维斯环境检测有限公司

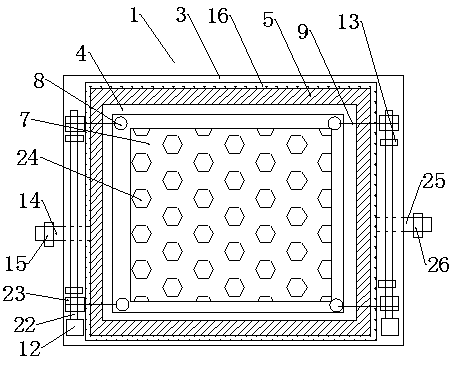

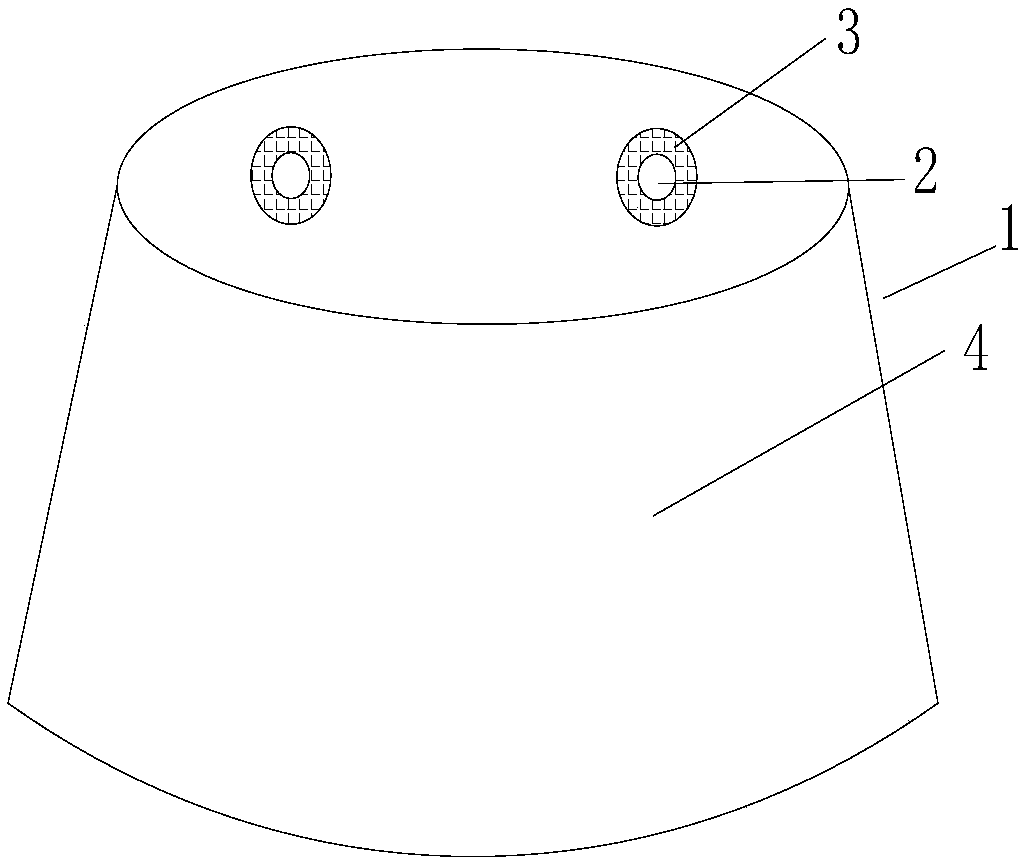

Traditional Chinese medicine pretreatment equipment

InactiveCN109482551AEasy accessEasy to placeDrying gas arrangementsCleaning using liquidsMedicinal herbsUltrasonic generator

The invention relates to traditional Chinese medicine pretreatment equipment which comprises a machine body, wherein the machine body comprises an interlayer and a cleaning tank; an ultrasonic transducer and ultrasonic generators are arranged at the bottom of the interlayer; a controller is arranged on the upper right of the interlayer; upper interlayers are arranged above the interlayer; motors are arranged in the upper interlayers; rotating shafts are connected with the output shaft ends of the motors; two rope winders are connected onto each rotating shaft in a clamping manner; a heating sheet is arranged on the outer wall of the cleaning tank; a water draining pipe is arranged at the bottom of the cleaning tank; a water draining solenoid valve is arranged on the water draining pipe; supporting columns are arranged at four corners of the bottom of the cleaning tank; an intercepting net is arranged above the supporting columns; hanging holes are formed in four corners of the intercepting net; water pipes are arranged around the upper part of the cleaning tank; a plurality of water nozzles are arranged on the water pipes; a water inlet pipe is connected with the water pipes; a water inlet solenoid valve is arranged on the water inlet pipe; a machine cover is connected with the upper part of the machine body; and a fan is arranged inside the machine cover. The traditional Chinese medicine pretreatment equipment provided by the invention has the advantages that the structure is simple, the cleaning efficiency is high, and traditional Chinese medicine is not easy to damage.

Owner:卢洒洒

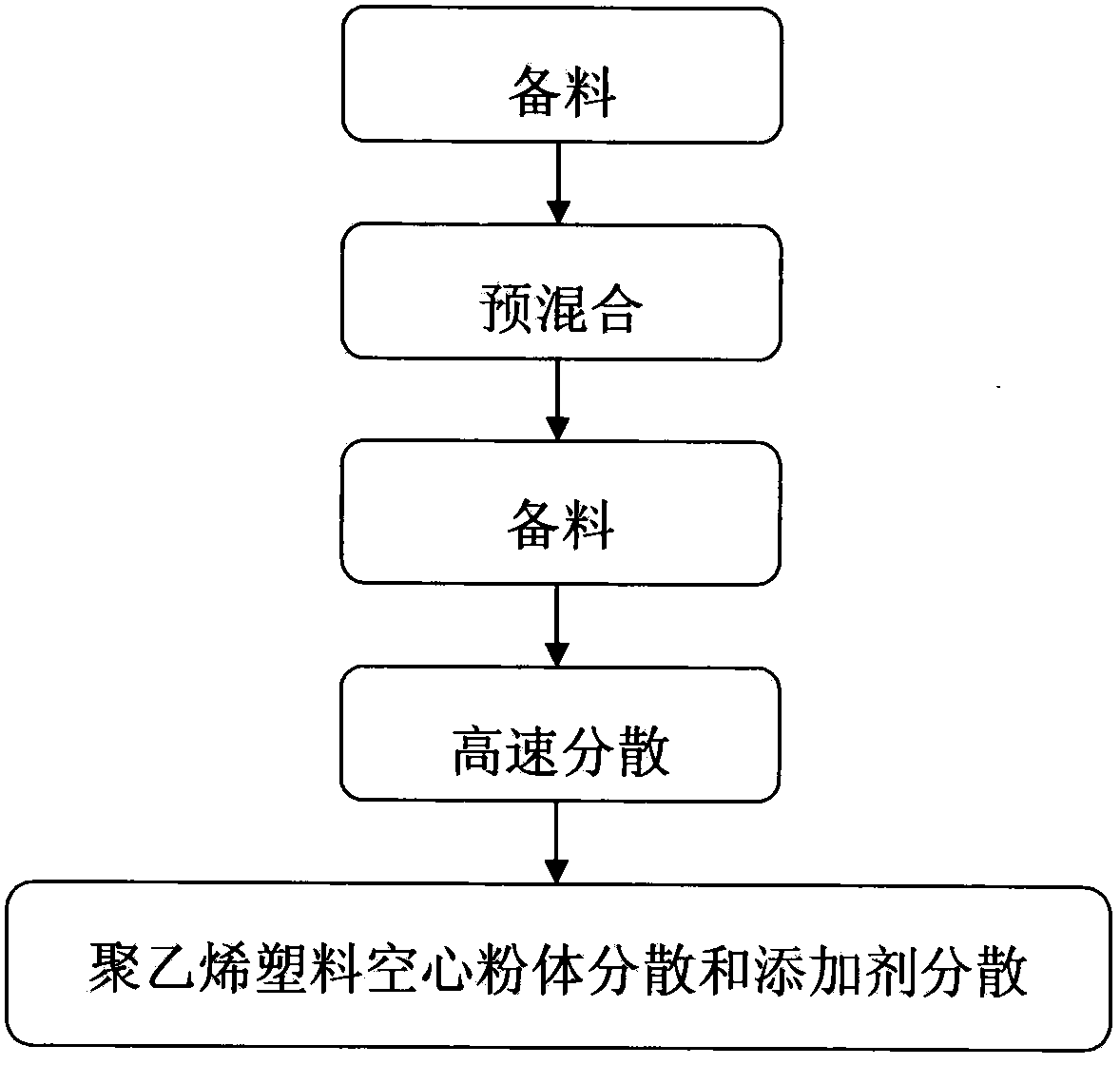

Heat-insulation coating

InactiveCN102702813BLow thermal conductivityImprove fire resistanceReflecting/signal paintsEpoxyAntioxidant

The invention relates to a heat-insulation coating which is prepared by blending the following raw materials in percent by weight: 20-25% of base epoxy resin, 15-20% of polyethylene plastic hollow powder as main body, 25-30% of water, 15-20% of adhesive A agent and 5-20% of additive B agent, wherein the A agent is composed of the following components in percentage by weight: 15% of methyl methacrylate, 35% of ethyl acrylate, 40% of butyl acrylate and 10% of activator; and the B agent is composed of the following components in percentage by weight: 20% of di-tertiary-butyl hydroquinone antioxidant, 25% of acid-resistant additive, 25% of alkaliproof additive, 10% of toughness additive and 20% of defoaming agent. After the coating is coated on the external walls of general cement houses, the room temperature can be decreased by 6-8 DEG C; flowing phenomenon does not exist when the temperature is more than 55-70 DEG C, and cracking and falling phenomena do not appear even if the temperature is lower than minus 40-minus 50 DEG C.

Owner:KARAMAY BEIDE CHEM

Manufacturing method of high-flatness VIA-IN-PAD circuit board

InactiveCN108882527AModerate hardnessEasy to removePrinted circuit aspectsPrinted circuit manufactureCooking & bakingElectroplating

The invention discloses a manufacturing method of a high-flatness VIA-IN-PAD circuit board. The manufacturing method comprises the following steps that through holes are drilled in a production boardwhich is subjected to early-stage pressing; then the through holes are metallized through a copper deposition and full-board electroplating process; the metallized through holes are filled with resin;pre-baking is carried out on the production board, and the filled resin is made to be in a semi-solidified state; the resin which is protruded out of the board surface after plugging is removed by adopting a non-woven grinding plate; then the production board is baked, so that the filled resin is completely solidified; and then secondary copper deposition and full-board electroplating is carriedout on the production board; and an outer-layer circuit, a solder-resistant layer and silk-screen characters are manufactured on the production board in sequence, and then surface treatment is performed to manufacture the circuit board. According to the method, the manufacturing process flow is optimized, the flatness of the surface of the resin and the board surface of the production board can beimproved, and the problem that the resin-plugged hole is sunken due to the leveling of an abrasive belt is solved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

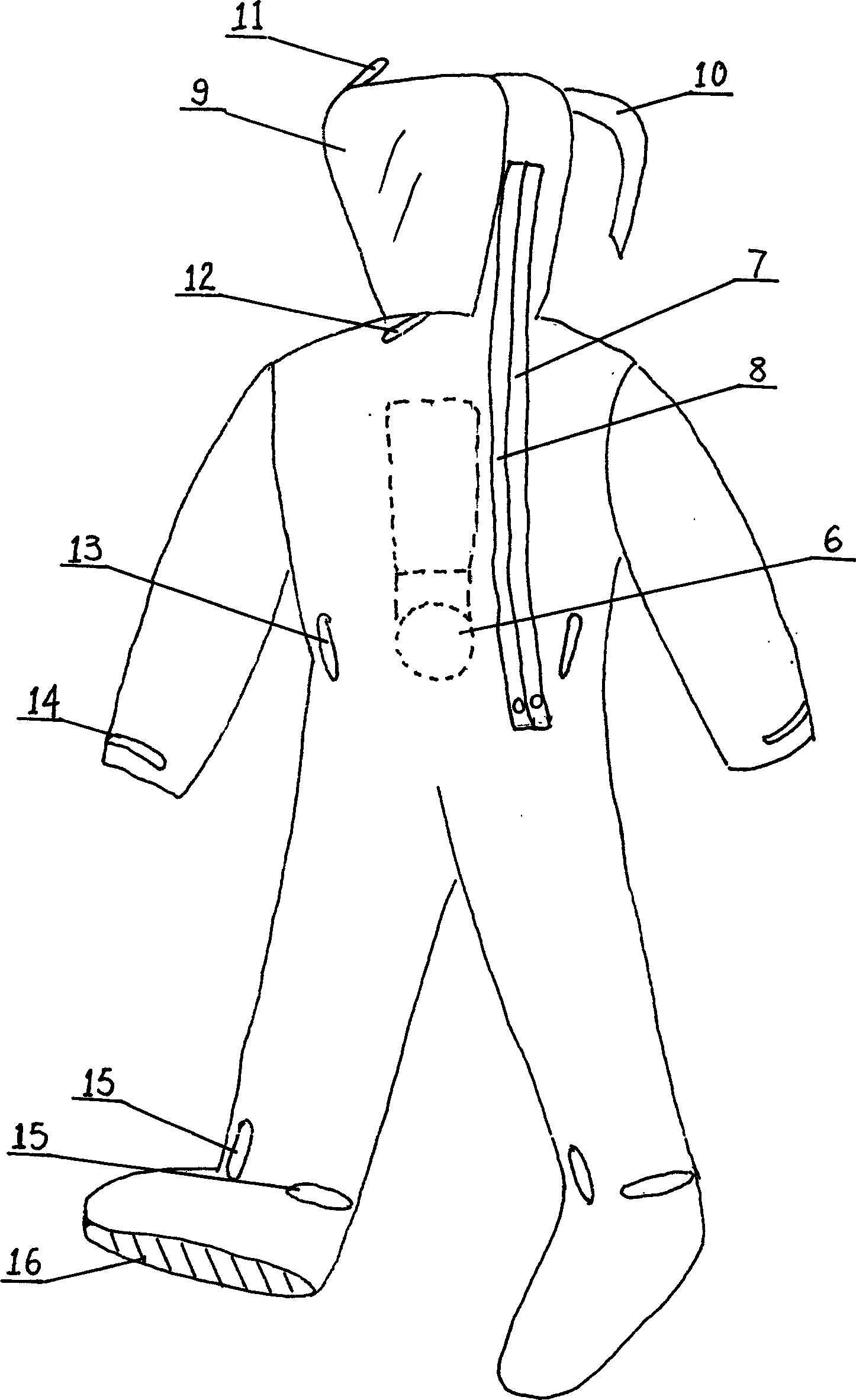

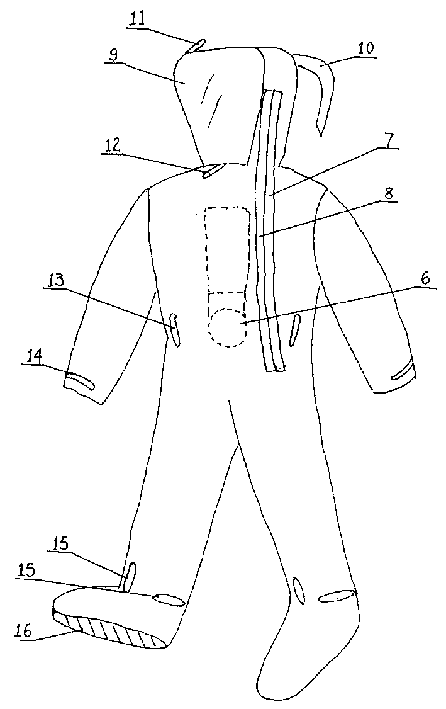

Enclosed integrated protective garment

InactiveCN1199595CNo flow phenomenonAvoid pollutionFire rescueRespiratory apparatusPathogenic microorganismEngineering

The invention discloses a kind of airtight one-piece protective clothing, which connects a hat, a mask, a jacket, trousers and foot covers into a closed body, and an opening is arranged on the front side of the jacket and trousers, and a zipper is arranged at the opening, and the outside of the zipper A flap is provided, the mask is made of transparent material, the cap is provided with a one-way valve, the bottom of the foot cover is provided with a groove or a convex groove, and an air purification device is provided at the waist of the jacket. Since the protective clothing of the present invention is airtight And there is an air purification device on it, which can make the protective clothing appear 1-100mmH 2 O pressure to ensure that the gas is discharged from the inside of the protective clothing to the outside under normal working conditions. Except for the normal pumping of purified gas, there will be no flow of substances from the outside to the inside of the protective clothing, so as to avoid the infection of pathogenic microorganisms to medical staff. Such as the infection caused by SARS virus, it can be used for the protection of serious infectious diseases.

Owner:TIANJIN UNIV

Manufacturing method for car damping materials

The invention provides a manufacturing method for car damping materials. The manufacturing method comprises the steps of: conducting banburying on NBR (Nitrile-Butadiene Rubber), SBR (Styrene Butadiene Rubber), rubber peptizer, CaCO3, and liquid isoprene rubber materials in a banbury mixer, kneading the master batch subjected to banburying, adding nano activated calcium carbonate for kneading, adding DINP (Diisonony Phthalate) for kneading, adding PVC (Polyvinyl Chloride) paste resin, DCP-40, powder dicyandiamide and a foaming agent OBSH for kneading, then adding PU (Poly Urethane) modified epoxy resin for kneading, then adding cross-linking agent trimethylolpropane trimethacrylate for kneading for 10 minutes, finally adjusting the viscosity by the DINP, filtering by a hopper and packaging to form finished products. The damping materials are used for binding internal and external boards of a car, meets the requirement on automatic production in the automobile industry, can well bind the internal and external boards of the car, and improve the production efficiency, and can also play a damping role after being foamed and swelled, wherein the cost on manually binding sheet damping materials can be lowered.

Owner:保光(天津)汽车零部件有限公司

Positive pressure enclosed protective garment

The invention discloses a positive-pressure sealed exposure suit, including one-piece clothes, air-purifying feeding system, power supply, and support wind board. The air-purifying feeding system includes shield, gas feeding system, purifying system and gas output passage. The air feeding system includes electric machine and fan. The purifying system includes filtering layer, inactivation layer, and absorbing layer. The under part of the purifying system is connected with the support wind board and is set on the one-piece clothes. It seals doctors and nurses in the exposure suit, and the micro fan blows the processed fresh air into the exposure suit for people to breathe and carries away heat and gas exhaled, so as to prevent serious infectious disease, like the infection caused by SARS virus. It can also be used as anti-chemical clothes and fire clothes.

Owner:TIANJIN UNIV

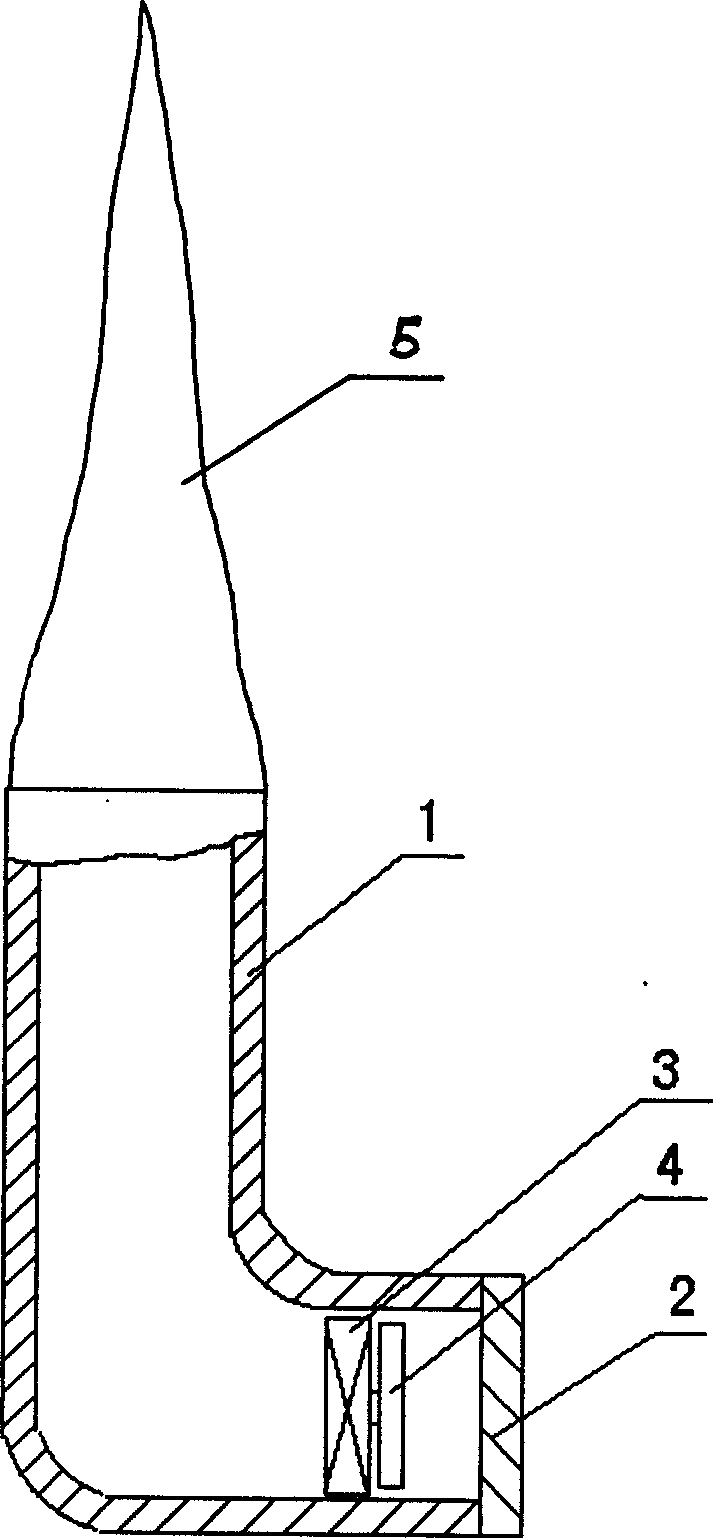

Copper removal brush for gun barrel

A copper removal brush for a gun barrel is formed by a brush head, a pipe brush and a brush handle which are connected into a whole; an air inlet plug and one end of a screw plug are connected with two ends of the brush handle respectively; the screw plug is provided with a liquid shifting hole and a liquid leakage hole which are communicated with each other; the brush head and the other end of the screw plug are connected with two ends of the pipe brush respectively; a screw plug end of the pipe brush is connected with a liquid coating plate which is closely attached to the liquid leakage hole formed in the screw plug. The diameter of the liquid shifting hole formed at the edge of the screw plug is small, the copper removal brush rotates to enable a solvent to be squeezed to the pipe wall under the action of the centrifugal force, easily enter the screw plug from the liquid shifting hole and flow onto wool felt through the needle point size of liquid leakage hole formed in the screw plug to be used, the liquid quantity is not large, and accordingly the flowing of liquid droplets is avoided, the use of a cleaning solution is reduced, and the pollution to the environment is not produced. The brush head is smooth and accordingly collisions and bruises of the inner wall of a gun bore are not produced, metal combustion materials and dirt of every position of the gun bore are removed through the spiral pipe brush, the sealing effect is achieved due to a sealing ring and the wool felt which are arranged at the brush handle end, and a copper removal agent can be uniformly brushed at every position of the inner wall of the gun bore without leakage due to the wool felt and accordingly the inner wall of the gun bore is fully utilized and is not damaged.

Owner:NINGBO JIABO BRUSH IND

A kind of high temperature resistant segmental curing epoxy paint and its application method

ActiveCN106010127BNo crackDoes not reduce adhesionFireproof paintsEpoxy resin coatingsNitrile rubberHexahydrophthalic anhydride

The invention relates to high-temperature resistant sectional curing epoxy paint and a use method thereof. The high-temperature resistant sectional curing epoxy paint comprises a component A, a component B and a component C which are mixed in a certain ratio, wherein the component A is an epoxy resin component which comprises E-20 bisphenol A epoxy resin, E-51 bisphenol A epoxy resin, F-51 phenolic epoxy resin, carboxyl terminated nitrile rubber modified tetra-glycidyl amide type epoxy resin, aluminium oxide, micron-grade and nanometer-grade aluminum nitride balls, fumed silica, a wetting dispersant and a coupling agent; the component B is a first curing agent component which comprises a YH-82 epoxy curing agent, a C-1041 cardanol epoxy resin curing agent, DMP(Dimethylphthalate)-30, fumed silica and micron-grade aluminum nitride balls; the component C is a second curing agent component which comprises hexahydrophthalic anhydride, fumed silica and micron-grade aluminum nitride balls. The high-temperature resistant sectional curing epoxy paint prepared by the invention has the effects of low temperature pre-curing for avoiding uniform paint films, and high temperature curing, thereby keeping high strength and good adhesion of the paint films formed by low temperature curing.

Owner:中国森田企业集团有限公司

Positive pressure closed protective clothes

InactiveCN100394873CEnsure normal dischargeNo flow phenomenonChemical protectionHeat protectionPositive pressureElectric machinery

Owner:TIANJIN UNIV

Polyurea rebar self-protection anti-corrosion concrete block

The invention relates to the field of civil engineering, in particular to a polyurea reinforced self-protection anti-corrosion concrete block, which includes steel bars and concrete, the outer layer of the steel bar has a polyurea protective layer, and the polyurea self-protection anti-corrosion concrete There may be a through hole in the block, and the cross section of the through hole may be circular, square, or triangular. The block may have an outrigger on the left side and an inner groove on the right side. The invention has the advantages of strong material corrosion resistance, fast and convenient construction operation, aging resistance, non-toxic and pollution-free construction and use, no potential safety hazards, safe and convenient installation and use, labor-saving, labor-saving, time-saving and economical advantages, and It can improve the fit and reduce the amount of cement, especially in the field of civil engineering.

Owner:杨海华

Paste-like high-expansion vibration-damping and sound-insulating adhesive for automobiles and its manufacturing process

Owner:保光(天津)汽车零部件有限公司

A kind of high voltage insulation sealing glue

ActiveCN104610905BStrong randomnessEasy to useNon-macromolecular adhesive additivesMacromolecular adhesive additivesElectricityCross-link

The invention relates to high-voltage-insulation sealing adhesive. The high-voltage-insulation sealing adhesive comprises a first composition and a second composition which are stored separately, wherein the first composition comprises the following components in parts by weight: 40-60 parts of hydroxy-terminated polysiloxane, 3-10 parts of silicon dioxide, 10-60 parts of a filler, 1-5 parts of a cross-linking agent and 0.2-1 part of a silane coupling agent; the second composition comprises the following components in parts by weight: 30-60 parts of hydroxy-terminated polysiloxane, 0-10 parts of polymethyl siloxane, 10-60 parts of a filler and 0.8-1.5 parts of a catalyst. The first composition and the second composition are stored separately, and during room-temperature mixing, sulfuration reaction is performed on the hydroxy-terminated polysiloxane, the cross-linking agent and the silane coupling agent under the action of the catalyst; after the sulfuration reaction, a product is excellent in flame retardance, electrical performance and bonding strength, and has shockproof and waterproof functions; the two compositions are shaped as blocks, and can be directly kneaded into any shapes by hands for sealing, so that the high-voltage-insulation sealing adhesive is easy and convenient to use.

Owner:FUJIAN RUISEN CHEM

A method for slope ecological protection and bare land vegetation protection

ActiveCN111406584BAvoid churnNo flow phenomenonPlant cultivationCultivating equipmentsBiologySeedling

A method for slope ecological protection and bare land vegetation protection relates to a method for slope ecological protection and bare land vegetation protection. It is mainly invented to solve the problems that the current slope or bare ground is difficult to retain water and grass seeds are difficult to survive. Pre-plant and water maintenance on the slope surface according to the method of planting grass seeds or seedlings. Spray the nano-superhydrophobic emulsion on a sunny day or a few days before the rainy season. The concentration of the nano-superhydrophobic emulsion for direct spraying after dilution is 0.5%-10%. Spray 1-5 kg of the diluted emulsion per square meter, per square meter The effective active ingredients of the rice-containing emulsion range from 5 grams to 200 grams. After spraying, generally two or three days in spring and summer, a hydrophobic soil layer can be formed. The thickness of the hydrophobic soil layer is controlled between 5 mm and 30 mm, with an average thickness of 10‑20 mm. The advantage is to protect the slope from soil loss and improve the drought resistance of plants.

Owner:疏科纳米疏水科技(嘉兴)有限公司

Positive pressure enclosed protective garment

The invention discloses a positive pressure airtight protective clothing, which comprises a one-piece suit, an air purification delivery system, a power source, and a supporting windshield. The air purification delivery system includes a protective cover, a gas delivery system, a purification system, an air outlet channel, and a protective cover It is connected with the gas delivery system, purification system, and air outlet channel in turn. The gas delivery system includes a motor and a fan. The motor and the power supply are connected through wires. The purification system includes a filter layer, an inactivation layer, and an adsorption layer. board connection, the air purification delivery system is set on the one-piece suit, and the one-piece suit is provided with an air outlet channel. The invention seals the medical personnel in the protective suit, and the protective suit is blown inward by a micro-fan to blow in treated fresh air. For people to breathe, take away heat and exhaled gas, make the air in the protective clothing fresh and cool, achieve the purpose of protection and cooling, prevent serious infectious diseases, such as infection caused by SARS virus, and can also be used as chemical protective clothing, fire protection Clothes.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com