Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232results about How to "Long-term work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

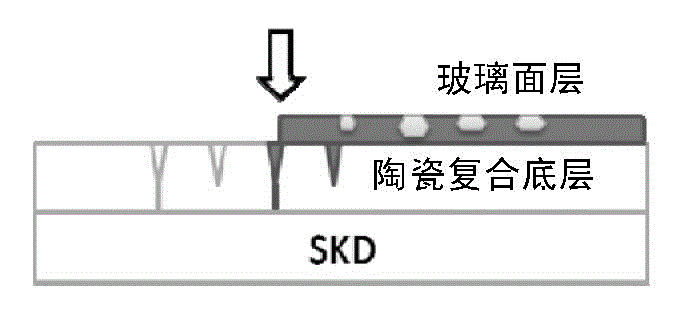

Protective coating for thermoelectric material or thermoelectric device

ActiveCN104890325AImprove antioxidant capacityReduce weightThermoelectric device with peltier/seeback effectCeramic layered productsThermoelectric materialsCeramic composite

The invention relates to a protective coating for a thermoelectric material or thermoelectric device. The protective coating comprises a ceramic composite bottom layer and a glass surface layer that are applied to the surface of the thermoelectric material or thermoelectric device in order. The thickness of the ceramic composite layer is 10-500micrometers, and the thickness of the glass surface layer is 10-1000micrometers. The glass surface layer can seal the defects of the ceramic composite bottom layer, ensure the coating integrity and avoid failure in high temperature and thermal cycle service process. Therefore, compared with single ceramic composite coating, the protective coating provided by the invention has better heat resistant durability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Building structure seismic damage assessment system and method based on wireless sensor network

InactiveCN102507121ALow costLong term workTransmission systemsVibration testingAngular velocityEngineering

The invention discloses a building structure seismic damage assessment system and a method based on a wireless sensor network. The system mainly comprises a plurality of wireless sensor nodes and a control computer center which are wirelessly connected. With the help of the characteristics of low cost and self-organization of the wireless sensor network technique, the building structure seismic damage assessment system based on the wireless sensor network is constructed, and the goals of zero line arrangement and long-term all-weather working are really realized from the aspect of functions. By using detected acceleration and angular velocity responses for conducting numerical analysis and calculation to obtain the velocity response and the inter-story displacement response of a structure, seismic damage assessment cannot only be conducted to the overall structure and structural members through inter-story displacement, but also can be conducted to nonstructural members such as velocity-sensitive or acceleration-sensitive members through the velocity and acceleration responses of the structure, and the performance-based seismic damage assessment requirement of the building structure is really met.

Owner:ZHEJIANG UNIV

Water body environment pollution monitoring system based on electrochemical sensor

InactiveCN101118229ASave human effortHigh degree of automationMaterial electrochemical variablesTurbidityData acquisition

The present invention discloses a water body environmental pollution monitoring system which is based on an electrochemical sensor, and comprises a floating body. The upper part of the floating body is fixed with an equipment bin which is provided with a GPRS wireless transmitting module inside. A data collecting equipment is appended at the lower part of the floating body. The data collecting equipment comprises an accumulator and a control circuit which are arranged in a sealed shell body, a pH value sensor, a H2S sensor, a dissolved oxygen sensor, a salinity sensor and a turbidity sensor which are fixed at one end of the shell body. Analog signal which is collected by each sensor is magnified by a magnified circuit, is converted to a digital signal by an A / D converting circuit and then is transmitted to a micro-controller. The time interval of the collected data is intercalated via software. The measured value is sent to a data monitoring center at a bank station via the GPRS wireless transmitting module. The present invention has the advantages of high automatization degree, real-time monitoring and large amount of datum memory. The water body polluting condition and the caused reasons of the monitored water area can be known in detail and a forecast can be made, and a scientific foundation can be provided for radically solving the pollution.

Owner:ZHEJIANG UNIV

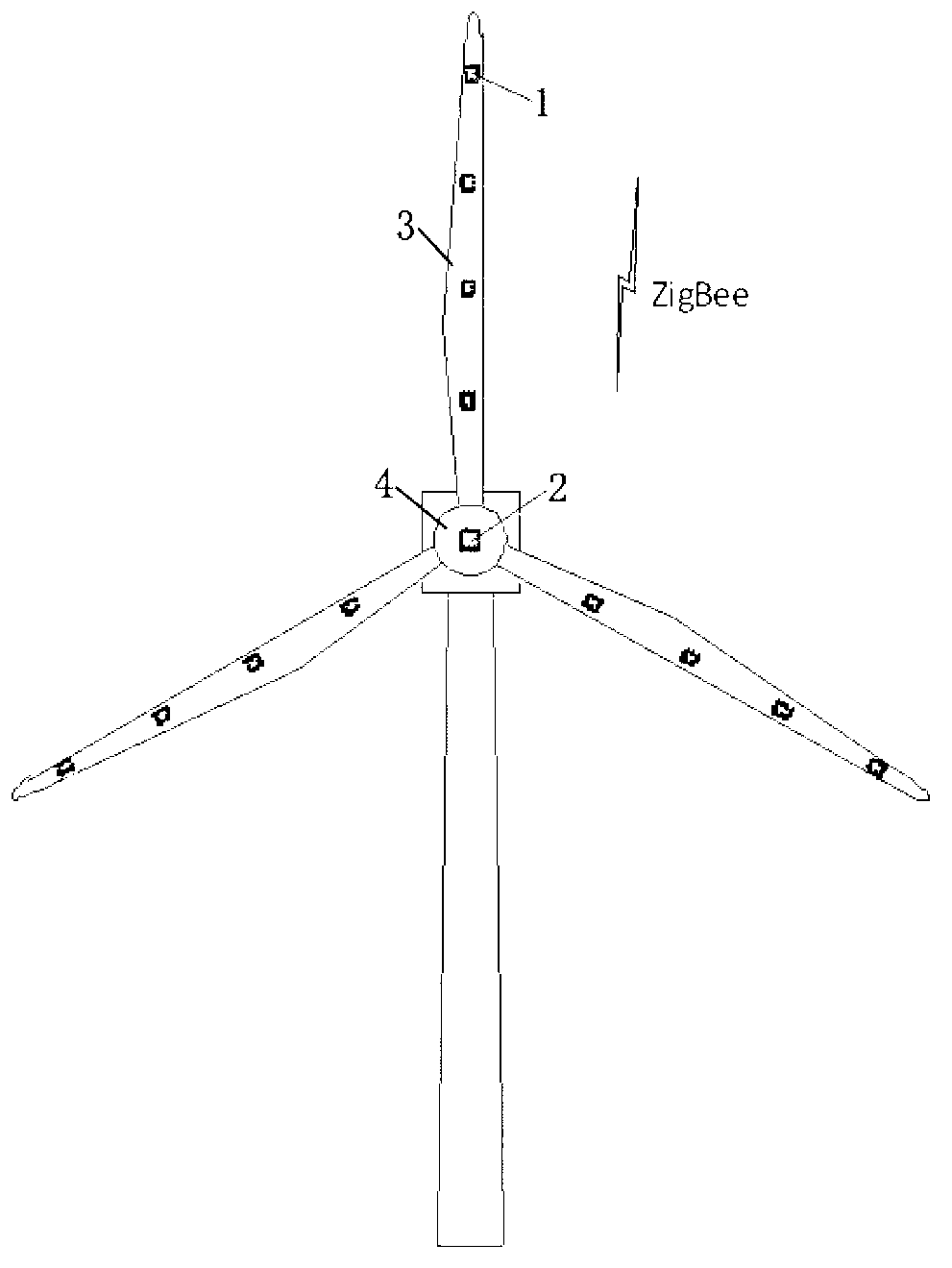

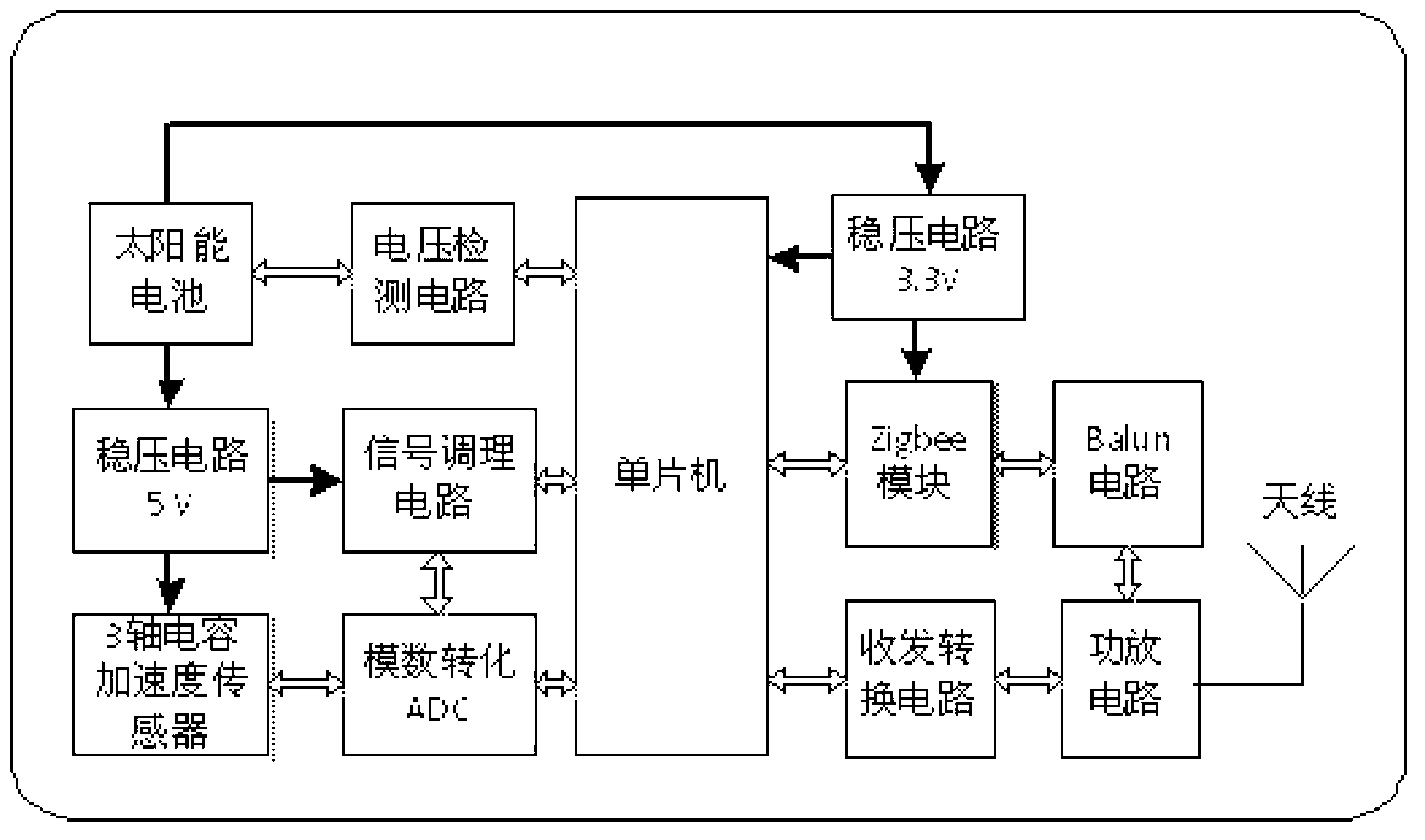

Wireless monitoring system and method for modal parameter of blade of fan

ActiveCN103063428AEasy to installReduce volumeMachine part testingTransmission systemsVibration accelerationStrain gauge

The invention relates to a wireless monitoring system and method for a modal parameter of a blade of a fan. The method comprises the following steps of: A, collecting a vibration acceleration signal of a blade according to periods; B, processing the signal collected in the step A to obtain a digital signal; C, processing the digital signal obtained in the step B to obtain the modal parameter of the blade, and meanwhile, reading the air speed of the fan and variable pitch data; D, storing the data obtained in the step C, and transmitting the data to a remote analysis terminal; and E, carrying out analytical calculation on the data to obtain the inherent frequency and vibration mode of the blade. The system comprises a coordinator and more than one sensor fixedly arranged on the blade. By using the wireless monitoring system for the modal parameter of the blade of the fan, provided by the invention, the real-time modal parameter of the blade of the fan can be obtained through monitoring the vibration of the blade; the monitoring method and a mounting way are simple; no strain gauge is used, and correction on a result is not needed; and the test process is independent from the operation process of the fan, therefore, stopping of the fan is not needed.

Owner:GUODIAN UNITED POWER TECH

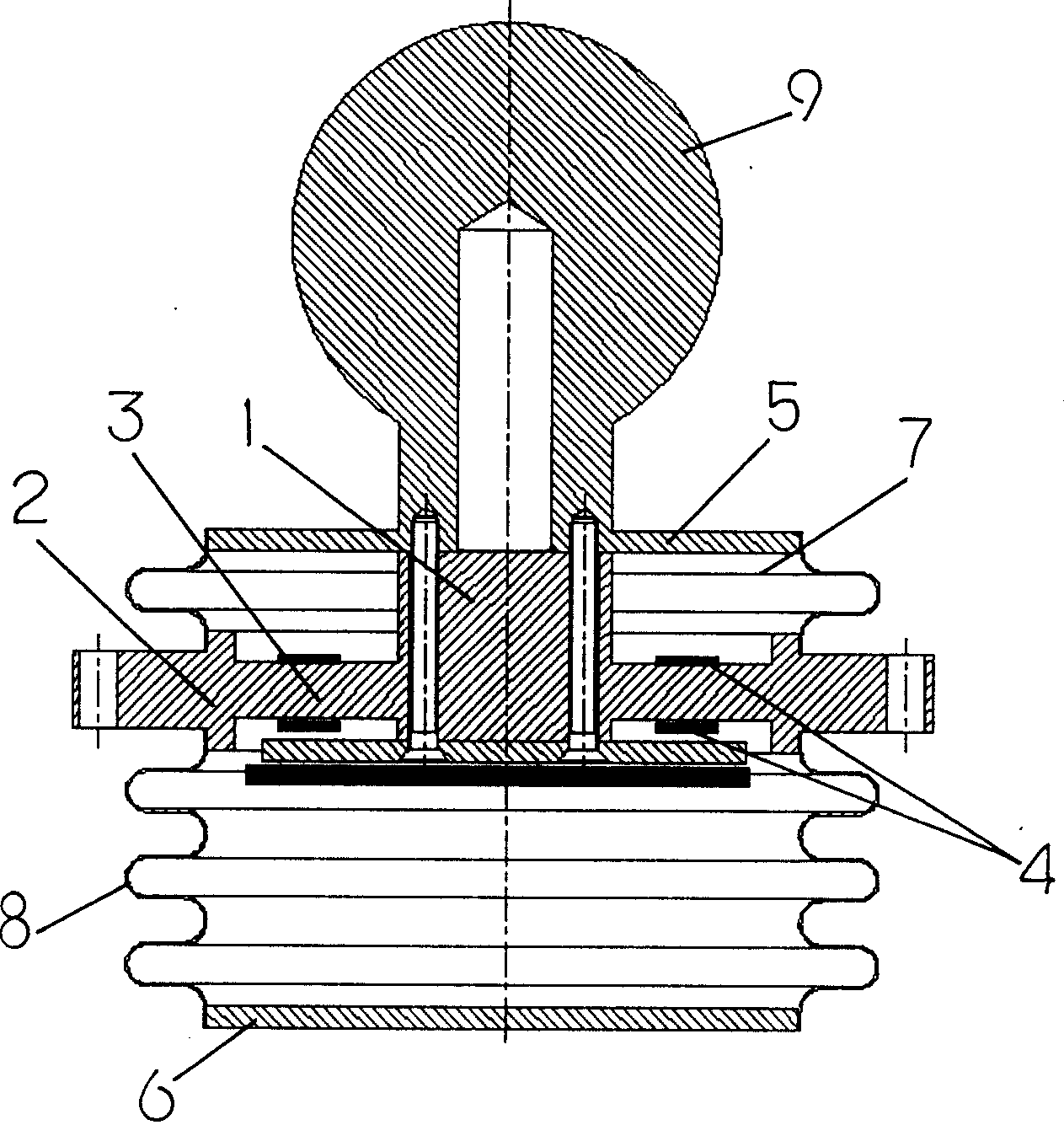

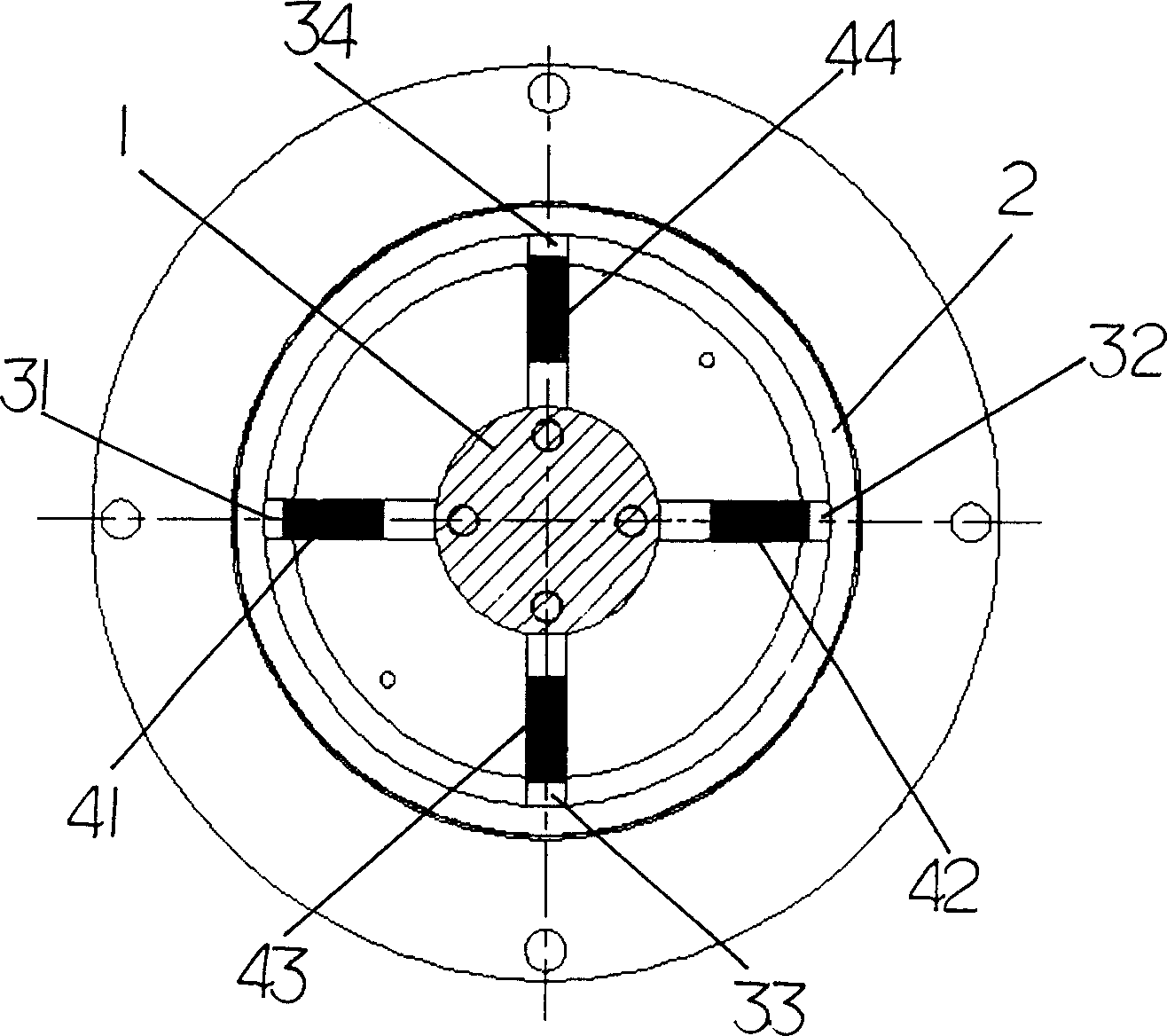

Deep sea pressure, flow speed and direction sensor and use thereof

InactiveCN1710394AImprove sealingGuaranteed to workFluid pressure measurement using elastically-deformable gaugesMarine engineeringTransducer

A transducer of pressure , flow speed and flow direction at deep sea features having column formed seat and its ring shell , setting elastic beam support used as strain plate carrier between seat and shell , setting four said beams on one plane vertical to seat axis and arranging them two by two symmetrically in cross based on seat axis , using top and bottom end covers as well as bellows to form closed oil cavity , using strain plate to output collected signal and solid connecting gyro-rotor with seat axis as rotation centre at centre of top end cover.

Owner:HEFEI UNIV OF TECH

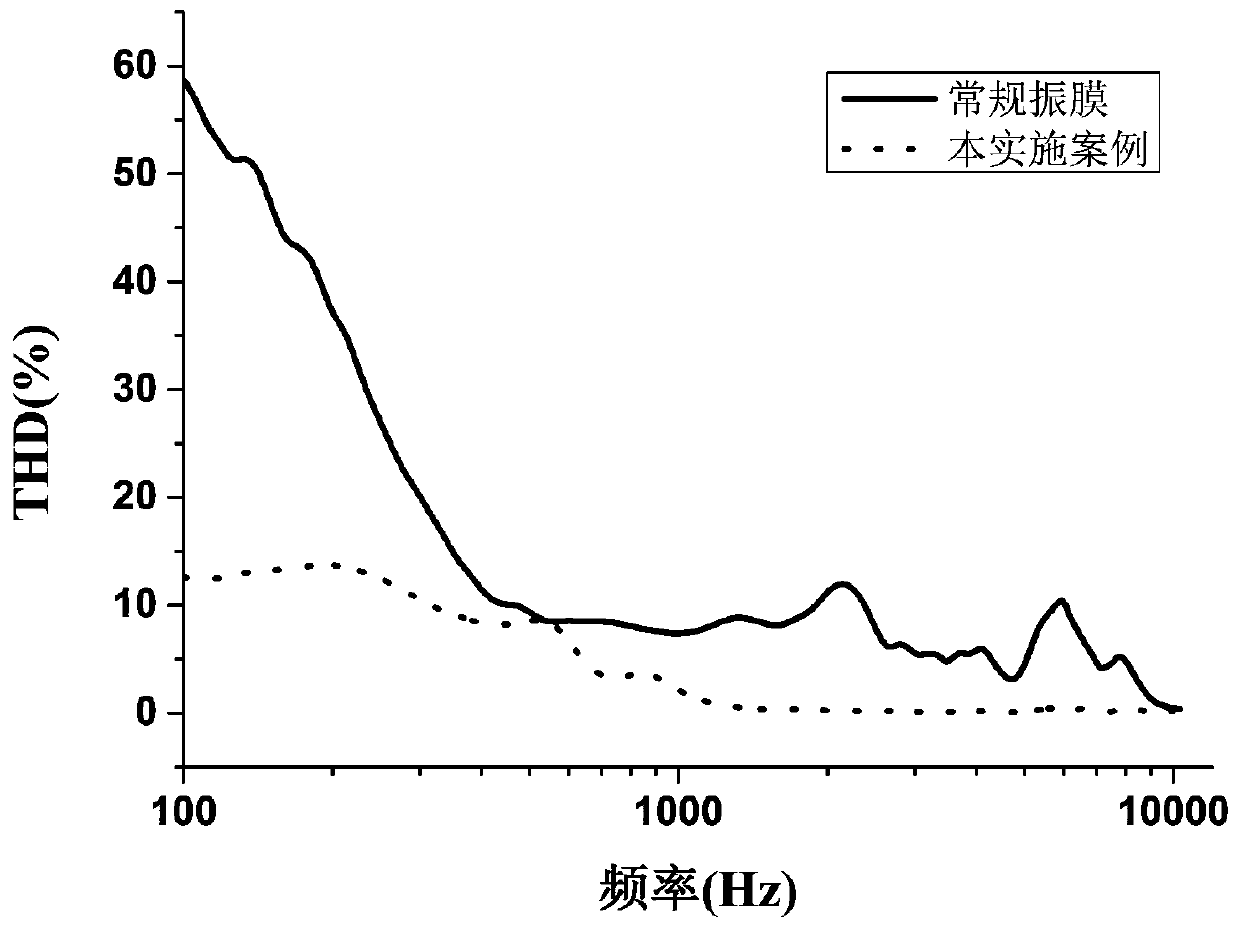

Vibrating diaphragm of sound production device and sound production device

ActiveCN110267167AGood resilienceIncrease elasticityPolymeric diaphragmsNon-planar diaphragms/conesChemistryPolymer

The invention discloses a vibrating diaphragm of a sound production device and the sound production device, the vibrating diaphragm comprises at least one elastomer layer, the elastomer layer is made of a hydrogenated butyronitrile polymer, the hydrogenated butyronitrile polymer comprises an acrylonitrile block, and the content range of the acrylonitrile block in the hydrogenated butyronitrile polymer is 10-70 wt%, the hydrogenated butyronitrile polymer is added with a vulcanizing agent, and the content of the vulcanizing agent is 1%-15% of the total amount of the hydrogenated butyronitrile polymer. The vibrating diaphragm is good in rebound resilience, can keep high elasticity in a low-temperature environment, and can work for a long time in a high-temperature environment, so that the sound production device can be applied to an extremely severe environment, and meanwhile, the acoustic performance of the sound production device is kept in a good state.

Owner:GOERTEK INC

High-temperature resistant anti-corrosion pump valve sealing gasket and preparation method thereof

ActiveCN103436029AImprove high temperature resistanceHigh mechanical strengthPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSilanesDiphenylsilanediol

The invention discloses a high-temperature resistant anti-corrosion pump valve sealing gasket and a preparation method thereof. The sealing gasket comprises the following raw materials in parts by weight: 60-70 parts of methyl vinyl silicone rubber, 20-30 parts of ethylene-propylene-diene monomer, 10-15 parts of polyethylene, 1-2 parts of a corundum powder, 5-10 parts of hydroxyl silicone oil, 15-20 parts of fumed silica, 2-3 parts of dihydroxydiphenylsilane, 2-3 parts of zinc oxide, 1-2 parts of alkylated diphenylamine, 4-8 parts of polyethylene wax, 0.5-1 part of 2,4-dihydroxy benaophenonel, 8-12 parts of nano argil, 10-15 parts of modified nano-diamond, 1-2 parts of triallyl cyanurate, 1-3 parts of vinyl-tris(beta-methoxyethoxy)silane, 1-2 parts of an accelerant CZ, 2-3 parts of an anti-aging agent RD, and 1-2 parts of an anti-aging agent 4020. The sealing gasket can resist high temperature, has high mechanical strength, high oil resistance and good corrosion resistance, can work in acids, alkalis, oil and other media for a long time, and is durable in use.

Owner:ANHUI TIANMA PUMP VALVE GROUP

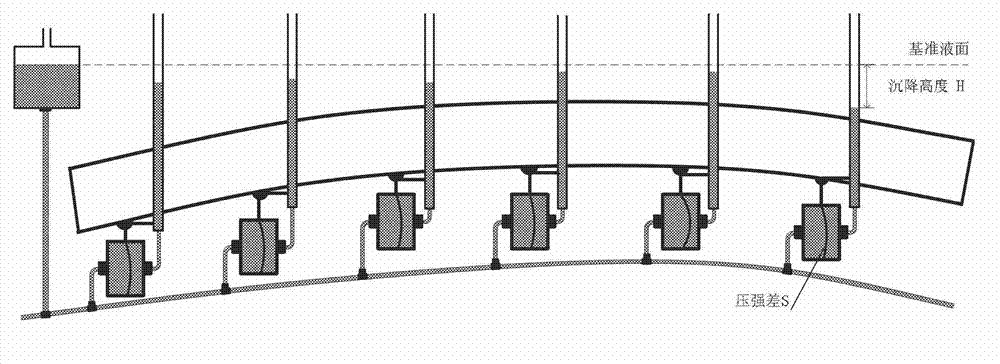

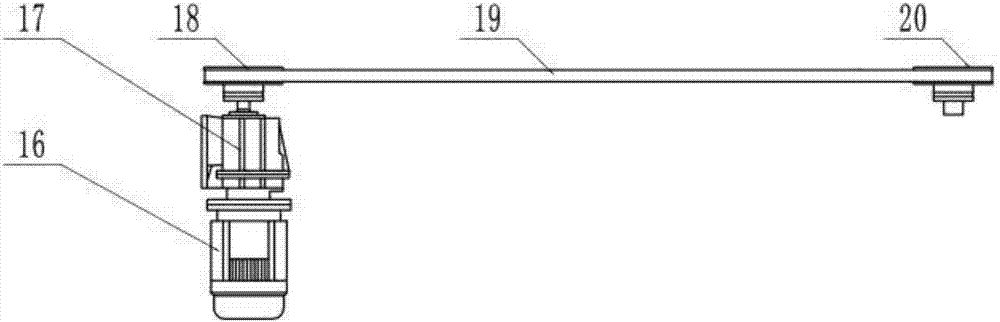

Method for improving monitoring accuracy of structural settlement

ActiveCN102927966AFully automatedNetworkingHydrostatic levellingStructural health monitoringEngineering

The invention provides a method for improving monitoring accuracy of structural settlement and belongs to the fields of structural health monitoring and sensor application. The method for improving the monitoring accuracy of the structural settlement is characterized in that a fixed liquid level retainer which does not subside along with the structural settlement is adopted to serve as a reference liquid level, simultaneously a hydraulic balancing pipe is added at one end of a liquid pressure sensor to offset initial pressure-intensity deviation of the liquid pressure sensor, the measuring range of the e liquid pressure sensor is decreased, the measuring sensitivity of the liquid pressure sensor is improved, and the monitoring accuracy of the structural settlement is improved. In addition, calibration procedures in the measurement process are simplified, and the method only needs primary static initialized calibration and overcomes the defects including low accuracy and complicated calibration procedures in traditional structural settlement monitoring.

Owner:TSINGHUA UNIV

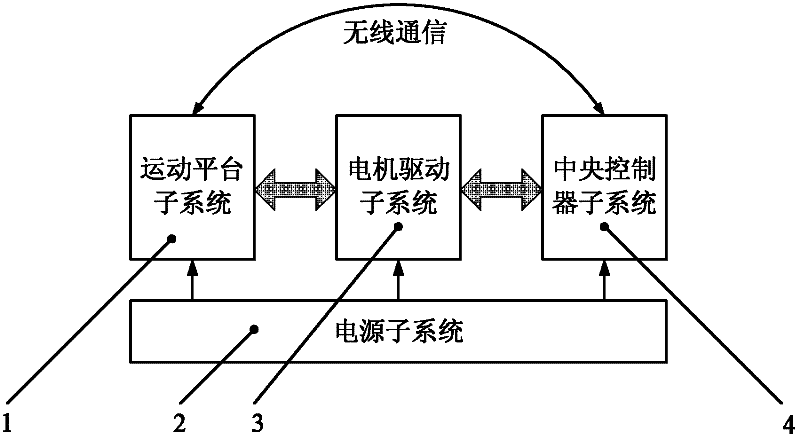

Differential pressure type airspeed sensor testing system

ActiveCN102360027AIncreased dynamic range and precisionImprove uniformityTesting/calibration of speed/acceleration/shock measurement devicesMovement controlCommunication interface

The invention discloses a differential pressure type airspeed sensor testing system. The system comprises a motion platform subsystem 1, a power supply subsystem 2, a motor driving subsystem 3 and a central controller subsystem 4. In the operation principle of the system, the central controller subsystem 4 is used for transmitting a motion control command to the motor driving subsystem 3, and themotor driving subsystem 3 is used for controlling the rotating speed of the motion platform subsystem 1 according to the command, so that differential pressure is generated on the two sides of a differential pressure type airspeed sensor 1111 and is converted into a voltage signal through the differential pressure type airspeed sensor 1111, and the voltage signal is processed by a signal conditioning / acquiring unit and a micro-processing unit and then is transmitted to the central controller subsystem 4 through a first wireless communication interface unit 1114 to finish testing and calibration. By the differential pressure type airspeed sensor testing system, the dynamic range of a test speed can be enlarged, the uniformity of the test speed can be improved, and the direction errors of the test speed can be reduced.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Continuous deformation magnesium alloy extruding method

InactiveCN1974045AReduce the temperatureWill not oxidizeExtrusion control devicesRams/plungersAviationNonferrous metal

The present invention is continuous deformation magnesium alloy extruding method, and belongs to the field of non-ferrous metal plastic forming technology. The technological scheme includes extruding deformation magnesium alloy wire blank in a continuous rotary extruder and regulating the contact surface length and running interval between the extruding wheel and the block so as to produce extrusion force between the deformation magnesium alloy blank and the rotary extruding wheel and friction heat for extruding the blank in the mold into product in continuous great shearing deformation mode. The product of the present invention may be used widely in aerospace, aviation, communication, computer, traffic and other fields.

Owner:HUNAN HUAKANG NEW MATERIAL

Intelligent watch

InactiveCN107065508AExtended working hoursLong term workBatteries circuit arrangementsElectric power supply circuitsElectricityExternal energy

The invention discloses an intelligent watch which comprises an energy acquisition module used for collecting external energy, a transducer for converting the external energy into electric energy, an electric energy storage module for storing the electric energy, and a power management module for supplying power to the intelligent watch through the electric energy stored by the electric energy storage module. The intelligent watch of the invention can collect the external energy and convert the external energy into the electric energy for storage, power is supplied to the intelligent watch, thus the working time of the intelligent watch is prolonged, and the intelligent watch can work for a long time.

Owner:SHANGHAI MORUAN COMM TECH

Decorative line covered by metallic film and producing method thereof

InactiveCN101352992AHigh bonding strengthImprove anti-aging propertiesPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentWeather resistancePliability

The invention provides a decorative line which coats metal films and a manufacturing method thereof and includes the following steps: a modeling substrate is preheated after being decontaminated and dusted and being coated with a surface affinity agent; a flexible metal film is coated with a hot-melt adhesive after being dusted and preheated; the metal film coated with the adhesive is rolled and coated with a modeling roll wheel on the surface of the modeling substrate on one surface of the surface affinity agent and the health is preserved. The decorative line made with the method is characterized by metal texture, high bonding strength, hydrolysis resistance, non-reversibility, weather resistance, and the like, and improves the texture grades of the decorative line.

Owner:北京市森诺家具材料有限公司

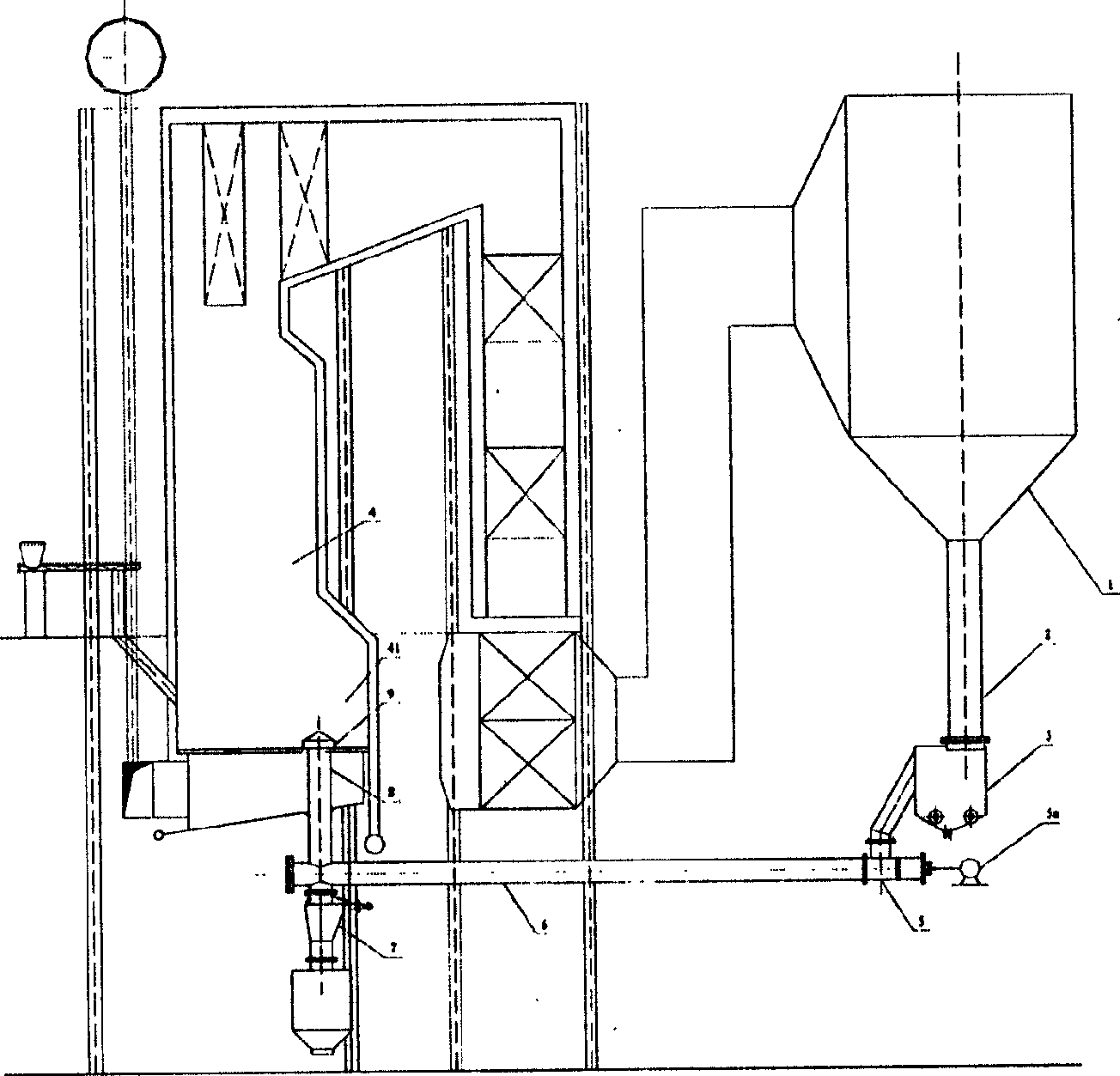

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

ActiveCN1529088AReduce leakageImprove sealing performanceFluidized bed combustionApparatus for fluidised bed combustionInjectorCorrosion

The invention provides a kind of fly ash bottom feeding circular fluidized-bed combustion method and the device, the method is: uses fly ash collector to collect the fly ash with high content in smoke, the fly ash are put into the back material controller through vertical pipe, then and they are carried to the return pipe through transmitting and ejector, and they are returned to the thick phase area of bed through bottom feeding spraying muzzle which is high temperature resisting and corrosion resisting. The device is: it is made up of fly ash collector, back material controller, gas transmitting ejector and the combustion furnace. The top of the combustion furnace connects with the inlet of fly ash collector, the fly ash through the fly ash collector outlet, are carried to the thick phase area of combustion furnace through the bottom feeding sprayer with gas transmitting ejector. The invention can enhance the combustion effect of the fly ash; it can save energy and protect the environment.

Owner:SOUTHEAST UNIV

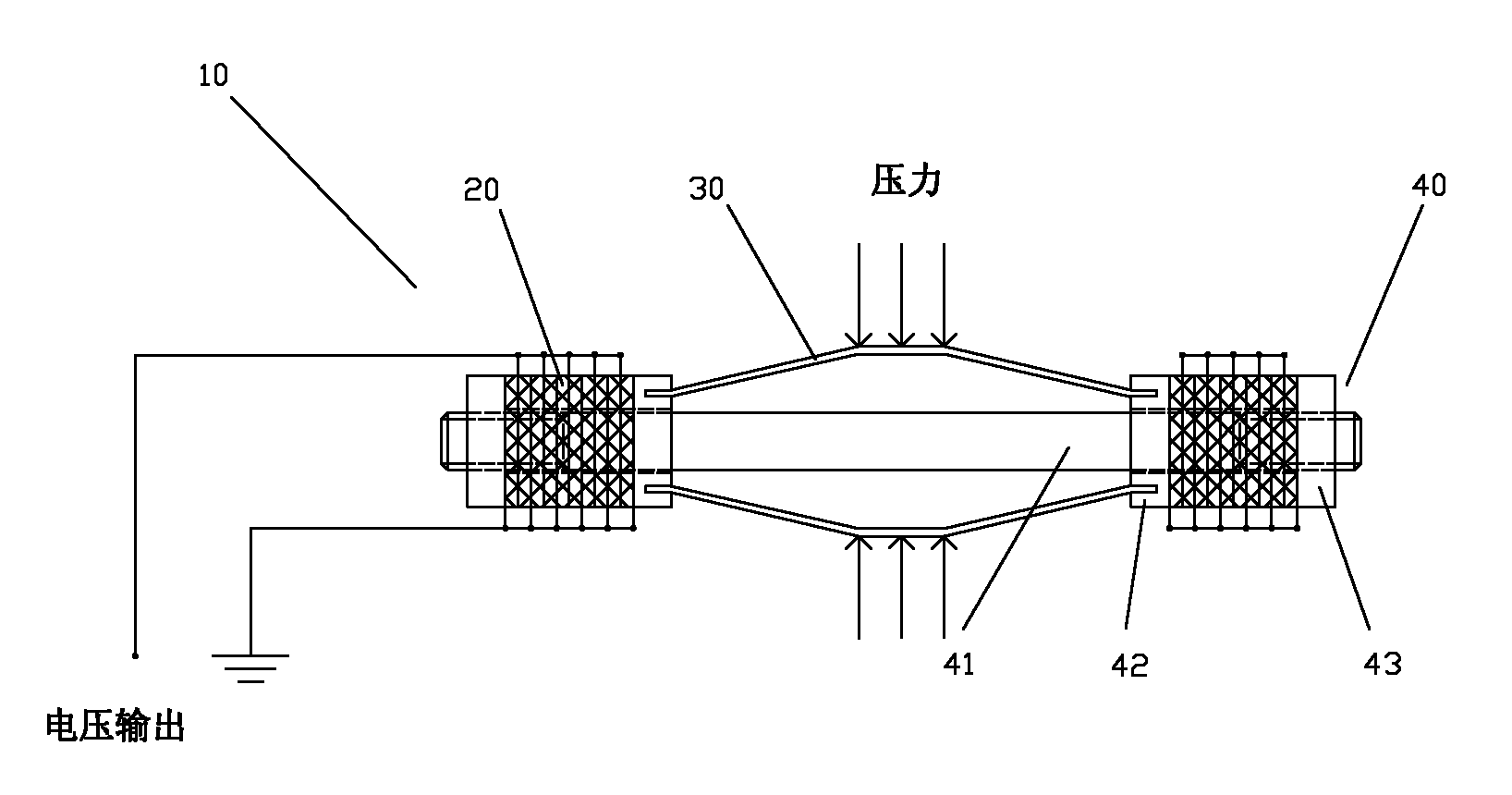

Force-electricity energy converter and array thereof

InactiveCN101854130ACompact structureSimple structurePiezoelectric/electrostriction/magnetostriction machinesMobile vehicleElectricity

The invention discloses a force-electricity energy converter and an array thereof. The energy converter works in a bending-pressing mode and converts vibration of an environment or energy generated when a human body walks into electric energy by using a piezoelectricity principle. The energy converter of the invention comprises a pair of piezoelectric units and a pair of bow-shaped elastic elements, wherein the piezoelectric units and the elastic elements are fixed by pre-loading devices; and the elastic elements convert a transverse force (or outside vibration) applied by the outside to an elastic strip into longitudinal (axial) pressure which is applied to the piezoelectric units and is amplified in the bending-pressing mode and then the piezoelectric units efficiently generate electricity through the piezoelectric effect. The invention further relates to the array of the force-electricity energy converter. The array is used for converting mechanical energy which is generated when the human body (including other moving vehicles) operates on a plate into the electric energy and outputting the electric energy. The force-electricity energy converter and the array thereof have the advantages of simple structure, low resonant frequency and low manufacturing cost and can guarantee to work for a long term under the high-pressure working condition.

Owner:PEKING UNIV

Hydraulic seal electrical connector

ActiveCN105428874AReduce the cross-sectional areaReduce forceSecuring/insulating coupling contact membersCouplings bases/casesElectricityEngineering

The invention discloses a hydraulic seal electrical connector, which comprises a housing, an interface sealing gasket and a contact pin, wherein a sintered single-core glass insulator is arranged in the housing; the contact pin is fixed in the middle of the single-core glass insulator; two ends of the contact pin extend to two sides of the single-core glass insulator respectively; the interface sealing gasket is arranged at the left side of the single-core glass insulator; the right side of the single-core glass insulator is filled with a sealant; the contact pin is fixed with the housing through a base; and one side, far away from the sealant, of the base is filled with a pouring sealant. The contact pin in the housing is doubly fixed through the single-core glass insulator and the base; the reliability of a product is ensured in structure; the sealant and the pouring sealant are respectively arranged at two ends of the base; the sealing property of a socket can be improved by the sealant; the electrical property of the socket can be improved by the pouring sealant; the condition that the connector can normally transmit an electric signal for a long period of time is ensured by the sealant and the pouring sealant; the interface sealing gasket is arranged between the housing and the contact pin, so that the interface sealing performance after the socket is inserted, and the operational capability at low air pressure are ensured.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Device and method for preparing titanium tetrachloride in manner of vibrating-type inner circulation fluidization

InactiveCN103979604ADestruction operationTake advantage ofTitanium halidesReaction temperatureNitrogen gas

The invention relates to a device and a method for preparing titanium tetrachloride in a manner of vibrating-type inner circulation fluidization, and belongs to the technical field of preparation of the titanium tetrachloride. The device mainly comprises an outer circulating fluidized bed, an inner circulating fluidized bed, a vibration distribution plate, a vibrator, a cyclone separator, a gas buffer tank, a gas distribution plate and the like. The method comprises the following steps: carrying out a chlorination reaction, cooling and gas-solid separation in the device by taking low-grade high titanium slags with a high calcium and magnesium content and coke as solid raw materials as well as taking chlorine gas, oxygen and nitrogen as gas raw materials, thereby preparing the titanium tetrachloride. The device has the characteristics of being compact in structure, easy to operate and overhaul, good in granule anti-bonding effect, high in titanium tetrachloride quality, favorable for continuous, stable and long-term operations, suitable for large-scale industrial production and the like. The method has the characteristics of being high in material heat utilization rate, uniform in reaction temperature distribution, convenient to control, high in titanium conversion rate and the like. Thus, the method and the device which are provided by the invention are particularly suitable for preparing the titanium tetrachloride from the low-grade high titanium slags with the high calcium and magnesium content.

Owner:CHONGQING UNIV

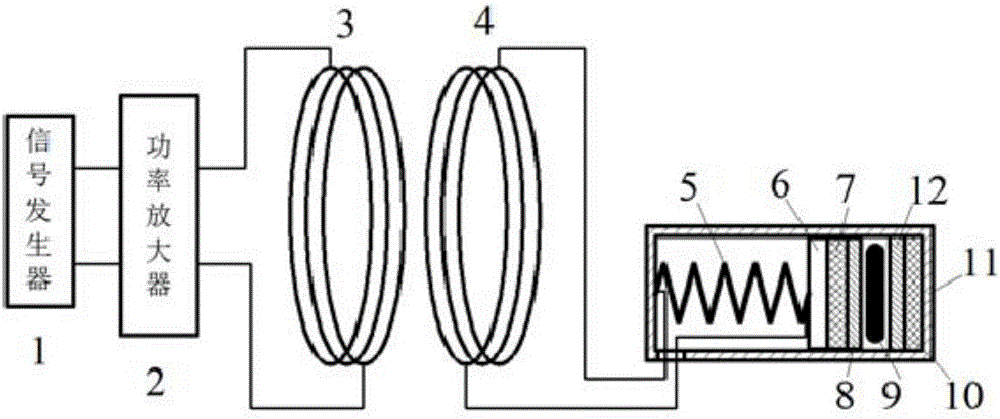

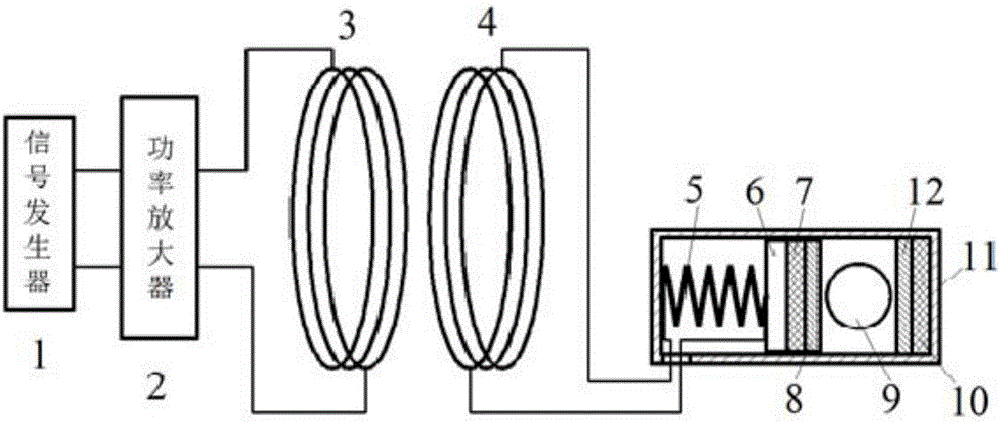

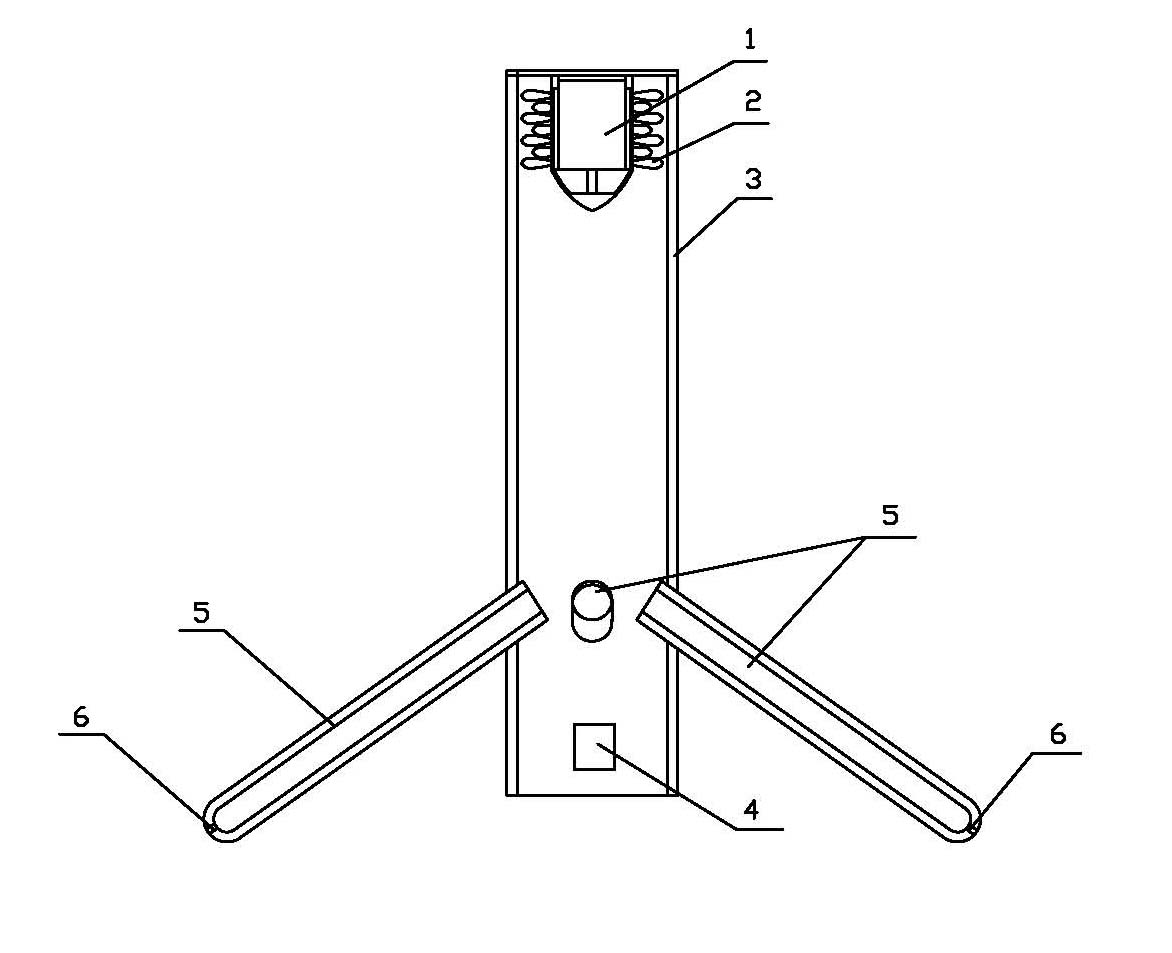

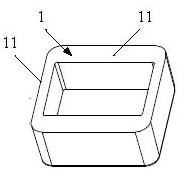

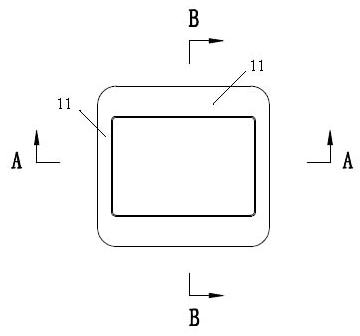

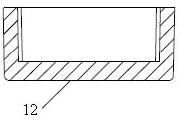

Urethra valve driven by wireless power shape memory alloy (SMA)

The embodiment of the invention discloses a urethra valve driven by a wireless power shape memory alloy (SMA). The SMA is short for a shape memory alloy. The urethra valve is used for solving the technical problems that in the prior art, urinary incontinence, caused by urethra sphincter disfunction, of a patient cannot be solved effectively by a conservative treatment, an operative treatment, nursing measures and the like. The urethra valve comprises a magnetic coupling resonance unit, an SMA spring, a valve element, a first permanent magnet, a second permanent magnet and a valve body. The valve body is of a hollow frame-shaped structure; the SMA spring, the valve element, the first permanent magnet and the second permanent magnet are arranged in a valve cavity of the valve body; and the valve body is used for being fixed on a pubis position of a human body. One end of the SMA spring is connected with the valve element, and the other end of the SMA spring is fixedly connected with the inner wall of one side of the valve cavity; the first permanent magnet adjoins the side, unconnected with the SMA spring, of the valve element; one side of the second permanent magnet adjoins the inner wall of the other side of the valve cavity and the other side of the valve cavity is opposite to the side connected with the SMA spring; and the gap between the first permanent magnet and the second permanent magnet is used for penetrating through a urethra position of the human body.

Owner:GUANGDONG UNIV OF TECH

Solar and wind driven generator

InactiveCN101975145AStable jobAvoid inconvenienceSolar heat devicesMachines/enginesWind drivenEngineering

The invention relates to a wind driven generator, in particular to a solar and wind driven generator which utilizes solar energy to produce wind energy and then converts the wind energy into electric energy. The solar and wind driven generator comprises a generator and a fan blade arranged on the rotating shaft of the generator, wherein the generator is arranged at the top of a fan drum, the rotating shaft of the generator and the central shaft of the fan drum are coaxial, the lower end of the fan drum is provided with an air inlet, and the side wall of the fan drum above the air inlet is inserted with a solar heat collector tube the upper opening of which is communicated with the inner cavity of the fan drum and the lower end of which is provided with an air inlet hole. In the solar and wind driven generator, airflow can be formed depending on hot air ascending and the chimney effect generated by the fan drum to blow the fan blade of the generator to rotate so as to enable the generator to generate electric energy, thus the produced wind power is stable and can be manually controlled, various inconveniences brought by adopting natural wind can be avoided, and the solar and wind driven generator can operate stably for long term.

Owner:钟绵章

Airplane emergency green intelligent bird-repelling device

InactiveCN107996556AAddressing Adaptive IssuesEffective bird repellentAnimal repellantsLoudspeakerAirplane

The invention discloses an airplane emergency green intelligent bird-repelling device, and belongs to the technical field of intelligent bird-repelling. The airplane emergency green intelligent bird-repelling device includes a wind light complementation module, a control module, an information acquisition module, and a bird-repelling module; the information acquisition module is connected to the control module, the control module is connected to the bird-repelling module; and the wind light complementation module is connected to the bird-repelling module. The airplane emergency green intelligent bird-repelling device can adopt a sound, light and action combined manner to repel birds, can prevent birds from generating adaptability, and can effectively repel the birds; the wind light complementation module can supply power to a first motor and a second motor, and can ensure long time working of the device so as to allow the device to repel the birds all the time and on all weathers; an infrared sensor and an image sensor can detect if the birds are close to an airport or not, and can send a detection signal to a single-chip microcomputer controller; and the single-chip microcomputercontroller can control a loudspeaker to give sounds and drive the first motor and the second motor to work, and can timely and effectively repel birds.

Owner:晨龙飞机(荆门)有限公司

Rubbish incineration and waste gas purification device and feeding machine thereof

ActiveCN104121585ALong-term job damageNot easy to damageIncinerator apparatusExhaust fumesEnvironmentally friendly

Provided is a rubbish incineration and waste gas purification device. A furnace body is provided with a water-injected interlayer filled with water used for temperature stabilizing, the furnace body is communicated with a hollow incineration grate at the bottom, a horizontal drying turning plate used for drying rubbish is additionally arranged in the furnace body, the drying turning plate and a sealing door are respectively of a cavity structure, and the drying turning plate is communicated with the water-injected interlayer through rotary connectors. Waste gas in the furnace body is exhausted through an exhaust duct, dust removal is conducted on the waste gas through a plurality of surge dust removing water tanks connected in series and a pair of water mist dust removing water tanks on the rear portion, lime water is arranged in the water tanks, isolation structures are arranged in the surge dust removal water tanks to enable the waste gas to pass through in a U shape on the water surface, and high-temperature surge foams are formed on the water surface. Spraying devices are arranged in the water mist dust removal water tanks for dust removal, an exhaust fan is arranged behind the water tank combination to enable air in the water tanks to be in negative pressure, and flow of the air is accelerated. The novel waste disposal equipment is environmentally friendly, capable of saving energy, free of pollution, low in furnace body temperature, long in service life, capable of conducting drying treatment on waste and sufficient in combustion, and the dust removal effect is excellent after the waste gas is treated through surge steam and mist spray.

Owner:广东联和环保科技有限公司

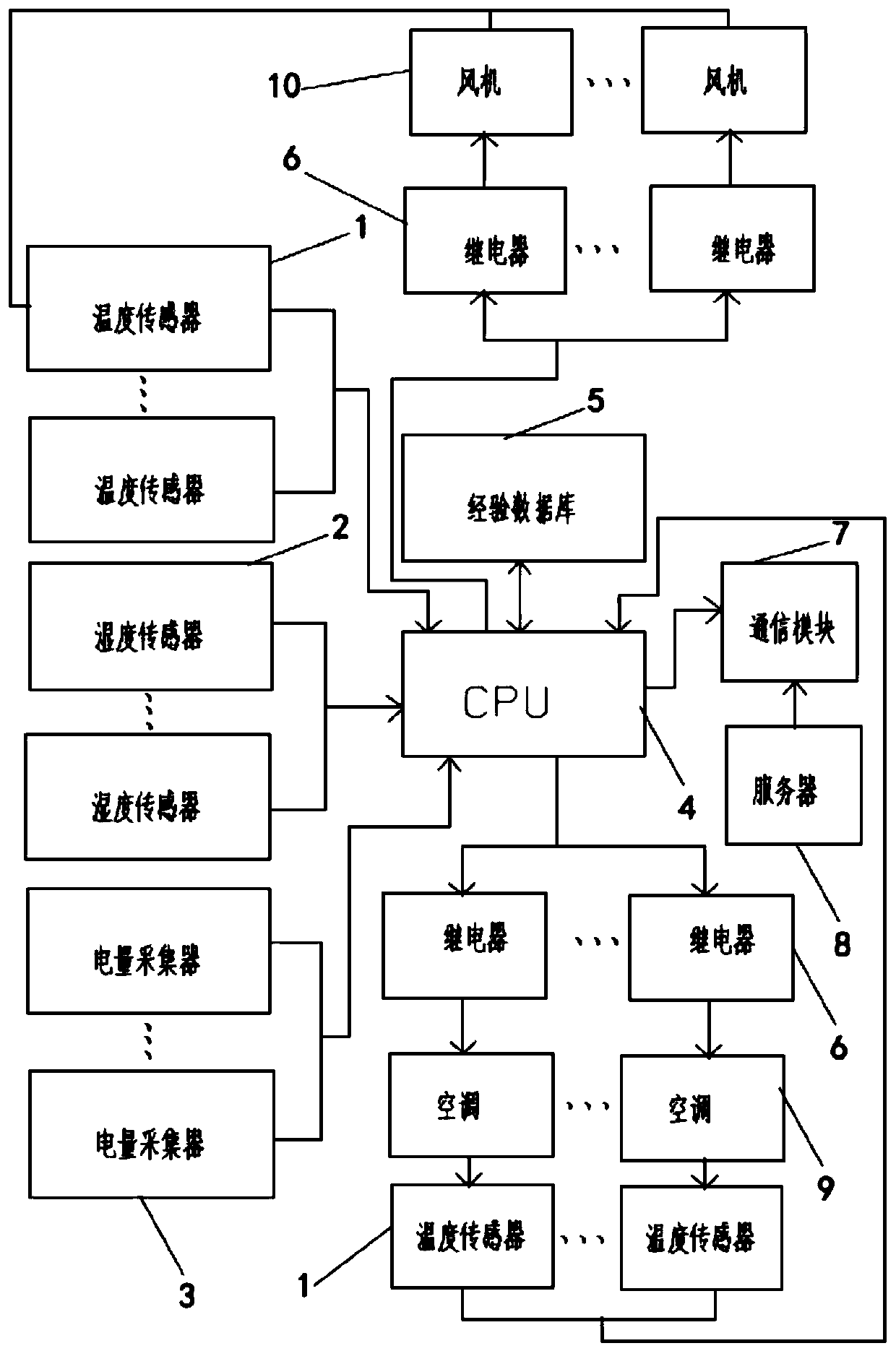

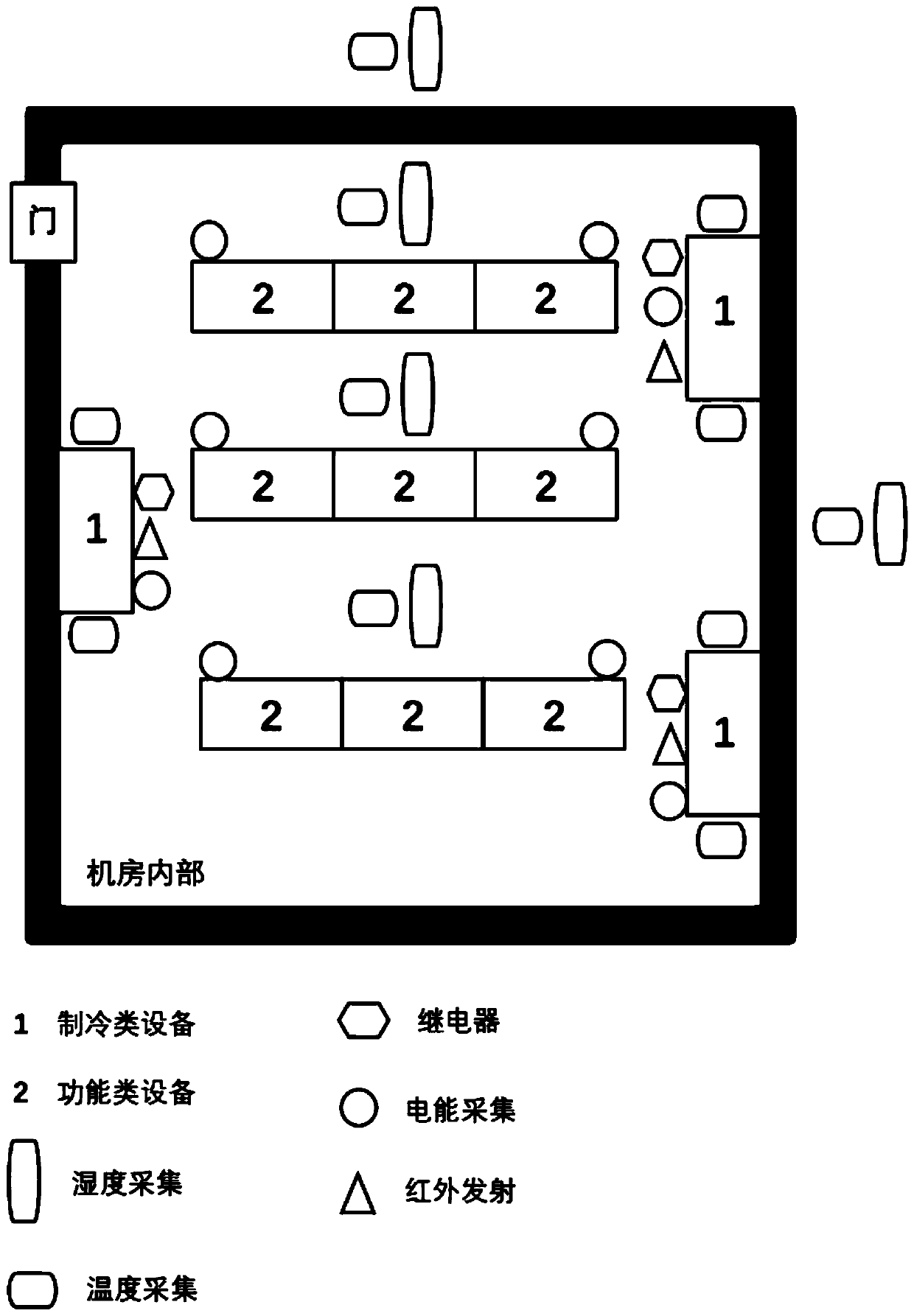

Communication machine room air-conditioner and fan linkage energy-saving method and device

PendingCN110925998AGuarantee the required temperatureShort efficient runtimeMechanical apparatusSpace heating and ventilation safety systemsEngineeringProcess engineering

The invention relates to the technical field of communication equipment and provides a communication machine room air-conditioner and fan linkage energy-saving method and device. The method includes the following steps that S1, the power consumptions of various devices in all moments are detected in real time, the total heating amount is worked out, and then a heat source Q1 is obtained; S2, the heat dynamic values between the outdoor and the indoor in all moments are detected dynamically in real time, and then a heat source Q2 is obtained; S3, the changes of the temperature and the humidity in relative time are calculated and analyzed, in combination with the machine room volume and the heat source Q1 and heat source Q2 at the same moment, the temperature change gradient of a machine roomin different periods is worked out, and then the heat capacity of the machine room is obtained; S4, the actual cooling capacity enthalpy value of an air-conditioner and a fan is detected and worked out in real time; and S5, the temperature dynamic change trends of all areas in the communication machine room are predicted, the air-conditioner and the fan are started in advance for linkage coolingwhen the interior of the communication machine room is about to reach a monitoring point, or linkage cooling of the air-conditioner and the fan is stopped in advance when the cooling amount meets thedemand of an exit from the monitoring point. By means of the communication machine room air-conditioner and fan linkage energy-saving method and device, the problem that the energy-saving effect of anexisting air-conditioner in the communication machine room is not ideal is solved.

Owner:FUJIAN NANHONG COMM TECH

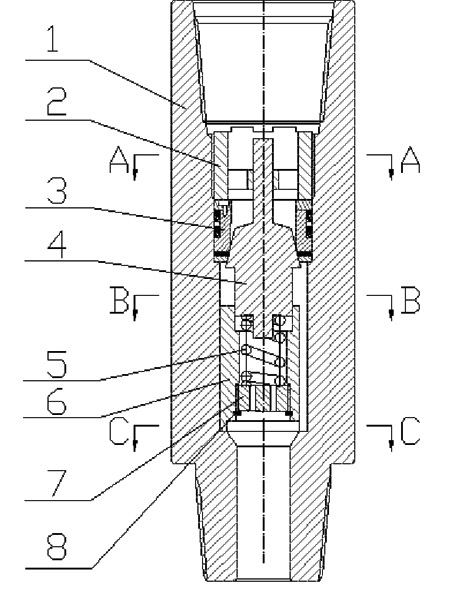

Underground floating valve with high-temperature resistance, high-pressure resistance and corrosion resistance

ActiveCN102561995AEasy to replaceAvoid overvoltage damageWell/borehole valve arrangementsSealing/packingEngineeringHigh pressure

The invention relates to an underground floating valve with high-temperature resistance, high-pressure resistance and corrosion resistance. According to the technical scheme, the underground floating valve mainly comprises a valve body, a valve core pressing sleeve, a seal assembly, a valve core, a spring, a valve seat, a spring wire plug and a wire plug positioning ring, wherein the valve core pressing sleeve, the seal assembly and the valve seat are assembled inside the valve body; the spring wire plug and the wire plug positioning ring are arranged on the valve seat; a return spring is positioned between the valve core and the spring wire plug; an upper shaft of the valve core is arranged in the valve core pressing sleeve; a conical surface is in contact fit with the seal assembly; a lower shaft is arranged in an inner cavity of the valve seat; and a bottom surface is contacted with the return spring. The invention has the advantages that: the service life of a tool can reach more than 100 hours under the working condition that an operating temperature is not less than 180 DEG C and resisted pressure is not less than 150Mpa, so that the requirements of preventing underground internal blowout and ensuring the normal operation of an underground instrument in the process of developing oil and gas resources in a deep formation are met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

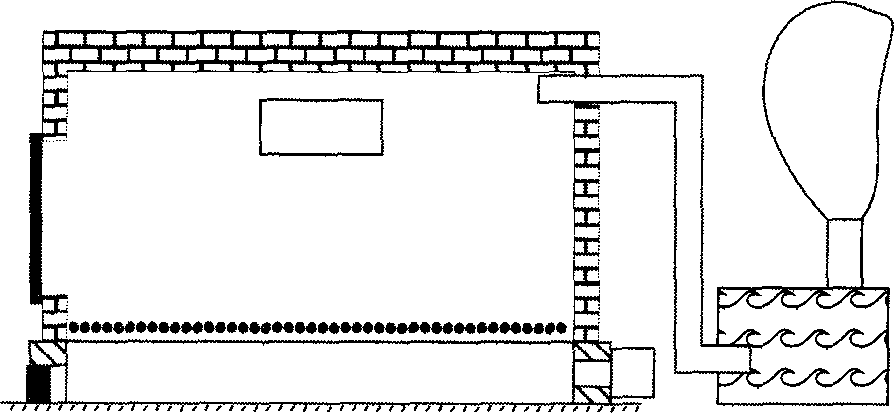

Wave energy absorbing and converting method and system

InactiveCN1811164AImprove energy conversion efficiencyLow energy conversion efficiencyMachines/enginesEngine componentsEnergy absorptionMechanical energy

The present invention relates to energy source absorption and conversion technology, and is especially wave energy absorbing and converting method and system by means of inertial pendulum mechanism. Based on the inertial pendulum energy absorbing mechanism, the inertial pendulum mechanism is driven by waves to move to absorb wave energy and drive a transmission mechanism to convert and store mechanical energy, and the mechanical energy is then released in an energy releasing device. The wave energy is obtained and utilized autonomously, and the amount of the absorbed energy may be estimated based on a wave energy converting and calculating mold. The present invention provides one completely new technological route for obtaining wave energy from sea.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

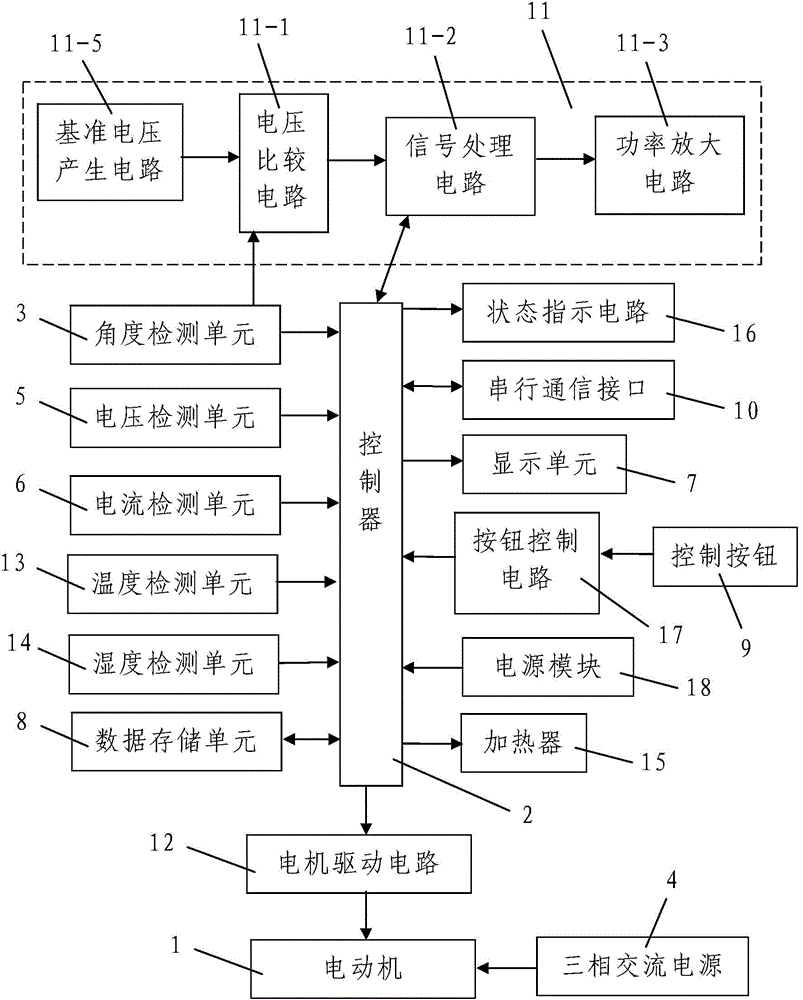

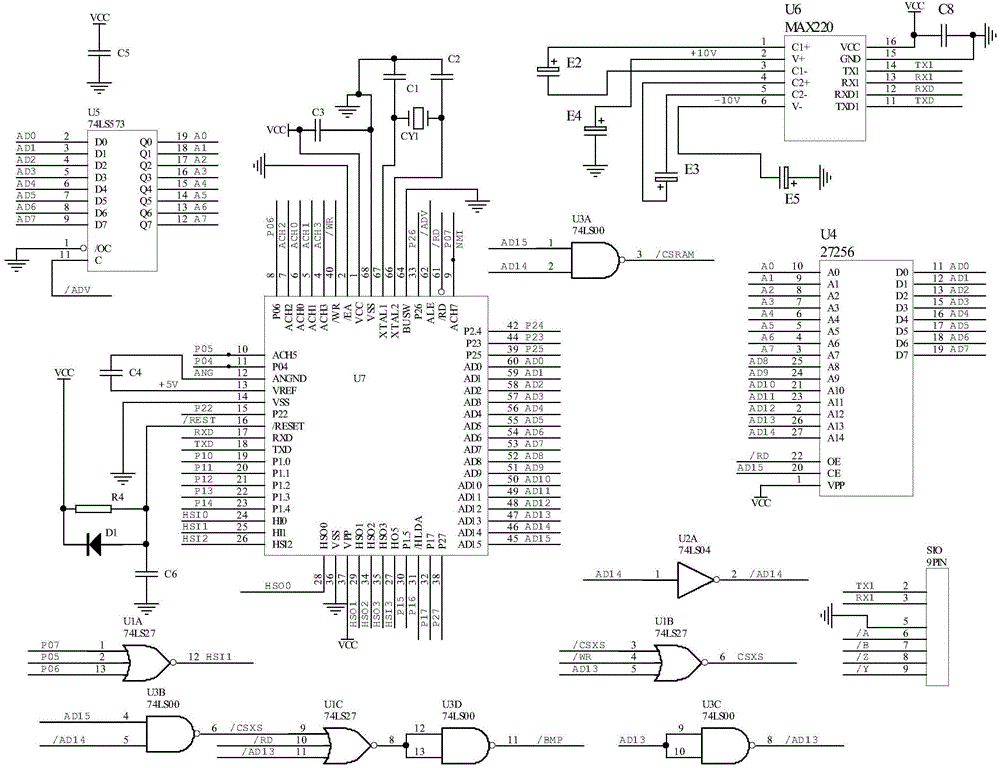

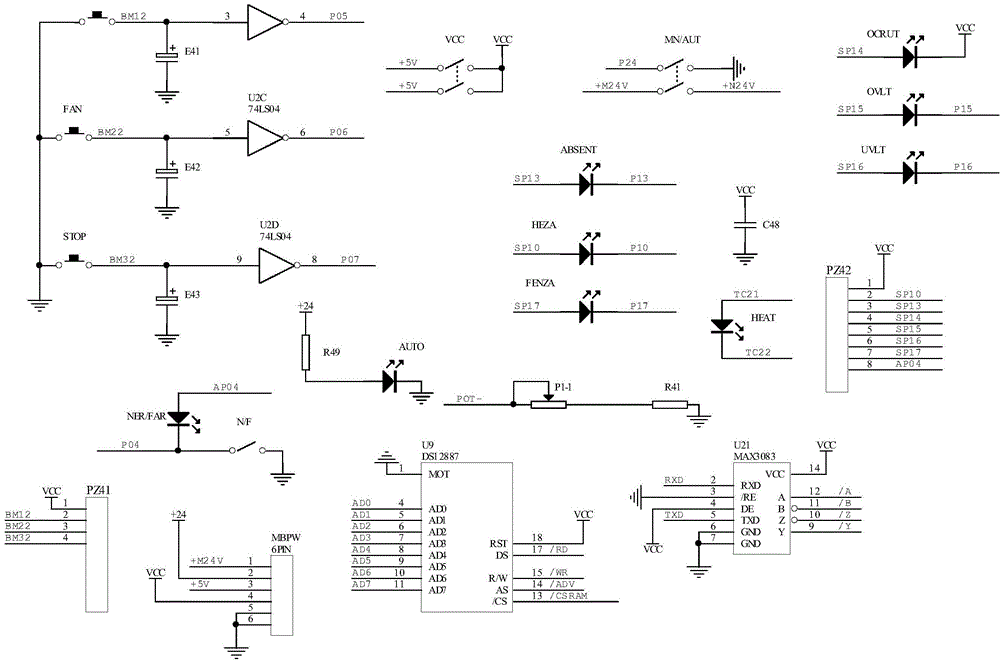

Operation mechanism of motor

InactiveCN104157477AReasonable designEasy wiringAC motor controlSwitch power arrangementsMotor speedSignal processing circuits

The invention discloses an operation mechanism of a motor. The operation mechanism comprises an auxiliary electronic switch, a controller, an angle detecting unit, a voltage detecting unit, a current detecting unit, a serial communication interface, a display unit, a data storage unit and a control button. The angle detecting unit is used for detecting the rotating angle of an output shaft of a motor speed reducer. The auxiliary electronic switch comprises a signal processing circuit and a power amplifying circuit, and the signal processing circuit comprises a TTL open collector six-normal-phase high-voltage driver, a TTL open collector six-reverse-phase high-voltage driver and multiple power amplifiers. The TTL open collector six-reverse-phase high-voltage driver is connected with the TTL open collector six-normal-phase high-voltage driver, and the power amplifiers are connected with the TTL open collector six-reverse-phase high-voltage driver. The TTL open collector six-normal-phase high-voltage driver is connected with the motor control end of the controller. The power amplifying circuit comprises multiple sets of solid relays. The operation mechanism is simple in circuit, reasonable in design, convenient to wire, good in using effect and capable of solving various problems existing in an existing operation mechanism of the motor.

Owner:西安华鑫电力设备有限责任公司

Device and method for protecting surface-mounted light emitting diode (LED)

InactiveCN102182988AGood weather resistanceGood adhesionPoint-like light sourceProtective devices for lightingAdhesiveSurface mounting

The invention provides a device and a method for protecting a surface-mounted light emitting diode (LED). The device comprises at least one transparent protection cover, wherein each transparent protection cover comprises a side wall and a light transmission surface; the side wall and the light transmission surface are moulded into a whole; the side wall is a four-sided rectangular enclosure frame; an opening is formed at the bottom of the enclosure frame; the light transmission surface is arranged at the top of the enclosure frame; the light transmission surface is one of a plane, a convex surface, a concave surface, an inclined surface and an inclined convex surface; and potting adhesives are filled among the protection cover, a circuit board and an LED lamp shell. By the invention, the surface-mounted LED which is only applied to indoor environments can be also applied to outdoor environments.

Owner:STRONGLED LIGHTING SYST SUZHOU CO LTD

Reinforcing ring for reversing device and preparation method thereof

The invention provides a reinforcing ring for a reversing device and belongs to the technical field of reversing devices. The reinforcing ring solves the technical problems that an existing reversing device is low in strength and poor in abrasion resistance. According to the technical scheme, the reinforcing ring for the reversing device comprises an annular body which is prepared from, by weight, 55-75 parts of epoxy resin, 5-15 parts of non-alkali glass fibers, 5-10 parts of aramid fibers, 15-30 parts of a curing agent, 3-8 parts of a toughening agent, 5-10 parts of a heat-resistant modifying agent and 4-7 parts of a lubricating agent. The reinforcing ring for the reversing device has the advantages that the glass fibers and the aramid fibers are added, so that the mechanical strength of the reinforcing ring is improved; meanwhile, the toughening agent is added, so that the toughness of the reinforcing ring is improved to a certain extent, and the reinforcing ring is not prone to breakage; the lubricating agent is added, so that the abrasion resistance of the reinforcing ring is improved, the reinforcing ring is not prone to abrasion, the integrality of the reinforcing ring is guaranteed to a certain extent; the heat-resistant modifying agent is added, so that the heat resistance of the reinforcing ring is improved, and the reinforcing ring can work in a high-temperature environment for a long time.

Owner:HUARUI ELECTRICAL APPLIANCE

Method for continuously extruding and molding zinc alloy structural materials

The invention relates to a method for continuously extruding and molding zinc alloy structural materials, belonging to the technical field of plastic molding of zinc alloy tubing, section bar and wire stocks. In the technology, the plastic processing performance of zinc and alloy thereof can be dramatically improved by the method of modified fine grain strengthening and polishing, and deformation strengthening-great cutting deformation mode is in favor of refining crystals. Sufficient extruding force and heat quantity can be generated by utilizing strong friction of the continuously extruding technique on the zinc alloy structural material stock such as rod materials, granules or molten metal and the like and the rotary extruding wheels of the extruding device, thus directly extruding the zinc alloy structural material stock into finished products by the great cutting deformation mode. The invention solves the problems of long flow, high energy consumption caused by multiple heating, low material utilization rate, high production cost and the like existing in the current conventional techniques.

Owner:HUNAN HUAKANG NEW MATERIAL

Intelligent kitchen garbage recovery barrel

PendingCN106347905AReduce power consumptionFlexible networkingWaste collection and transferRefuse receptaclesLiquid level sensorLiquid storage

The invention relates to an intelligent kitchen garbage recovery barrel, which comprises a machine frame, a case and an electronic control device, wherein a garbage throwing opening, a solid garbage barrel and an oil liquid storage barrel are arranged in the garbage recovery barrel from top to bottom; the inner bottom of the solid garbage barrel is an inclined surface with the higher outer part and the lower inner part, and a plurality of small oil leaking holes are formed in the center position; a hanging edge which is outwards turned and is matched with a garbage recovery vehicle barrel lifting device is arranged at one side of an opening formed in the top in the garbage recovery barrel; a liquid level sensor connected with the electronic control device is arranged in the liquid level storage box. The intelligent kitchen garbage recovery barrel has the advantages that the solid liquid separation can be realized; meanwhile, the intelligent kitchen garbage recovery barrel is used as a kitchen garbage recovery terminal; the existing kitchen garbage recovery flow process can be optimized; the garbage recovery treatment efficiency is improved.

Owner:湖州福睿祺环保科技有限公司

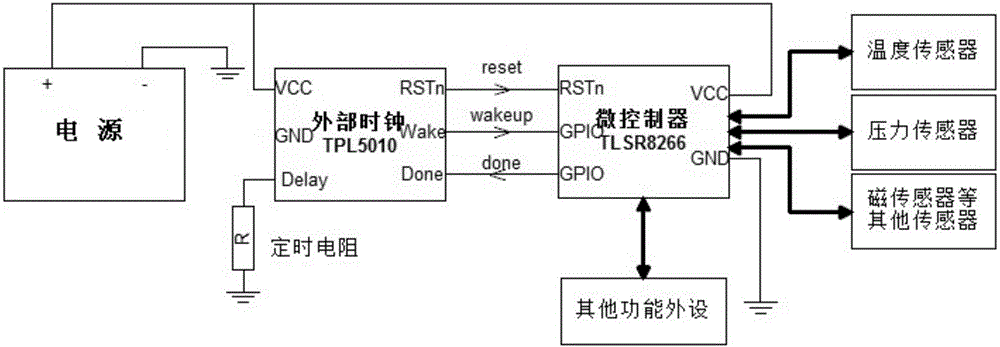

Data broadcasting method for low power consumption circuit and low power consumption circuit

ActiveCN106648021AReduce power consumptionSave electricityPower managementPower supply for data processingMicrocontrollerOperation mode

The invention relates to the field of wireless communication and discloses a data broadcasting method for a low power consumption circuit and the low power consumption circuit. In the data broadcasting method for a low power consumption circuit and the low power consumption circuit, the low power consumption circuit comprises an external clock and a microcontroller used for wireless communication, wherein the microcontroller comprises a normal operation mode, a first sleep mode and a second sleep mode. In the first sleep mode, a sleep timer in the microcontroller is started, in the second sleep mode, the sleep timer in the microcontroller is closed, the power consumption of the microcontroller in the first sleep mode is higher than that of the microcontroller in the second sleep mode, and the power consumption of the external clock is lower than that of the microcontroller in the first sleep mode. Before a wireless broadcasting signal is retransmitted, the microcontroller sleeps in the first sleep mode; after all retransmission is completed, the microcontroller enters the second sleep mode and is awakened through the external clock lower in power consumption. Accordingly, precious electrical energy can be saved, and long-time operation is achieved.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

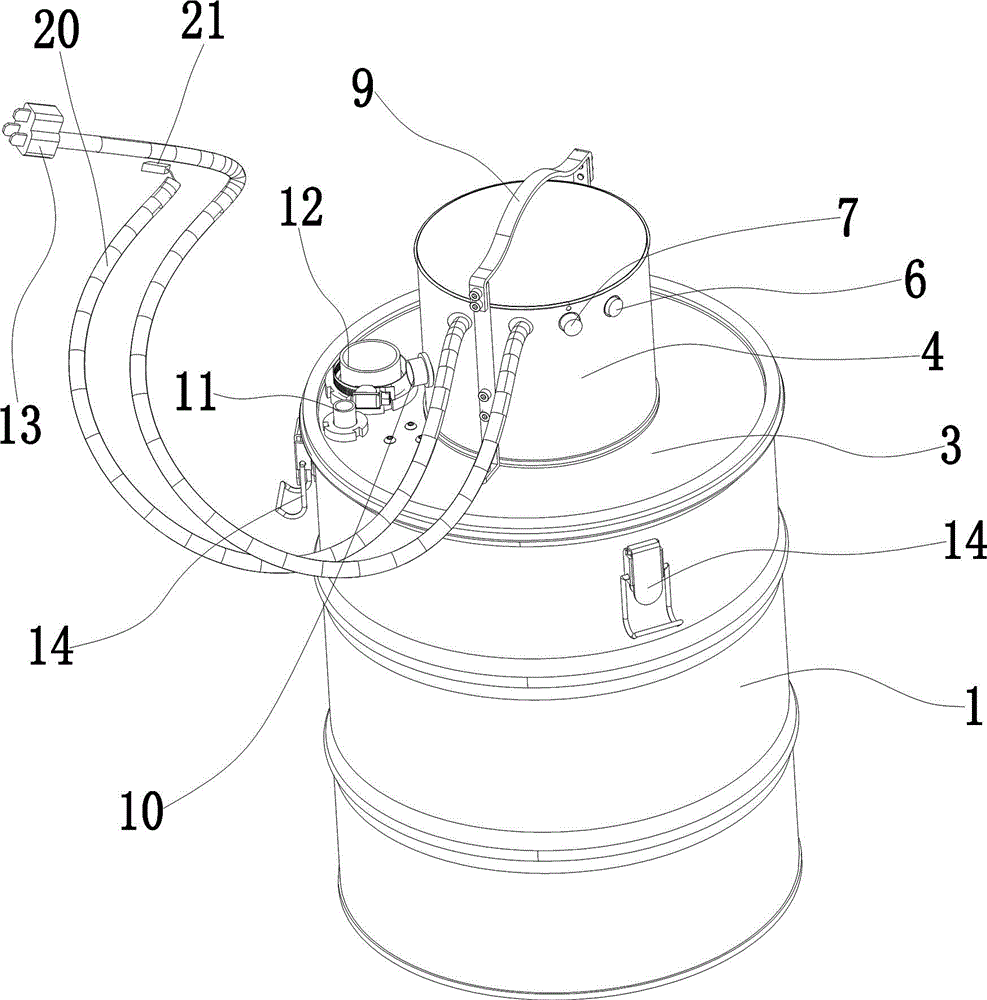

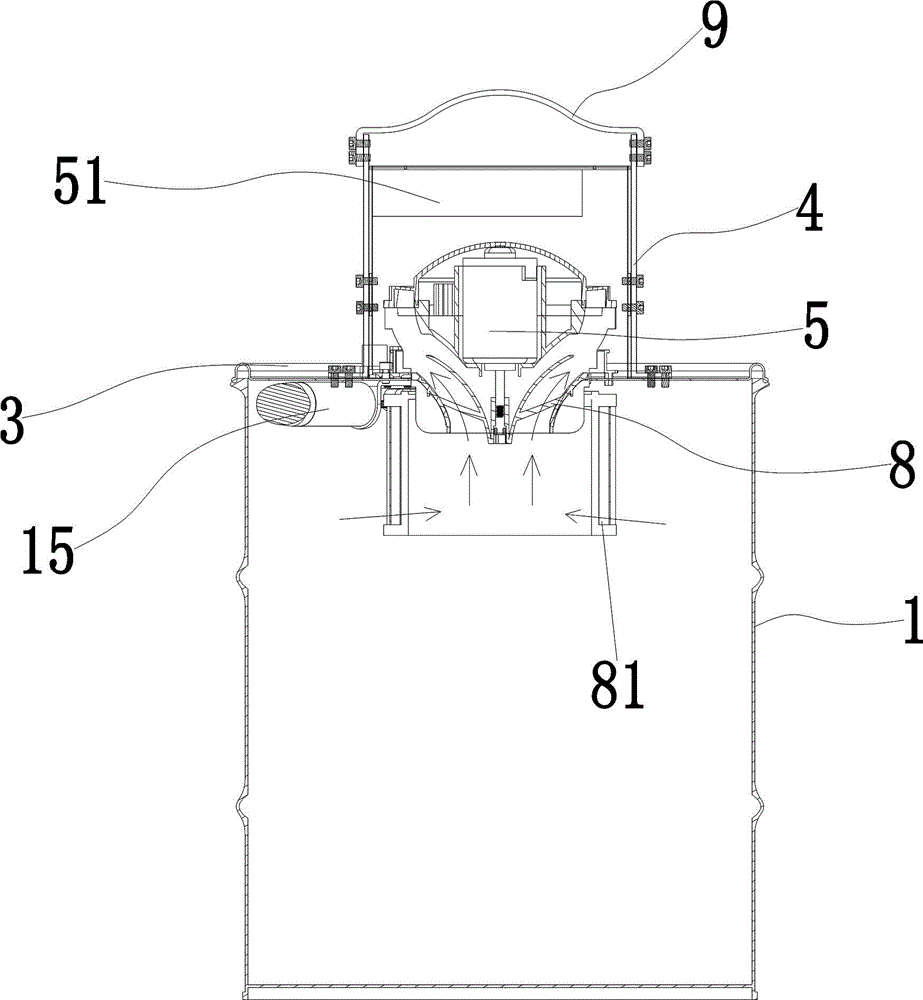

Dust barrel for a sewing machine

ActiveCN105002675AExtended service lifeReduce noiseSewing-machine elementsBrushless motorsInterior space

The invention discloses a dust barrel for a sewing machine. The barrel comprises a sewing machine, a controller arranged on the sewing machine and a barrel body, and the upper end of the barrel body is provided with an opening; the opening of the barrel body is provided with a barrel cover, and a protective hood is fixedly mounted above the barrel cover; the protective hood is provided with a brushless motor therein; the brushless motor is connected to a control system; the control system is connected to a switch, and a speed-adjustment knob; the brushless motor is connected to a fan blade which is positioned inside the barrel body; the fan blade is covered with a filtering cartridge; the protective hood is provided with a lifting handle; the protective hood is provided with an air exhaust opening; the barrel cover is provided with a first air opening and a second air opening thereon; the first air opening and the second air opening are communicated with the inner space of the barrel body; the control system is connected to a plug. The dust barrel of the invention can collect dust without the cooperation with an external air source, thus preventing the problem of loud noise in dust collection. The dust barrel has a wide range of application and is not subject to any limitation.

Owner:YUHUAN YI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com