Rubbish incineration and waste gas purification device and feeding machine thereof

A waste gas purification device and waste incineration technology, applied in the field of feeder, can solve the problems of uneven waste incineration, complicated engineering, low combustion efficiency, etc., to eliminate tiny dust and harmful bacteria, prevent secondary pollution, and long-term work damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Because the drawings involved in the present invention involve large-scale devices and small components, the small components are enlarged in the composition to facilitate their description. Therefore, the relative sizes of the components in the composition are not in actual proportion, and should not be understood as Scale constraints on relative sizes.

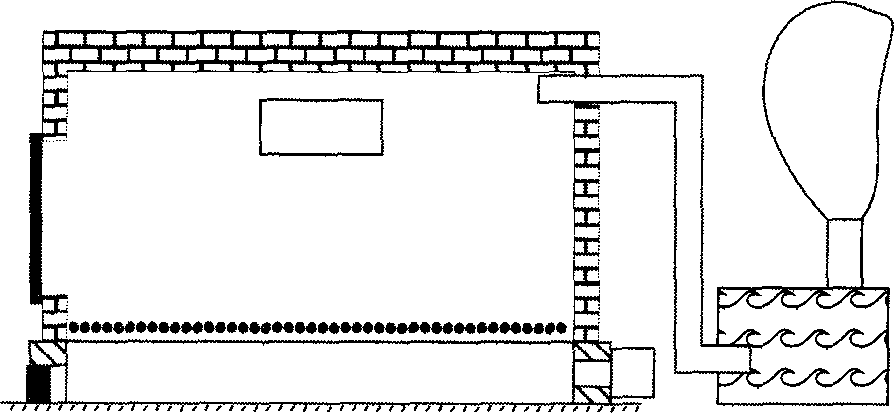

[0060] Such as figure 1 In the existing small incinerator shown, the four walls of the existing furnace body are solid structures, and the middle is a combustion chamber. Usually, refractory bricks are used as building materials. A row of incineration grates is laid on the bottom of the furnace body to support the burning waste The distance between the support tubes is 2-5CM for ventilation and combustion, and the combustion residue can fall into the furnace base below. The existing incineration grate is a solid material; the furnace base below the furnace is the furnace base. The load-bearing base of the furnace bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com