Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Large heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant polymer blends

InactiveUS20070066737A1Improve flame retardant performanceGood solvent resistancePolyesterPolyetherimide

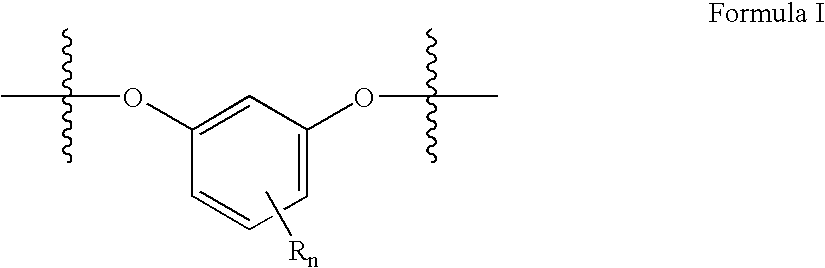

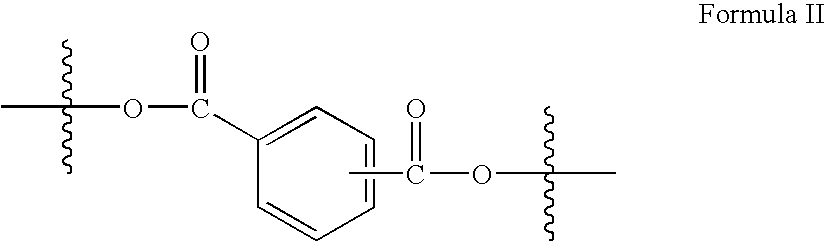

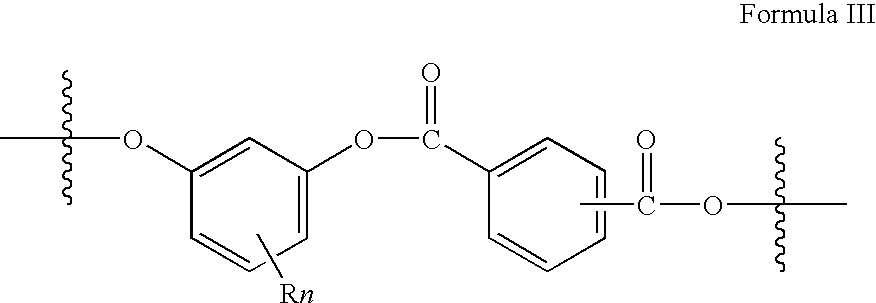

Blends of polyimides, polyetherimides or polyetherimide sulfones with resorcinol based polyesters, or resorcinol based polyester carbonate polymers, and silicone copolymers, have improved flame resistance. Peak heat release energy is reduced and the time to reach peak heat release is increased. In some instances the flame retardant blends show high percent transmission with low haze. Addition of metal oxides may further improve flame resistance.

Owner:SABIC GLOBAL TECH BV

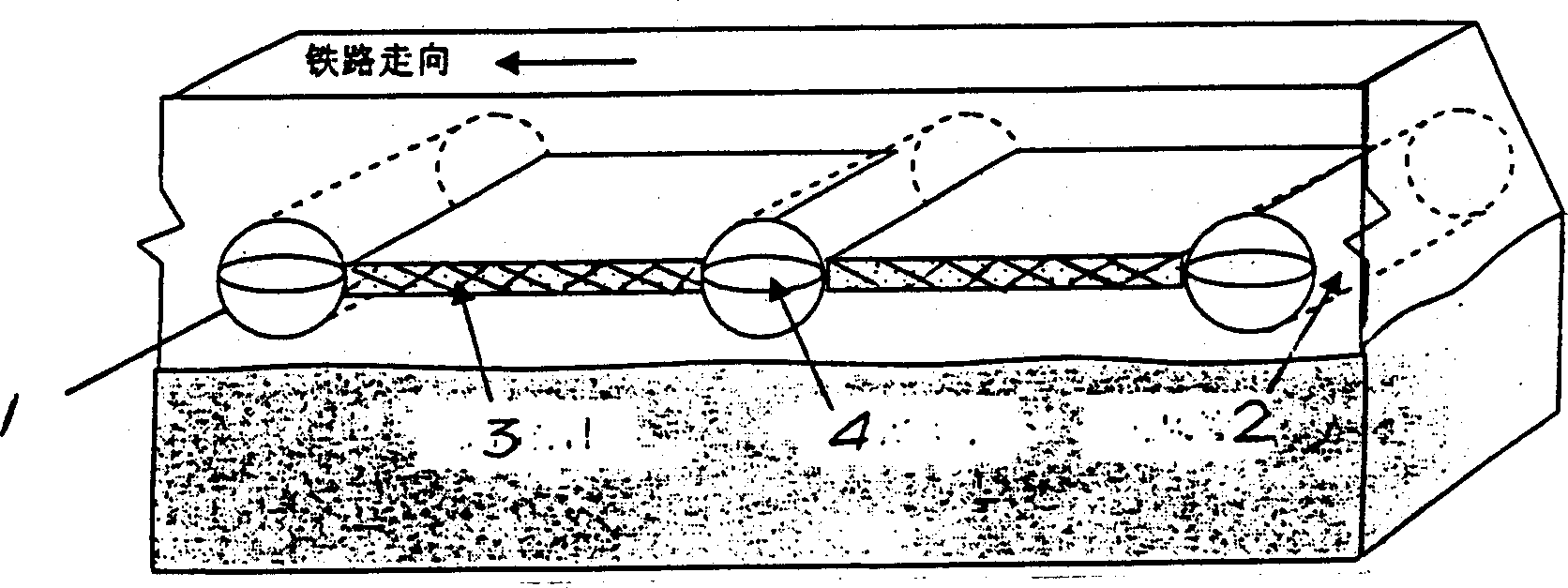

Composite temperature controlled ventilation roadbed

InactiveCN1556284AStop the flowBlock incomingRoadwaysFoundation engineeringVentilation tubeTemperature control

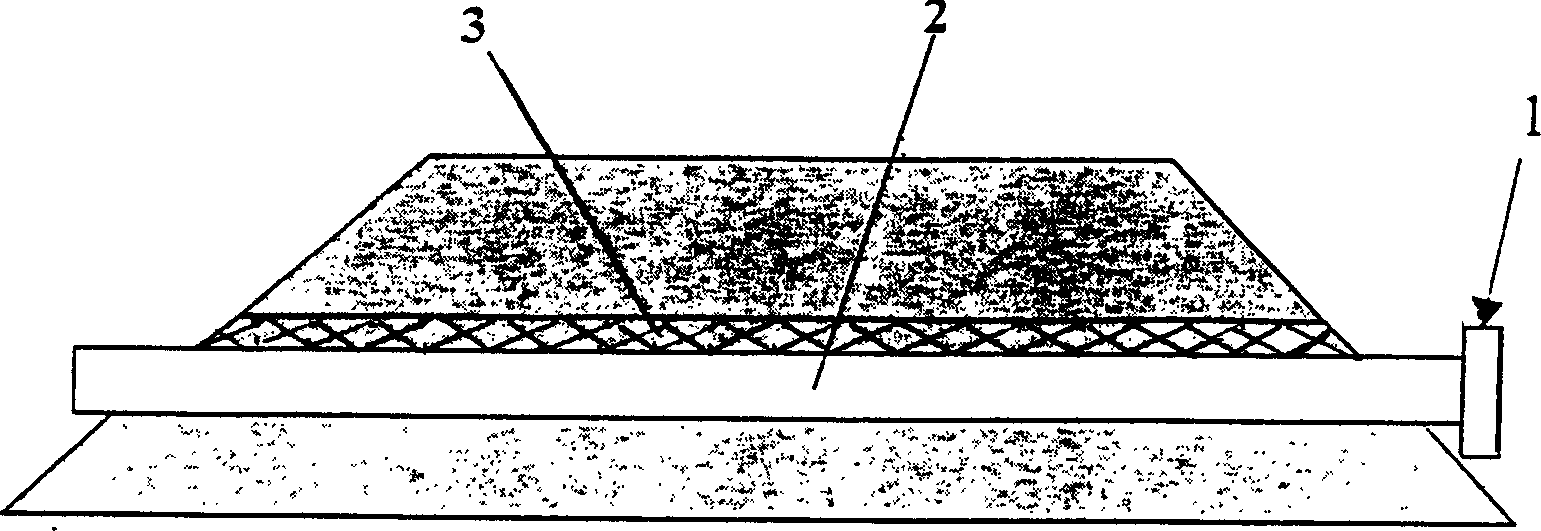

Construction features of roadbed are as follows: building vent-pipes perpendicular to direction of roadbed in certain depth of road embankment; installing ventilating units of automatic controlling temperature at end part of vent-pipe; setting up thermal-protection material between vent-pipes / entire up part of vent-pipes with earth material being covered and tamped. The said automatic controlling ventilating units carries out heat exchange between inside roadbed and airflow in low temperature outside. The thermal-protection material protects ever frost effectively. Thus, the invention prevents frost heave and thaw collapse caused by season change so as to keep stability of roadbed in high level. The invention solves issue of carrying construction in zone of frozen earth.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

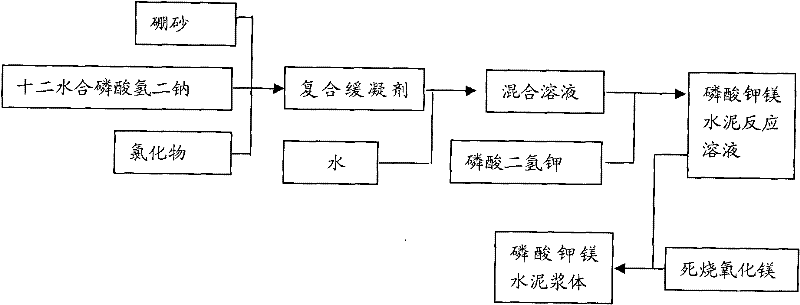

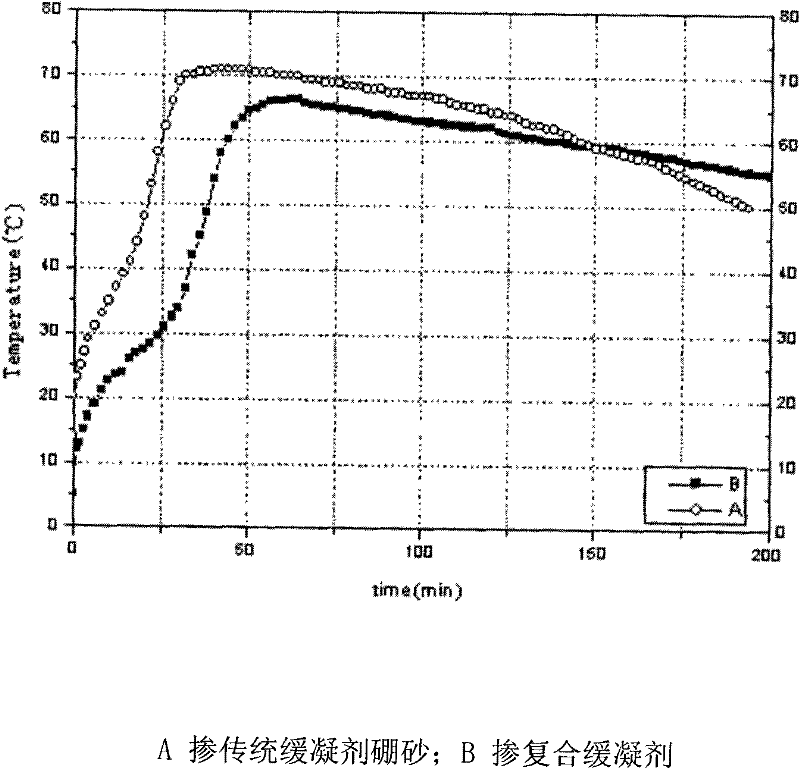

Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

InactiveCN102234200AEffective adjustment of clotting timeEffective control of clotting timeControl setOperability

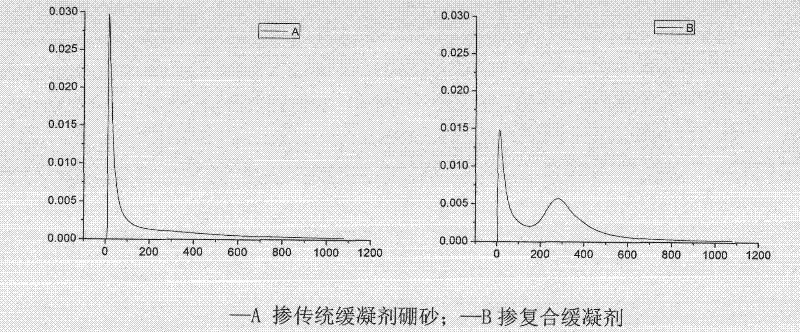

The invention relates to a method for controlling the setting time and early hydration speed of magnesium potassium phosphate cement, and belongs to an early strength quick hardening cement cementing material. A composite retarder can effectively adjust the setting time of magnesium potassium phosphate cement slurry, and the setting time of the magnesium potassium phosphate cement slurry can be effectively controlled in the range of 10 minutes to 6 hours by adjusting the content of chloride and disodium hydrogen phosphate dodecahydrate in the composite retarder, so that the problems of a limited retarding effect, low operability and the like are solved; the composite retarder can change the hydration heat release characteristic of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement slurry doped with the conventional retarder borax has a hydration heat release peak at the initial reaction stage and has a high heat release speed and large heat release amount, and the magnesium potassium phosphate cement doped with the composite retarder has two hydration heat release peaks and has small hydration heat release amount at the initial hydration stage; and the doped composite retarder improves the microstructure and later strength of a hardened magnesium potassium phosphate cement body, so that enough construction operable time can be ensured while the magnesium potassium phosphate cement slurry has early strength and is quickly hardened.

Owner:苏州诚开新材料有限公司

Automatic ignition powder for gas generator of air bag restraint system of automobile and preparation method of automatic ignition powder

ActiveCN105777458AEasy to igniteAppropriate thermal decomposition temperatureNon-explosive/non-thermic compositionsDecompositionRare earth

The invention provides automatic ignition powder for a gas generator of an air bag restraint system of an automobile and a preparation method of the automatic ignition powder.The automatic ignition powder contains fuel, oxidant and flame accelerator; the flame accelerator is rare earth and perovskite type composite metal oxide; the general formula of the flame accelerator is La1-xAxMnO3, wherein A is Ce and / or Cu, and x is greater than zero and less than one.According to the automatic ignition powder, the specific flame accelerator is adopted and can effectively promote a redox reaction in the powder, thereby thermal decomposition of the automatic ignition powder is promoted, the decomposition temperature of the powder is lowered, and automatic ignition performance of the powder is improved.

Owner:BYD CO LTD

Two-stage flash evaporation and two-stage compression heat pump device with double heat sources and operating method

ActiveCN107461961ALess destructiveGood effectSolar heating energyHeat pumpsCollection systemEvaporation

The invention discloses a two-stage flash evaporation and two-stage compression heat pump device with double heat sources and an operating method. The device comprises a heat collection system, a primary flash evaporation system, a secondary flash evaporation system and a steam compression system. The method comprises the following steps: producing hot water introduced into a hot water tank according to different low-grade heat sources through three operation methods of a single heat source including solar heat, double heat sources including solar heat and waste heat and a single heat source including waste heat, and recycling low-grade heat such as solar heat and waste heat through manners of two-stage flash evaporation and two-stage compression. Compared with the organic heat pump working medium, the evaporation latent heat value of the water is high; a large amount of low-grade heat is recycled; the coefficient of performance of the heat pump device is greater than 10; the low-pressure steam is compressed for two times through a low-pressure steam compressor and a high-pressure steam compressor; the quality of the steam can be effectively improved; the temperature of the steam reaches 120 DEG C or higher; the high-temperature heating requirement can be met; the problem of haze pollution caused when the fire coal is used for heating in the northern regions of China in winter is fundamentally solved.

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing fuel by using biological oils and fats

ActiveUS20140135542A1Large heat releaseFast inactivationFatty acid hydrogenationCatalytic crackingOil and greaseHydrogen

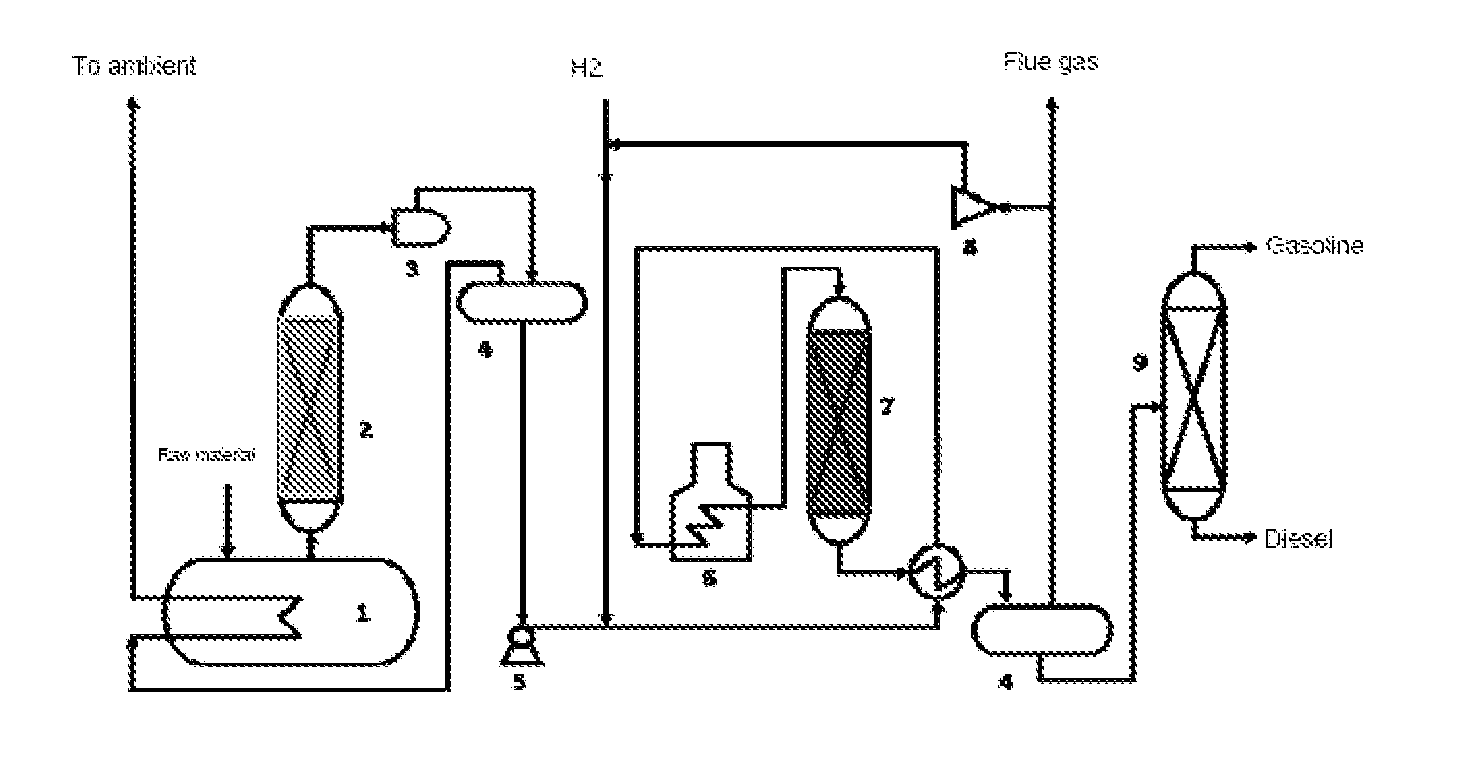

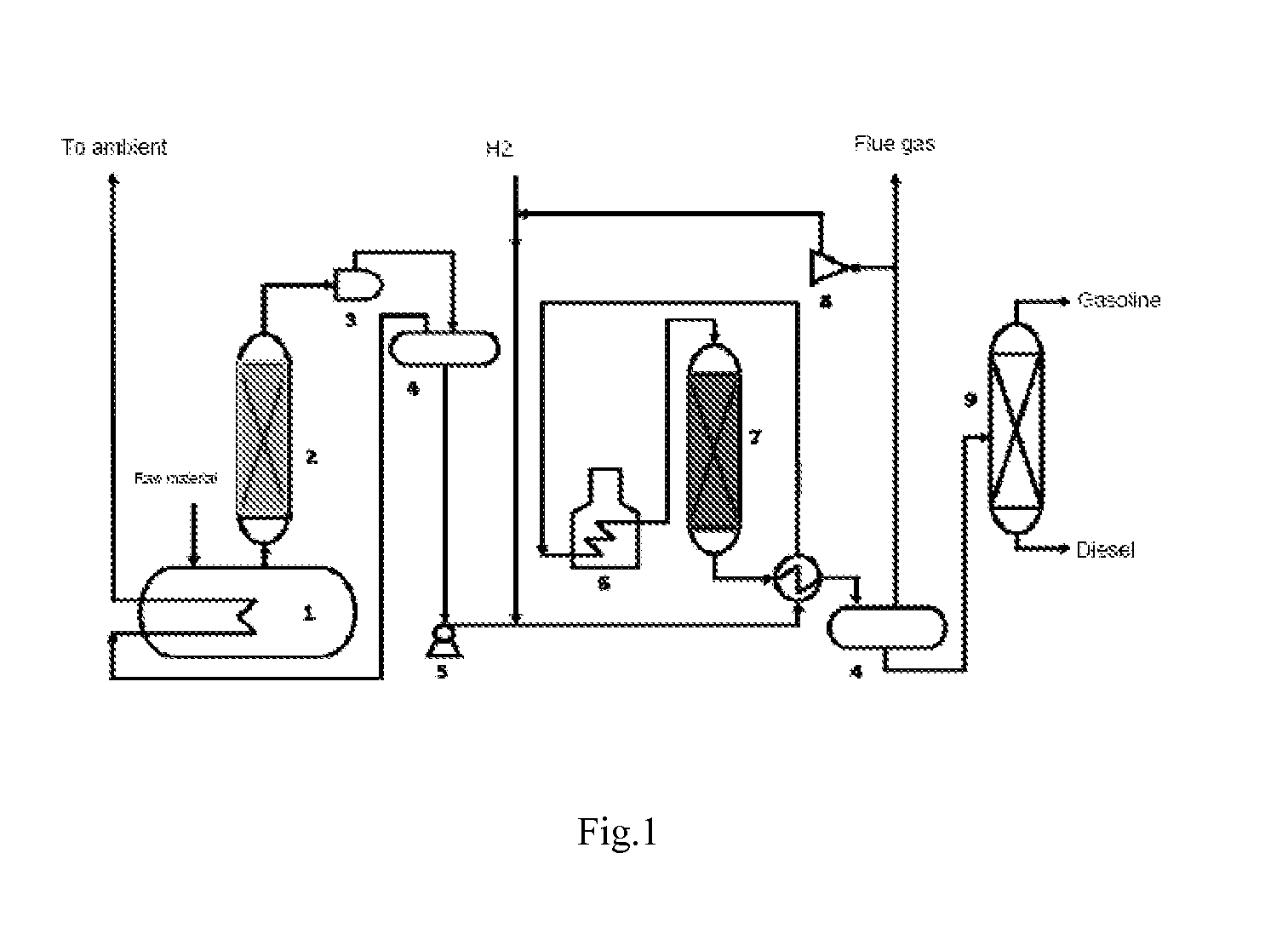

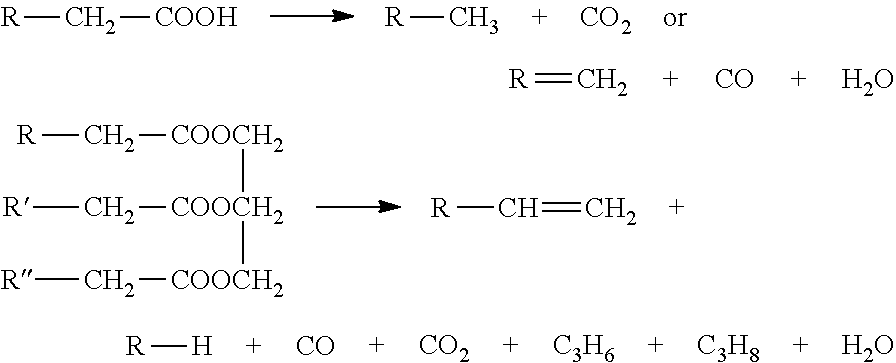

A new method of producing fuel from biological oils and fats is provided, which comprises following steps: (a) proceeding with a catalytic cracking-deoxygenation reaction for the biological oils and fats under heating in the presence of a cracking-deoxygenation catalyst; (b) mixing the product of step (a) with hydrogen gas; and (c) proceeding with a catalytic hydrodeoxygenation reaction for the mixture from step (b) under heating in the presence of a hydrodeoxygenation catalyst. By means of the method of the present invention, clean fuel produced by using biological oils and fats as raw materials is compatible to the fuel composition produced from crude oil refining.

Owner:ECO BIOMASS TECH CO LTD +1

Method for producing foamable phenol formaldehyde resin by using paraformaldehyde

The present invention discloses a method for producing a foamable phenol formaldehyde resin by using paraformaldehyde. The method comprises the following steps: (1) preparing raw materials, wherein the raw materials comprise, by mass, 100-120 parts of phenol, 49.8-75.7 parts of paraformaldehyde, 0.5-5 parts of an alkali catalyst, 1-5 parts of urea, and 4-10 parts of a diluent; (2) adding the phenol, the paraformaldehyde, the alkali catalyst and the urea to a reaction kettle according to the mass parts, and carrying out a reaction at a temperature of 55-90 DEG C under atmospheric pressure; and (3) adding the diluent to the reaction kettle after the reaction, cooling and terminating the reaction. With the method of the present invention, the problem of heat emission of formaldehyde is sloved, the uniformity of the whole product can be ensured, the foamable phenol formaldehyde resin can be obtained, and the late stage phenol formaldehyde foam production can be prompted, wherein the viscosity of the obtained foamable phenol formaldehyde resin is not more than 15 Pa.s.

Owner:四川景文材料科技有限公司

Nanometer bismuth oxide-coated modified boron fuel and preparation methods thereof

The invention discloses a nanometer bismuth oxide-coated modified boron fuel and two kinds of preparation methods thereof. The modified boron fuel comprises the components, in percentage by mass: 30-60 of superfine boron powder, and 70-40 of nanometer bismuth oxide. The first preparation method comprises the steps of metering raw materials, preparing a raw material solution, adding the boron powder, preparing a precursor and calcinating; and the second preparation method comprises the steps of metering raw materials, preparing the precursor and calcinating. The nanometer bismuth oxide-coated modified boron fuel has low ignition temperature, releases a large amount of heat, has high combustion efficiency, and has a stable combustion state when be added in an explosive formula.

Owner:NANJING UNIV OF SCI & TECH

Ultraviolet light chain type initiated self-reaction low-viscosity high-thickness full-curing glue

ActiveCN113088239ALow viscosityImprove wettabilityPolyureas/polyurethane adhesivesMethacrylatePolymer science

The invention discloses an ultraviolet light chain type initiated self-reaction low-viscosity high-thickness full-curing glue. The ultraviolet curing glue is prepared from the following substances in parts by mass: 10 to 30 parts of polyurethane (methyl) acrylate, 0 to 10 parts of trifunctional / multifunctional (methyl) acrylate, 5 to 30 parts of bifunctional (methyl) acrylate, 50 to 80 parts of monofunctional (methyl) acrylate and 0.1 to 3.0 parts of photoinitiator. The ultraviolet curing glue is low in viscosity, easy to defoam, good in wettability, convenient to use, high in curing speed, moderate in heat release, high in test block transparency and good in surface state, is suitable for packaging of electronic products, and is particularly suitable for packaging detection of metallographic cold-embedded printed circuit boards needing rapid testing.

Owner:YANTAI UNIV

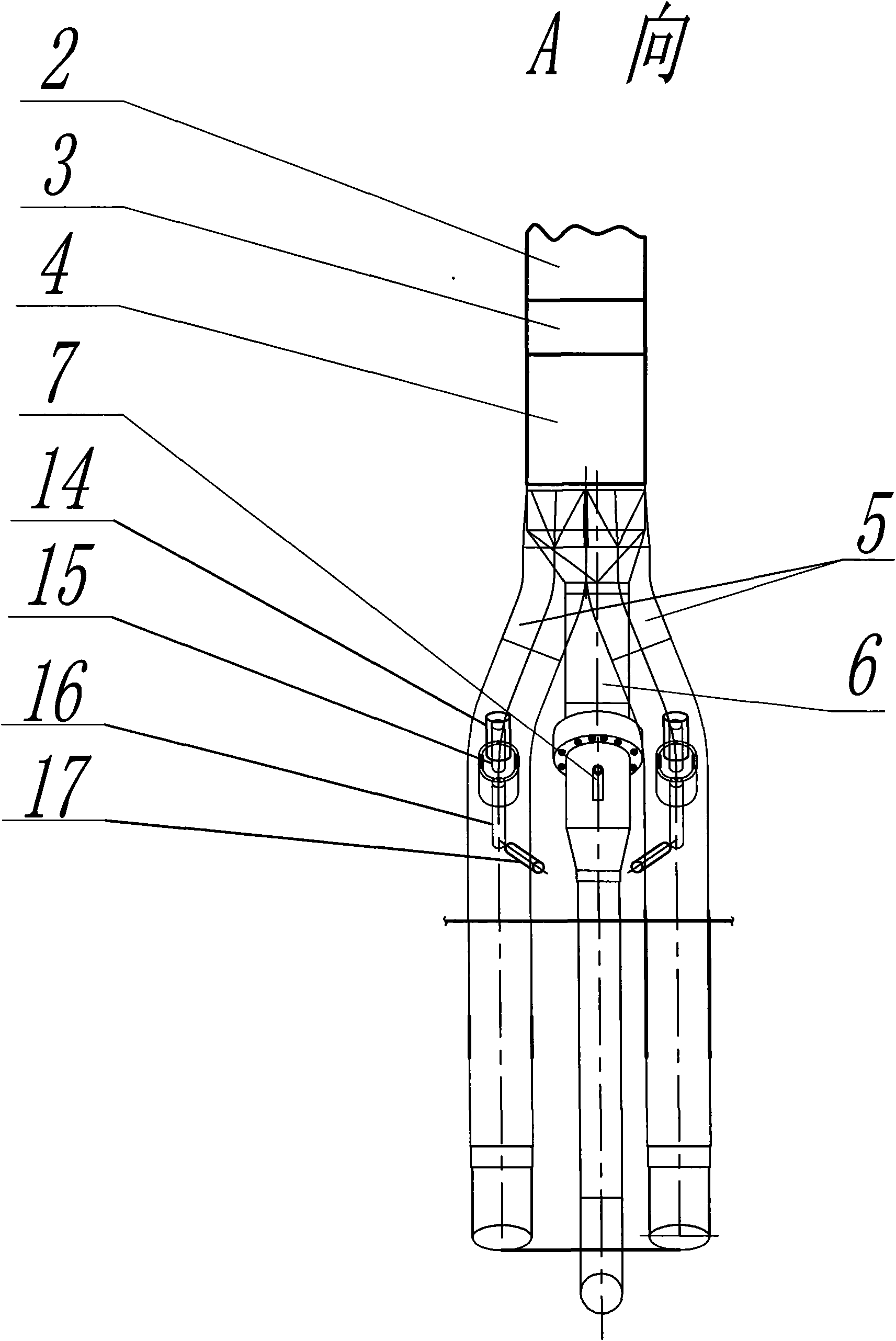

Micro oil content ignition coal powder burner capable of improving initial ignition heat

ActiveCN101806452AReduce outputNot easy to ignitePulverulent fuel combustion burnersCoalPetroleum engineering

The invention provides a micro oil content ignition coal powder burner capable of improving initial ignition heat, which relates to a burner. The invention solves the problems of difficult ignition of coal powder and unstable burning of the existing burner. The invention has the technical scheme that the micro oil content ignition coal powder burner capable of improving the initial ignition heat of the invention comprises a No.1 main oil gun, a No.2 main oil gun, an oil gun installing branch pipe and a heat insulation burning sleeve barrel, wherein the heat insulation burning sleeve barrel is arranged in the inlet end of the oil gun installing branch pipe, the No.1 main oil gun and the No.2 main oil gun are arranged in the inlet end of the oil gun installing branch pipe from top to bottom, and both of the No.1 main oil gun and the No.2 main oil gun are communicated with an inner cavity of the heat insulation burning sleeve barrel. The invention is mainly applied to W flame boilers, the burnt and used coal types belong to lean coal and blind coal with the characteristics of low volatilization constituent content, high ignition temperature and difficult ignition.

Owner:HARBIN INST OF TECH

Air conditioner for vehicle

ActiveCN107953750AWide range temperature controlPromote circulationMechanical apparatusEvaporators/condensersEngineeringRefrigerant

The invention provides an air conditioner for a vehicle having a simple configuration and capable of controlling temperature in a wide range. In a dehumidification heating operation in which a refrigerant is circulated through a first heat exchanger, a second heat exchanger, an evaporator and a compressor in the order named so as to radiate the heat of the refrigerant into the first heat exchanger, there is provided a refrigerant heating means which heats the refrigerant when an outside air temperature is not higher than a predetermined temperature and when an opening degree of the second expansion valve which expands the refrigerant flowing out from the second heat exchanger is larger than an opening degree of the first expansion valve which expands the refrigerant flowing out from the first heat exchanger.

Owner:HONDA MOTOR CO LTD

Fischer-Tropsch synthesis oil hydrofining method

InactiveCN110028987AGood deoxidation effectAvoid inactivationTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionReaction temperature

The invention provides a Fischer-Tropsch synthesis oil hydrofining method which comprises the following steps: S1, mixing Fischer-Tropsch synthesis oil with hydrogen, carrying out a low-temperature pre-hydrogenation reaction, and converting unsaturated olefins in the Fischer-Tropsch synthesis oil into corresponding saturated hydrocarbons to obtain a pre-hydrogenation product; S2, performing a deephydrodeoxygenation reaction on the pre-hydrogenation product to obtain a hydrofining product; and S3, circulating a part of the hydrofining product, conducting mixing with Fischer-Tropsch synthesis oil, and then carrying out a low-temperature pre-hydrogenation reaction. Through circulation of a part of the hydrofining product, reaction temperature rise can be reduced, coking carbon deposition andinactivation of a catalyst are prevented, stable operation of the reaction is easy to maintain, and a high olefin conversion rate and a high oxygen-containing compound conversion rate are maintainedfor a long time.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Fischer-Tropsch synthetic oil hydrofining catalyst and preparation method and application thereof

InactiveCN109985620ALow coking carbon deposition rateSolution to short lifeRefining by selective hydrogenationMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationOxygen

The present invention provides a Fischer-Tropsch synthetic oil hydrotreating catalyst comprising a precious metal and a gamma-Al2O3 carrier, wherein the mass of the noble metal is 0.2% to 2.0% of themass of the gamma-Al2O3 carrier. By controlling the content of the precious metal, the catalyst reaches a balance between metallization and acidity, the hydrogenation function is enhanced, and cokingcarbon of the catalyst due to a dehydrogenation reaction of olefins is reduced. Therefore, the invention only adopts one catalyst, and can complete the hydrofining of the Fischer-Tropsch synthetic oilwithout step reaction. The catalyst has a low coking and carbon deposition rate and long service life, and can ensure a higher olefin conversion rate and oxygen-containing compound conversion rate for a long time.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

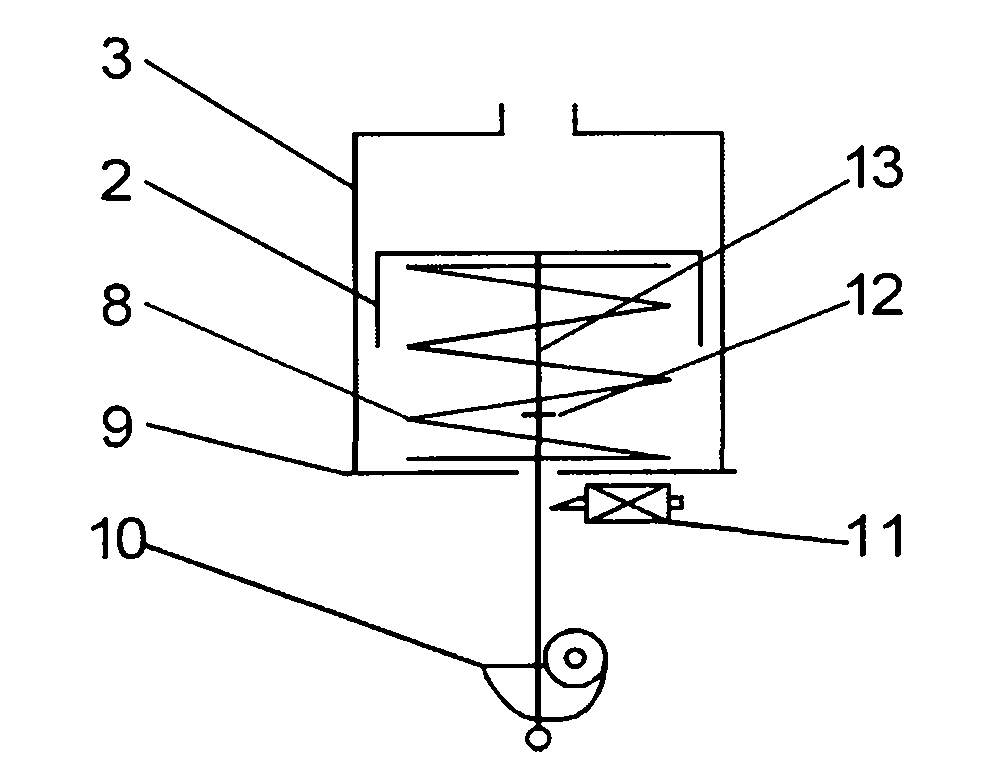

Humidity controller

InactiveCN1826495ALarge heat releaseImprove recovery efficiencyCompression machines with non-reversible cycleDispersed particle separationEngineeringRefrigerant

The amount of heat for thermal regeneration of an adsorber ( 80 ) is increased by making the sensible heat zone ( R ) for refrigerant ( 106 ) in a refrigeration cycle larger than that for R22.

Owner:DAIKIN IND LTD

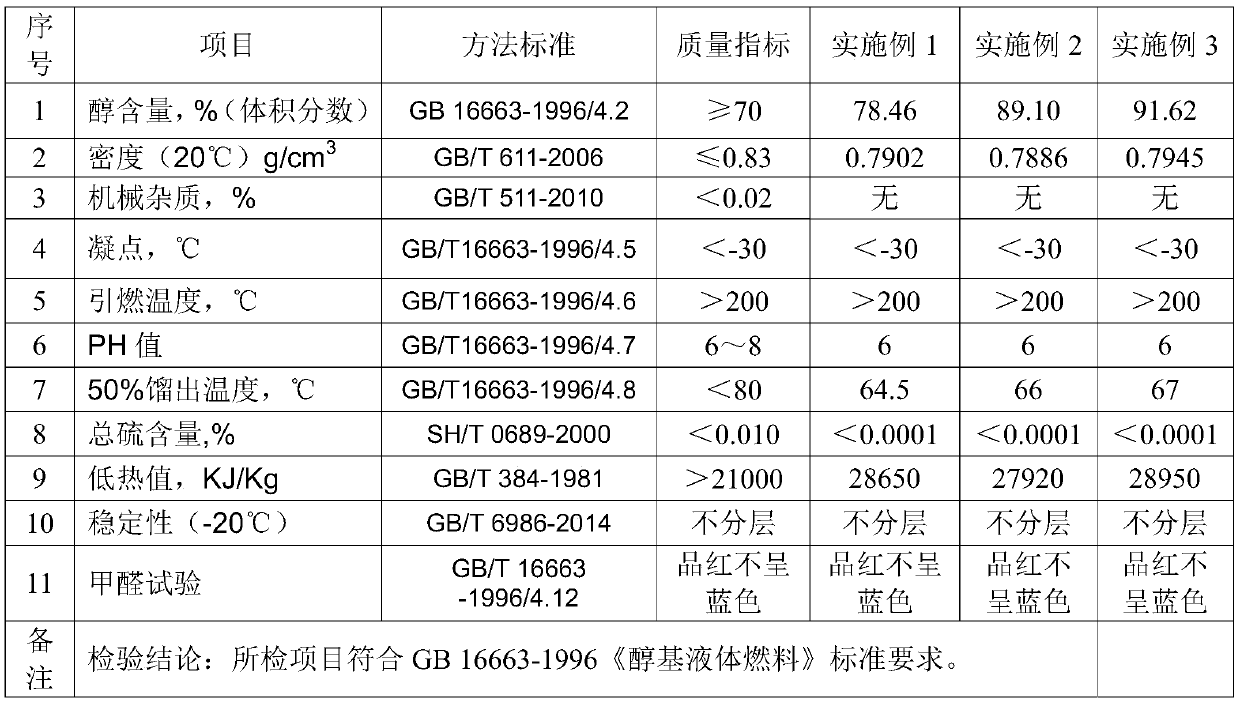

Rapid demolding combined polyether, and polyurethane and preparation method thereof

Rapid demolding combined polyether comprises the following components in parts by weight: 50-60 parts of a first type of polyether polyol, 30-40 parts of a second type of polyether polyol, 5-10 partsof a third type of polyether polyol, 5-6 parts of an auxiliary agent, 12-13 parts of a foaming agent and 2-2.5 parts of water. According to the combined polyether, high-functionality sugar ether, sorbitol ether and oil ether are used as the first type of polyether polyol, and more high-functionality amine ether is used as the second type of polyether polyol, so that the mixing affinity and the crosslinking degree of a reaction system are effectively improved, and curing is accelerated; and polyether modified silicone oil is used as a surfactant to improve the intersolubility between componentsin the system and a black material, an amine catalyst, an organic metal catalyst and a trimerization catalyst are used as composite catalysts, the foaming time is balanced, and the demolding effect is synergistically improved.

Owner:GUANGZHOU LONGTANG POLYURETHANE

Induction heating cooker and cooking table using the same

InactiveCN1875661AIncrease the total output valueReduce outputInduction heating controlInduction heating apparatusEngineeringControl unit

An induction heating cooker includes: an external shell, a heating coil, a power source circuit, a plurality of temperature detection elements, and a control unit for controlling output of the heating coil. The heating coil is arranged in the external shell. The power source circuit has a plurality of heating elements and supplies a high-frequency current to the heating coil. The temperature detection elements respectively detect temperatures of the heating elements. When one of the temperatures detected by the temperature detection elements has reached a temperature predetermined for each of the temperature detection elements, the control unit lowers the output of the heating coil. When one of the temperatures detected by the temperature detection elements is higher than a first temperature and has reached a second temperature predetermined for each of the temperature detection elements, the output of the heating coil is further lowered.

Owner:PANASONIC CORP

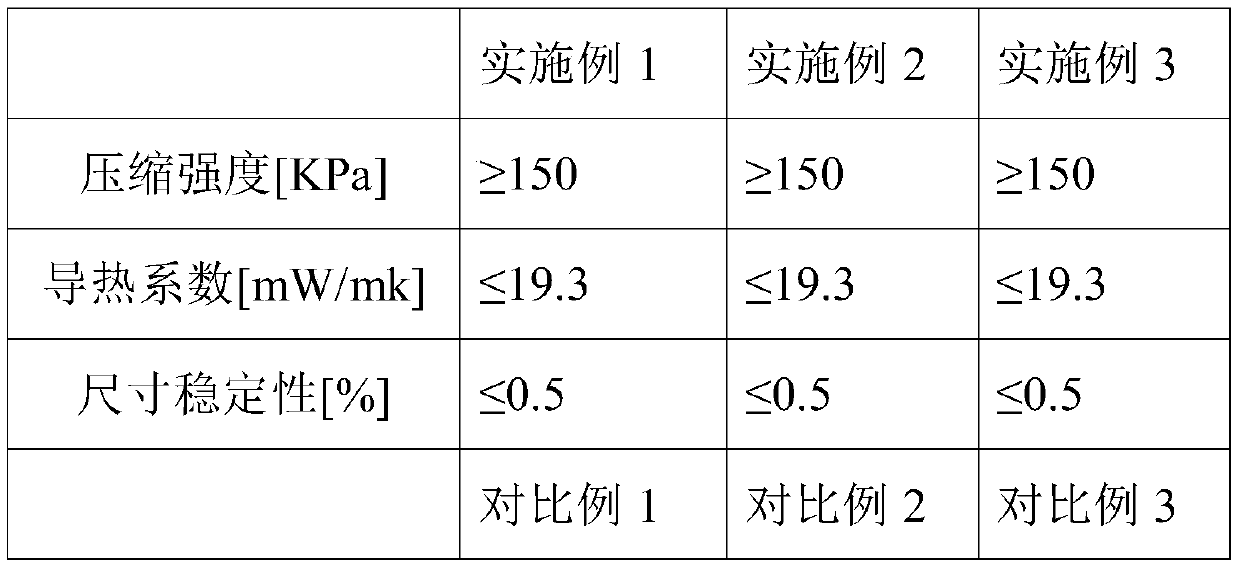

High-energy alcohol-based liquid fuel and preparation method thereof

PendingCN110003959ATransparent and clear textureGood miscibilityLiquid carbonaceous fuelsFuel additivesAlcoholHigh energy

The invention discloses a high-energy alcohol-based liquid fuel and a preparation method thereof, and belongs to the technical field of alcohol-based liquid fuels. The high-energy alcohol-based liquidfuel comprises an alcohol-based liquid, an auxiliary fuel and a composite additive. The preparation method comprises the following steps: compounding and blending a plurality of chemical raw materials to form the composite additive, compounding and denaturing the alcohol-based liquid with the composite additive, and blending with the matched high-energy stable auxiliary fuel to prepare the high-energy alcohol-based liquid fuel with a high combustion efficiency, a high calorific value, strong power, a good intersolubility, a low energy consumption and a low pollution discharge. The preparationmethod of the high-energy alcohol-based liquid fuel has the advantages of simplicity, no large devices, safe production process, no environmental pollution and wide sources of the raw materials; andthe product has the advantages of safety in storage and transportation, fullness in combustion, high effective heat value, reduction of air pollution, effectiveness in alleviation of energy shortage,great social and economic benefit, suitableness for large-scale quantitative production, and universal promotion values.

Owner:刘安平 +2

Sintering-mineralizing energy-saving combustion adjuvant and its preparing method

This invention discloses an energy save combustion accelerator and its manufacturing method for agglomerate, which mixes borax 45%-50% boric acid 10%-14%, NaHCO3 24%-30%, NaCl 21%-6% in the proportion of a formula to mix them evenly and put them in bags. The chemical reaction of said accelerator is carried out in the sintering process, which can further increase its smelting strength and reduce the coke ratio.

Owner:刘志伟

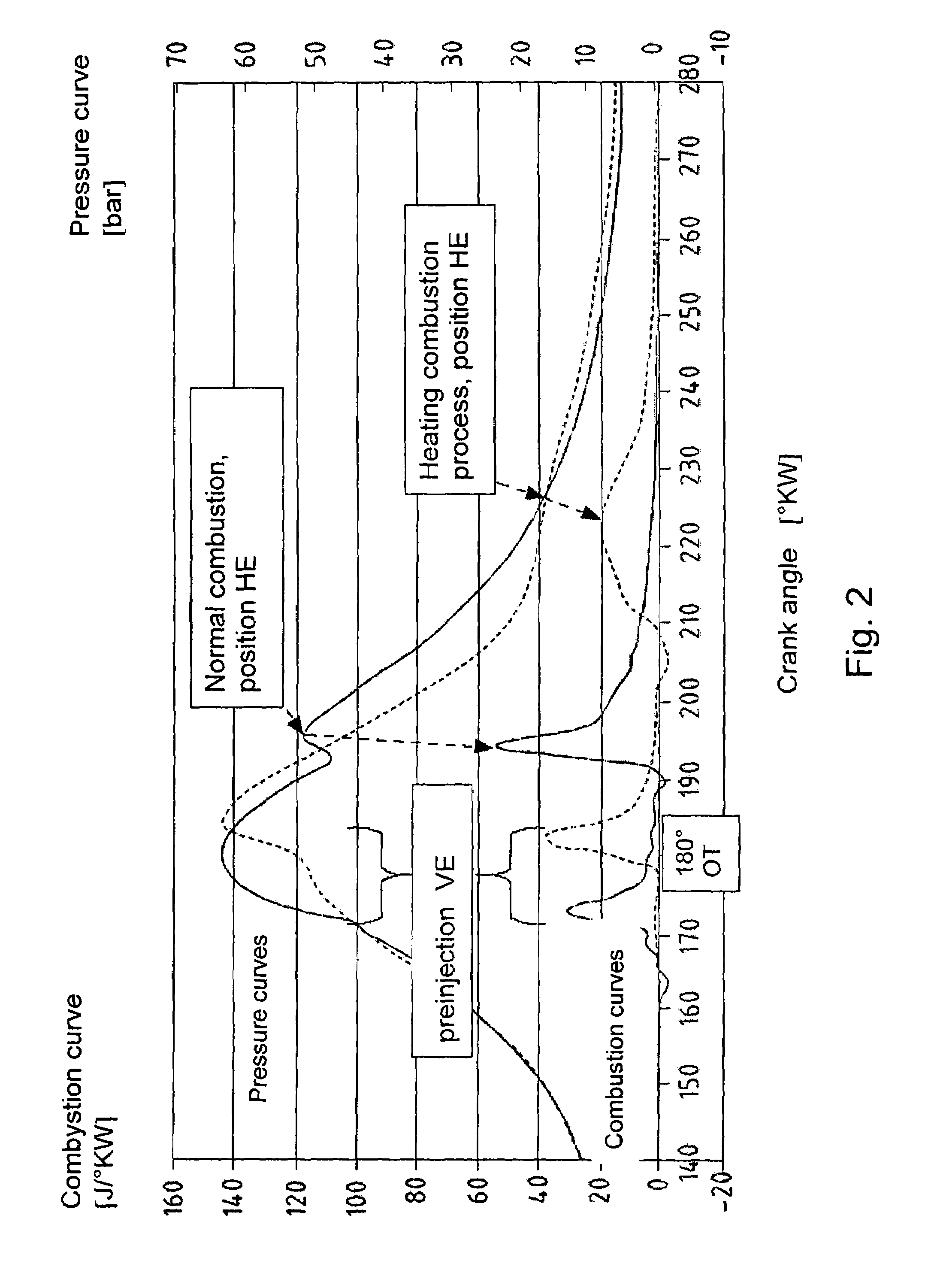

Method of operating an internal combustion engine in an engine warm-up phase

InactiveUS7610895B2Heating fastRapid and adequate heatingElectrical controlCoolant flow controlMobile vehicleExternal combustion engine

Owner:DAIMLER AG

Low-heat-release and high-biological-activity compound bone cement and preparation method thereof

InactiveCN109621013ALarge specific surface areaGood mechanical propertiesInorganic non-active ingredientsSkeletal disorderSolid phasesHydroquinone Compound

The invention discloses low-heat-release and high-biological-activity compound bone cement and a preparation method thereof. The compound bone cement is prepared by mutually mixing 40-80% of solid phase powder and 10-50% of a liquid phase, wherein the solid phase powder comprises graphene, polymethyl methacrylate and hydroxyapatite; the liquid phase comprises methyl methacrylate, hydroquinone anddimethyl-p-toluidine. The compound bone cement is high in syringeability and biological activity; by adding the graphene with the super-high specific surface area, it is ensured that in the using process of the PMMA bone cement, the reaction heat of the PMMA bone cement is gradually released without injuring surrounding bone tissue, and it is ensured that the bone cement has a high plasticity andis capable of being shaped at random. In the solidification process, the polymerization heat release temperature is greatly lowered, the overall performance is excellent, the bone cement can meet requirements of filling and repair of bone defects, and the bone cement can be used as a drug carrier to treat orthopedic related diseases.

Owner:SHANDONG RIENTECH MEDICAL TECH

Welding flux used for ferrum-based material heat-released jointing and igniting agent thereof

ActiveCN103894755AAccelerateLarge heat releaseWelding/cutting media/materialsSoldering mediaFerrosiliconLanthanum

The invention relates to a welding flux used for ferrum-based material heat-released jointing and an igniting agent of the welding flux. The welding flux and the igniting agent aim to solve the problems that supply of welding fluxes special for heat-released jointing of ferrum-based materials is not enough, welding joints acquired through prior heat-released jointing welding fluxes contain impurities, large residual stress is caused by difference in coefficients of thermal expansion, and welding joint performance is poor. The welding flux used for ferrum-based material heat-released jointing is composed of ferric oxide powder, 304 stainless steel powder, commercial-purity aluminum powder, niobium powder, copper powder, ferrosilicon powder, ferromanganese powder, fluorite powder, marble powder and lanthanum-cerium alloy powder. The igniting agent of the welding flux used for ferrum-based material heat-released jointing is composed of magnesium powder, barite powder, commercial-purity aluminum powder, red phosphorus powder and fluorite powder. In the using process, the weight ratio of the welding flux used for ferrum-based material heat-released jointing to the igniting agent is (50-60):1. The welding flux and the igniting agent are used for ferrum-based material jointing.

Owner:HARBIN INST OF TECH

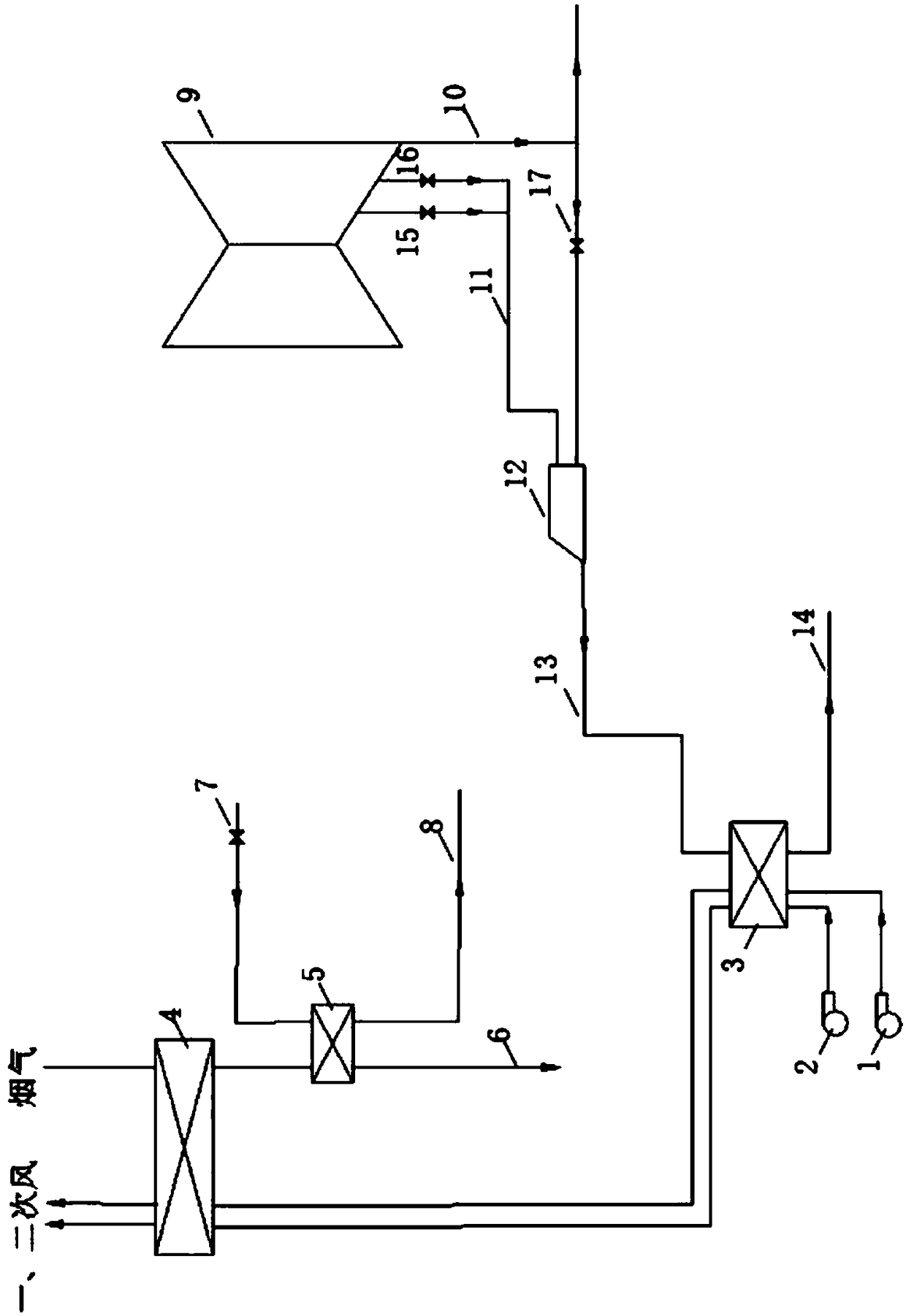

Machine furnace waste heat coupling and utilizing system with pressure matcher

The invention relates to a machine furnace waste heat coupling and utilizing system with a pressure matcher. The machine furnace waste heat coupling and utilizing system comprises a turbine low-pressure cylinder, the pressure matcher, an air heater, an air preheater and a low-temperature coal economizer. The input end of the pressure matcher is connected with the turbine low-pressure cylinder through a low-pressure cylinder gas extraction pipeline and a steam exhaust and extraction pipeline, and the steam exhaust and extraction pipeline is connected with a low-pressure cylinder gas exhaust pipeline, so that low-pressure exhaust gases of a turbine are extracted under the drive of low-pressure gas extraction of the turbine, and steam with pressure between low-pressure steam extraction and low-pressure steam exhaust is generated. The input end of the air heater is connected with the output end of the pressure matcher through a steam pipeline, and the output end of the air heater is connected with the air preheater, so that primary cold air and secondary cold air, which enter the air heater, are preheated by the steam, and the preheated primary cold air and the preheated secondary coldair are outputted to the air preheater. The air preheater is connected with the low-temperature coal economizer. The low-temperature coal economizer is connected with a circulating-water inlet pipeline and a circulating-water outlet pipeline. By the machine furnace waste heat coupling and utilizing system, waste heat utilization of exhaust steam of turbosets is realized.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

Special HCCI (Homogeneous Charge Compression Ignition) engine and realization method thereof

InactiveCN102182543AImprove formation qualityImprove cold start performanceCombustion enginesHcci combustionAtmospheric pressure

The invention relates to a special HCCI (Homogeneous Charge Compression Ignition) engine and a realization method thereof. A volume-variable container is arranged to be communicated with a space in a cylinder, the volume of the cylinder is accordingly changed by changing the volume of the volume-variable container, and the compression ratio of the cylinder is changed accordingly, that is to say, the volume of the volume-variable container is increased before ignition time, so that the condition required by HCCI can not be achieved in the cylinder; and the volume of the volume-variable container is rapidly reduced at ignition time, so that the pressure and the temperature in the cylinder are instantaneously increased to realize the HCCI, and the purpose of engine HCCI is achieved.

Owner:王洪泽

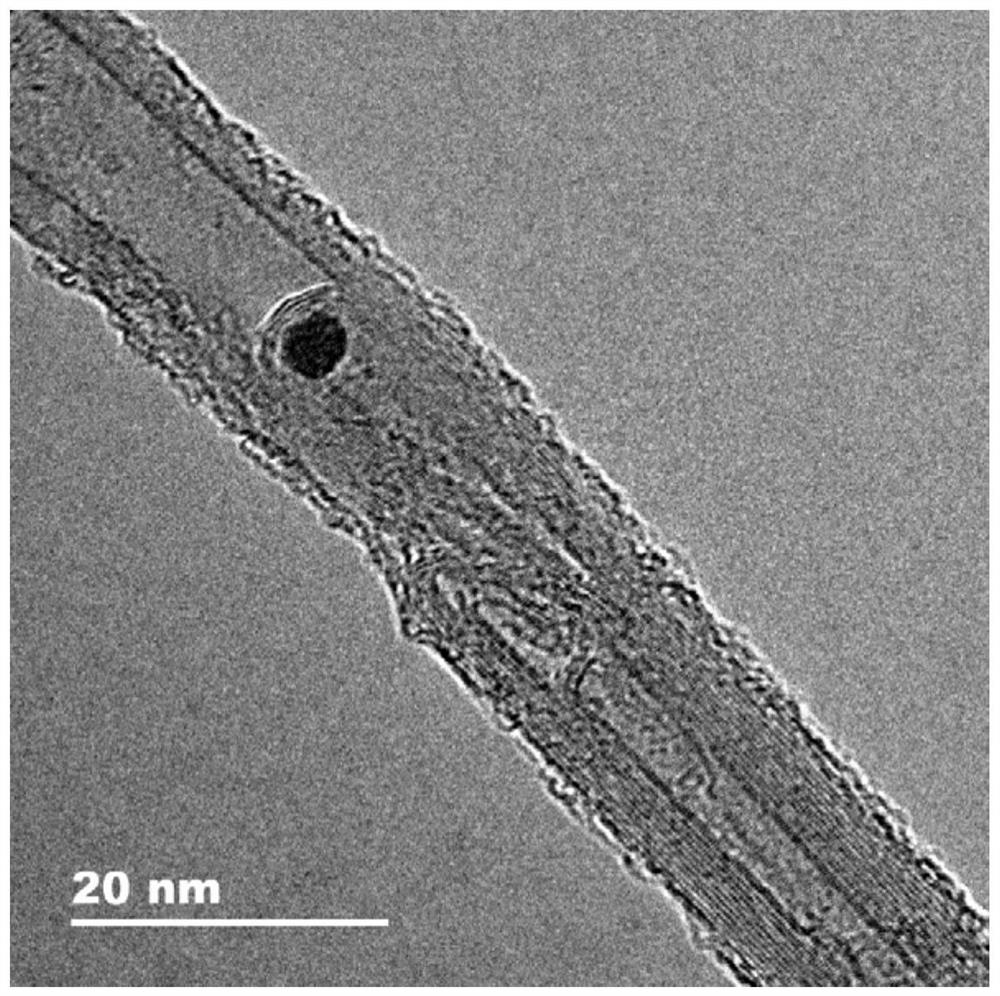

Carbon nanotube-filled copper acetylacetonate composite burning rate catalyst

ActiveCN113548931AStrong "synergistic effect"Strong synergyNon-explosive/non-thermic compositionsAmmonium perchlorate explosive compositionsPtru catalystCopper acetylacetonate

The invention discloses a carbon nanotube-filled copper acetylacetonate composite burning rate catalyst, which is prepared by the following steps: carrying out ultrasonic treatment on multi-walled carbon nanotubes with different tube diameters through a mixed acid solution to obtain oxidized carbon nanotubes with openings at two ends, then adding the oxidized carbon nanotubes into a saturated solution of copper acetylacetonate, and carrying out ultrasonic treatment to fill the tube cavities of the oxidized carbon nano tubes with acetylacetone copper, thereby obtaining the composite burning rate catalyst with the carbon nano tubes filled with acetylacetone copper. The preparation method is simple, and the obtained carbon nano tube filled acetylacetone copper composite burning rate catalyst is good in catalytic effect and easy to prepare in an enlarged mode.

Owner:SHAANXI NORMAL UNIV

Stepped waste heat recycling device and working method

ActiveCN108895708AAchieve effectImprove energy efficiency ratioMachines/enginesFluid circulation arrangementWater vaporSuperheater

The invention discloses a stepped waste heat recycling device and a working method. The stepped waste heat recycling device comprises an absorption-type heat pump system and a heat-work conversion system. The device is integrated with an absorption-type heat pump and heat engine technology and is driven by a waste heat working medium, the waste heat working medium sequentially passes through a superheater, a high-pressure generator, a low-pressure generator and a waste heat recoverer, high-temperature and high-pressure steam produced by the high-pressure generator of the device is super-heated, then a turbine motor expands to output mechanical work for generating power, the dead steam exhausted by the turbine motor and the high-temperature and high-pressure steam produced by the low-pressure generator enters a condenser to be condensed and to release heat for heat supply and heating in winter, a steam generator produces cold energy for refrigeration and cooling, and the effects of combined heat and power generation in winter and combined cold and power generation in summer are achieved. The device fully recovers waste heat energy of a working medium in a stepped waste heat recycling mode, makes waste heat mass-energy utilization most economized, effectively reduces atmosphere heat pollution while the energy utilization rate is improved and has the lots of advantages of saving energy, reducing emissions, economic in operation and wide in application range.

Owner:JIANGSU UNIV OF SCI & TECH

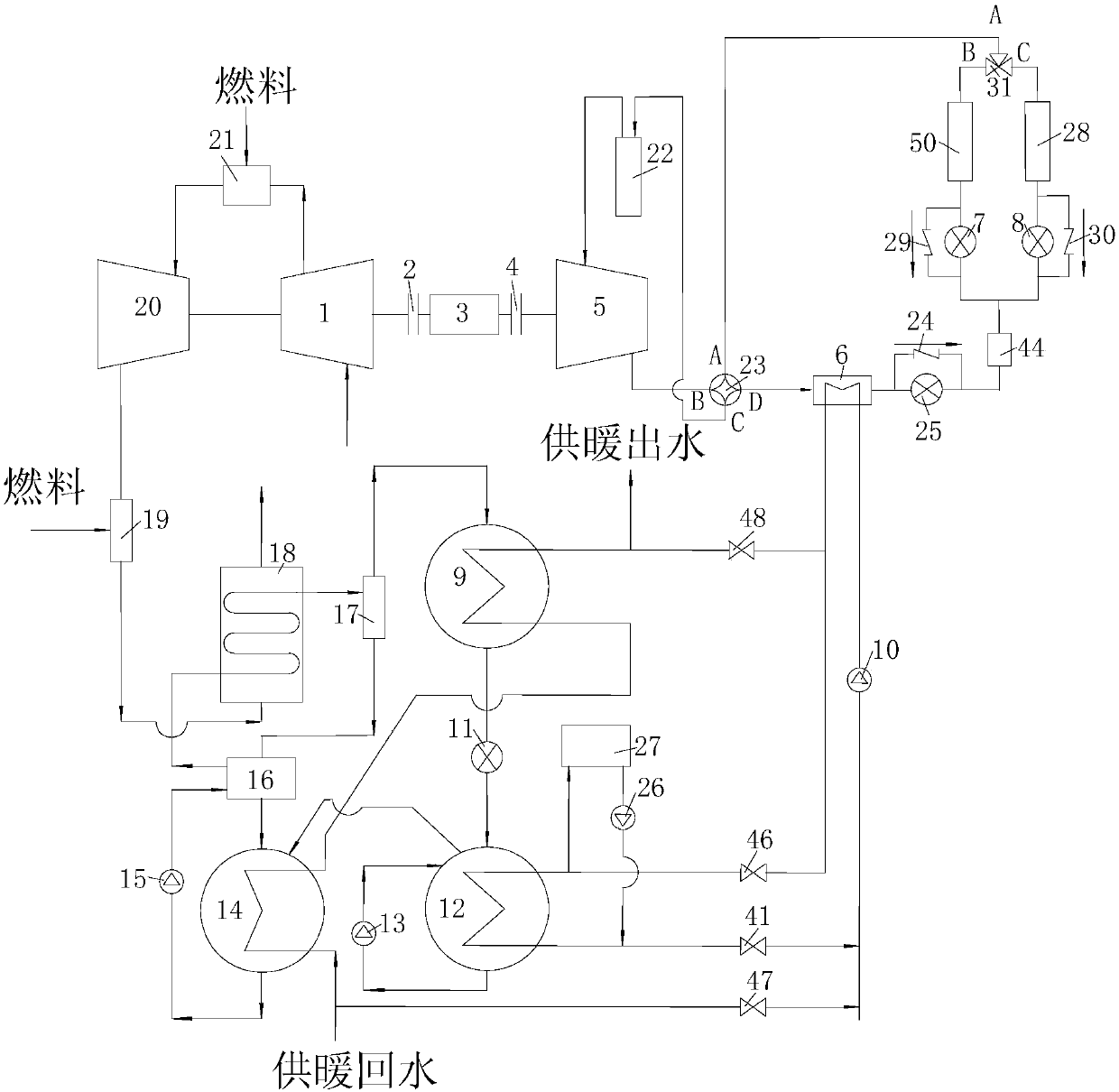

Fuel-engine-driven compression-absorption combined type heat pump system

InactiveCN109682114ALarge heat releaseReduce the compression ratioRefrigeration machinesCombustion chamberFour-way valve

The invention provides a fuel-engine-driven compression-absorption combined type heat pump system. The fuel-engine-driven compression-absorption combined type heat pump system comprises a gas compressor, a compressor, a condenser, a condenser, an evaporator, an absorber, a solution heat exchanger, a gas-liquid separator, a generator, a fuel replenishing combustion chamber, a turbine, a combustionchamber, a gas-liquid separator, a four-way valve and a three-way valve. The invention further provides an application method of the fuel-engine-driven compression-absorption combined type heat pump system. The application method comprises the steps that firstly, fuel works in an engine, output shaft work is used for driving the compressor, and steam compression heat pump cycles are implemented through the compressor; heat with the amount being several times that of the shaft work is absorbed out of a low-temperature environment, and the heat and input shaft work release heat into a middle-temperature heat source; and meanwhile, waste heat generated after the fuel works in the engine is utilized, an absorption type heat pump device is driven, the waste heat is input into an absorption typeheat pump, heat absorbed by the middle-temperature heat source, together with the input waste heat, releases heat to a high-temperature heat source through the absorption type heat pump, and therefore, the heat release amount is greater than the heat absorption amount obtained out of the middle-temperature heat source.

Owner:ZHEJIANG SCI-TECH UNIV

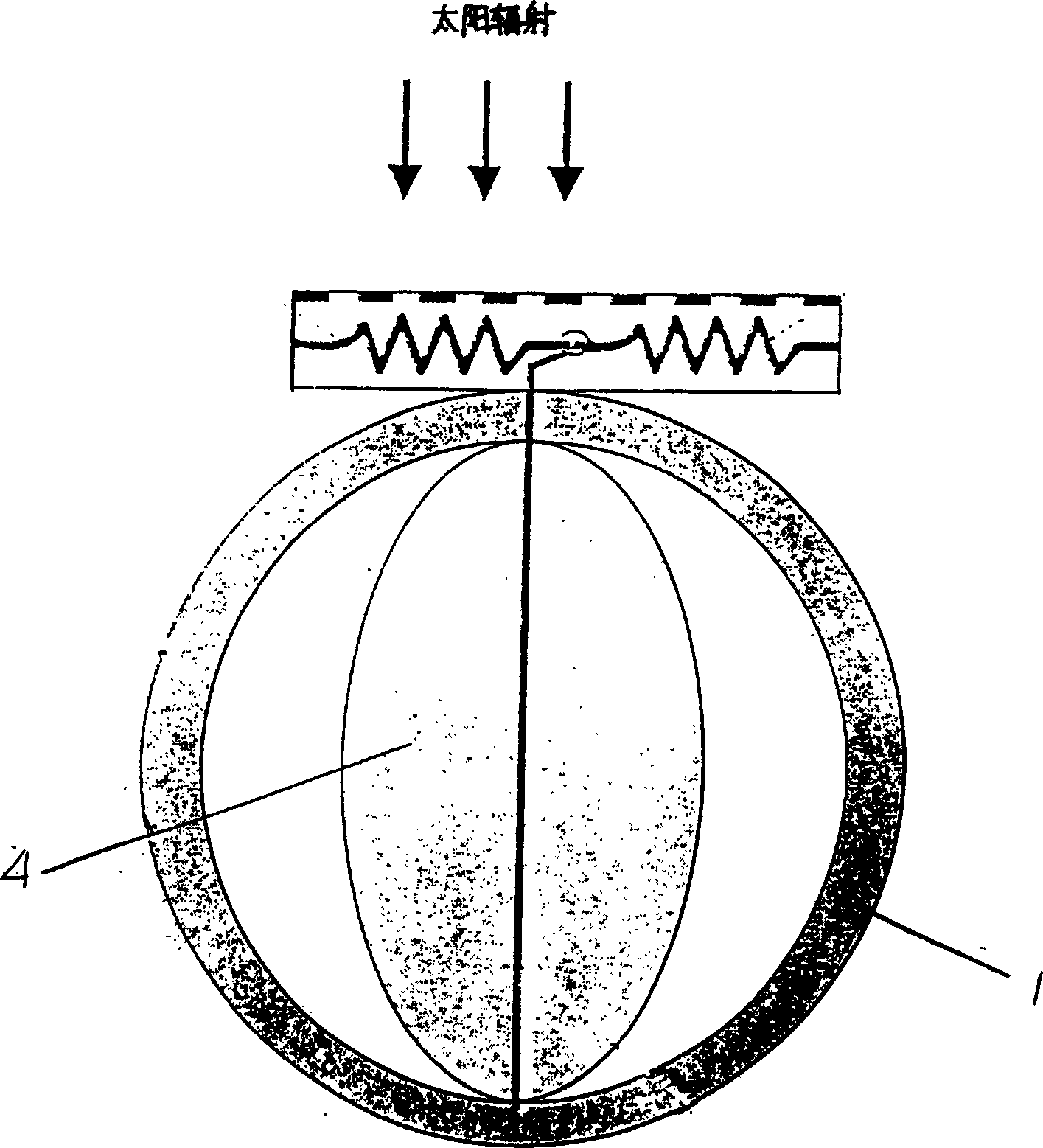

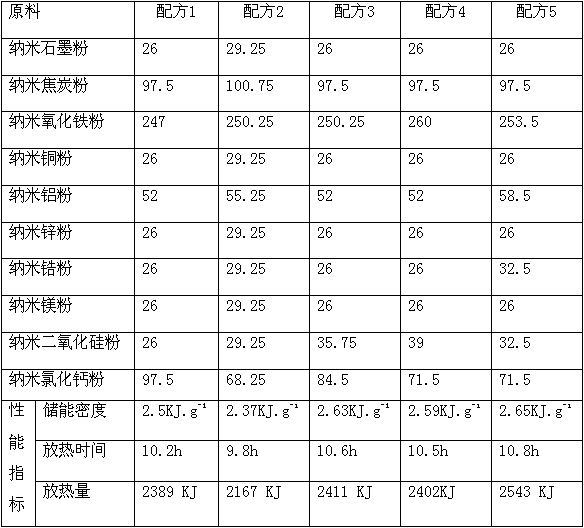

Nanocomposite energy storage ball and preparation method thereof

InactiveCN103194174AHigh energy storage densityExtend heat release timeHeat-exchange elementsSilicon dioxideNanocomposite

The invention discloses a nanocomposite energy storage ball and a preparation method thereof. The nanocomposite energy storage ball is prepared from 60 to 70 percent of nanocomposite material and 30 to 40 percent of refractory material, wherein the nanocomposite material is prepared from the raw materials as follows: 4 to 6 percent of nano-graphite powder, 15 to 18 percent of nano-coke powder, 38 to 42 percent of nano ferric oxide powder, 4 to 6 percent of nano-copper powder, 8 to 12 percent of nano-aluminum powder, 4 to 6 percent of nano-silica powder and the balance of nano calcium chloride powder; and the refractory material is prepared from 80 to 90 percent of refractory clay and 10 to 20 percent of refractory cement. The nanocomposite energy storage ball prepared according to the formula has high density, long heat release time and large heat release quantity, can be made into ball-shaped structures of different sizes, is applied to hotel kitchen ranges conveniently, and has energy gathering and energy storage effects.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

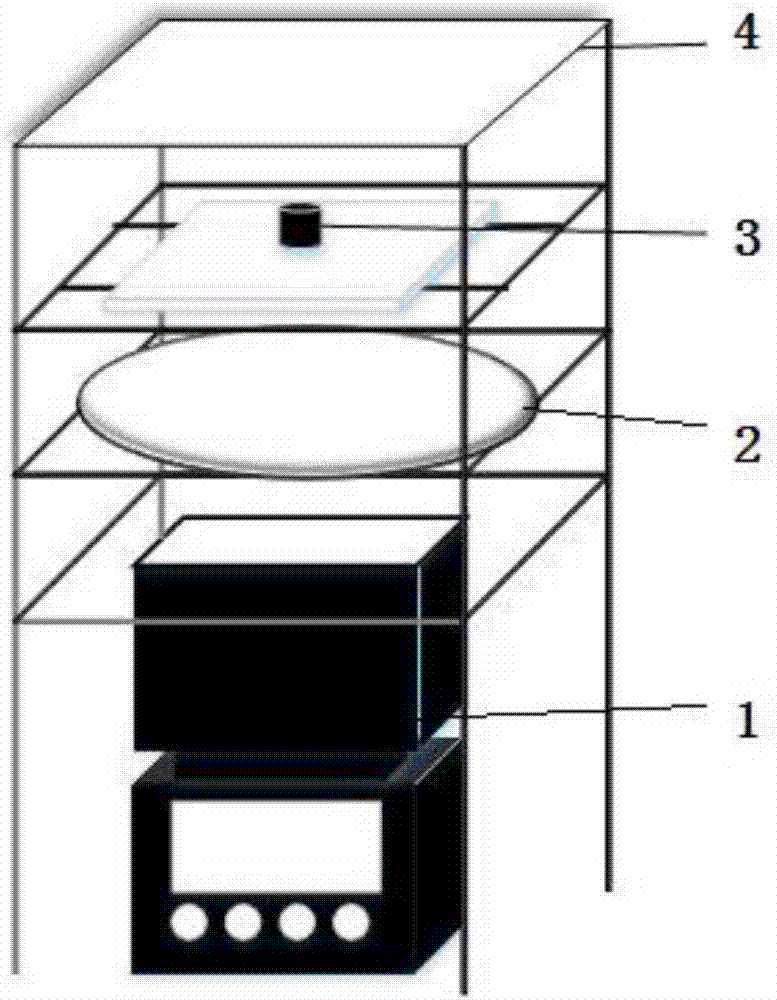

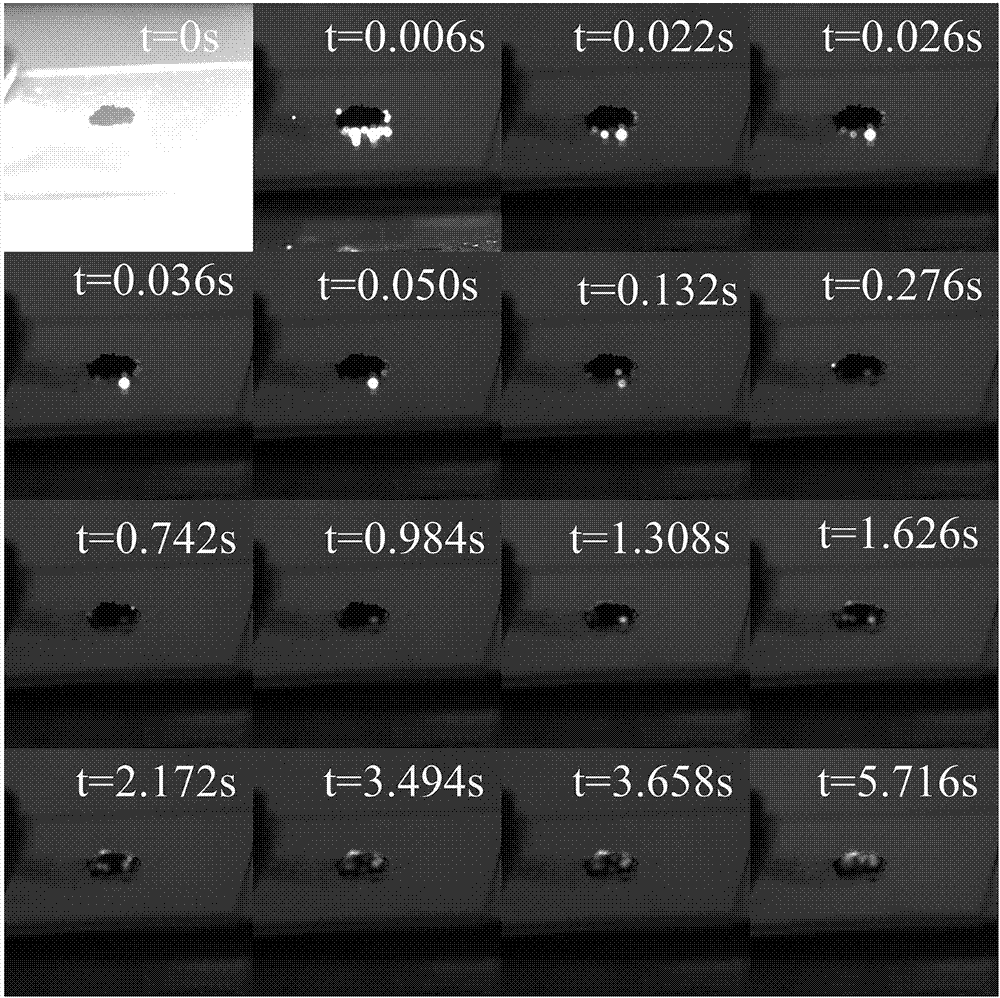

Nanometer iron powder light igniting device

The invention provides a nanometer iron powder light igniting device which comprises a flashlight and nanometer iron powder. The flashlight releases light pulse energy in an ultra-short time, the nanometer iron powder absorbs the light energy, oxide layer on the surface of the nanometer iron powder is destroyed, and so that nanometer iron particles in the nanometer iron powder reacts with surrounding air.

Owner:NANJING UNIV OF SCI & TECH

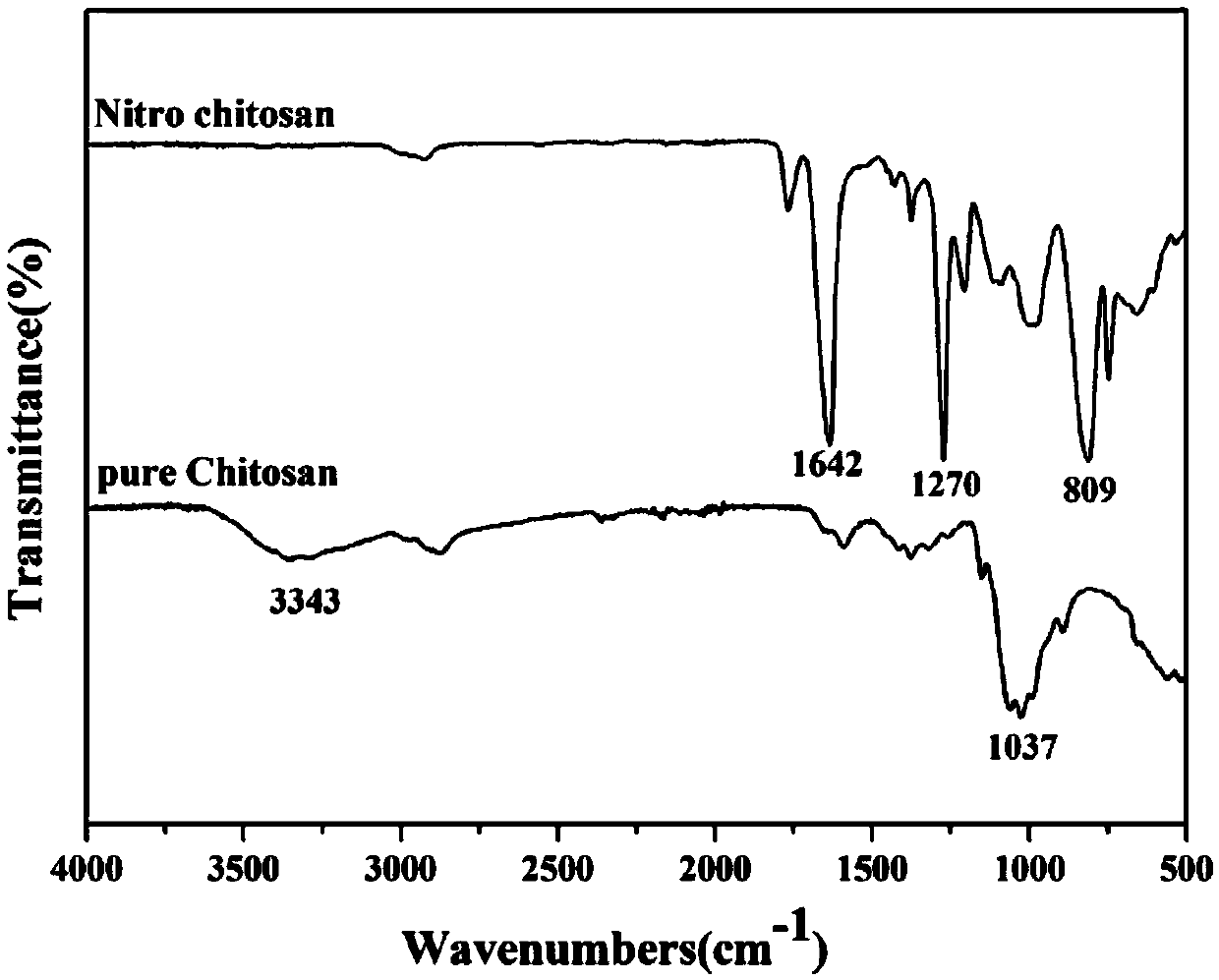

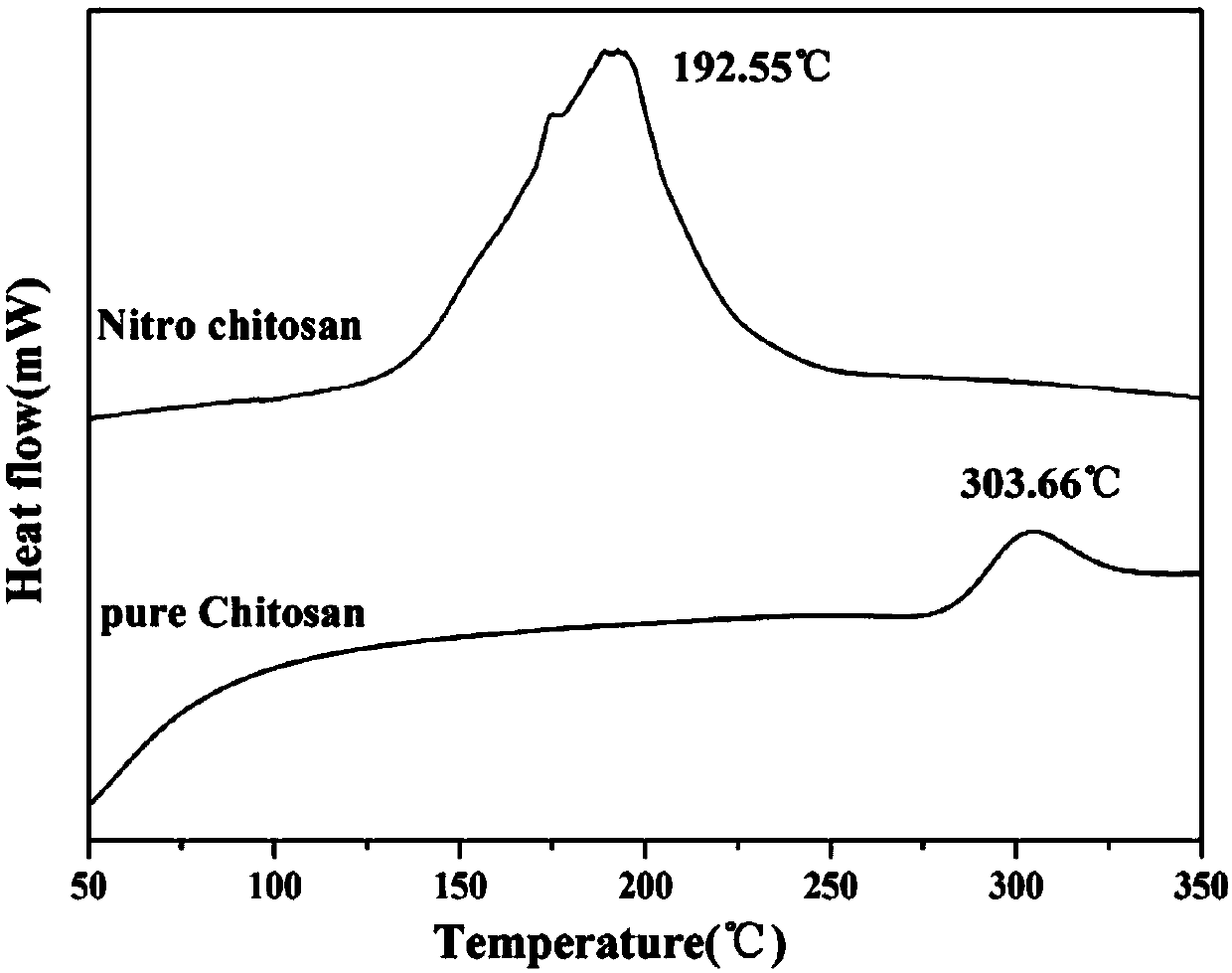

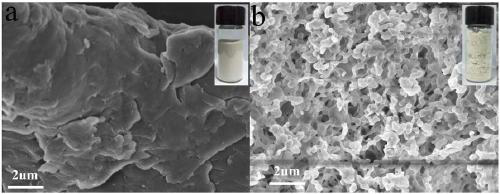

Preparation method of nitrified chitosan and application thereof

ActiveCN109627358AHigh degree of substitutionLarge heat releaseStarch/sugar nitrate explosive compositionsAcetic anhydrideDecomposition

The invention relates to a preparation method of nitrified chitosan and application thereof. The related application is the application of nitrated chitosan as an energetic material, and the nitrification substitution degree of the nitrified chitosan is greater than 1.8. The related preparation method comprises the steps of adding chitosan into acetic anhydride according to the formula amount, adding fuming nitric acid in the stirring process, then adding concentrated sulfuric acid, executing reaction at a low temperature for a suitable time, and then conducting post-treatment on a reactant toobtain the nitrified chitosan. sugar. The nitrified chitosan prepared by the preparation method has large released decomposition heat amount and low sensitivity.

Owner:NORTHWEST UNIV(CN)

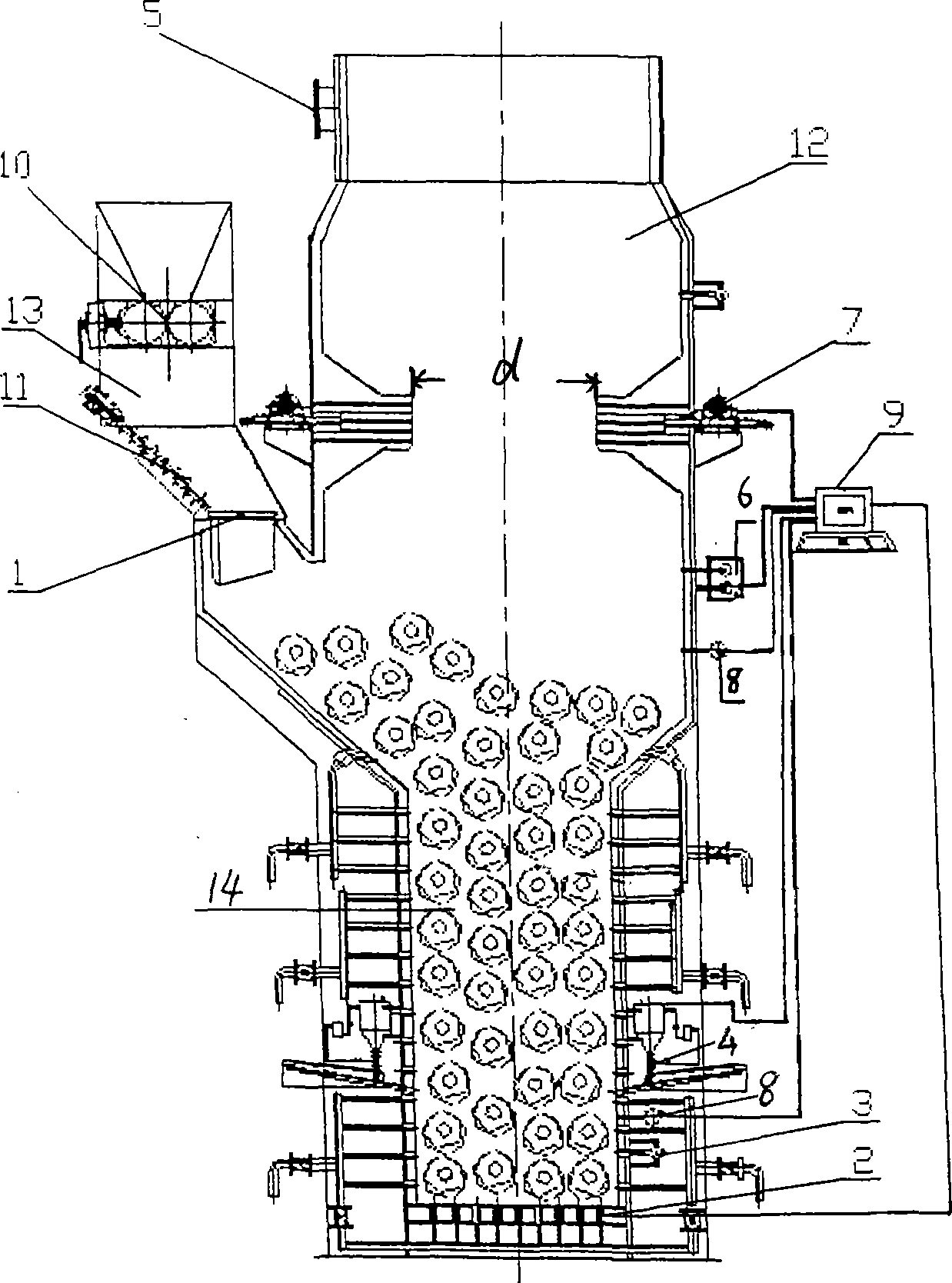

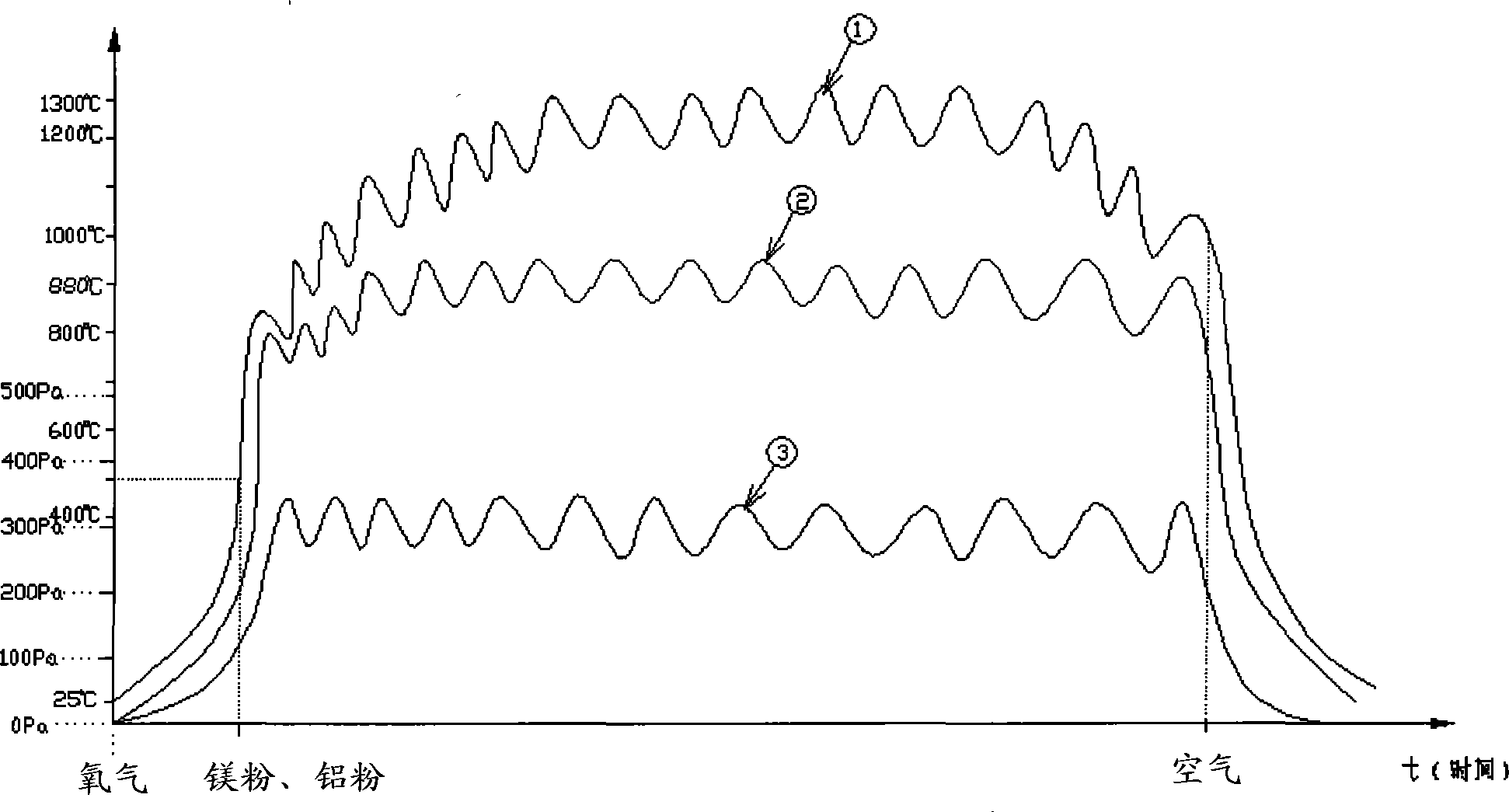

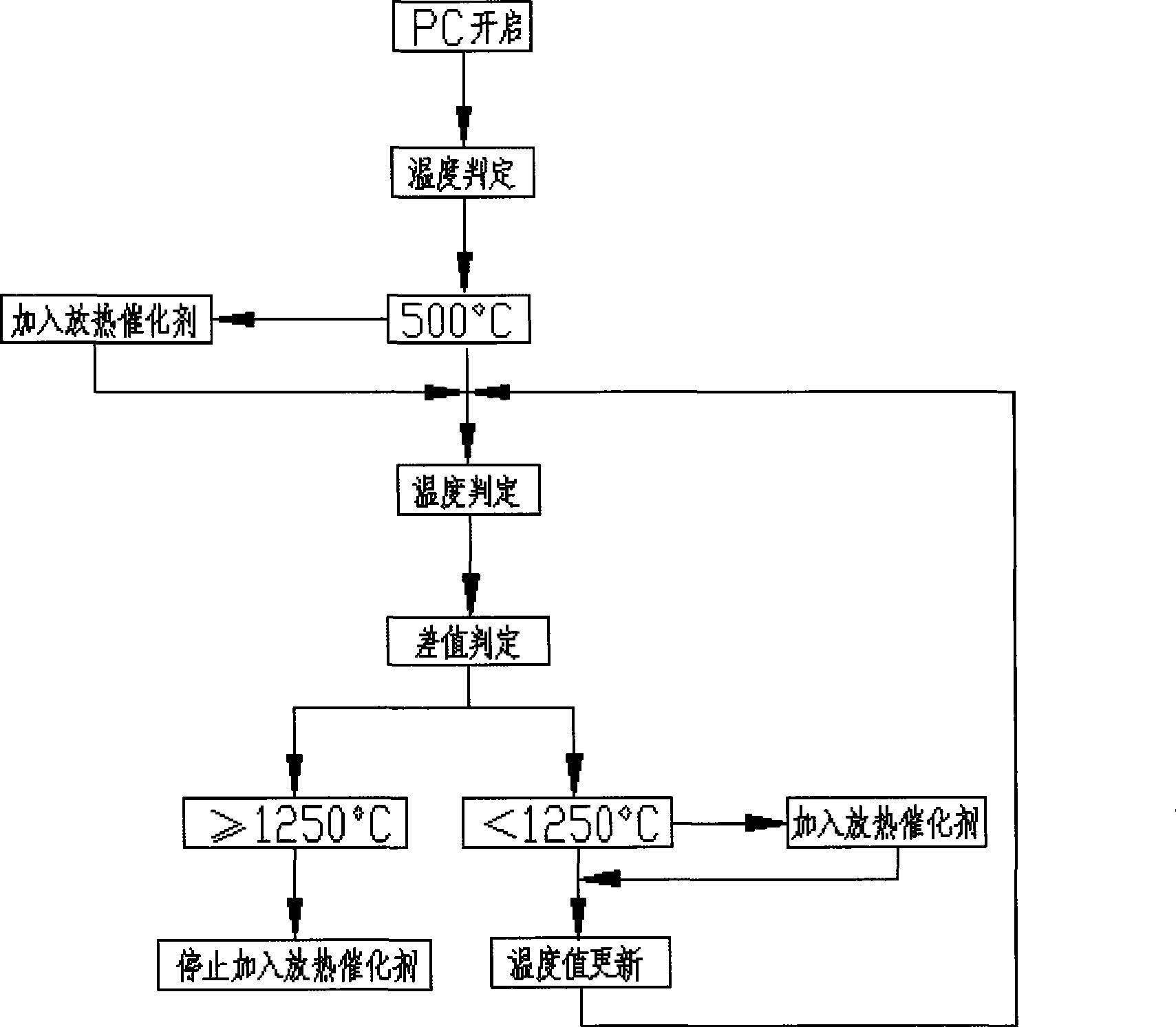

Exothermic catalytic combustion method for pyrolysis gasification submelting furnace under pure oxygen conditions

InactiveCN101520176AReduce lossEmission reductionCombustion using catalytic materialIncinerator apparatusInternal pressureCatalytic combustion

The invention provides an exothermic catalytic combustion method for a pyrolysis gasification submelting furnace under pure oxygen conditions, which is characterized in that pure oxygen is directly introduced into the pyrolysis gasification submelting furnace for pyrolysis after the ignition. During the pyrolysis, catalysts, namely magnesium powder, aluminum powder or a mixture of the magnesium powder and the aluminum powder is added from the furnace bottom, and the adding amount of the catalysts is between 0.1 and 1.0 kg for each ton of treated substance. During the pyrolysis gasification, the pressure in the furnace is adjusted by adjusting the opening degree of a rectification mechanism to ensure that the pressure inside the pyrolysis furnace is stable. The method has the advantages of low cost, energy conservation, and environmental protection.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com