Rapid demolding combined polyether, and polyurethane and preparation method thereof

A technology of combining polyether and demoulding, applied in the field of rapid demoulding combined polyether and its polyurethane and preparation, can solve the problems of controlled production efficiency, inability to meet production, etc. Effect of low temperature shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

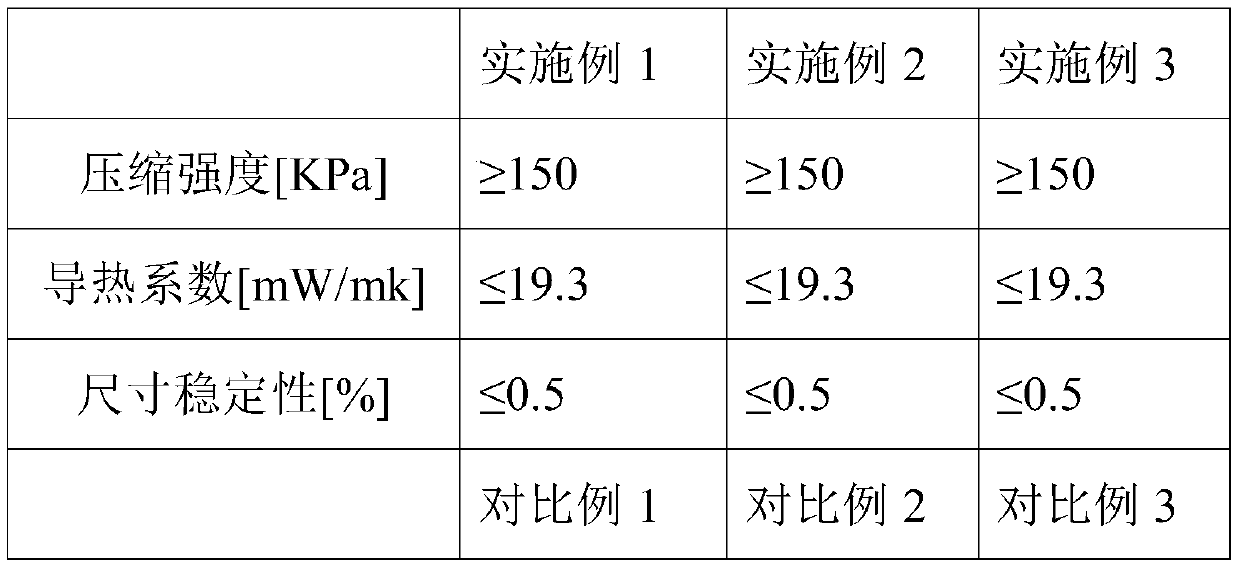

Embodiment 1

[0041] A kind of quick-release polyurethane, comprises quick-release combination polyether and black material, wherein, quick-release combination polyether is made up of following components by weight: 15 parts of sugar ethers, 15 parts of sorbitol ethers, 25 parts Parts of oil ether, 40 parts of amine ether, 5 parts of low viscosity ether, 2.5 parts of polyether modified silicone oil, 12.5 parts of blowing agent, 1 part of amine catalyst, 1 part of organometallic catalyst, 1.5 parts of TMR-2 and 2.3 parts of water ; The combined polyether and black material are mixed in a ratio of 1:1.25;

[0042] The preparation method is a method for quickly demolding polyurethane, comprising the following steps:

[0043] 1) Weighing sugar ether, sorbitol ether, oil ether, low-viscosity ether, polyether-modified silicone oil, amine catalyst, organometallic catalyst, TMR-2 and water, and mixing to obtain the first material;

[0044] 2) Mixing the first material and the blowing agent of the ...

Embodiment 2

[0047] A kind of quick release polyurethane, comprises quick release combination polyether and black material, wherein, quick release combination polyether is made of the following components by weight: 20 parts of sugar ethers, 20 parts of sorbitol ethers, 20 parts Parts of oil ether, 35 parts of amine ether, 5 parts of low viscosity ether, 2.5 parts of polyether modified silicone oil, 12 parts of blowing agent, 1 part of amine catalyst, 1 part of organometallic catalyst, 1.5 parts of TMR-2 and 2.3 parts of water ; The combined polyether and black material are mixed in a ratio of 1:1.25;

[0048] The preparation method is a method for quickly demolding polyurethane, comprising the following steps:

[0049] 1) Weighing sugar ether, sorbitol ether, oil ether, low-viscosity ether, polyether-modified silicone oil, amine catalyst, organometallic catalyst, TMR-2 and water, and mixing to obtain the first material;

[0050] 2) Mixing the first material and the blowing agent of the f...

Embodiment 3

[0053] A kind of quick-release polyurethane, comprising quick-release combined polyether and black material, wherein, quick-release combined polyether is made of the following components by weight: 25 parts of sugar ethers, 25 parts of sorbitol ethers, 15 parts Parts of oil ether, 30 parts of amine ether, 5 parts of low viscosity ether, 2.5 parts of polyether modified silicone oil, 12 parts of blowing agent, 1 part of amine catalyst, 1 part of organometallic catalyst, 1.5 parts of TMR-2 and 2.3 parts of water ; The combined polyether and black material are mixed in a ratio of 1:1.25;

[0054] The preparation method is a method for quickly demolding polyurethane, comprising the following steps:

[0055] 1) Weighing sugar ether, sorbitol ether, oil ether, low-viscosity ether, polyether-modified silicone oil, amine catalyst, organometallic catalyst, TMR-2 and water, and mixing to obtain the first material;

[0056] 2) Mixing the first material and the blowing agent of the formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com