Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Improve welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

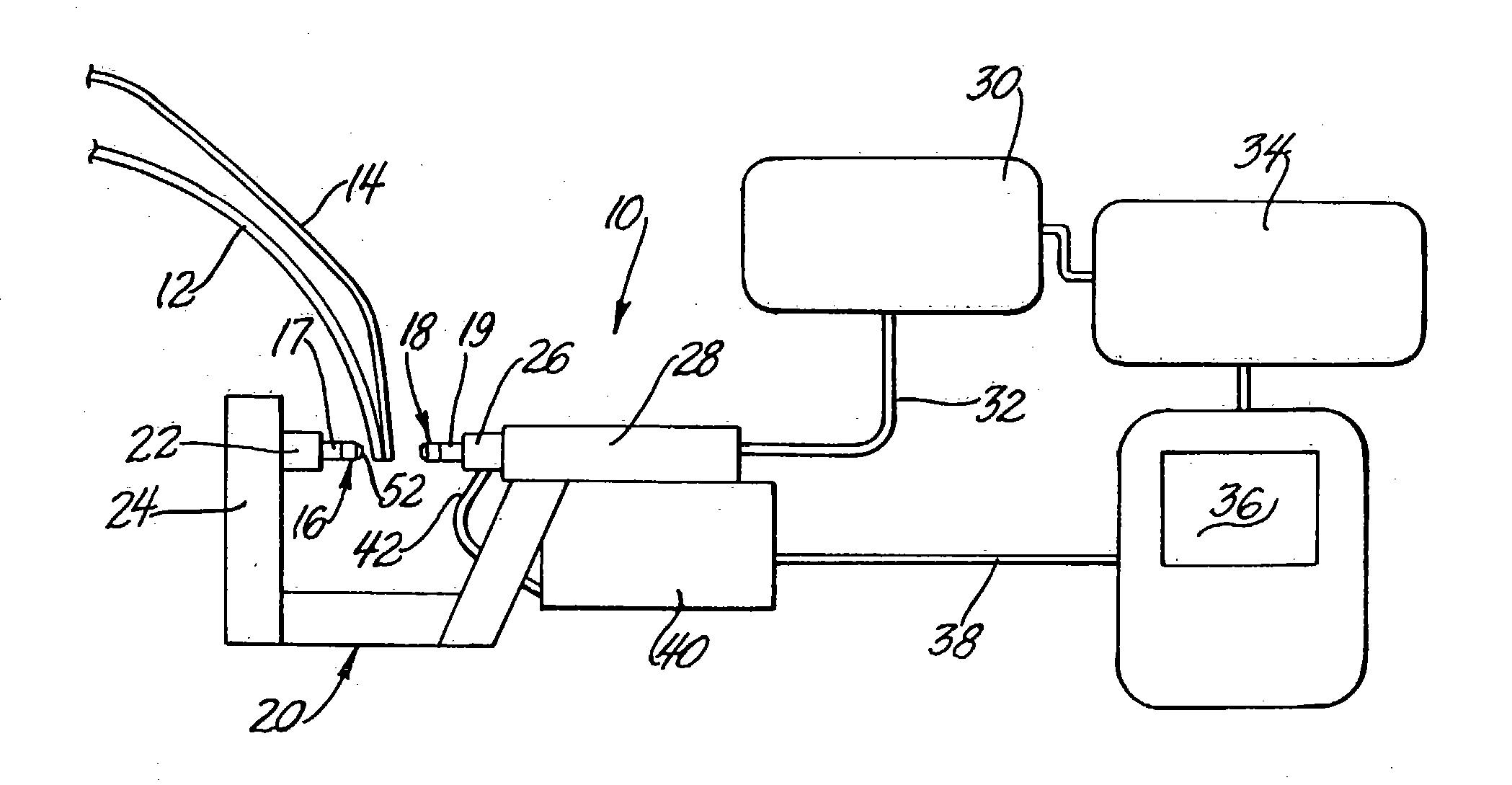

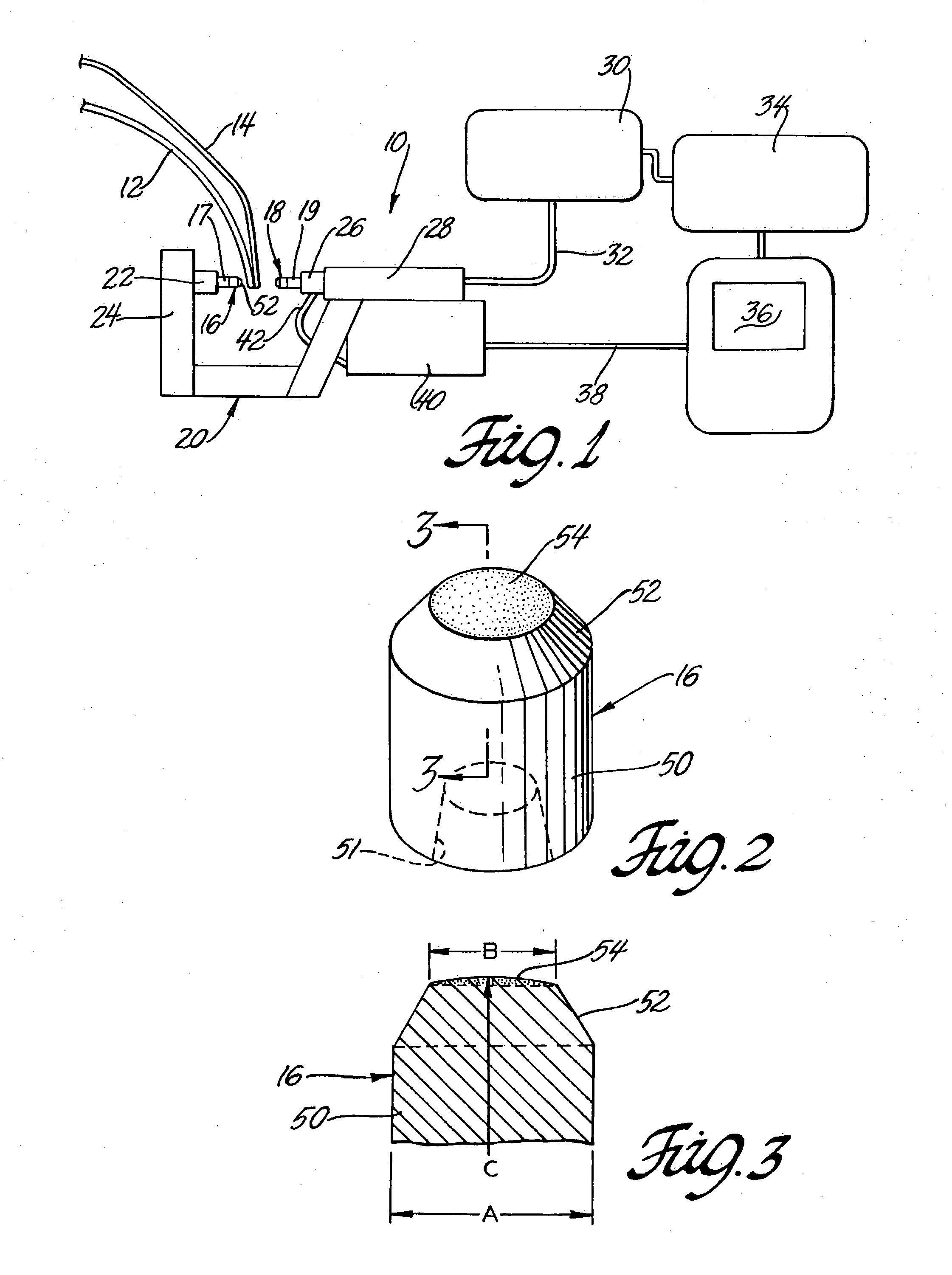

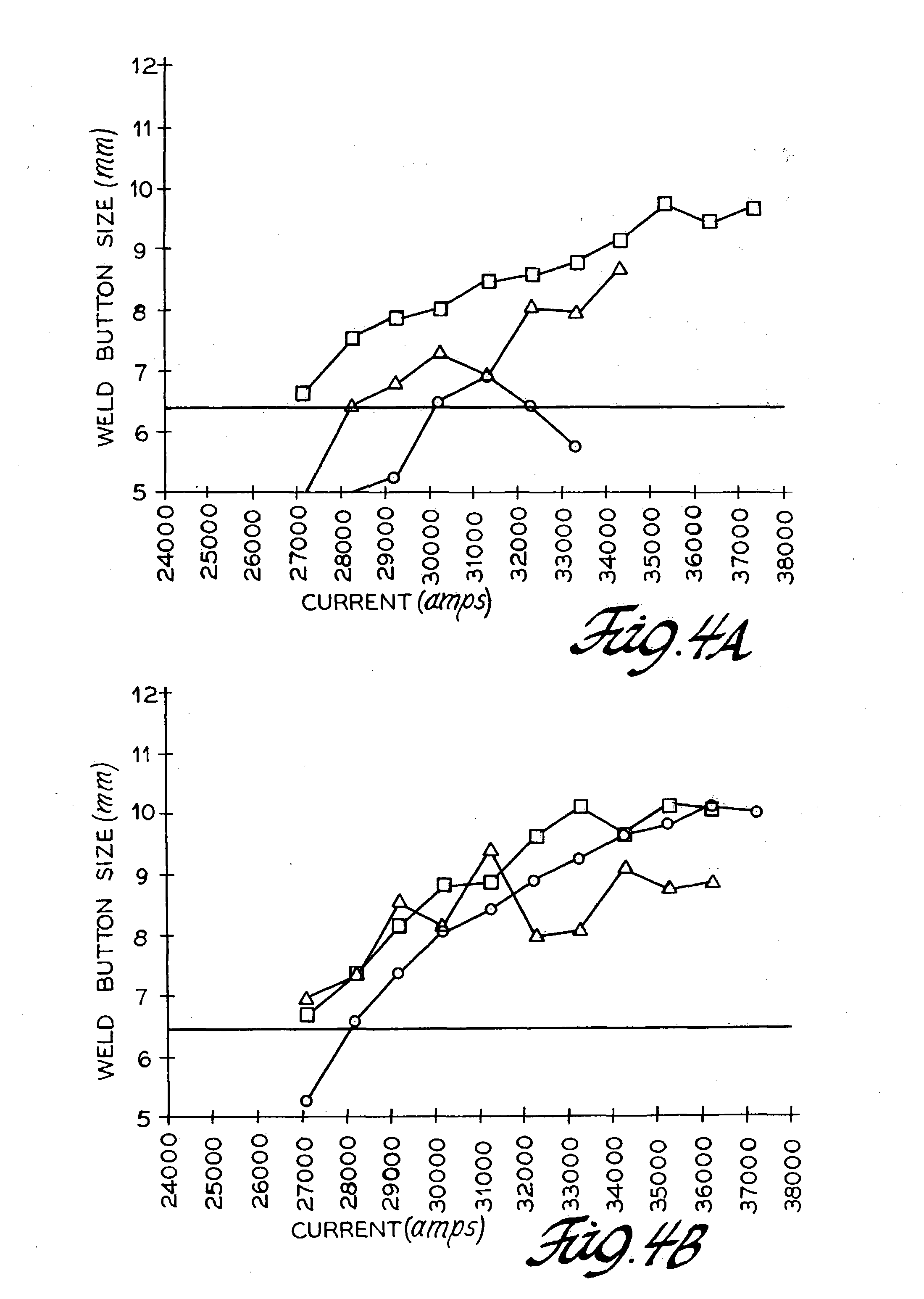

Welding electrode for aluminum sheets

ActiveUS20050000947A1Good welding performanceCurvature of the face is more pronouncedOhmic-resistance electrodesPressure electrodesEngineeringCopper

A design of a copper welding electrode is disclosed. The electrode can be used in successive spot welding operations on assembled aluminum alloy sheet parts of widely varying thicknesses, e.g., from 0.9 to 4+ mm. The electrode has a round body terminating in a truncated cone with a crowned face. The face has a diameter of about eleven millimeters up to the diameter of the body and the radius of the crowned face is about twenty to thirty five millimeters. The dimensions and shape of the electrode provide robust welding performances despite varying part thicknesses and off angle electrode positioning, and the textured surface provides good electrical contact.

Owner:GM GLOBAL TECH OPERATIONS LLC

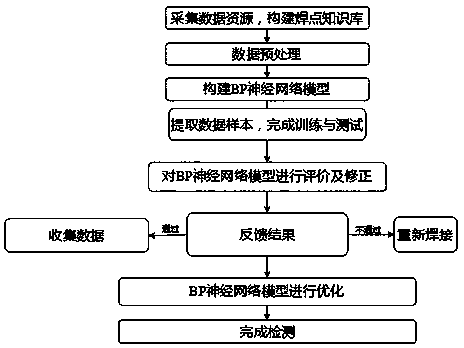

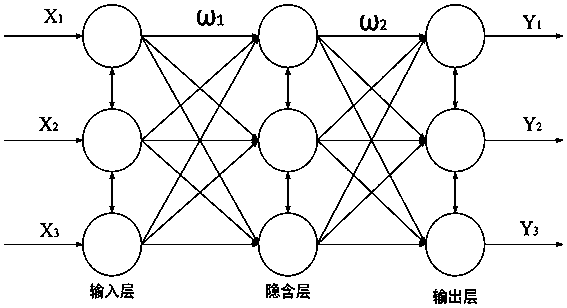

Quality evaluation method for SMT surface assembly component welding spots based on edge side model processing

ActiveCN111047225AEasy to controlImprove efficiencyResourcesNeural architecturesEngineeringNetwork model

The invention discloses a quality evaluation method for SMT surface assembly component welding spots based on edge side model processing, and the method comprises the steps: collecting data resources,and constructing a welding spot knowledge base; preprocessing the data; constructing a BP neural network model; extracting a data sample, and performing coding analysis on the key influence factor data influencing the welding spot quality through a BP neural network model; evaluating and correcting the BP neural network model; collecting key influence factors of the welding spot quality online inreal time, performing real-time judgment through the BP neural network model, and obtaining a feedback result; and according to the feedback result, optimizing the BP neural network model and outputting a final defect category. According to the invention, the neural network model can be trained by means of the edge device, an intelligent service platform for quickly feeding back a result is provided for a user, the process parameters are corrected according to the adjustment value, the operation of a predetermined design scheme of the machine device is guided, and the formation of welding spots is accurately controlled.

Owner:HUIZHOU GUANGHONG TECH CO LTD

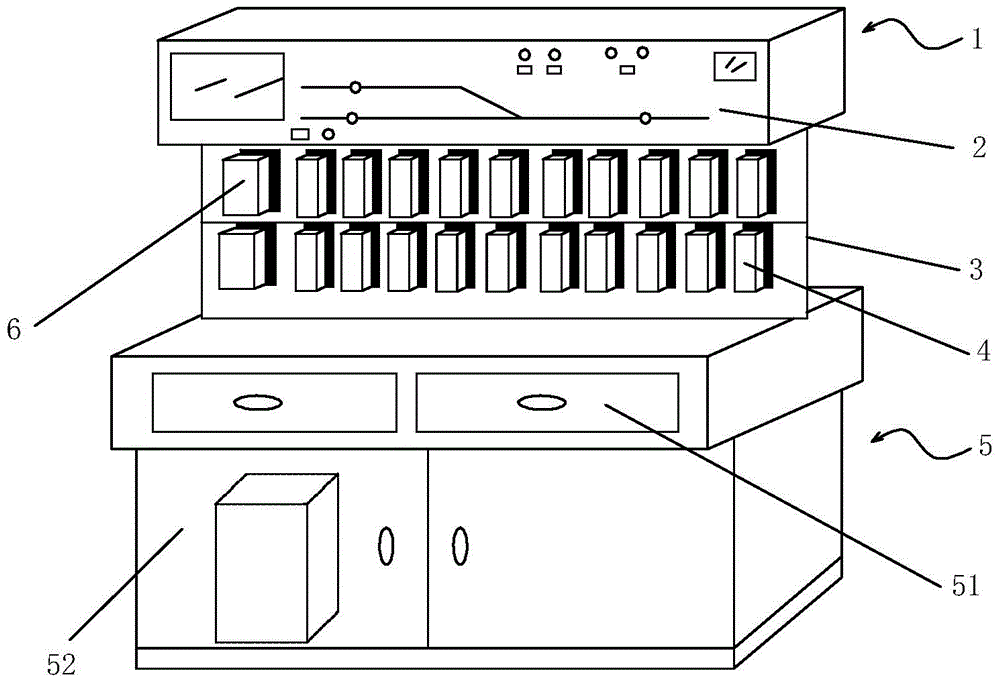

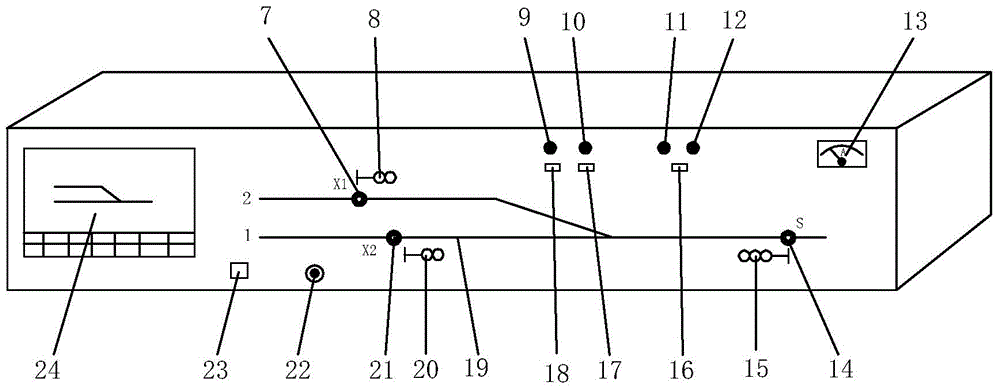

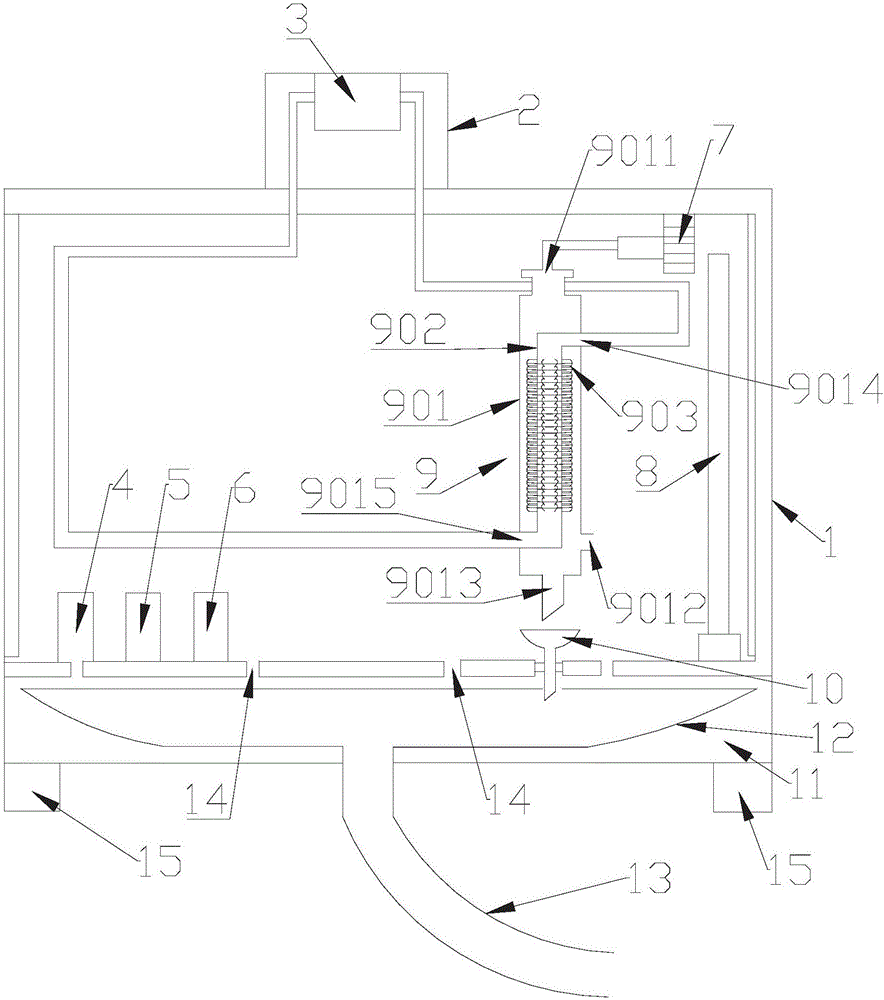

Switch machine control unit integrated training platform

InactiveCN104978881AEasy to controlImprove welding processCosmonautic condition simulationsEducational modelsCurrent meterMachine control

The present invention provides a switch machine control unit integrated training platform, relating to railroad experiment training teaching equipment. The platform comprises a training table, a control cabinet and a main control circuit. The control cabinet is positioned on the training table by a support plate. A safety relay and a circuit breaker are positioned on the support plate. The operation control panel of the control cabinet is provided with a track light band, operation buttons, indication lamps, a signal repeater, a current meter and an LCD screen. The main control circuit comprises a power supply module, a switching unit module, a 6502 electric centralized control circuit, a computer interlock control circuit and a turnout control unit circuit. According to the training platform, the space occupation is small, the manufacturing cost is low, a plurality of experiment training programs can be carried out, the turnout control unit study and the computer interlock control principle study can be effectively carried out, and the field teaching needs of railway electrical work departments and railway colleges are satisfied.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

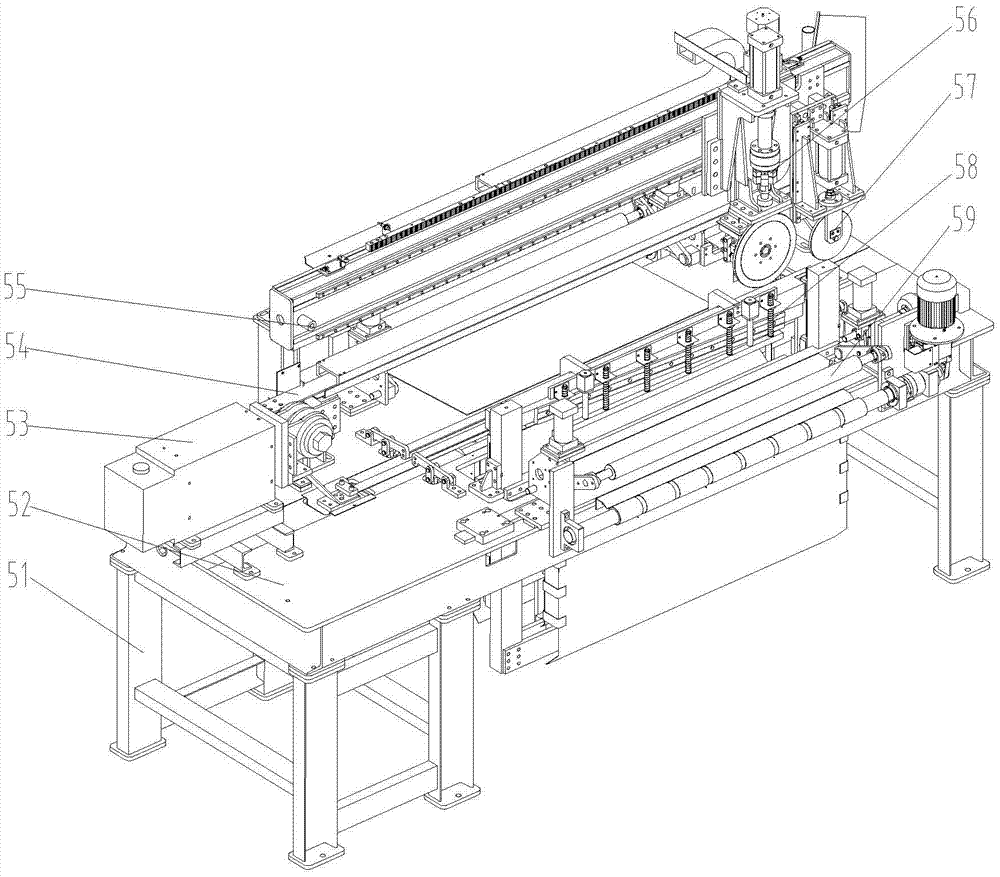

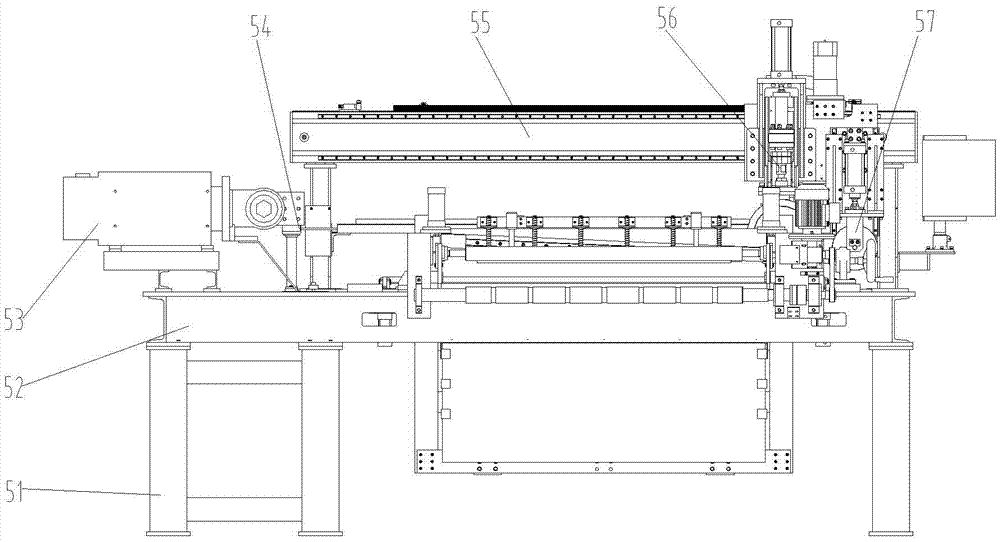

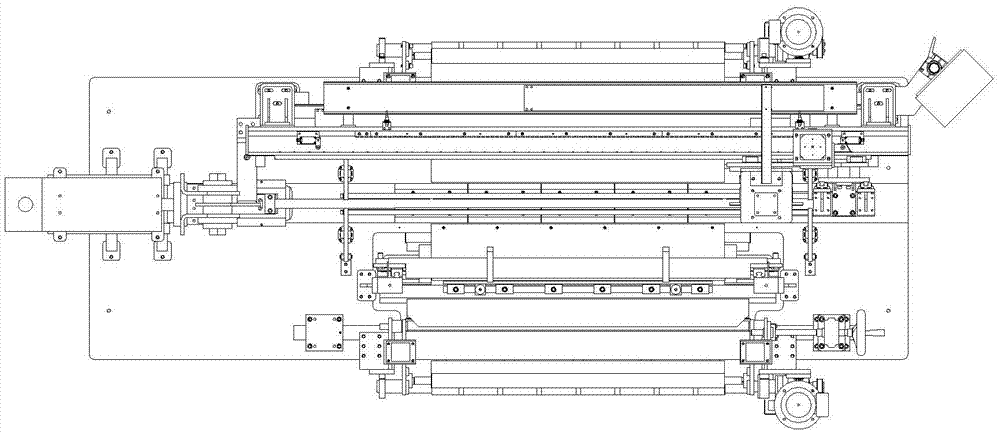

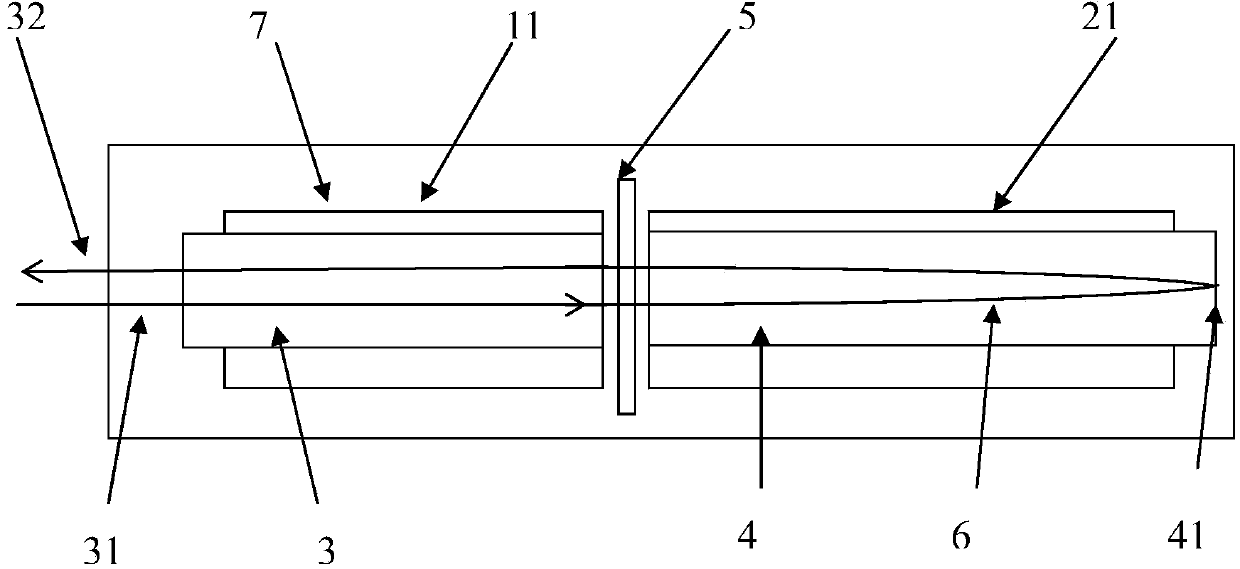

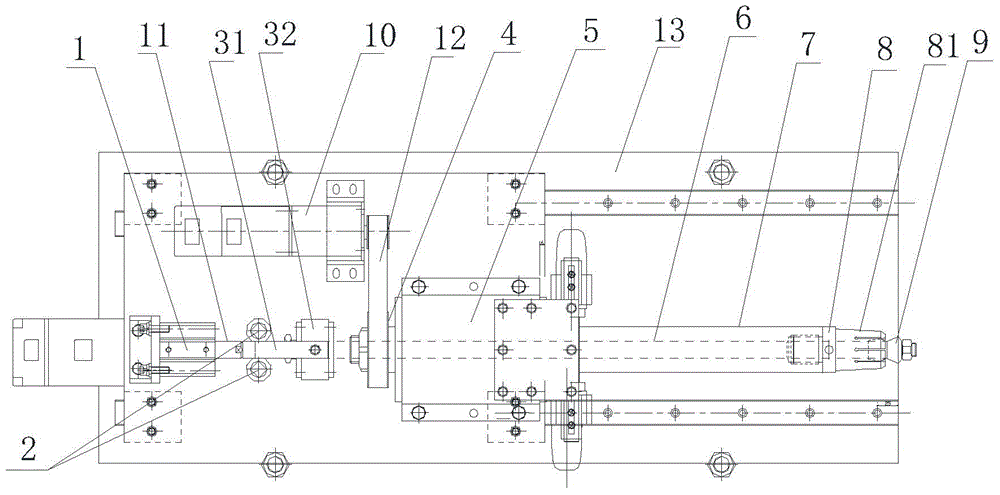

Fully-automatic narrow lap electric-resistance seam-welding machine for thin plates

ActiveCN105436681AReduce processing timeReduce processing efficiencyResistance electrode holdersShearing machinesEngineeringMetal sheet

The invention discloses a fully-automatic narrow lap electric-resistance seam-welding machine for thin plates, belongs to a thin plate seam-welding machine in the welding technical field, and aims to provide the fully-automatic narrow lap electric-resistance seam-welding machine, which is high in shearing efficiency and long in service life, for thin plates. According to the technical scheme, the fully-automatic narrow lap electric-resistance seam-welding machine comprises a rack and a workbench, wherein a clamping and delivering device and a single-blade shear are arranged on the rack or the workbench; a beam assembly is connected on the rack; a resistance welding device and a grinding device are connected on the beam assembly; the single-blade shear comprises a framework, wherein an upper shearing sheet, a lower shearing sheet and a shearing air cylinder are connected on the framework; a synchronous slide block is connected on the shearing air cylinder; link mechanisms are connected on the synchronous slide block; the two groups of link mechanisms are symmetrically arranged at left and right sides of the synchronous slide block, the upper shearing sheet and the lower shearing sheet; and the other ends of the link mechanisms are connected to the upper shearing sheet or the lower shearing sheet. The fully-automatic narrow lap electric-resistance seam-welding machine is suitable for shearing and welding metal thin plates in a finish machining continuous line of the metal thin plates.

Owner:CHENGDU HANYAN TECH

Automobile welding side wall line conveying mechanism

The invention relates to an automobile welding side wall line conveying mechanism comprising conveying beams, jacking cylinders and a synchronizing mechanism. The upper portion of a piston rod of each jacking cylinder is fixedly connected with a bracket, the parallel conveying beams are supported at two ends of each bracket, a conveying slide capable of sliding along the conveying beams is arranged on each conveying beam, a guide roller is arranged on each conveying beam, and the synchronizing mechanism is parallel to the jacking cylinders and used for controlling the jacking cylinders to lift simultaneously. Locking mechanisms used for limiting the conveying slides are arranged at two ends of each conveying beam. The automobile welding side wall line conveying mechanism is simple in structure and lightweight, labor intensity of worker is reduced, manpower and material resources are saved, proceeding of welding processes is facilitated, and processing efficiency of workpieces is improved greatly.

Owner:烟台宇信科技有限公司

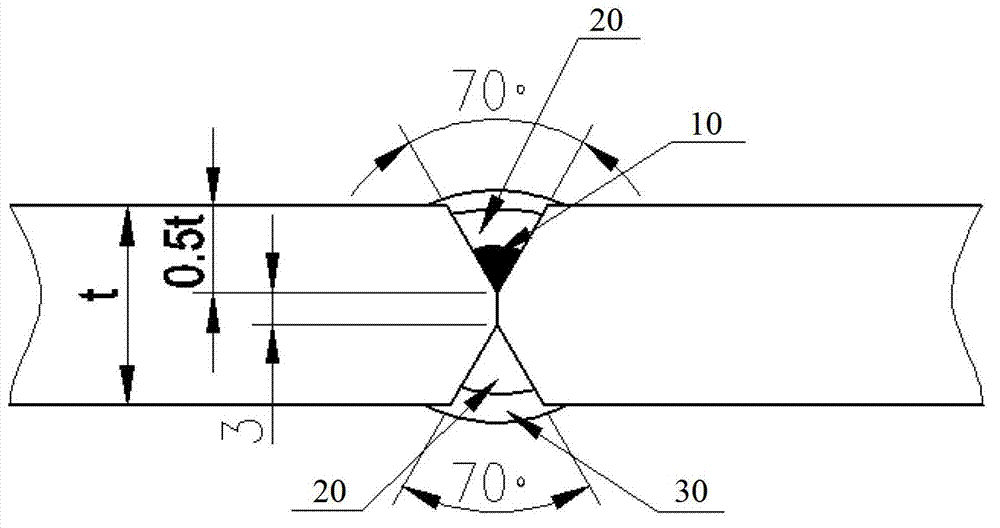

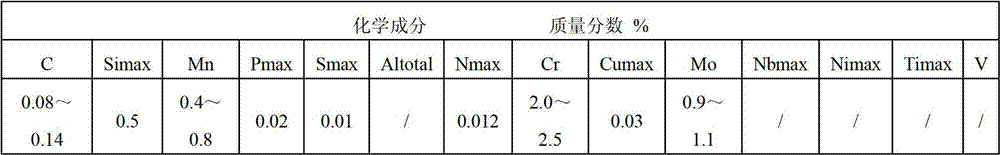

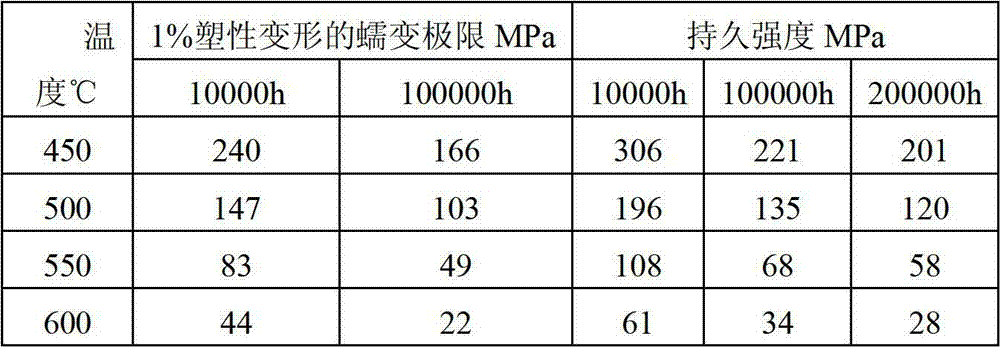

Welding method for 10CrMo9-10 steel

InactiveCN103084718AWith physical propertiesImprove physical performanceArc welding apparatusWorkpiece edge portionsSurface layerHydrogen

The invention discloses a welding method for 10CrMo9-10 steel. The method comprises the following steps of: S1), machining a welding groove to obtain an X-shaped groove, milling a piece to be welded by using an edge milling machine, wherein the groove angle is 70 degrees, cleaning the groove and parts in the ranges of 25mm on two sides of inner and outer walls of the groove until metal luster is exposed; S2), welding a positioning layer of the piece to be welded by a mixed gas protective welding mode; S3), welding a priming coat of the piece to be welded by the mixed gas protective welding mode; S4), welding a filling layer and a cover surface layer of the piece to be welded by a double-wire submerged-arc welding mode; and S5) tempering the welded piece to release stress, wherein the tempering temperature is 680 to 730 DEG C. A welded joint welded by the method has the high-temperature endurance strength, the creep limit, the physical property, the hydrogen resistance, the oxidation resistance, and the brittle fracture resistance which are basically the same as those of a base material; cold crack can be effectively prevented; high production efficiency can be achieved; and the welding process for the steel is greatly improved.

Owner:上海月月潮管道科技有限公司

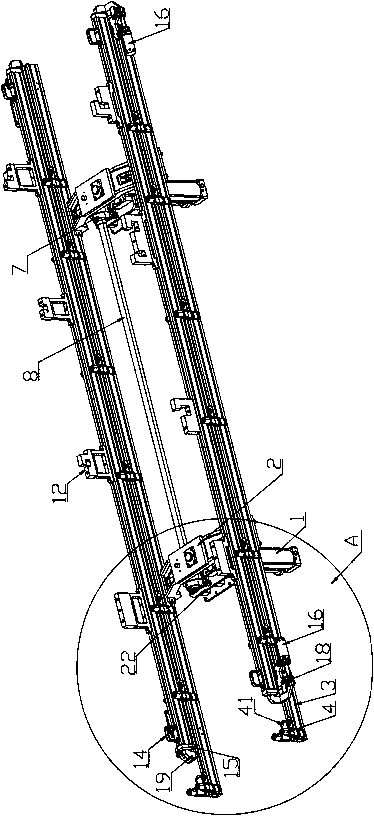

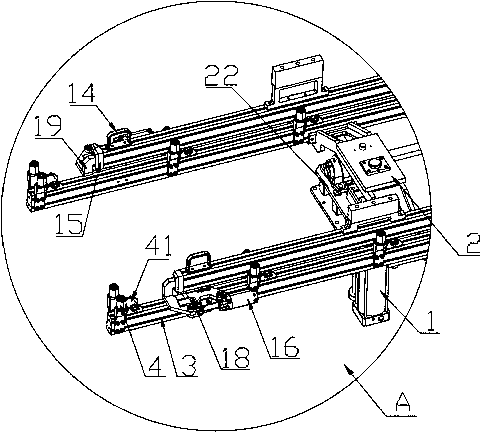

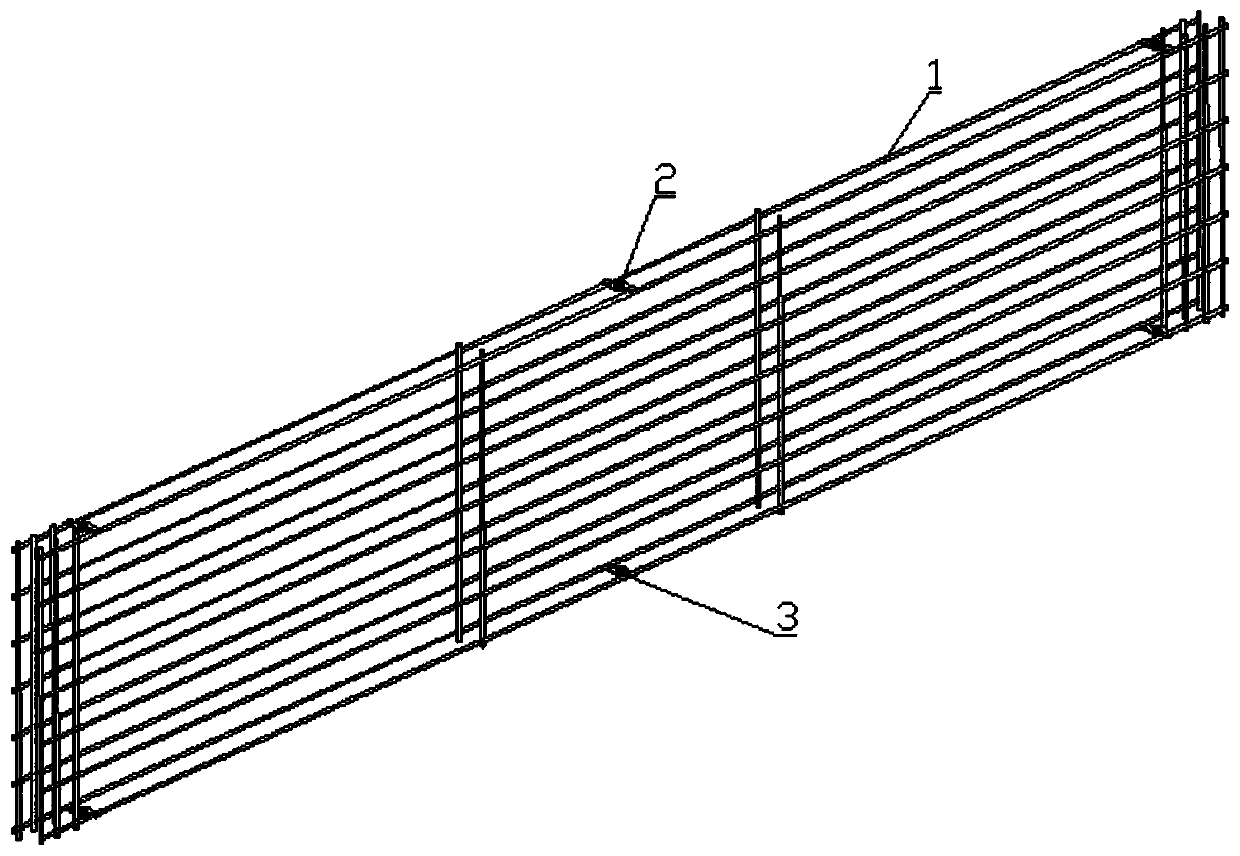

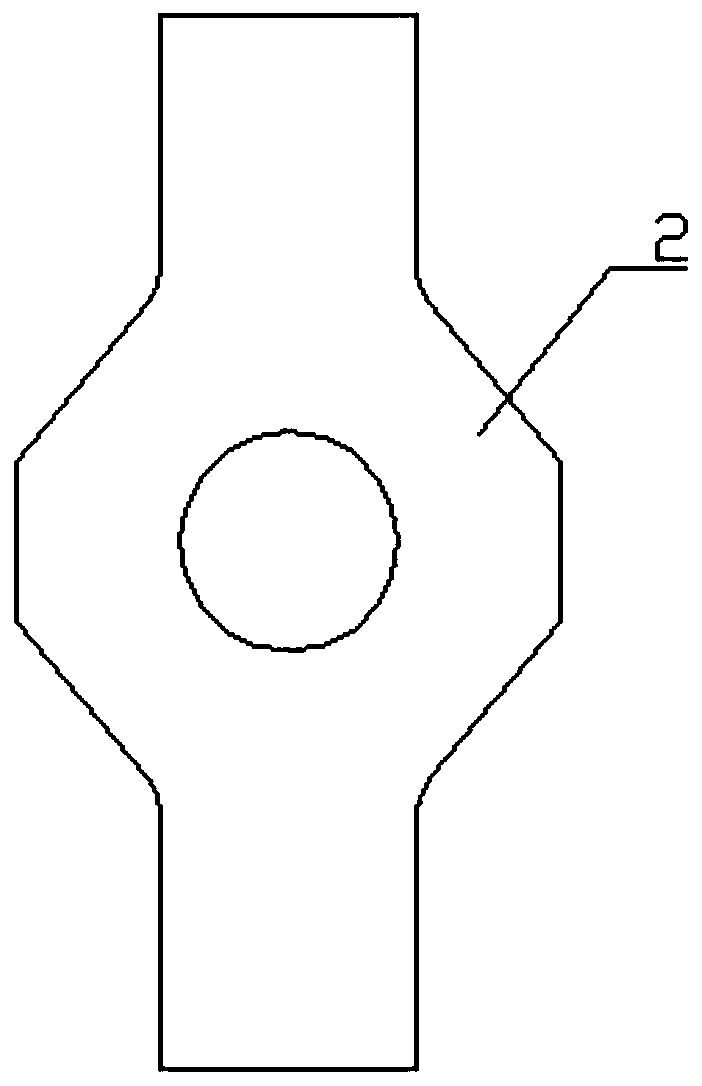

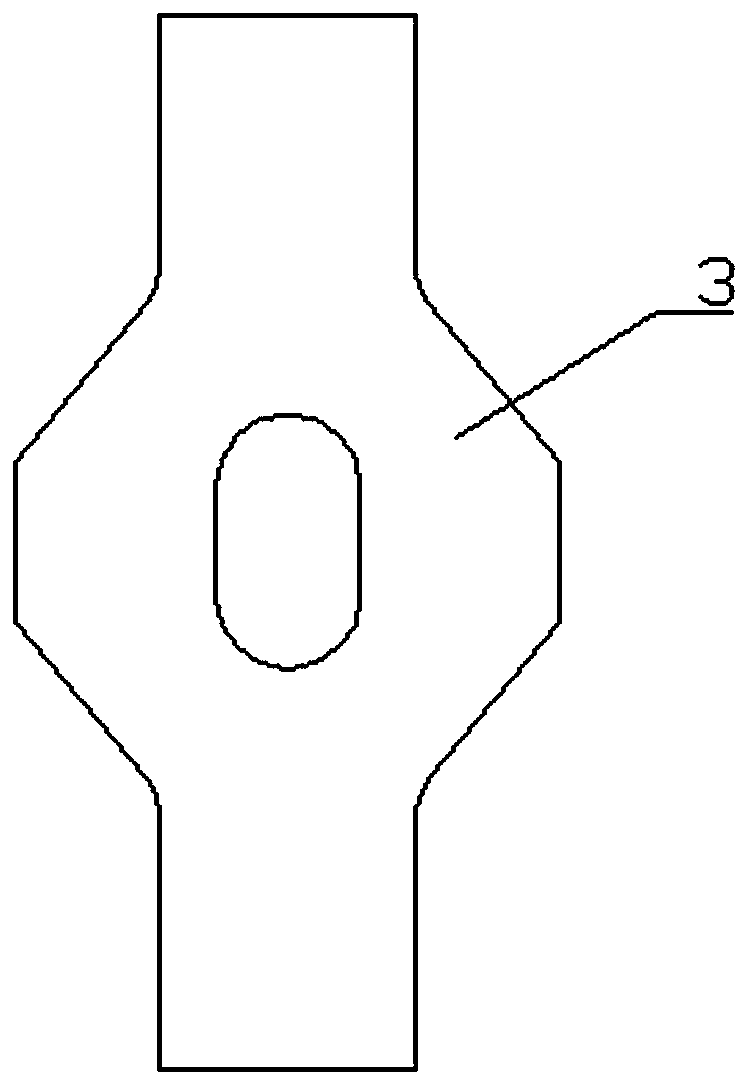

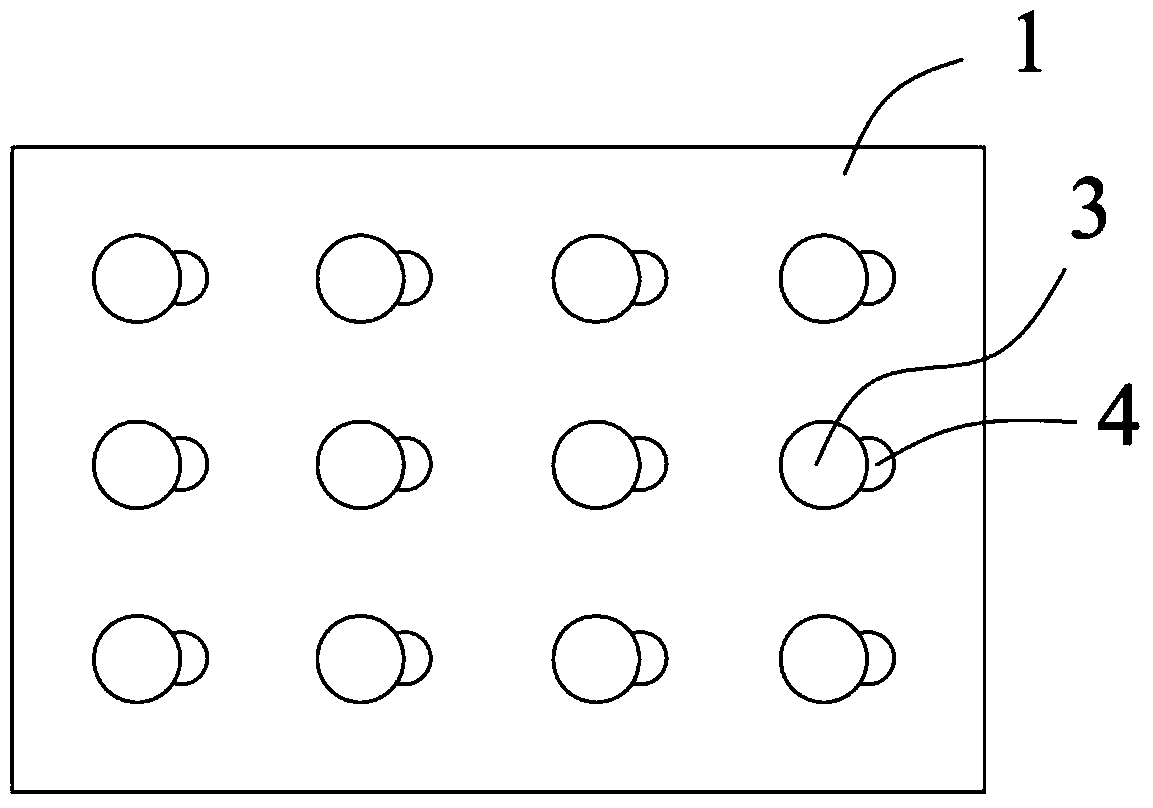

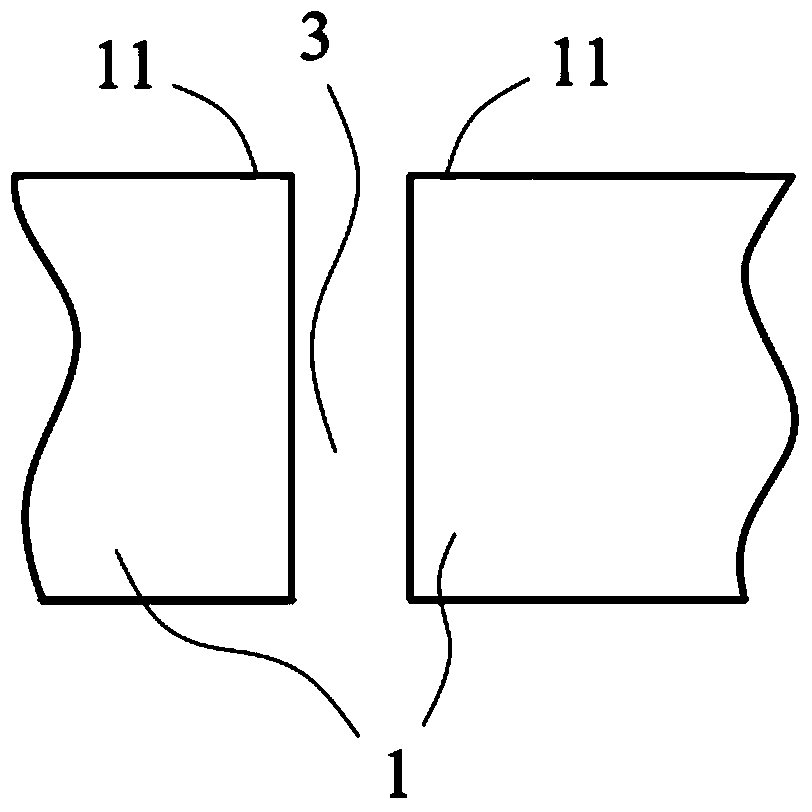

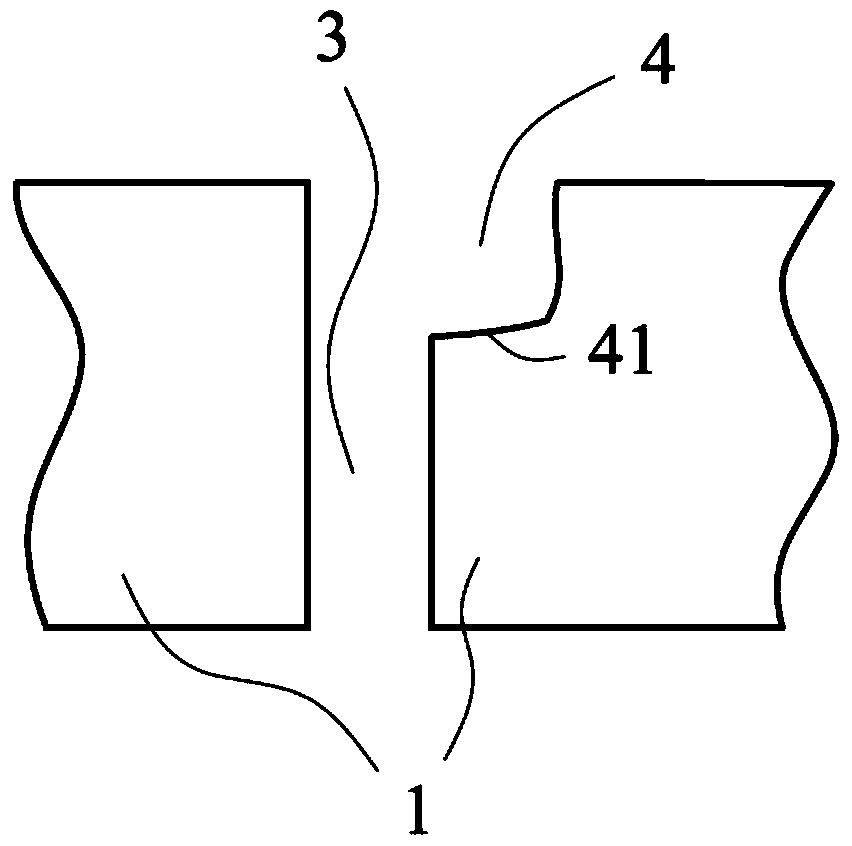

Plate mesh cage and plate mesh cage welding and positioning and transferring devices

ActiveCN110076508AEfficient automatic transportImprove welding processWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismAutomation

The invention discloses a plate mesh cage and plate mesh cage welding and positioning and transferring devices. The plate mesh cage comprises a mesh cage body. The upper portion of the mesh cage bodyis connected with multiple upper connecting pieces in the length direction, and the lower portion of the mesh cage body is connected with multiple lower connecting pieces in the length direction. A plate mesh cage welding and positioning device comprises a base, guide rails, end assemblies connected with the guide rails, and multiple middle assemblies. A plate mesh cage transferring device comprises a rack. A walking assembly is movably connected to the rack, a lifting assembly is connected to the walking assembly, and the lower portion of the lifting assembly is connected with a locking mechanism. The plate mesh cage has a specific connecting structure, and can tightly cooperate with the plate mesh cage transferring device under the assistance of the plate mesh cage welding and positioning device to achieve efficient automatic transferring. Meanwhile, the plate mesh cage welding and positioning device further achieves the effects of normalizing the sizes and the flatness of mesh cagesin the welding process and improving the welding process and the automation degree.

Owner:ANHUI KEDA IND CO LTD

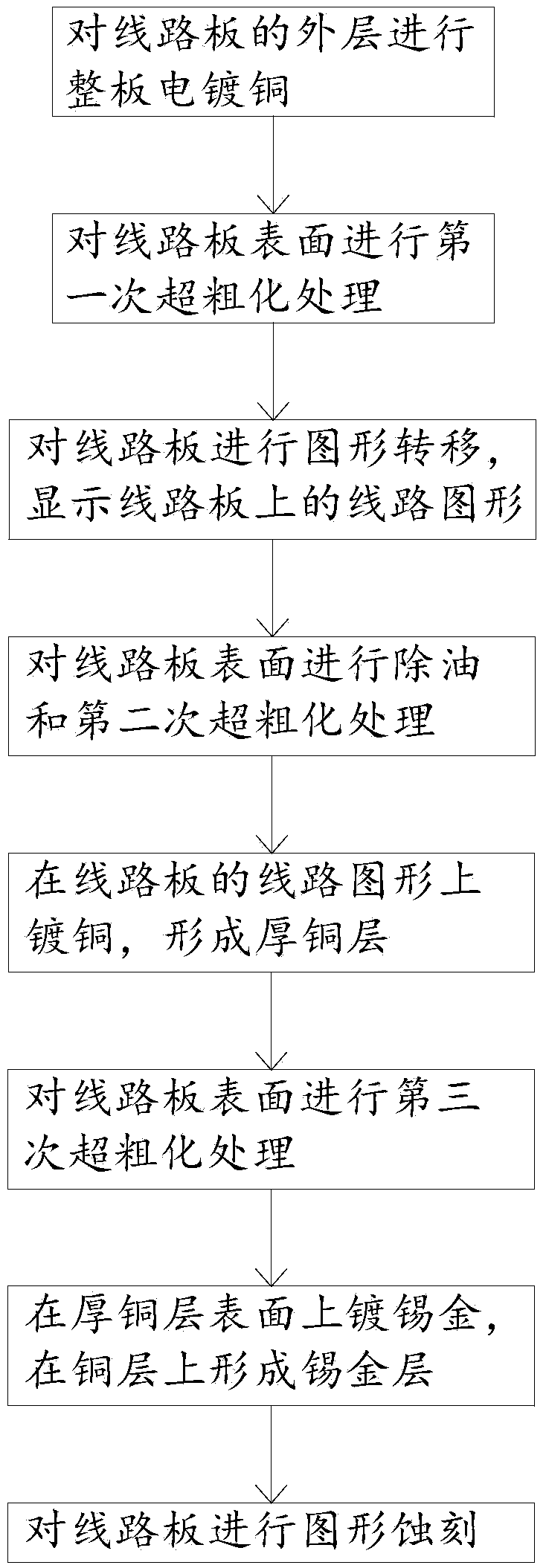

Circuit board surface treatment method

ActiveCN105376958AImprove bindingAvoid Layering DefectsInsulating substrate metal adhesion improvementConductive pattern reinforcementCopper platingEngineering

The invention relates to a circuit board surface treatment method. The circuit board surface treatment method comprises the following steps: performing entire-board copper electroplating on the outer layer of the circuit board; performing the first time of super-roughening treatment on the surface of the circuit board; performing pattern transferring on the circuit board and displaying the circuit pattern on the circuit board; performing oil removing and the second time of super-roughening treatment on the surface of the circuit board; plating copper on the circuit pattern of the circuit board to form a thick copper layer; performing the third time of super-roughening treatment on the surface of the circuit board; and plating nickel-gold alloy on the surface of the thick copper layer to form a nickel-gold alloy layer on the thick copper layer. Before the nickel-gold alloy is plated, the copper surface of the circuit board is roughened by the three times of super-roughening treatment; the roughened copper surface enables the gold surface that is plated with the nickel-gold alloy to be dark so as to satisfy the requirement on a matte gold color; the circuit board, after performing the pattern transferring and before performing the nickel-gold alloy plating, is also subjected to two times of super-roughening treatment in order to prevent the circuit copper surface, that is developed after performing the pattern transferring, from being directly electroplated with the nickel-gold alloy in the non-oxidized condition, so that the shortcoming that the copper layer is separated from the nickel-gold alloy layer is avoided.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

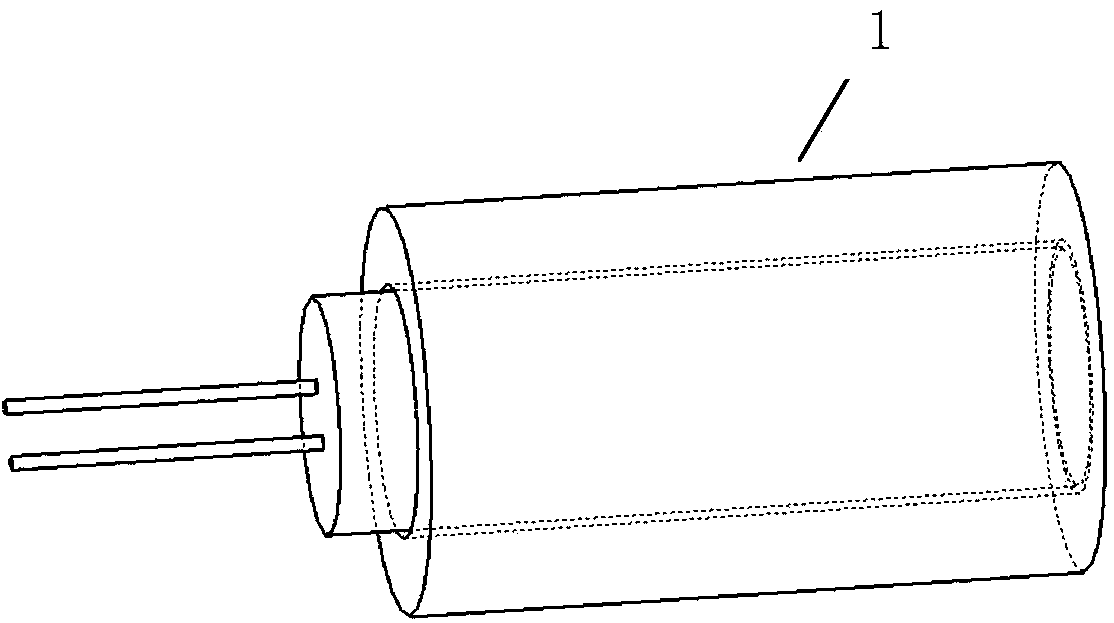

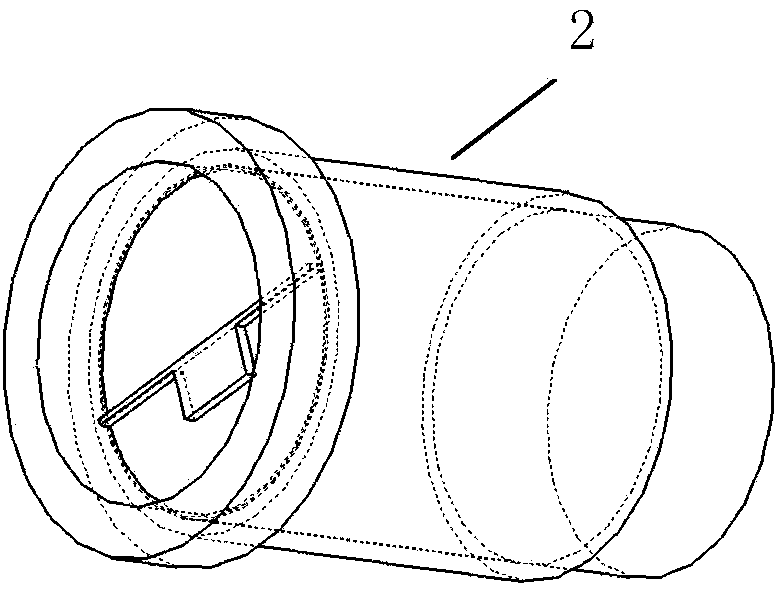

Encapsulation structure and encapsulation method for MEMS (micro-electromechanical system) variable optical attenuator

The invention relates to an encapsulation structure for an MEMS (micro-electromechanical system) variable optical attenuator. The encapsulation structure comprises a focusing lens, a tail fiber sleeve and an optical chip, wherein the optical chip is manufactured by adopting the MEMS, the tail fiber sleeve is fixedly arranged in a hollow cylindrical magnet through bonding glue for forming a magnetic assembly 1, one end of the focusing lens is a light signal incident surface, the other end of the focusing lens is provided with a light reflecting surface, the focusing lens is fixedly arranged in the other hollow cylindrical magnet through bonding agents, the optical chip is fixedly arranged on the end part, used for being sucked with the magnetic assembly 1, on the hollow cylindrical magnet through bonding agents, and a magnetic assembly 2 is formed; the magnetic assembly 1 and the magnetic assembly 2 which are in a mutual magnetic suction state and are reinforced through the bonding agents form a variable optical attenuator assembly, the optical attenuator assembly is arranged in a hollow external protecting sleeve, in addition, two ends of the external protecting sleeve are filled and encapsulated by bonding agents, and the variable optical attenuator is formed. The invention aims at providing the encapsulation structure and an encapsulation method for the MEMS with the advantages of miniaturization, low cost and high reliability.

Owner:苏州盛维新电子科技有限公司

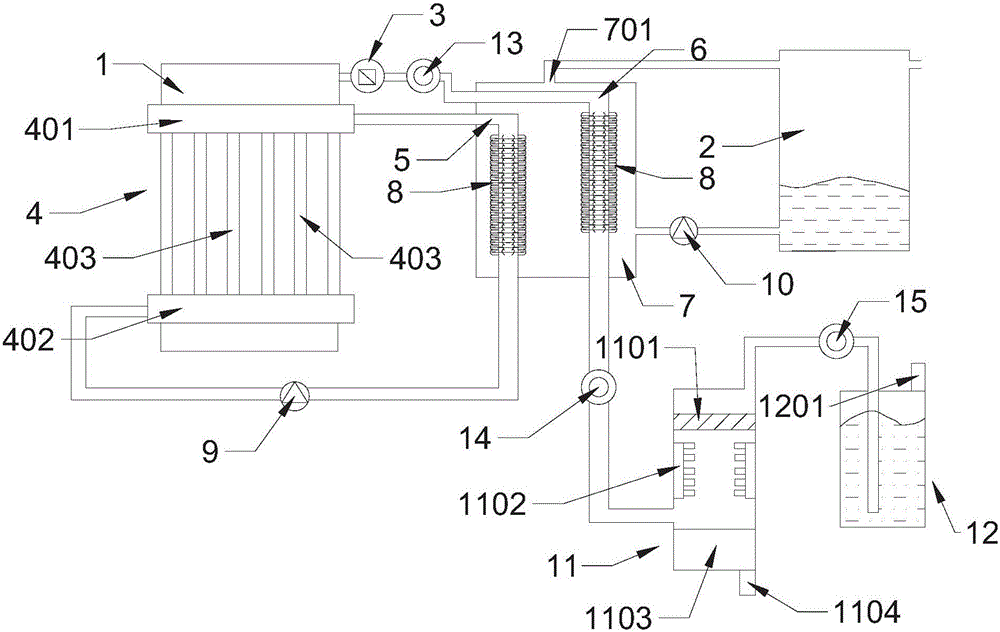

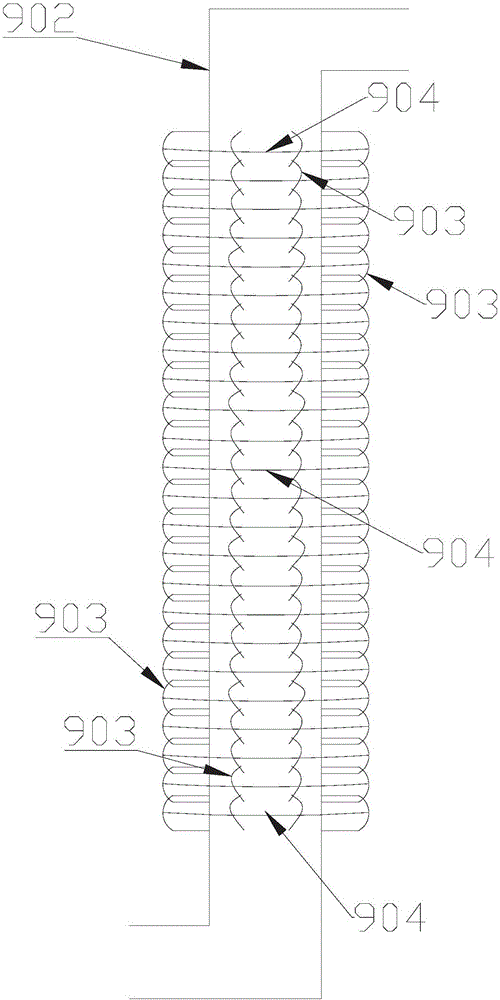

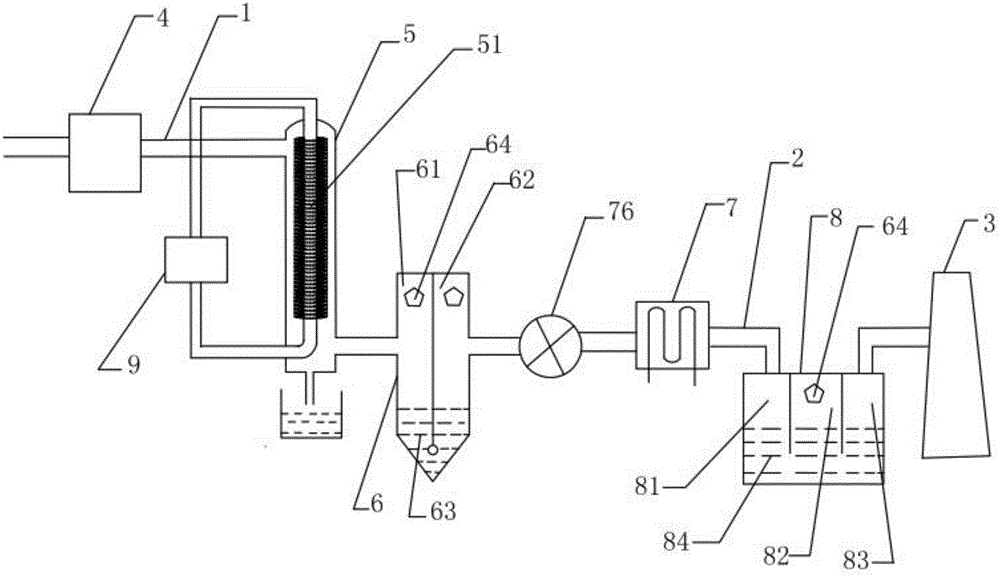

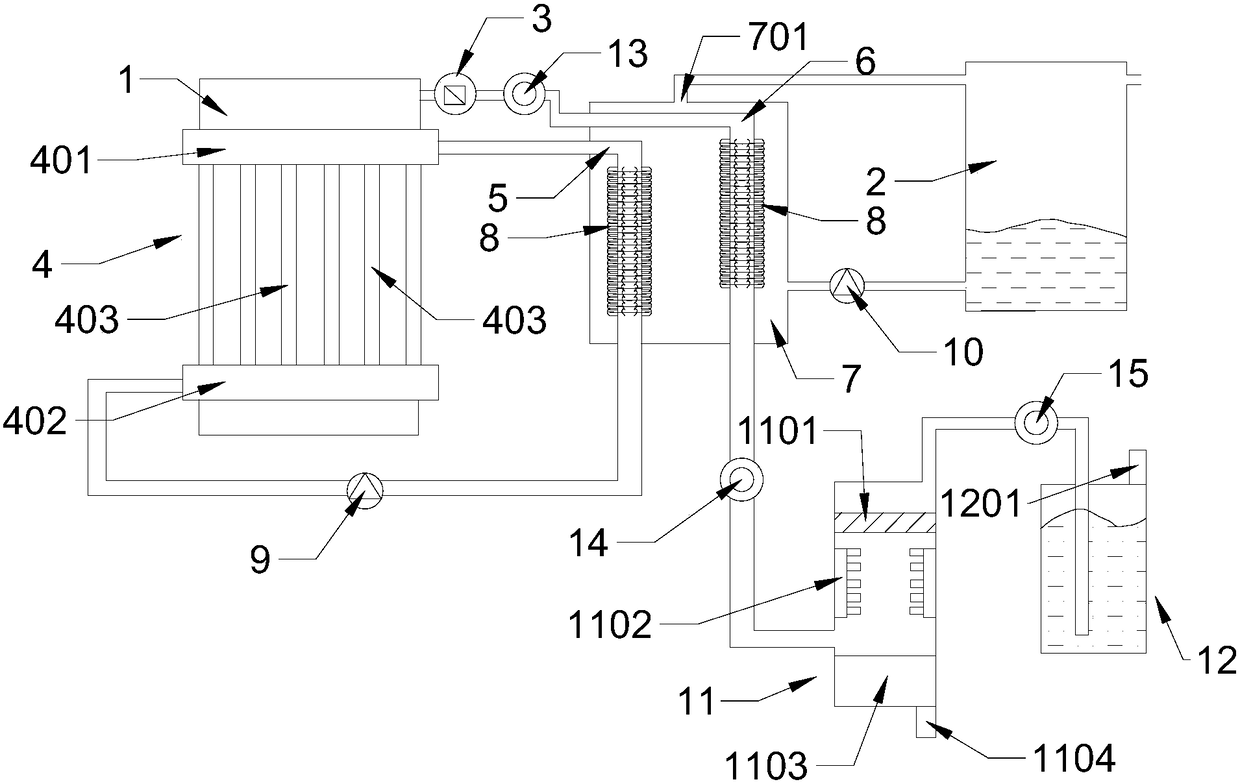

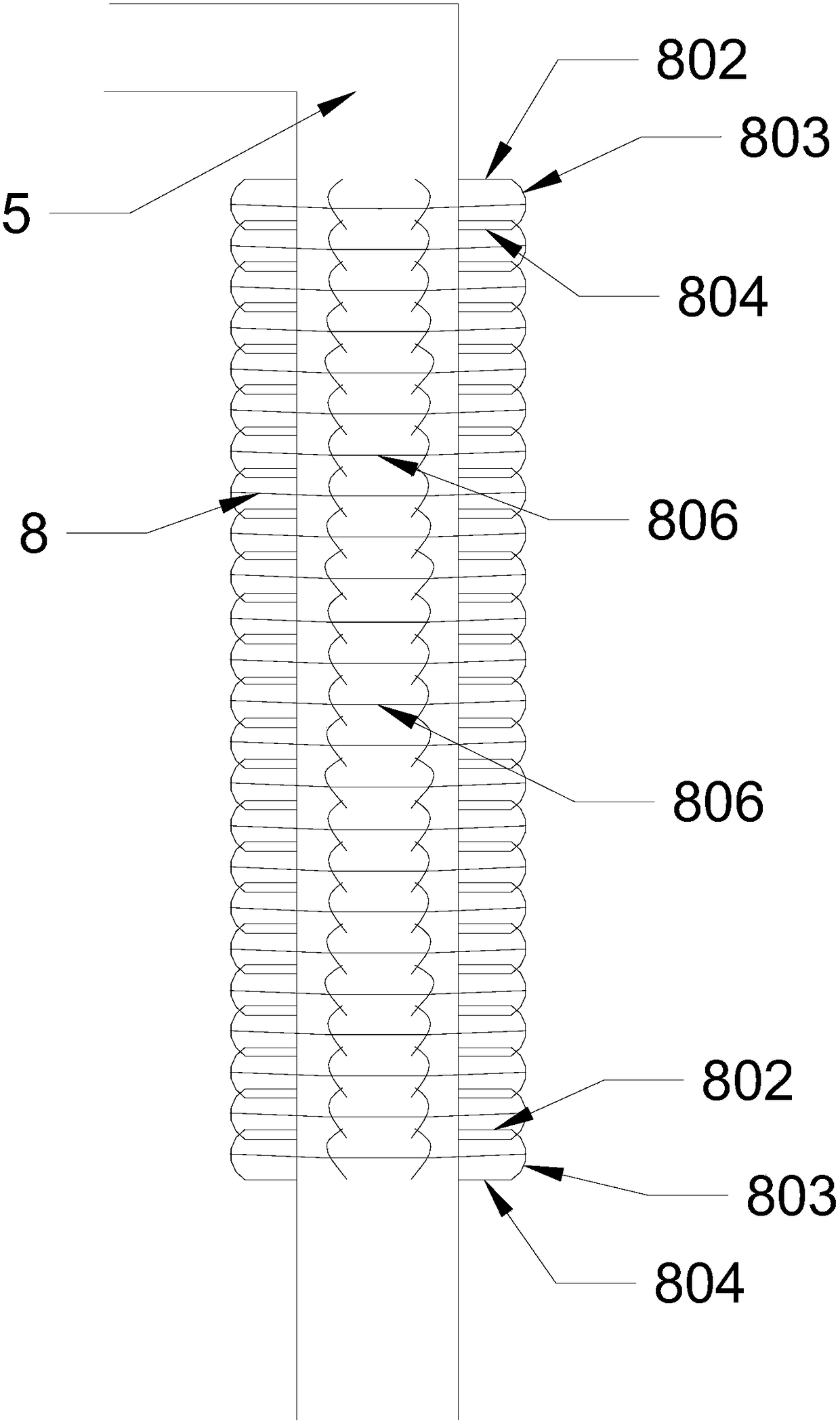

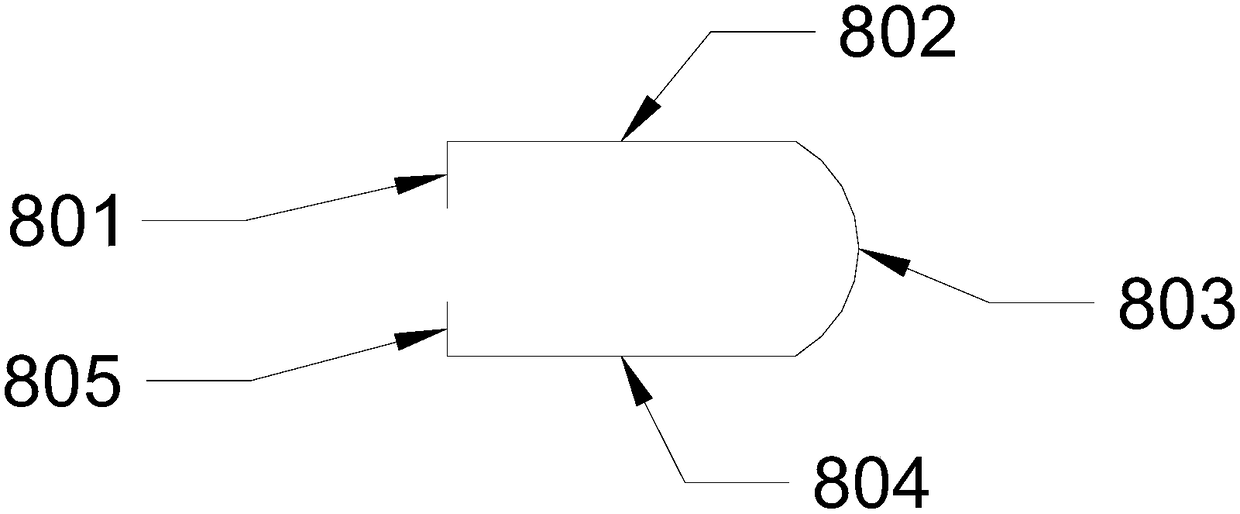

Boiler afterheat recovery system with vertical low-resistance cooling system

ActiveCN106224932AAvoid cloggingIncrease contact heat transfer areaEnergy industryIncreasing energy efficiencyHigh densityEngineering

The invention discloses a boiler afterheat recovery system with a vertical low-resistance cooling system. The boiler afterheat recovery system comprises a boiler, afterheat recovery equipment, a smoke treatment device and a steam tank; the afterheat recovery equipment includes a heat exchange module, a first heat exchange pipe, a second heat exchange pipe and a heat exchange water tank; a first circulating pump is arranged between the heat exchange module and the first heat exchange pipe; the heat exchange module, the first heat exchange pipe and the first circulating pump form a refrigerant circulating loop; a first induced draft fan is arranged between a cyclone dust remover and the second heat exchange pipe; an intake pipe of the cyclone dust remover is communicated with a smoke outlet of the boiler; an exhaust pipe of the cyclone dust remover is communicated with an intake port of the second heat exchange pipe through the first induced draft fan; an exhaust port of the second heat exchange pipe is connected with the smoke treatment device by a second induced draft fan; multiple layers and multiple rows of high-density linear bent heat exchange pieces are arranged on the surface of the middle part of the second heat exchange pipe; the smoke treatment device comprises a filter chamber; a spraying device is arranged on the middle inner wall; and a settling pool is arranged at the lower end. The boiler afterheat recovery system is better in heat exchange effect, higher in afterheat recovery rate and more environment-friendly.

Owner:SUZHOU BSE AIR CONDITIONER

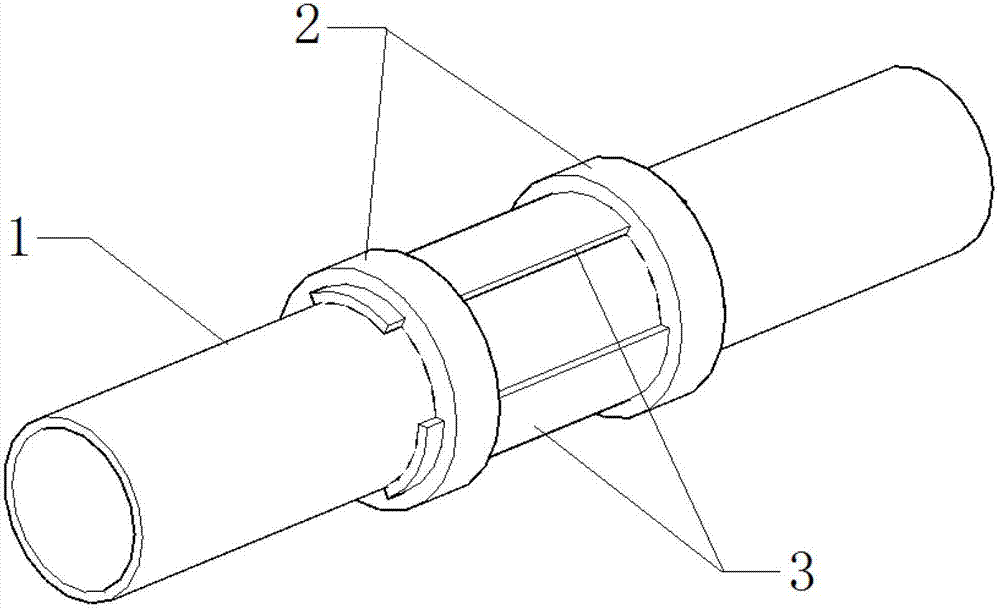

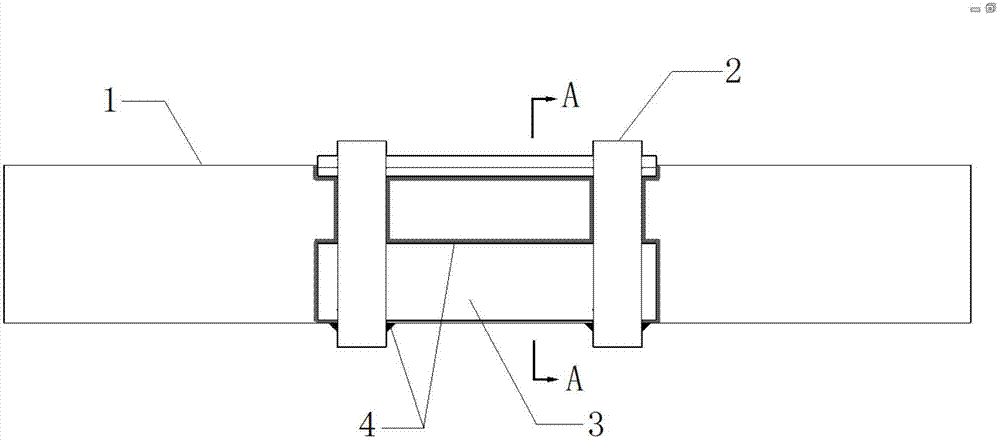

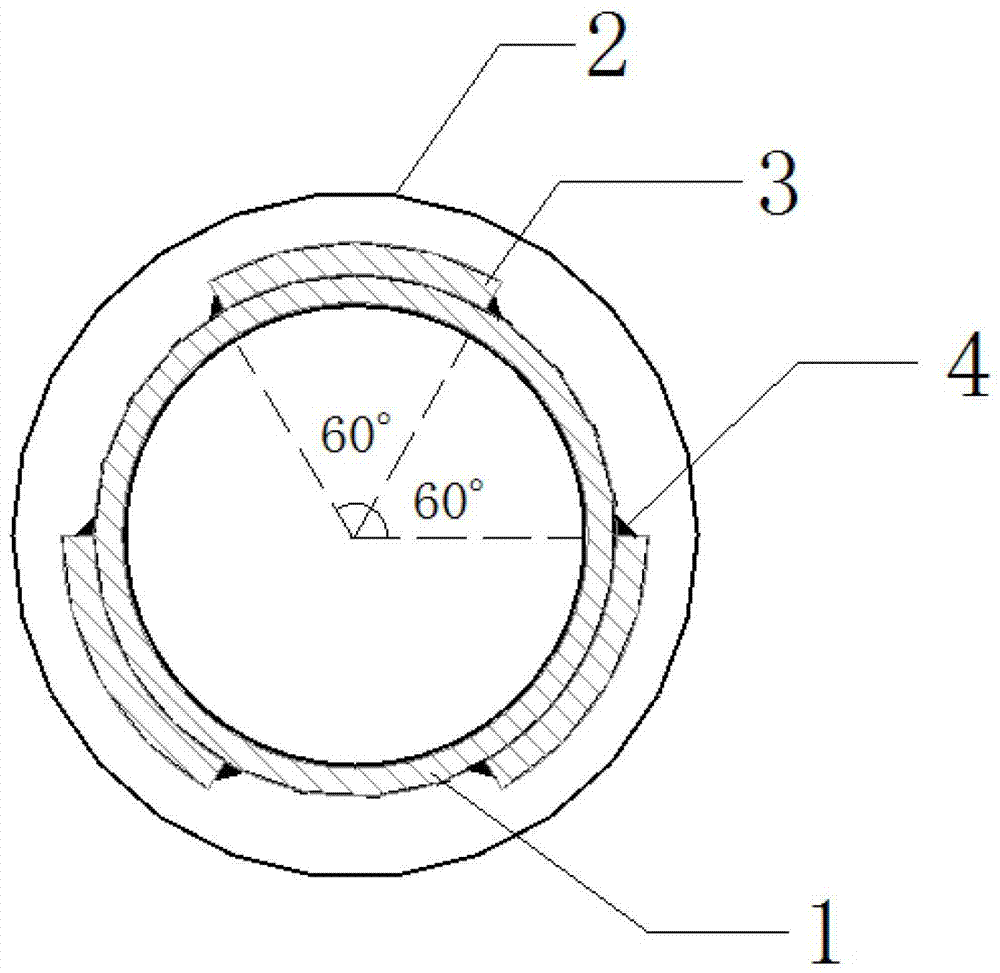

Combined strengthening type bulking-preventing device capable of preventing submarine pipeline from bulking-propagation

InactiveCN103162013AImprove the anti-bending effectPlay a blocking rolePipe laying and repairSheet steelEngineering

The invention belongs to the technical field of submarine pipeline paving and relates to a combined strengthening type bulking-preventing device capable of preventing a submarine pipeline from bulking-propagation. The combined strengthening type bulking-preventing device capable of preventing the submarine pipeline from bulking-propagation is fixed on the exterior of the submarine pipeline which is needed to be protected. The combined strengthening type bulking-preventing device capable of preventing the submarine pipeline from bulking-propagation comprises at least two arc-shaped long-striped steel plates and at least two steel rings. A cross section of every arc-shaped long-striped steel plate is a section of a circular arc. The inner radius of the circular arc is equal to the outer radius of the submarine pipeline. A plurality of arc-shaped grooves are arranged inside of the steel rings. The inner diameters of the steel rings are equal to the outer diameter of the submarine pipeline. The number of the arc-shaped grooves is not less than the number of the arc-shaped long-striped steel plates. The width of the grooves is equal to the width of the arc-shaped long-striped. Each arc-shaped long-striped steel plate is uniformly distributed on the exterior of the submarine pipeline along the axial direction of the pipeline. Each arc-shaped long-striped steel plate is fit with the submarine pipeline and is embedded in an arc-shaped groove of each steel ring. The combined strengthening type bulking-preventing device capable of preventing a submarine pipeline from bulking-propagation is light in weight, easy to install and capable of having high efficiency at the same time.

Owner:TIANJIN UNIV

Tin wire cutting machine controllable in tin amount

ActiveCN103100612ACut off accuratelyPrecise tin volume controlSoldering auxillary devicesReciprocating motionWire cutting

The invention relates to a tin wire cutting machine controllable in tin amount. The tin wire cutting machine comprises a motor. A motor shaft of the motor is provided with a wire cutting device capable of being in reciprocating motion in the radial direction relative to the motor. A wire cutting position of the cutting device is provided with a tin wire feeding tube pile for consecutive feeding of wires. A blanking position of the wire cutting device is provided with a tin outlet tube connector. The tin wire cutting machine is precise and quantitative in tin wire, completely uniform in tin amount, reasonable in structure, and capable of discharging cut tin wires quickly, removing tin blocking phenomena, and improving automation working efficiency.

Owner:QUICK INTELLIGENT EQUIP CO LTD

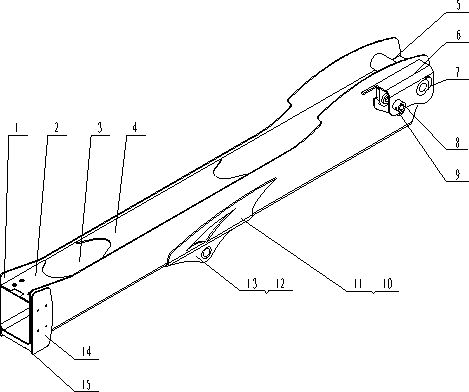

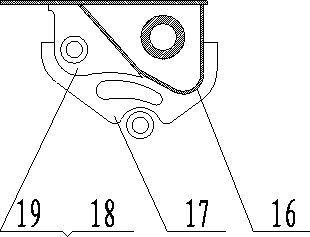

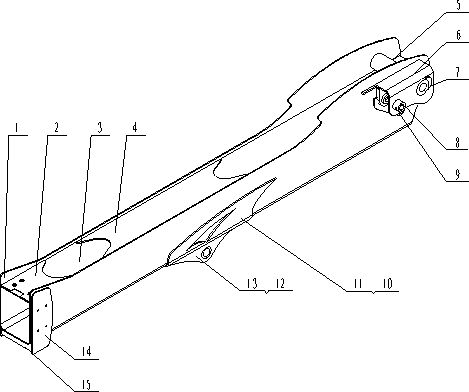

Main jib structure for fork installing machine

ActiveCN102249170AProtect against distortionReduce widthLifting devicesStress distributionEngineering

The invention discloses a main jib structure for a fork installing machine and belongs to main jib structures of engineering machinery. The upper cover plate of a main jib is welded at the inner side of a U-shaped main jib plate to form a high-strength box structure; second shaft sleeves are respectively welded on the two sides of the rear surface of the wallboard of the U-shaped main jib plate; a bend cover plate is welded on one side of the rear surface of the wallboard of the U-shaped main jib plate; a crescent plate is welded on the rear surface of a main shaft sleeve at the upper face ofthe wallboard of the U-shaped main jib plate; a rear web plate, a rear inner web plate and a forth shaft sleeve are respectively welded on one side of the rear surface of the wallboard of the U-shaped main jib plate; cylinder support plates are symmetrically welded on a left web plate and a right web plate; third shaft sleeves are welded on the left web plate and the right web plate; and a front lower rib plate is welded in the middle of a front plate at the lower part of the front end of the U-shaped main jib plate. The main jib structure of the fork installing machine has the advantages that the U-shaped main jib plate and the upper cover plate are combined to greatly reduce welding lines; each web plate is in a curved shape combined with jib rest stress distribution, thus effectively ensuring the stress of the main jib structure to be more uniform and improving the integral strength; and the bearing capability is strong, the structure is concise and the weight is light.

Owner:XUZHOU XUGONG SPECIAL CONSTR MASCH CO LTD

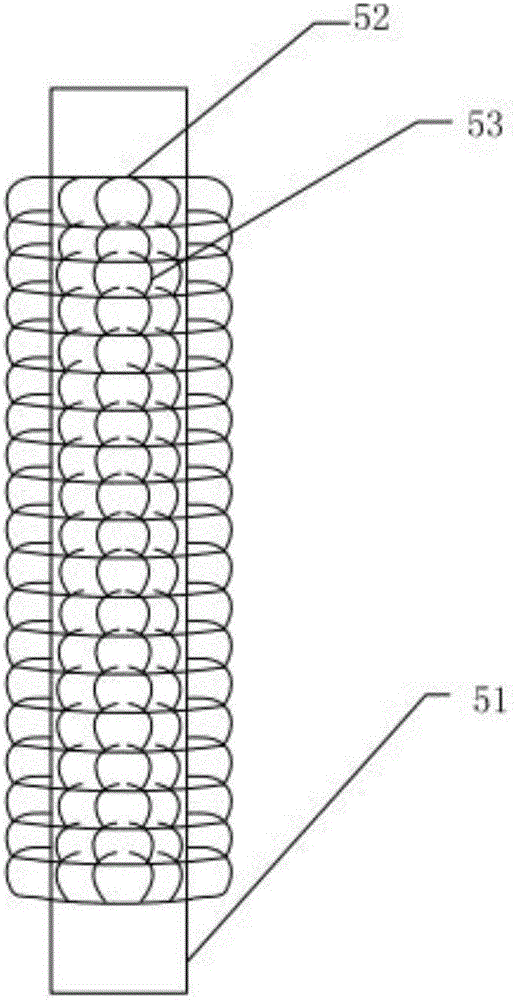

Power distribution box dehumidification device with vertical low resistance cooling system

InactiveCN106025818AKeep dryIncrease contact heat transfer areaSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsWater vaporMaster controller

The invention discloses a dehumidification device for a distribution box with a vertical low-resistance cooling system, which comprises a main box body and a first storage compartment, and a refrigeration device is arranged in the first storage compartment; a humidity sensor and a temperature sensor are arranged inside the main box body , main controller, exhaust fan, heater and heat exchanger, humidity sensor, temperature sensor, exhaust fan, heater and refrigeration device are all connected with the main controller, heat exchanger includes outer tube and heat exchange tube, heat exchange tube Placed in the outer tube, the two ends of the heat exchange tube are connected with the refrigerant inlet and the refrigerant outlet. A water storage container and a drain pipe are provided, and the top of the water storage container communicates with the drainage funnel. In the present invention, the middle surface of the heat exchange tube is provided with multi-layer and multi-row linear bending heat exchange parts, so that the effect of heat exchange, refrigeration and dehumidification is better, and the water vapor in the humid air is discharged through the drainage funnel after being condensed at the heat exchange tube. Thereby keep the dryness of the air in the main cabinet.

Owner:SUZHOU BSE AIR CONDITIONER

Distribution box dehumidification device with vertical low-resistance cooling system

InactiveCN106058687AKeep dryIncrease contact heat transfer areaSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPlate heat exchangerWater vapor

The invention discloses a distribution box dehumidification device with a vertical low-resistance cooling system. The device comprises a main box body and a first placement warehouse, the first placement warehouse is configured above the top panel of the main box body, and a refrigeration device is arranged inside the first placement warehouse. The main box body is internally equipped with a humidity sensor, a temperature sensor, a main controller, an exhaust fan, a heater and a heat exchanger. The humidity sensor, the temperature sensor, the exhaust fan, the heater and the refrigeration device are connected with the main controller. The heat exchanger includes an outer tube and a heat exchange tube, the heat exchange tube is arranged inside the outer tube, the two ends of the heat exchange tube are respectively connected with a refrigerant inlet and a refrigerant outlet, and the middle surface of the heat exchange tube is provided with a multi-layer and multi-column linear bent heat exchange member. According to the invention, as the middle surface of the heat exchange tube is provided with the multi-layer and multi-column linear bent heat exchange member, the heat exchange, refrigeration and dehumidification effects are better, water vapor in moist air is cooled and condensed at the heat exchange tube and then drained by a drainage funnel, and thus, the air in the main box body is kept dry.

Owner:SUZHOU BSE AIR CONDITIONER

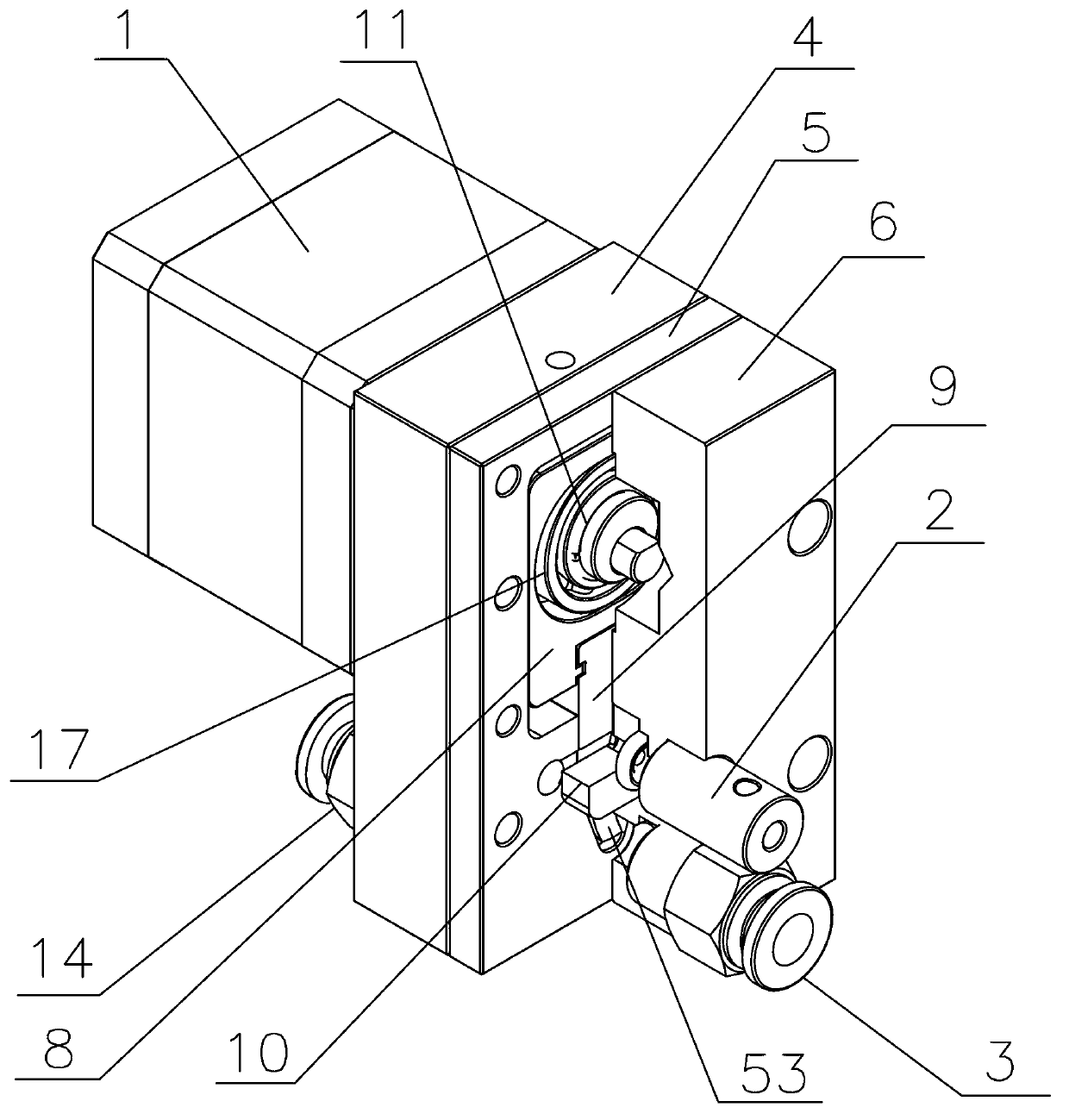

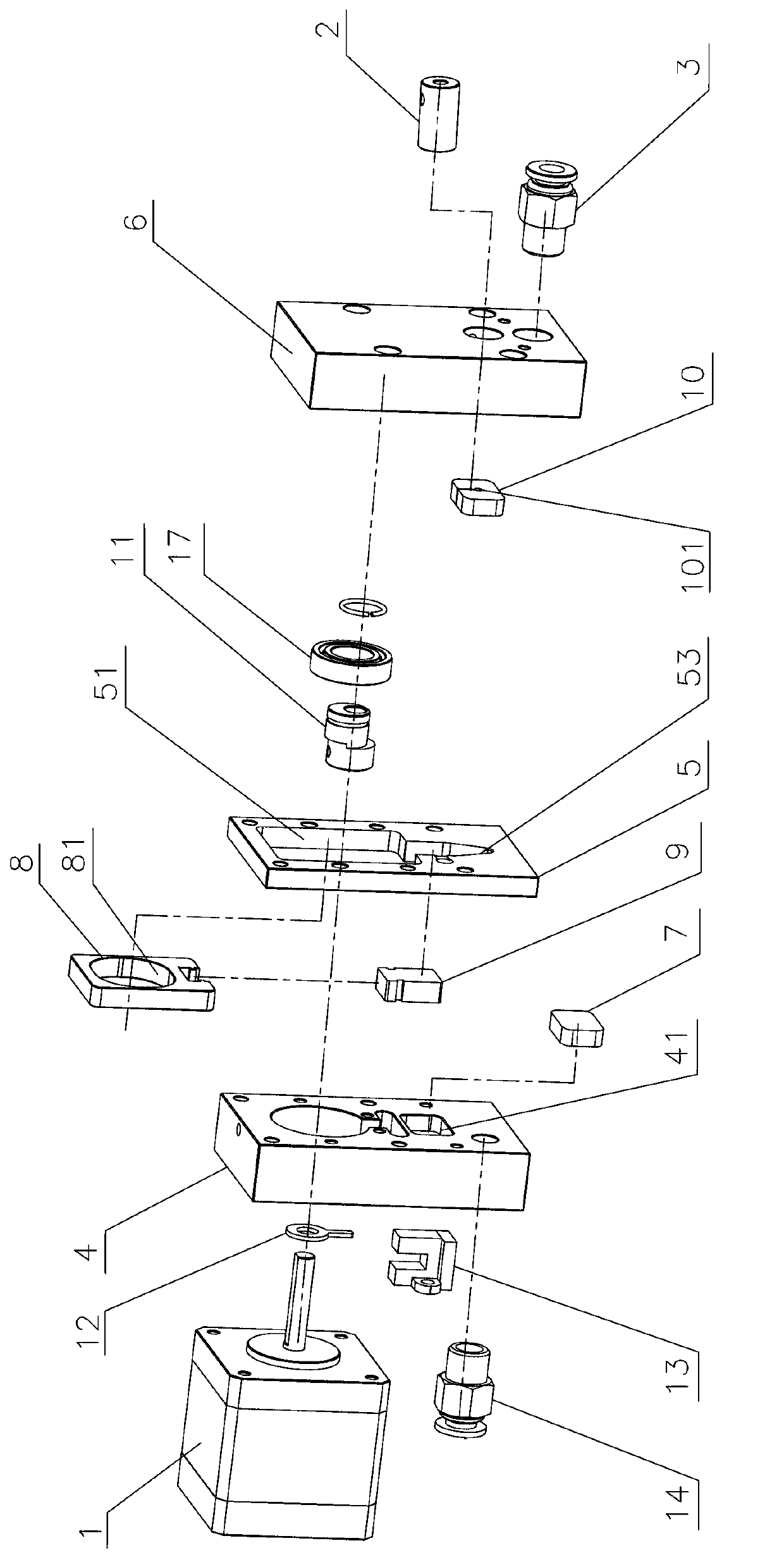

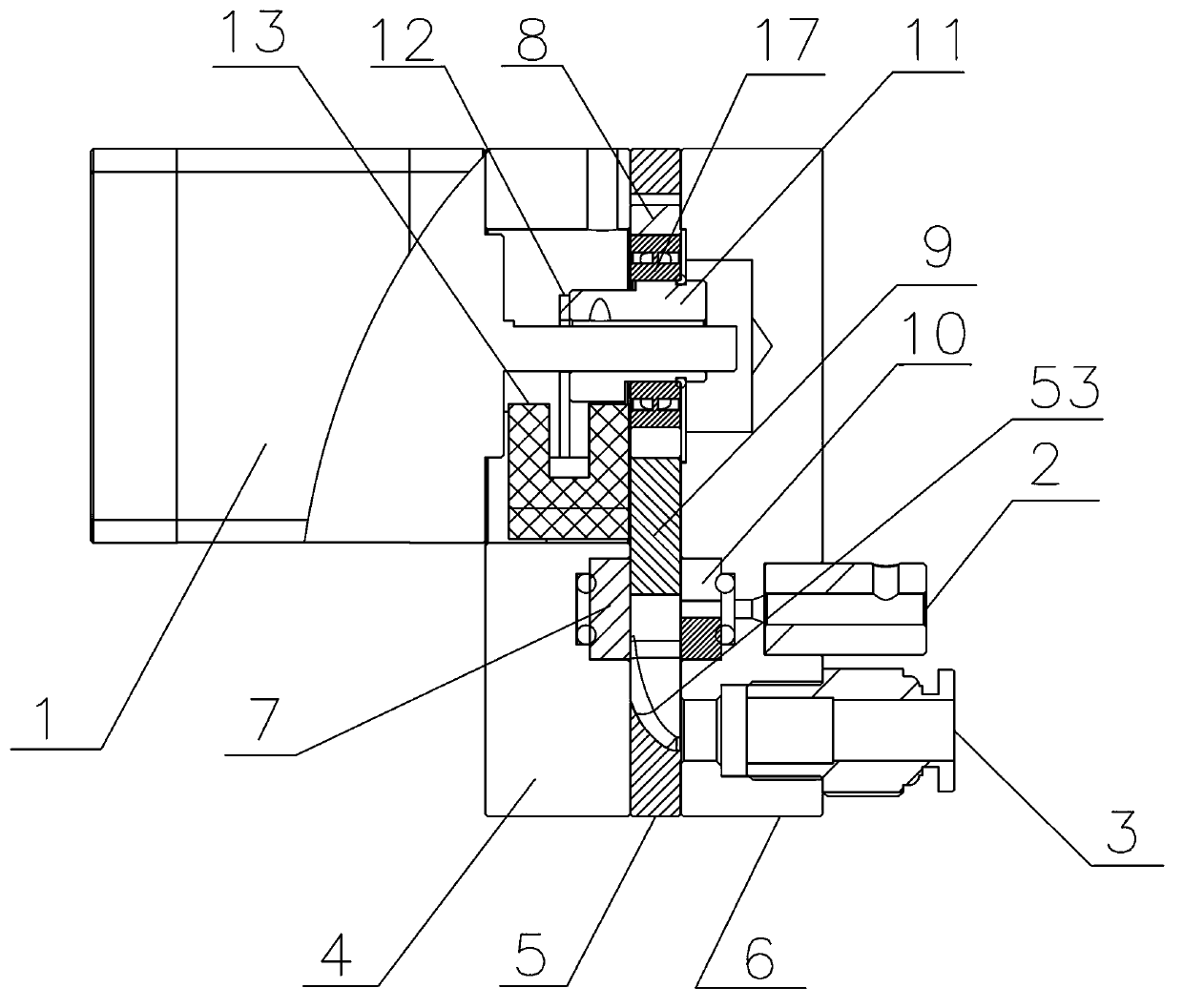

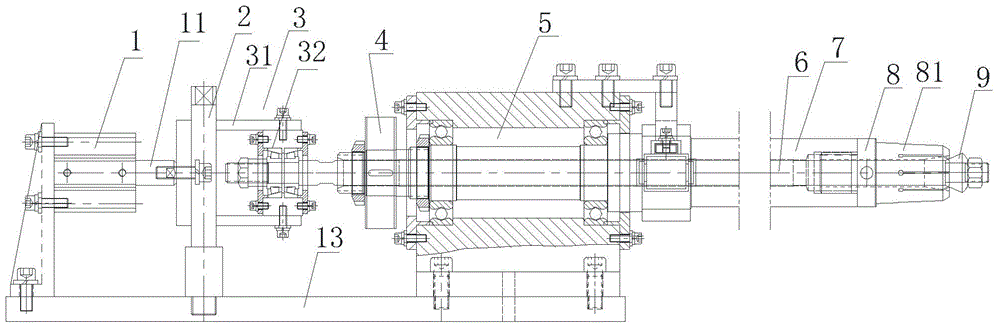

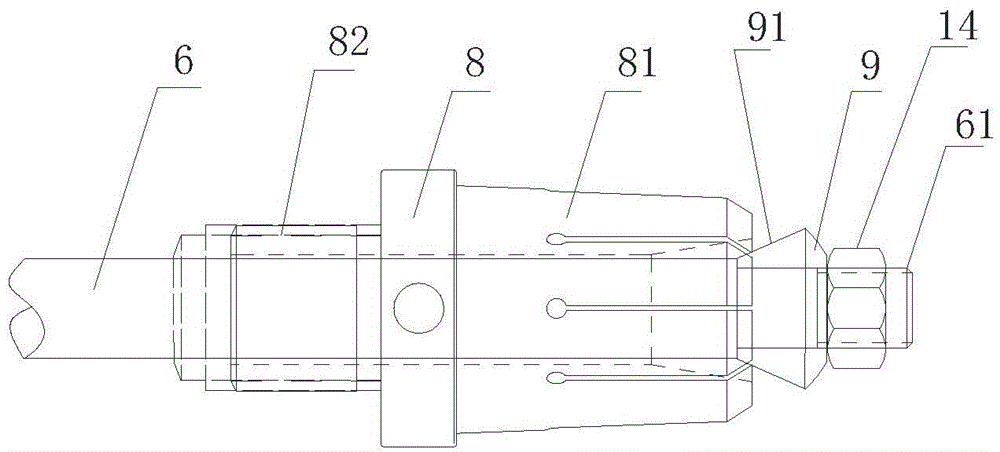

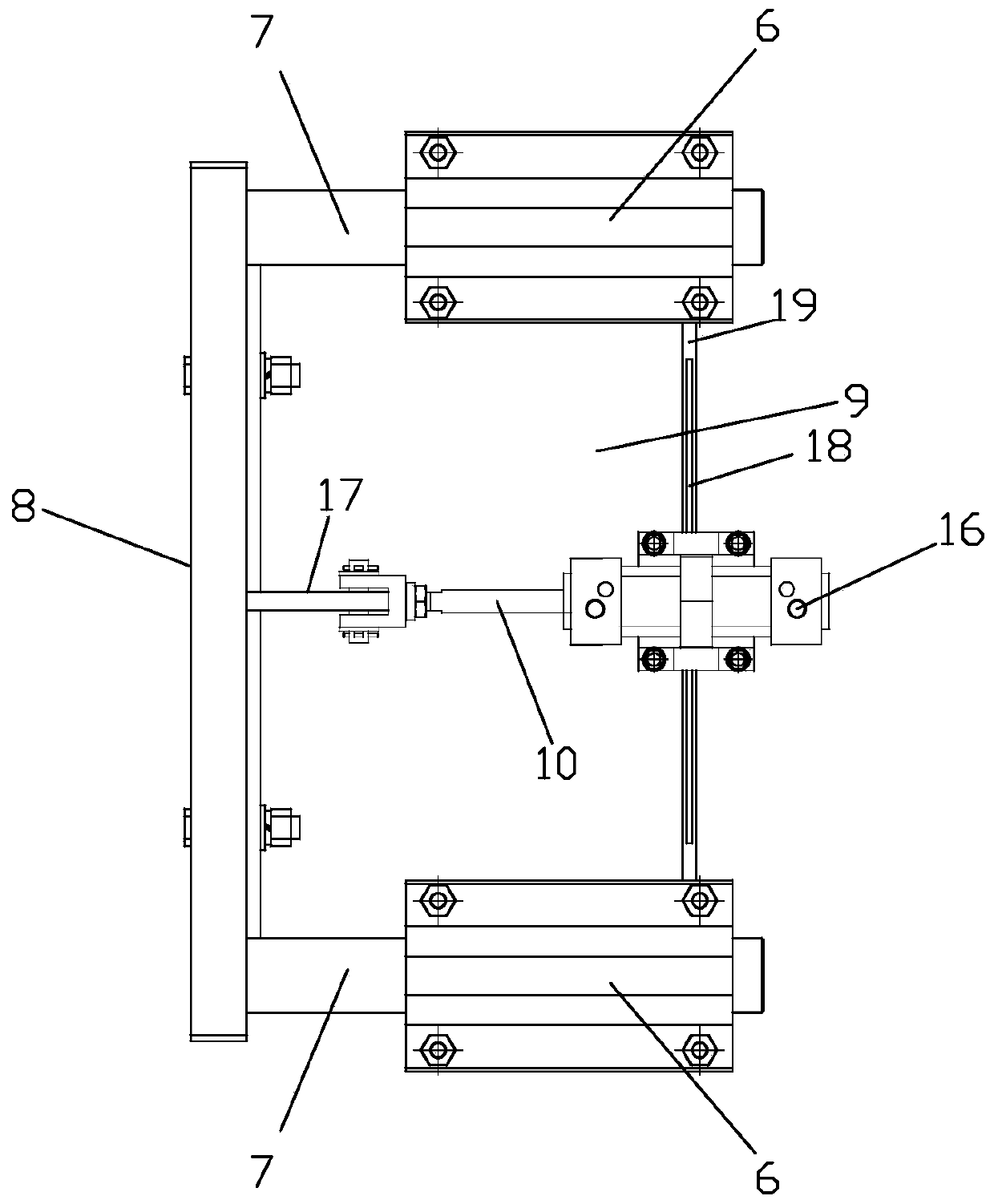

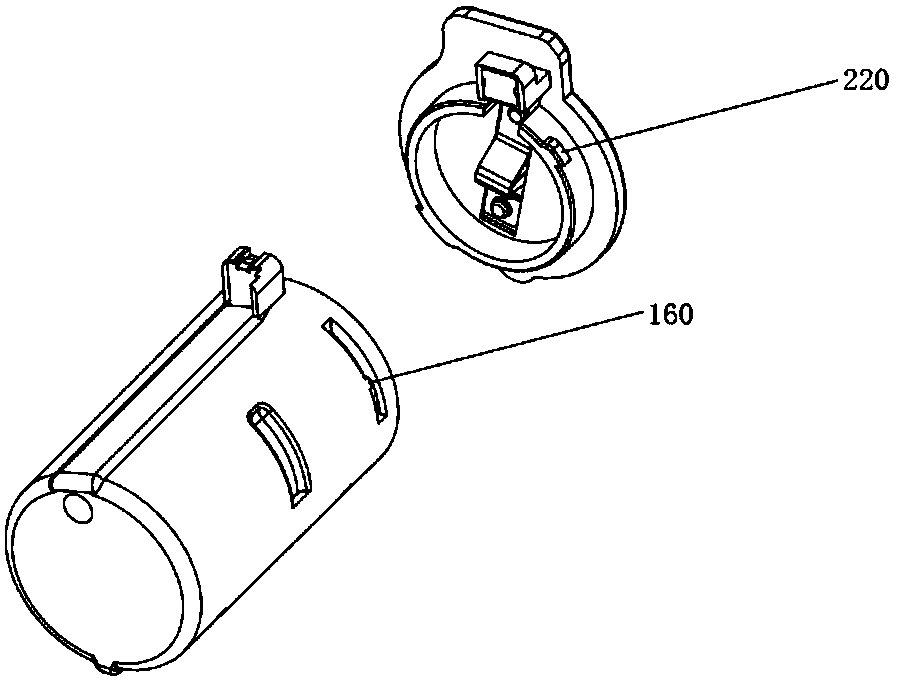

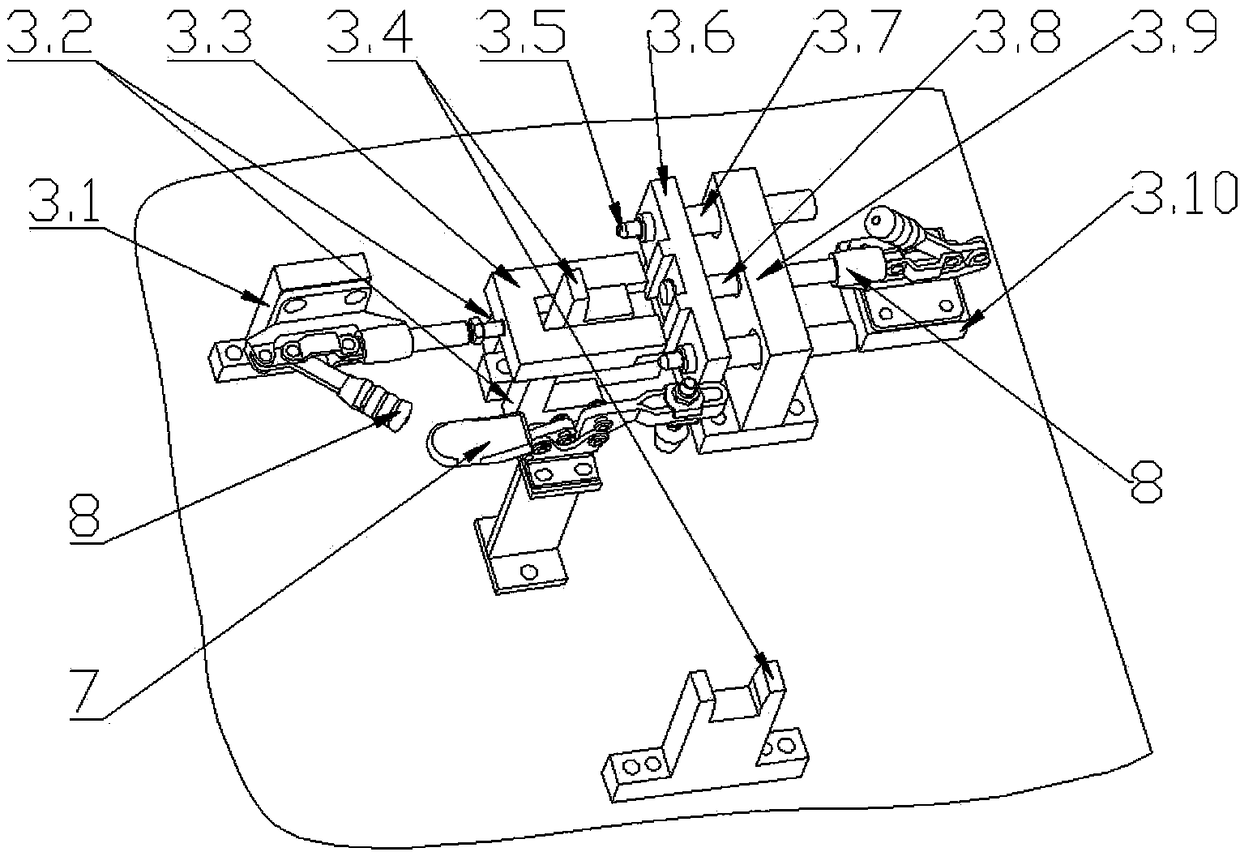

Fastening, indexing and rotating mechanism for central pipe

InactiveCN104690477AImprove welding processCompact structureWelding/cutting auxillary devicesAuxillary welding devicesAxial transmissionMechanical engineering

The invention relates to a fastening, indexing and rotating mechanism for a central pipe. The fastening, indexing and rotating mechanism comprises a base, a motor with a brake, an inner expanding rod, a cylinder, an inner expanding head, an indexing shaft, a conical expanding core and an indexing head, wherein both the motor and the cylinder are fixedly connected with the base, the middle of the indexing shaft is mounted in a central mounting hole of the indexing head in a penetrating manner, the right end of the indexing shaft is connected with the inner expanding head, a central through hole is axially formed in the indexing shaft, the inner expanding rod is connected with the conical expanding core at the right side of the inner expanding head after penetrating through the central through hole and the inner expanding head, a claw part cooperatively coordinating with the conical expanding core is arranged at the right end of the inner expanding head, the cylinder is arranged on the outer side at the left end of the inner expanding rod, the piston rod end of the cylinder is in axial transmission connection with the left end of the inner expanding rod, and the end, extending out of the indexing head, of the left end of the indexing shaft is in transmission connection with the motor.

Owner:HANGZHOU LONGHU M&E TECH

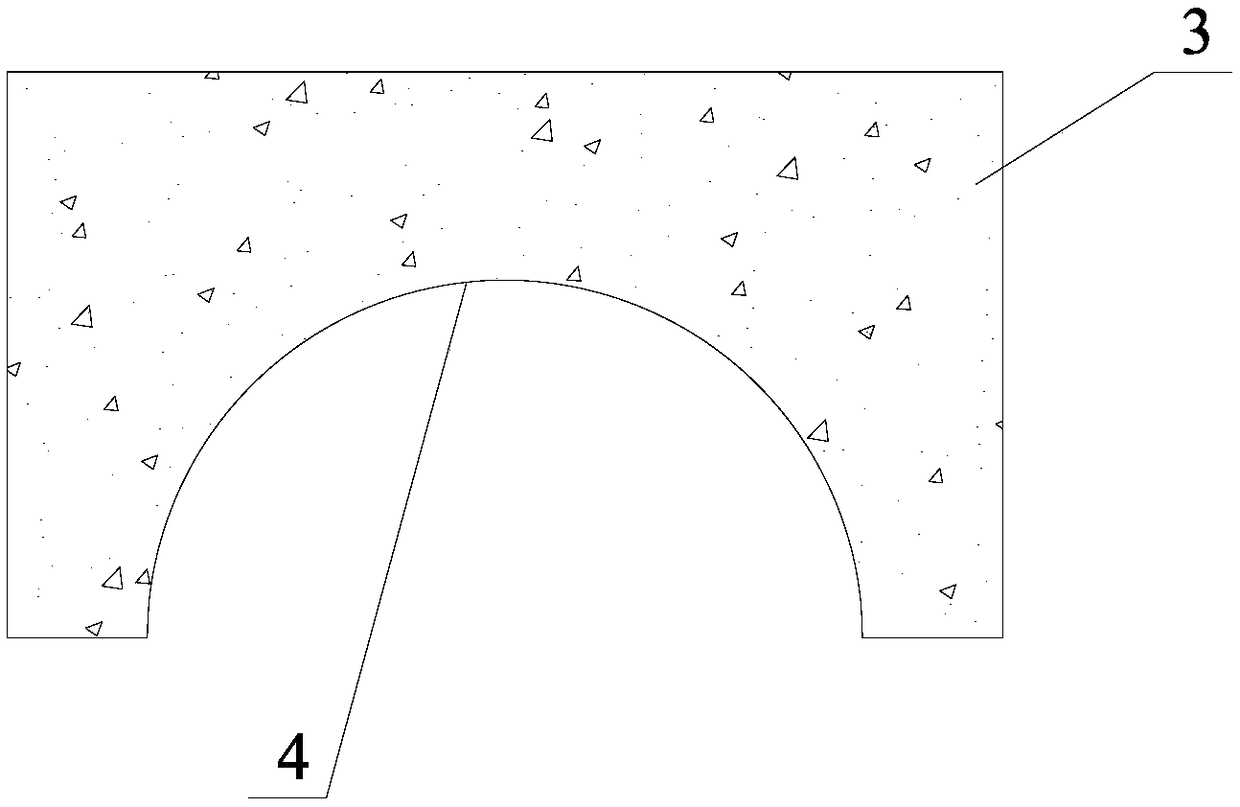

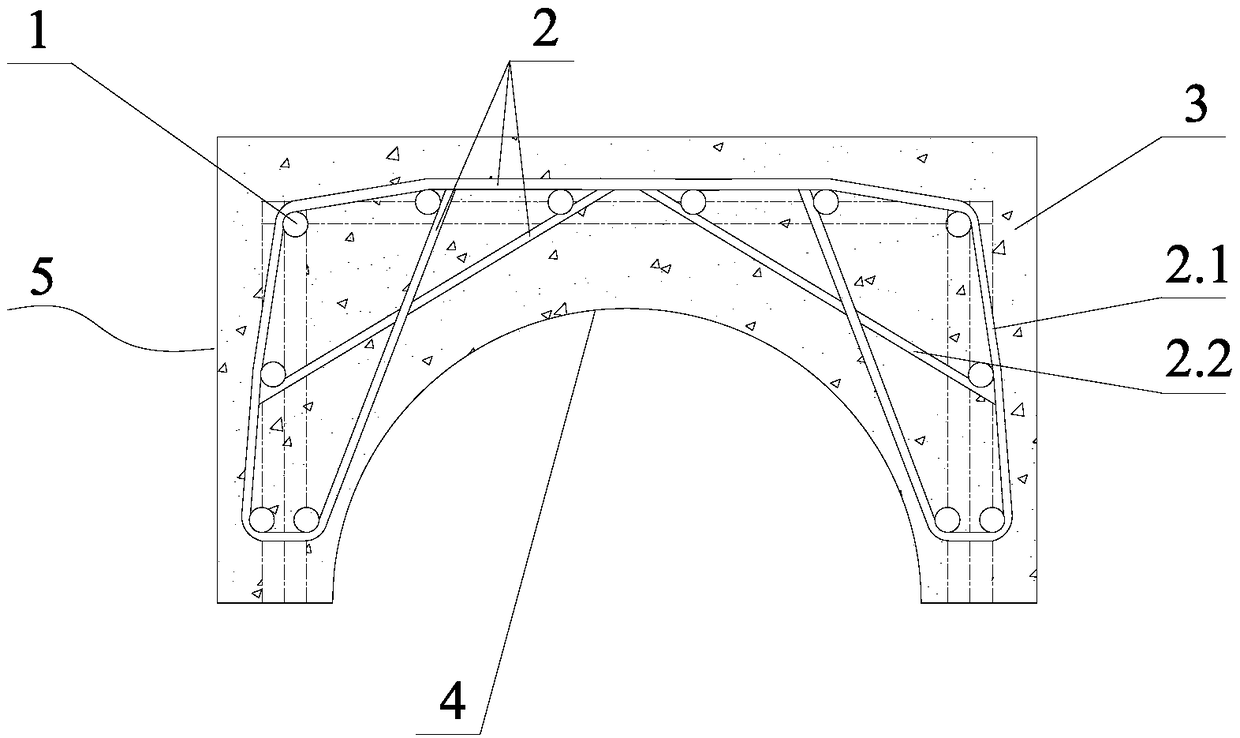

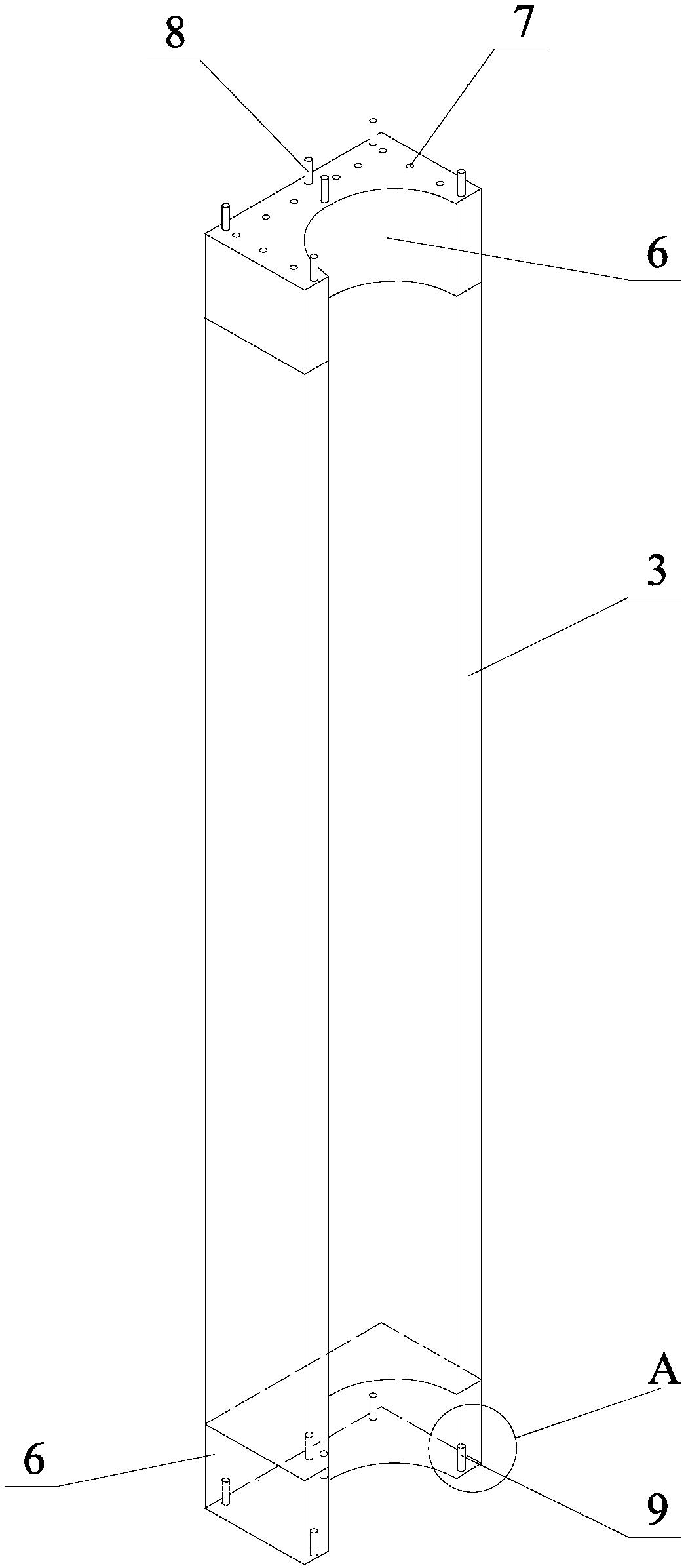

Supporting and protecting pile and composed supporting and protecting row pile

The invention discloses a supporting and protecting pile and a composed supporting and protecting row pile. The supporting and protecting pile comprises a precast concrete pile body with a reinforcingsteel bar cage composed of multiple vertical prestressed reinforcing steel bars and multiple transverse stirrups, and the cross section of the pile body is in a first rectangular shape with a first semicircular groove in one side. The supporting and protecting pile further comprises metal end plates at the two ends. Multiple through holes allowing the multiple vertical prestressed reinforcing steel bars to penetrate are formed in the metal end plates. Multiple guide insertion connection columns are arranged on one end plate, insertion connection blind holes which are in one-to-one correspondence with the multiple guide insertion connection columns are formed in the other end plate, horn mouth clamp rings with the large upper portions and the small lower portions are arranged in the holes,and each horn mouth clamp ring is composed of multiple metal elastic pieces. The long side of the supporting and protecting pile is close to the contact face of the foundation pit inner side around afoundation pit and the supporting and protecting pile and forms a ceaseless connection line extending in the length direction. The supporting and protecting pile and the composed supporting and protecting row pile have a small earth squeezing effect, are good in compactness, are large in contact area of the contact face of the foundation pit inner side around the foundation pit and the supportingand protecting pile, and are high in bending resistance.

Owner:浙江华展工程研究设计院有限公司

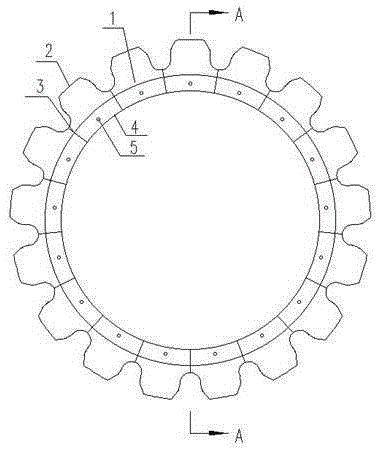

Large gear

InactiveCN105402370AHigh densitySave raw materialsPortable liftingGearing elementsGear wheelEngineering

The invention relates to a large gear composed of single gear bodies, teeth, welding points, center holes and positioning holes. The large gear is characterized in that the large gear is formed in the manner that the welding points are evenly distributed on the single gear bodies and welded; each single gear body is composed of one center hole and the positioning holes and formed through casting of 42GrMo materials; and integral welding is achieved through positioning of the center holes and the positioning holes after thermal treatment machining. The large gear has the beneficial effects of being large in density, high in tenacity, simple in structure, easy to weld and the like, and the reliability and using safety of the gear are improved.

Owner:SHANDONG HAOAN GOLDTECH NEW MATERIALS

Boiler tail gas dedusting device with vertical low-resistance cooling system

InactiveCN106334429AEasy to remove dustGood deacid effectCombination devicesGas treatmentFlue gasExhaust pipe

The invention discloses a boiler tail gas dedusting device with a vertical low-resistance cooling system. The boiler tail gas dedusting device with the vertical low-resistance cooling system comprises a boiler discharge flue, an exhaust pipe communicated with the boiler discharge flue and a chimney communicated with the exhaust pipe. The front end of the boiler discharge flue is provided with a dry deduster, and an outlet end of the boiler discharge flue is communicated with an input end of the vertical low-resistance cooling system. An output end of the vertical low-resistance cooling system is communicated with a dedusting tank. A front end and a rear end of the exhaust pipe are respectively connected to a flue gas condenser and a wet dust collector. According to the invention, waste heat of tail gas is recovered, tail gas temperature is effectively reduced, and dust and acid gas in tail gas are effectively removed. The device of the invention is beneficial to environment protection of the atmosphere and energy-saving.

Owner:SUZHOU BSE AIR CONDITIONER

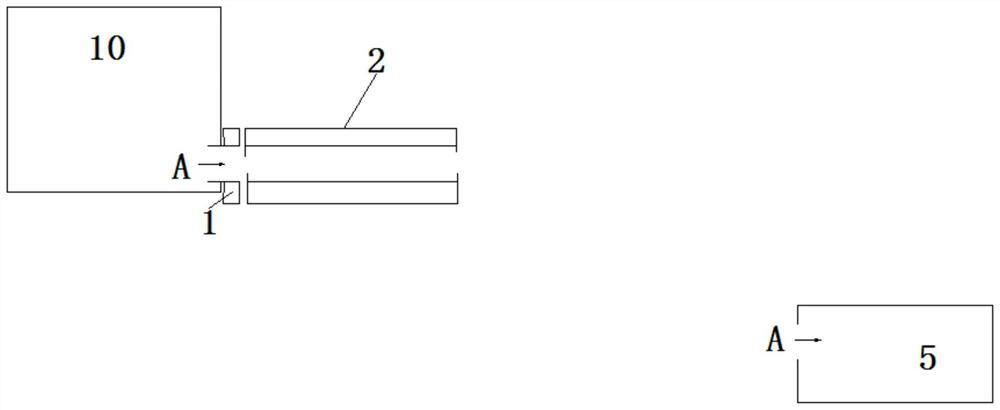

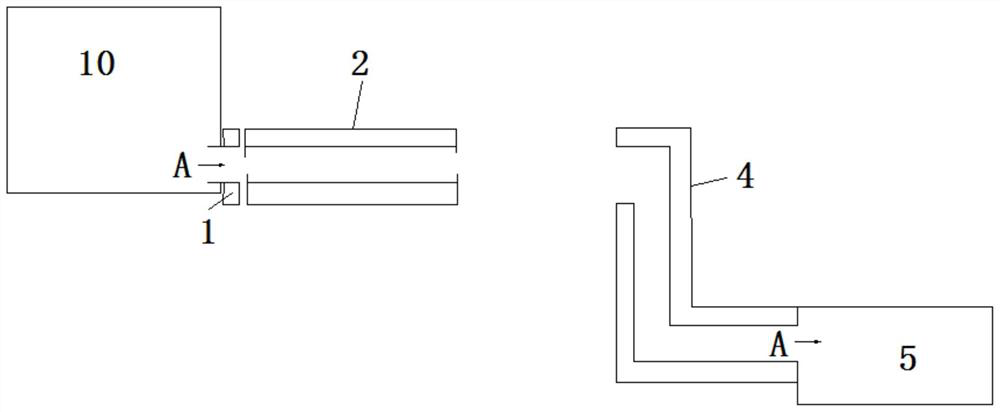

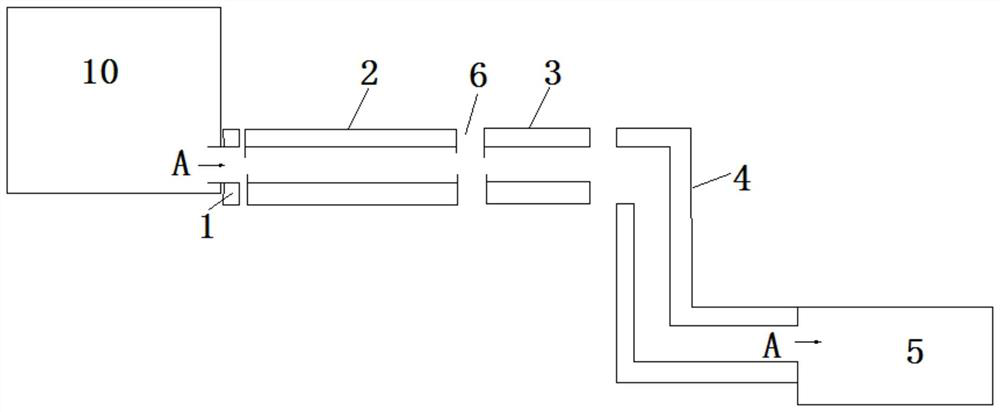

Platinum channel installation method considering expansion characteristic and platinum channel

ActiveCN112209600APrecise installation technologyFulfill construction technical requirementsForehearthsEngineeringMechanical engineering

The invention discloses a platinum channel installation method considering the expansion characteristic and a platinum channel. The method comprises the steps that a throat pipe is installed at a molten glass outflow hole of a glass kiln, a heating clarification section is built and installed, so that the heating clarification section is communicated with the throat pipe, a masonry stirring feeding section is installed, so that the stirring feeding section is communicated with the forming equipment, and meanwhile, a reserved position is reserved between the stirring feeding section and the heating clarification section, a cooling section is installed at the reserved position, an expansion reserved gap is reserved between the cooling section and the heating clarification section, and the cooling section and the stirring feeding section are welded together. The method is used for installing the platinum channel, the installation technology and process of the platinum channel in the installation process can be more accurate, and the expansion size needing to be reserved is more accurate and controllable. The technical requirements of high-quality glass kiln construction are met.

Owner:IRICO

Positioning and clamping device for circuit board welding fabrication and positioning and clamping method of positioning and clamping device

PendingCN111438480AHigh precisionImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a positioning and clamping device for circuit board welding fabrication and a positioning and clamping method of the positioning and clamping device. The positioning and clamping device comprises a machine base, a table top and clamping mechanisms, wherein the clamping mechanisms are respectively arranged on the two sides of the table top; each clamping mechanism comprisesa straight-line motion mechanism and a clamping board; each clamping board is connected with the corresponding straight-line motion mechanism; each clamping board is pushed by the corresponding straight-line motion mechanism to do straight-line motion on the table top; and a contact switch is mounted on the contact surface of each clamping board. According to the positioning and clamping device disclosed by the invention, through the straight-line motion mechanisms and the clamping boards, mechanized clamping is realized, based on the situation that a circuit board is positioned to the middleposition of the table top, a welding procedure is performed, the accurate degree and the accuracy of welding are improved, and welding quality is improved and the mechanized positioning and clamping device is time-saving and labor-saving, the welding procedure is accelerated, and labor cost is reduced.

Owner:浙江新连宇电子有限公司

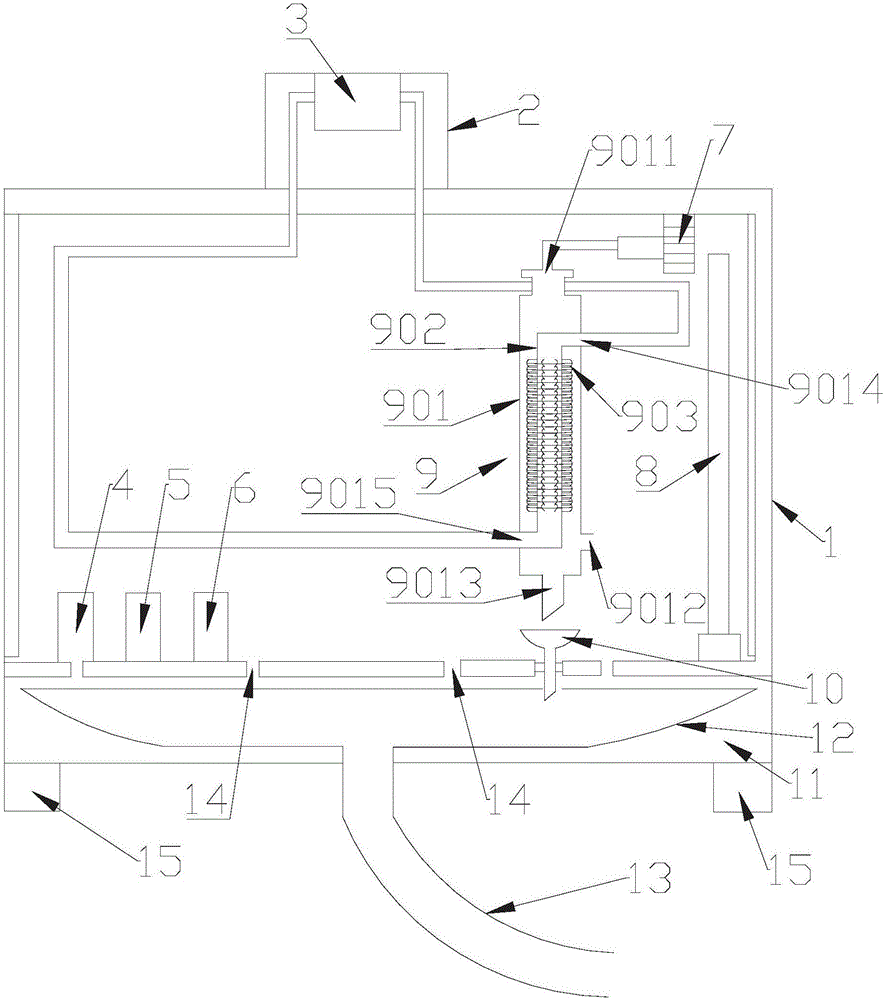

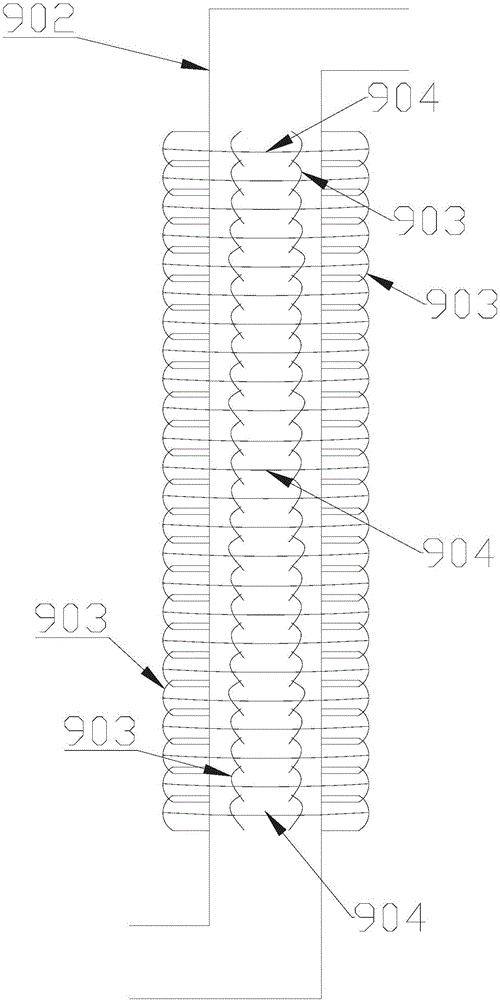

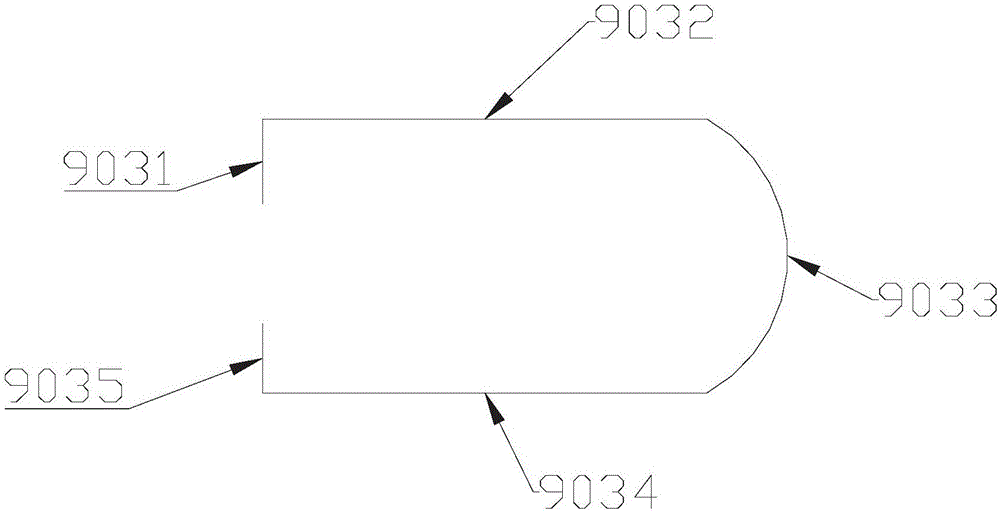

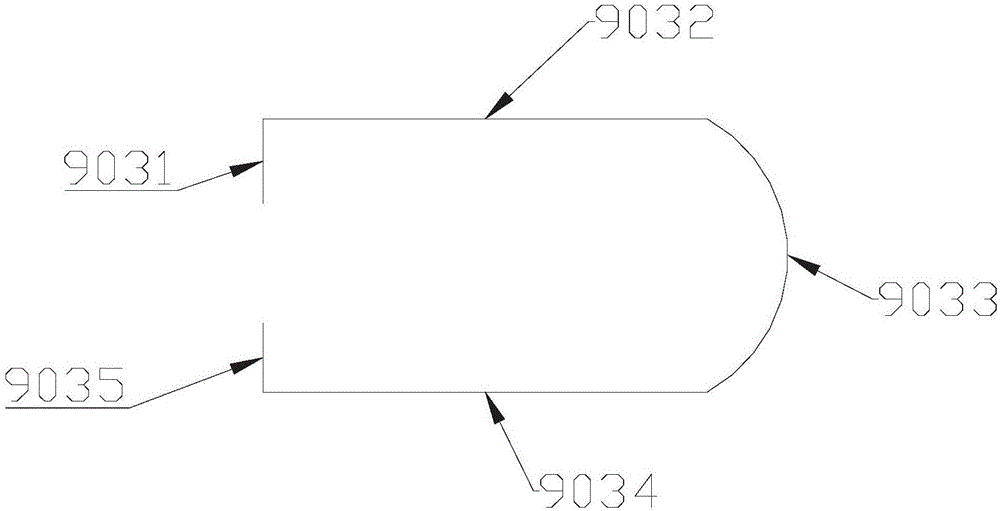

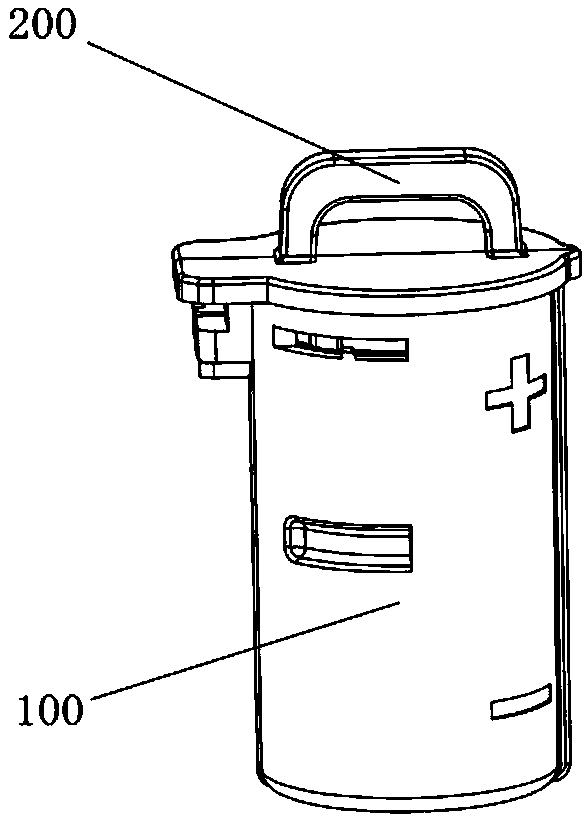

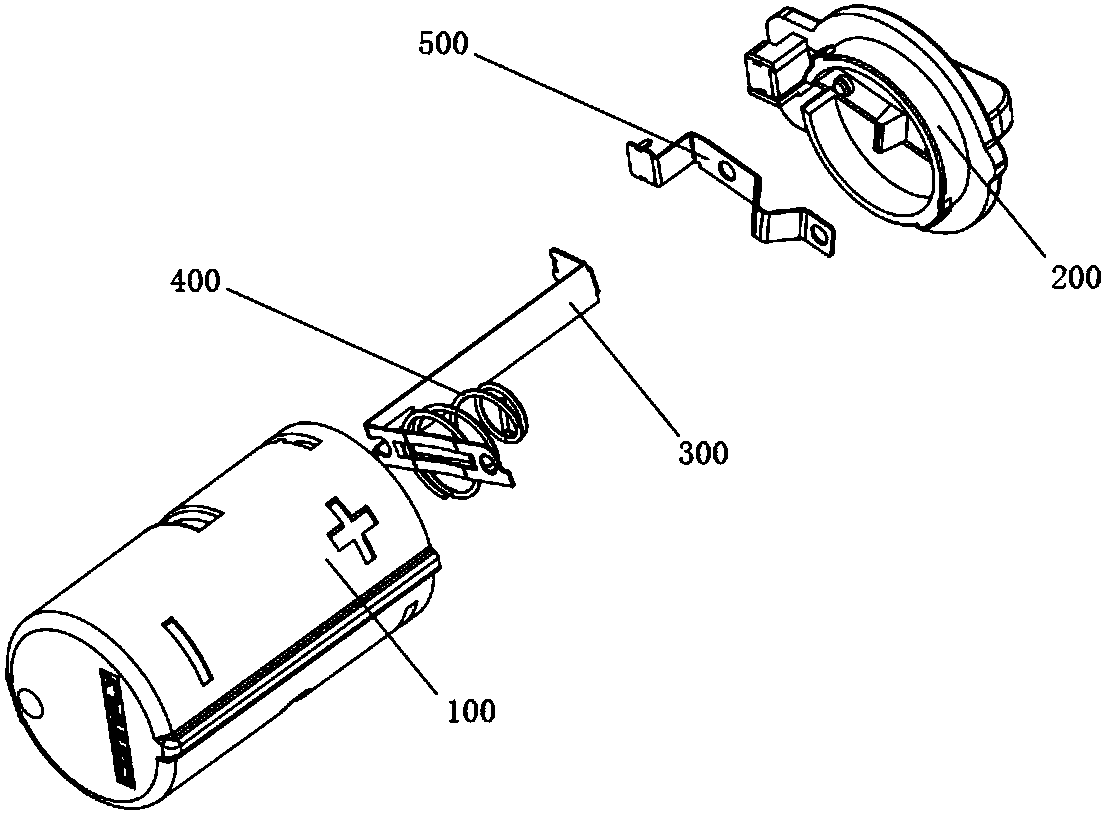

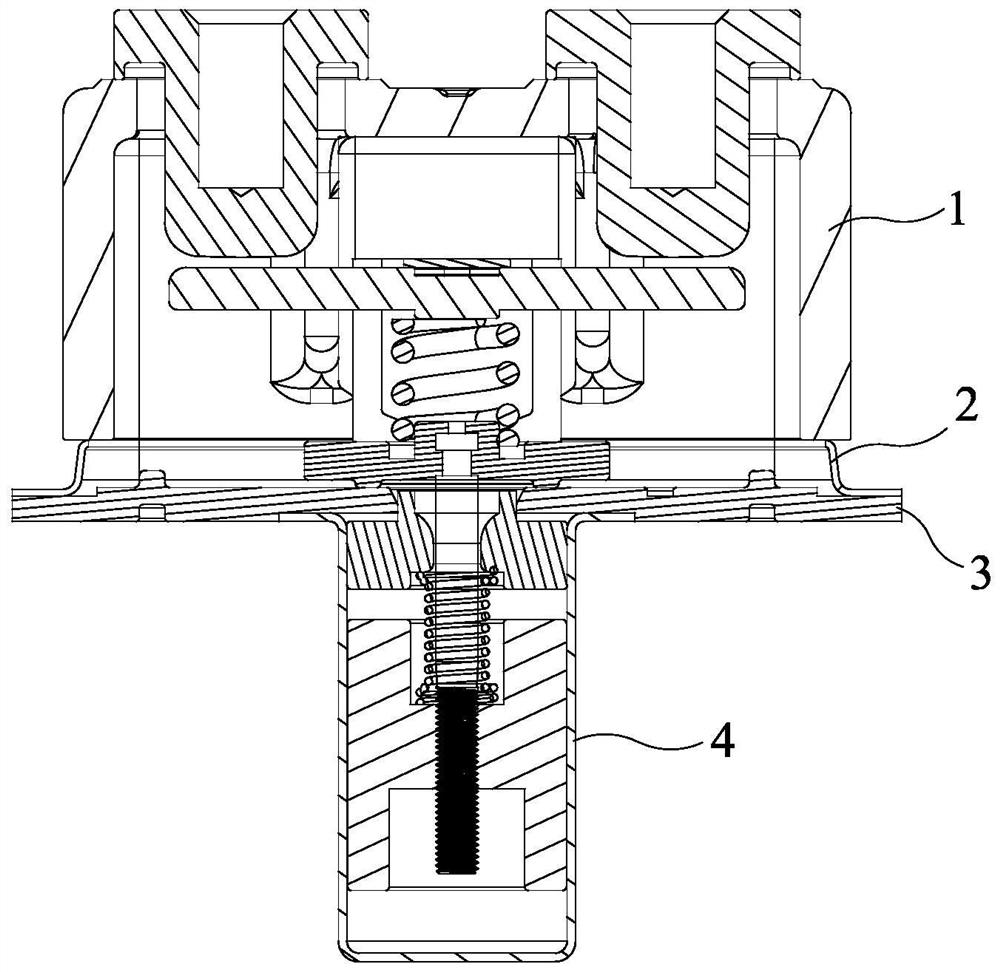

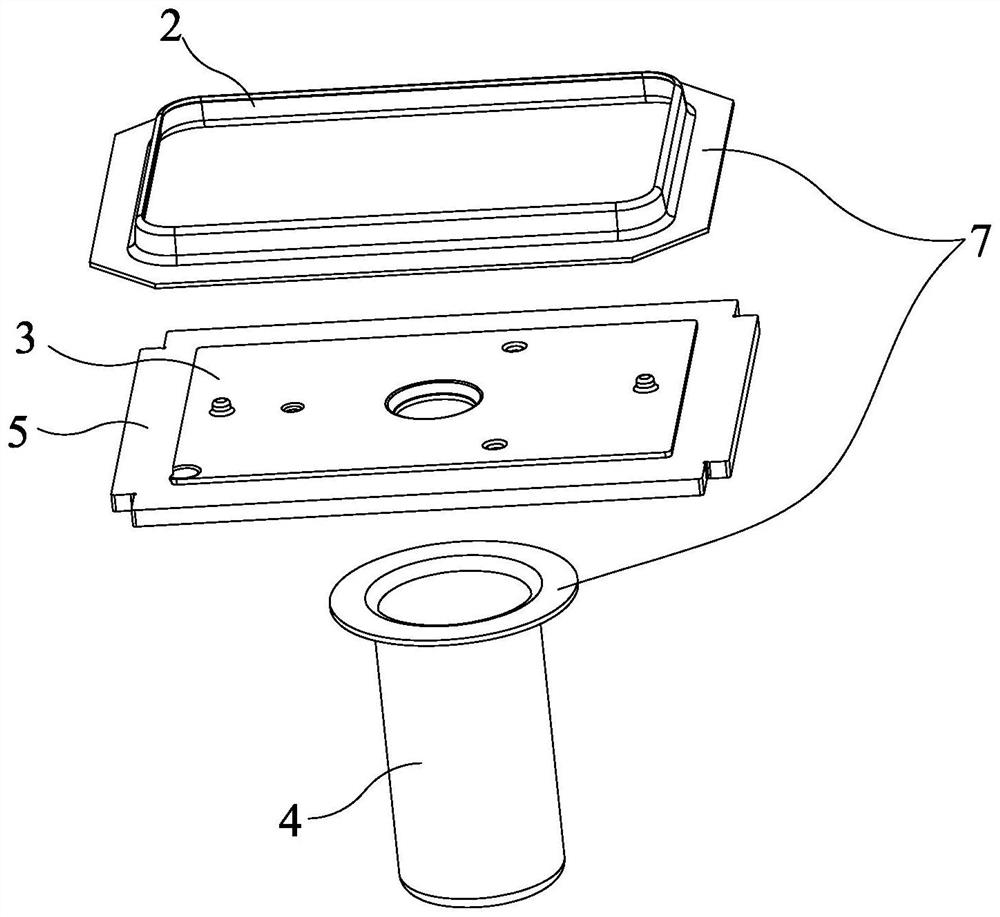

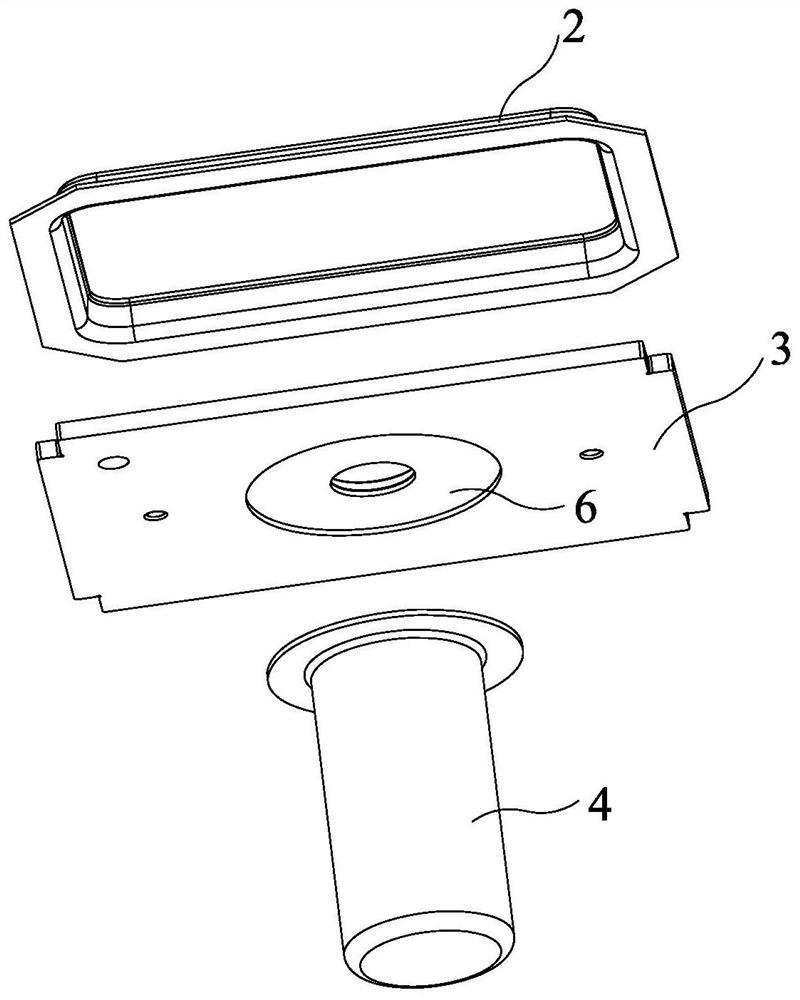

Battery box assembly with low impedance output

InactiveCN108389988AGuaranteed tightnessImprove welding processBattery isolationSoldered/welded conductive connectionsEngineeringLow impedance

The invention discloses a battery box assembly with low impedance output. The battery box assembly comprises a base, a cover cap, a positive electrode terminal, a negative electrode terminal and a spring, wherein the negative electrode terminal is mounted in a manner of being clung to the inner side of the base; the positive electrode terminal is mounted in a manner of being clung to the inner side of the cover cap; one end of the spring is connected with the negative electrode terminal and the other end of the spring is connected with a battery negative electrode arranged in the base; the positive electrode terminal is connected with a battery positive electrode; after the cover cap is arranged in the base, the cover cap is rotated; then the cover cap is locked through the matching of ananti-backing block arranged on the base and an anti-backing clamping block arranged on the cover cap. According to the battery box assembly provided by the invention, all components are in tight contact with one another, so that the impedance value output by a product is very stable; meanwhile, the anti-vibration performance also can be improved.

Owner:NINGBO CONNFLY ELECTRONIC CO LTD

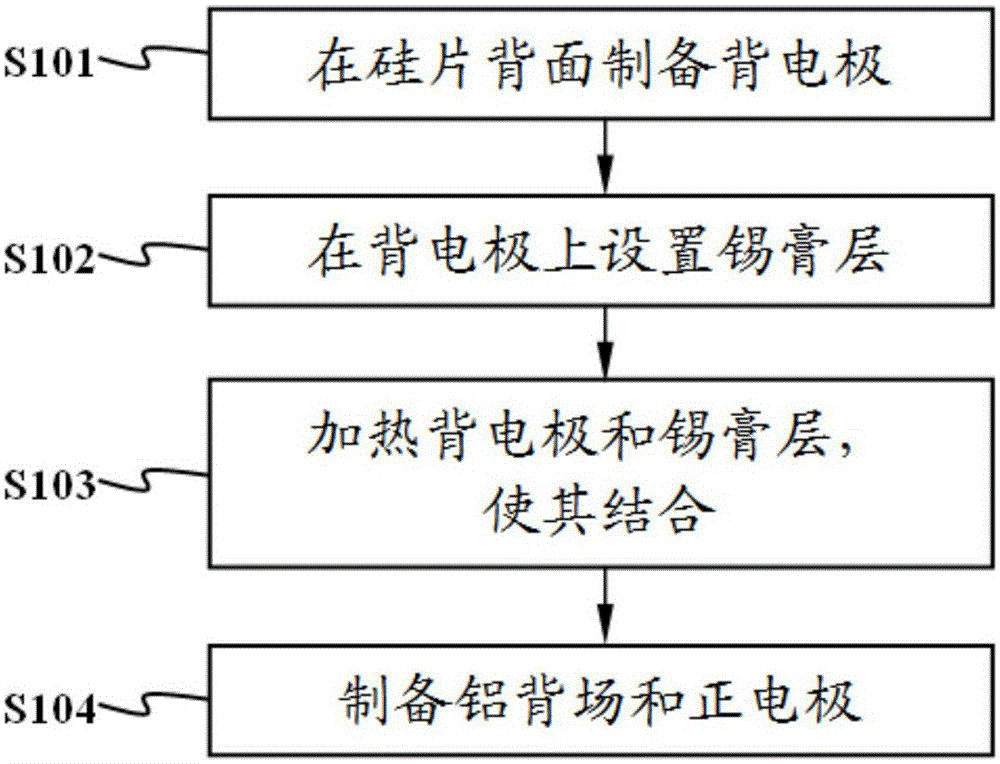

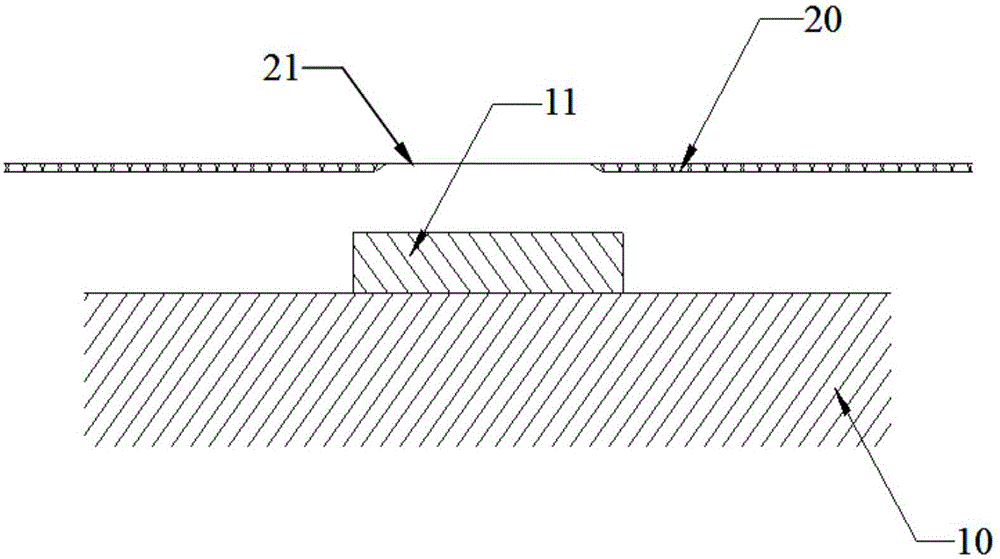

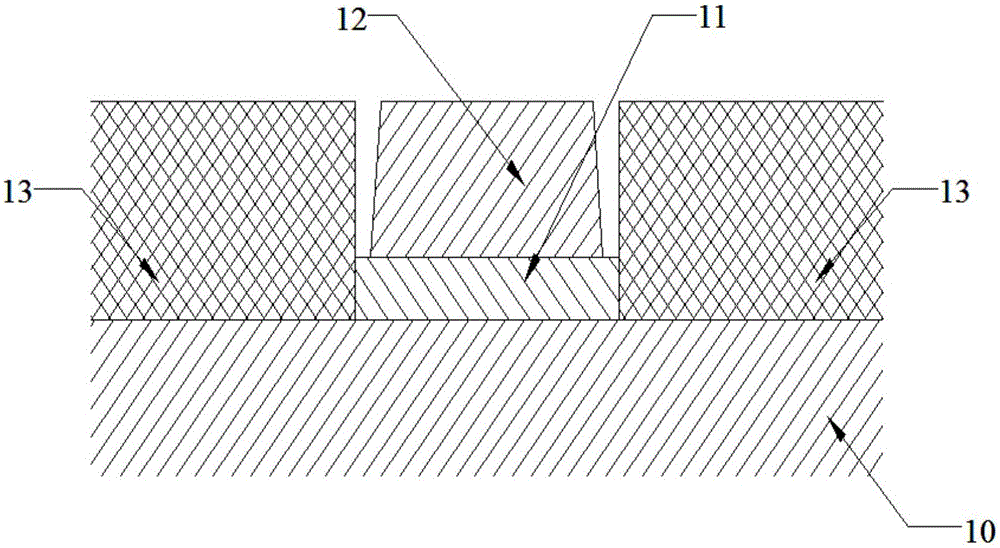

Solar battery cell and fabrication method thereof

InactiveCN106328725AImprove welding processHigh tin contentFinal product manufacturePhotovoltaic energy generationAluminiumHeight difference

The invention provides a solar battery cell and a fabrication method thereof. The fabrication method comprises the steps of fabricating a back electrode on a back surface of a silicon wafer; arranging a tin paste layer on the back electrode; heating the back electrode and the tin paste layer to make the back electrode and the tin paste layer combined; and fabricating an aluminum back field and a positive electrode. The tin paste layer is additionally arranged on the surface of the back electrode, thus, the height difference between the back electrode and the aluminum back field is greatly eliminated, the problem of unfavorable contact of a welding strip and the back electrode caused by the height difference is prevented, and the welding process of the back electrode and the welding strip is more convenient; and meanwhile, with the arrangement of the tin paste layer, the tin content between the welding strip and the back electrode is increased, and an infrared welding process of a fine welding strip can be improved.

Owner:CSI CELLS CO LTD +1

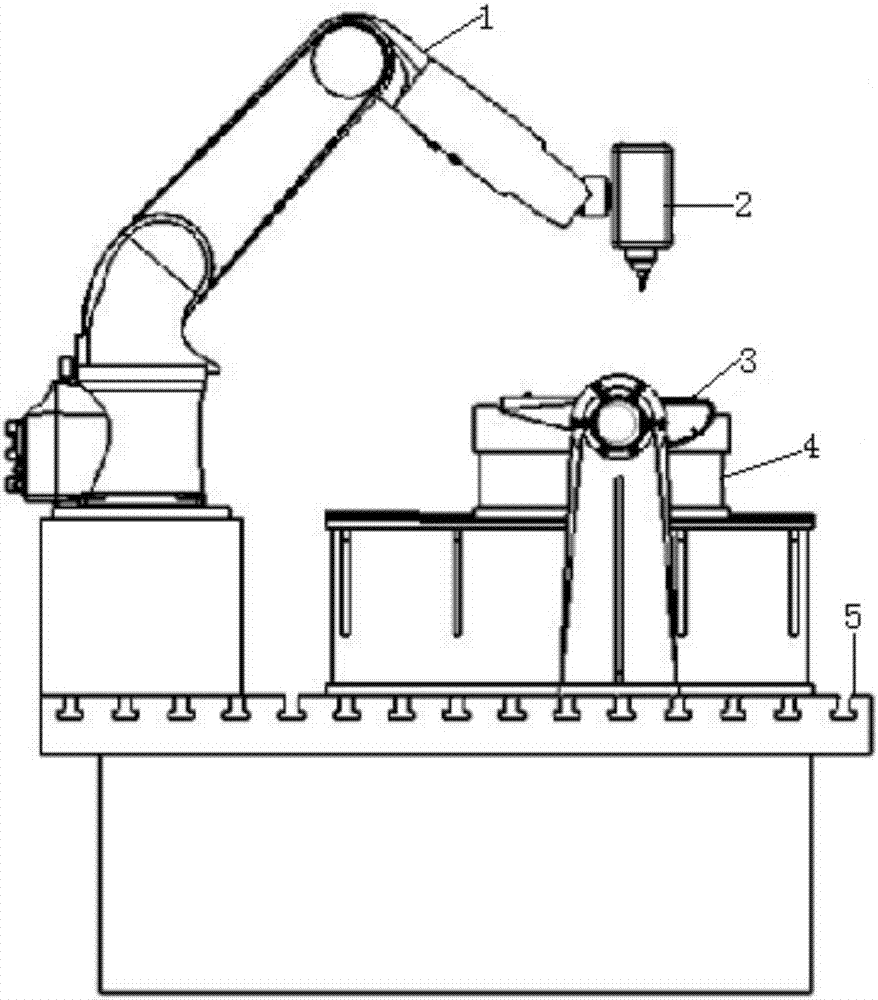

Welding equipment for friction stir welding of airframe

ActiveCN107344262AImprove mechanical propertiesHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingUltimate tensile strength

The invention provides welding equipment for friction stir welding of an airframe. The welding equipment comprises a welding platform. A welding arm is fixedly arranged on the left side of the top of the welding platform. A welding head is mounted on the right side of the welding arm. A component positioning device is arranged on the right side of the top of the welding platform. An airframe structure component is clamped to a component positioning clamp. The welding platform is precise to position, the structure is simple, workpieces can be disassembled and assembled conveniently and fast, and the welding equipment is convenient to use. By applying a friction stir welding technology, no rivet connection is needed during the welding of the airframe component, the weight of an airplane is reduced, and the cost of the airplane is lowered as well; and besides, mostly, the aerodynamic environment of the airplane is improved, the oil consumption is reduced, the performance of the airplane is improved, and the structural strength of the airplane is enhanced.

Owner:HEBEI CHUANGLIAN MACHINERY MFG

PCB structure

InactiveCN104244572AMeet the amount of solderIncrease profitPrinted circuit detailsEngineeringElectronic component

The invention discloses a PCB structure. A PCB is provided with a plurality of plugging piece holes allowing plugging pieces to be installed. A storage tank used for storing welding flux is formed in the position of at least one plugging piece hole of the PCB. The storage tanks are communicated with the plugging piece holes. In this way, the PCB structure not only can improve the utilization rate of the welding flux and meet the requirement for the amount of welding flux of welding the plugging pieces to the PCB, but also can improve the welding technology, and electronic components are welded to the PCB more reliably.

Owner:NEW H3C TECH CO LTD

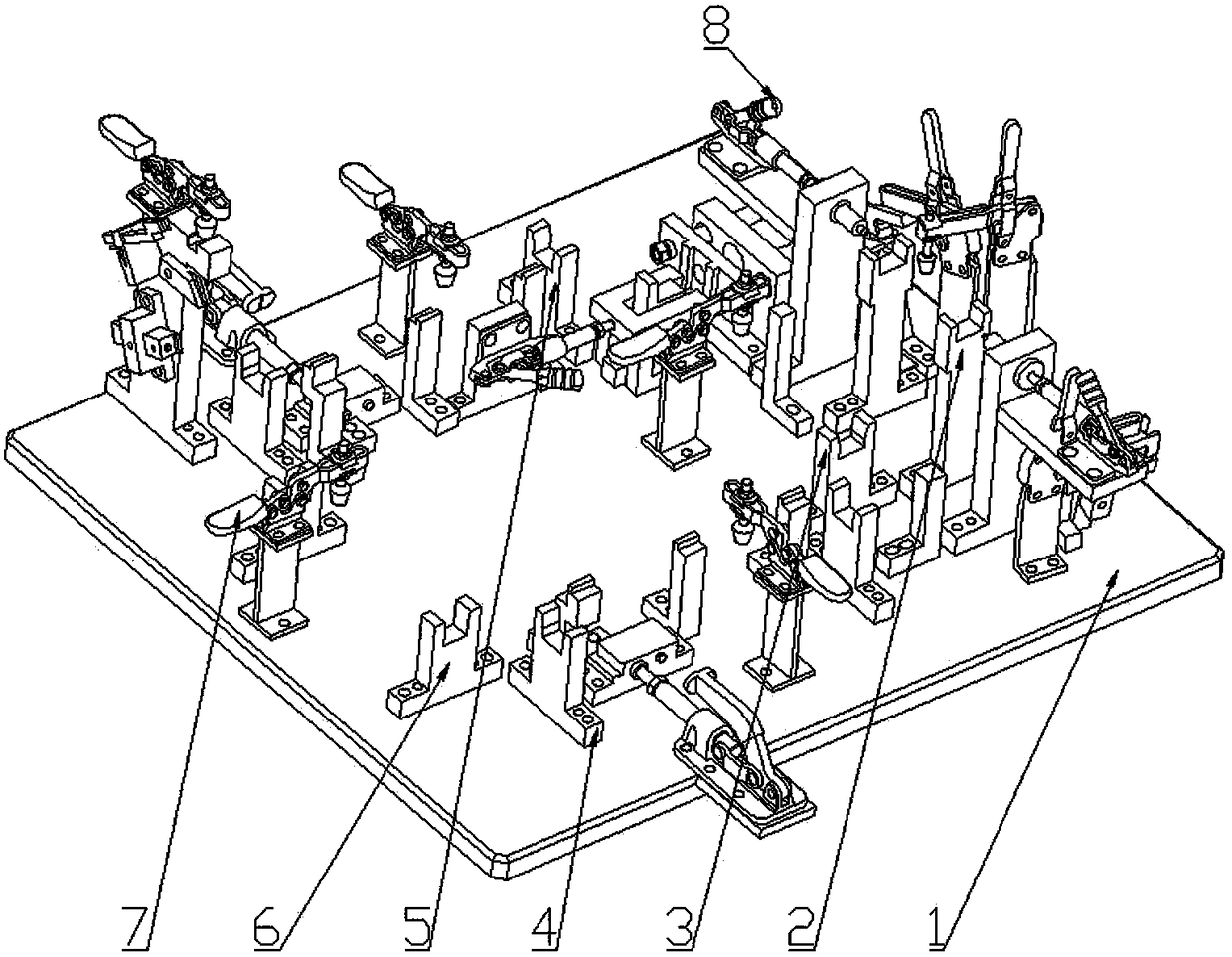

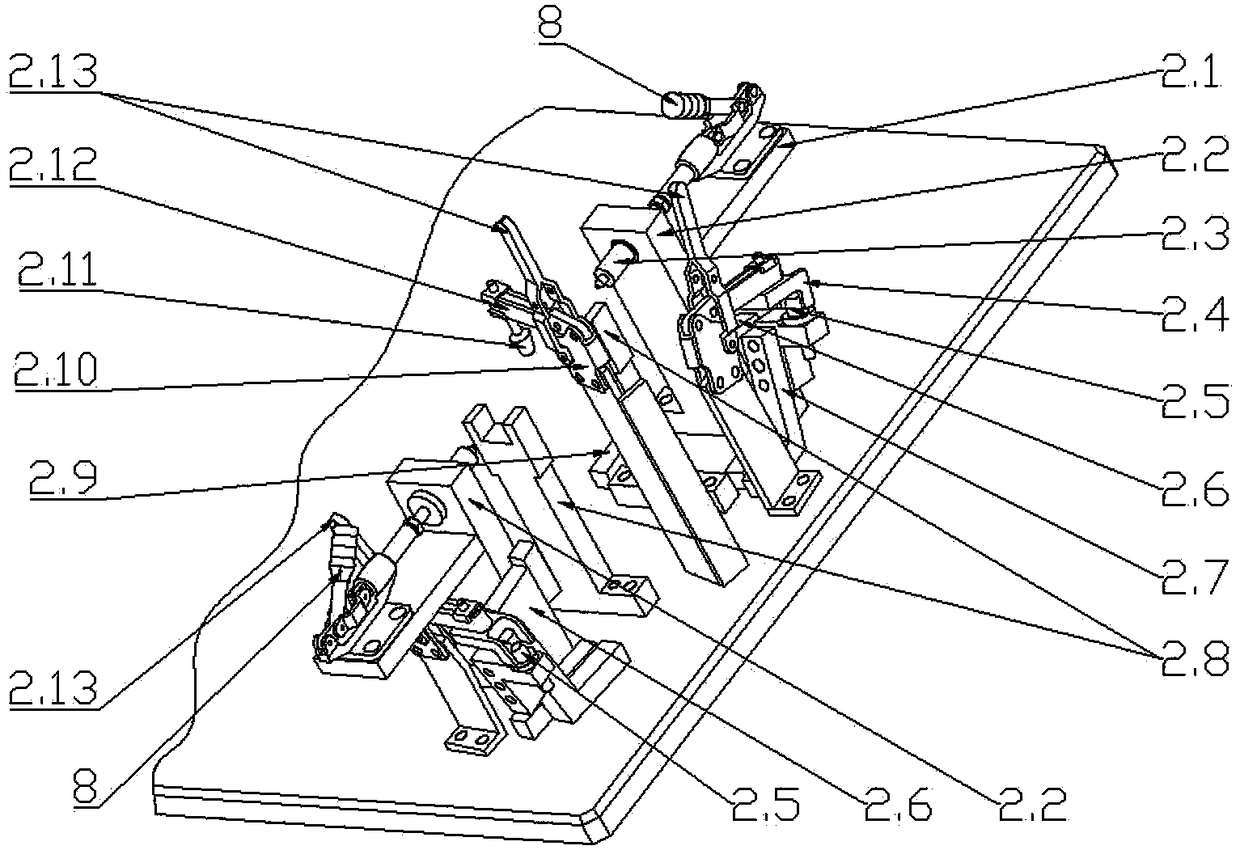

Welding method of cushion framework of left seat on back row of automobile

PendingCN108465970APrecise positioningPrecise clampingWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyEngineering

The invention discloses a welding method of a cushion framework of a left seat on the back row of an automobile, and relates to the technical field of automobile manufacturing. The welding method comprises the following steps of A, welding tool manufacturing; B, assembling, wherein various parts of the cushion framework are assembled on a welding tool; C, spot welding, wherein the assembled partsare subjected to spot welding to form an overall cushion framework; D, transferring, wherein the assembled and welded overall cushion framework is transferred to a welding station; E, welding, whereina welding robot is adopted for overall welding the assembled and welded cushion framework; and F, residue cleaning checking, wherein the welded cushion framework is cleaned, and completion checking is carried out. According to the welding method, the problems that in an existing welding method for the cushion framework of the left seat on the back row of the automobile, welding tool locating arrangement and a pressing mechanism are not reasonable, and the welding work efficiency is low can be solved.

Owner:LIUZHOU YUHUA TECH

Method for improving welding performance of direct-current relay

PendingCN114505570AImprove heat transfer efficiencyShorten welding timeResistance welding apparatusElectrical resistance and conductanceStructural engineering

The invention discloses a method for improving the welding performance of a direct-current relay, and relates to a lower yoke plate, a metal shell and a frame sheet, the method comprises the frame sheet welding step: firstly, the thickness of one surface, opposite to the frame sheet, of the lower yoke plate is thinned, a first sinking groove is machined, and the shape of the first sinking groove is matched with the connecting position of the frame sheet; then aligning the frame sheet to be connected with the first sinking groove and then embedding the frame sheet into the first sinking groove in a matching manner; and finally welding the frame sheet and the first sinking groove together through electric resistance welding. And a metal shell welding step: firstly, the thickness of one surface, opposite to the metal shell, of the lower yoke plate is thinned, a second sinking groove is processed, the shape of the second sinking groove is matched with that of the joint of the metal shell, then the metal shell to be connected is aligned with the second sinking groove and then is embedded into the second sinking groove in a matched manner, and finally, the metal shell and the second sinking groove are welded together through electric resistance welding. The sinking groove is designed to reduce the thickness of the lower yoke plate so as to reduce the current of the welding machine, materials can be saved, and the production efficiency is improved.

Owner:施生面

Soldering paste preparation and canning process for Micro Led

InactiveCN113478124AImprove welding effectReduce ingredient usageWelding/cutting media/materialsLiquid materialEconomic benefitsAlloy

The invention provides a solder paste preparation and canning process for Micro Led, and relates to the technical field of solder paste. According to the preparation and canning process of the soldering paste for the Micro Led, the soldering paste is composed of alloy tin powder and scaling powder, the weight percentage of the alloy tin powder is 89%-91%, the weight percentage of the scaling powder is 9%-11%, and the alloy tin powder comprises the following components in parts by weight: 35%-55% of tin powder, 35%-65% of lead powder, 1%-10% of bismuth powder and 0.5%-2% of reinforcing metal. According to the soldering paste preparation and canning process for Micro Led, the formula design is unique and reasonable, the components and the proportion of the soldering powder and the soldering flux are optimized, the welding effect of the soldering paste can be effectively improved, compared with common alloy soldering powder Sn63Pb37, the component dosage of tin is reduced, the production cost of the soldering paste is reduced, the packaging cost of an LED product is reduced, and the economic benefit of soldering paste production is improved.

Owner:烟台固邦新材料有限公司

Boiler Waste Heat Recovery System with Vertical Low Resistance Cooling System

ActiveCN106224932BAvoid cloggingIncrease contact heat transfer areaEnergy industryIncreasing energy efficiencyHigh densityEngineering

The invention discloses a boiler afterheat recovery system with a vertical low-resistance cooling system. The boiler afterheat recovery system comprises a boiler, afterheat recovery equipment, a smoke treatment device and a steam tank; the afterheat recovery equipment includes a heat exchange module, a first heat exchange pipe, a second heat exchange pipe and a heat exchange water tank; a first circulating pump is arranged between the heat exchange module and the first heat exchange pipe; the heat exchange module, the first heat exchange pipe and the first circulating pump form a refrigerant circulating loop; a first induced draft fan is arranged between a cyclone dust remover and the second heat exchange pipe; an intake pipe of the cyclone dust remover is communicated with a smoke outlet of the boiler; an exhaust pipe of the cyclone dust remover is communicated with an intake port of the second heat exchange pipe through the first induced draft fan; an exhaust port of the second heat exchange pipe is connected with the smoke treatment device by a second induced draft fan; multiple layers and multiple rows of high-density linear bent heat exchange pieces are arranged on the surface of the middle part of the second heat exchange pipe; the smoke treatment device comprises a filter chamber; a spraying device is arranged on the middle inner wall; and a settling pool is arranged at the lower end. The boiler afterheat recovery system is better in heat exchange effect, higher in afterheat recovery rate and more environment-friendly.

Owner:SUZHOU BSE AIR CONDITIONER

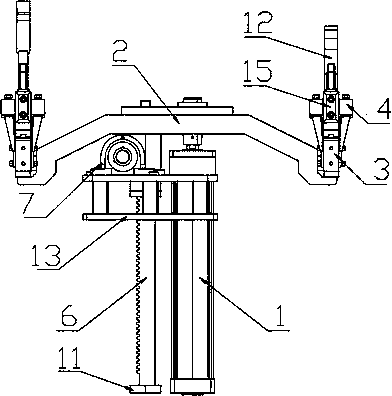

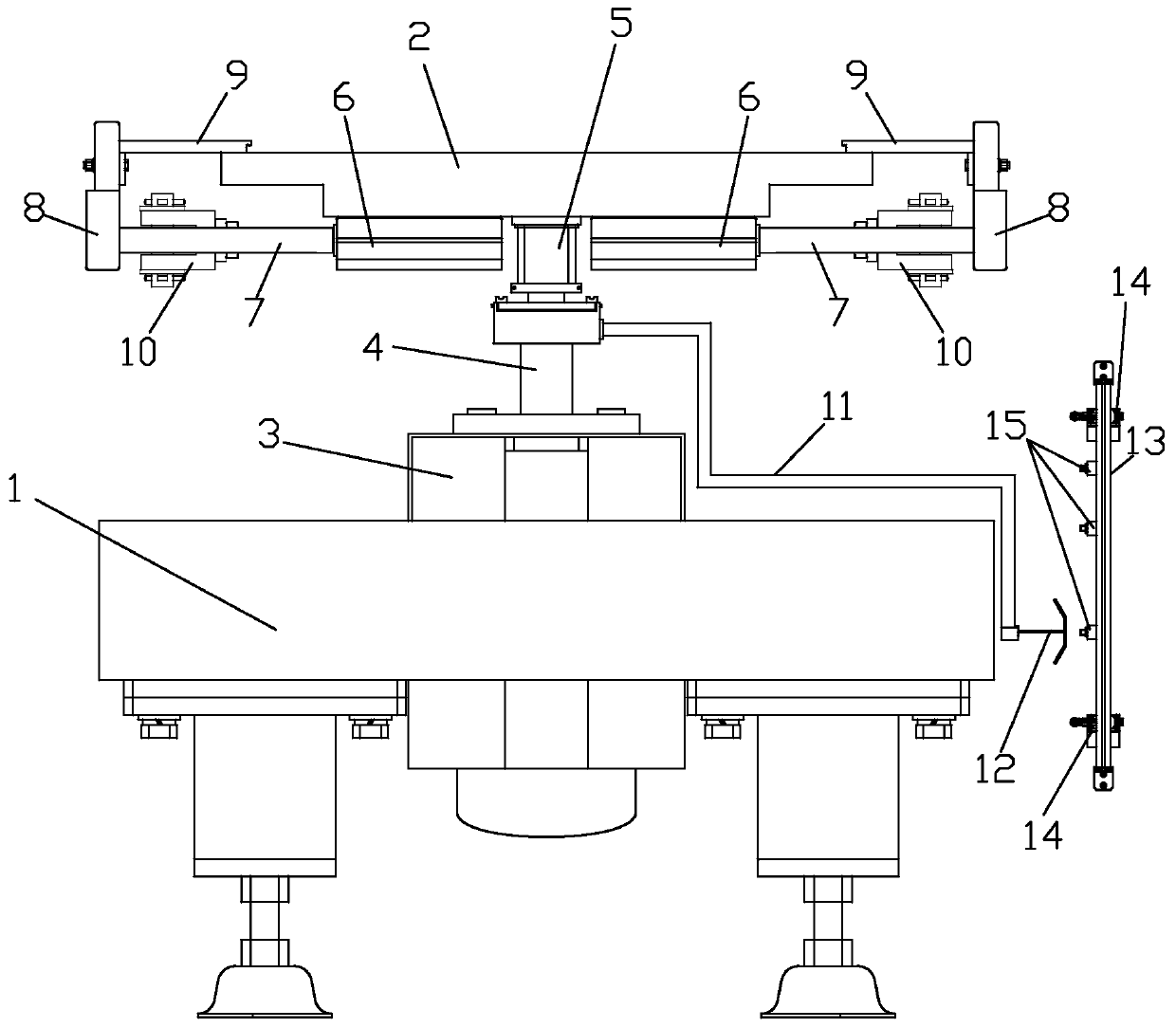

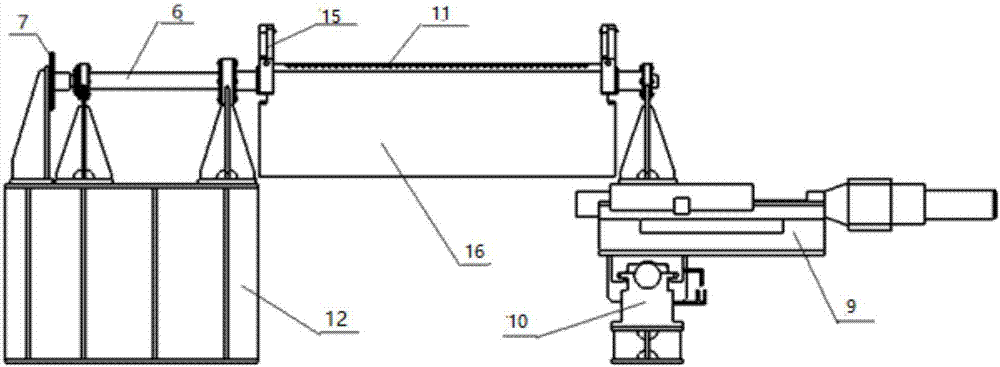

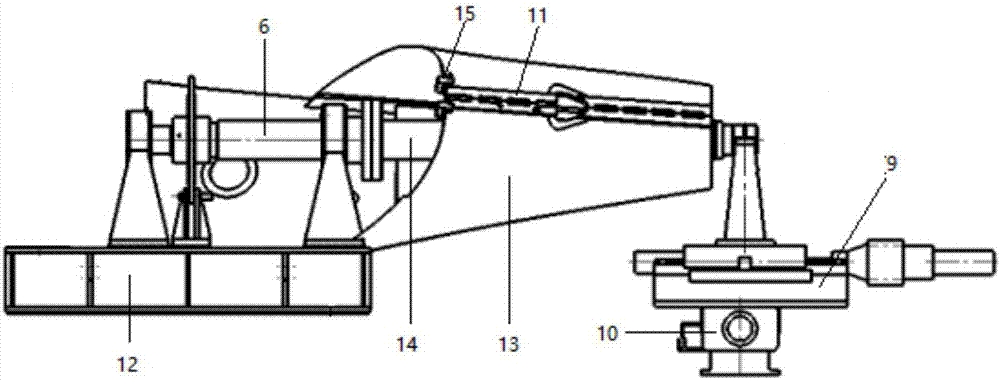

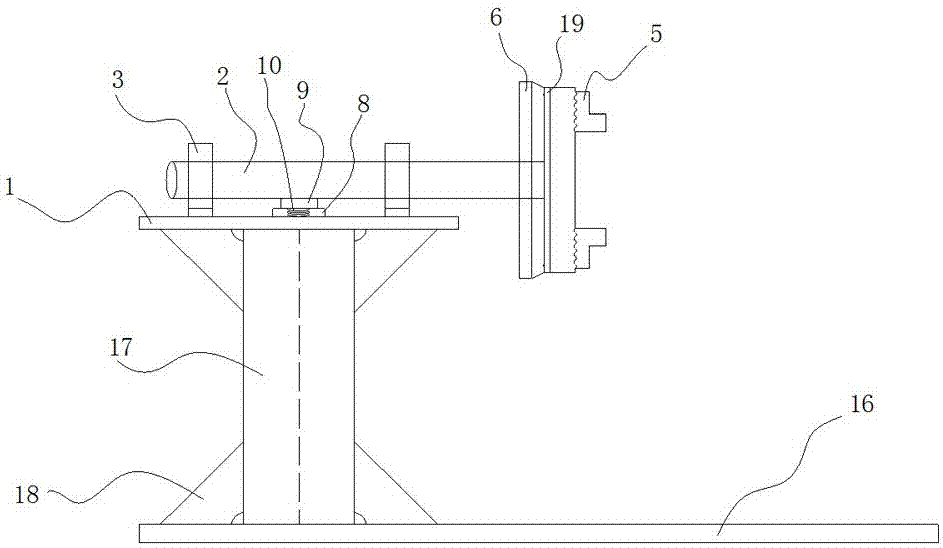

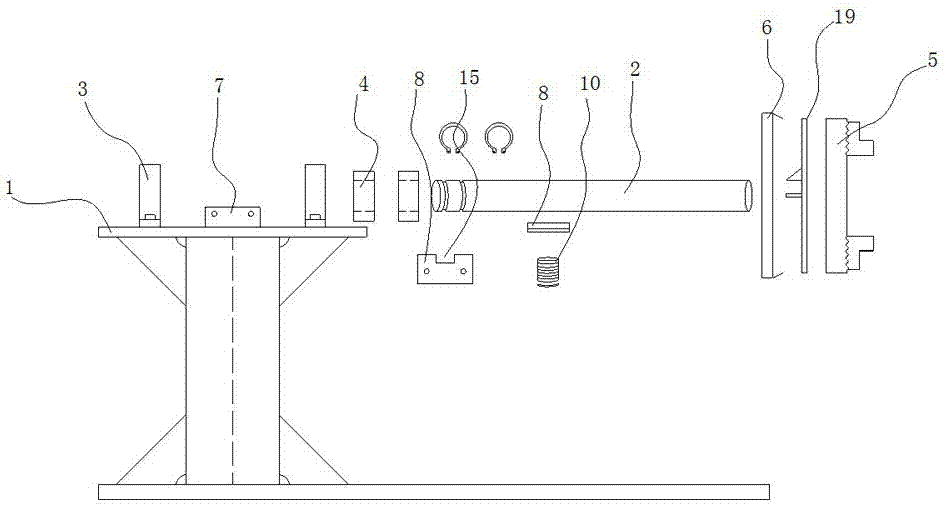

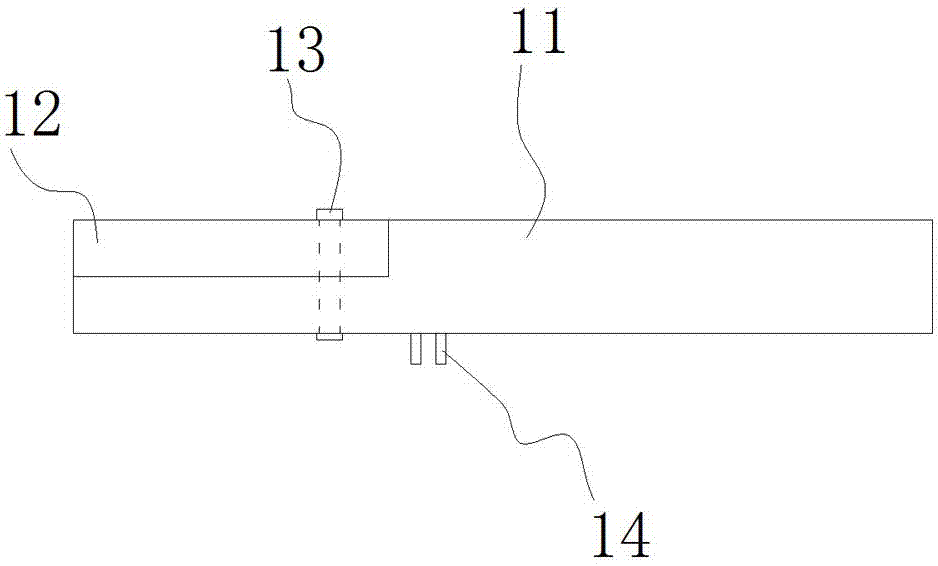

Circular pipe butt joint welding test rotating device and operation method thereof

ActiveCN107030443ACompact structureImprove welding processWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention relates to a test rotating device, in particular to a circular pipe butt joint welding test rotating device and an operation method thereof, and belongs to the field of steel structures. The device comprises a base module and an operation platform module; and the operation platform module is arranged at the upper part of the base module. The circular pipe butt joint welding test rotating device and the operation method thereof are compact in structure, and further improve the welding process through simulation assessment.

Owner:浙江东南网架股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com