Supporting and protecting pile and composed supporting and protecting row pile

A technology for supporting piles and pile bodies, which is used in foundation structure engineering, excavation, construction, etc., can solve the problem of poor force uniformity, poor water stop effect between piles, and poor compactness of concrete piles. Ideal and other problems, to achieve good water-stop effect, ideal pile body stability, good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

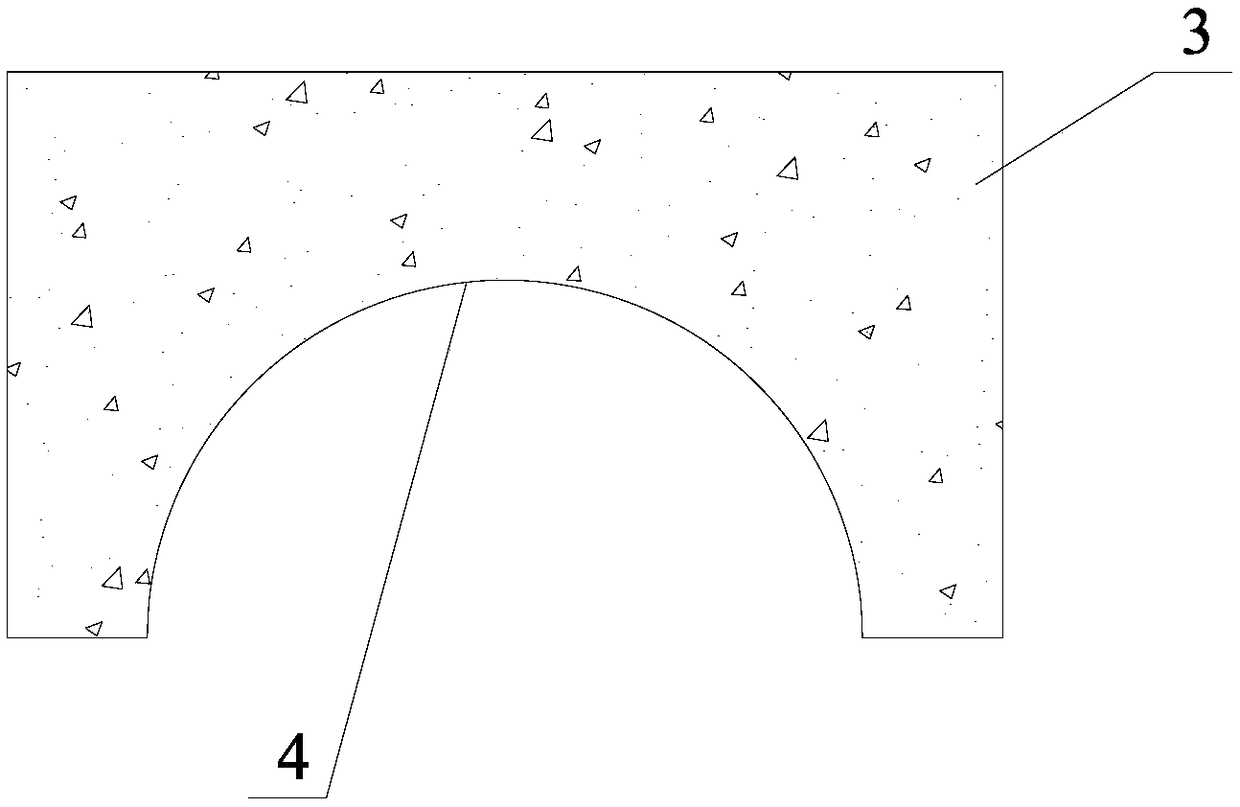

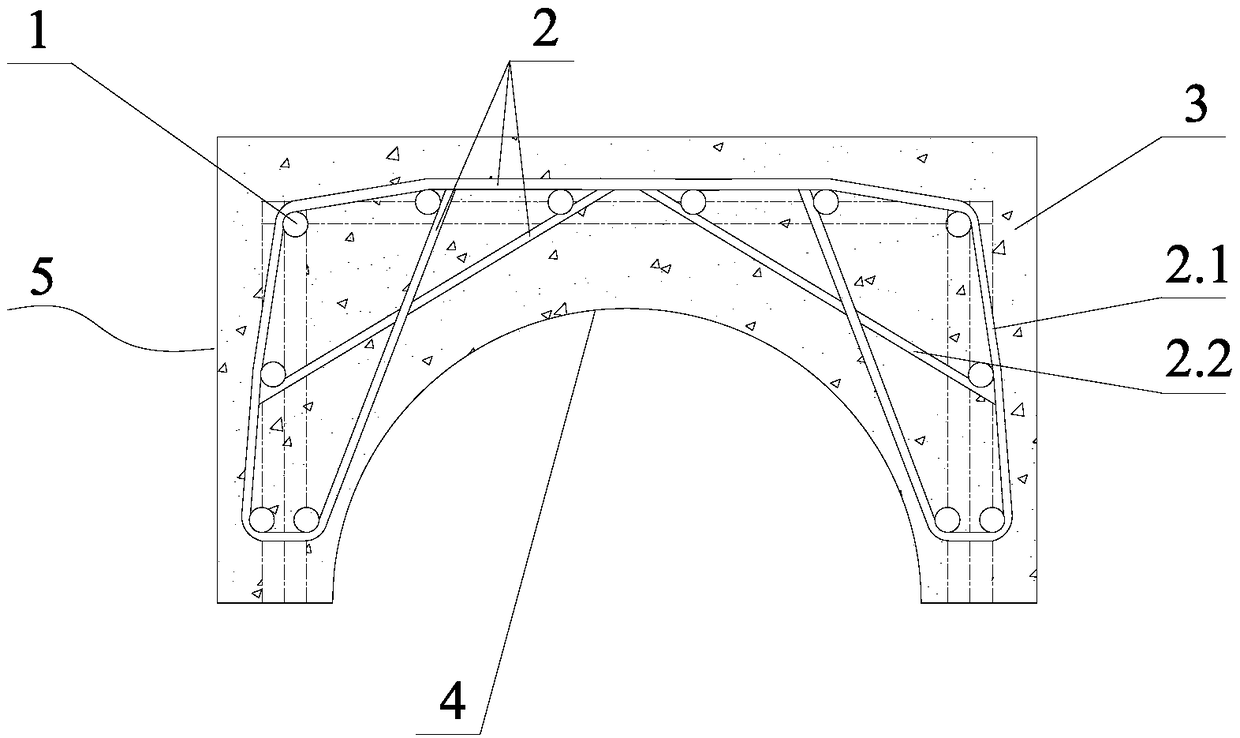

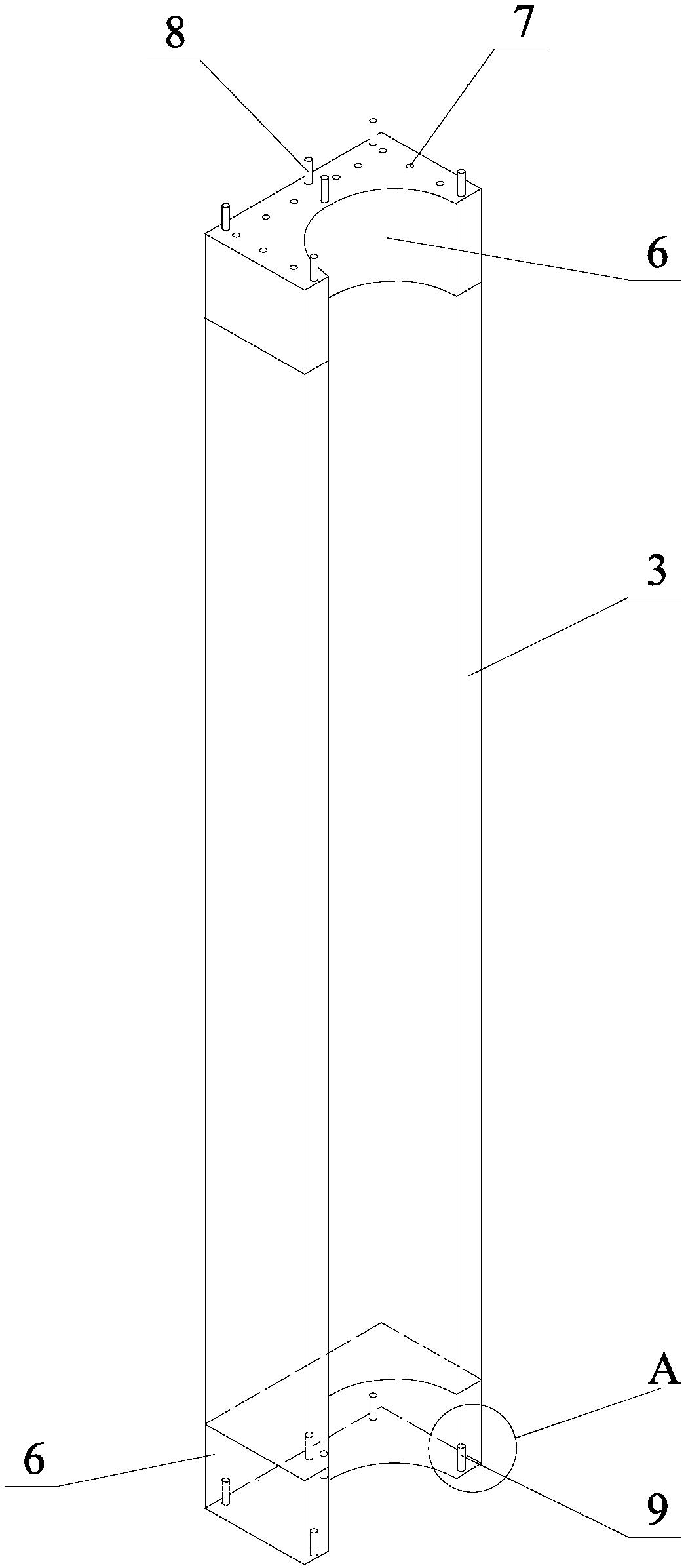

[0028] The supporting pile of the present invention includes a precast concrete pile body 3 with a steel cage composed of a plurality of vertical prestressed steel bars 1 and a plurality of transverse stirrups 2. The cross section of the pile body 3 is a rectangle 5 with a first semicircular groove 4 on one side, which can be called a half square pile or a saddle pile. Each transverse stirrup 2 includes a transverse reinforcement 2.1 that is fixed, such as welded or tied, on the outside of a number of vertical prestressed reinforcements 1. Both ends of the transverse reinforcement 2.1 are respectively bypassed and fixed, such as welded or tied, in the first semicircular recess The vertical pre-stressed steel bar 1 at the edge of the groove and the end of the vertical pre-stressed steel bar 1 are respectively fixed, such as welded or tied, to a vertical pre-stressed steel bar 1 at the bottom of the first semicircular groove. The transverse stirrup 2 also includes two reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com