Method for improving welding performance of direct-current relay

A DC relay and welding performance technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of increased current consumption, low heat transfer efficiency, and slow production cycle, so as to promote welding process, Effect of improving heat transfer efficiency and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

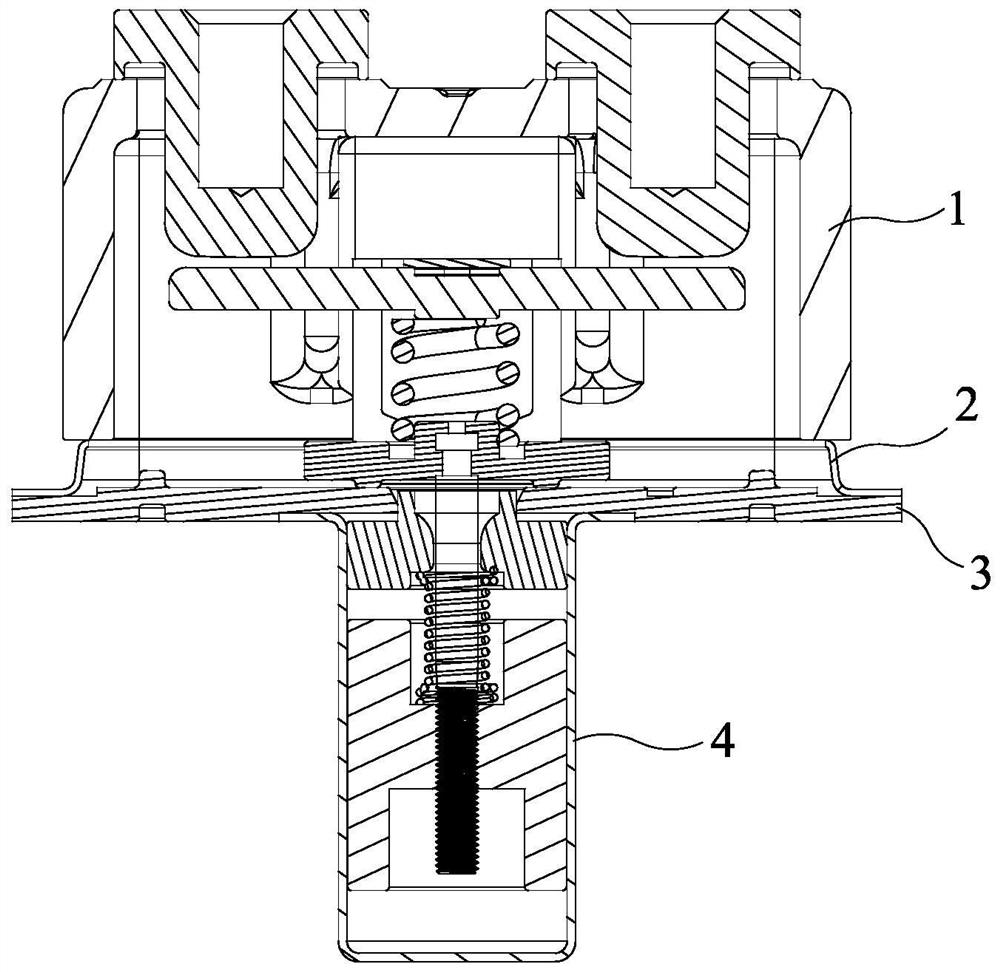

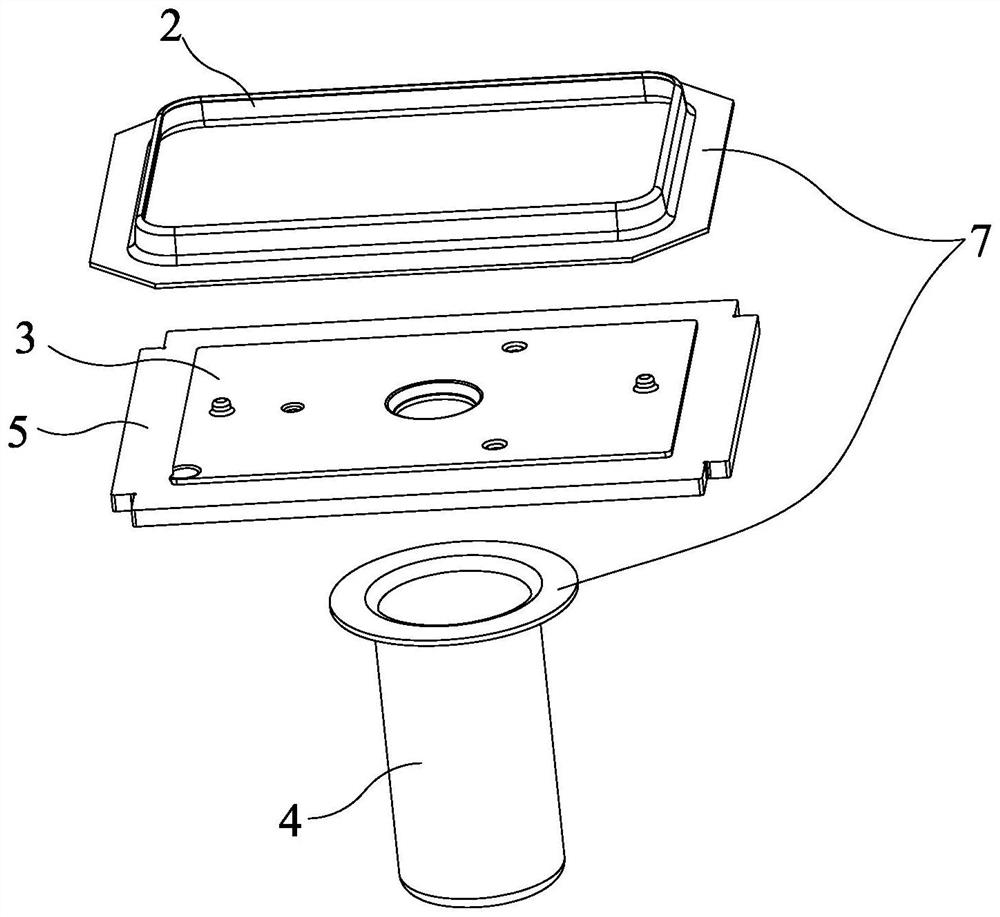

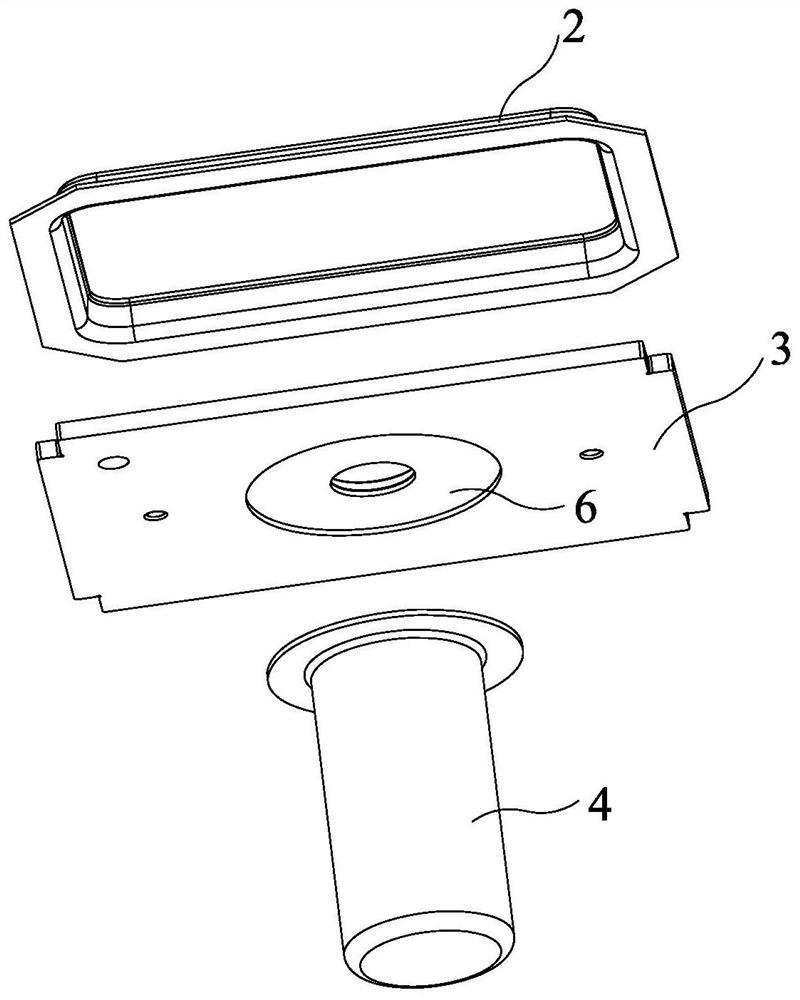

[0025] Such as figure 1 As shown, the present invention provides a method for improving the welding performance of a DC relay, involving a ceramic cover assembly 1, a frame piece 2, a lower yoke plate 3 and a metal shell 4, such as figure 2 As shown, the thickness of one side of the lower yoke plate 3 is reduced at the connection position relative to the frame piece 2 to form a first sinker 5. The shape of the first sinker 5 is the same as that of the connection point of the frame piece 2, which can be Square, circular, or other shapes, the frame piece 2 and the metal shell 4 each form an outward flange 7 at the joint to be welded. For the frame piece 2, the flange of the frame piece 2 is square , so the shape of the first sinking groove 5 corresponds to a square, and the first sinking groove 5 is located at the edge of the lower yoke plate 3, and the frame piece 2 is fitted into the first sinking groove 5 and welded; as image 3 As shown, the thickness of the other side of ...

Embodiment 2

[0031] Such as Figure 4 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the first sinking groove 5 is located in the middle of the lower yoke plate 3 instead of the edge, so that the outer circumference of the joint of the frame piece 2 is more A limiting edge is provided so that the joint of the frame piece 2 can be completely embedded in the first sinking groove 5, which is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com