Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Compact package" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

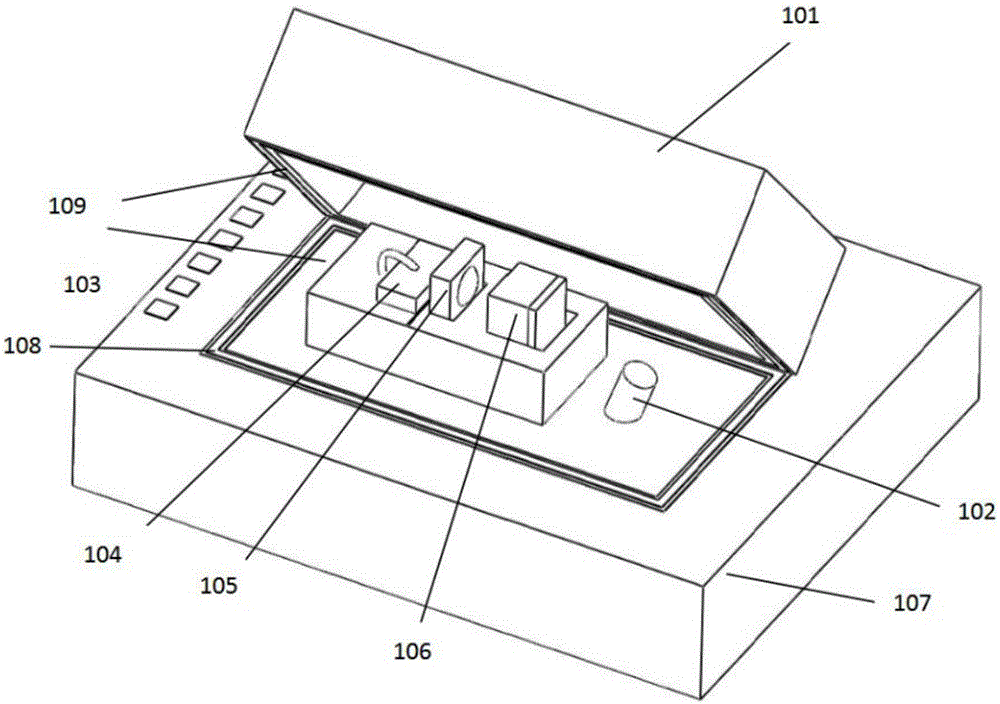

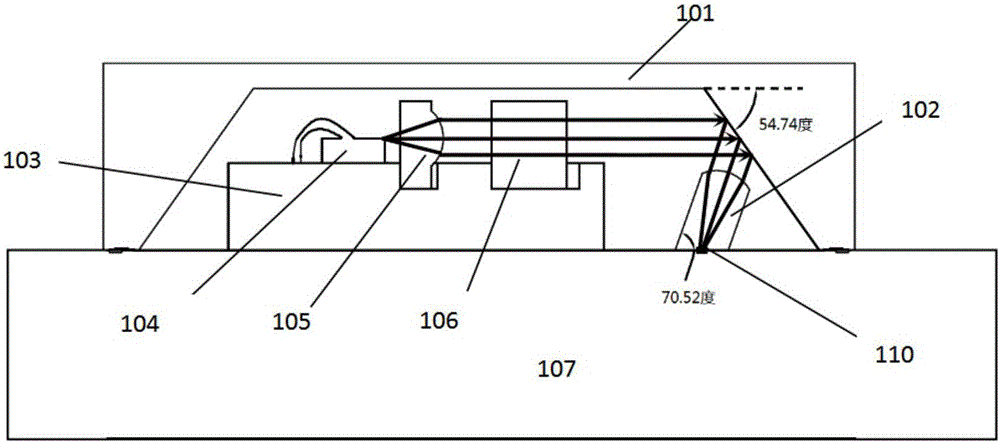

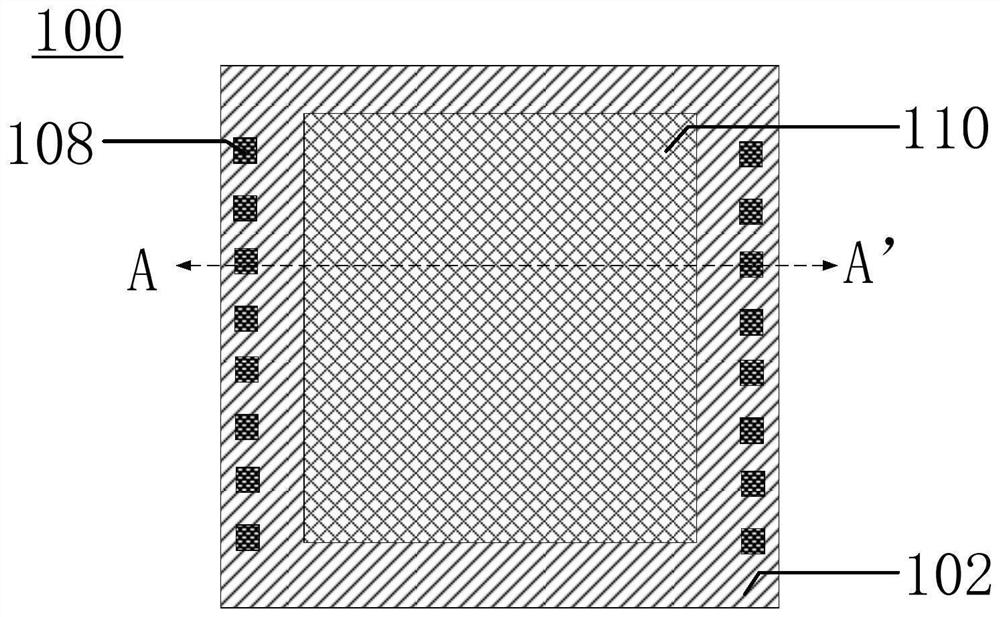

Light source packaging structure, and positioning and coupling method thereof

ActiveCN106019496AExtended service lifeInsulate from moistureCoupling light guidesPosition toleranceGrating

The invention provides a light source packaging structure, and a positioning and coupling method thereof. The light source packaging structure comprises a sealing box cover (101), a C lens (102), a silicon based heat sink (103), a laser chip (104), an isolator assembly (106), and a silicon light chip (107). The laser chip (104), a collimating lens (105), and the isolator assembly (106) are sequentially disposed on the silicon based heat sink (103). The C lens (102) is aligned with the grating coupler (110) of the silicon light chip (107) in a fixed and coupled manner. The sealed box cover (101) is provided with an inclined inner wall used to reflect light emitted by the laser chip (104) to the C lens, and the lower surface of the C lens (102) is provided with a polishing surface matched with the incident angle of the reflected light. The side of the C lens (102) inclined toward the direction away from the silicon based heat sink (103), and the optical axis of the C lens (102) is consistent with the transmission direction of the light, and the main light is superposed with the optical axis. A coupling structure is compact, and position tolerance is large.

Owner:GUANGXUN SCI & TECH WUHAN

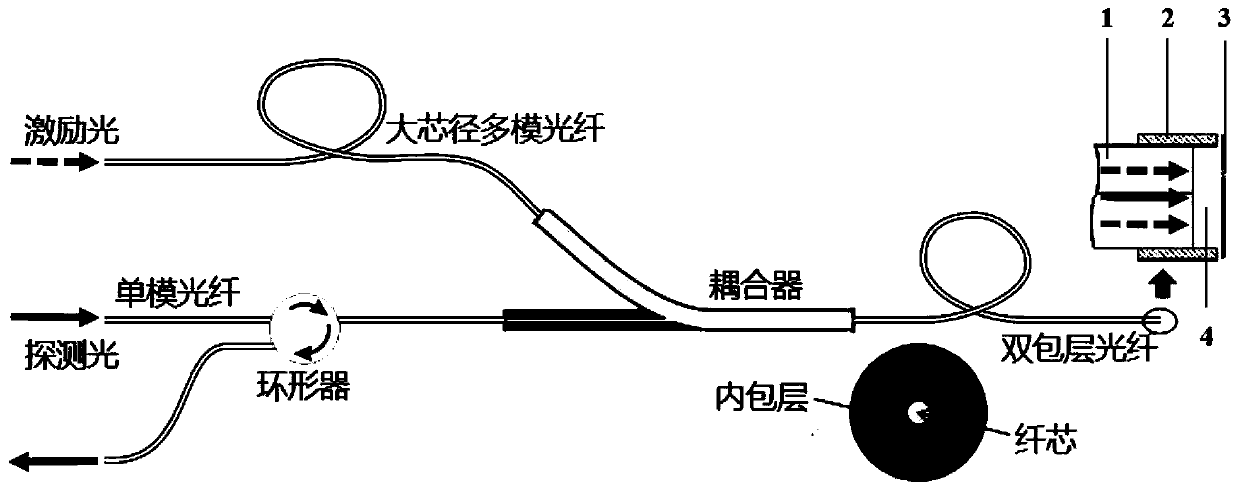

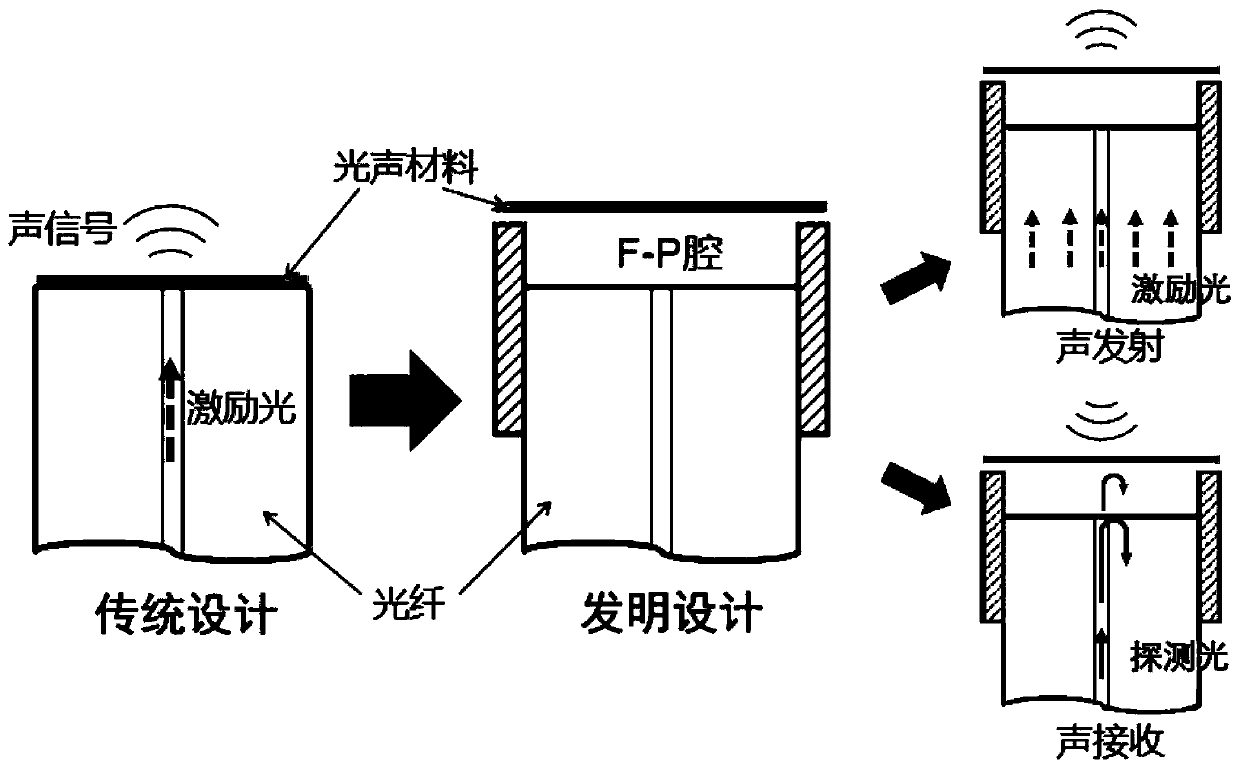

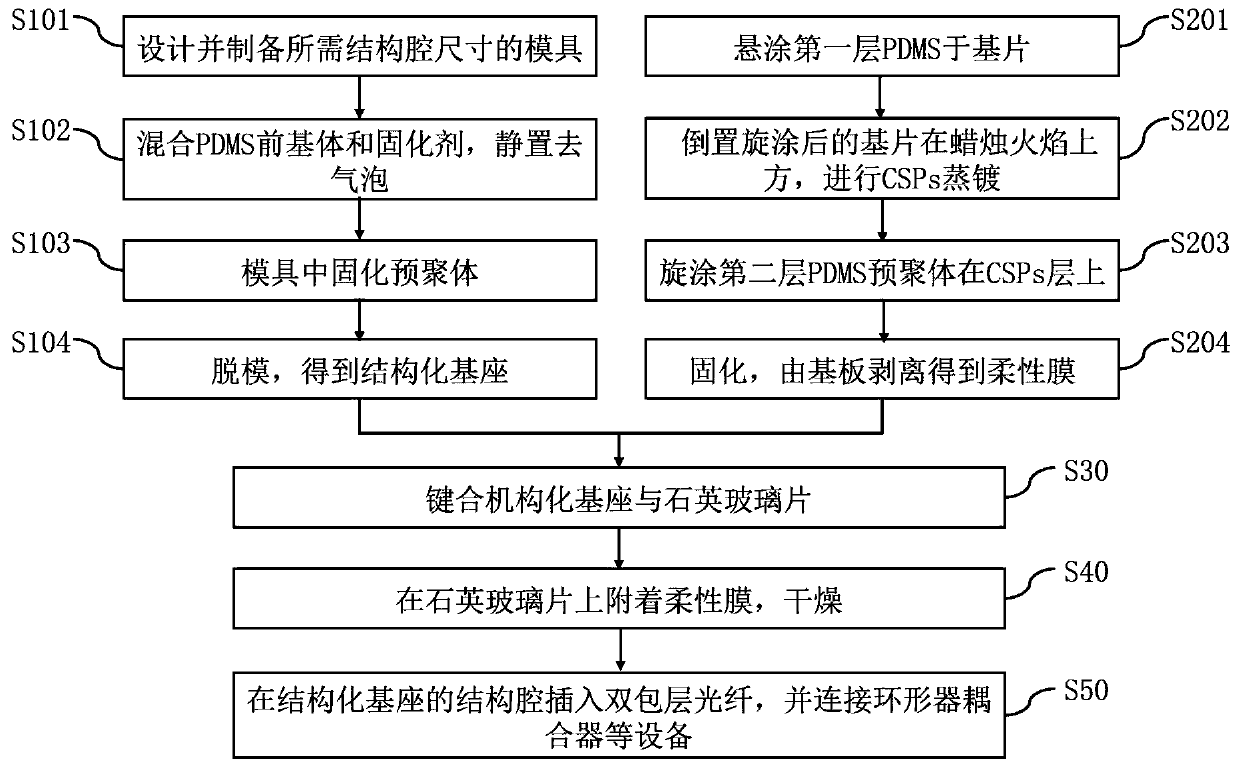

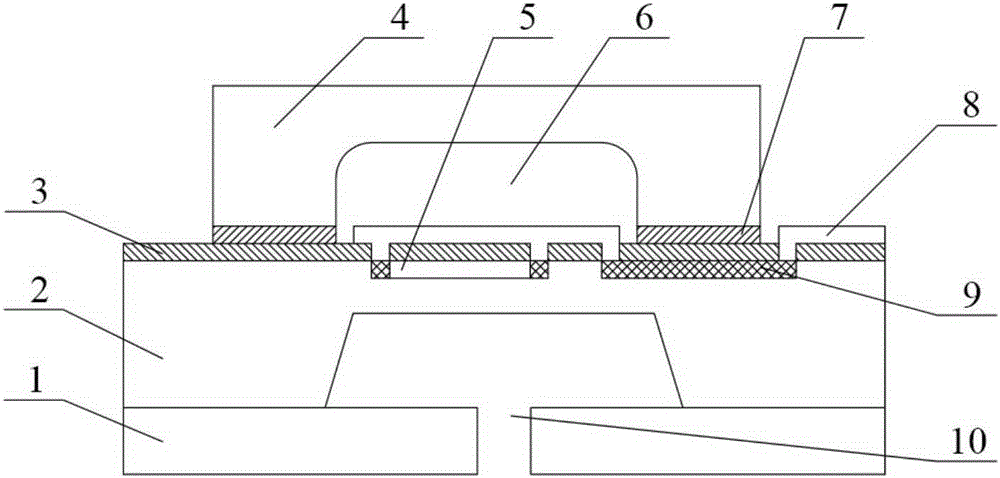

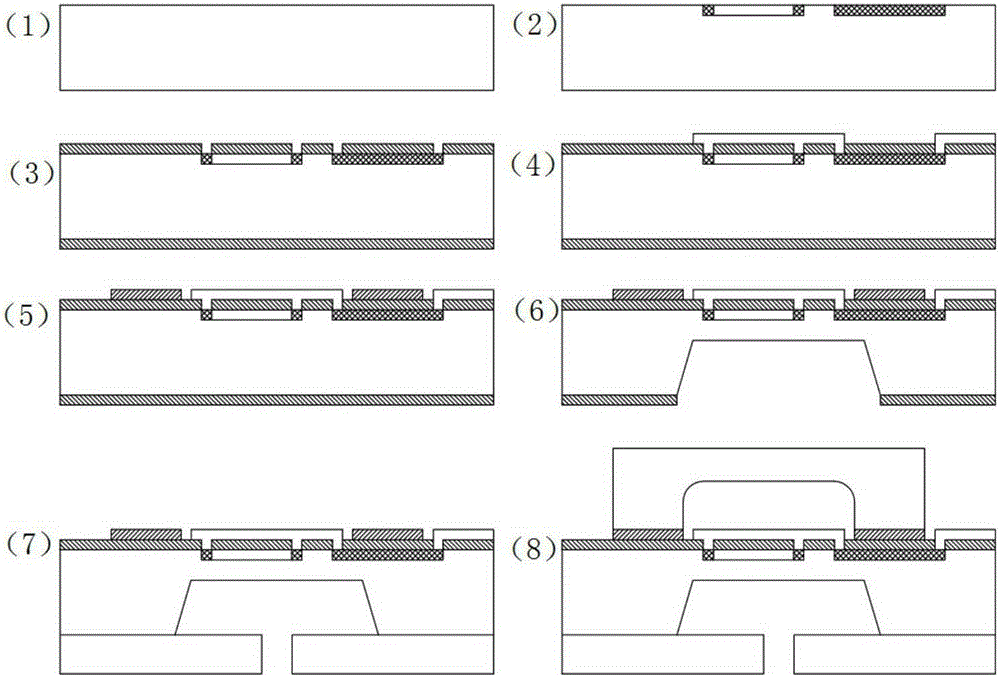

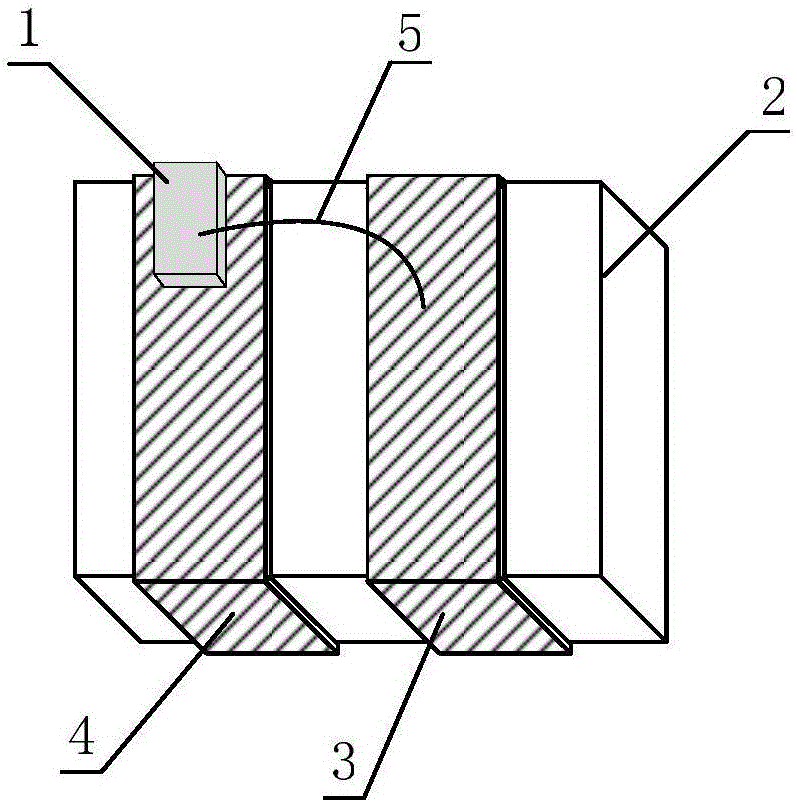

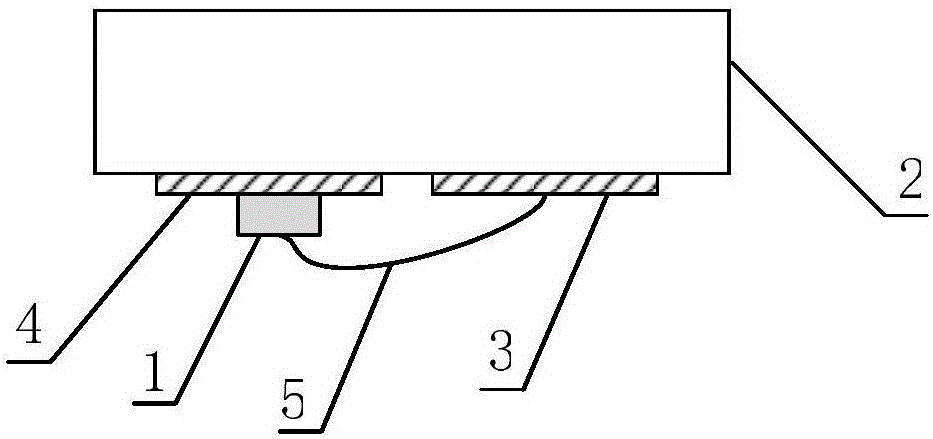

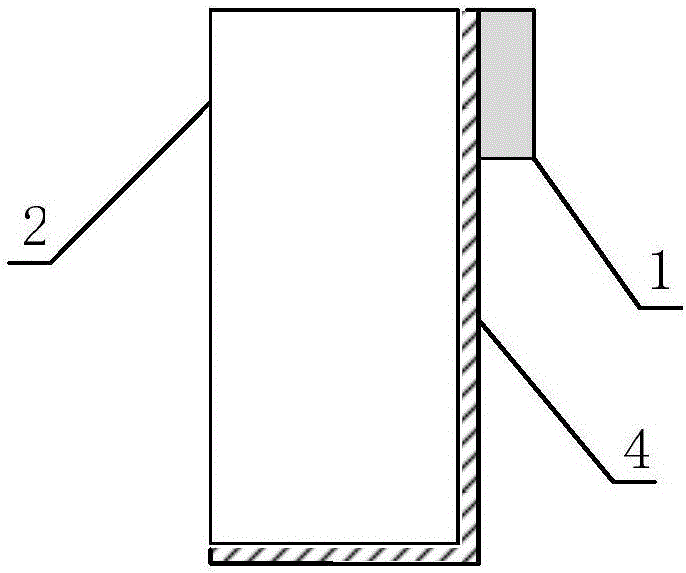

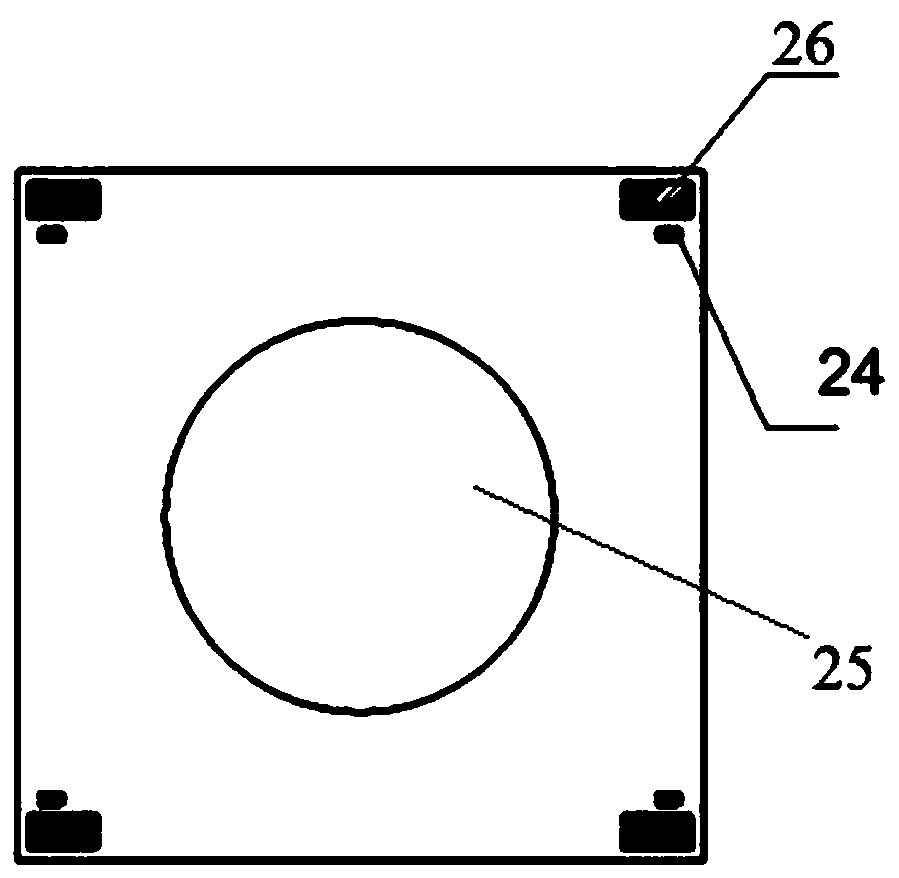

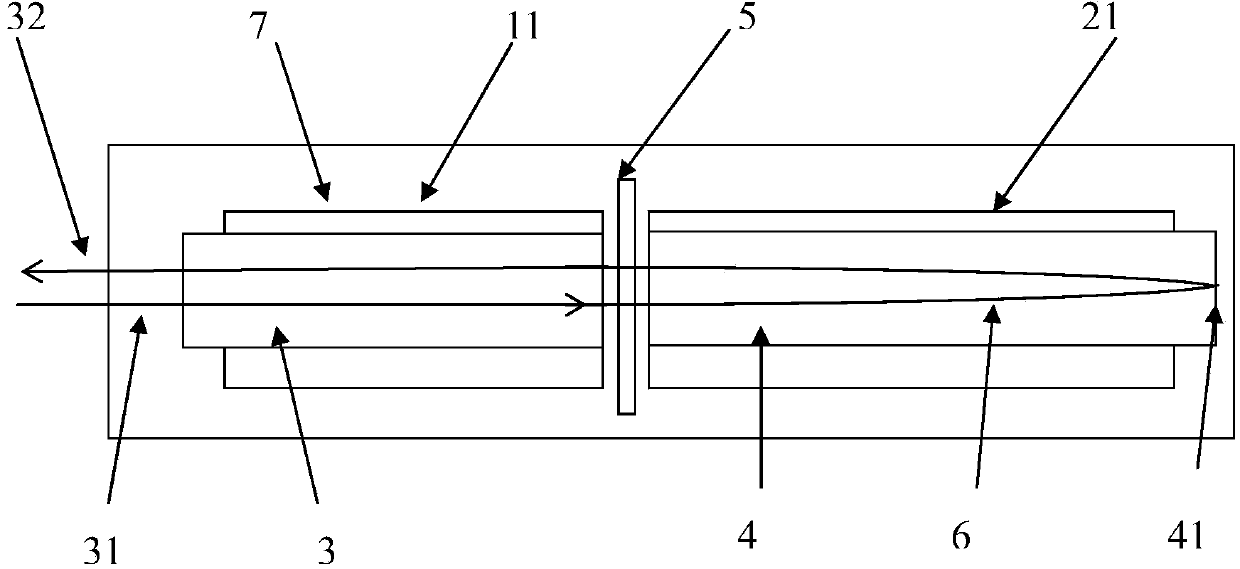

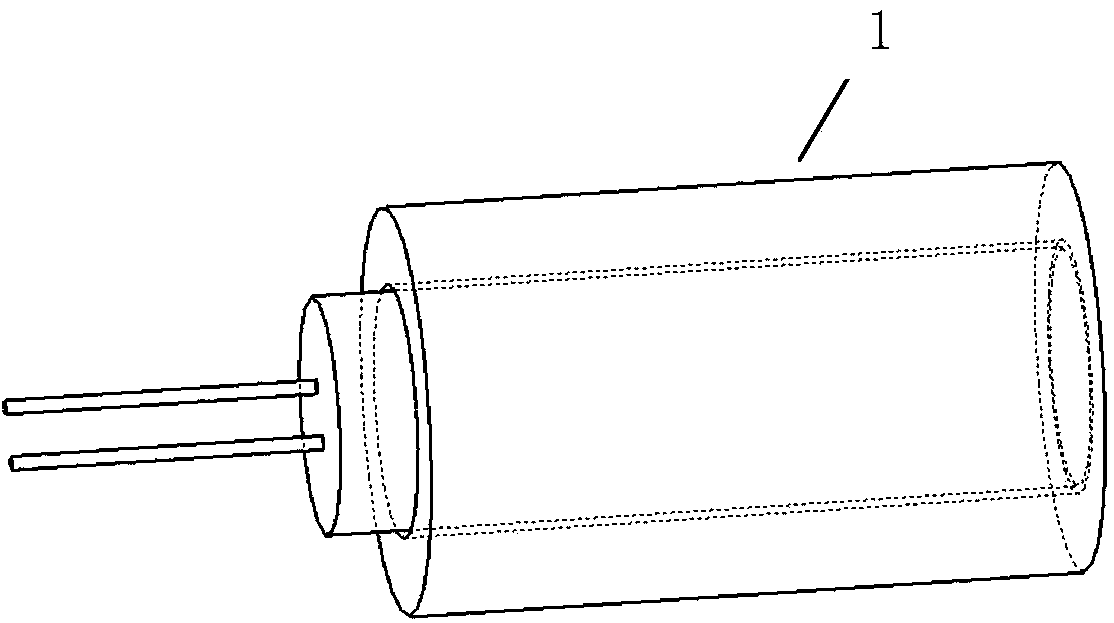

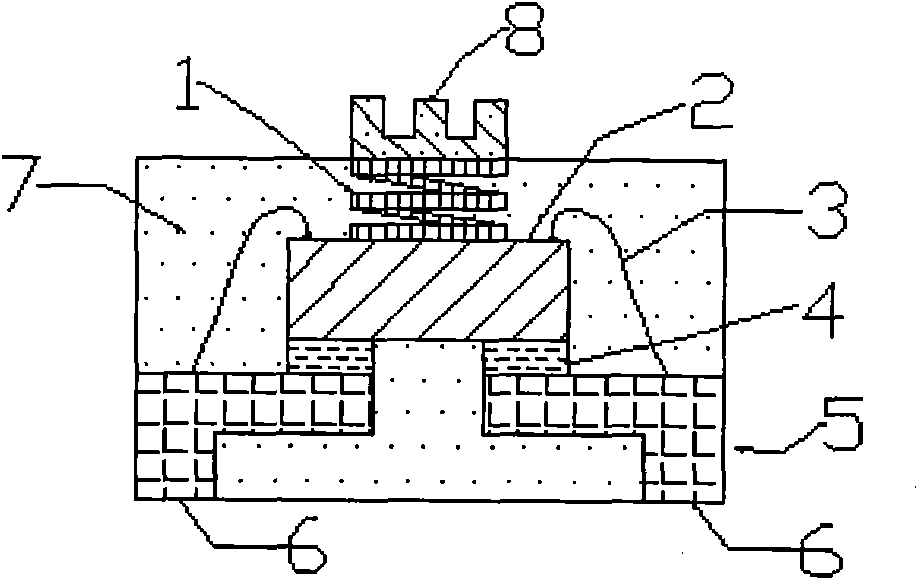

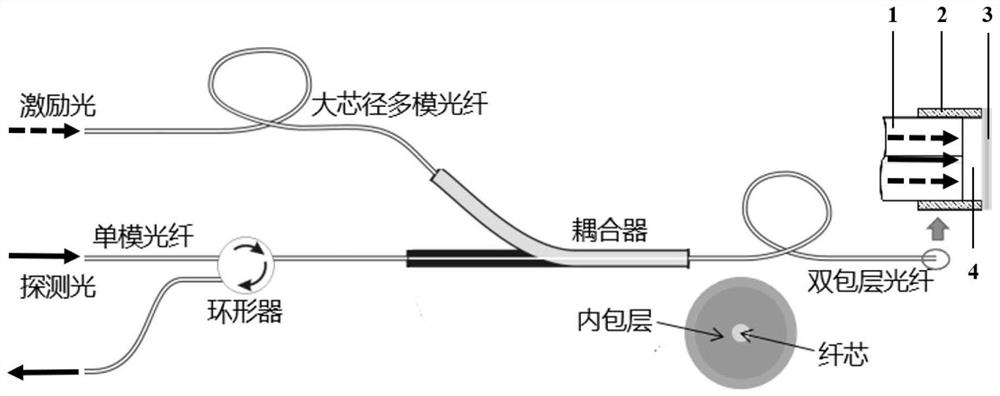

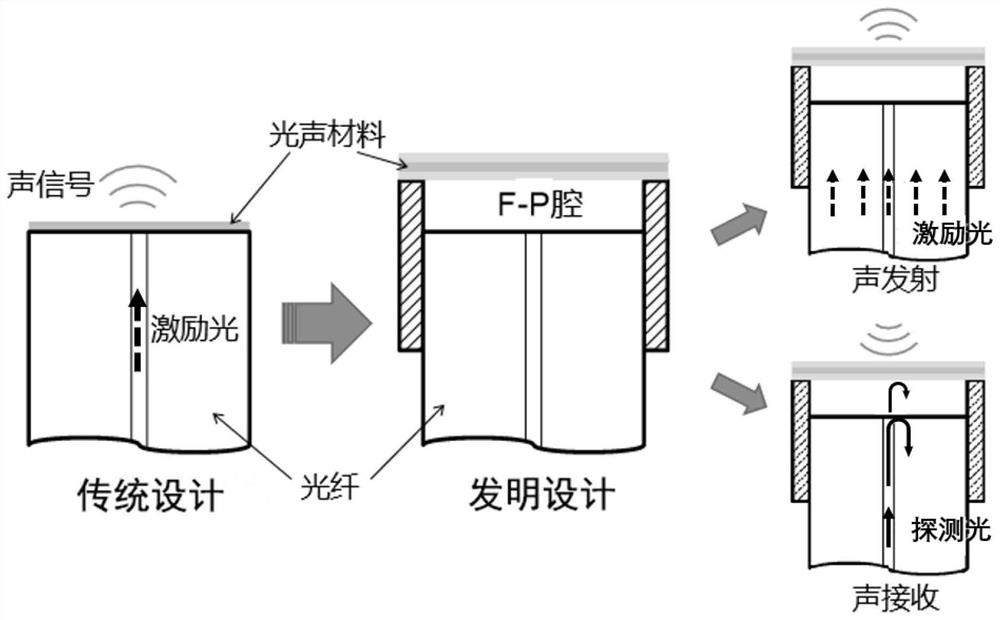

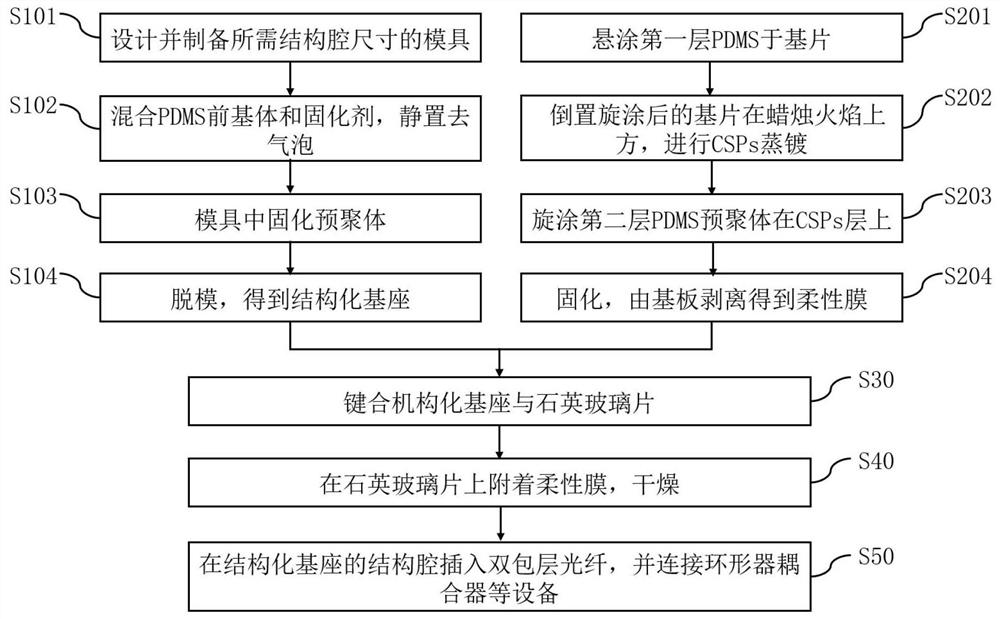

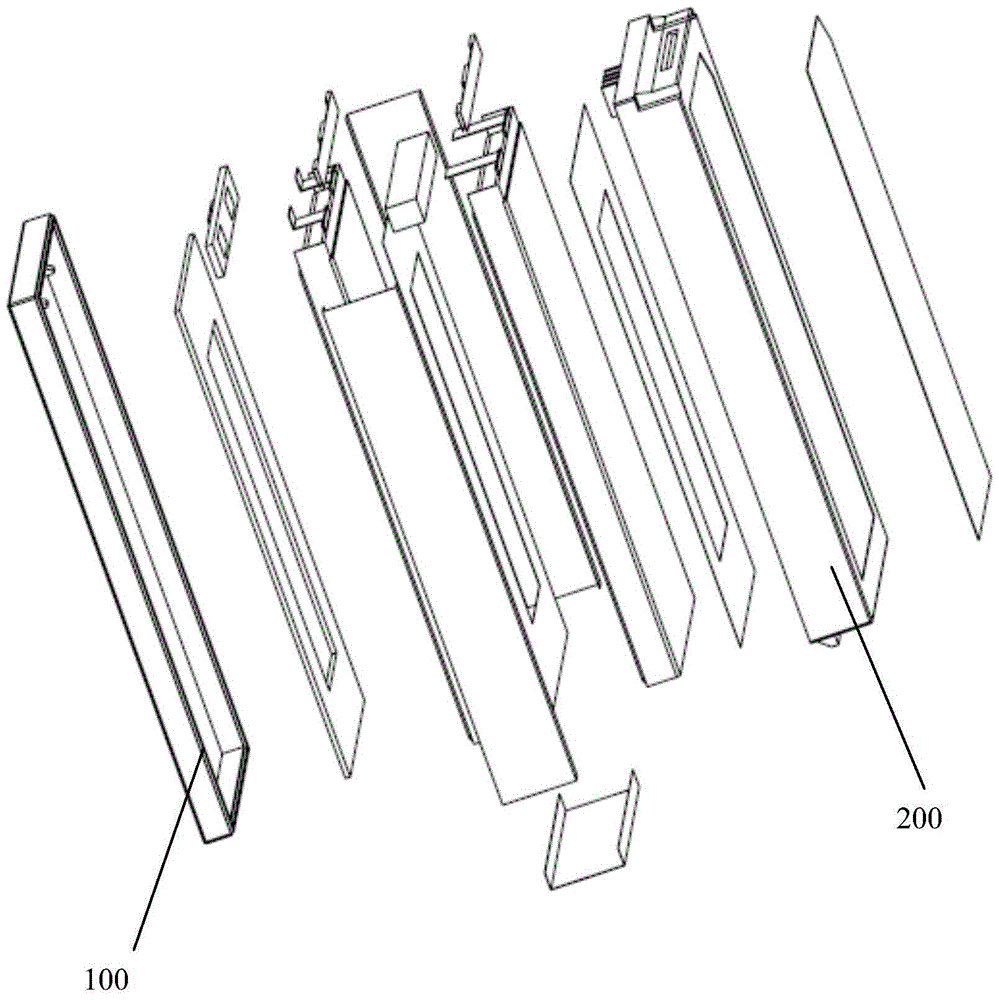

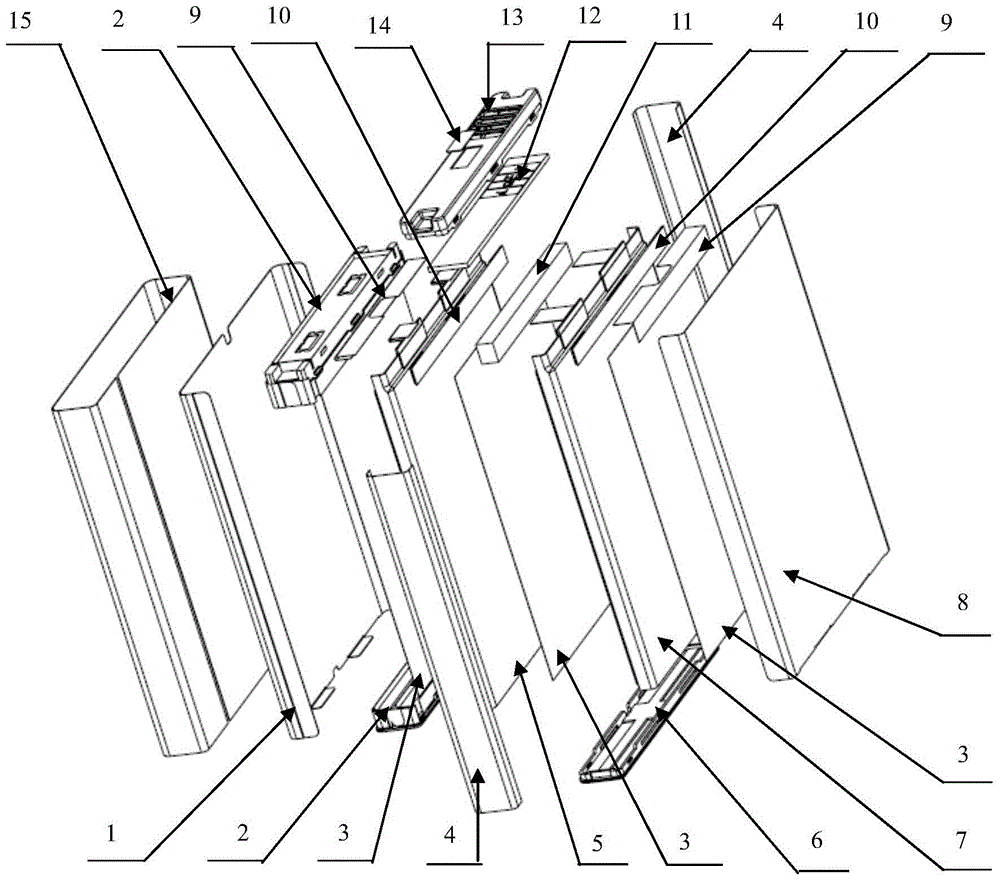

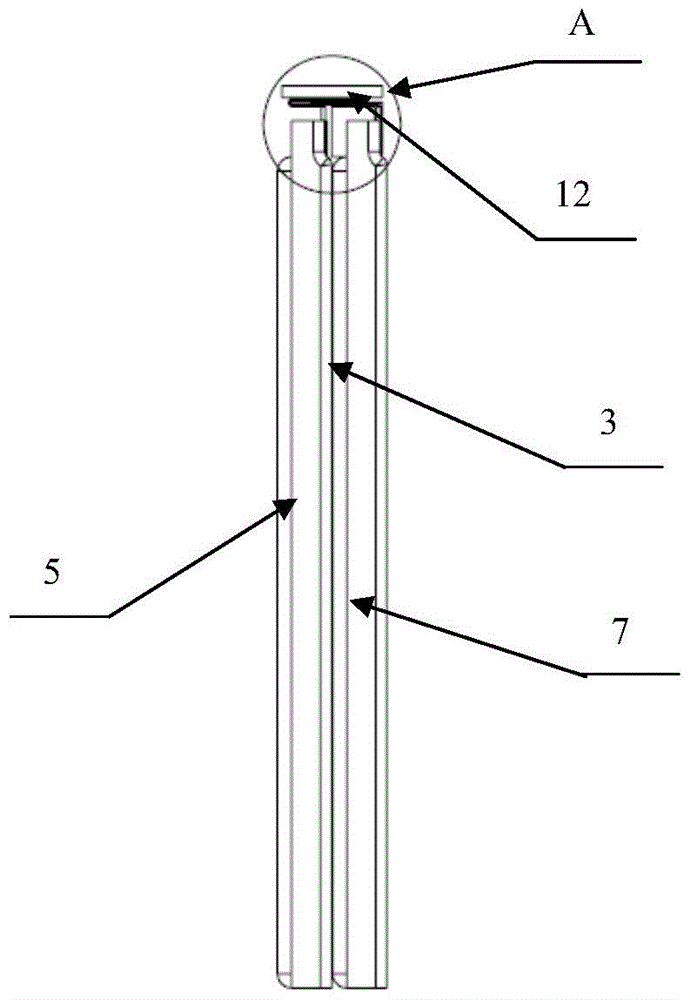

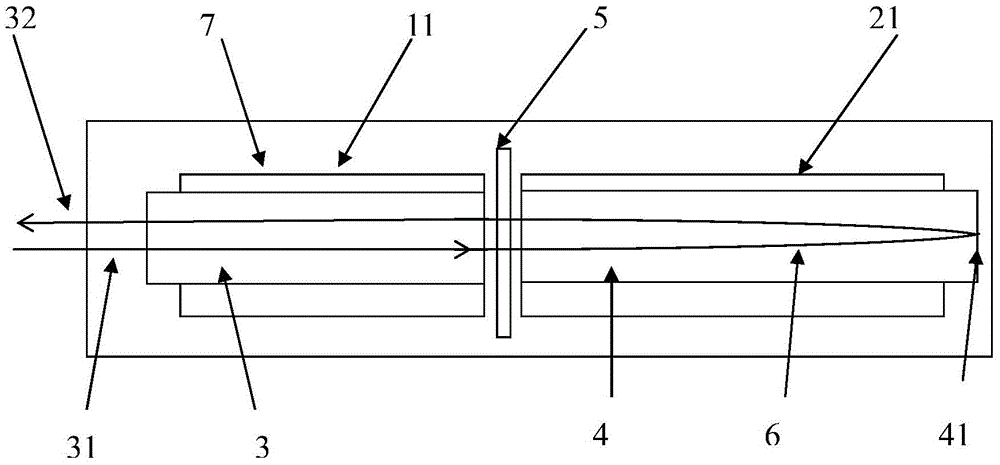

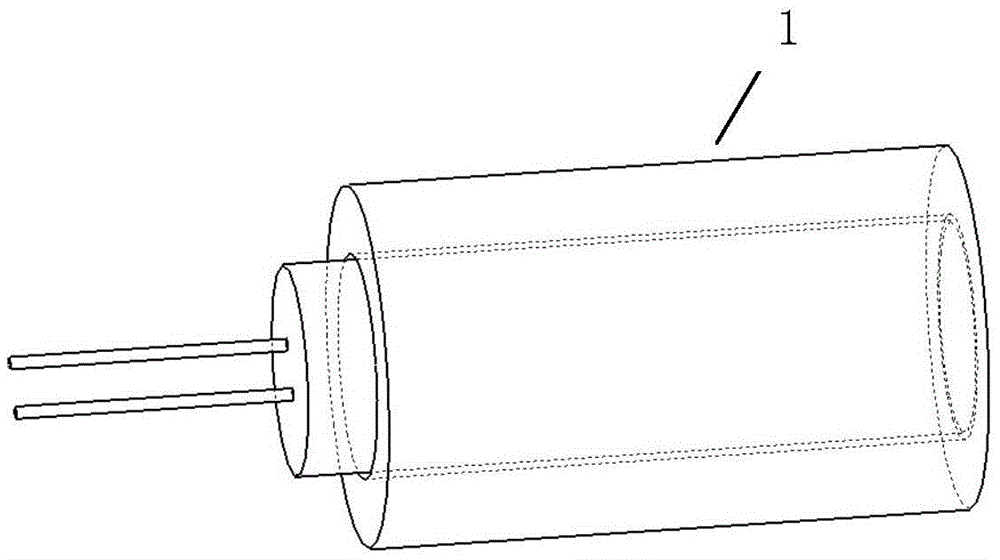

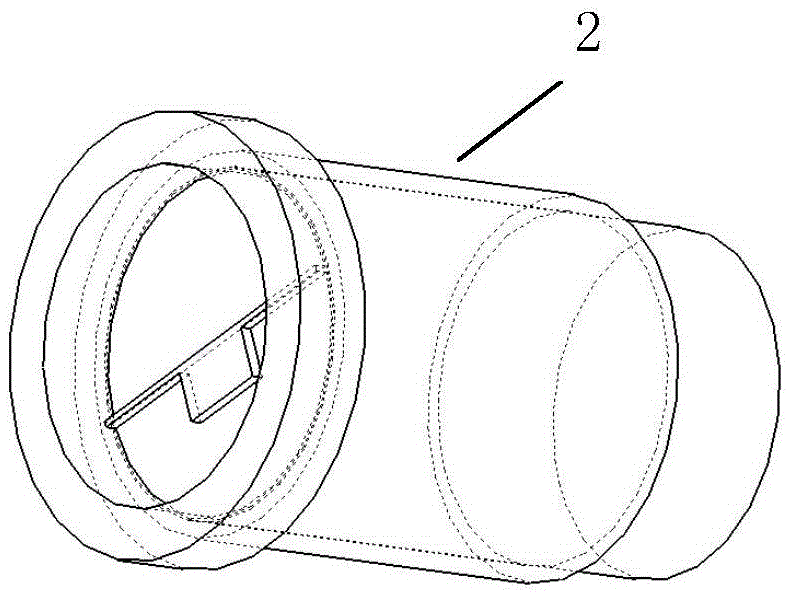

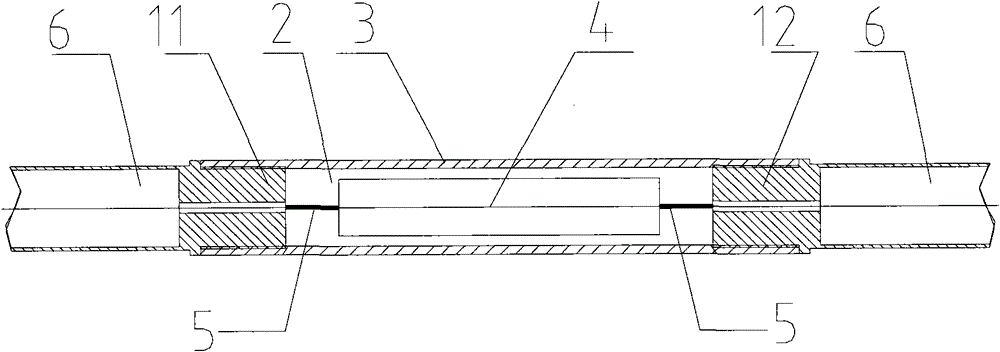

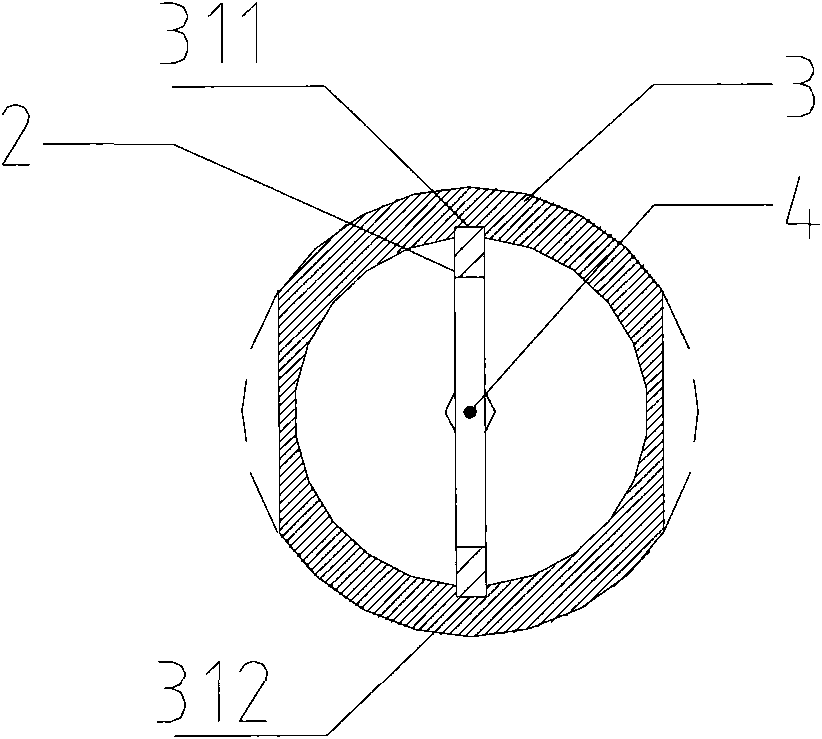

Transceiving integrated all-optical ultrasonic transducer device and preparation method thereof

ActiveCN111112035ACompact packageSimple signal processingMechanical vibrations separationDouble-clad fiberTransducer

The invention belongs to the technical field of photoacoustic detection, and discloses a transceiving integrated all-optical ultrasonic transducer device and a preparation method thereof. The device comprises a structured base (2), a suspension film (3), a double-clad fiber (1) and an F-P cavity (4), wherein the F-P cavity is constructed by the cooperation of the structured base, the suspension film and the double-clad fiber; the suspension film is a composite photoacoustic conversion film, laser beam energy of an excitation light can absorbed and the laser beam energy can be converted into ultrasonic waves which is emitted outwards, and transmission of sound waves are realized; and meanwhile, the ultrasonic echo can be received, acoustic wave return signals are sensed by deformation, thecavity length of the F-P cavity and the returned detection optical signals are influenced, and the returned detection optical signals are detected, so that receiving of sound waves can be realized. According to the invention, the structures of all components and the cooperation working mode of the components are improved, the whole process of ultrasonic transmission and reception can be completedon one suspension film by utilizing the suspension film and the F-P cavity which is further constructed, the device is more compact in structure, the photoacoustic imaging operation is simpler, and the result is more accurate.

Owner:HUAZHONG UNIV OF SCI & TECH

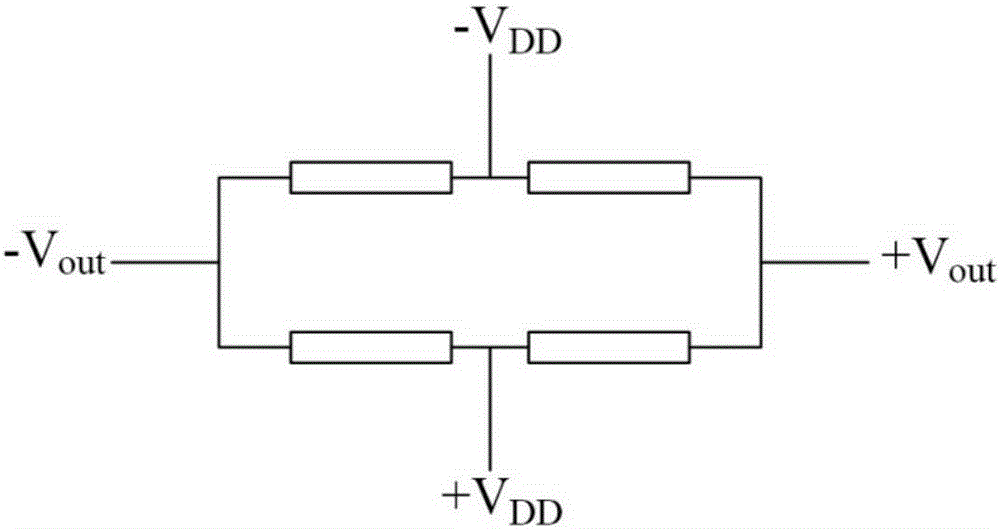

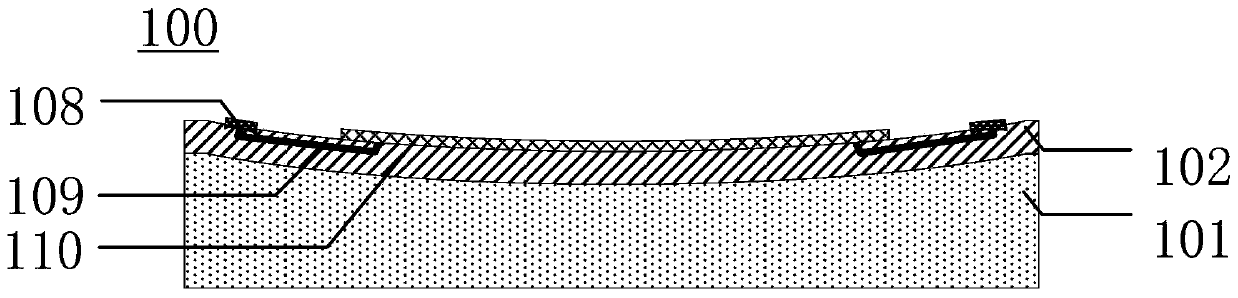

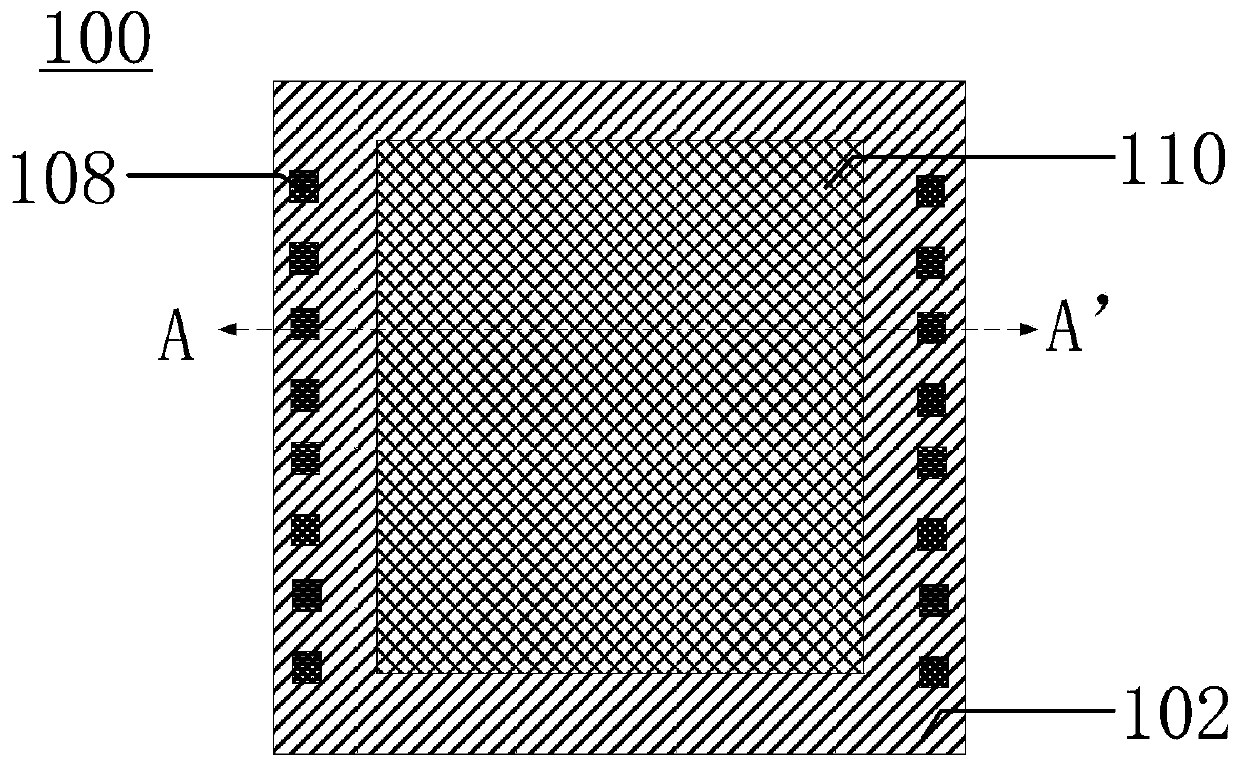

Pressure sensor of packaging structure and preparation method thereof

InactiveCN105181231APackage structure is simpleSimple preparation processFluid pressure measurement using ohmic-resistance variationFull bridgeBoron

The invention discloses a pressure sensor of a packaging structure and a preparation method thereof. A lightly boron-doped region and a heavily boron-doped region are prepared by doping on the front of a silicon wafer. A groove is arranged on the back of the silicon wafer through etching. A silicon pressure film is formed between the bottom of the groove and the lightly boron-doped region. An insulating layer is laid on the front of the silicon wafer. A metal lead is arranged on the top of the insulating layer, and is connected with the lightly boron-doped region and the heavily boron-doped region. Four piezoresistive strips are formed in the lightly boron-doped region. The piezoresistive strips and the metal lead form a Wheatstone full-bridge structure. The front of the silicon wafer is bonded to a piece of front bonding glass through a middle layer. A piece of back bonding glass is bonded to the back of the silicon wafer, and the side, directly facing the silicon pressure film, of the back bonding glass is provided with an air guide hole. The part, directly facing the silicon pressure film, of the front bonding glass is provided with a cavity. The packaging structure of the invention is simple and compact, and highly reliable. The manufacturing process is simple, wafer level packaging can be realized, and low-cost mass production is facilitated.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Ceramic packaging device of semiconductor laser

ActiveCN106300005ASmall sizeEffective cooling environmentLaser detailsSemiconductor lasersSemiconductor chipSemiconductor package

The invention discloses a ceramic packaging device of a semiconductor laser. The device comprises an L-shaped anode soldering lug, an L-shaped cathode soldering lug and a semiconductor laser chip, wherein the L-shaped anode soldering lug is attached onto two adjacent surfaces of a heat sink carrier to form an L shape; the L-shaped cathode soldering lug and the L-shaped anode soldering lug are adjacent and parallel, and are attached onto two adjacent surfaces of the heat sink carrier to form another L shape; the semiconductor laser chip is adhered onto the top of one side of the L-shaped cathode soldering lug through a soldering material, and an anode of the semiconductor laser chip is bonded to one side of the L-shaped anode soldering lug with a soldering wire; and an anode soldering pad and a cathode soldering pad, positioned on one side of the bottom surface of the heat sink carrier, of the L-shaped anode soldering lug and the L-shaped cathode soldering lug are directly welded with a circuit board. The device is applicable to packaging of pulse type semiconductor lasers with small power, the dimensions of devices can be compressed to a greater extent, and meanwhile a more effective heat dissipation environment is provided.

Owner:BEIJING SURESTAR TECH

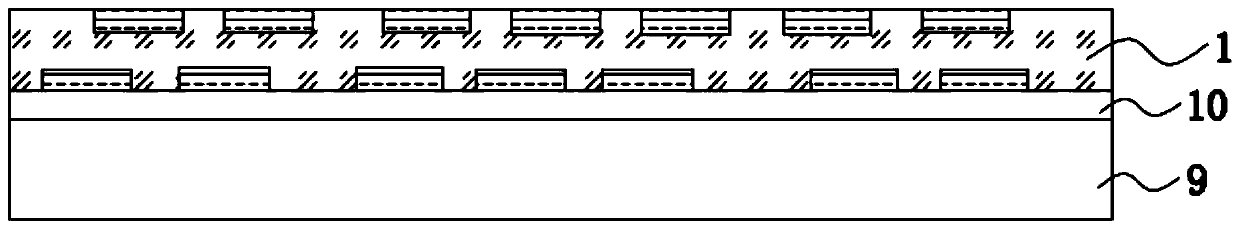

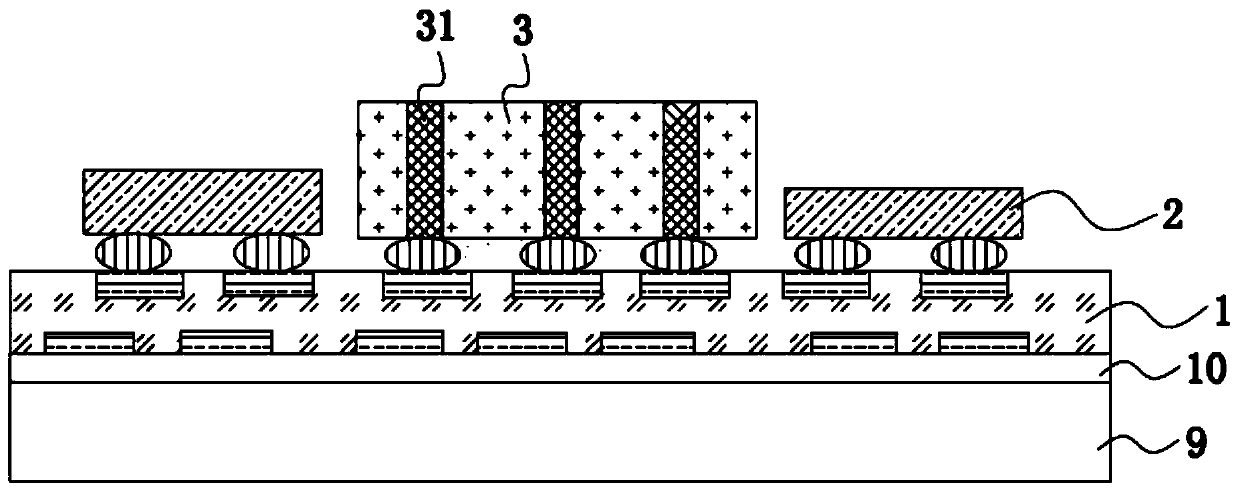

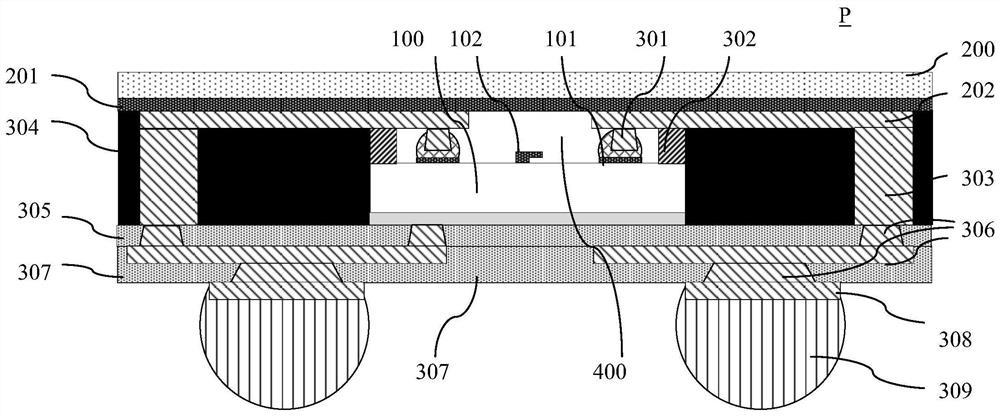

TSV-based multi-chip package structure and method for fabricating same

PendingCN110335859AExpand and diversifyPlay the role of conduction circuitSemiconductor/solid-state device detailsSolid-state devicesInterconnectionEngineering

The present invention relates to the field of chip packaging and in particular to a TSV-based multi-chip package structure and a method for fabricating the same. The multi-chip package structure comprises an interconnection structure; a first chip disposed on the interconnection structure; an adapter plate disposed on the interconnection structure at the same side as well as the first chip, and having a thickness greater than that of the first chip; a second chip disposed on the adapter plate and opposite to the interconnection structure; and a packaging layer. By means of the interconnectionstructure and the adapter plate which has a certain thickness and on which the second chip is mounted, the first chip and the second chip can be located on two planes at different heights, thereby realizing the three-dimensional package of the multiple chips. Compared with the prior art, the package structure provided by the present invention has the size sum of the first chip and the second chipno longer limited by the plan view size of the interconnection structure, thereby expanding the diversified development of the chip packaging structure.

Owner:SHANGHAI XIANFANG SEMICON CO LTD

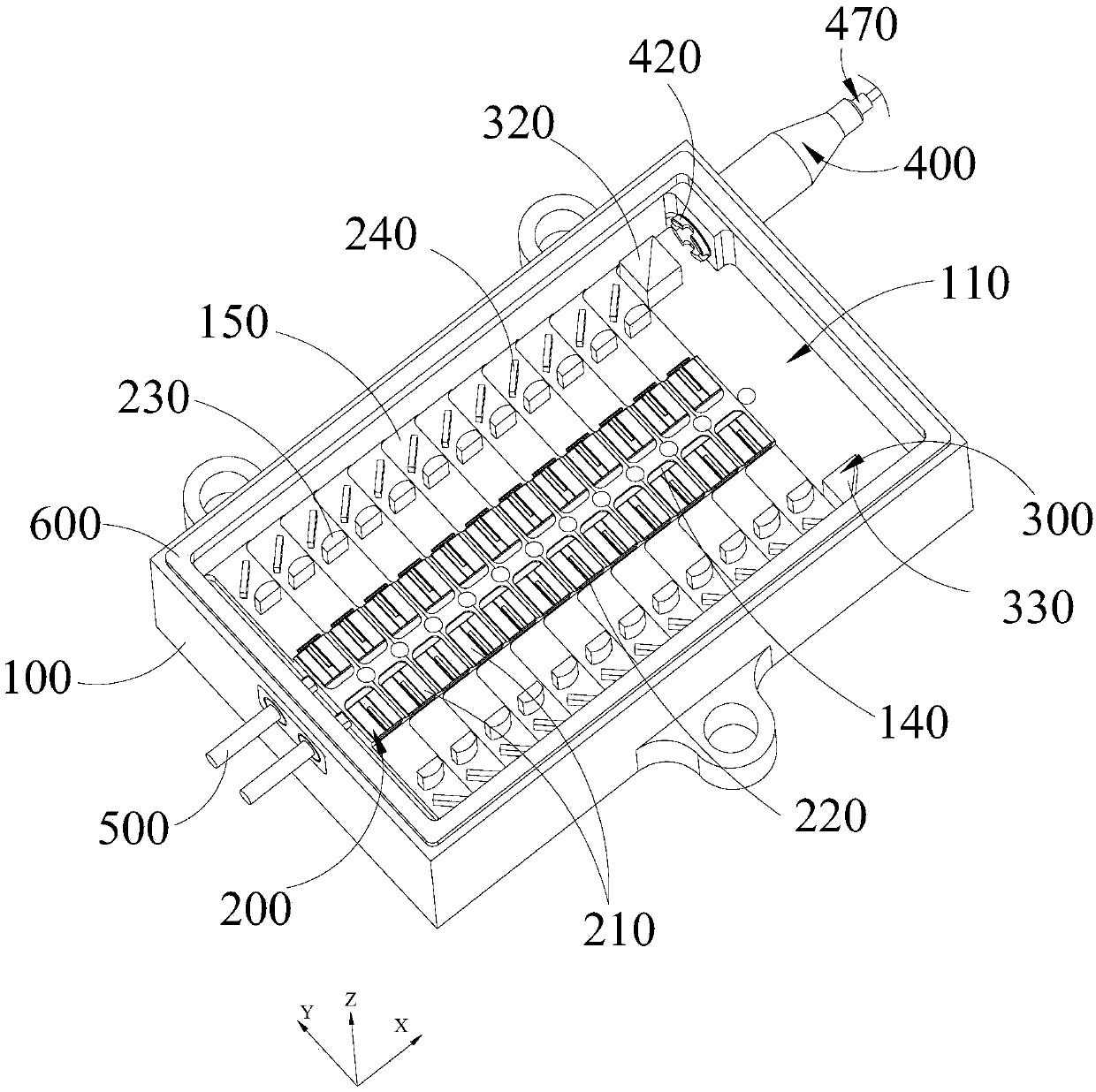

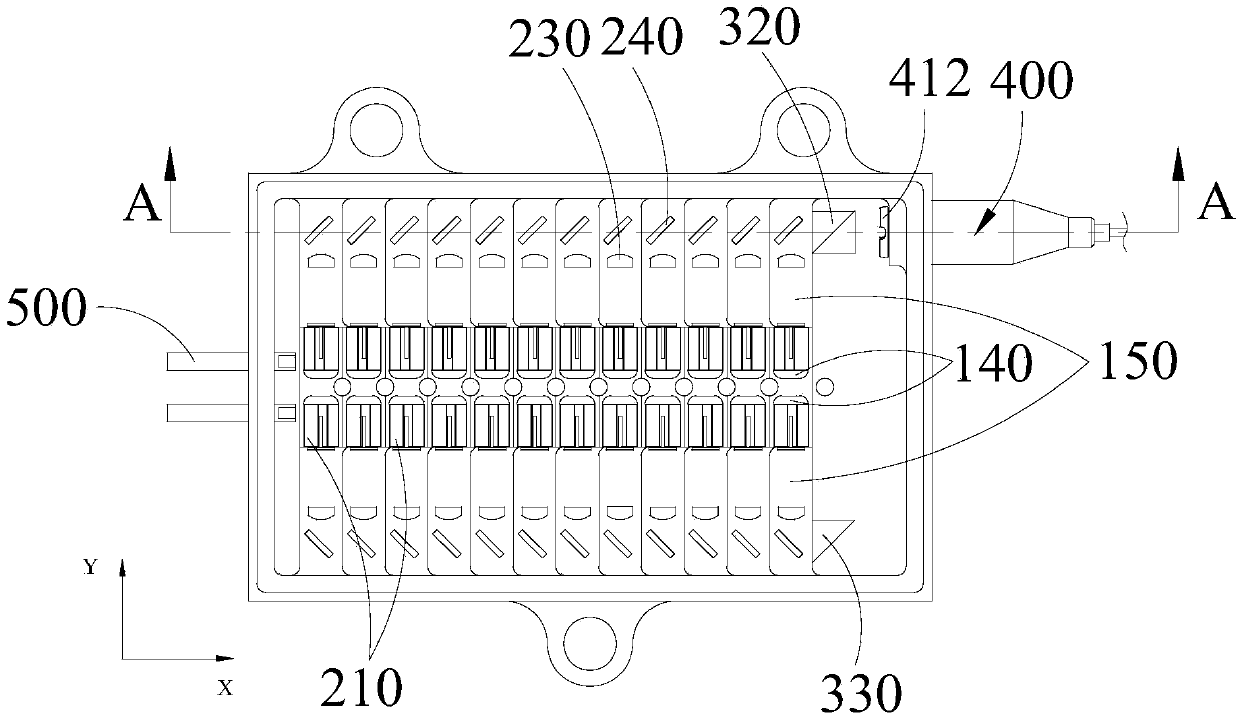

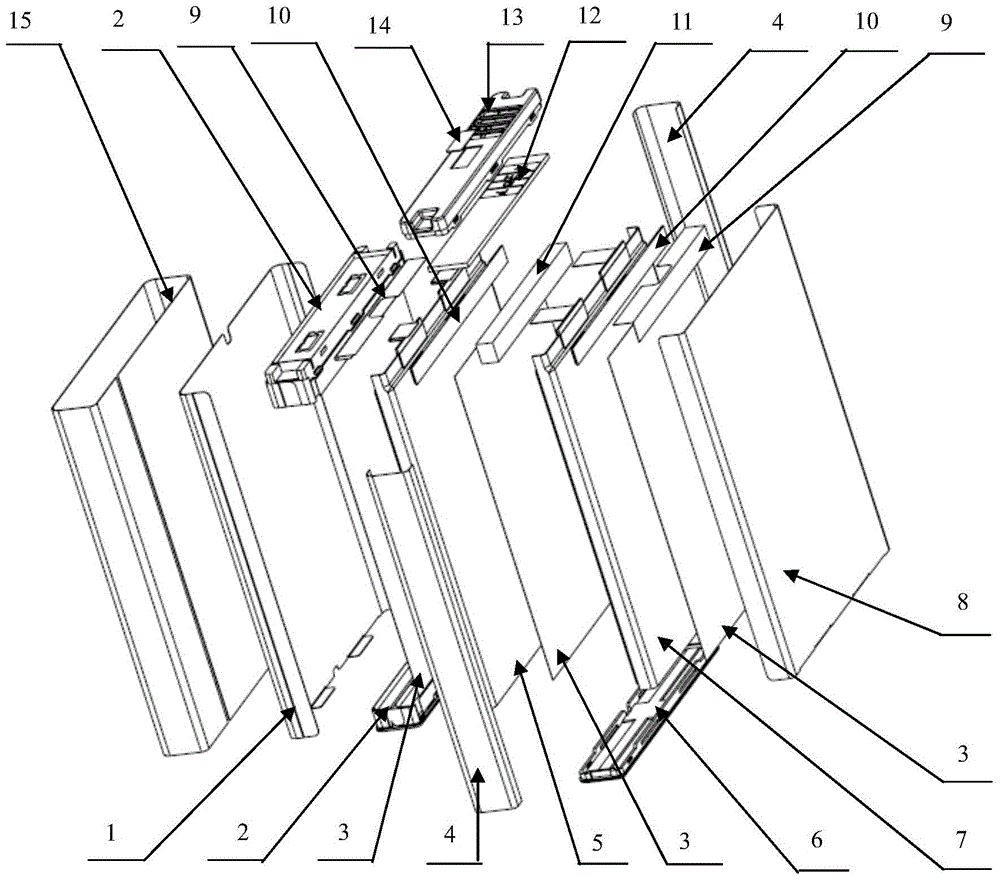

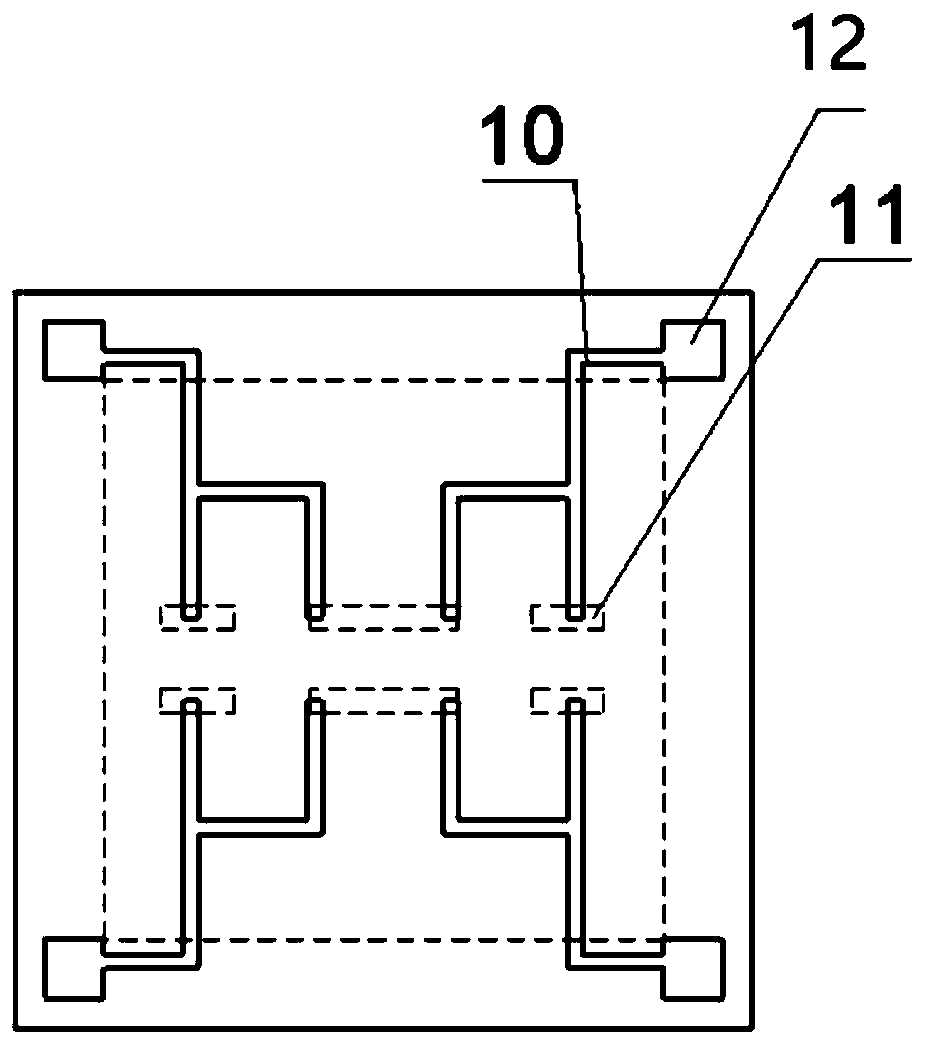

Multi-single tube large-power semiconductor laser package structure and laser

ActiveCN109586163AReduce material costReduce manufacturing costLaser detailsSemiconductor lasersOptical pathPositive direction

The invention belongs to the technical field of laser manufacturing, and aims to provide a multi-single tube large-power semiconductor laser package structure and a laser. The package structure comprises a base shell, wherein a package groove is formed in the base shell, a plurality of first steps are arranged at a central region of the groove bottom of the package groove and are integratedly formed along an X-axis direction so as to achieve integrated design of the package shell, the material cost and the production cost; and moreover, the height of a step surface of each step along a Z-axisdirection is sequentially and gradually reduced along a positive direction of an X axis, two groups of COS assemblies are arranged on the step surface of the corresponding step in a back-to-back way,and light emitted from each light-emitting unit is converted to collimating parallel light, gathered in the package groove and then is introduced to a light path coupling assembly outside the packagegroove for focusing and coupling. Apparently, the laser forms a new light path and electrical-thermal-mechanical balance, the volume is greatly reduced, concentrated heat dissipation is beneficial forcontrolling the integral temperature, light beam subsequent coupling is small in influence on the light-emitting unit, the output power of the laser is large, and the laser is more stable in performance.

Owner:深圳朗光科技有限公司

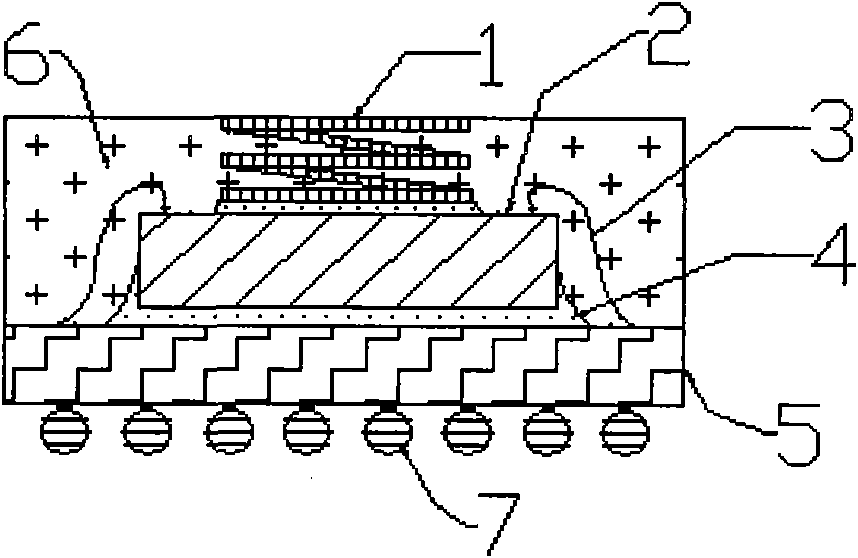

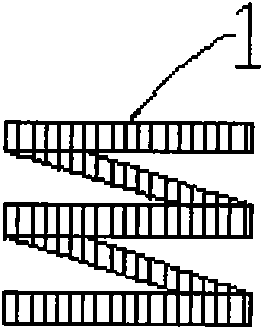

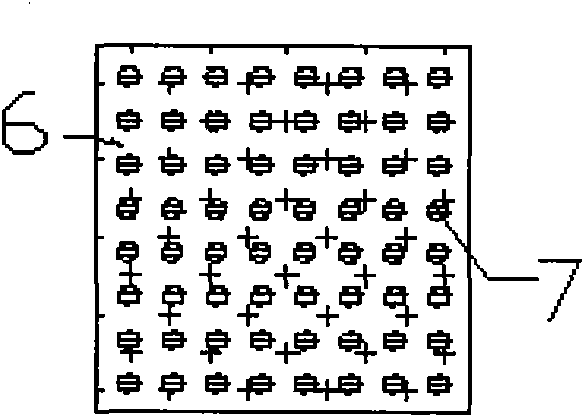

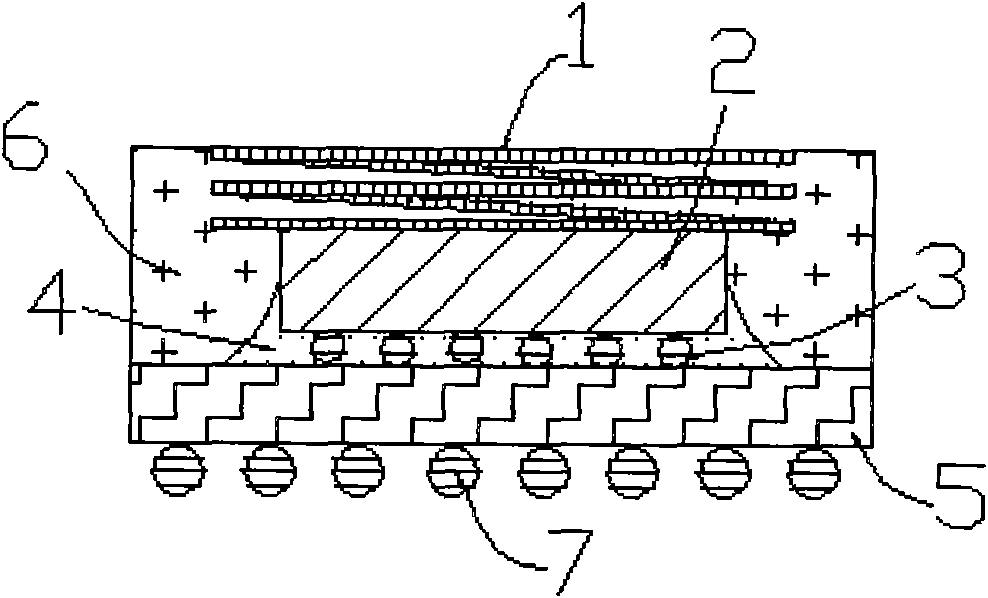

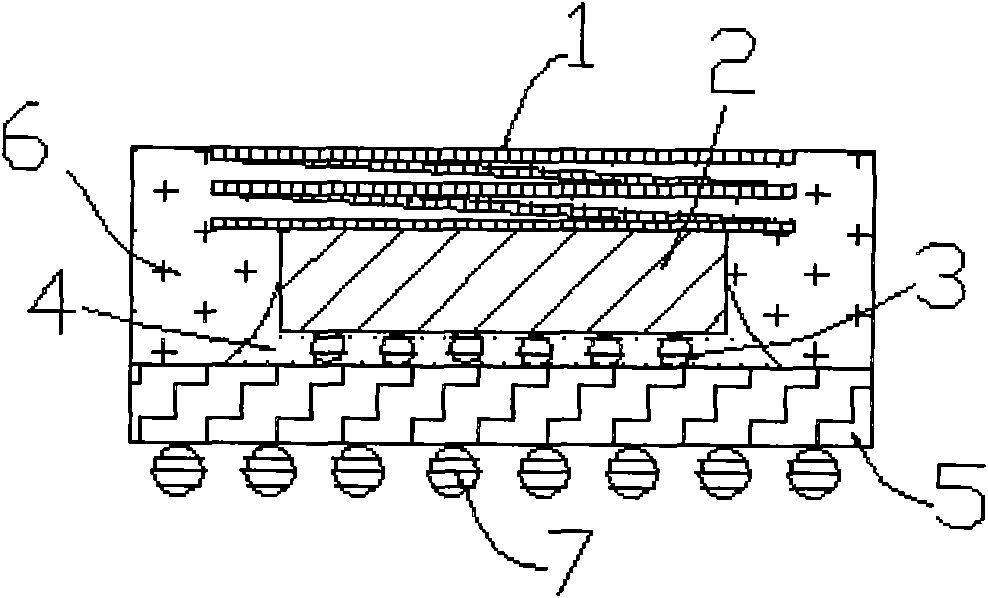

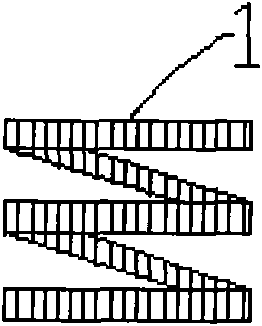

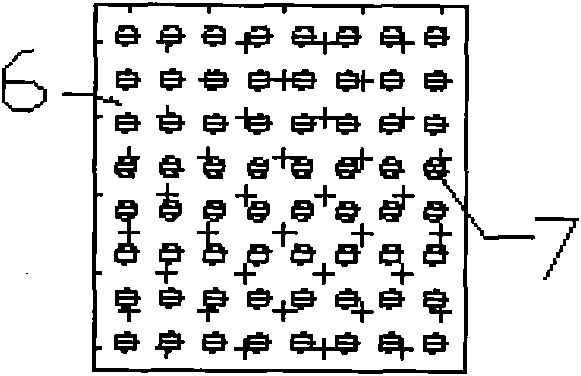

High-heat-dispersion spherical array encapsulation method

ActiveCN101834150AIncrease cooling areaSolve package heat dissipation problemsSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringMetal

The invention relates to a high-heat-dispersion reverse solder spherical array encapsulation method which comprises the following steps of: implanting a chip into a substrate by using a binding material; pasting a spring radiator on the chip; electrically connecting the chip and the substrate by a metal lead; plastically encapsulating the spring radiator, the chip, the metal lead, the binding material and the substrate with a plastic encapsulating material to form a plastic encapsulated body; and fixing the periphery of the spring radiator by the plastic encapsulating material, wherein one end of the spring radiator is connected with the chip, and the other end is exposed out of the surface of the encapsulated body so that the heat of the chip is dispersed out of the encapsulated body. The invention solves the problems of heat dispersion in encapsulation without an exposed metal carrier plates and greatly improves the electrothermal performance and the reliability of the product.

Owner:NANTONG FUJITSU MICROELECTRONICS

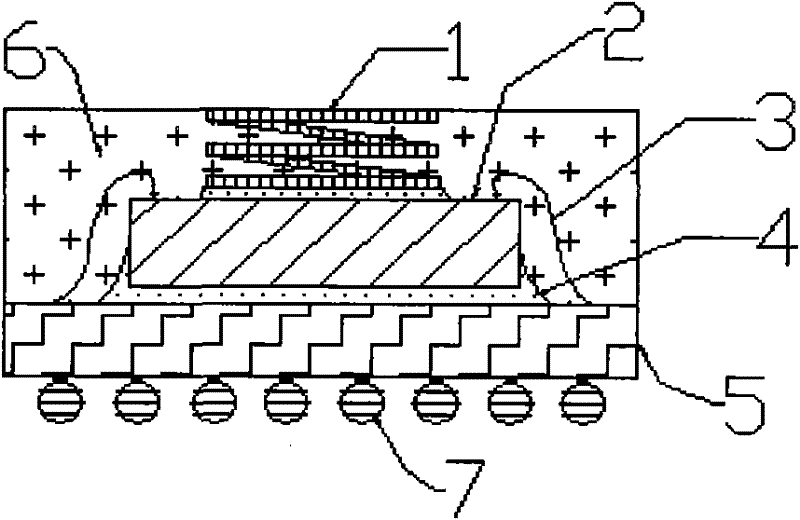

Flip-chip high-heat-radiation spheroidal array encapsulation structure

ActiveCN101840896AIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesSolder ballInterconnection

The invention relates to a flip-chip high-heat-radiation spheroidal array encapsulation structure, which comprises a chip, an electric interconnection material, a lower filling material, a base plate, a plastic sealing material and a welding ball. A spring heat radiator is also arranged in the encapsulation structure. The electric interconnection material is planted on the front side of the chip, and is inversely arranged on the base plate, and the electric interconnection between the chip and the base plate is realized through the electric interconnection material, the lower filing material fills a gap between the chip and the base plate, the plastic sealing material plastically seals the spring heat radiator, the chip, the electric interconnection material, the lower filling material and the base plate for forming a plastic sealing body, the circumambience of the spring heat radiator is fixed by the plastic sealing material, one end of the spring heat radiator is connected with the chip, and the other end of the spring heat radiator is exposed on the surface of the plastic sealing body for radiating the heat of the chip out of the plastic sealing body. The problem of heat radiation of the encapsulation of carrying bases or inversely arranged chips without exposed metals is solved, and the electric heating performance and the reliability of the products are greatly improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

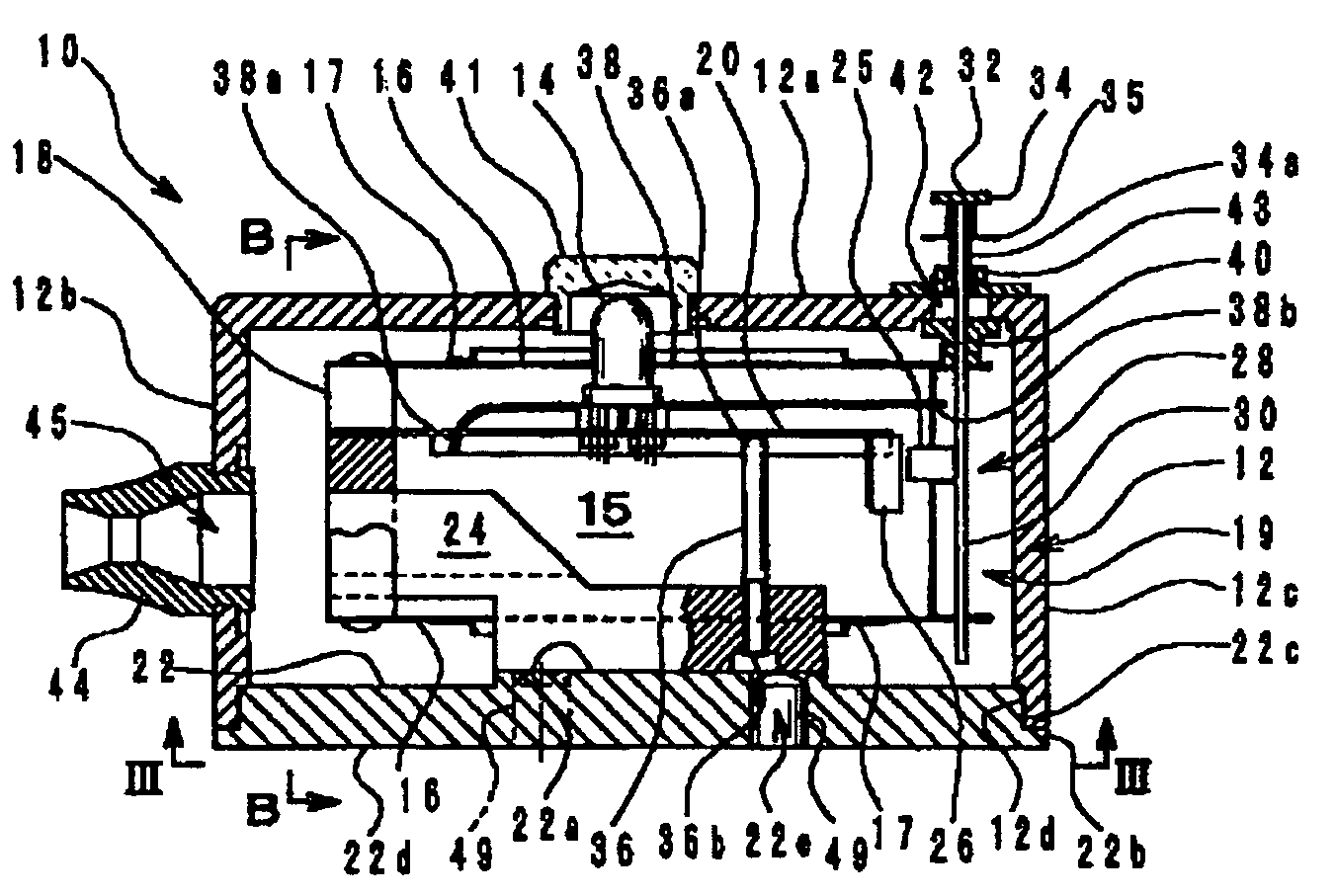

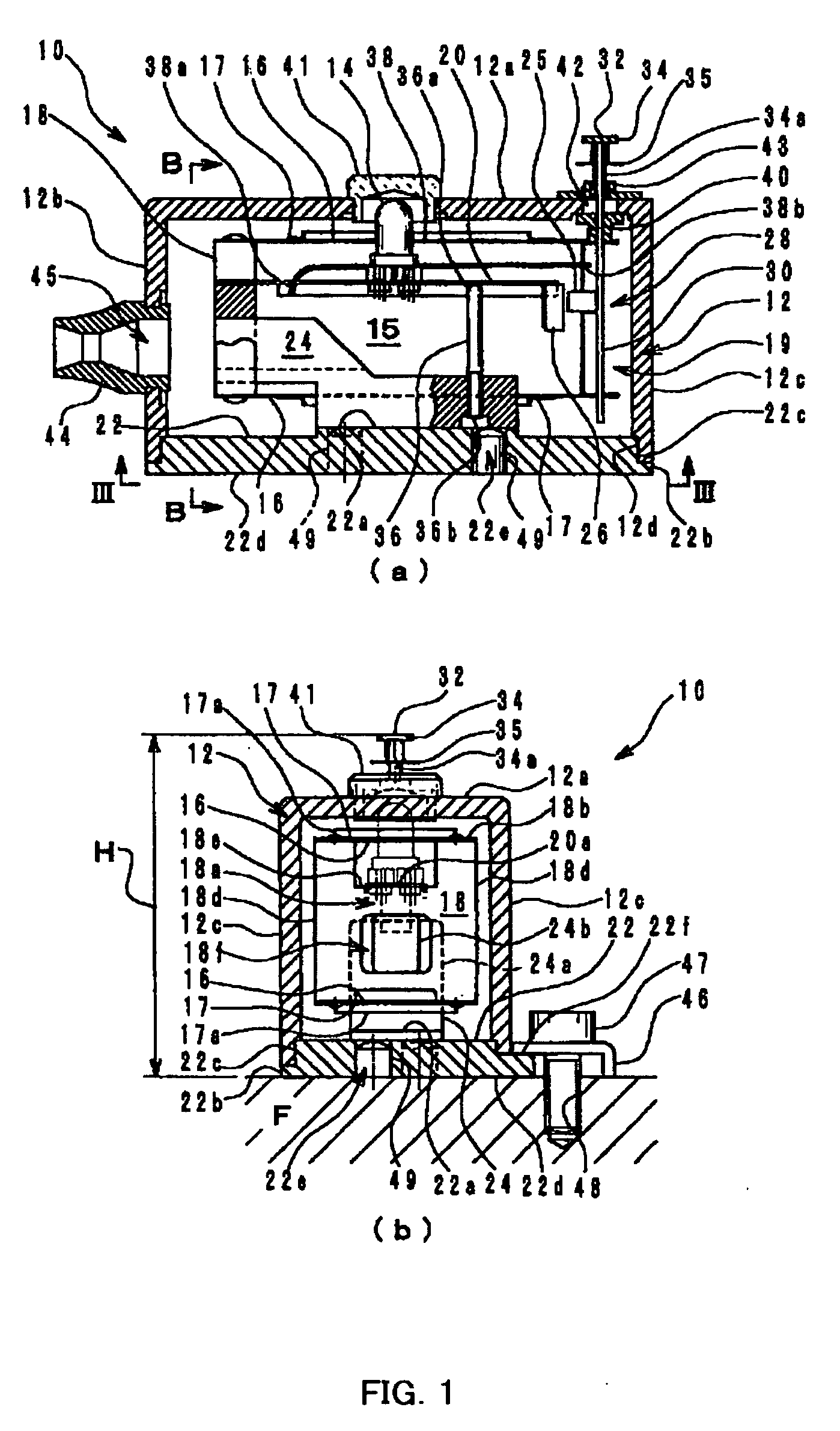

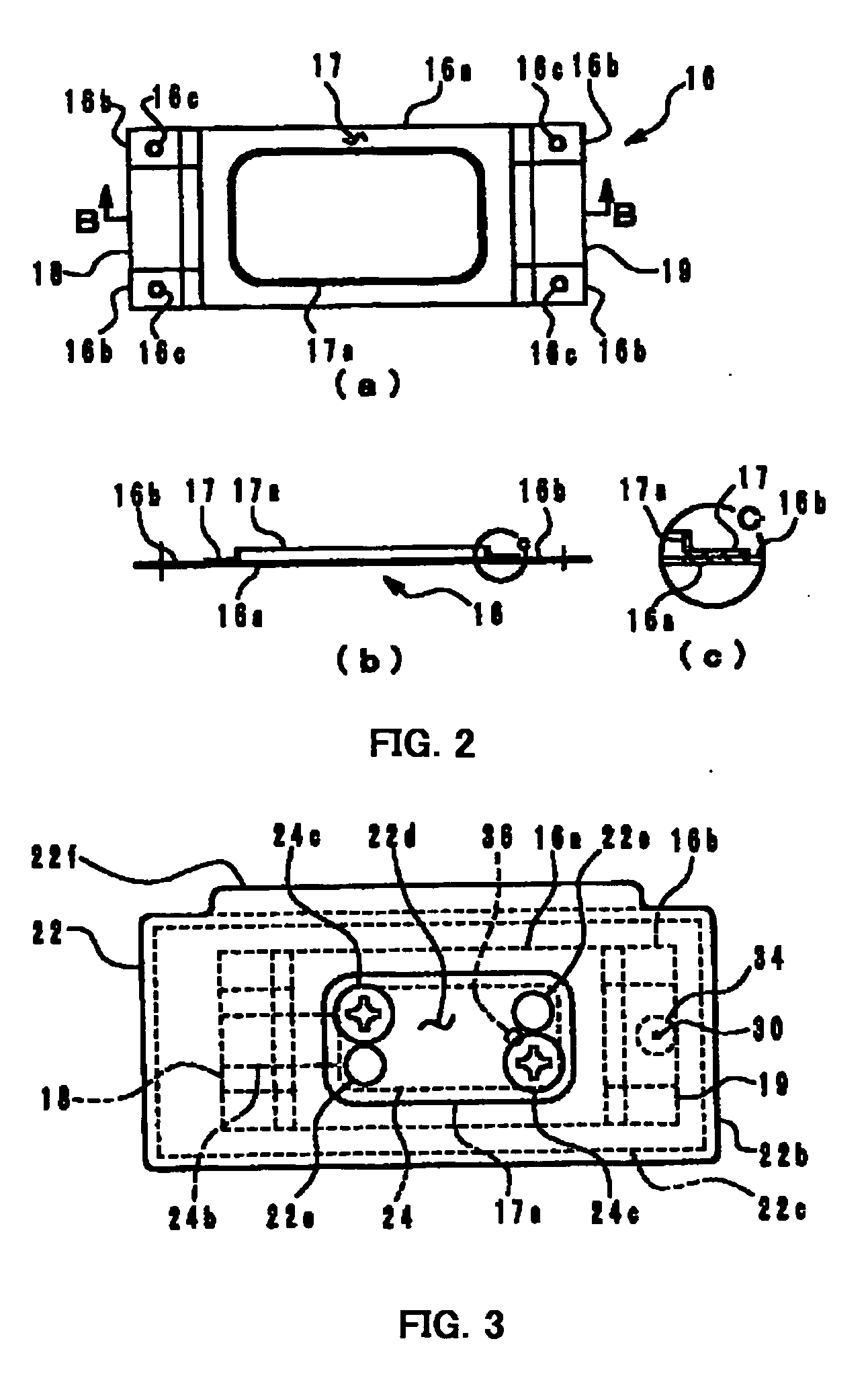

Touch sensor

ActiveUS20050231195A1Held stablyCompact packageMechanical counters/curvatures measurementsMeasurement/indication equipmentsSelf weightEngineering

A touch sensor using a Hall IC is provided. To this end, in a cantilever mechanism 15 of a parallel link by two plate springs 16, a coupling member 18 on the fixed side is fixed to a supporting block 24 which penetrates through the center of a plate spring 16 on a lower side and uprightly provided on a pedestal 22. A movable portion 28 on the free end side is a lightweight coupling member 19 provided by bend-processing an aluminum thin plate, to which a rare-earth magnet 25 is adhered. An elastic part 20a of a Hall IC supporting member 20 is fixed to the coupling member 18 on the fixed side, and a rigid part 20b with a rib 17a is supported by an adjusting rod 36 to fine-adjust relative position of a Hall IC 26 provided on the free end with respect to the magnet 25. Elastic wire materials 38s are fixed to the Hall IC supporting members 20s which hold at a free end 38b the self-weight of the movable portion 28, and abutted with a lower surface 40a of a bush on the inner surface of a housing 12, so that the movable portion 28 is stabilized in its position. A light load of 0.6 gf or less activates an anvil 34, and the Hall IC 26 detects a minute displacement of 0.1 mm or less of the magnet 25, in order to light up a signal light 14.

Owner:ASA ELECTRONICS IND

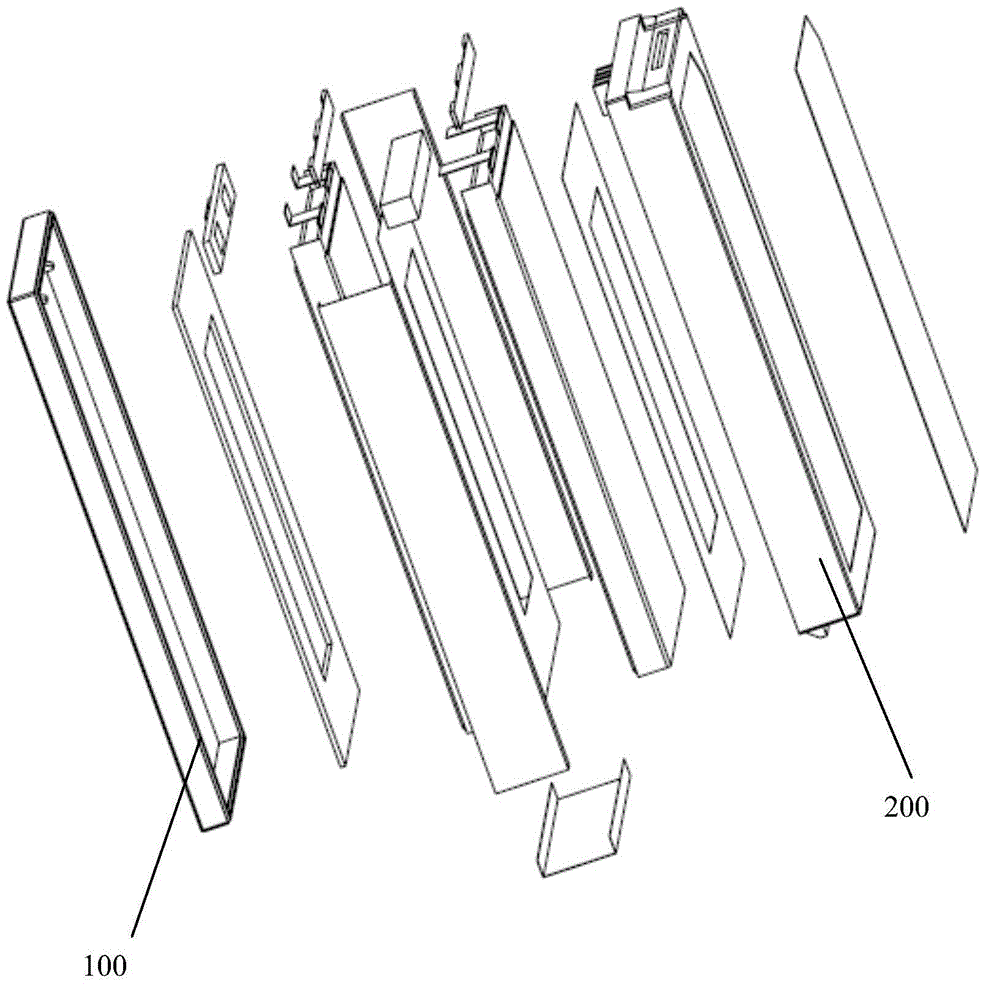

Detachable polymer lithium ion battery and assembling method thereof

ActiveCN104466235APackaging precisionStable structureFinal product manufactureElectrolyte accumulators manufactureMetallic enclosureLap joint

The invention discloses a detachable polymer lithium ion battery. The detachable polymer lithium ion battery comprises at least two parallel polymer lithium ion battery cells, and an upper stainless steel sheet, a lower stainless steel sheet, a top shell and a bottom shell which are connected fixedly to form a cell containing cavity, wherein the two sides and the bottoms of the upper stainless steel sheet and the lower stainless steel sheet are inwards bent respectively to form side connection edges and inserting teeth; inserting grooves corresponding to the inserting teeth are formed in the bottom shell; the tops of the upper stainless steel sheet and the lower stainless steel sheet are in injection molding connection with the top shell; and the lap joint parts of the side connection edges on the two sides of the upper stainless steel sheet and the lower stainless steel sheet are welded together. The invention provides a cell packaging structure which has high packaging precision and maximized capacity density and low cost; the two or more than two polymer cells are overlapped and connected in parallel and are welded, and then are welded on a protection plate; and a battery shell packaging structure is combined by a plastic shell and a metal shell and the packaging size is saved, so that the battery packaging structure is more compact.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

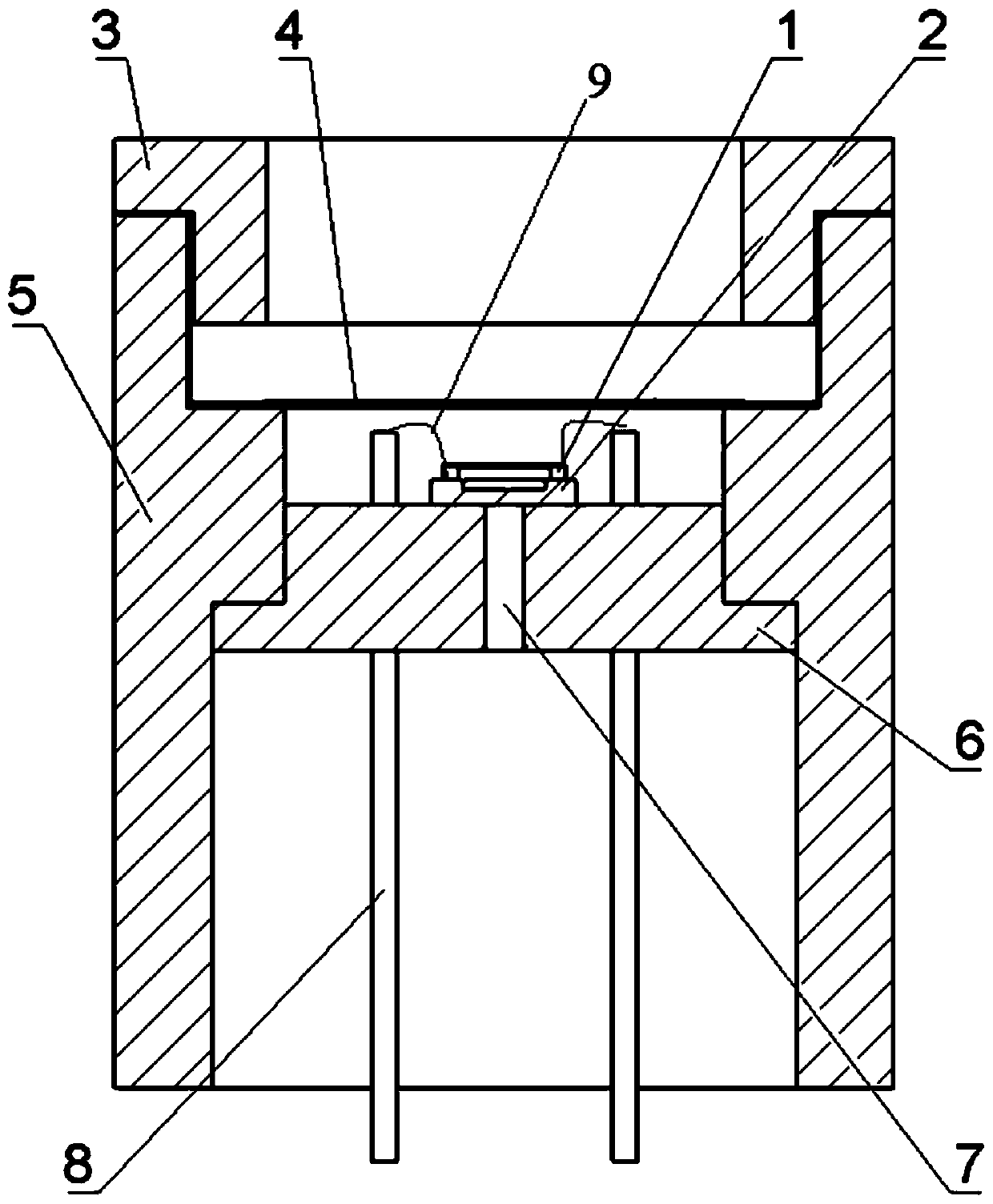

SiC high-temperature pressure sensor and packaging method thereof

ActiveCN111003683AReduce manufacturing costHigh hardnessThermometer detailsTelevision system detailsEngineeringSilicone oil

The invention discloses a SiC high-temperature pressure sensor and a packaging method thereof. The sensor comprises a SiC MEMS chip, an AlN carrier, an elastic metal film, a supporting tube shell, a heat conduction base and a plurality of conductive binding posts; the heat conduction base is installed in the supporting tube shell; the AlN carrier is fixedly installed on the heat conduction base; the SiC MEMS chip is fixedly arranged on the AlN carrier; the elastic metal film is arranged on the supporting tube shell above the SiC MEMS chip; a thinned self-sealing cavity is etched in the face, attached to the AlN carrier, of the SiC MEMS chip; the conductive binding posts penetrate through the heat conduction base from the lower end of the supporting tube shell and then are connected with anelectrode of the SiC MEMS chip; and an insulating layer is arranged between the conductive binding posts and the heat conduction base. The assembly structure is put into heat conduction silicone oil,and the elastic metal film is pressed into the supporting tube shell in a matched mode through an annular plug cap, so the SiC high-temperature pressure sensor packaging is completed. The chip packaging structure is low in packaging cost and good in reliability, completely isolates the chip from a medium, and can continuously work at the high temperature of 500 DEG C or above.

Owner:WUHAN UNIV

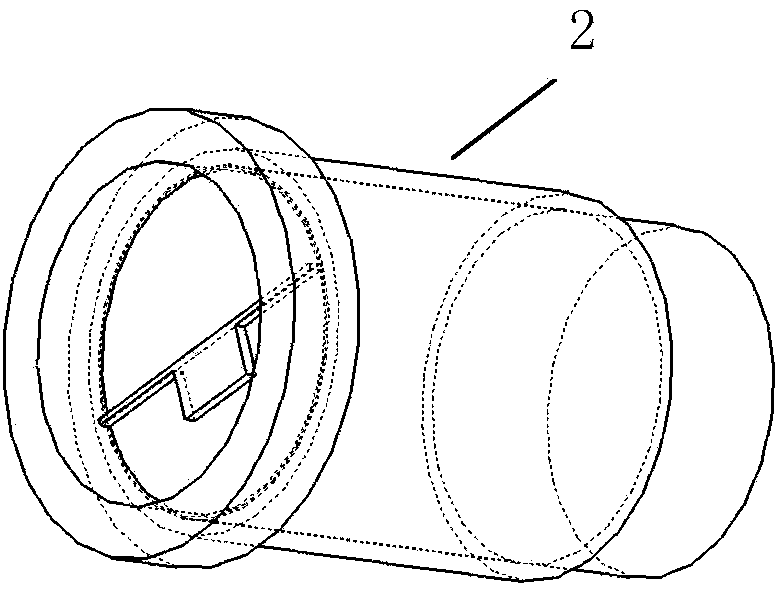

Encapsulation structure and encapsulation method for MEMS (micro-electromechanical system) variable optical attenuator

The invention relates to an encapsulation structure for an MEMS (micro-electromechanical system) variable optical attenuator. The encapsulation structure comprises a focusing lens, a tail fiber sleeve and an optical chip, wherein the optical chip is manufactured by adopting the MEMS, the tail fiber sleeve is fixedly arranged in a hollow cylindrical magnet through bonding glue for forming a magnetic assembly 1, one end of the focusing lens is a light signal incident surface, the other end of the focusing lens is provided with a light reflecting surface, the focusing lens is fixedly arranged in the other hollow cylindrical magnet through bonding agents, the optical chip is fixedly arranged on the end part, used for being sucked with the magnetic assembly 1, on the hollow cylindrical magnet through bonding agents, and a magnetic assembly 2 is formed; the magnetic assembly 1 and the magnetic assembly 2 which are in a mutual magnetic suction state and are reinforced through the bonding agents form a variable optical attenuator assembly, the optical attenuator assembly is arranged in a hollow external protecting sleeve, in addition, two ends of the external protecting sleeve are filled and encapsulated by bonding agents, and the variable optical attenuator is formed. The invention aims at providing the encapsulation structure and an encapsulation method for the MEMS with the advantages of miniaturization, low cost and high reliability.

Owner:苏州盛维新电子科技有限公司

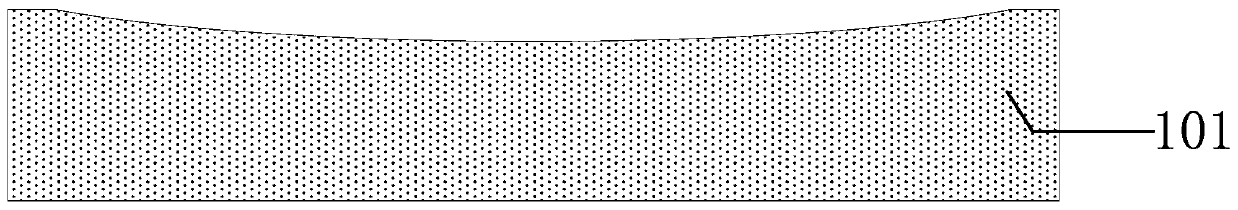

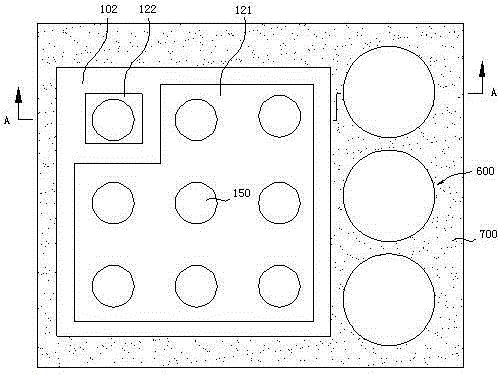

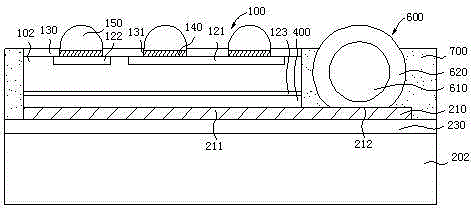

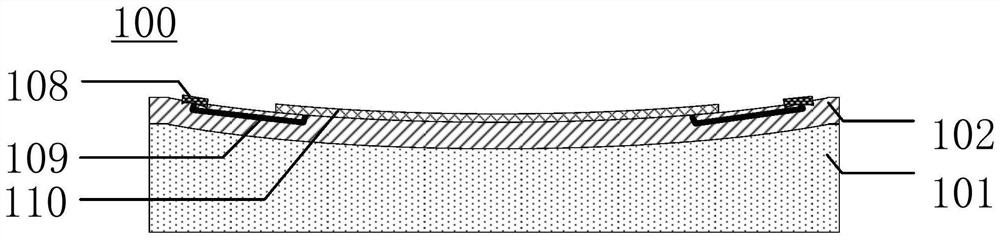

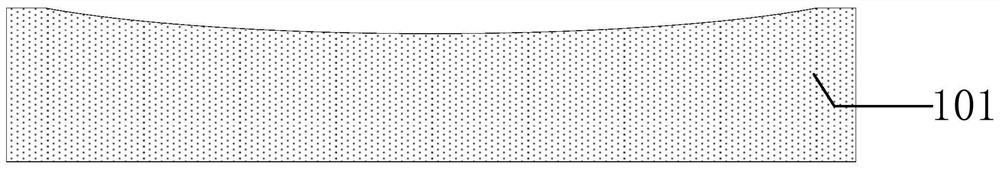

Infrared detector and forming method thereof, and infrared detector packaging structure and method thereof

ActiveCN111092126AReduce in quantitySmall sizeFinal product manufacturePyrometry using electric radation detectorsHemt circuitsEngineering

The invention relates to an infrared detector and a forming method thereof, and an infrared detector packaging structure and a forming method thereof. The infrared detector comprises a detector and abase, wherein the detector comprises a substrate, the substrate is provided with a first surface and a second surface which are opposite to each other, a sensing circuit is formed on the first surface, the surface of the base is provided with a recess, a bottom surface of the recess is a curved surface, and the position of the recess corresponds to that of the sensing circuit, the detector is fixed on a surface of the base, and the second surface of the substrate is attached to the bottom surface of the recess, so a sensing surface of the detector is a curved surface. The infrared detector islow in cost.

Owner:ZHEJIANG DALI TECH

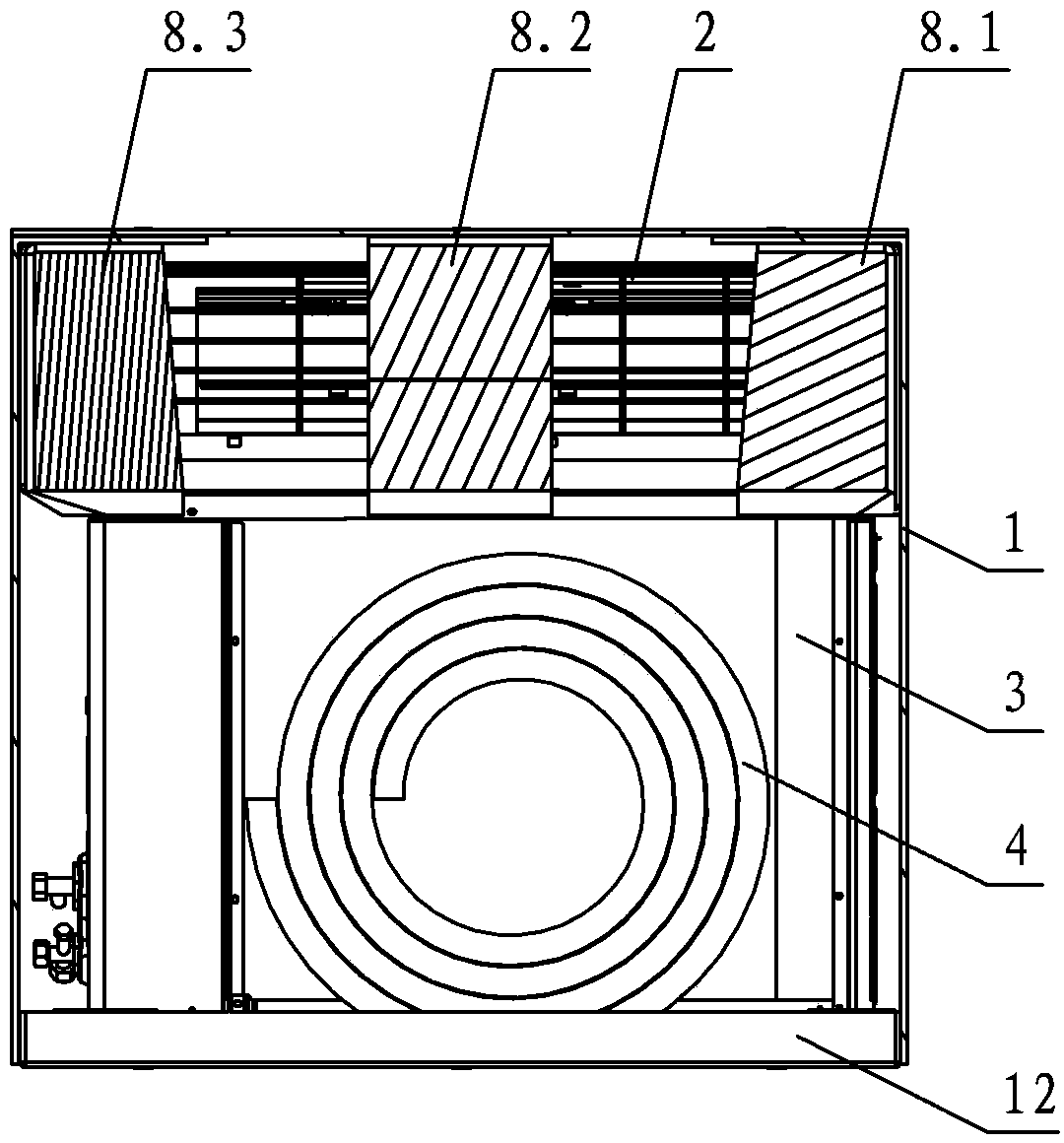

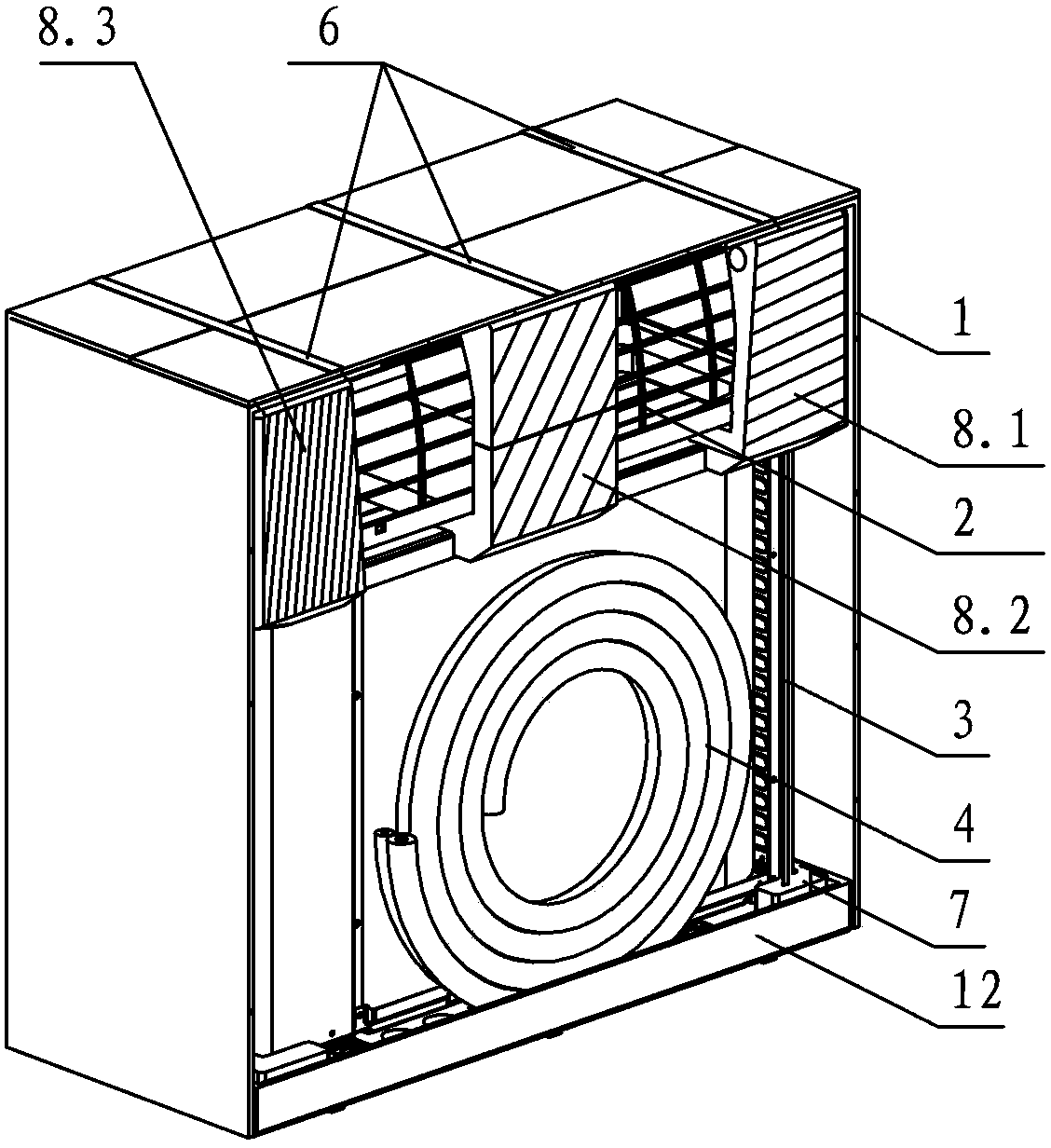

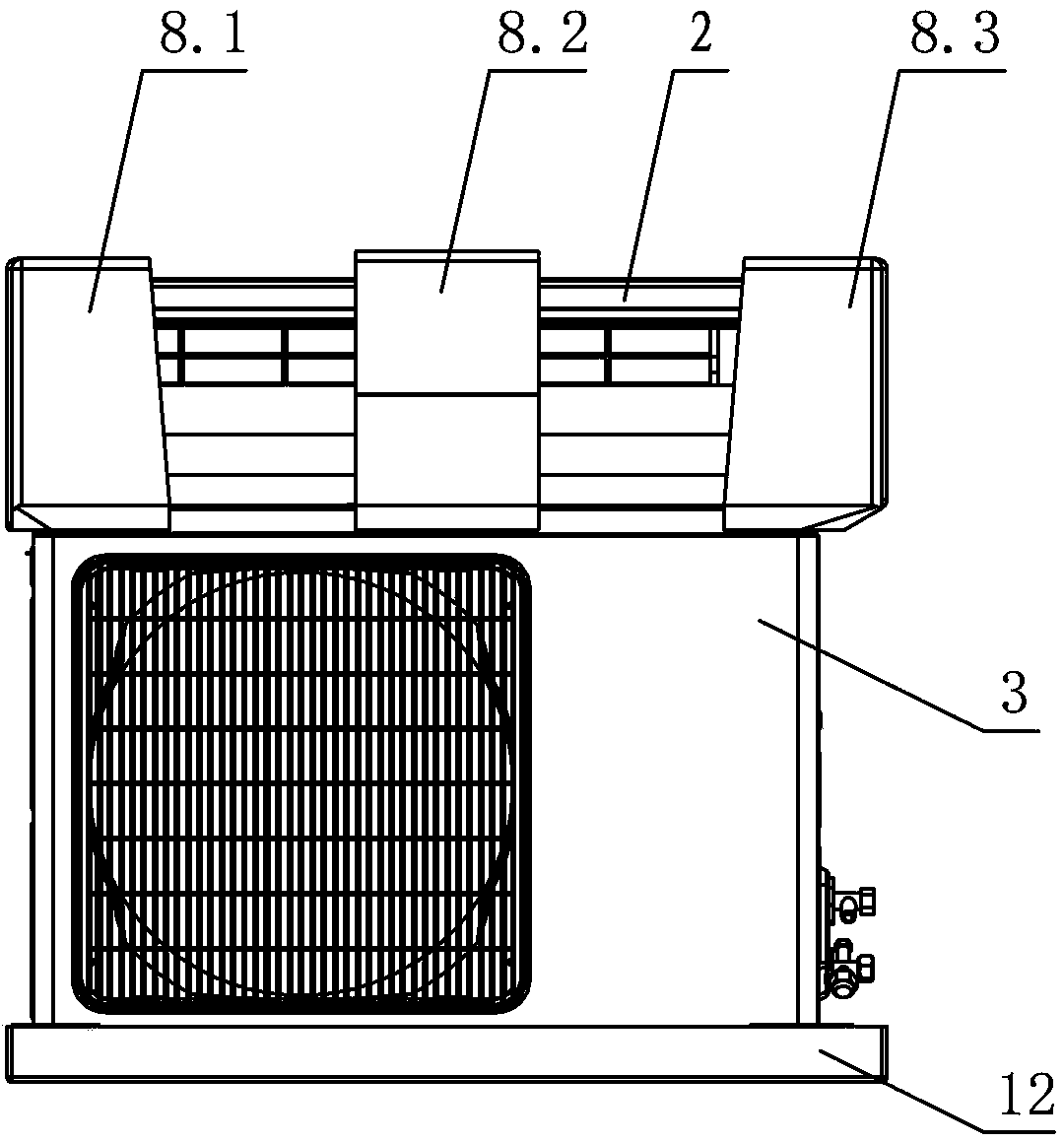

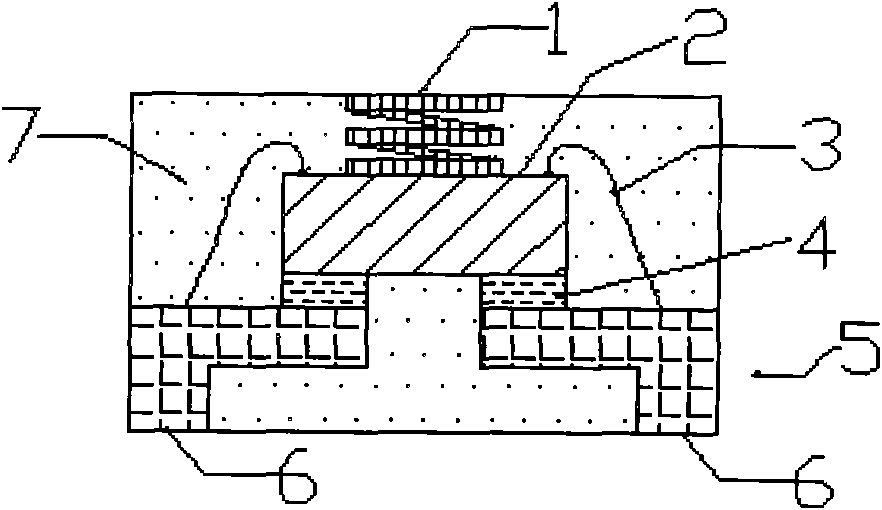

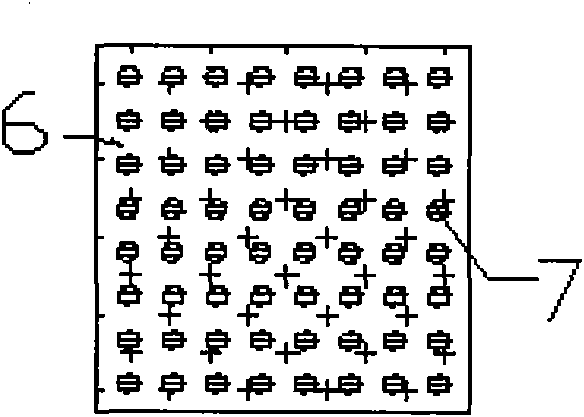

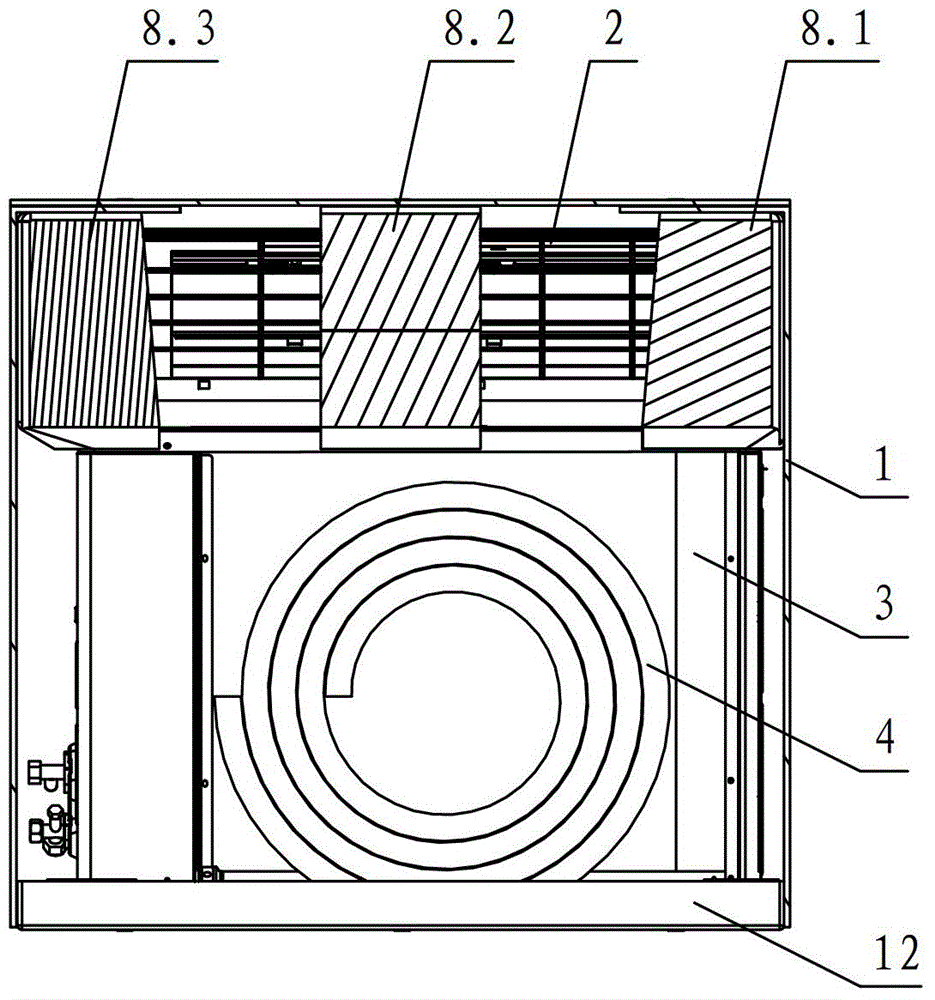

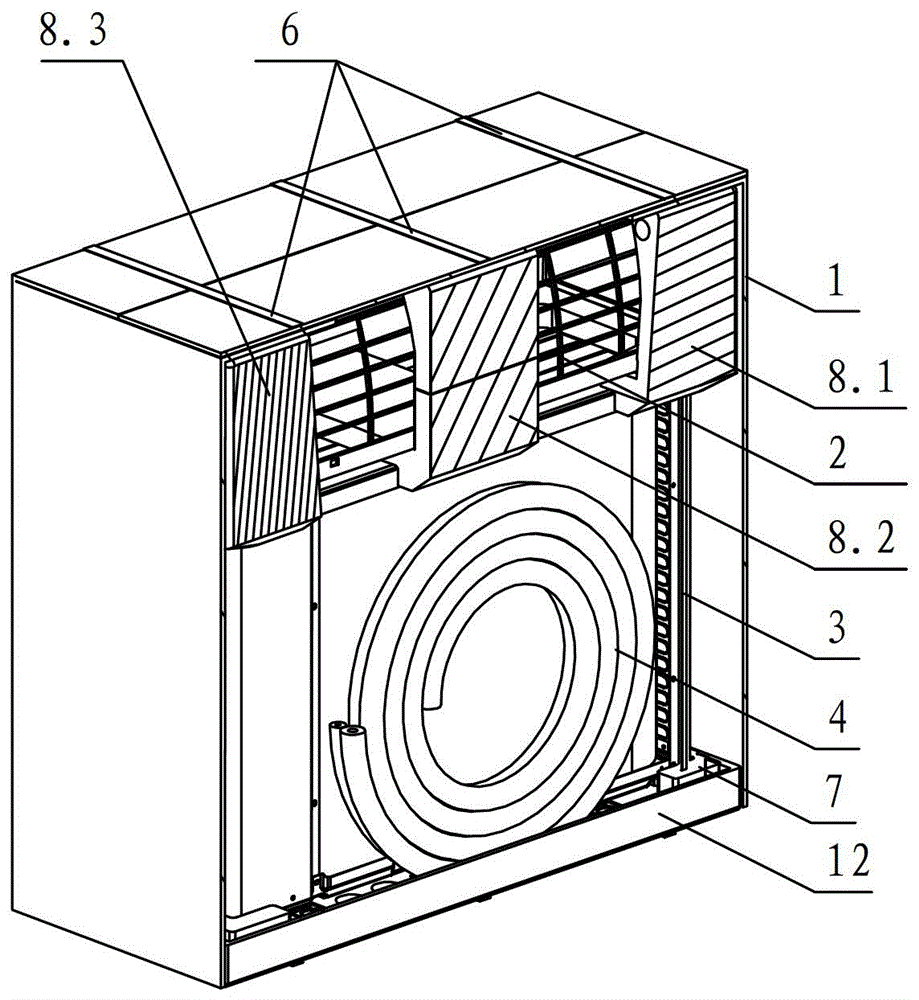

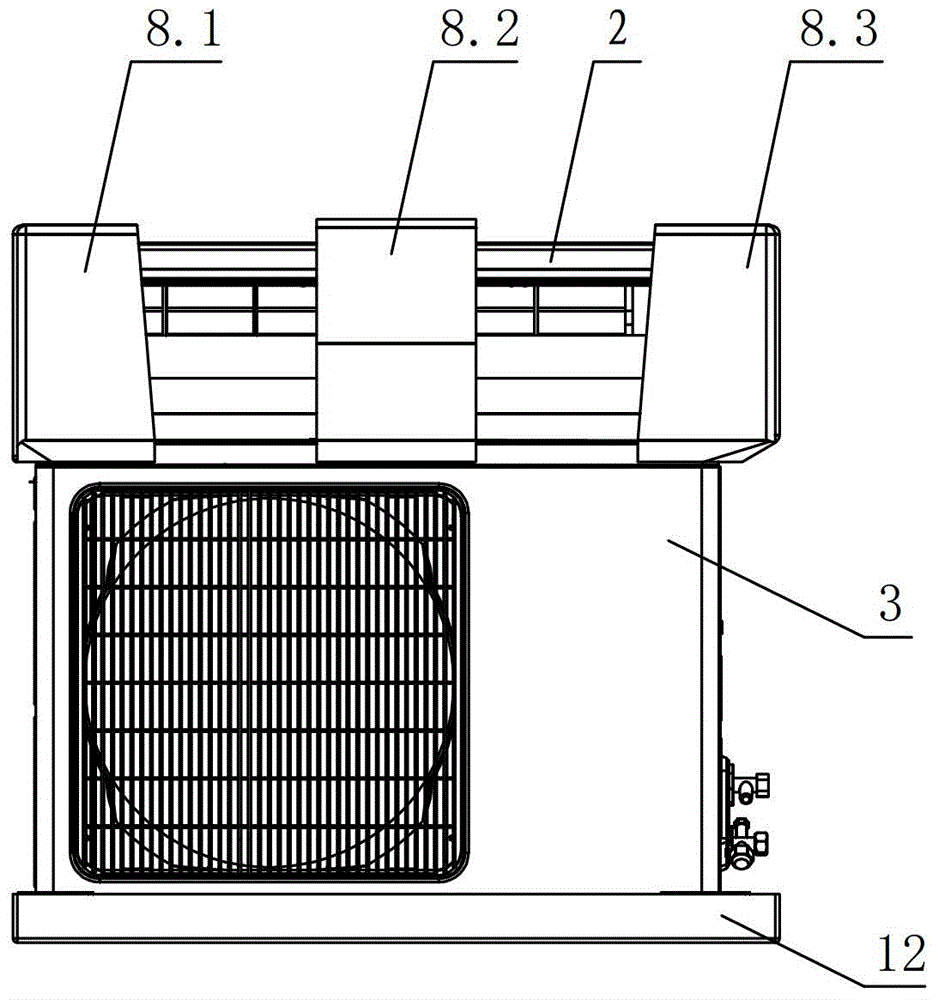

Packing device of split air conditioner and method for packing split air conditioner by using packing device

ActiveCN103350832AHigh strengthThere will be no deformationPackaging vehiclesContainers for machinesCartonCopper

The invention discloses a packing device of a split air conditioner and a method for packing the split air conditioner by using the packing device. The split air conditioner comprises an indoor unit, an outdoor unit and an installing attachment, wherein the installing attachment comprises a connecting copper pipe and a connecting cable, and the indoor unit, the outdoor unit and the installing attachment are arranged in one packing paper box together; the packing paper box is of an upper-down separating structure, and the packing paper box is fixedly bundled through more than two packing belts; the indoor unit is arranged on the upper part and the side surface of the outdoor unit, the front side, the rear side or the right side of the outdoor unit and a packing liner of the outdoor unit and the inner wall of the packing paper box can form a gap together, and the installing attachment is arranged in the gap; and the left and right end surfaces and the middle part of the indoor unit are all provided with upper packing liners matched with the shapes of the left and right end surfaces and the middle part of the indoor unit in the length direction. The packing device and the packing method disclosed by the invention have the characteristics that the structure is simple and reasonable, the volume of the complete machine is small, the rigidity is good, the strength is high, the operation is flexible, the fabricating cost is low, and the packing device is easy to pack.

Owner:GUANGDONG GALANZ GRP CO LTD +1

Chip-suspension-type packaging heat dissipation improved structure of semiconductor

ActiveCN101826492BIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageInterconnection

The invention relates to a chip-suspension-type packaging heat dissipation improved structure of a semiconductor, which comprises a chip, metal leads, a bonding material, a lead frame and a plastic package material, and also comprises a spring heat dissipater, wherein transmission pins are arranged on the lead frame, and the chip is arranged on the transmission pins through the bonding material and is in electrical interconnection with the lead frame through the metal leads; the spring heat dissipater, the chip, the metal leads, the bonding material and the lead frame are plastic-packaged bythe plastic package material to form a plastic package body, and the periphery of the spring heat dissipater is fixed by the plastic package material; and one end of the spring heat dissipater is connected with the chip, and the other end thereof is exposed to the surface of the plastic package body to dissipate the heat of the chip out of the plastic package body, thereby solving the heat dissipation difficulties that no exposed chip bears a base or a flip chip is packaged, and greatly improving the electrothermal performance and reliability of products.

Owner:NANTONG FUJITSU MICROELECTRONICS

Package structure for silicon-based module and package method for silicon-based module

ActiveCN105226040AReduce processing difficultyEasy to useSemiconductor/solid-state device detailsSolid-state devicesSolder ballElectrical connection

The invention relates to a package structure for a silicon-based module and a package method for the silicon-based module, and belongs to the technical field of semiconductor packaging. The package structure comprises a silicon-based body, a silicon-based chip and a metal core solder ball, wherein the front surface of the silicon-based chip is covered with a patterned passivation layer and is provided with an passivation layer opening for exposing the upper surface of an electrode; a nickel / gold layer and a solder ball are arranged in the passivation layer opening; the metal core solder ball is arranged at the side of the silicon-based chip; the upper surface of the silicon-based body is selectively provided with a rewiring metal layer; the metal core solder ball is fixedly connected with the rewiring metal layer; the silicon-based chip and the rewiring metal layer are positively arranged and fixedly connected, and achieve electrical connection; and the top height of the solder ball and the top height of the metal core solder ball are located on the same plane. The package structure for the silicon-based module provided by the invention is simple; various performance indexes are ensured; and meanwhile, the process difficulty of the package method is lowered.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

Method and structure for encapsulating transparent substrate detector chip

InactiveCN103663356AConvenient temperature controlCompact packageRadiation pyrometryPrecision positioning equipmentBonding processOptoelectronics

The invention provides a method for encapsulating a transparent substrate infrared detector chip. The chip comprises a transparent substrate and a chip sensitive structure arranged on the transparent substrate; the method comprises the steps of growing a first intermediate on the transparent substrate to form a first pattern surrounding the chip sensitive structure; growing a second intermediate corresponding to the first intermediate on an other substrate made of a material with high transmittance of rays with preset wave band; and encapsulating the chip sensitive structure by the first intermediate and the second intermediate through a bonding process. The encapsulating structure by the method is simple, has good air tightness and simple manufacture process and is low in cost and suitable for wafer level encapsulation.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

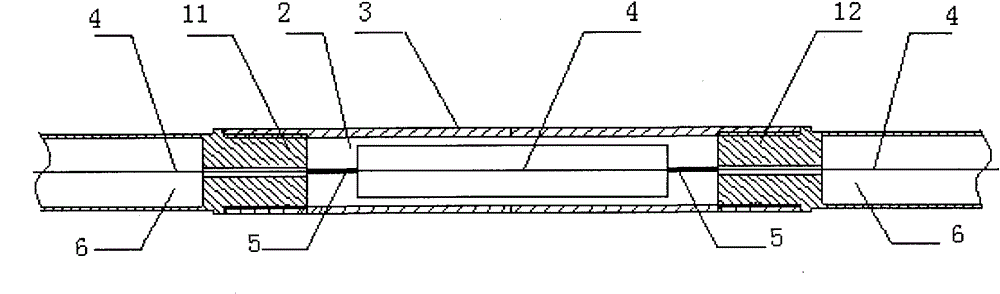

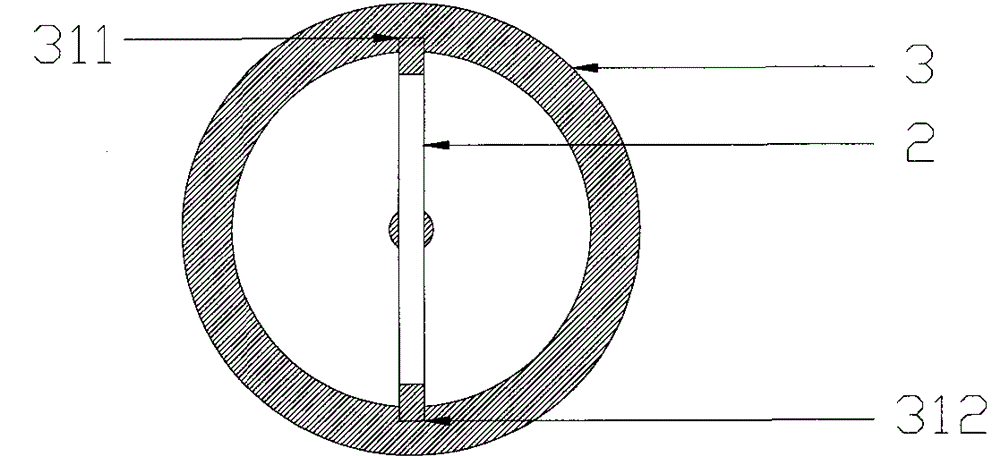

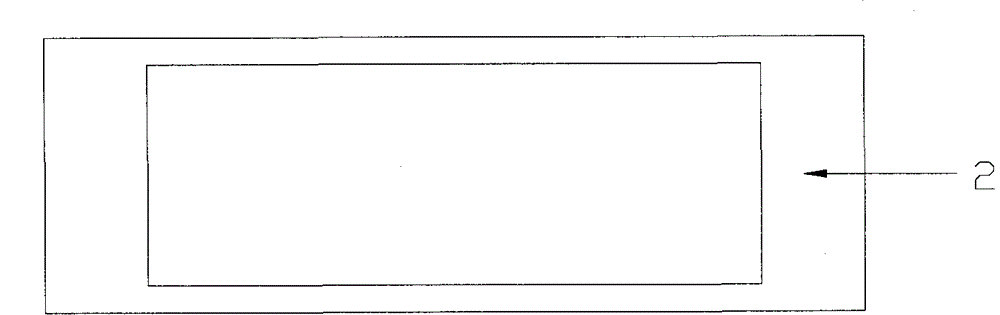

A Fiber Bragg Grating Temperature Sensor

ActiveCN102213625BImprove protection strengthPackage structure is simpleThermometers using physical/chemical changesCoupling light guidesFiberEngineering

The invention discloses an optical fiber grating temperature sensor, which comprises an optical fiber grating, an optical fiber fixing sheet for fixing the optical fiber grating, the optical fiber fixing sheet is built into a packaging tube, and two optical cable connectors with a through hole opened in the center of the cross section along the axial direction are connected to the At both ends of the packaging tube, the fiber fixing piece is located between the two optical cable connectors, and the fiber gratings fixed on the fiber fixing piece respectively pass through the through holes of the two optical cable connectors. The fiber grating temperature sensor adopting this packaging structure, on the one hand, the packaging tube has a certain thickness and strength, and the packaging through the packaging tube ensures a strong protection for the fiber grating; on the other hand, the temperature of the fiber grating is greatly improved. The sensor's response speed to ambient temperature. At the same time, the packaging structure of the fiber grating temperature sensor is simple and compact, and is convenient for implementation.

Owner:SHANGHAI KNP CHEM +1

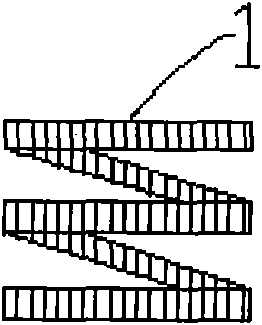

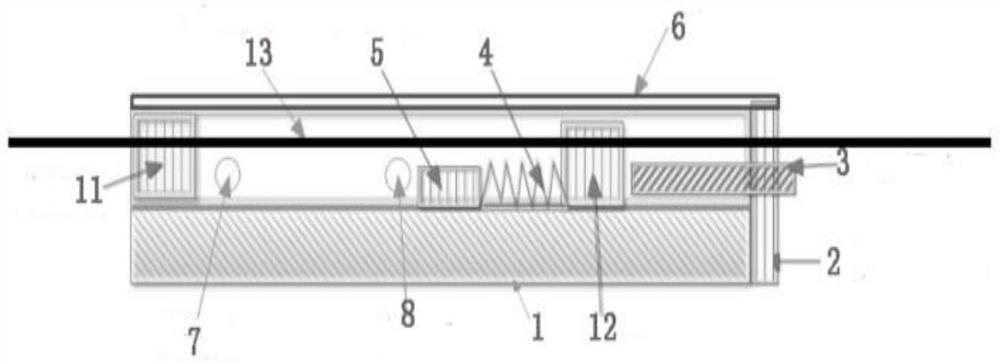

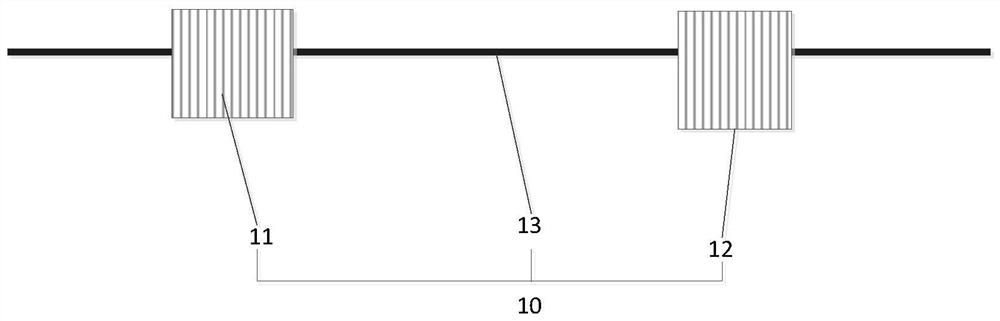

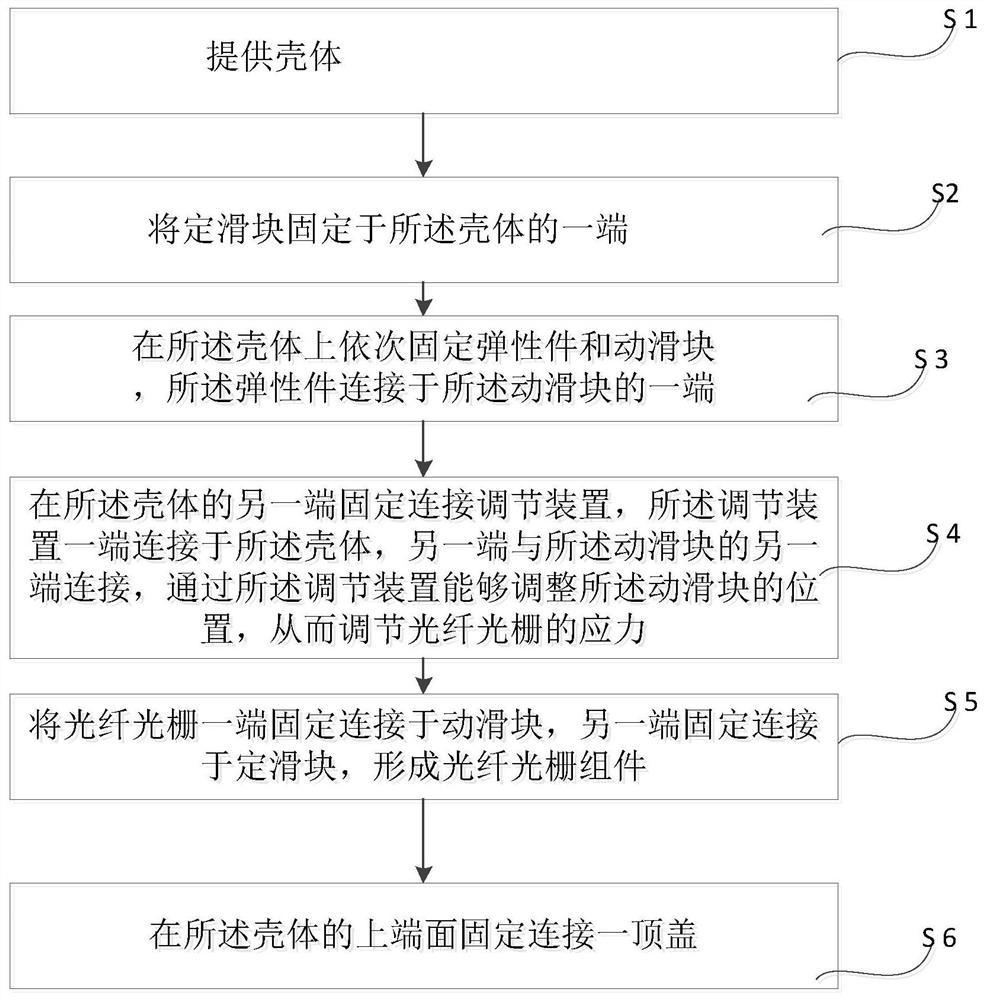

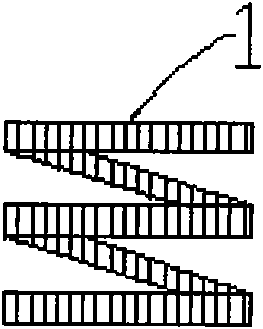

Fiber bragg grating packaging structure and packaging method

PendingCN113156576AAdjust the tensionAdjustable stressOptical waveguide light guideFibre with gratingsFiberElasterell

The invention discloses a fiber bragg grating packaging structure and packaging method, and belongs to the technical field of fiber packaging, the fiber bragg grating packaging structure comprises a shell and further comprises: a fiber bragg grating assembly, wherein the fiber bragg grating assembly comprises a fixed sliding block, a movable sliding block and a fiber bragg grating, the two ends of the fiber bragg grating are fixedly connected to the fixed sliding block and the movable sliding block respectively, and the fixed sliding block is connected with one end of the shell; an elastic piece which is connected with one end of the movable sliding block; and an adjusting device, wherein one end of the adjusting device is connected to the shell, the other end of the adjusting device is connected with the other end of the movable sliding block, the position of the movable sliding block can be adjusted through the adjusting device, and therefore the stress of the fiber bragg grating is adjusted. The shell is provided with the fiber bragg grating assembly, the elastic piece and the adjusting device, the position of the movable sliding block is changed by adjusting the expansion degree of the elastic piece through the adjusting device, and therefore the tensioning degree of the fiber bragg grating connected between the movable sliding block and the fixed sliding block can be adjusted, and the stress of the fiber bragg grating can be adjusted.

Owner:NANKAI UNIV

Transceiver integrated all-optical ultrasonic transducer device and preparation method thereof

ActiveCN111112035BCompact packageSimple signal processingMechanical vibrations separationDouble-clad fiberTransceiver

Owner:HUAZHONG UNIV OF SCI & TECH

Assembly method of detachable polymer lithium ion battery

ActiveCN104466235BPackaging precisionStable structureFinal product manufactureElectrolyte accumulators manufactureElectrical batteryStructural engineering

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

Flip-chip high-heat-radiation spheroidal array encapsulation structure

ActiveCN101840896BIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesElectricitySolder ball

The invention relates to a flip-chip high-heat-radiation spheroidal array encapsulation structure, which comprises a chip, an electric interconnection material, a lower filling material, a base plate, a plastic sealing material and a welding ball. A spring heat radiator is also arranged in the encapsulation structure. The electric interconnection material is planted on the front side of the chip, and is inversely arranged on the base plate, and the electric interconnection between the chip and the base plate is realized through the electric interconnection material, the lower filing material fills a gap between the chip and the base plate, the plastic sealing material plastically seals the spring heat radiator, the chip, the electric interconnection material, the lower filling material and the base plate for forming a plastic sealing body, the circumambience of the spring heat radiator is fixed by the plastic sealing material, one end of the spring heat radiator is connected with the chip, and the other end of the spring heat radiator is exposed on the surface of the plastic sealing body for radiating the heat of the chip out of the plastic sealing body. The problem of heat radiation of the encapsulation of carrying bases or inversely arranged chips without exposed metals is solved, and the electric heating performance and the reliability of the products are greatly improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

High-heat-dispersion spherical array encapsulation method

ActiveCN101834150BIncrease cooling areaSolve package heat dissipation problemsSemiconductor/solid-state device detailsSolid-state devicesElectricityBiomedical engineering

The invention relates to a high-heat-dispersion reverse solder spherical array encapsulation method which comprises the following steps of: implanting a chip into a substrate by using a binding material; pasting a spring radiator on the chip; electrically connecting the chip and the substrate by a metal lead; plastically encapsulating the spring radiator, the chip, the metal lead, the binding material and the substrate with a plastic encapsulating material to form a plastic encapsulated body; and fixing the periphery of the spring radiator by the plastic encapsulating material, wherein one end of the spring radiator is connected with the chip, and the other end is exposed out of the surface of the encapsulated body so that the heat of the chip is dispersed out of the encapsulated body. The invention solves the problems of heat dispersion in encapsulation without an exposed metal carrier plates and greatly improves the electrothermal performance and the reliability of the product.

Owner:NANTONG FUJITSU MICROELECTRONICS

Packaging device and packaging method for split-type air conditioner

ActiveCN103350832BHigh strengthThere will be no deformationPackaging vehiclesContainers for machinesCartonStructural engineering

The invention discloses a packing device of a split air conditioner and a method for packing the split air conditioner by using the packing device. The split air conditioner comprises an indoor unit, an outdoor unit and an installing attachment, wherein the installing attachment comprises a connecting copper pipe and a connecting cable, and the indoor unit, the outdoor unit and the installing attachment are arranged in one packing paper box together; the packing paper box is of an upper-down separating structure, and the packing paper box is fixedly bundled through more than two packing belts; the indoor unit is arranged on the upper part and the side surface of the outdoor unit, the front side, the rear side or the right side of the outdoor unit and a packing liner of the outdoor unit and the inner wall of the packing paper box can form a gap together, and the installing attachment is arranged in the gap; and the left and right end surfaces and the middle part of the indoor unit are all provided with upper packing liners matched with the shapes of the left and right end surfaces and the middle part of the indoor unit in the length direction. The packing device and the packing method disclosed by the invention have the characteristics that the structure is simple and reasonable, the volume of the complete machine is small, the rigidity is good, the strength is high, the operation is flexible, the fabricating cost is low, and the packing device is easy to pack.

Owner:GUANGDONG GALANZ GRP CO LTD +1

A packaging structure and packaging method of a mems adjustable optical attenuator

ActiveCN103698854BReduce volumeHighly integratedCoupling light guidesLight reflectionMiniaturization

Owner:苏州盛维新电子科技有限公司

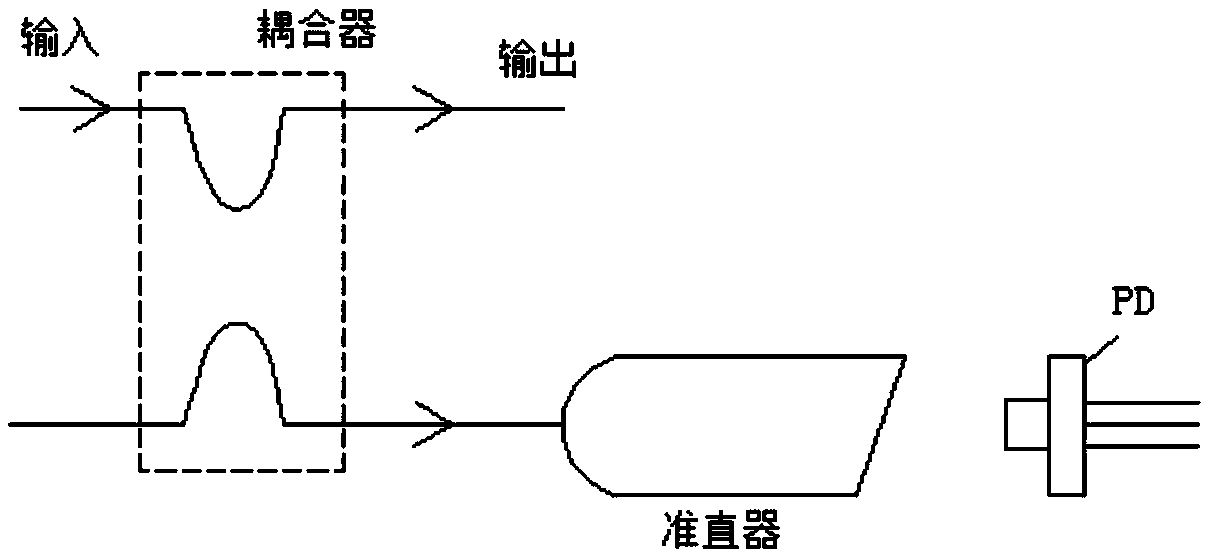

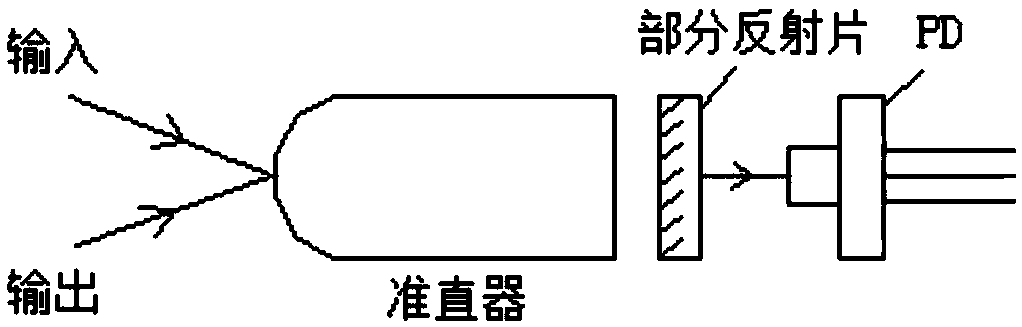

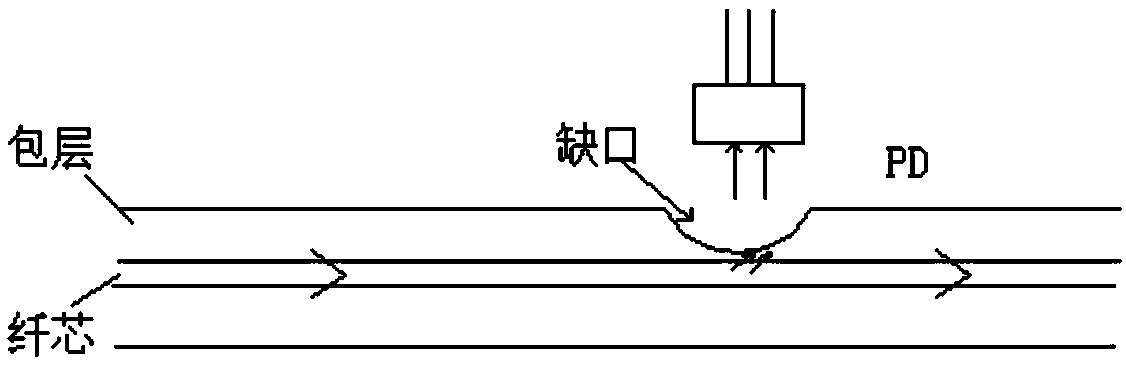

Optical fiber power monitoring structure

InactiveCN110518972AImprove efficiencyLow costCoupling light guidesElectromagnetic transmissionOptical fiber cableFiber Bragg grating

The invention discloses an optical fiber power monitoring structure. The optical fiber power monitoring structure comprises an optical fiber and a photosensitive receiving element used for monitoringoptical signal energy or power; a fiber bragg grating forming an inclination angle with the light transmission direction is arranged in a fiber core of the optical fiber, and part of optical signals transmitted in the fiber core are reflected by the fiber bragg grating, then leaked out of a cladding of the optical fiber in the form of a radiation mode and received by the photosensitive receiving element. By utilizing the characteristics of the fiber bragg grating, power or energy of different wavelengths can be monitored, and the optical fiber power monitoring structure has the characteristicsof simple structure, low cost and the like.

Owner:FUZHOU PHOTOP QPTICS CO LTD

Infrared detector and its forming method, infrared detector packaging structure and its method

ActiveCN111092126BReduce in quantitySmall sizeFinal product manufacturePyrometry using electric radation detectorsHemt circuitsMaterials science

The present invention relates to an infrared detector and its forming method, an infrared detector packaging structure and its forming method. The infrared detector includes: a detector including a substrate, and the substrate has a first surface and a second surface opposite to each other. A sensing circuit is formed on the first surface; a base, the base surface has a depression, the bottom surface of the depression is a curved surface, and the position of the depression corresponds to the sensing circuit; the detector is fixed on the base surface, the second surface of the substrate is in contact with the bottom surface of the depression, so that the sensing surface of the detector is a curved surface. The infrared detector has a relatively low cost.

Owner:ZHEJIANG DALI TECH

A Fast Response Fiber Bragg Grating Temperature Sensor

ActiveCN102213624BImprove protection strengthEasy to implementThermometers using physical/chemical changesFiberGrating

The invention discloses a fast response fiber bragg grating temperature sensor which comprises a fiber bragg grating, a fiber fixing sheet used for fixing the fiber bragg grating, a first optical cable connector and a second optical cable connector, wherein the fiber fixing sheet is arranged in a packaging tube, centers of cross sections of the first and the second optical cable connectors are provided with through holes along the axial direction, the fiber bragg grating fixed on the fiber fixing sheet respectively passes through the through holes of the first and the second optical cable connectors; and a tube wall material on one surface is at least removed from the outer wall of the packaging tube along the axial direction. According to the fiber bragg grating temperature sensor provided by the invention, the thickness of the partial region of the packaging tube is larger, so that higher protection strength is obtained for the fiber bragg grating, and response speed of the fiber bragg grating temperature sensor to the environment temperature is greatly increased. Meanwhile, the fiber bragg grating temperature sensor has a simple and compact packaging structure and is convenient for implementation.

Owner:SHANGHAI KNP CHEM +2

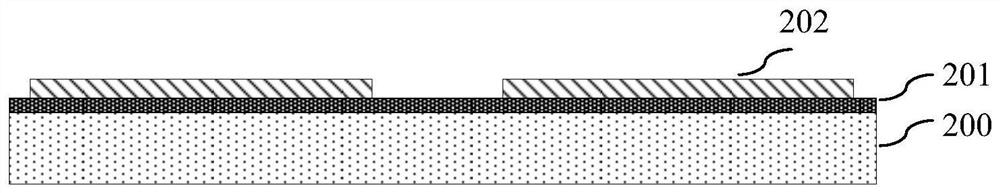

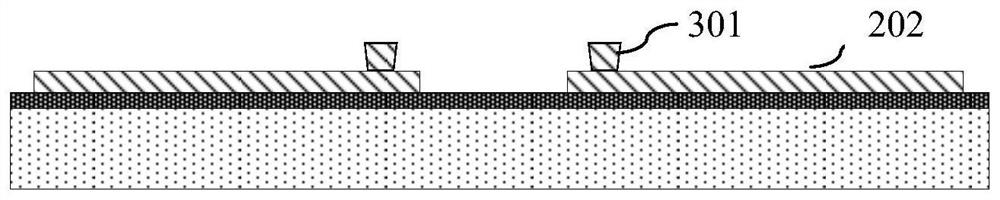

Wafer level chip packaging structure and packaging method

PendingCN113889445ASimple processTightly boundTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsClosed cavity

The invention discloses a wafer level chip packaging structure and a corresponding packaging method. The wafer level chip packaging structure comprises a substrate and a chip, wherein the chip is inversely mounted on the surface of the substrate, and a closed cavity is formed between the functional surface of the chip and the substrate. According to the invention, the packaging structure can be formed on one substrate, the process is simple, the packaging size can be effectively reduced, the thickness can be reduced, and the air tightness of the whole structure can be effectively guaranteed.

Owner:江苏中科智芯集成科技有限公司

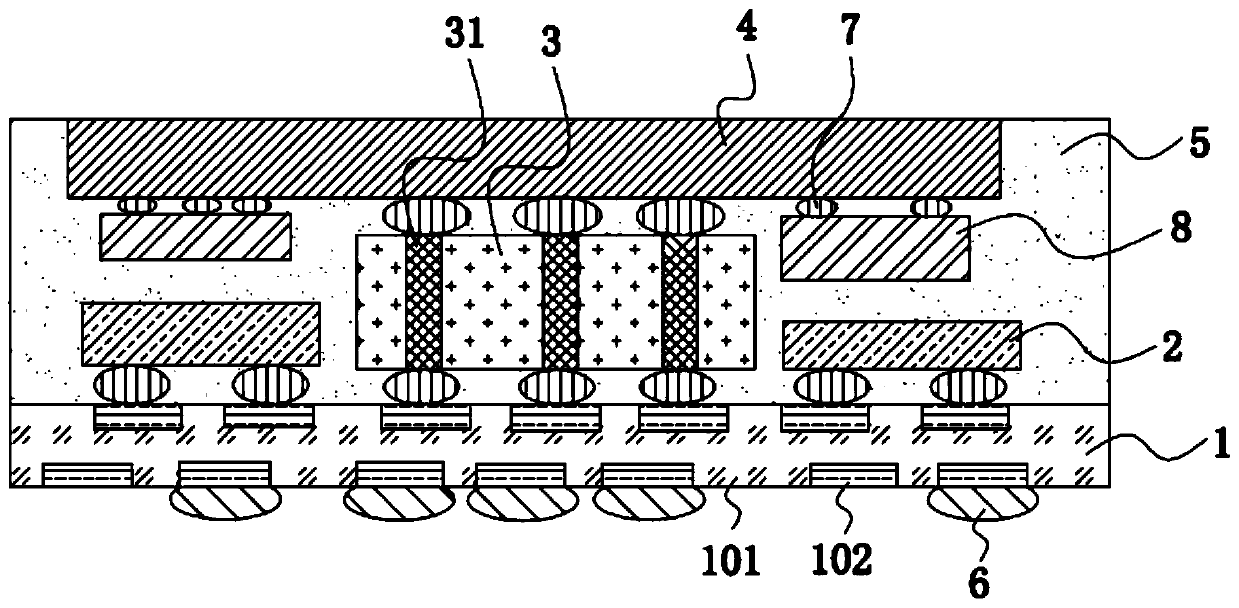

Semiconductor package with passive devices and stacking method thereof

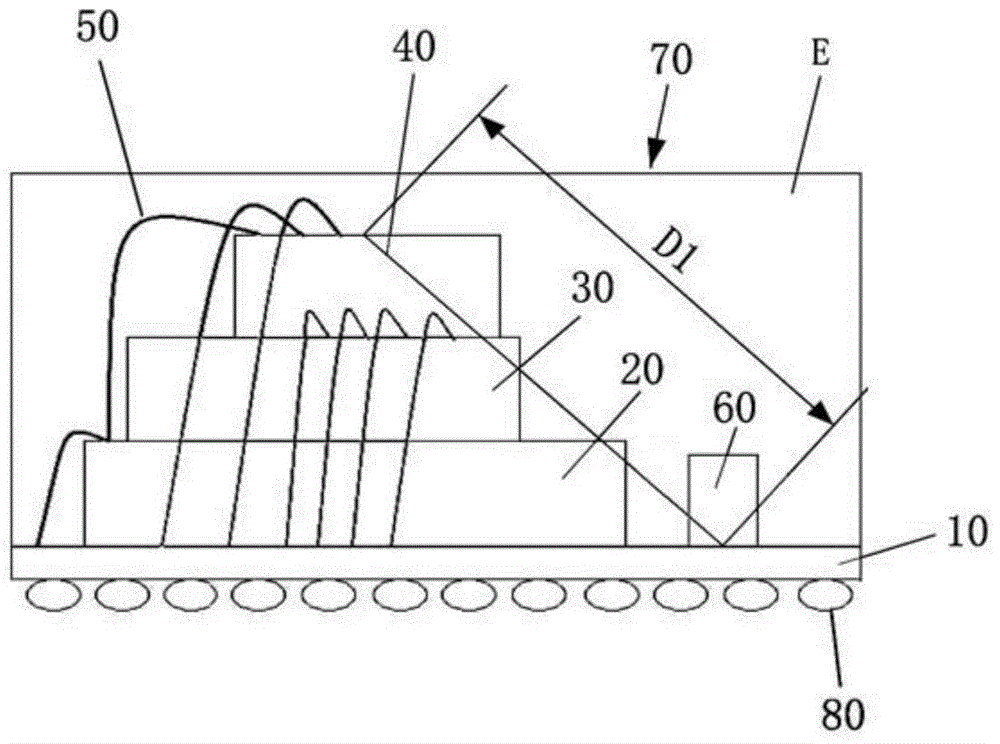

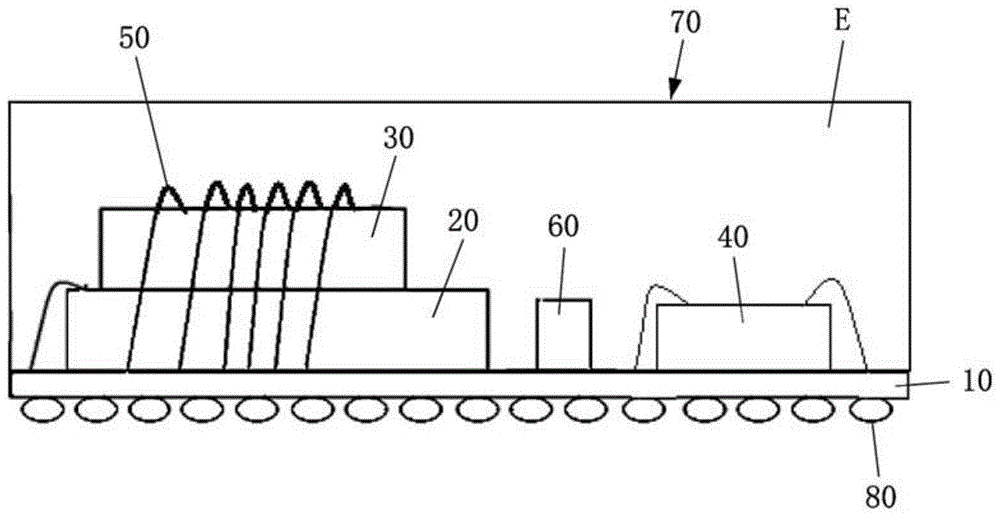

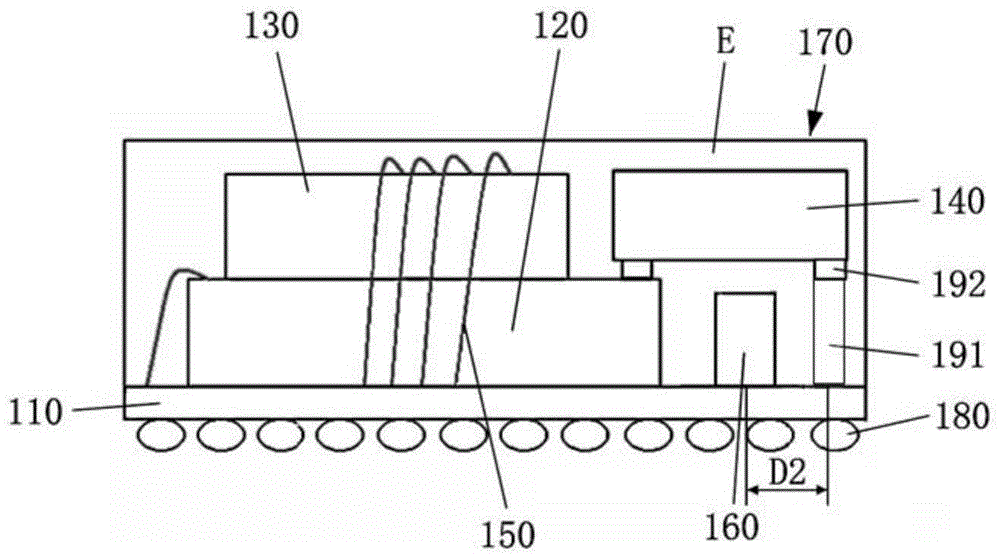

ActiveCN103928416BCompact packageGood signalSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention provides a semiconductor package with passive devices and a stacking method of the semiconductor package. The semiconductor package with the passive devices comprises a first device, a second device and at least one independent passive device, wherein one part of the first device is connected to a substrate, the other part of the first device is connected to the second device, and the independent passive devices are arranged below the first device. The semiconductor package with the passive devices can have a compact packaging structure, obtain better signals and provide the improved electrical characteristics.

Owner:SAMSUNG SEMICON CHINA RES & DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com