Pressure sensor of packaging structure and preparation method thereof

A technology of pressure sensor and packaging structure, which is applied in the direction of measuring fluid pressure by changing ohmic resistance, measuring fluid pressure, instruments, etc. It can solve the problems of complicated process and difficulty in mass production, and achieve simple packaging structure, which is conducive to long-term reliability Sex and stability, convenient and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

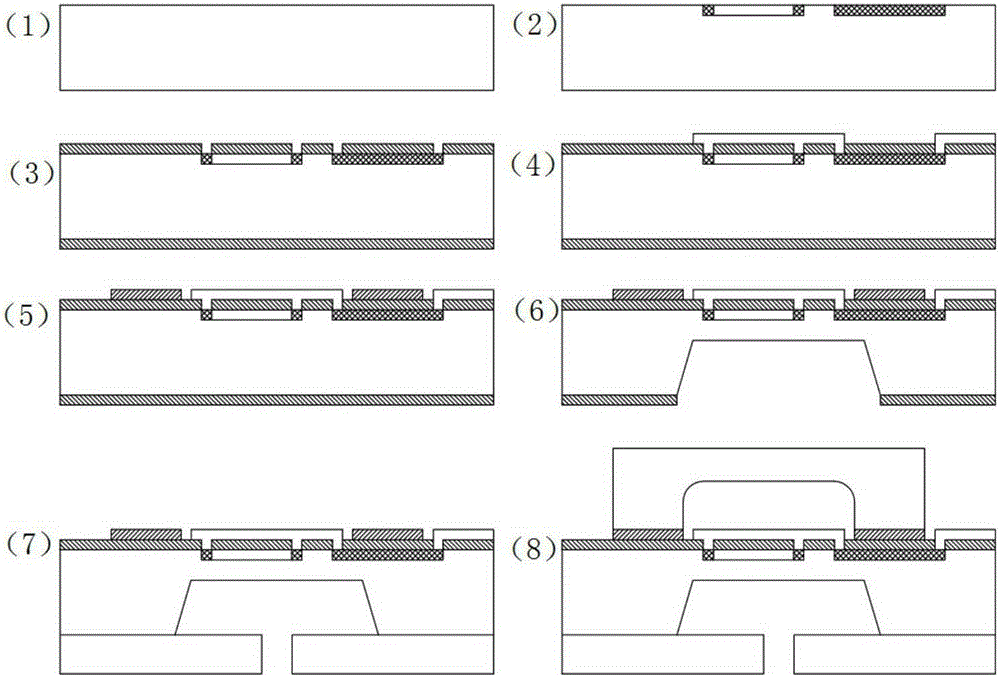

[0030] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

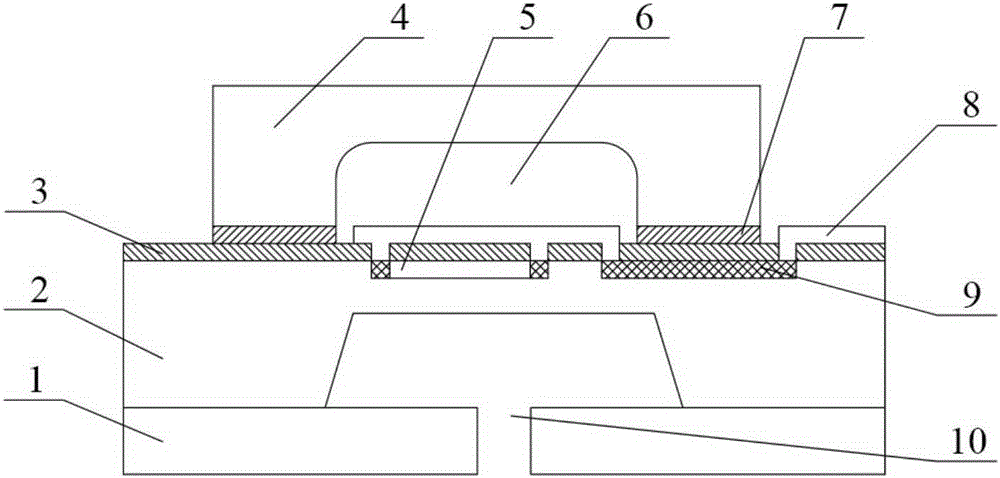

[0031] Such as image 3 As shown, this embodiment includes the following steps:

[0032] (1) Prepare substrate monocrystalline silicon wafer;

[0033] (2) Light boron doping and concentrated boron doping are performed on the front side of the monocrystalline silicon wafer to form a piezoresistive bar structure and a concentrated boron doped area;

[0034] (3) Deposit an insulating layer on both the front and back of the silicon wafer, and etch the piezoresistive bar and the electrical contact holes of the dense boron doped area on the front of the silicon wafer;

[0035] (4) Depositing a metal film on the insulating layer on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com