Packaging structure for microphone with embedded substrate

A packaging structure and microphone technology, applied in the field of microphones, can solve problems such as low efficiency and difficulty in realizing automatic production, and achieve the effects of simple packaging structure, cost reduction, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

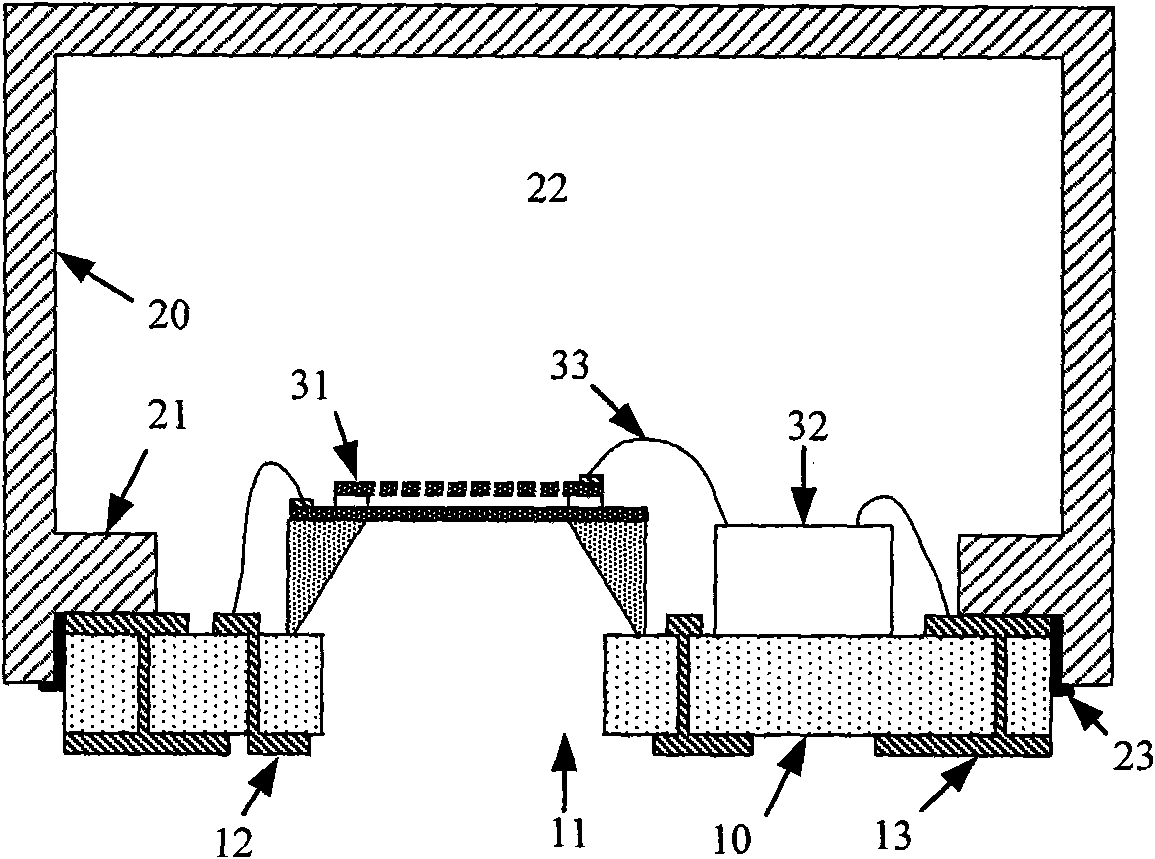

[0044] figure 2A cross-sectional view of the substrate-embedded silicon micro-microphone package of the present invention is shown. The present invention provides a substrate-embedded silicon micro-microphone package, which includes a substrate 10, a top cover 20 with a limiting structure 21, and chips and components 30 mounted on the substrate. The substrate 10 is embedded into the top cover 20 with the chip carrying surface upward, and its embedded depth is adjusted by the position of the limiting structure 21 on the top cover. At the same time, the top cover is connected to the ground electrode on the substrate 10 through the limiting structure 21 to achieve good electromagnetic shielding.

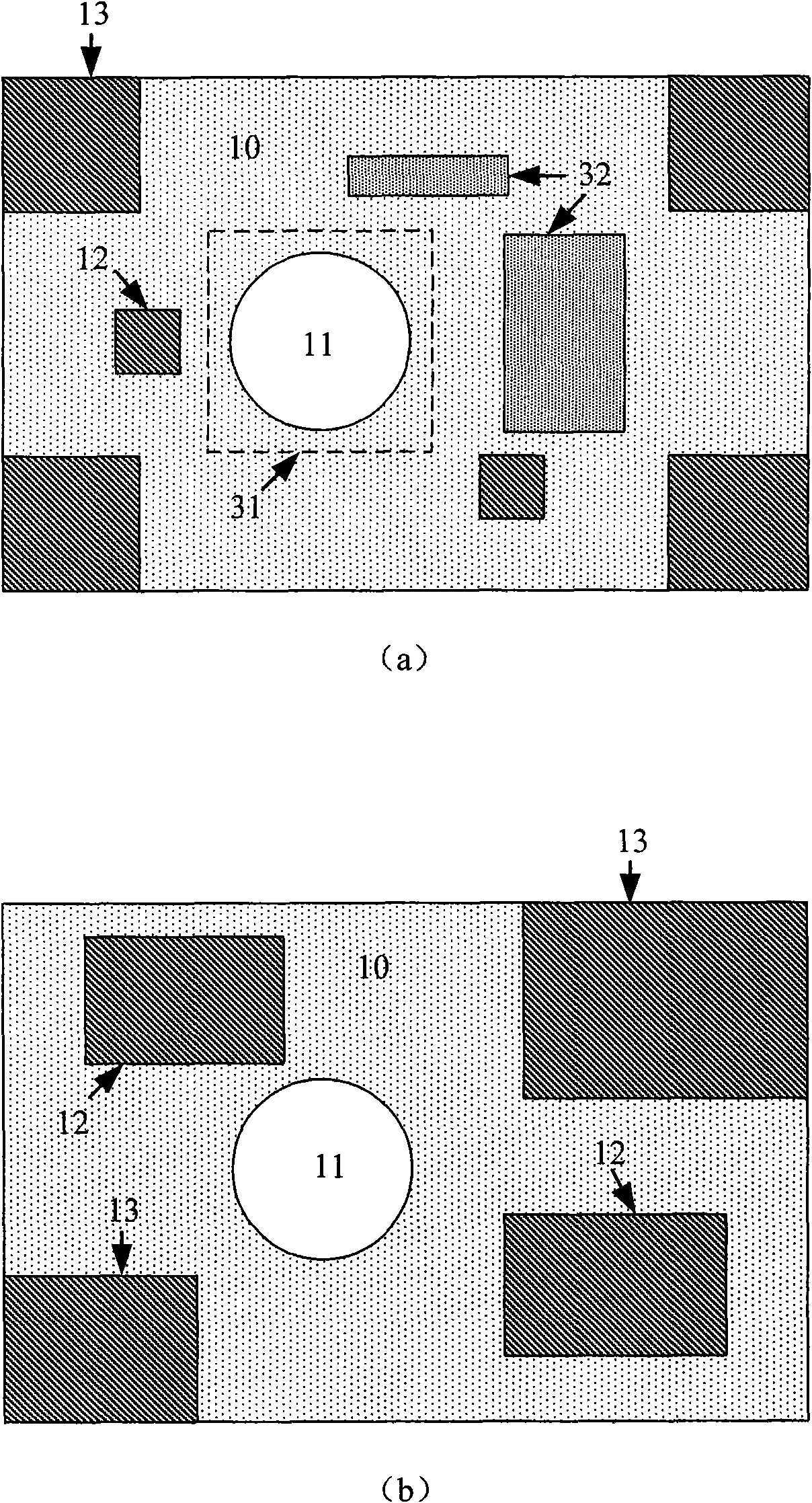

[0045] The top view and bottom view of the substrate 10, such as image 3 (a) and 3(b). A sound hole 11 is formed on the substrate 10. The sound hole 11 is a through hole, generally close to the middle of the substrate, and its size is similar to that of the vibrating membrane of th...

Embodiment 2

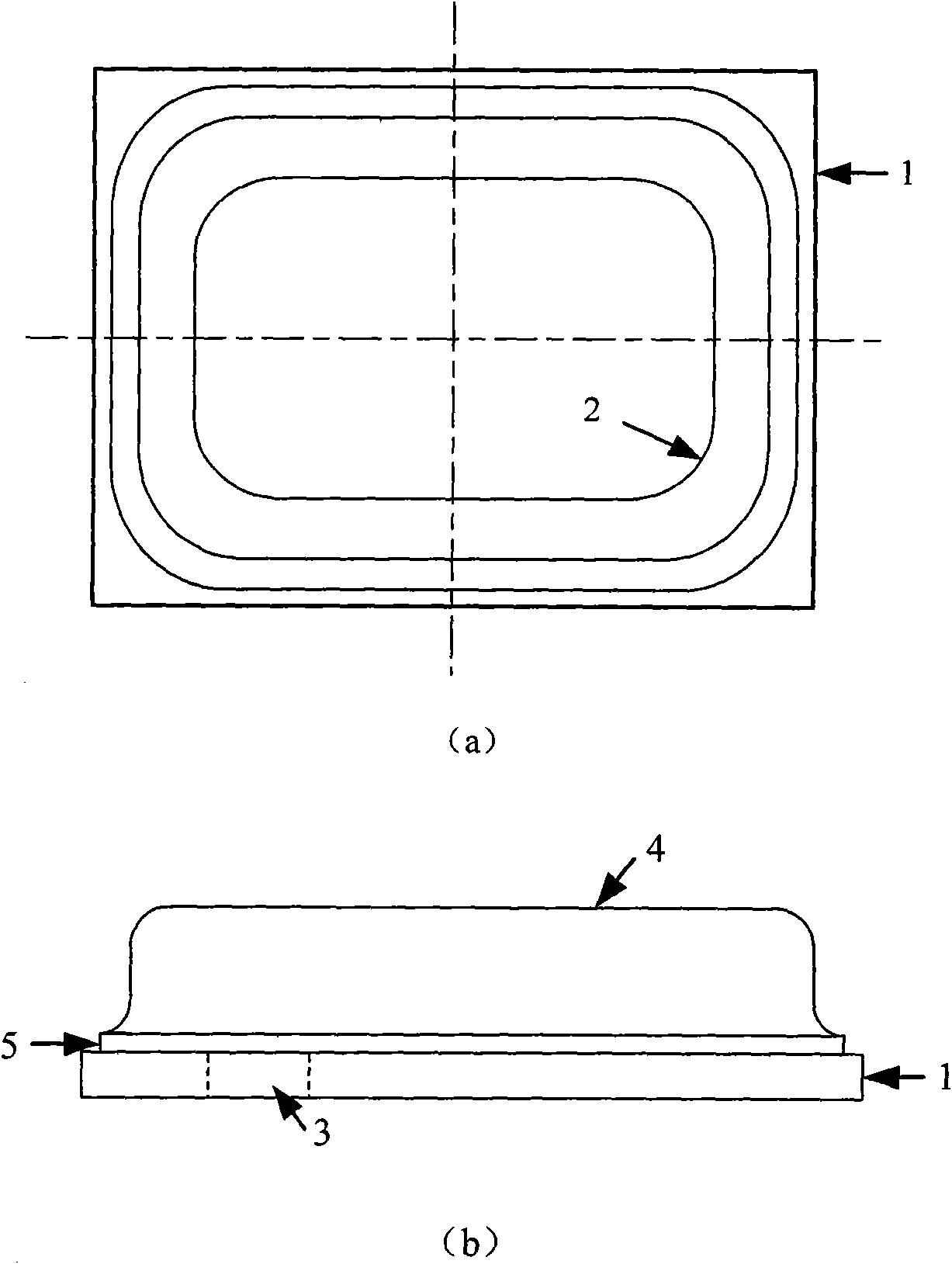

[0052] Figure 4 An embodiment of the substrate-embedded silicon micro-microphone package of the present invention is shown, especially the detailed structure of the top cover 20 .

[0053] Such as Figure 4 (a), the top cover 20 is generally rectangular in plan view, with four inwardly recessed rectangular structures on its four corners. The rectangular flange part at the bottom of the rectangular metal top cover formed by the inwardly recessed rectangular structure at the four corners of the upper part is the position-limiting structure 21 of the top cover. Such as Figure 4 (b), the bottom surfaces of the four limiting structures 21 are located on a plane and parallel to the plane where the bottom edge of the top cover 20 is located. The distance between the bottom surface of the limiting structure 21 and the plane where the bottom edge of the top cover 20 is located can be adjusted freely, but generally not greater than the thickness of the substrate 10 . Such as Fig...

Embodiment 3

[0057] Image 6 An embodiment of the substrate-embedded silicon micro-microphone package of the present invention is shown, especially the detailed structure of the top cover 20 .

[0058] Such as Image 6 (a), the top cover 20 is generally rectangular in plan view, and three rectangular concave structures are distributed on two opposite sides of the top cover 20 . The side wall of the bottom of the metal top cover is radially and vertically inwardly recessed, which is the position-limiting structure 21 of the top cover. Image 6 (b) for Image 6 (a) The cross-sectional view of section A-A in (a), it can be seen that the limiting structure 21 in this embodiment is formed by making some parts of the side wall of the top cover inwardly recessed. The bottom surfaces of the three limiting structures 21 are on a plane, and the plane is parallel to the plane where the bottom edge of the top cover 20 is located. The distance between the bottom surface of the limiting structure 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com