Organic electric-excitation luminescent displaying panel package structure

An electroluminescence and display panel technology, applied in electroluminescence light source, electric light source, light source, etc., can solve the problems of abnormal process, poor electrical condition and yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

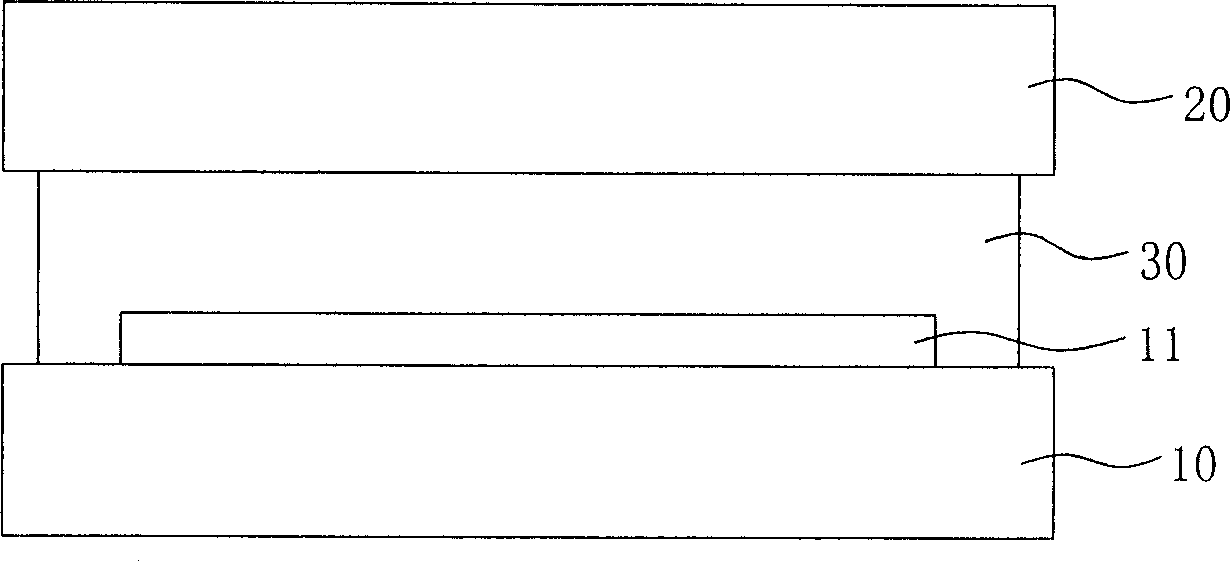

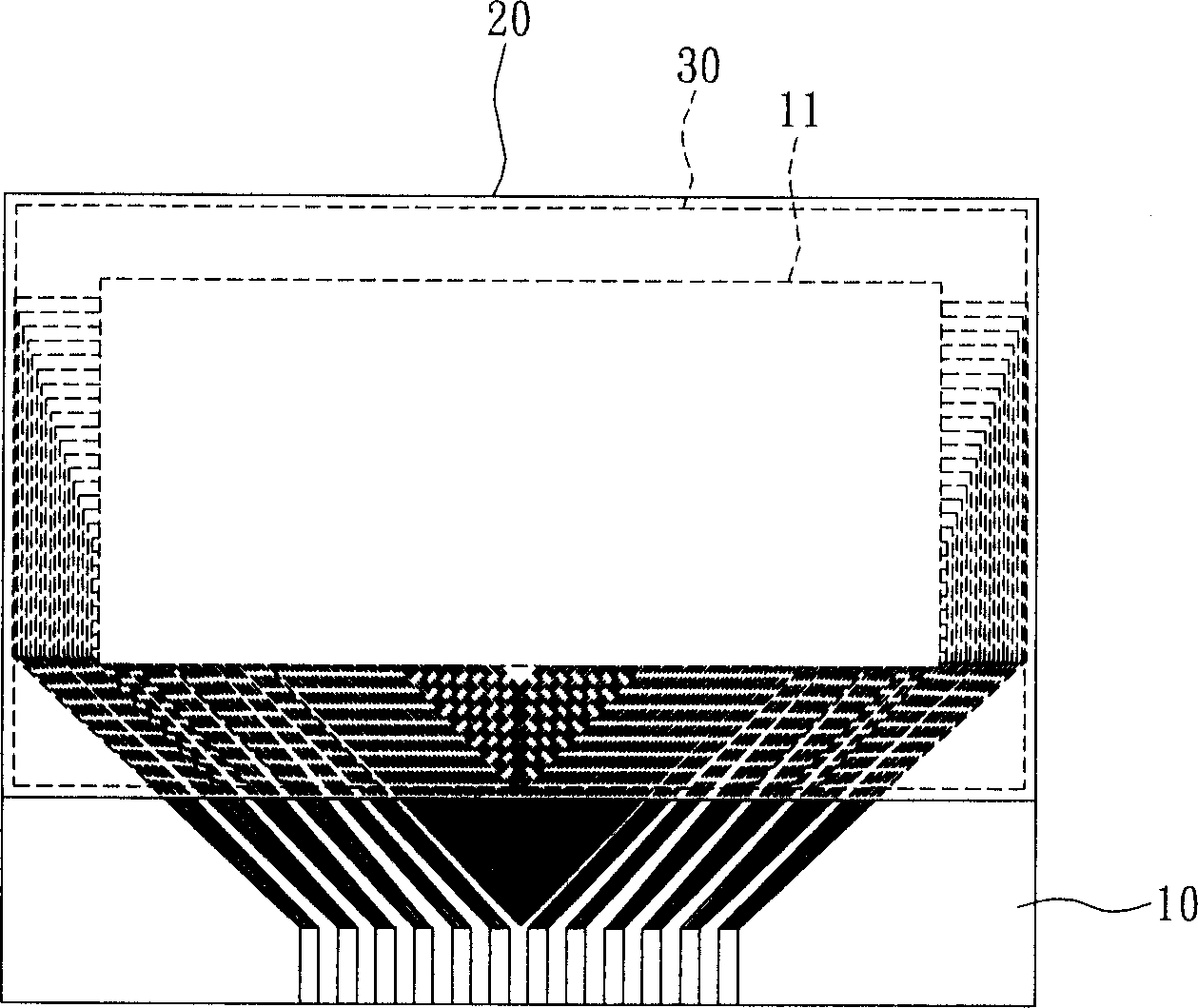

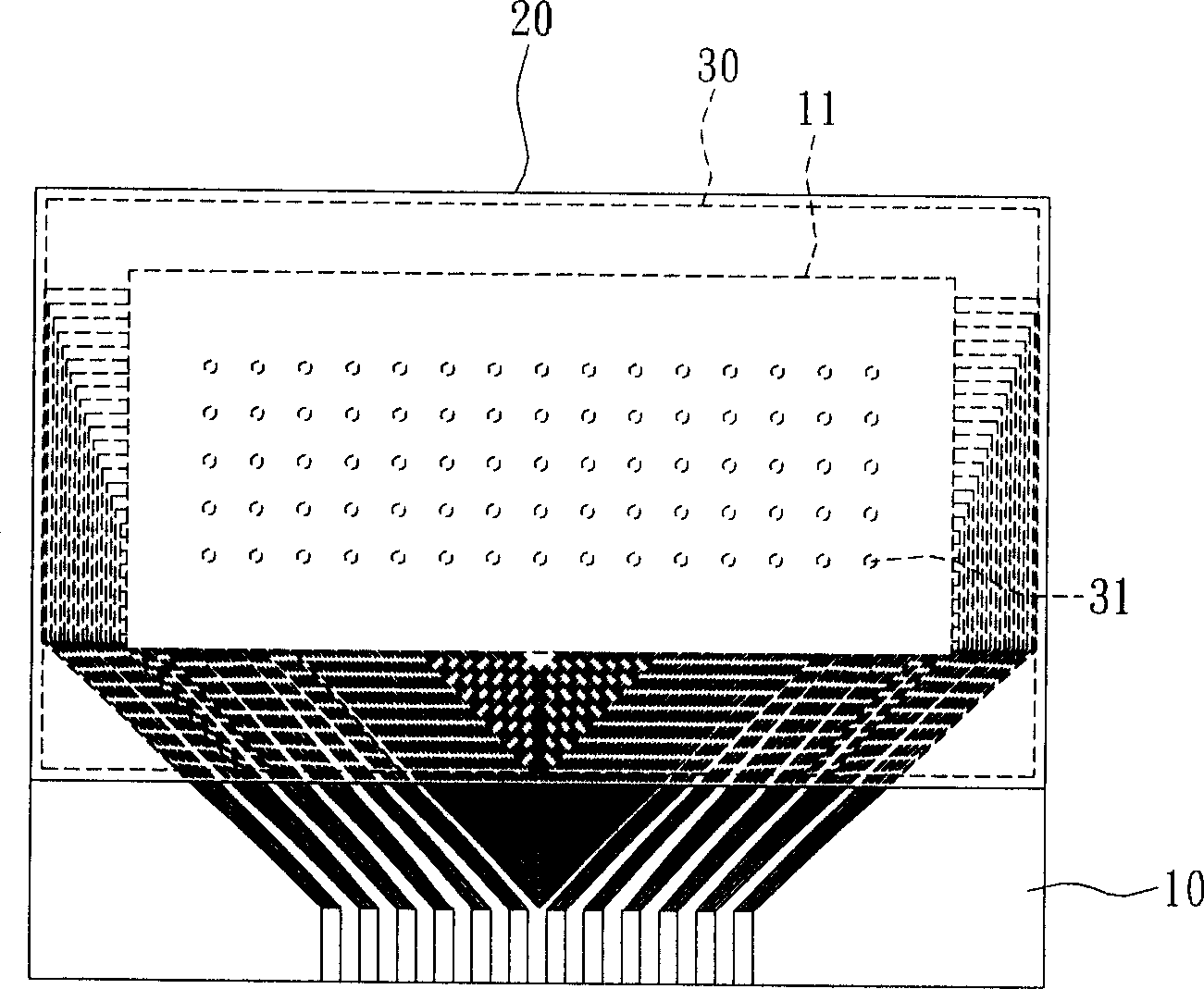

[0034] see figure 1 As shown, the present invention provides an organic light emitting diode (OLED) display panel packaging structure, which includes a glass substrate 10 with an organic light emitting diode 11 formed thereon, and sealed with the glass substrate 10 The cover 20 can be made of glass material, metal material or ceramic material, and a double-sided adhesive film 30 adhered between the glass substrate 10 and the cover 20 . The adhesive film 30 is made of a non-conductive material to avoid damage caused by conduction between the organic electroluminescent display unit 11 fabricated on the glass substrate 10 and the cover 20; and the adhesive film 30 has high plasticity (high plasticity), high weather resistance, anti-ultraviolet, and / or low moisture absorption (low moisture absorption) and other properties that can not deteriorate, and bond the glass substrate 10 and the sealing in a comprehensive sheet form. Cover 20; the adhesive film 30 can match the configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com