A Fast Response Fiber Bragg Grating Temperature Sensor

A technology of temperature sensor and optical fiber grating, which is applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problem that the optical fiber grating temperature sensor cannot have strong protection strength and response speed at the same time, so as to achieve easy implementation and strong protection The effect of strength and simple package structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

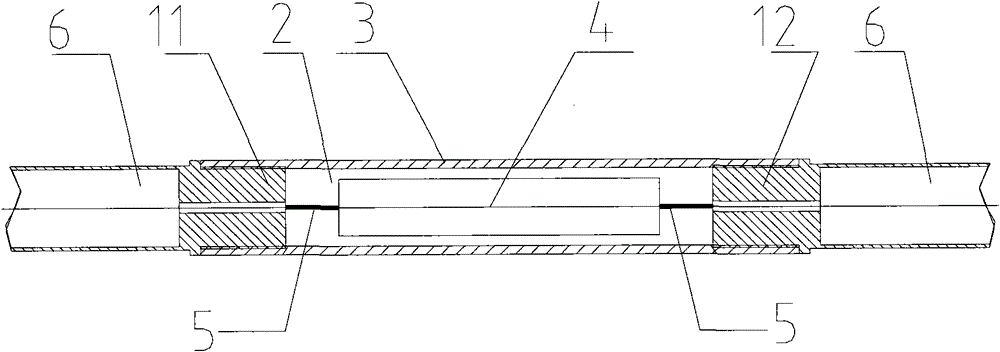

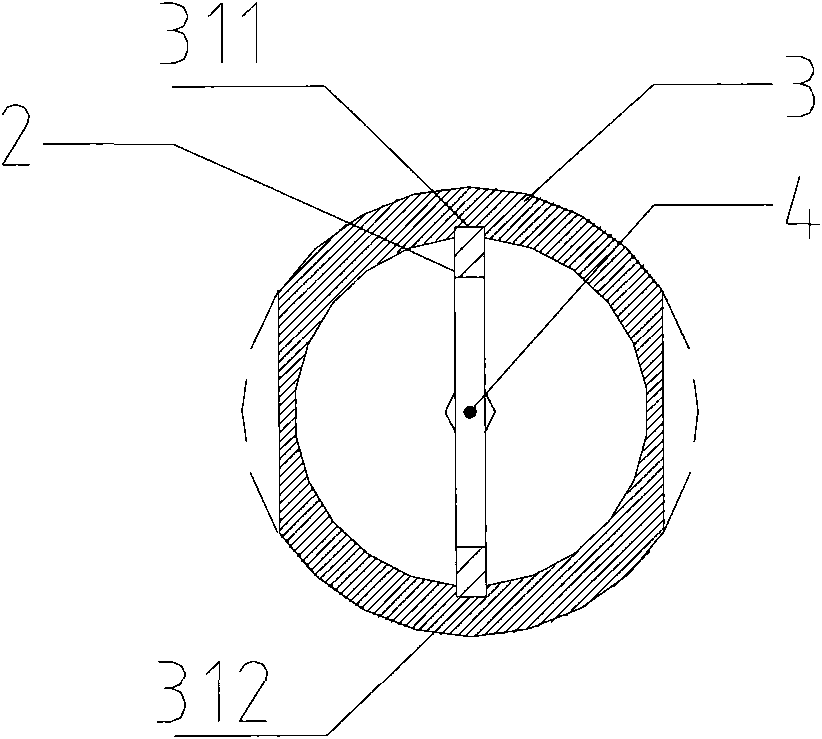

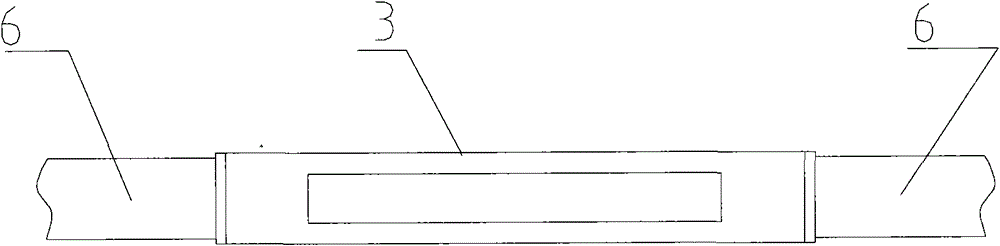

[0022] Example 1: Please also refer to Figure 1 to Figure 6 , figure 1 is a structural schematic diagram of the first embodiment of the present invention, figure 2 yes figure 1 side view diagram of image 3 is a schematic diagram of the appearance of the first embodiment of the present invention, Figure 4 is a schematic diagram of the appearance of the packaging tube in the first embodiment of the present invention, Figure 5 yes Figure 4 side view of the sectional view, Image 6 It is a schematic diagram of the structure of the rectangular optical fiber fixing sheet. As shown in the figure, the fast-response fiber grating temperature sensor includes a fiber grating 4, a fiber fixing sheet 2 for fixing the fiber grating 4, the fiber fixing sheet 2 is built into the packaging tube 3, and the center of the cross section opens a first through hole along the axial direction. The optical cable connector 11 and the second optical cable connector 12 are connected to the tw...

Embodiment 2

[0028] Example 2: Please also refer to Figure 7 to Figure 9 , Figure 7 is a schematic diagram of the appearance of the packaging tube in the second embodiment of the present invention, Figure 8 yes Figure 7 side view diagram of Figure 9 It is a structural schematic diagram of a dumbbell-shaped optical fiber fixing piece. The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the tube wall material on the four sides is removed symmetrically in the axial direction on the outer wall of the packaging tube 3, such as Figure 8 As shown, the blank space in the dotted line is to remove the part of the tube wall material, so that the thickness of the packaging tube 3 is reduced, and the heat can be transmitted to the fiber grating 4 inside the packaging tube 3 more quickly, and the fiber grating 4 can control the ambient temperature. Changes in the system play a role of rapid response, and send out signals in a timely and accurate manner.

[0029]The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com