Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Reduce material cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

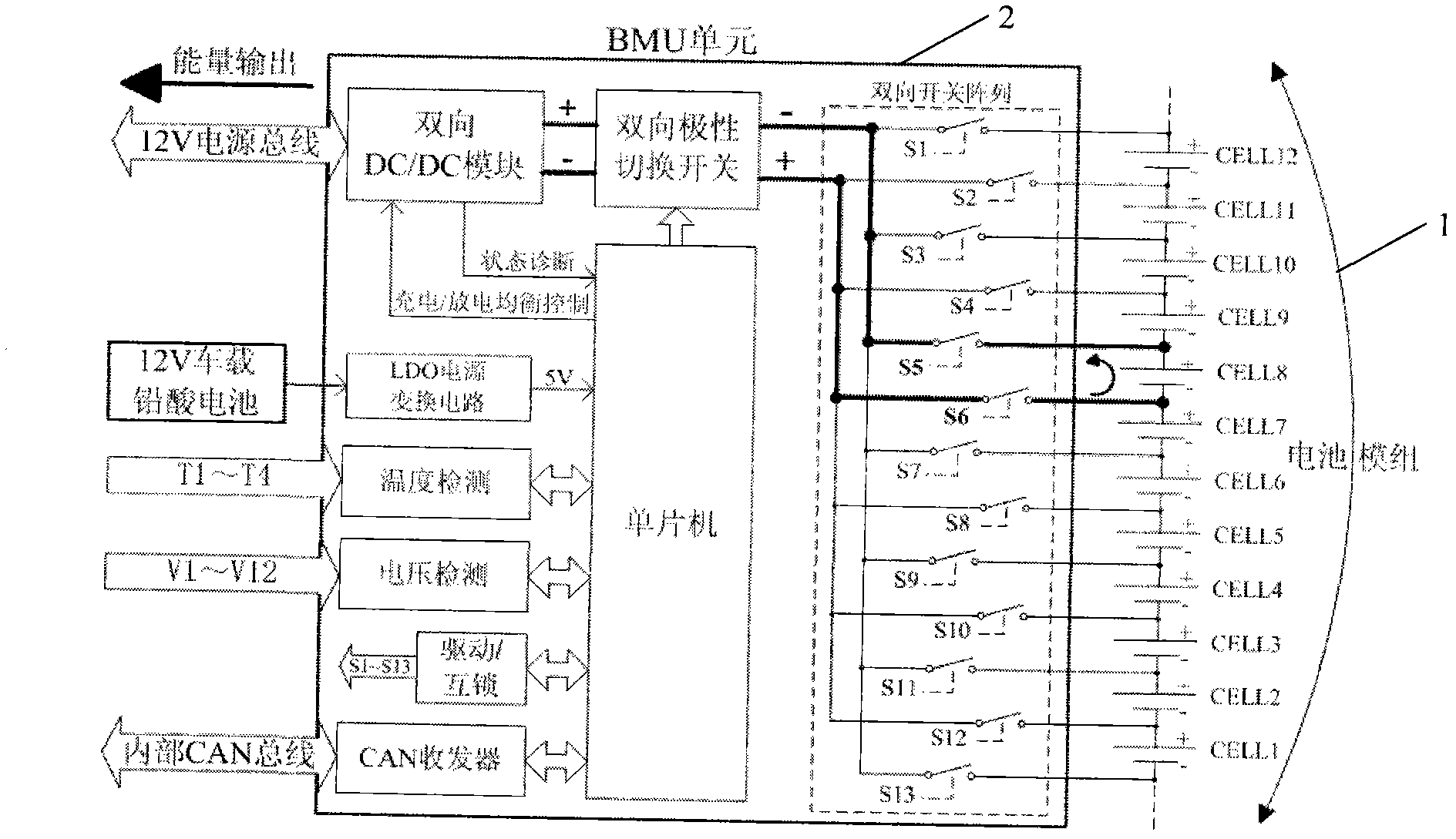

Cell equalization system based on bidirectional DC/DC

InactiveCN102664433AReduce material costSolve fever problemBatteries circuit arrangementsElectric powerTime-sharingCharge and discharge

The invention relates to the cell equalization system technology field and especially relates to a cell equalization system based on bidirectional DC / DC. The cell equalization system comprises a cell module, a cell management unit and a power supply bus. The cell management unit comprises a single chip microcomputer, a bidirectional DC / DC module, a bidirectional polarity switch and a driving / interlocking circuit. An input terminal of the bidirectional DC / DC module is connected with the power supply bus. An output terminal of the bidirectional DC / DC module is connected with the input terminal of the bidirectional polarity switch. A charging / discharging equalization control terminal of the single chip microcomputer is connected with a control terminal of the bidirectional DC / DC module. A polarity switch control terminal of the single chip microcomputer is connected with the control terminal of the bidirectional polarity switch. The single chip microcomputer controls a bidirectional switch array through the driving / interlocking circuit. According to the invention, through using the single chip microcomputer to control the bidirectional DC / DC module, the bidirectional polarity switch and the bidirectional switch array, time sharing charging and discharging equalization of each cell in the cell module can be realized.

Owner:DONGGUAN NVT TECH

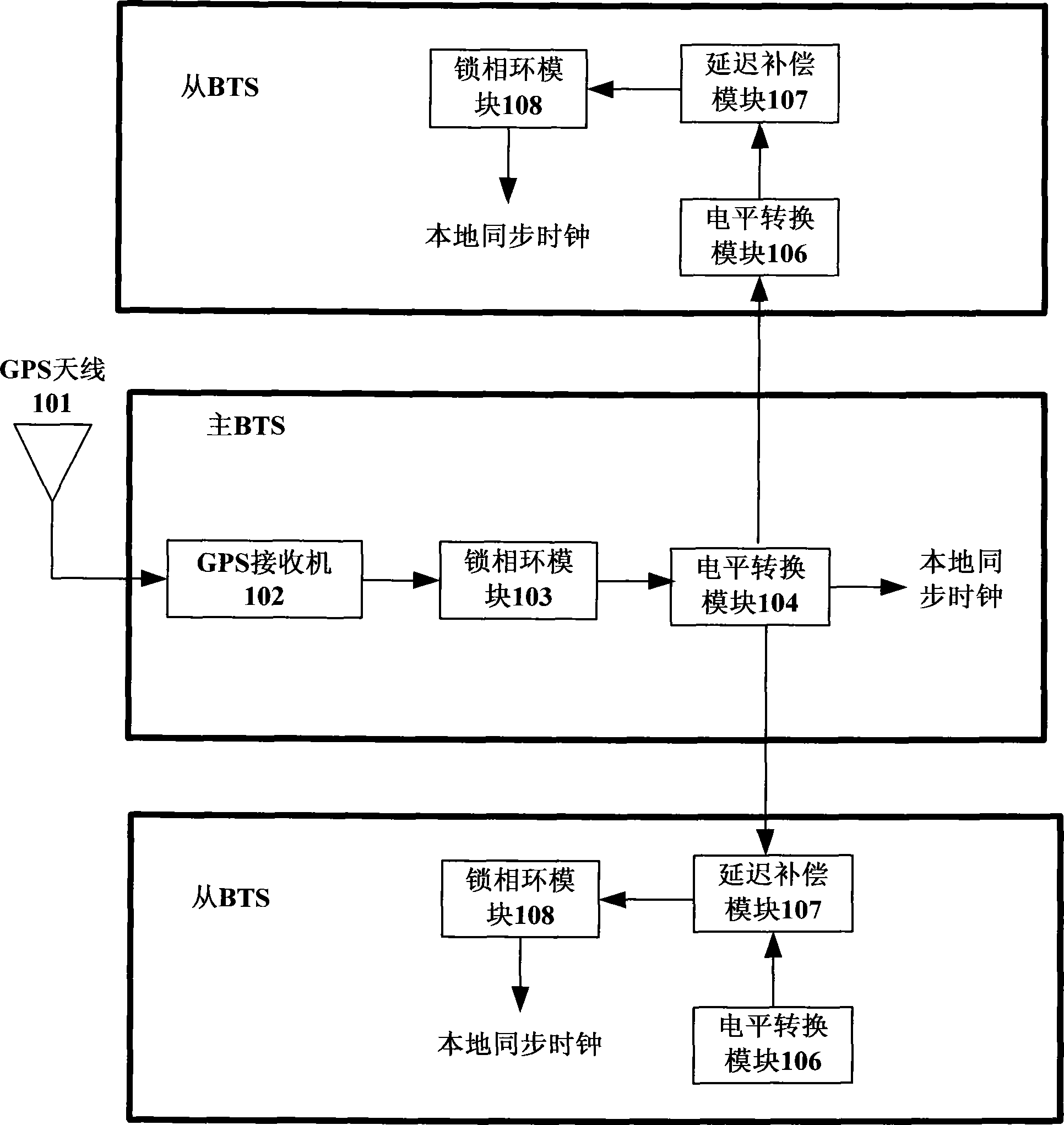

Method and network for realizing multi-sector base transceiver station clock cascade synchronization

InactiveCN102098776AReduce engineering costsReduce material costSynchronisation arrangementSynchronisation information channelsTransceiverBase transceiver station

The invention discloses a method and a network for realizing multi-sector base transceiver station clock cascade synchronization. The method comprises that: the network formed by uniting a plurality of base transceiver stations (BTS) comprises a master BTS and at least one slave BTS; only the master BTS is configured with a global positioning system (GPS) antenna; the master BTS acquires a GPS signal through the GPS antenna on the master BTS, converts the GPS signal into a local synchronous clock signal and transmits the synchronous clock signal to each slave BTS; and the slave BTS performs local clock synchronization after receiving the synchronous clock signal from the master BTS. The network is formed by uniting the plurality of BTSs, and comprises the master BTS and the at least one slave BTS, wherein only the master BTS is configured with the GPS antenna. The method and the network can save GPS related equipment comprising the GPS antenna and a GPS receiver required by the BTS, thereby greatly saving engineering cost and material cost.

Owner:ZTE CORP

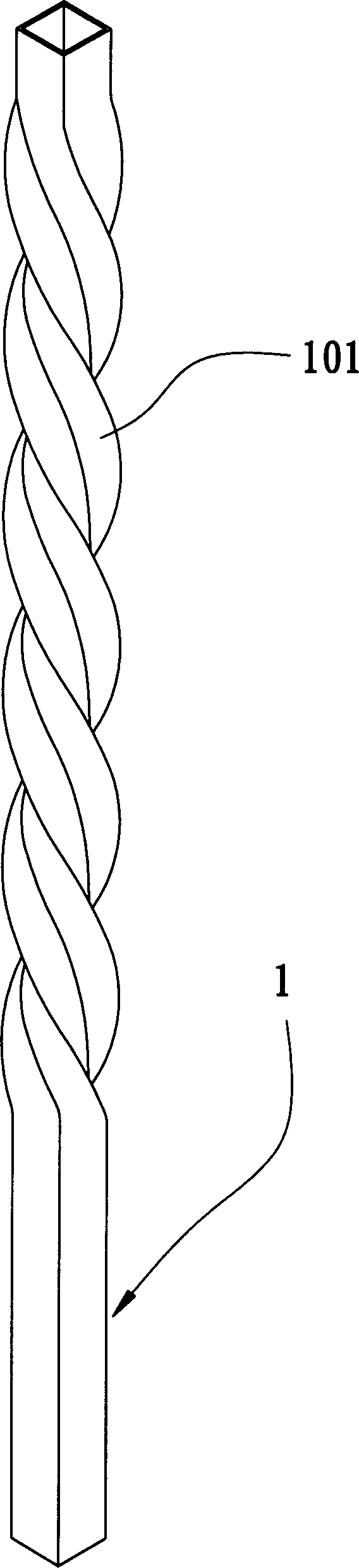

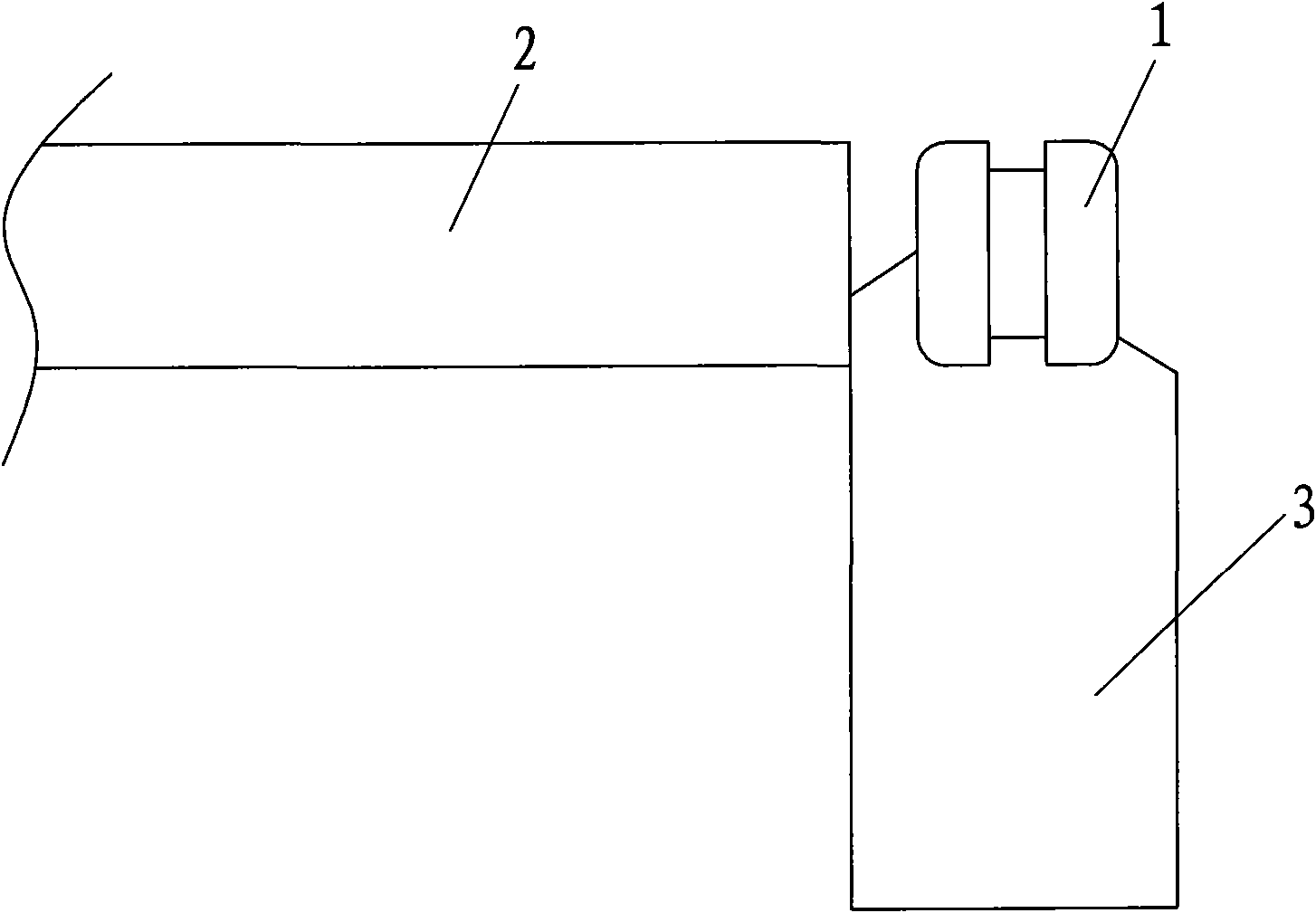

Hollow metal pipe twisting formation method

The metal pipe twisting formation process includes the following steps: A. preparing one metal pipe with one first locating section, one second locating section and one pre-twisted section in between, and one reinforcing part with cross section shape corresponding to that of the inner holes of the first locating section and the second locating section and length greater than that of the pre-twisted section; B. setting the reinforcing part inside the inner hole of the pre-twisted section with two ends of the reinforcing part stretched into the inner holes of the first locating section and the second locating section separately; and C. twisting the first locating section and the second locating section relatively to make the pre-twisted section form one twisting structure along the axis. The present invention has simple process, no influence on the support and rotation of fixture and no leakage.

Owner:钟 旻儒

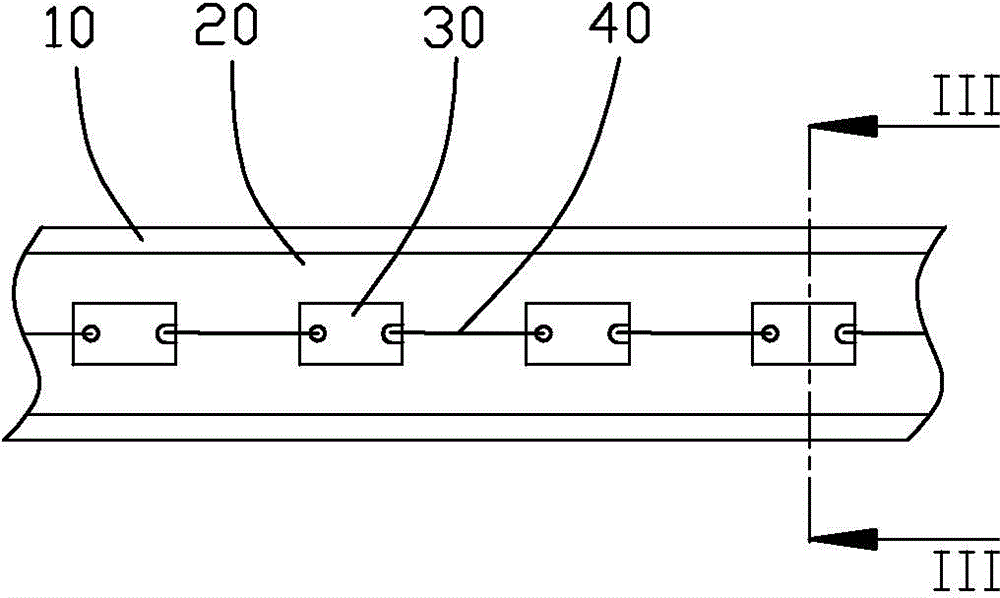

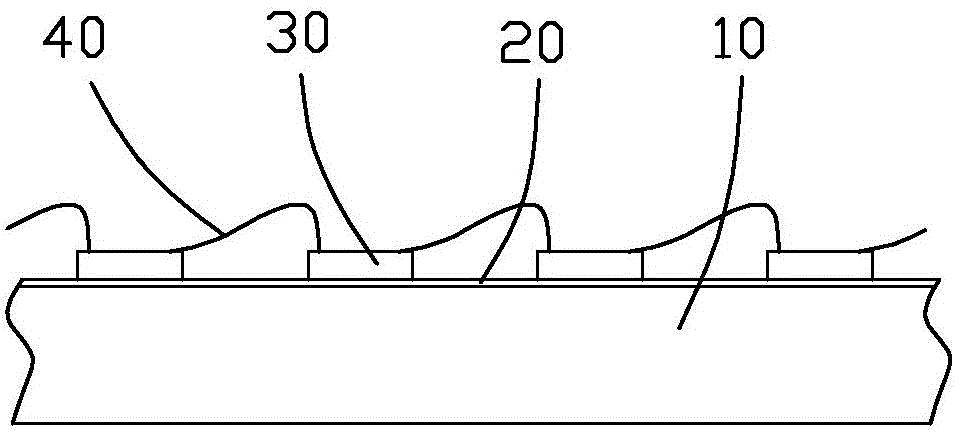

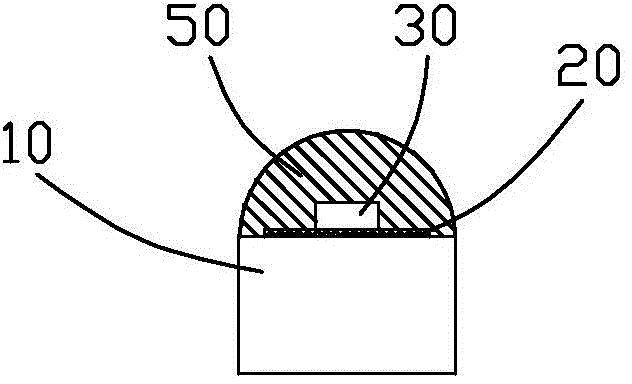

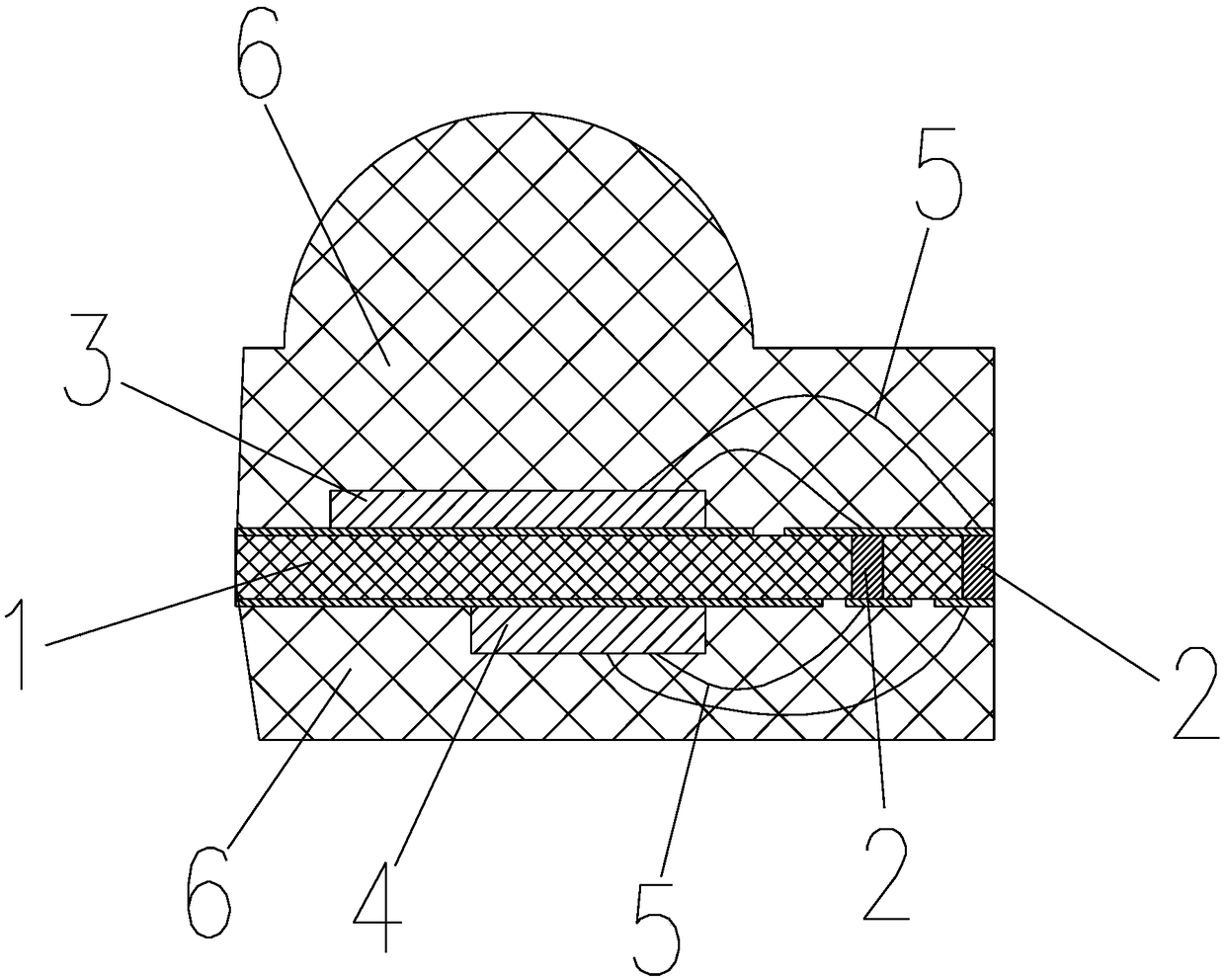

LED filament

InactiveCN104319342AReduce material costNo leakage blueSolid-state devicesSemiconductor devicesFluorescenceLED filament

An LED filament comprises a transparent substrate and LED wafers arranged on the transparent substrate. The LED wafers are electrically connected through metal wires to form a closed circuit, a fluorescent adhesive layer is formed in a physical or chemical mode on one wafer fixing side of the substrate, the LED wafers are fixedly arranged on the fluorescent adhesive layer and completely located within the range of the fluorescent adhesive layer, and a fluorescent adhesive coating layer is formed on the wafers in an adhesive dispensing or die pressing mode and completely wraps the LED wafers and the wires. According to the LED filament, the wafers are fixedly arranged on the fluorescent adhesive layer formed on the wafer fixing side of the transparent substrate, the fluorescent adhesive coating layer is formed on the wafers in an adhesive dispensing or die pressing mode, the dosage of fluorescent powder and adhesive can be reduced, and the material cost is reduced; and the side of the filament is free of blue leakage.

Owner:SHENZHEN REFOND OPTOELECTRONICS

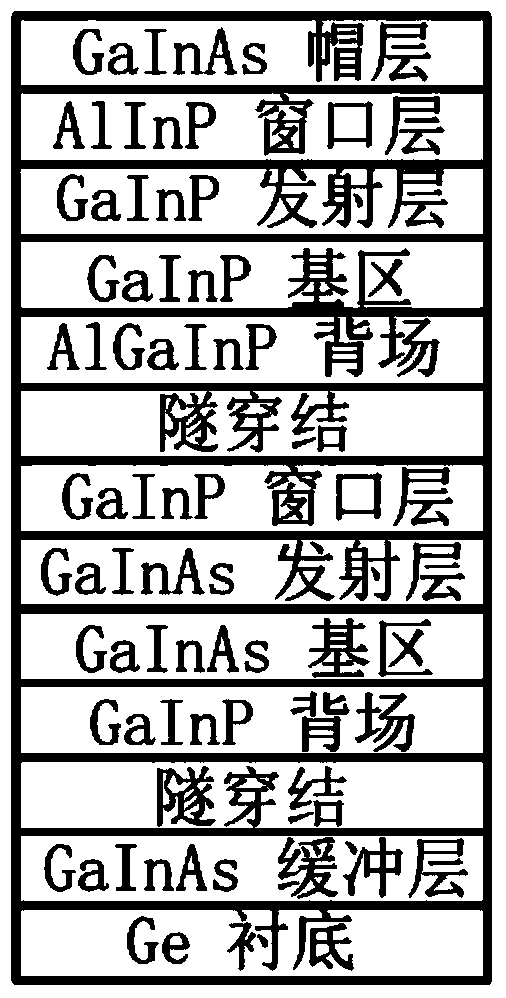

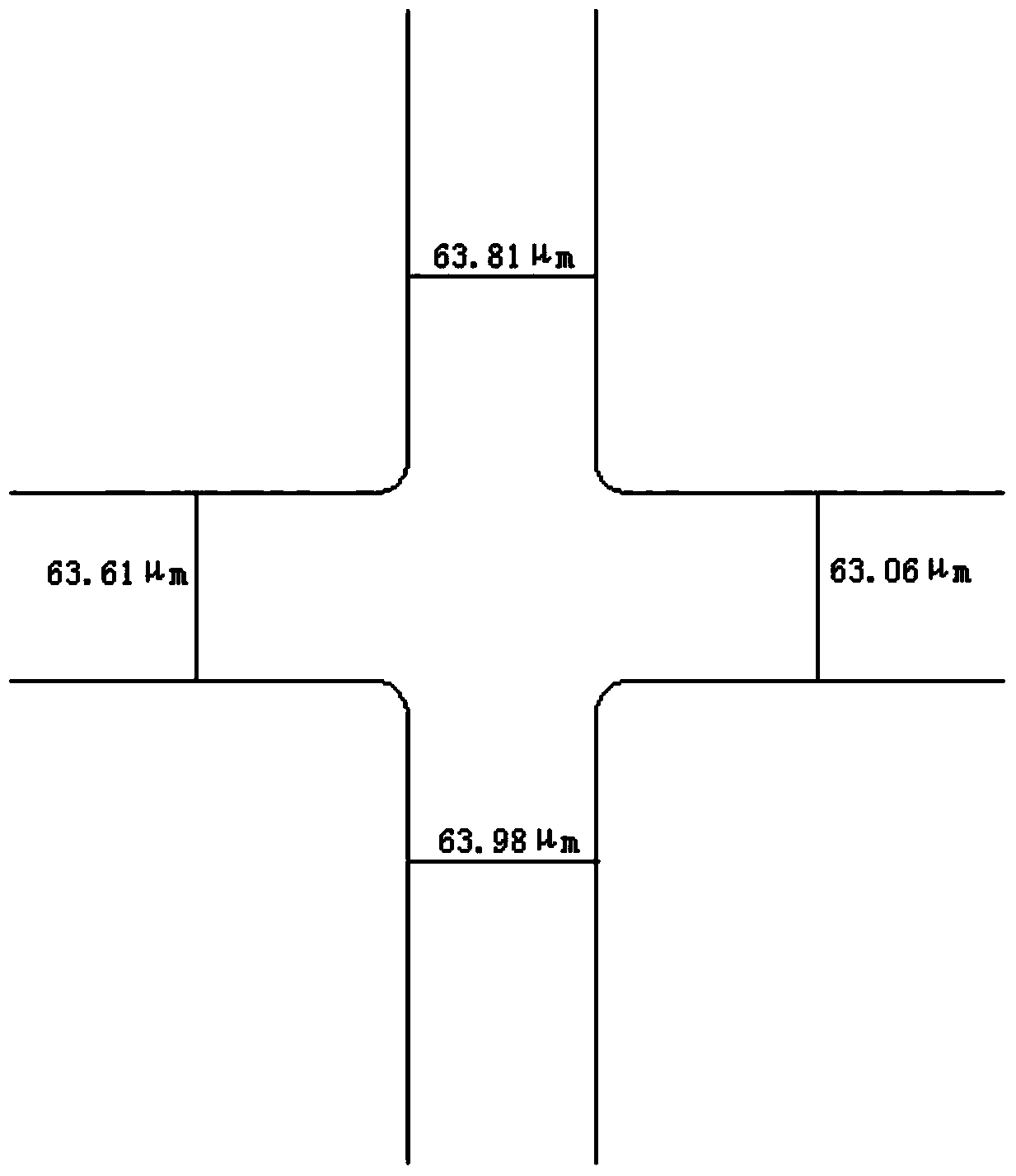

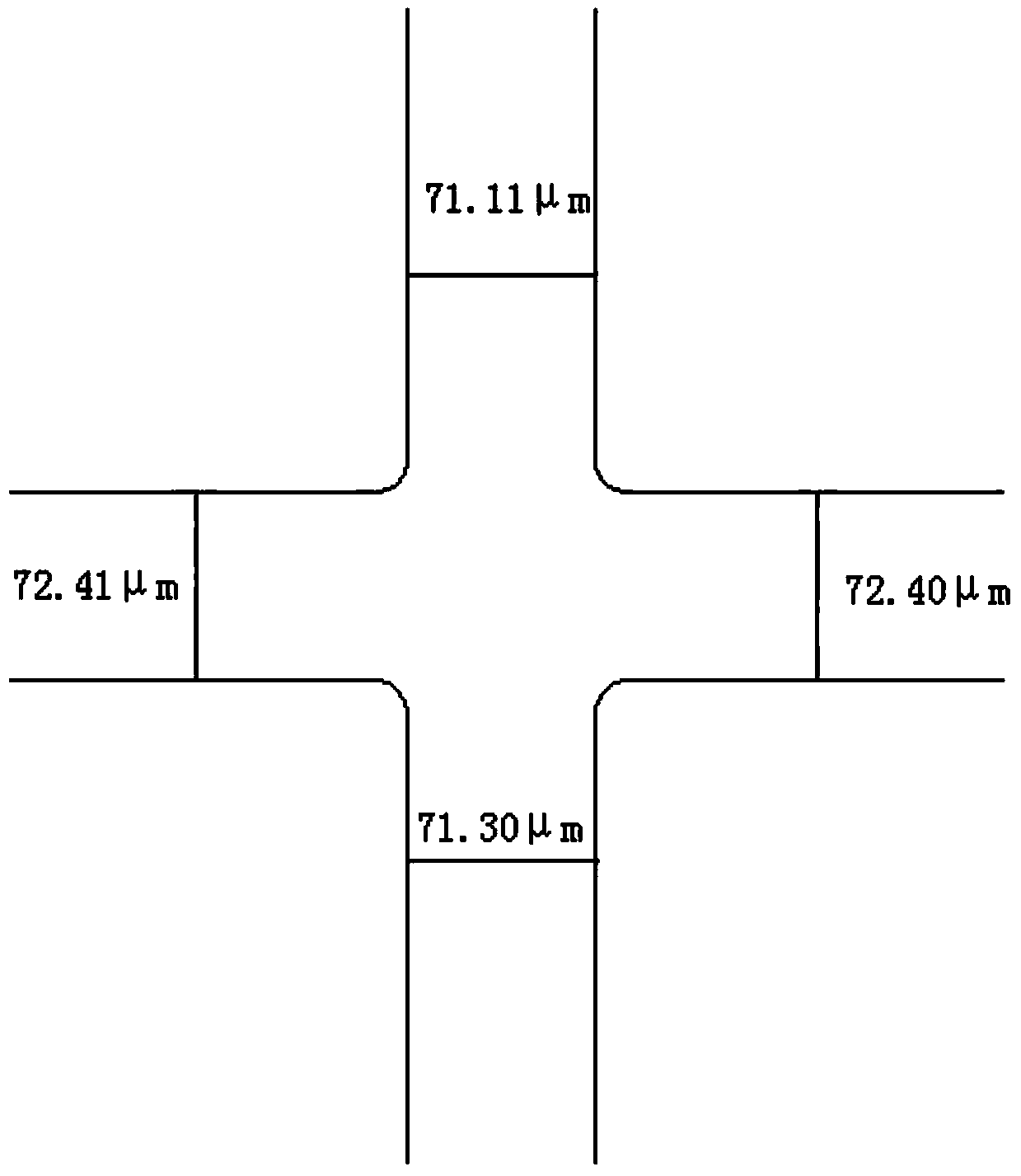

Non-selective wet etching solution for III-V semiconductor materials as well as preparation method and application of non-selective wet etching solution

ActiveCN104388092ASimple processReduce material costSurface treatment compositionsQuaternary compoundPhosphoric acid

The invention discloses a non-selective wet etching solution for III-V semiconductor materials as well as a preparation method and application of the non-selective wet etching solution. The etching solution comprises the following components in percentage by weight: 4%-8% of potassium dichromate, 18%-51% of concentrated hydrochloric acid, 36%-66% of phosphoric acid and 8-9% of deionized water. By the etching solution, the non-selective wet etching of polybasic compounds such as elemental, binary, ternary and quaternary compounds combined by GaAs system, InP system and III-V family can be achieved and meanwhile, the non-selective wet etching for metal materials such as a Ge substrate and Au / Ag / AuGeNi can also be achieved. The formula of the etching solution is not affected by virtue of the epitaxial doping concentration. By the etching solution, only one photoetching protection procedure is needed to complete the etching process, the etching deviation can be controlled within + / - 4%, the wet-etching process is superior to other dry-etching process and is simple, stable, feasible and low in material cost and is suitable for industrial production and laboratory use.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

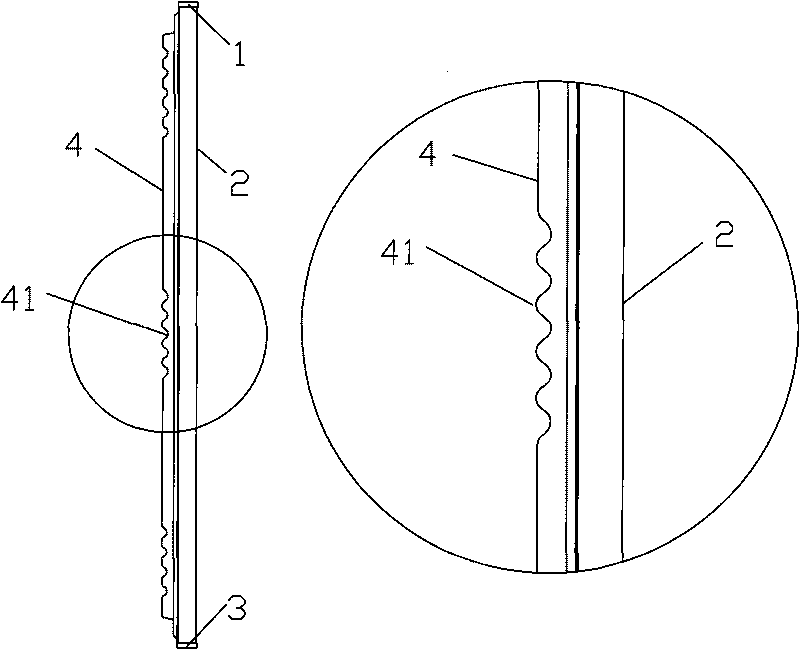

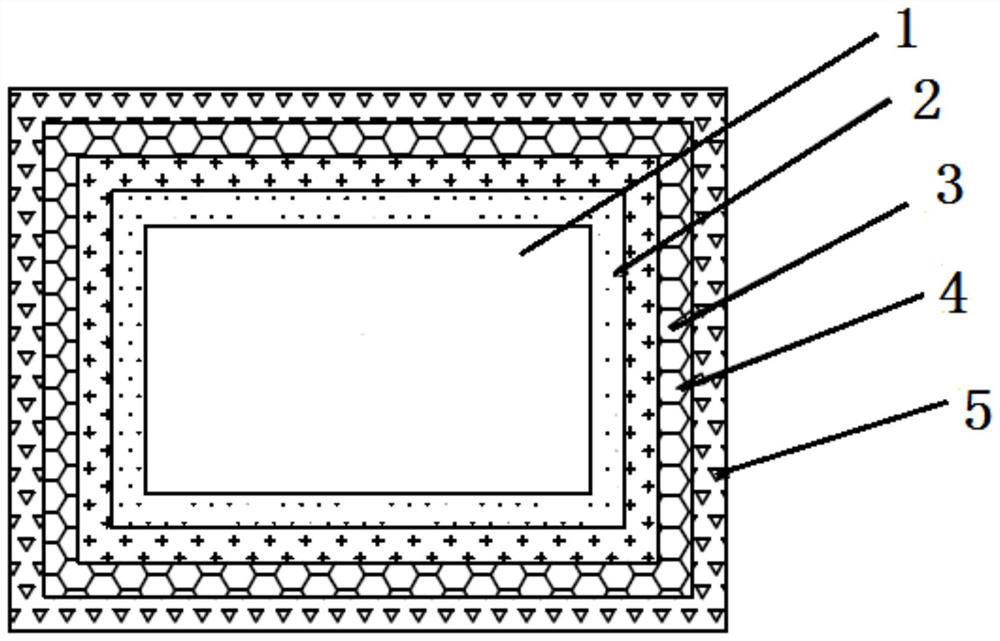

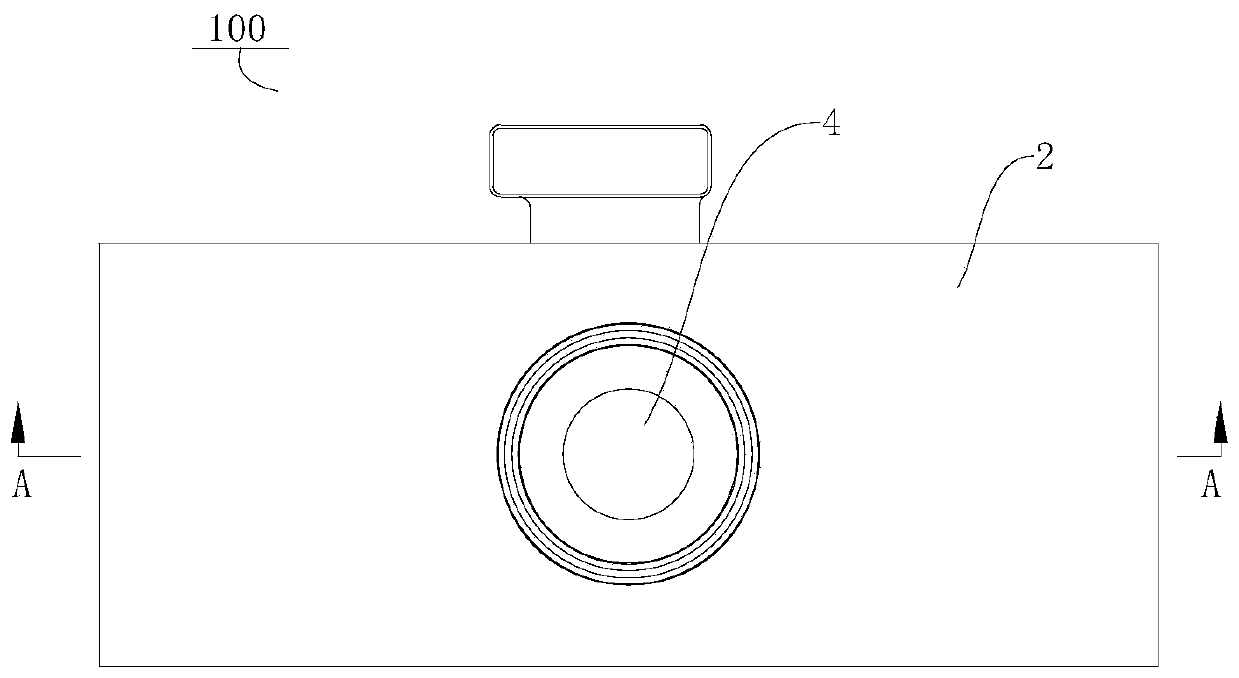

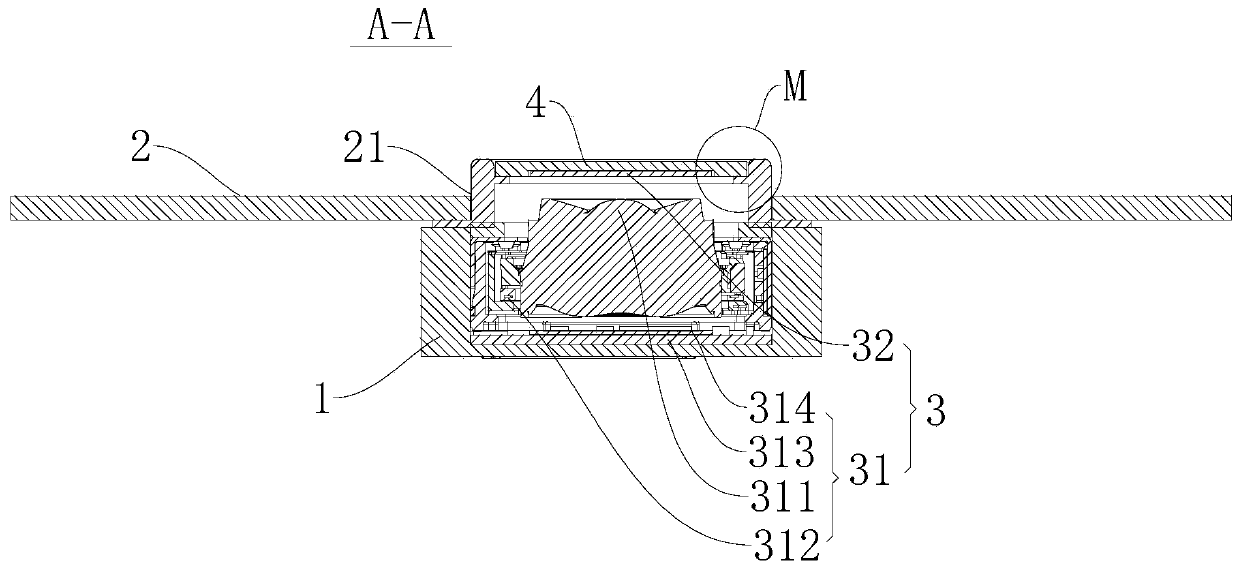

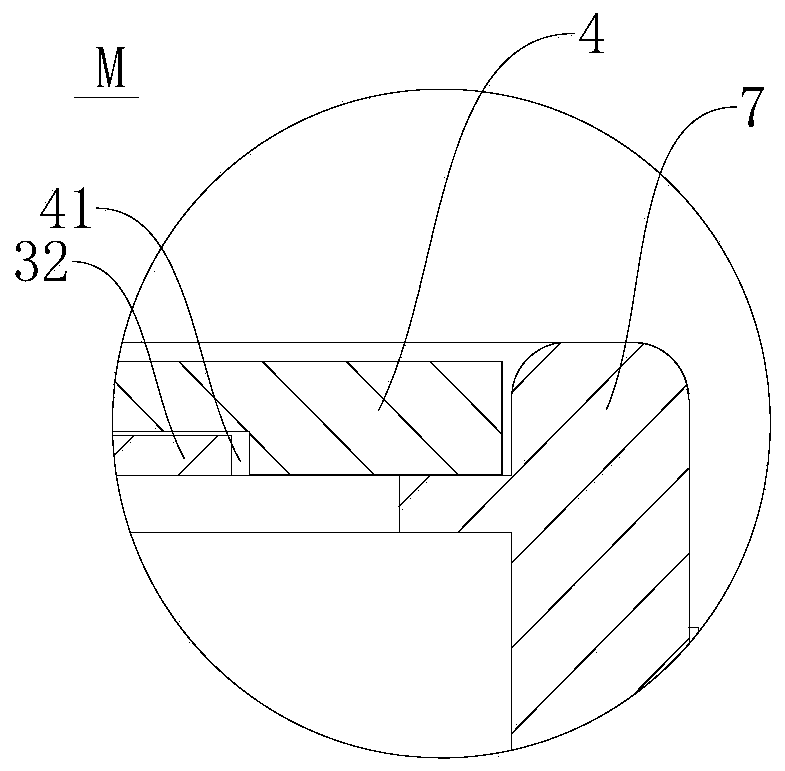

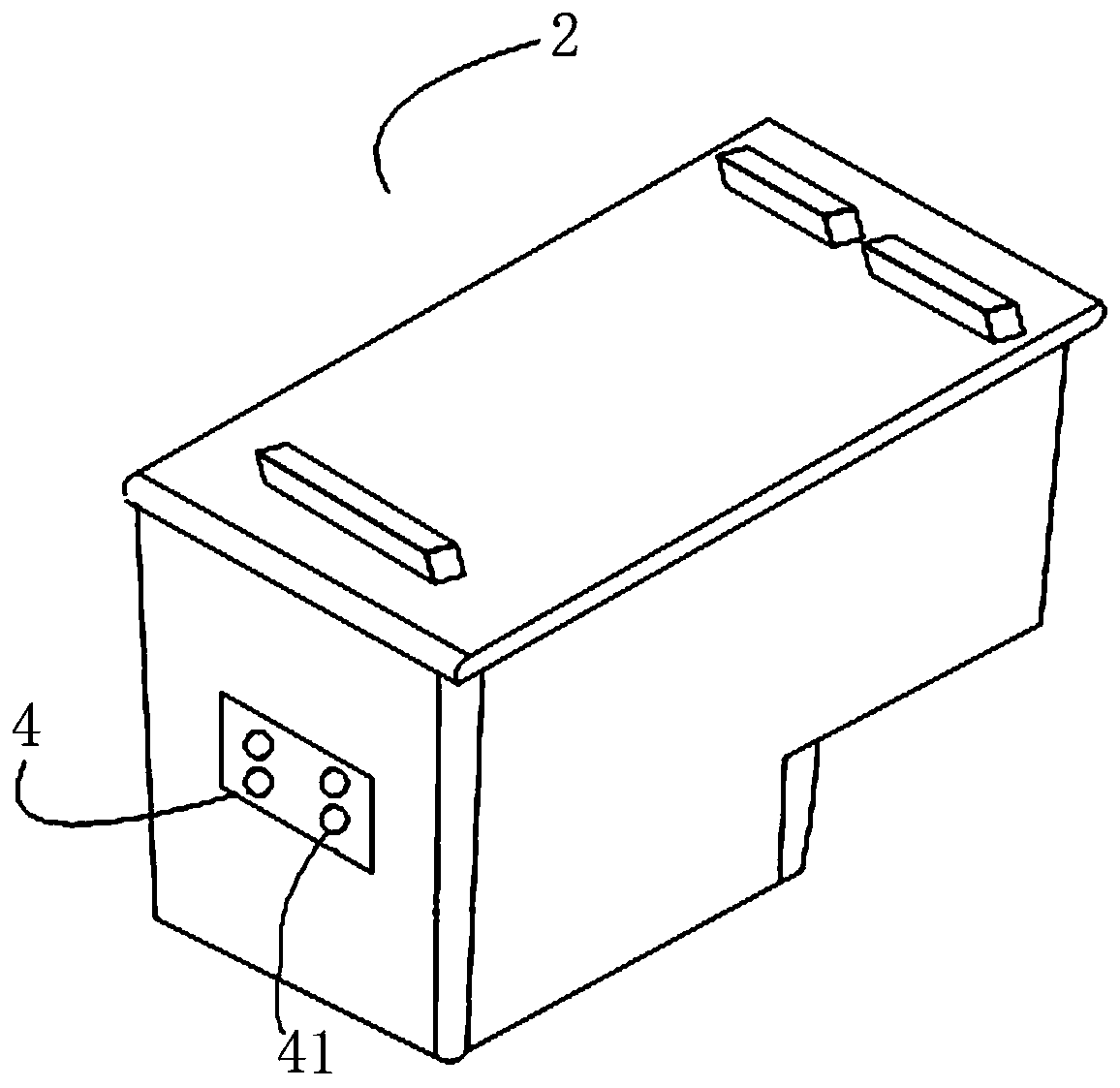

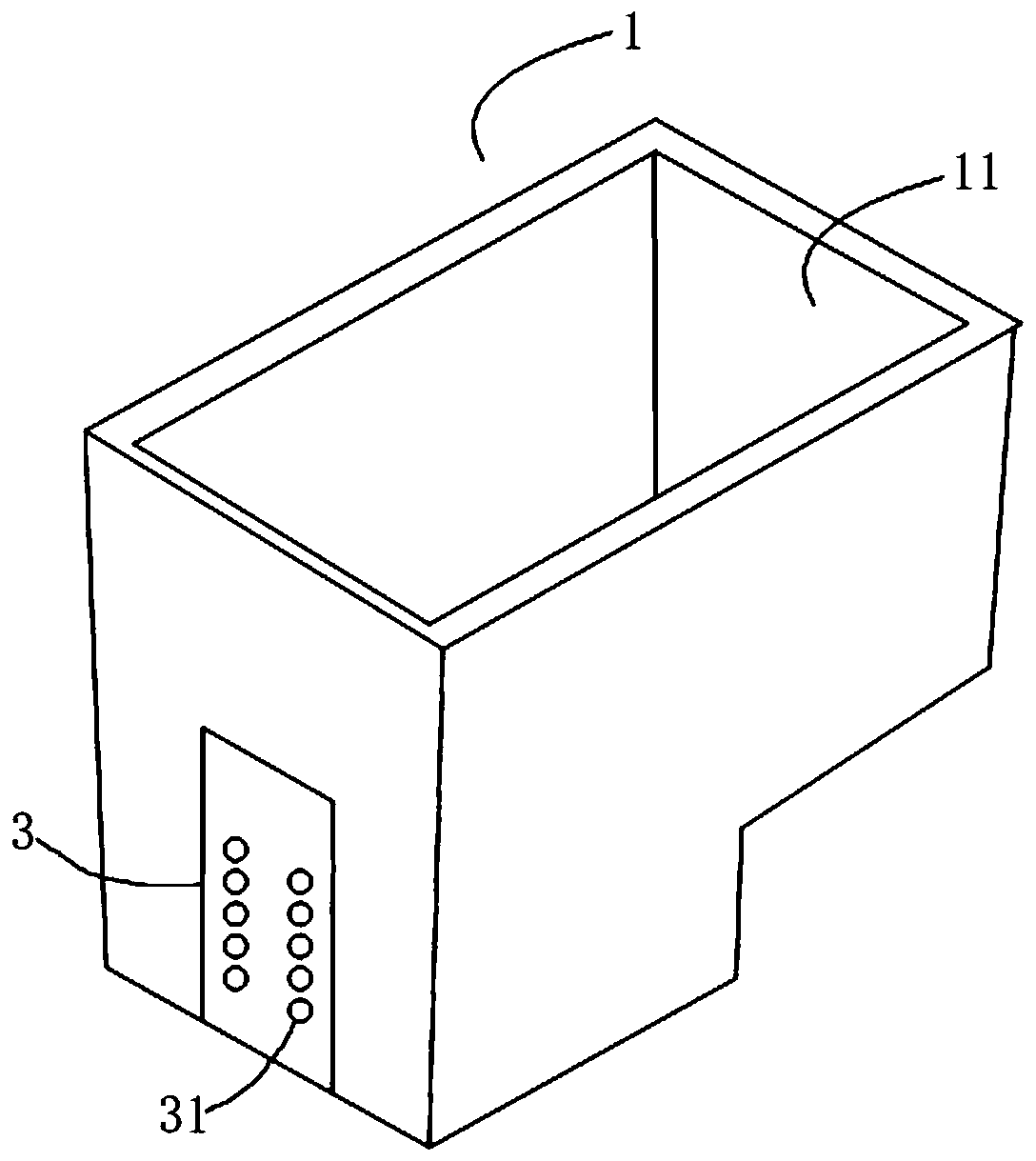

Refrigerator door body

ActiveCN101696841AAvoid deformationReduce material costDomestic cooling apparatusLighting and heating apparatusDistortionPlastic molding

The invention relates to the technical field of refrigerators of domestic appliances, in particular to a refrigerator door body which comprises an inner door liner (4), a foaming layer and a front door panel (2). The foaming layer is arranged between the inner door liner (4) and the front door panel (2), wherein the inner door liner (4) is provided with a plurality of horizontal grooves or flanges (41). In the invention, the grooves or flanges (41) which can extend and retract freely are arranged on the inner door liner (4), stress generated during the shrinkage distortion of the inner door liner (4) when the inner door liner is cooled can be cushioned effectively, thereby preventing the refrigerator door body from deforming. No door reinforced iron is used in the invention, thereby greatly reducing the material cost of the door body; and only the grooves or flanges (41) are added during the plastic molding of the inner door liner without changing the original processes and producing beats, thus the invention has the advantages of simple and easy implementation, labor saving and material saving.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

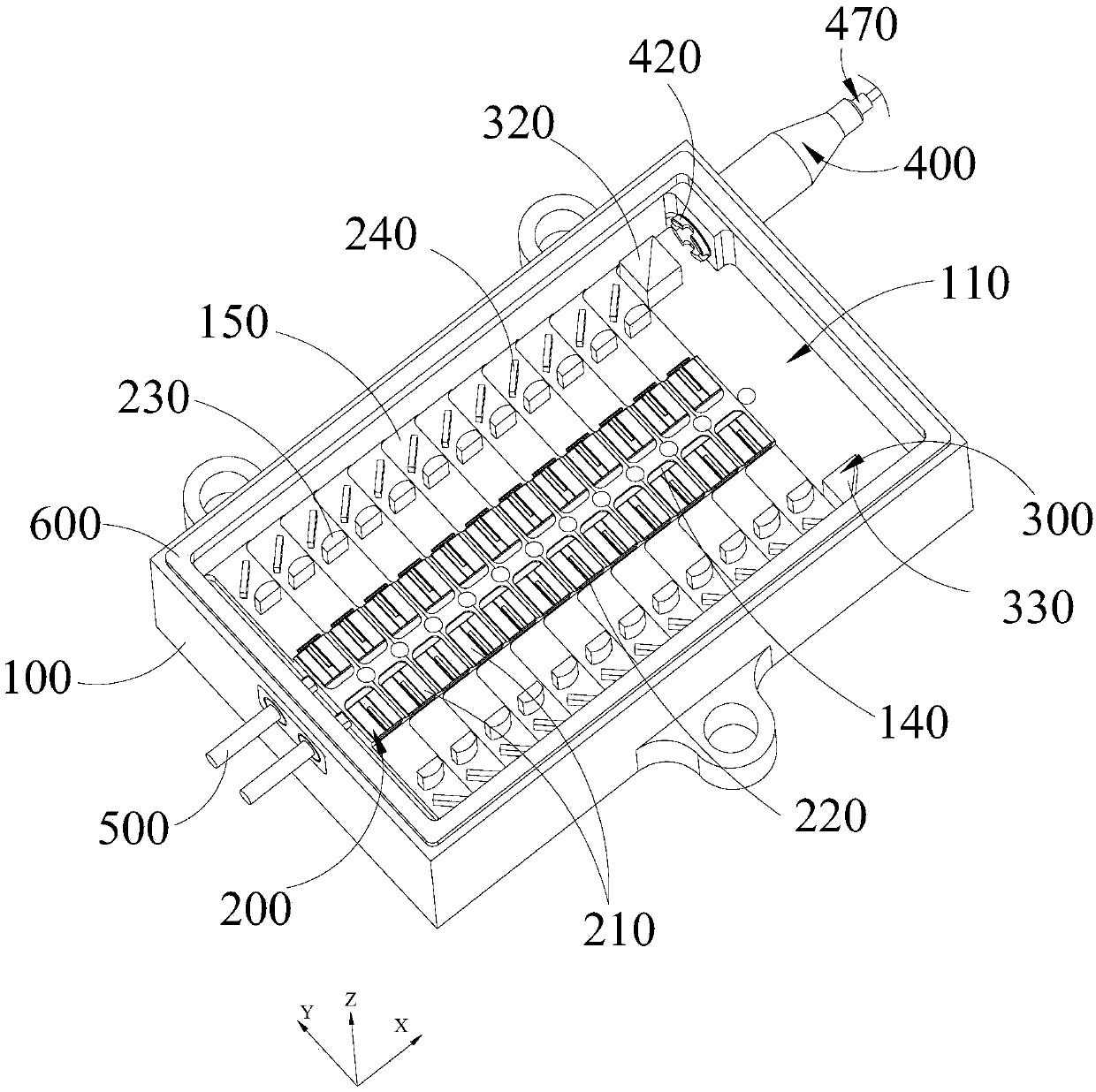

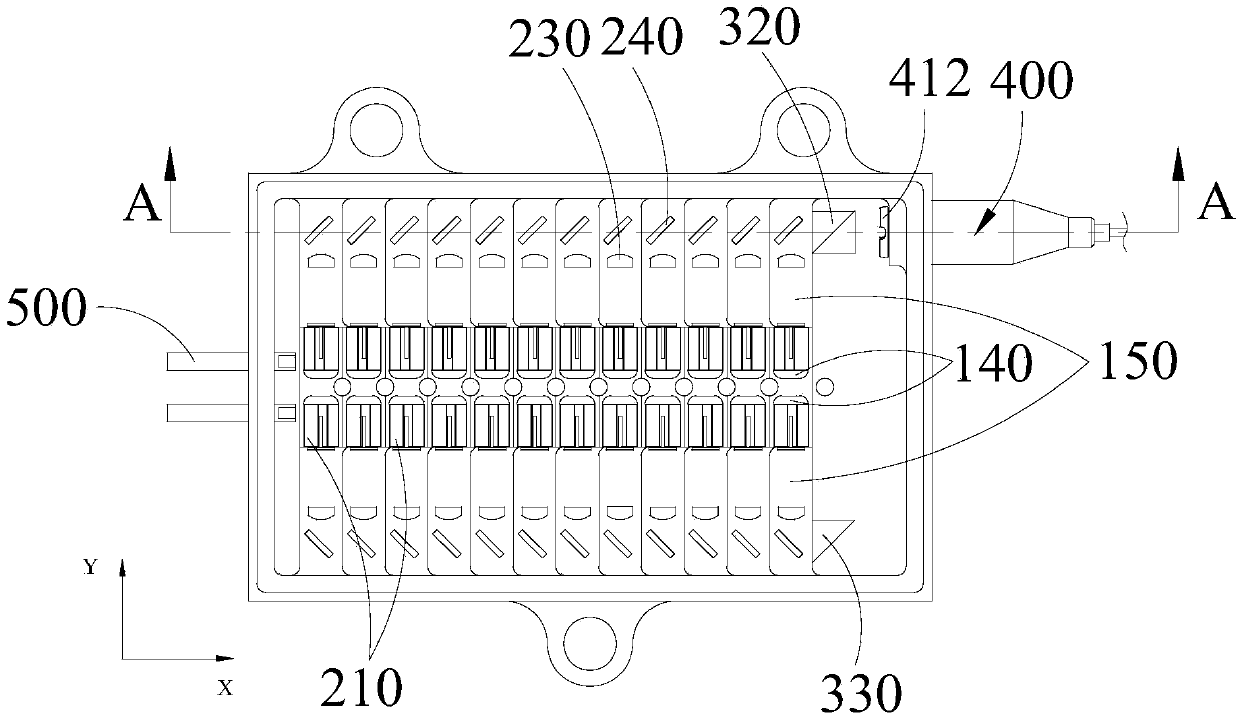

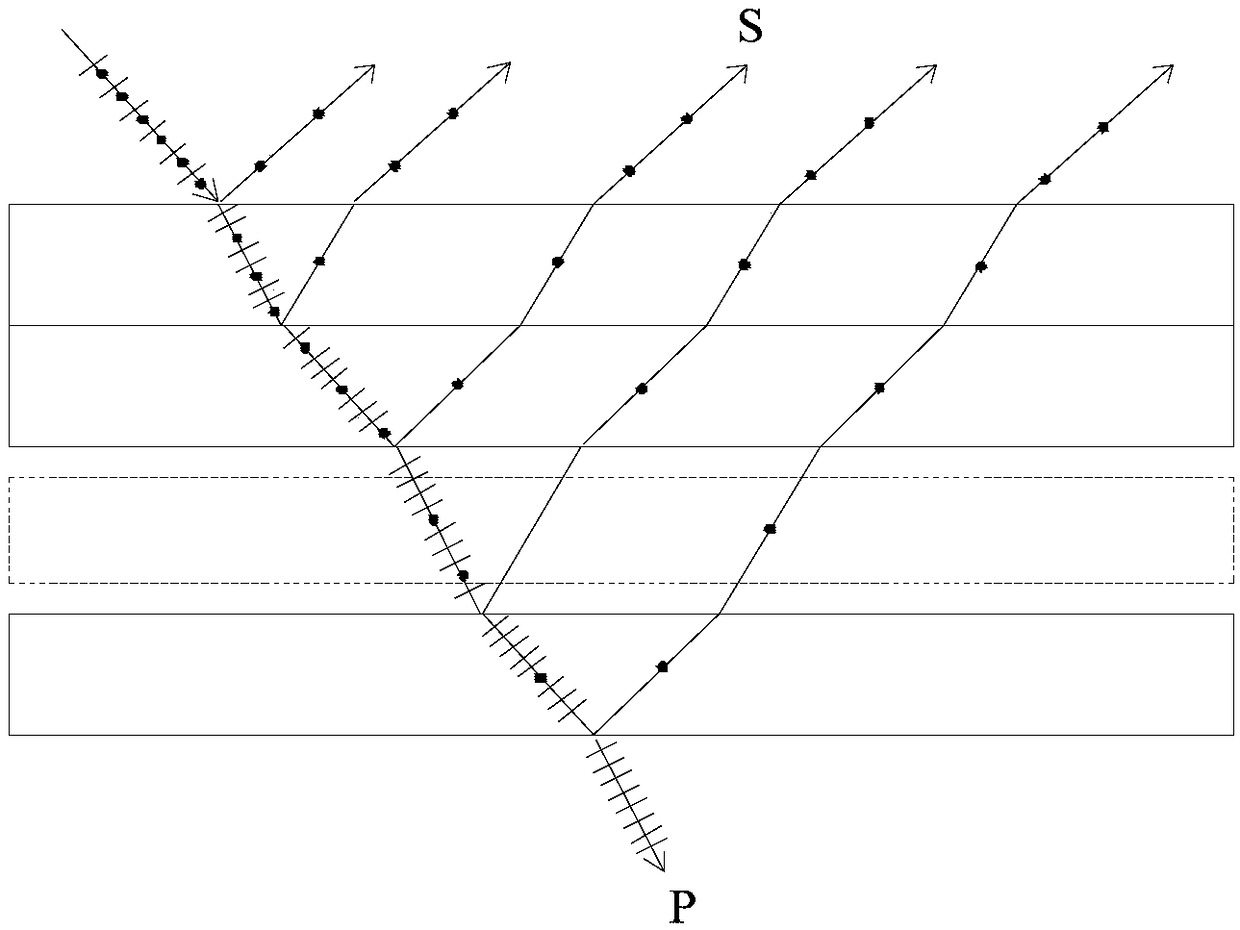

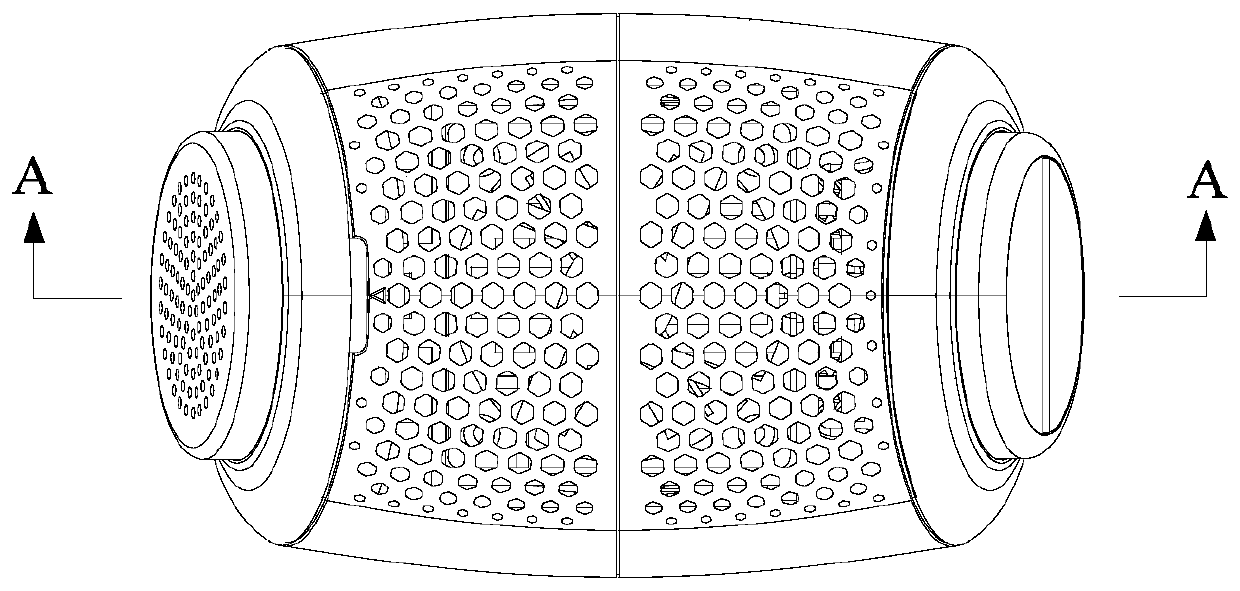

Multi-single tube large-power semiconductor laser package structure and laser

ActiveCN109586163AReduce material costReduce manufacturing costLaser detailsSemiconductor lasersOptical pathPositive direction

The invention belongs to the technical field of laser manufacturing, and aims to provide a multi-single tube large-power semiconductor laser package structure and a laser. The package structure comprises a base shell, wherein a package groove is formed in the base shell, a plurality of first steps are arranged at a central region of the groove bottom of the package groove and are integratedly formed along an X-axis direction so as to achieve integrated design of the package shell, the material cost and the production cost; and moreover, the height of a step surface of each step along a Z-axisdirection is sequentially and gradually reduced along a positive direction of an X axis, two groups of COS assemblies are arranged on the step surface of the corresponding step in a back-to-back way,and light emitted from each light-emitting unit is converted to collimating parallel light, gathered in the package groove and then is introduced to a light path coupling assembly outside the packagegroove for focusing and coupling. Apparently, the laser forms a new light path and electrical-thermal-mechanical balance, the volume is greatly reduced, concentrated heat dissipation is beneficial forcontrolling the integral temperature, light beam subsequent coupling is small in influence on the light-emitting unit, the output power of the laser is large, and the laser is more stable in performance.

Owner:深圳朗光科技有限公司

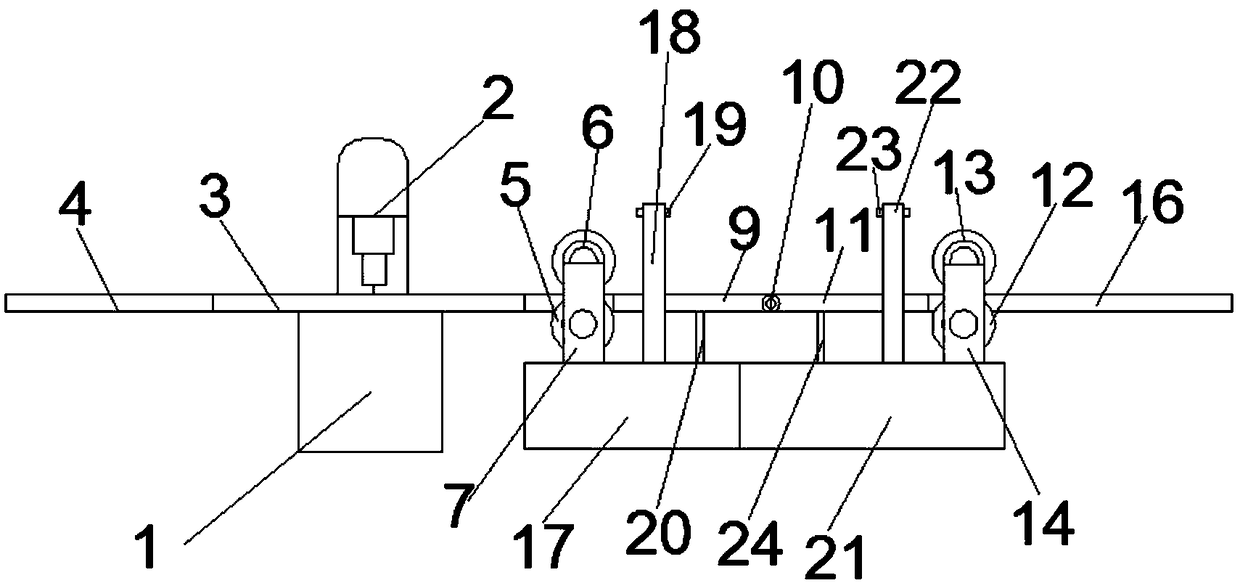

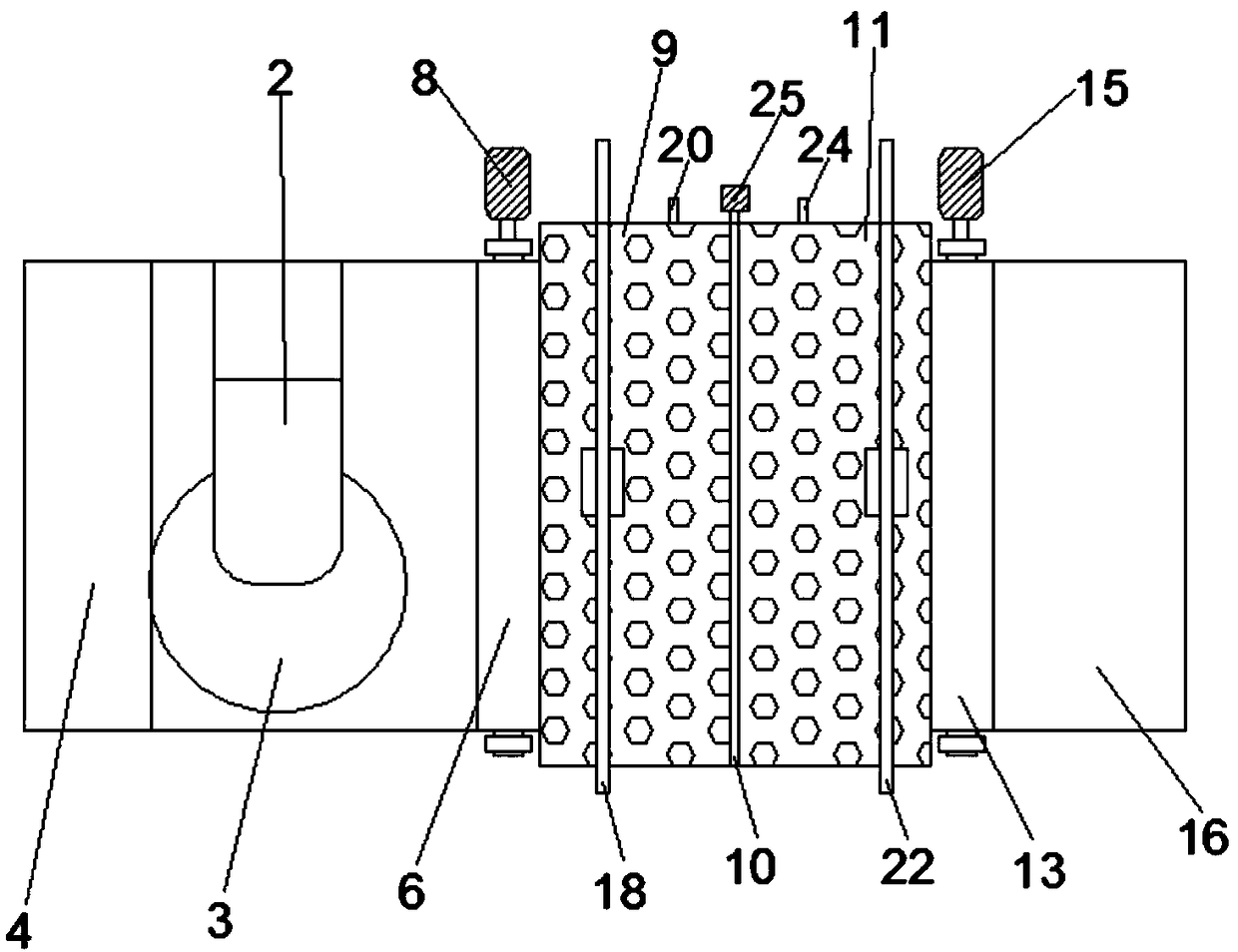

Excessive dyeing liquid extrusion discharging device for cloth

PendingCN109056241AShorten process timeReduce material costLiquid/gas/vapor removal by squeezing rollersDyeingEngineering

The invention discloses an excessive dyeing liquid extrusion discharging device for cloth. The device comprises a base plate, the base plate is provided with a connecting column and a vertical plate,the upper end of the connecting column is provided with a diagonal plate, a guide rod is arranged between the side faces of the vertical plate and the connecting column and provided with a sleeve, thesleeve is provided with a rack in the length direction, the rack is provided with an incomplete gear, and a spring is arranged between the sleeve and the vertical plate; the sleeve is provided with abracket, the end portion of the bracket is provided with a through hole, a gravity lifting rod penetrates through the through hole, and the end, facing the diagonal plate, of the gravity lifting rodis provided with an extruding plate. Compared with the prior art, the excessive dyeing liquid extrusion discharging device for the cloth has the advantages that through the high-speed rotation of theincomplete gear, the sleeve reciprocates at the high speed to drive the extruding plate to quickly slide on the diagonal plate, excessive dyeing liquid on the dyed cloth can be quickly discharged in cooperation with gravity without draining or air-drying the cloth, the process time is saved, and the material cost is reduced.

Owner:YI HE STOCK

Magnetic suspension molecular pump stator temperature monitoring system and method based on resistance identification

ActiveCN112628159AReduce material costSimplify the assembly processPump componentsPump controlPhysicsCommunication interface

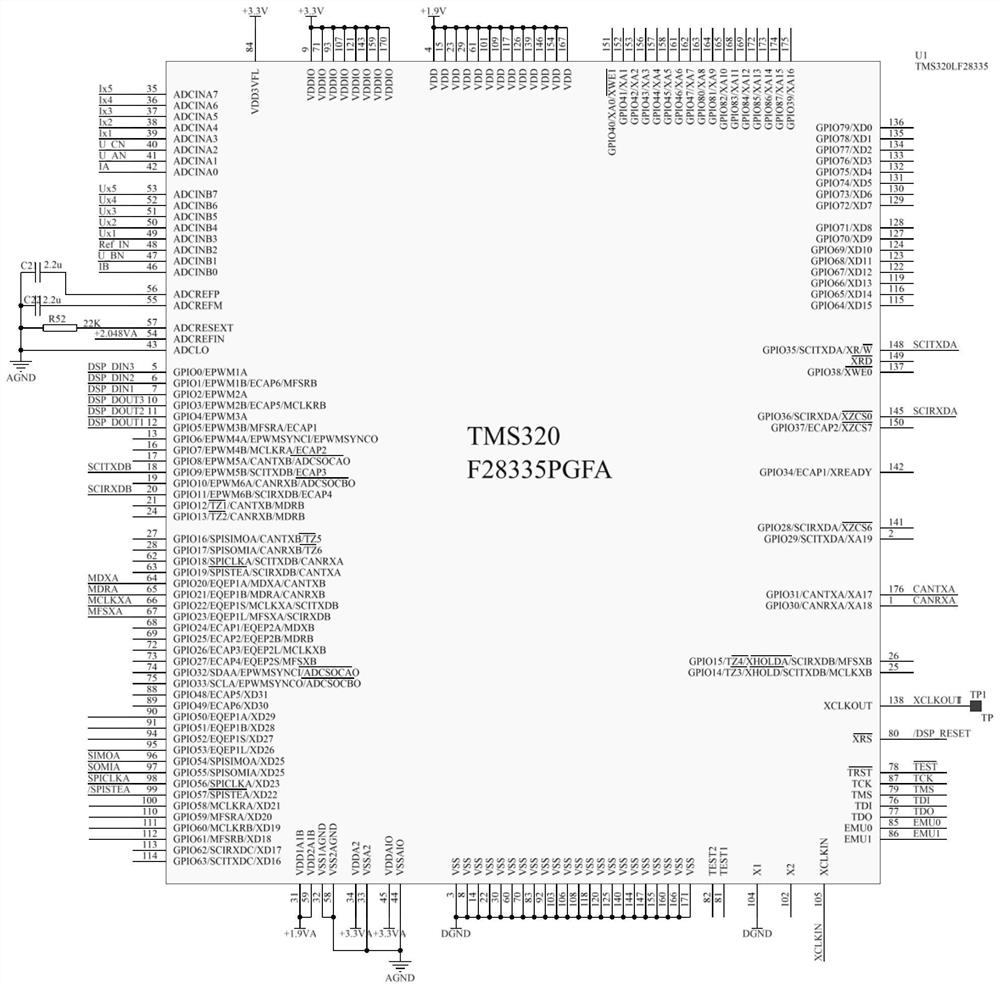

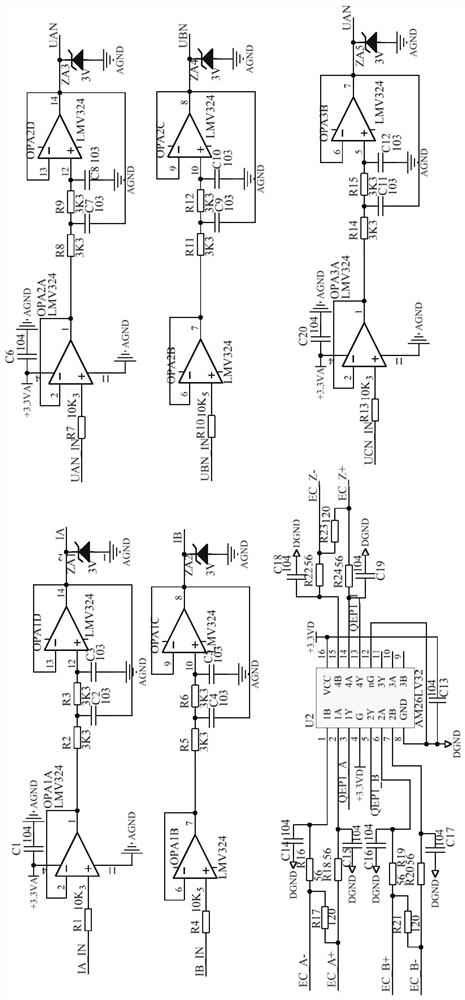

The invention discloses a magnetic suspension molecular pump stator temperature monitoring system and method based on resistance identification. The magnetic suspension molecular pump stator temperature monitoring system and method are used for monitoring the temperature of a magnetic suspension molecular pump stator system in real time, and a hardware part of the system comprises a DSP circuit, a motor information interface circuit, a magnetic bearing information interface circuit, an external interface circuit and a communication interface circuit. According to the system, the motor winding current, the motor winding voltage, the rotor position, the magnetic bearing winding current and the magnetic bearing winding voltage collected by a control system of a magnetic suspension molecular pump motor and a magnetic bearing can be utilized to obtain the stator resistance values of the motor and the magnetic bearing through an identification algorithm; and then according to the relationship between related materials and the temperature, the stator temperature of a magnetic suspension molecular pump is estimated, a traditional temperature sensor is not needed, the reliability of the molecular pump temperature monitoring system is improved, and the assembly process is simplified.

Owner:BEIHANG UNIV

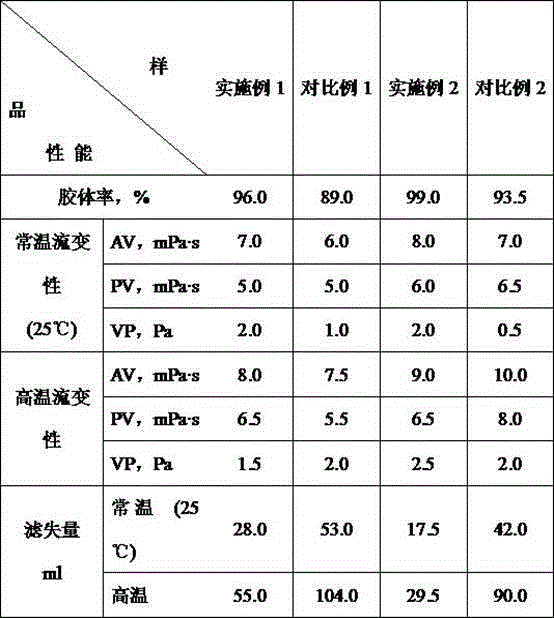

Production method of novel organic rectorite for oil-based drilling fluid

ActiveCN105567181AReduce material costImprove competitivenessDrilling compositionCation exchange reactionCationic exchange

Disclosed is a production method of novel organic rectorite for oil-based drilling fluid. The organic rectorite comprises rectorite and quaternary ammonium salt as main components. The production method includes the steps of A, sodium-modification / lithiation pretreatment; B, organic modification reaction; C, filtering and washing; and D, ageing, drying and grinding. The production method has the advantages that since calcium-based rectorite raw material is subjected to the sodium-modification / lithiation pretreatment according to the sodium salt and lithium salt compound modification technology, colloid rheological property of the organic rectorite product is improved; chemical reaction of organic-modification cation exchange is promoted completely by a controllable high-temperature organic modification process, and thus quality of the organic rectorite is much stable; residual dissoluble ion of products from the organic modification cation exchange reaction is removed by a washing and filtering process, so that high-temperature stability of the products is improved further while content of impurity thereof is reduced.

Owner:WUHAN HUAKUANG COLLOID CHEM CO LTD

Medical coating applied to implanted medical instrument and preparation method of medical coating

PendingCN111632205AReduce material costGood plastic deformation abilitySurgeryVacuum evaporation coatingBone tissueBiofilm

The invention discloses a medical coating applied to an implanted medical instrument. The coating comprises a titanium-yttrium coating, a titanium nitride-yttrium alloy layer, a tantalum-yttrium coating and a tantalum-zinc-silver coating; the titanium-yttrium coating coats the outer layer of a base material of an implanted medical instrument; the titanium nitride-yttrium alloy layer coats the outer layer of the titanium-yttrium coating; the tantalum-yttrium coating coats the outer layer of the titanium nitride-yttrium alloy layer; and the tantalum-zinc-silver coating coats the outer layer of the tantalum-yttrium coating, wherein the tantalum-zinc-silver coating can be converted to a tantalum-magnesium-silver coating. The silver element of the medical coating can effectively inhibit generation of bacterial biofilms and inflammation, the zinc element and the magnesium element can effectively promote healing of wounds and growth of bone tissues, the yttrium element and the tantalum element can effectively improve fatigue resistance of a metal material, and the tantalum element can effectively enhance development performance of an X-ray machine. Harmful metal ions are embedded, so thatthe corrosion-resistant potential is improved, the biocompatibility is improved, electromagnetism of the metal implant is shielded, and CT diagnosis is realized.

Owner:北京华钽生物科技开发有限公司

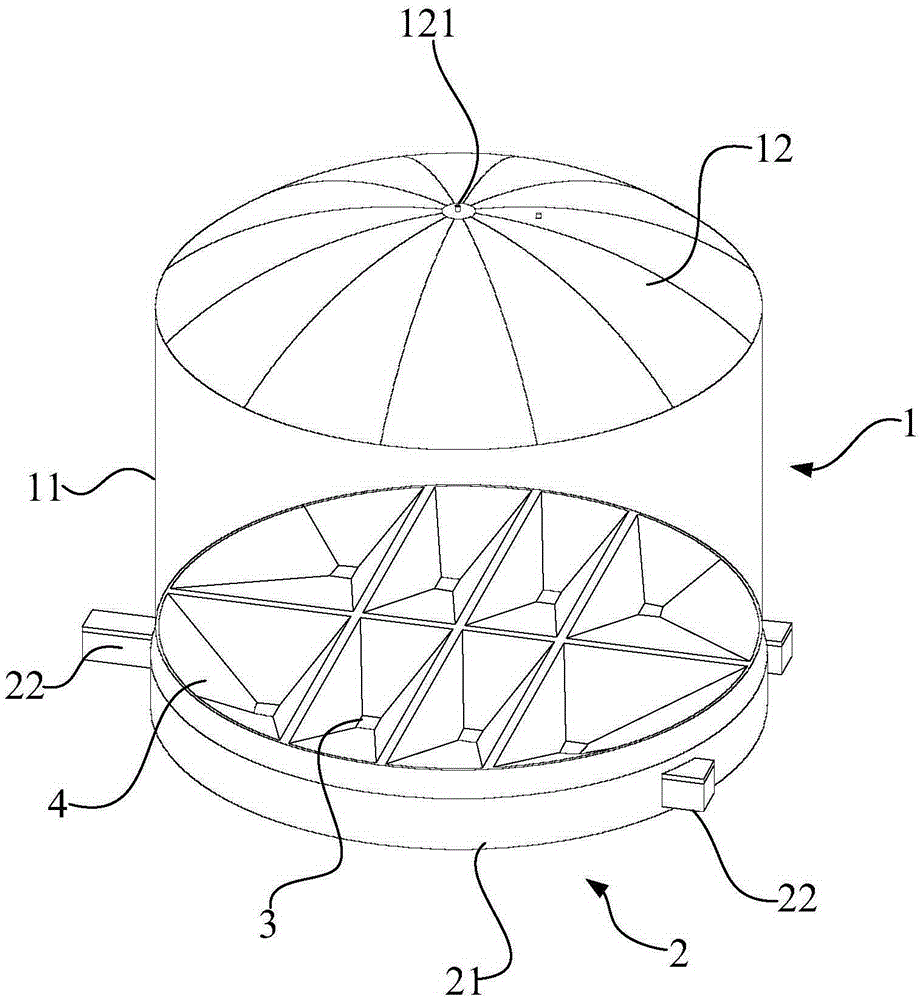

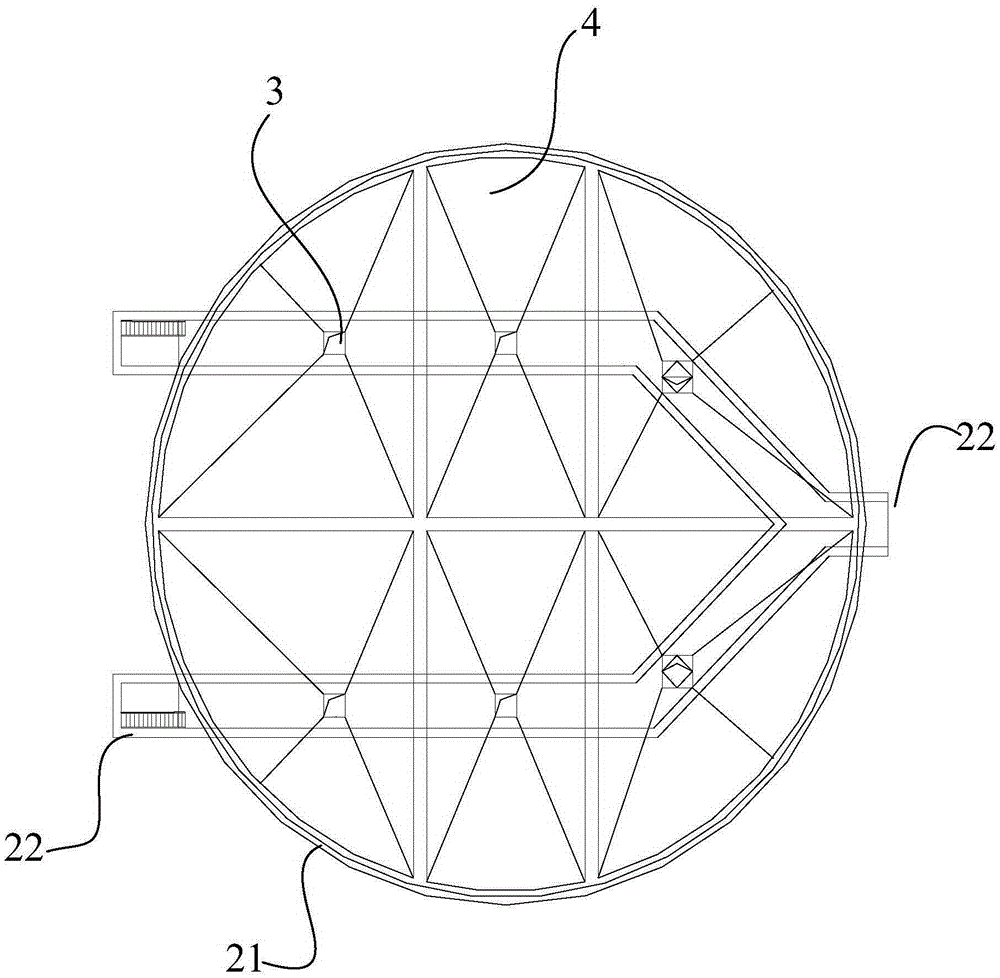

Multi-point multi-gallery energy-saving environmental-protection storage device and discharging method thereof

InactiveCN105350806AOptimize output time and resource consumptionReduce material costBulk storage containerMulti pointSilo

The invention belongs to the field of storage devices, and especially relates to a multi-point multi-gallery energy-saving environmental-protection storage device and a discharging method thereof. The multi-point multi-gallery energy-saving environmental-protection storage device comprises a silo body and an annular base under the silo body. The silo body comprises a barrel body and a silo top arranged on the top of the barrel body, discharging openings are uniformly arranged in the bottom of the barrel body in row, the discharging openings are arranged in parallel in row, the periphery of each discharging opening is provided with a material-guiding cone, any two adjacent material-guiding cones are arranged in a tangent manner, and the annular base comprises an annular pouring body used for fixing the silo body and discharging galleries which penetrate the annular pouring body and correspond to the discharging openings. According to the invention, the discharging openings are uniformly arranged in the bottom of the barrel body in row, the storage device is virtually divided into several storage units with a smaller diameter, at the same time, the material-guiding cones are combined with fluidization units, and therefore the multi-point multi-gallery energy-saving environmental-protection storage device does not have blind angles, and technical problems that a conventional device is not fully used, and the using effect is increasingly poor are solved.

Owner:SHANDONG YUANFENG CONSTR

Shirt cuff processing complete device

InactiveCN108796847AThe operation of the equipment is simple and convenientReduce material costWork-feeding meansTextile shapingEngineeringButt joint

The invention relates to the technical field of garment processing, in particular to a shirt cuff processing complete device. The shirt cuff processing complete device includes a sewing main control box, a sewing machine assembly is welded to one end of the top face of the main control box, a disc is arranged between the sewing machine assembly and the main control box, one end of the disk is in butt joint with a discharging plate, and the end, away from the discharging plate, of the disc is in butt joint with a first drive rolling shaft; the upper end of the first drive rolling shaft is in butt joint with a first driven rolling shaft, the two ends of the first driven rolling shaft are in sleeved connected with support rods, and the ends, away from first driven rolling shaft, of the support rods are in sleeved connected with the first drive rolling shaft, the first drive rolling shaft and the first driven rolling shaft are parallel in a support rod plane, one end of the first drive rolling shaft is welded to the output end of a first motor, the first drive rolling shaft is in butt joint with a folded ironing plate, and a rolling shaft hinge is welded to the end, away from the firstdrive rolling shaft, of the folded ironing plate; a folded air blowing and suction plate is welded to the end, away from the folded ironing plate, of the rolling shaft hinge. The shirt cuff processing complete device runs efficiently through a series of control programming.

Owner:池州市达宏信息技术有限公司

SMD-type IRM high shielding structure and making process thereof

PendingCN108281395AReduce light interferenceReduce material costSemiconductor/solid-state device detailsSolid-state devicesPrinted circuit boardEngineering

The invention belongs to the technical field of infrared signal receiving and particularly relates to a SMD-type IRM high shielding structure which comprises a PCB (printed circuit board). A pluralityof on holes are penetratingly formed in the PCB, a copper column is plugged in each on hole, a PD wafer is arranged on the front of the PCB, an IC chip is arranged on the back of the PCB, and one endof each copper column is connected onto the PD wafer through a bonding wire while the other end of the same is connected onto the IC chip through a bonding wire; packaging glue is cured on each of two sides of the PCB, and the PD wafer and the IC chip are arranged in the packaging glue on the two sides of the PCB. The SMD-type IRM high shielding structure has the advantages that material and process cost of an inner shielding cover or an outer shielding cover is saved while light interference is blocked; the making process is simplified, multiple processes are reduced when compared with plug-in products and SMD support-type products, and high-cost electrotinning procedures causing wastewater and waste gas pollution are reduced; compared with SMD-type PCB products, assembly difficulty andlabor cost of the outer shielding cover are reduced.

Owner:苏州雷霆光电科技有限公司

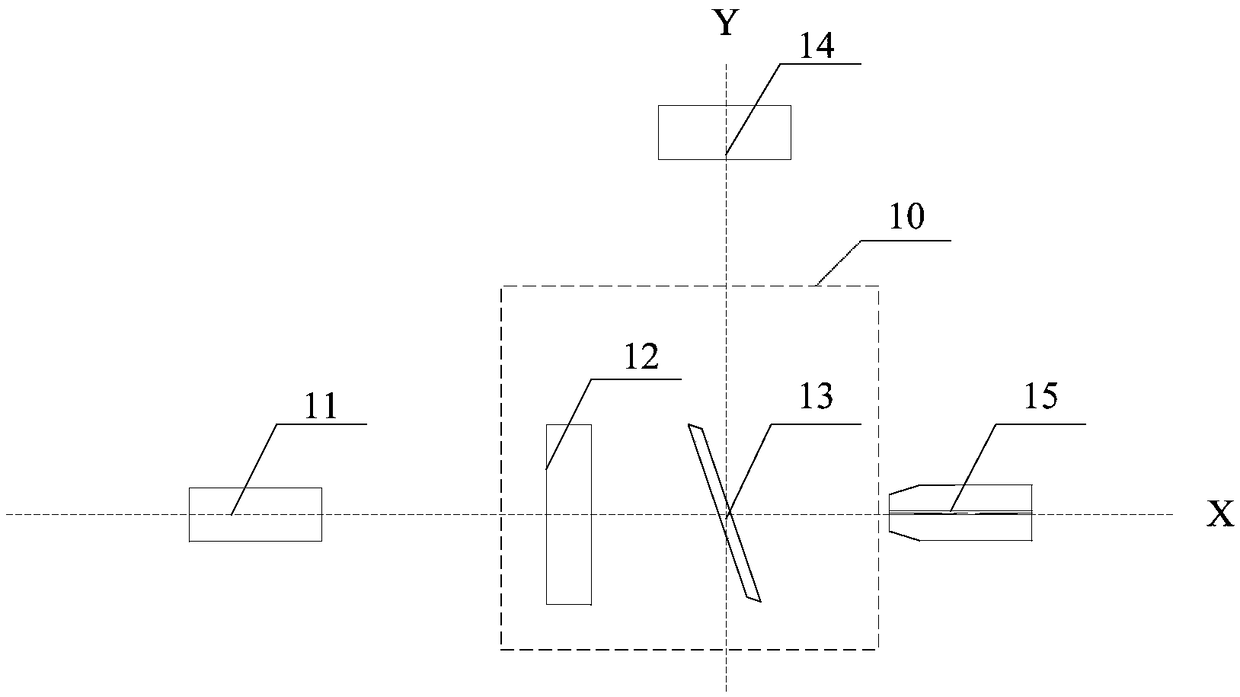

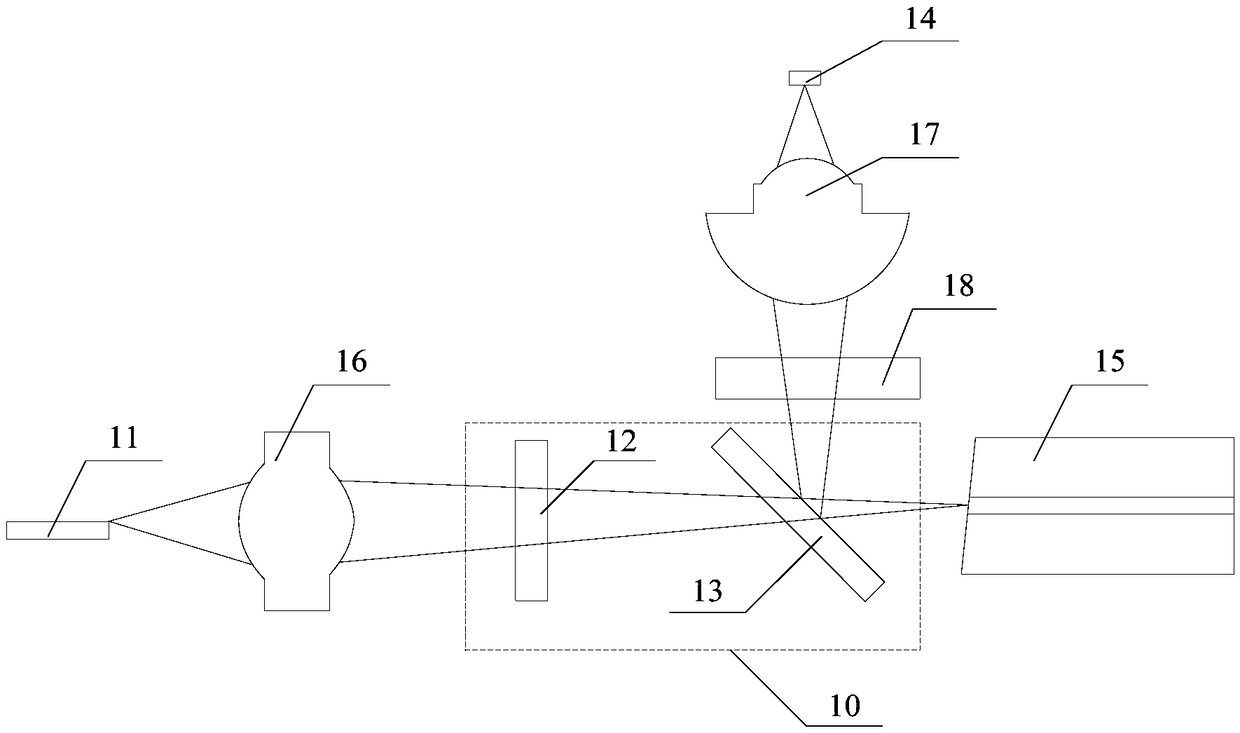

Single-fiber bi-directional optical component and optical module

InactiveCN109212690ASimple light pathReduce material costCoupling light guidesBidirectional transmissionOptical pathOptical axis

An embodiment of the invention provides a single-fiber bi-directional optical component and an optical module. The single-fiber bi-directional optical component comprises a laser chip, a Faraday rotator, a polarization detection filter, a detector chip and an optical fiber ferrule. The laser chip, the Faraday rotator, the polarization detection filter and the optical fiber ferrule are sequentiallyarranged on a first optical axis. The detector chip is arranged on a second optical axis. The polarization detection filter is obliquely arranged at an intersection of the first optical axis and thesecond optical axis. After a polarized light emitted by the laser chip rotates by the Faraday rotator, the polarization state direction of the polarized light is consistent with the polarization detection direction of the polarization detection filter. The polarized light enters the optical fiber ferrule to transmit, and the light from the optical fiber ferrual is reflected by the polarization detection filter to enter the detector chip. According to the single-fiber bi-directional optical component provided by the embodiment of the invention, dual functions of isolation and light splitting are realized by the Faraday rotator and the polarization detection filter, so that the optical path is simplified, and the material cost is reduced.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

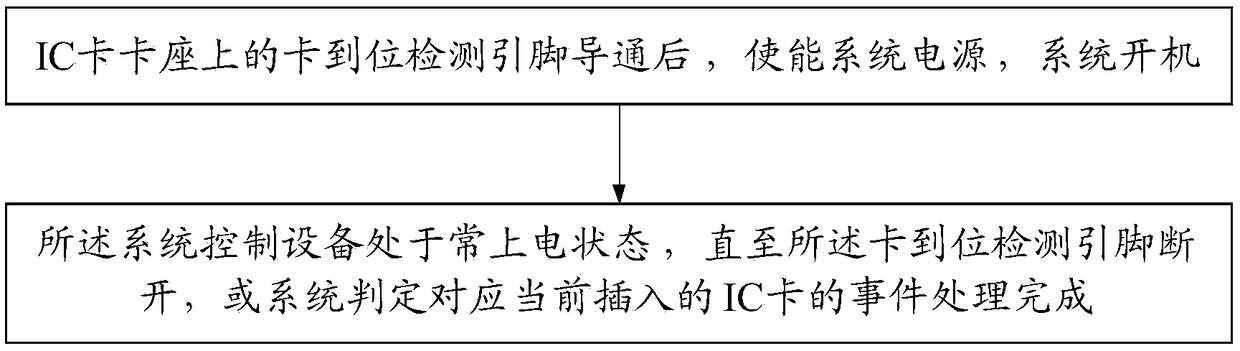

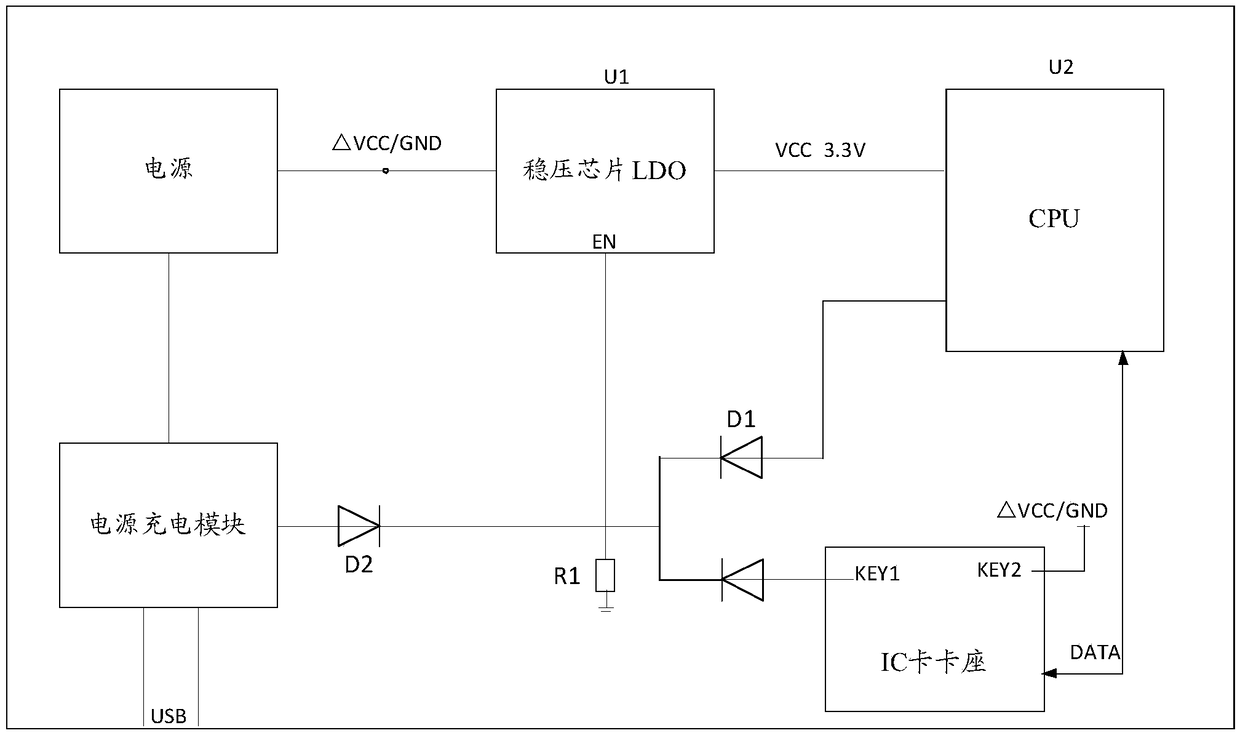

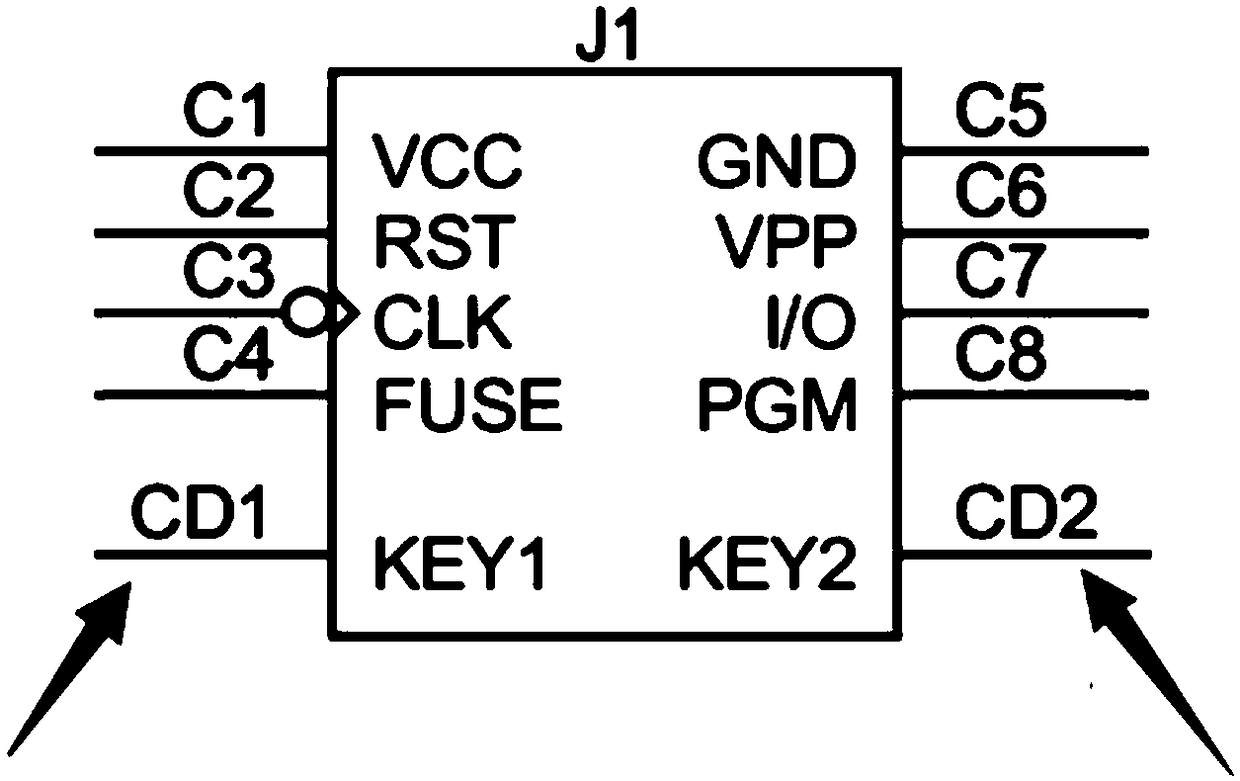

Boot-up control method of card insertion device and circuit thereof, POS machine

InactiveCN109063524AImprove button boot modeReduce material costCash registersSensing record carriersEmbedded systemX-machine

The invention provides a startup control method of a card insertion device and a circuit thereof. The POS machine comprises a card position detecting pin in an IC card holder, a voltage stabilizing chip LDO, a CPU and a power supply. The card bit detection pin is respectively connected with the voltage regulator chip LDO and the CPU through a first logic control device; CPU, voltage stabilize chipLDO and power supply are connected in turn; The first logic control device is used for controlling conduction after the card bit detection pin is electrically connected with an IC card; The voltage stabilizing chip LDO is used for enabling the power supply and booting the system; The CPU is configured to control the regulator chip LDO to be in a normally powered state until the first logic control device is turned off after the system is powered on. The utility model not only reduces the material cost, but also improves the convenience of the shutdown and on-off machine, which is more in linewith the needs of the development of the micro-miniature equipment.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Electronic equipment

InactiveCN110392196AReduce material costLower assembly costsTelevision system detailsColor television detailsCamera lensLight filter

The invention discloses electronic equipment. The electronic equipment comprises a front shell; a cover body which is arranged on the front shell, wherein a camera hole is formed in the cover body; acamera module which comprises a camera main body and an optical filter, wherein the camera main body is installed on the front shell, a lens of the camera main body is right opposite to the camera hole, the optical filter and the camera main body are arranged in a split mode, and the optical filter is arranged at the camera hole. According to the electronic equipment, the optical filter is independent from the camera main body and is externally arranged at the camera hole, and in this way, the arrangement of an optical filter bracket in the camera main body can be cancelled; the material costand the assembly cost are reduced, the thickness of the camera main body is reduced, the optical filter is arranged at the camera hole, the installation space at the camera hole is fully utilized, theoverall structural layout of the electronic equipment is more reasonable, and the light and thin design of the electronic equipment is realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

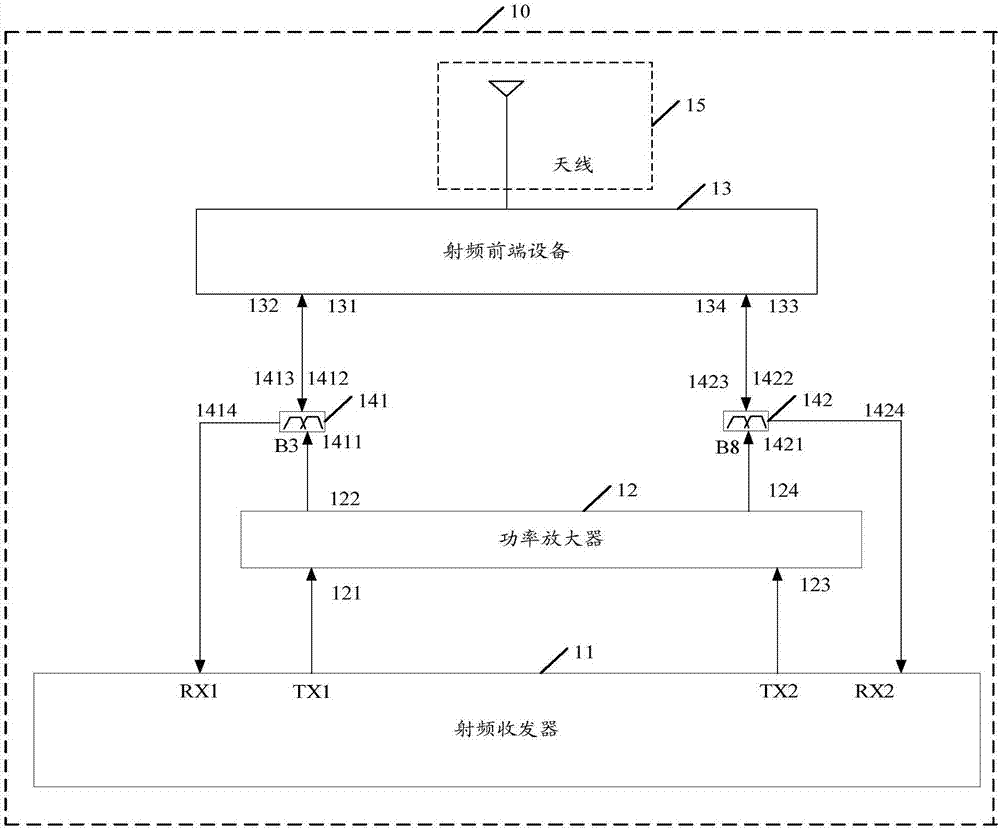

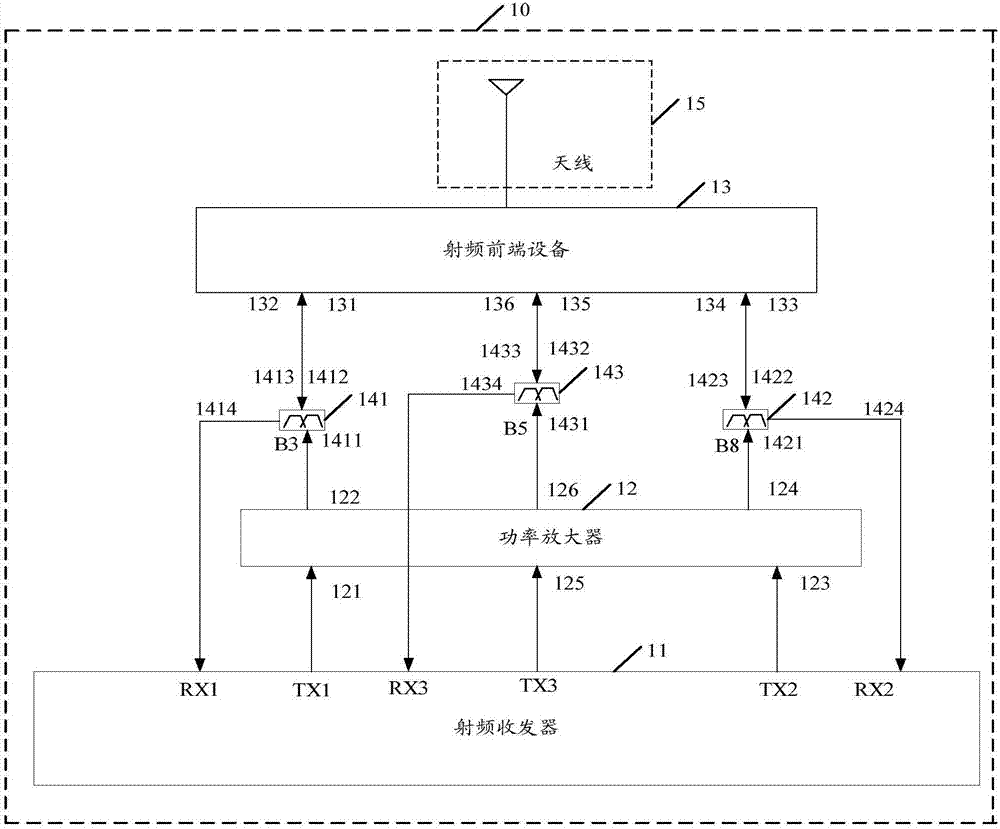

Carrier aggregation radio frequency circuit and mobile terminal

The embodiment of the invention discloses a carrier aggregation radio frequency circuit and a mobile terminal. The carrier aggregation radio frequency circuit comprise a radio frequency transceiver, a power amplifier, a radio frequency front-end facility and at least two duplexers, wherein the first sending of the radio frequency transceiver is connected with the first receiving end of the power amplifier, the first sending end of the power amplifier is connected with the first receiving end of the first duplexer, the first sending end of the first duplexer is connected with the first receiving end of the radio frequency front-end facility, the first sending end of the radio frequency front-end facility is connected with the second receiving end of the first duplexer, the second sending end of the first duplexer is connected with the first receiving end of the radio frequency transceiver, and the first duplexer is any one of at least two duplexers. Through the carrier aggregation radio frequency circuit disclosed by the embodiment of the invention, the use number of the power amplifier can be saved when performing carrier aggregation, and the material cost is saved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Lemon Sushi vinegar

The invention discloses a table vinegar, in particular to a lemon Sushi vinegar, and belongs to the technical field of food processing. The lemon Sushi vinegar comprises the following raw components in parts by mass: 38-45 parts of rice vinegar, 20-30 parts of fructose-glucose syrup, 20-25 parts of white granulated sugar, 3-7 parts of salt, 2-5 parts of lactic acid and 0.5-3 parts of lemon essence. After adoption of the raw components in parts by mass, due to reasonable collocation of the components and reasonable selection of proportions of the components, through addition of a lemon flavor, the lemon Sushi vinegar is good in taste, needs of people on acetic acid with special aroma can be met, and the lemon Sushi vinegar is specially suitable for non-vegetarian food; the material cost is low, so that the production cost is greatly reduced.

Owner:镇江刘恒记食品有限公司

Ink box

ActiveCN110202943AReduce in quantityReduce material costPrintingEngineeringElectrical and Electronics engineering

The invention discloses an ink box. The ink box comprises an ink box body, an ink bin, a first chip and a second chip, wherein a containing cavity and a first through hole are formed in the ink box body, the first through hole communicates with the containing cavity, the ink bin is detachably arranged in the containing cavity, the first chip is arranged on the outer surface of the ink box body, the first chip comprises a first terminal, the second chip is arranged on the outer surface of the ink bin, the second chip comprises a second terminal, and the second terminal is in contact with the first terminal through the first through hole so as to realize electric connection. According to the ink box, when the ink bin is put into the containing cavity of the ink box body, the second terminalattached to the second chip on the ink bin can be in contact with the first terminal attached to the first chip on the ink box body through the first through hole, so that the first terminal is used as a terminal shared by the first chip and the second chip, the number of the terminals is reduced, and the material cost is reduced.

Owner:APEX MICROELECTRONICS CO LTD

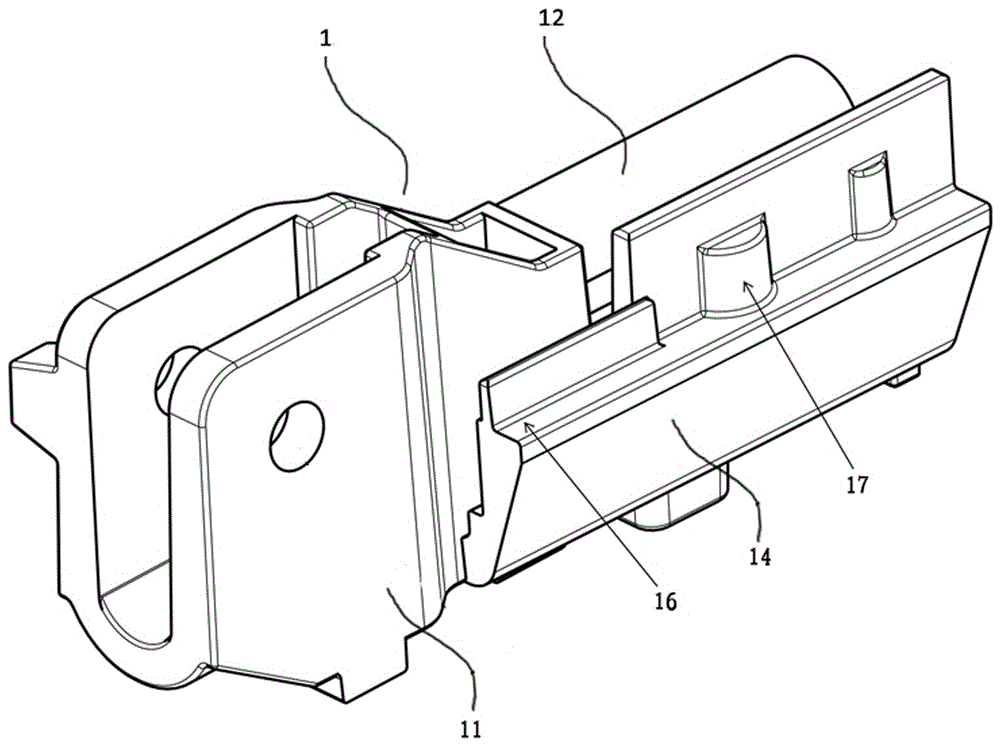

Fixing block for car skylight wind-shielding net

InactiveCN106218377AImplement inheritanceRealize platformizationRoofsEngineeringMechanical engineering

The invention relates to a fixing block for a car skylight wind-shielding net. The fixing block is characterized in that the fixing block is arranged inside a skylight rail clamp groove and arranged front and back; the fixing block comprises a mounting part used for being pin-connected with a wind-shielding net crank arm and a positioning part used for positioning and tightly clamping the skylight rail clamping groove; the positioning part comprises an inner side protrusion, an outer side protrusion and a plurality of positioning bosses; the inner side protrusion and the outer side protrusion are arranged on the inner side wall and the outer side wall correspondingly in the front-back direction of the positioning part, and the positioning bosses are arranged on the inner side protrusion and the outer side protrusion; and the positioning bosses are in clamped connection with positioning grooves formed in the inner side of the skylight rail clamping groove correspondingly, and the inner side protrusion and the outer side protrusion are in a boss-clamped-connection perpendicular limiting state with the two inward and outward inner walls of the skylight rail clamping groove.

Owner:JIANGSU DEFULAI AUTOMOTIVE PARTS

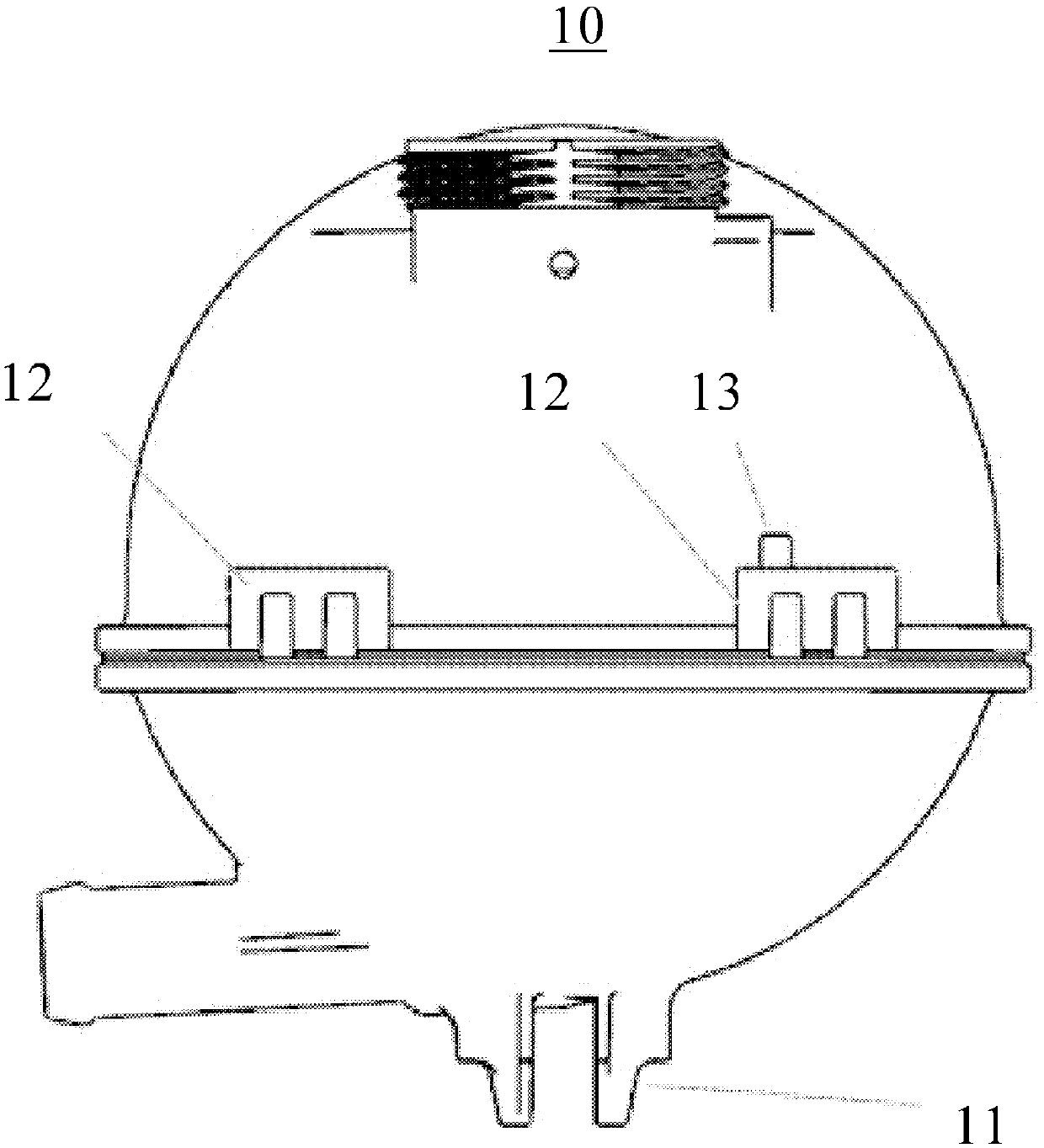

LED fin lamp

PendingCN105805652ASimple structureReduce material costElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLight source

The invention discloses an LED fin lamp which comprises an integrated fin support, a COB light source, a transmitting shell, a power source and a lamp cap. The LED fin lamp is characterized in that the lamp cap is connected to the integrated fin support, the COB light source is arranged on the outer side face of a fin of the integrated fin support, and the COB light source is provided with the transmitting shell and connected with the power source through a wire by means of a through groove. By the adoption of the integrated fin support made of heat-conducting plastic and epoxy resin, the COB light source is directly supported, fixed and sealed, and meanwhile heat on the COB light source is dissipated into air through the shortest path by means of the heat-conducting plastic. Bulky aluminum products or glass broken easily are not used in the whole lamp. The LED fin lamp has the beneficial effects of being long in service life, high in lighting effect, simple in structure and extremely low in labor cost, appearance plasticity is high, the material cost is low, and the LED fin lamp is suitable for industrial robot assembly.

Owner:林家英

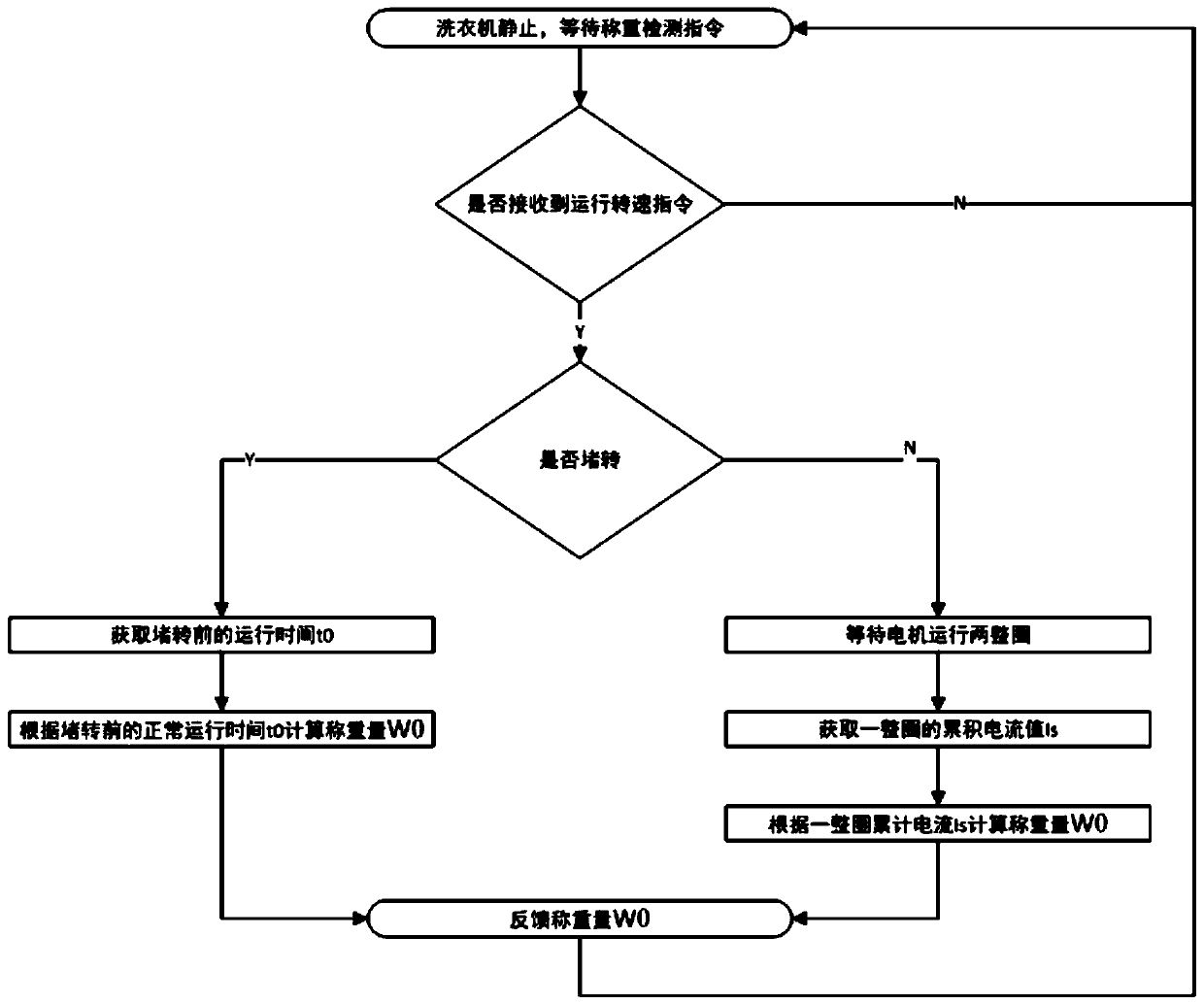

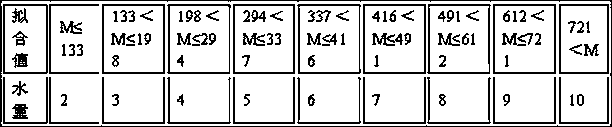

Weighing method applied to non-sensor pulsator washing machine

ActiveCN110284299AReduce material costShorten the time required for weighingOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention discloses a weighing method applied to a non-sensor pulsator washing machine and belongs to the technical field of household appliances. The washing machine is the pulsator washing machine and comprises a motor for driving an inner drum to rotate and an upper computer MCU electrically connected with the motor, the pulsator washing machine rotates multiple times before washing is started, and in the period, whether or not the motor is in a blocked operation state is judged; if yes, the operation time of the motor is acquired; if the motor normally operates, an accumulation current value of the motor during a whole circle of operation is calculated; according to the two states, by using the operation time or accumulation current value of the motor, the weight is obtained through weighing and transmitted to the upper computer MCU, and the upper computer MCU gives a proper water level. According to the weighing method, for the pulsator washing machine, under the condition of not additionally increasing the material cost, garments in the drum can be weighed, the upper computer MCU automatically gives the proper water level, and the operation difficulty of a user is lowered.

Owner:上海景能电气有限公司

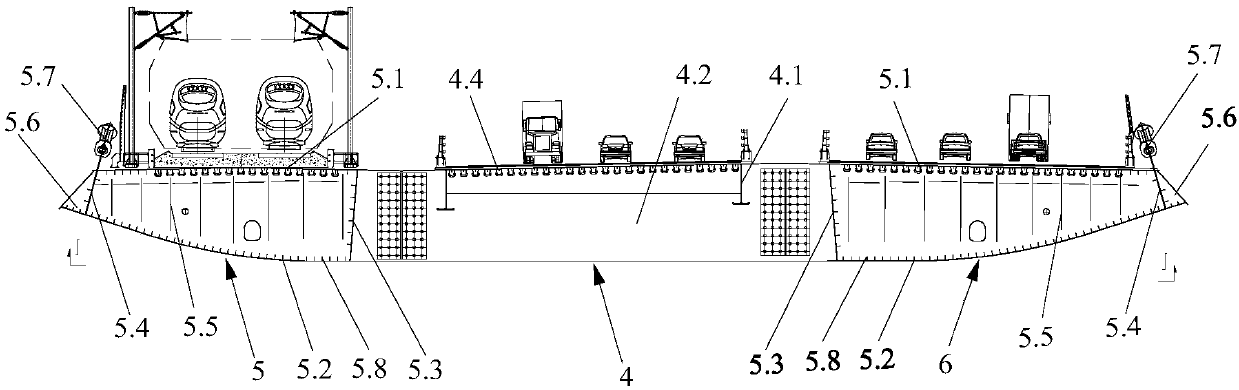

Highway and railway same-floor eccentric-load placed cable-stayed bridge with main girder running through bridge towers

PendingCN110607740ALower the elevationImprove wiring conditionsCable-stayed bridgeBridge structural detailsCable stayedTower

The invention discloses a highway and railway same-floor eccentric-load placed cable-stayed bridge with a main girder running through bridge towers. The highway and railway same-floor eccentric-load placed cable-stayed bridge with the main girder running through the bridge towers comprises the main girder, multiple bridge towers and multiple stay cables, wherein the multiple bridge towers are placed along the main girder in the bridge direction; the multiple stay cables are used for connecting the bridge towers with the two sides, in the bridge direction, of the main girder; the main girder comprises a horizontal and horizontal lattice girder for placing a first highway; a first steel box boundary girder for placing a railway and a second steel box boundary girder for placing a second highway are correspondingly arranged on the two sides of the transverse bridge direction of the horizontal and horizontal lattice girder; and the horizontal and horizontal lattice girder is spliced with the first steel box boundary girder and the second steel box boundary girder through bolts. As the main girder adopts an asymmetrical placing form, the highway and railway same-floor eccentric-load placed cable-stayed bridge with the main girder running through the bridge towers has the advantages that the line elevation is small when being compared with the line elevation of layered arrangement, the highway and railway wiring condition of the is improved when being compared with the highway and railway wiring condition of same-floor symmetric arrangement, the space and ramp arrangement are saved, engineering investment can be saved, and the view is wide.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Music string ball head with the function of differentiating music strings and manufacturing process thereof

ActiveCN101609663ALow raw material costReduce material costWind musical instrumentsEngineeringInjection moulding

The invention discloses a music string ball head with the function of differentiating music strings and a manufacturing process thereof. The music string ball head has an I-shaped wheel structure and is made of plastic mixture. The musical string ball head is made of plastics of various colors and has low cost, can be processed and molded conveniently, as well as has extremely good music string differentiating function. The invention also discloses the manufacturing process of the music string ball head, which comprises the following steps: (1) the molding step of the sectional material of the music string ball head: adopting an injection molding technology, taking the plastic mixture as the raw material and manufacturing the strip-shaped sectional material of the music string ball head; and (2) the processing and molding step of the music string ball head: turning and processing the obtained sectional material obtained from the step (1) and manufacturing the sectional material into the music string ball head.

Owner:GUANGZHOU ROMANCE MUSICAL INSTR

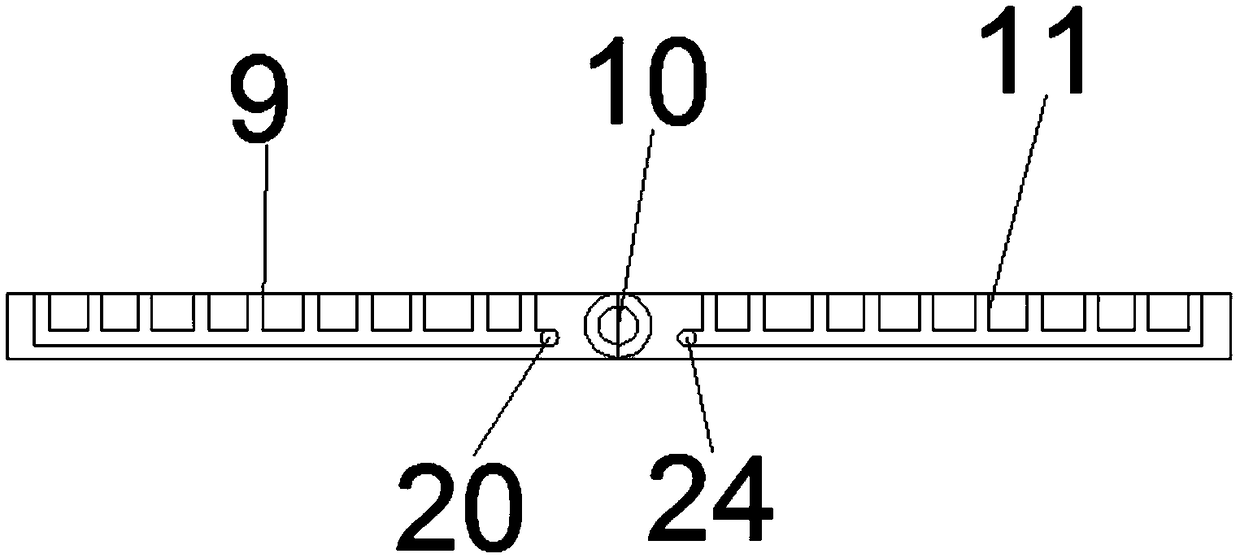

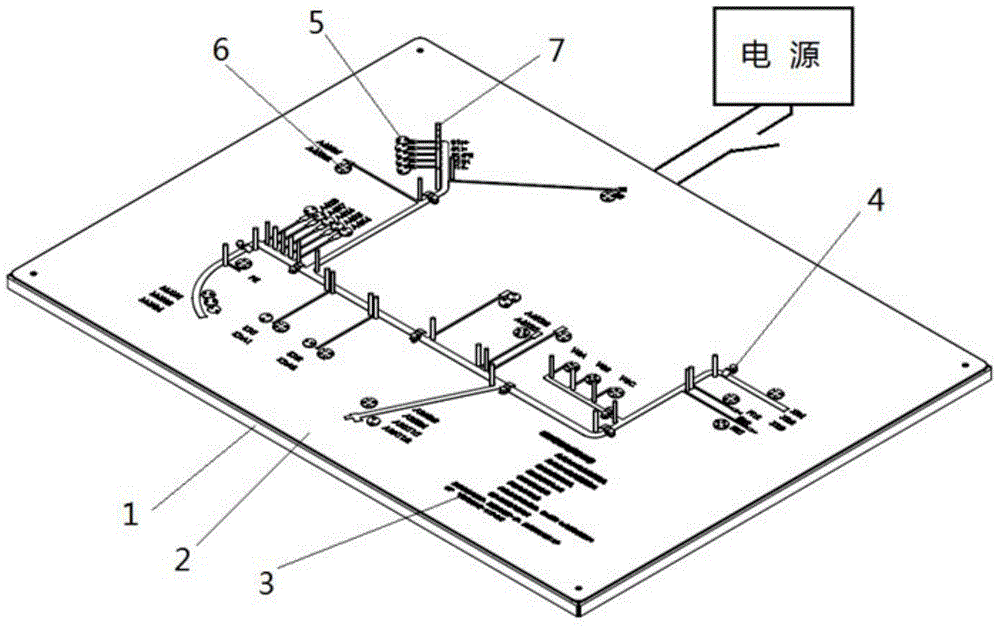

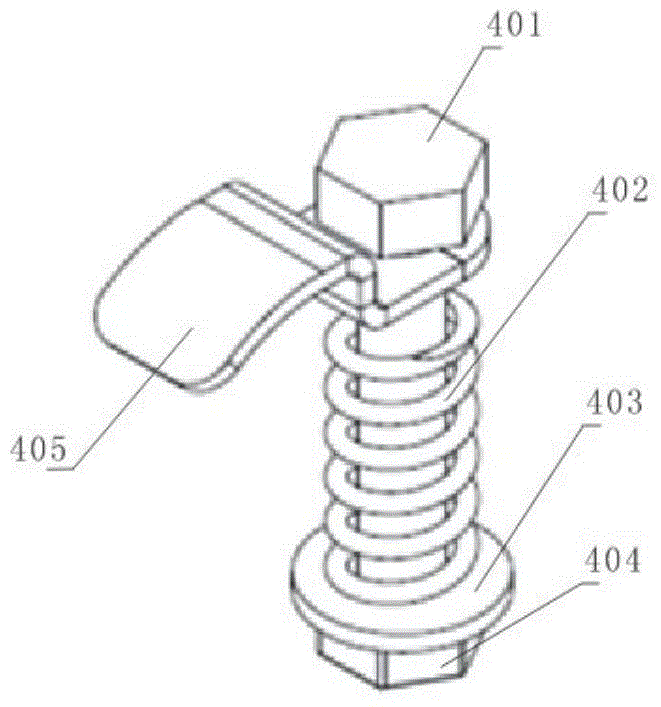

Wire harness bundling test plate and application method thereof

ActiveCN104483515AIncrease productivityReduce material costElectrical testingMeasurement instrument housingEngineeringMetal

The invention relates to a wire harness bundling test plate and an application method thereof. A cover plate is laid and fixedly mounted at the upper end of a metal base; a layer of wire harness bundling step map is clamped between the metal base and the cover plate; through holes are formed in the cover plate correspondingly; a wire harness positioning column and a wire harness clamp used for assisting wire harness positioning as well as a positive pole clamp and a negative pole clamp used for detecting the circuit are mounted in the through holes respectively; the positive pole clamp and the negative pole clamp are connected to a test circuit at the lower end of the metal base respectively; the test circuit is connected to an external power supply through conducting wires. According to the invention, the production efficiency of the wire harness bundling plate is improved; the material cost and the labor cost are reduced; wire harness bundling difficulty is greatly reduced; a testing function is added; bundling errors are reduced; the bundling efficiency and quality are effectively improved; the bundling specification is unified.

Owner:TIANJIN RES INST OF ELECTRIC SCI

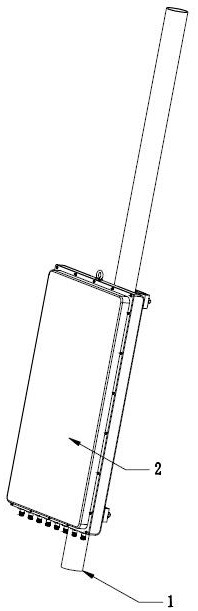

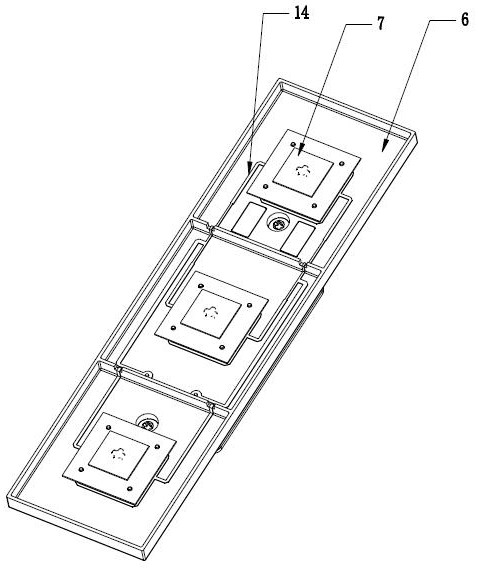

Modular AFU structure

PendingCN111987410ASave assembly timeReduce material costAntenna supports/mountingsAntennas earthing switches associationRadomeDividing circuits

The invention provides a modular AFU structure comprising a holding pole and an antenna unit detachably mounted on the holding pole. The antenna unit comprises an antenna cover, an antenna filter module, a power dividing plate, a rack and a power supply transceiving module, wherein the rack and the power supply transceiving module are mounted on the holding pole. The antenna filter module is mounted on the power dividing plate; the antenna filter module is composed of a plurality of integrated plastic carriers which are distributed in an array. High-performance plastic is used as a carrier; oscillators, the power dividing plate, a reflecting plate and filters are integrally formed. An oscillator power dividing circuit, a reflecting surface and a filter cavity are processed by using LDS andan electroplating process, the assembly time is greatly saved, and the cost of materials is greatly reduced; in addition, the module is used as an assembly unit, and the filters are relatively uniformly fixed relative to the oscillator units, that is to say, the positions of the filters corresponding to each group of oscillators are fixed, so that the phase consistency of the AFU is greatly improved, and the design of a filter matching circuit is simplified.

Owner:TONGYU COMM INC

Portable skin therapeutic instrument

PendingCN111529055AReduce material costEasy to useDiagnosticsSurgical instruments for heatingFunctional TreatmentBiomedical engineering

The invention discloses a portable skin therapeutic instrument. The portable skin therapeutic instrument comprises a shell, a single-function treatment head and a multifunctional treatment head, and is characterized in that the shell is provided with a holding part for being held by a hand and a mounting part connected with the holding part; the single-function treatment head is arranged in the shell; the single-function treatment head is provided with a first treatment surface, and the first treatment surface is exposed from the mounting part; the multifunctional treatment head is arranged inthe shell, and the multifunctional treatment head is provided with a second treatment surface; and the second treatment surface is exposed out of the mounting part, and the second treatment surface and the first treatment surface are independent of each other. The portable skin therapeutic instrument can break time and space constraints, treatment of uncomfortable skin can be realized anytime andanywhere, the material cost is lowered and the use convenience is improved.

Owner:SHENZHEN PENINSULA MEDICAL CO LTD

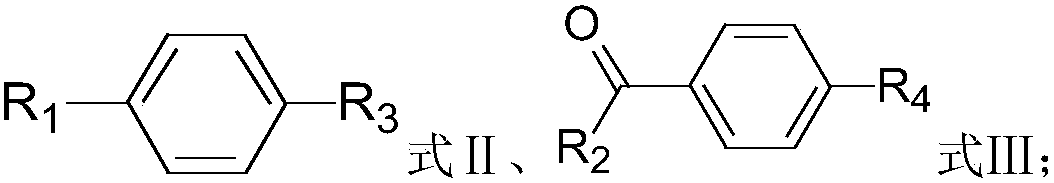

Method for synthesizing substituted biphenyl compound

ActiveCN108250109ALow priceReduce material costOrganic chemistryOrganic compound preparationSolventBiphenyl compound

The invention belongs to the field of organic synthesis, and relates to a method for synthesizing a substituted biphenyl compound. Technical problems to be solved in the invention are tedious operation and high cost of existing preparation methods. The method for synthesizing the substituted biphenyl compound having structural formula I, provided to solve the technical problems, comprises the following steps: a compound of formula II reacts with a compound of formula III in a mixed solvent in the presence of an alkali under the catalysis of palladium on carbon under the protection of an inertgas; and a reaction solution obtained after the reaction ends is filtered, the obtained filtrate is extracted with an extractant, and the obtained extract is concentrated to obtain the biphenyl compound represented by formula (I). The method for synthesizing the substituted biphenyl compound has the advantages of simplification of the post-treatment process, simplification of the product refiningand purifying process, and realization of great reduction of the energy consumption in the reaction and facilitation of industrial production due to the reaction being effectively performed at room temperature. The structure of the substituted biphenyl compound is represented by the formula I shown in the description; and the structures of the formula II and the formula III are also shown in the description.

Owner:SUZHOU KELUN PHARMA RES CO LTD +1

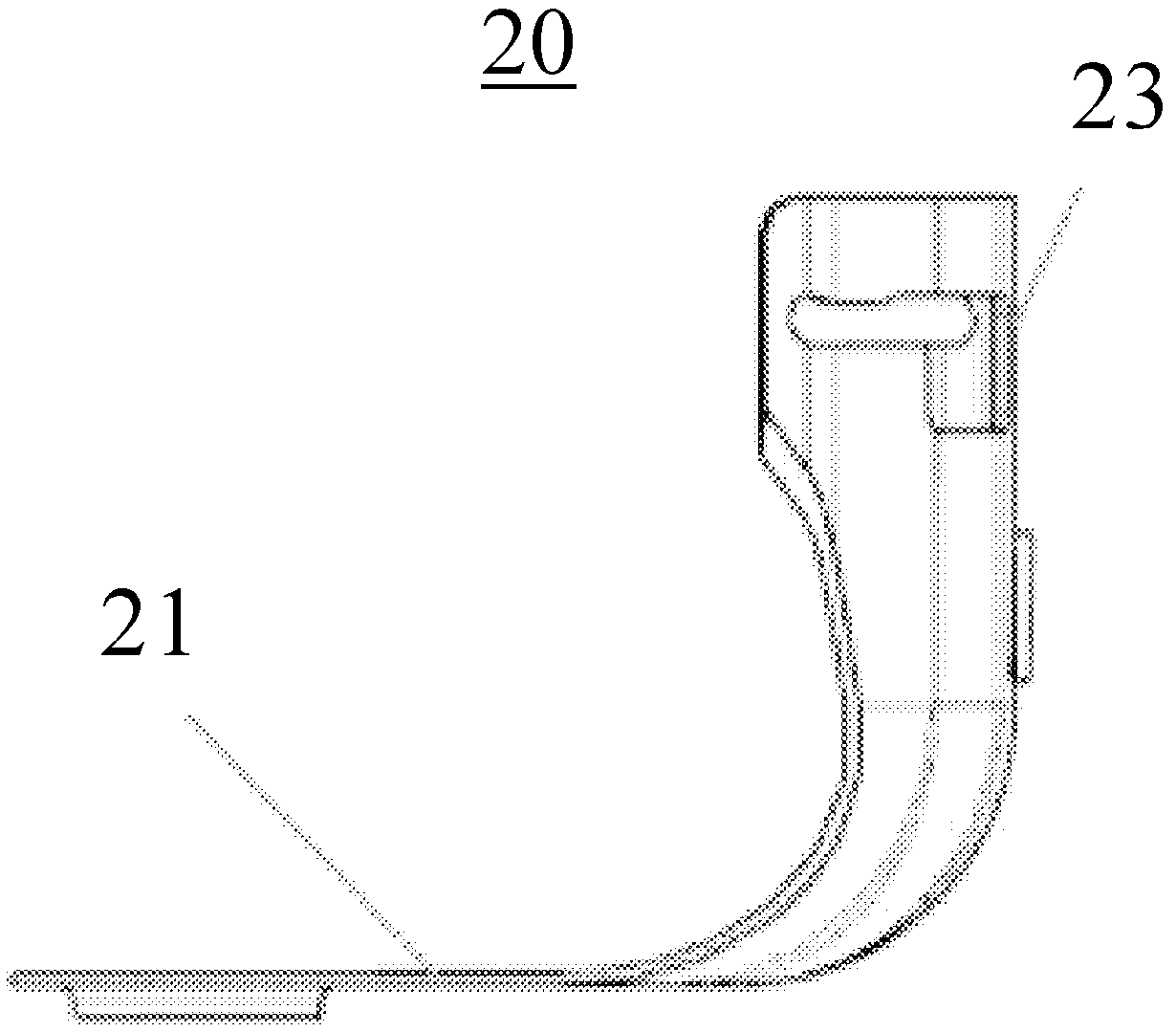

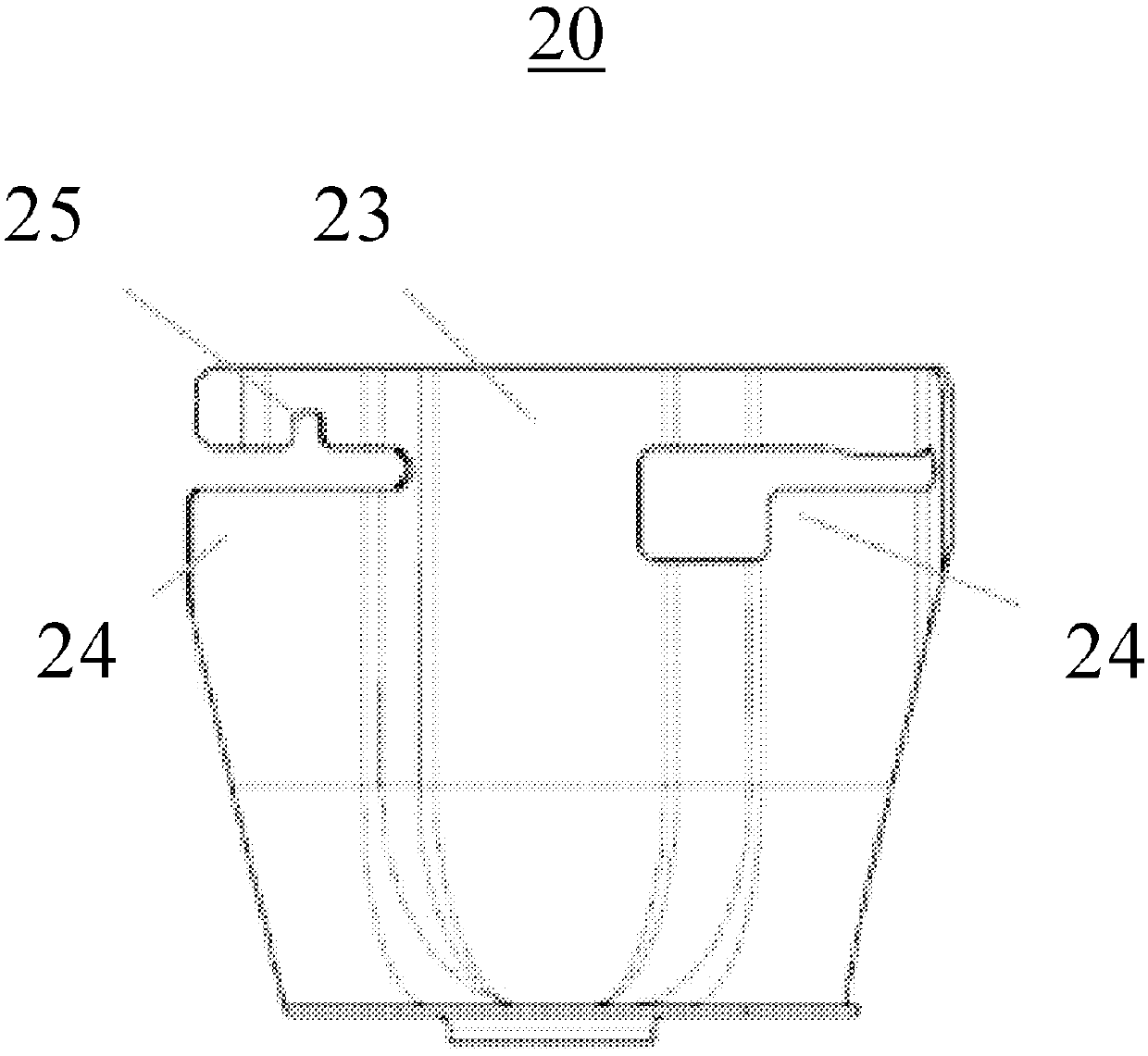

Cooling liquid pot installation structure, cooling liquid pot and installation support frame

InactiveCN110671188ASimple installation structureReduce material costMachines/enginesEngine cooling apparatusManufacturing engineeringCooling fluid

The invention discloses a cooling liquid pot installation structure, a cooling liquid pot and an installation support frame. The cooling liquid pot installation structure comprises the cooling liquidpot and the installation support frame used for the cooling liquid pot. The cooling liquid pot comprises a support seat, an installation tooth part and a boss. The installation support frame comprisesa support face, a support hole in the support face, a pre-locating face, an installation face and a groove. The support face is used for bearing the cooling liquid pot. The support hole is used for fixing the support seat of the cooling liquid pot. The pre-locating face is used for pre-locating of the cooling liquid pot. The installation face is used for being matched with the installation toothpart of the cooling liquid pot so as to limit the cooling liquid pot. The groove is used for being matched with the boss of the cooling liquid pot so as to limit the cooling liquid pot. According to the cooling liquid pot installation structure, the installation space can be reduced, and the installation process is optimized.

Owner:SAIC GENERAL MOTORS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com