Music string ball head with the function of differentiating music strings and manufacturing process thereof

A preparation process and technology for strings, applied in the field of the preparation process of the bead head of the strings, can solve the problems of extended processing time, high processing cost, and high processing equipment requirements, so as to save material costs, improve processing efficiency, and shorten processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

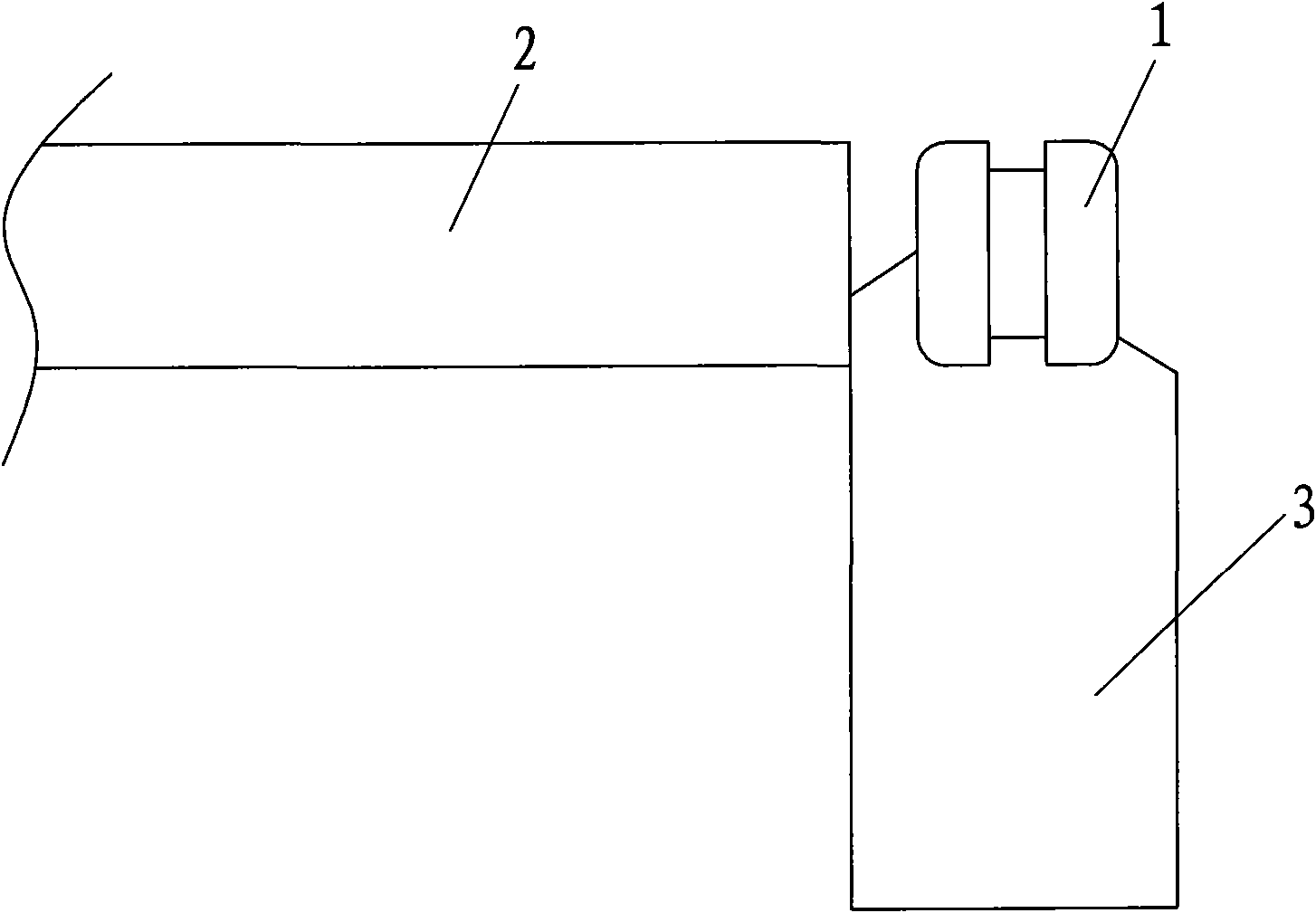

[0027] like figure 1 Shown is a string bead head 1 with the function of distinguishing the strings, the string bead head 1 is an I-shaped wheel structure, and the material of the string bead head 1 is a plastic mixture.

[0028] The plastic mixture is composed of plastic and color masterbatch, wherein the color masterbatch is red color masterbatch, and its weight ratio to plastic is 6:1000.

[0029] The above-mentioned color masterbatch can also use color masterbatches such as green, yellow, blue and other colors. The weight ratio of color masterbatch and plastic can be between 5 and 30:1000, such as 8:1000, 10: 1000, 12:1000, 15:1000, 20:1000, 25:1000, etc., the color masterbatch is selected from commercially available color masterbatch, and the plastic can be ABS or PC with a certain strength.

[0030] The colored string bead head of the present invention not only has the function of distinguishing the strings, but also has the function of permanent marking which never fade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com