A Fiber Bragg Grating Temperature Sensor

A technology of temperature sensor and optical fiber grating, which is applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problem that the optical fiber grating temperature sensor cannot have strong protection strength and response speed at the same time, so as to achieve easy implementation and strong protection The effect of strength and simple package structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

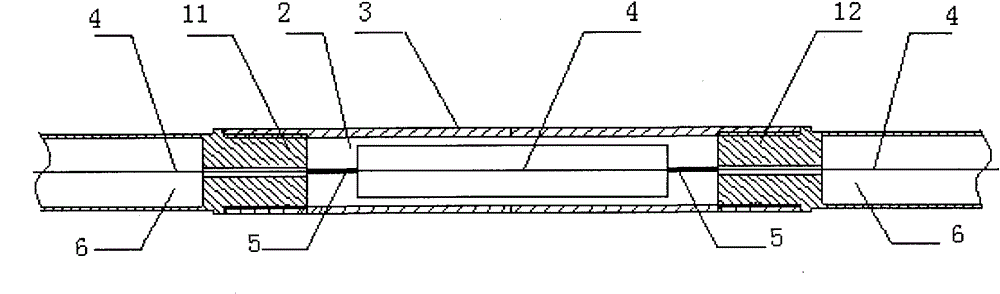

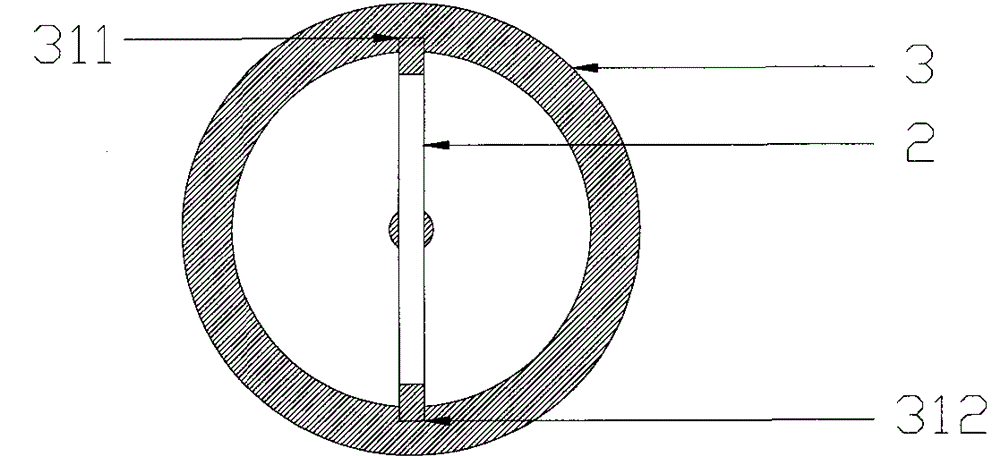

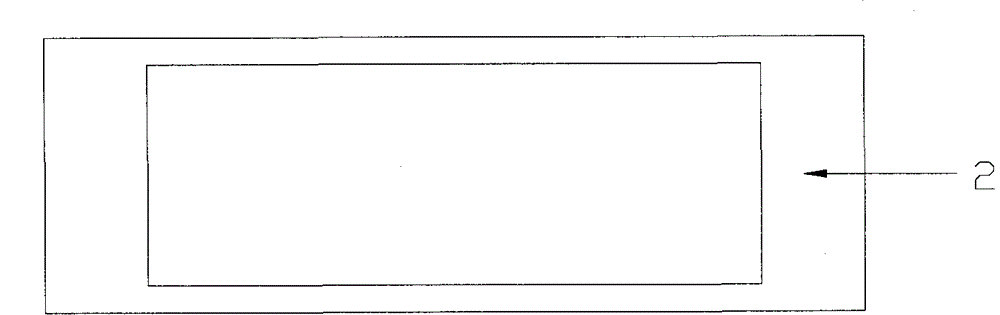

[0019] Example 1: Please also refer to Figure 1 to Figure 3 , figure 1 It is a structural schematic diagram of the first embodiment of the present invention; figure 2 yes figure 1 side view of the sectional view; image 3 It is a schematic diagram of the structure of a rectangular optical fiber fixing sheet. As shown in the figure, the fiber grating temperature sensor includes a fiber grating 4, an optical fiber fixing piece 2 for fixing the fiber grating 4, the fiber fixing piece 2 is built into the packaging tube 3, and two optical cable connectors with a through hole in the center of the cross section 11, 12 are connected with the two ends of the packaging tube 3, and the two ends of the fiber grating 4 fixed on the optical fiber fixing sheet 2 are respectively passed through the through holes in the two optical cable connectors 11, 12, and connected to the optical cable 6. connect.

[0020] Two grooves 311, 312 are arranged axially symmetrically on the inner wall of...

Embodiment 2

[0024] Example 2: Please also refer to Figure 4 to Figure 6 , Figure 4 It is a structural schematic diagram of the second embodiment of the present invention; Figure 5 yes Figure 4 side view of the sectional view; Figure 6 It is a structural schematic diagram of a dumbbell-shaped optical fiber fixing sheet. The difference between embodiment 2 and embodiment 1 is that the fiber fixing sheet 2 used in embodiment 2 is dumbbell-shaped, and the fiber grating 4 is fixed to the fixed parts 5 at both ends of the fiber fixing sheet 2 by gluing or welding. place, such as Figure 4 As shown, the two ends of the fiber fixing sheet 2 are inserted into the two grooves 311, 312 of the packaging tube 3, and the middle parts of the fiber fixing sheet 2 and the fiber grating 4 are placed inside the cavity of the packaging tube 3. Since the fiber fixing sheet 2 is dumbbell-shaped, and the upper and lower edges of the middle part are not in contact with the packaging tube 3, that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com