Detachable polymer lithium ion battery and assembling method thereof

A lithium-ion battery and polymer technology, applied in the field of lithium-ion batteries, can solve the problems of inability to maximize the battery capacity density and occupy a large space, and achieve the effect of compact structure, low cost and reliable structure of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

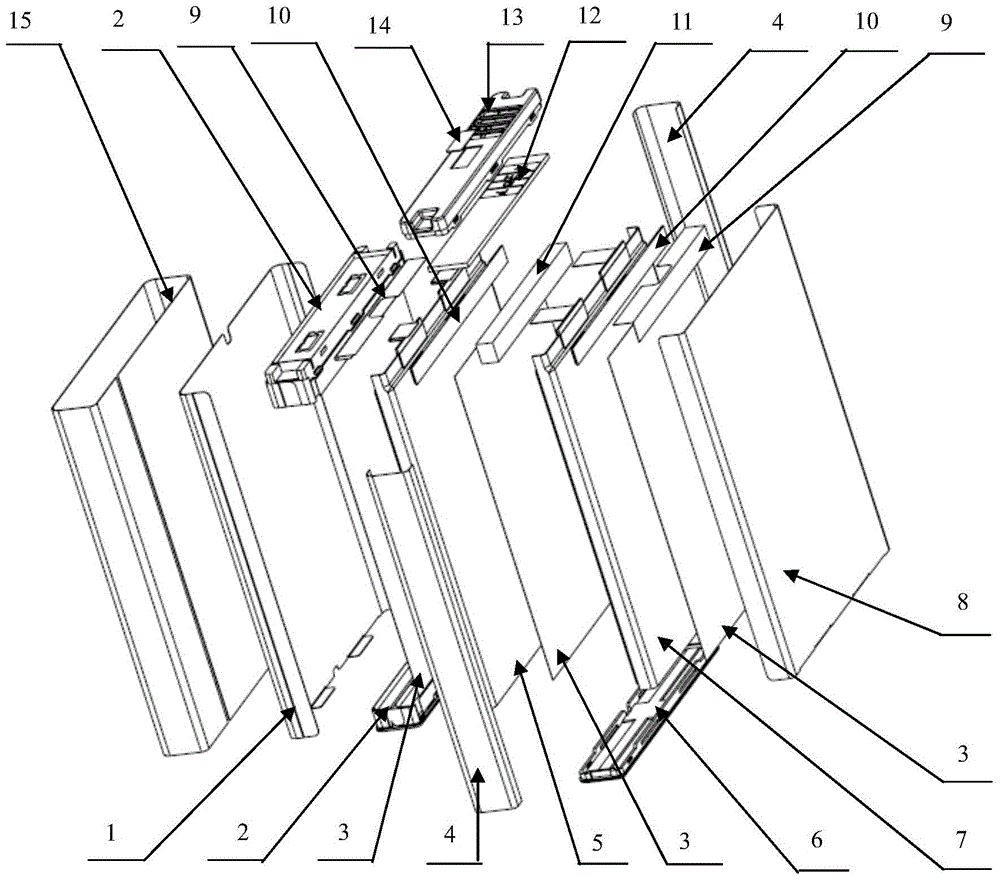

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

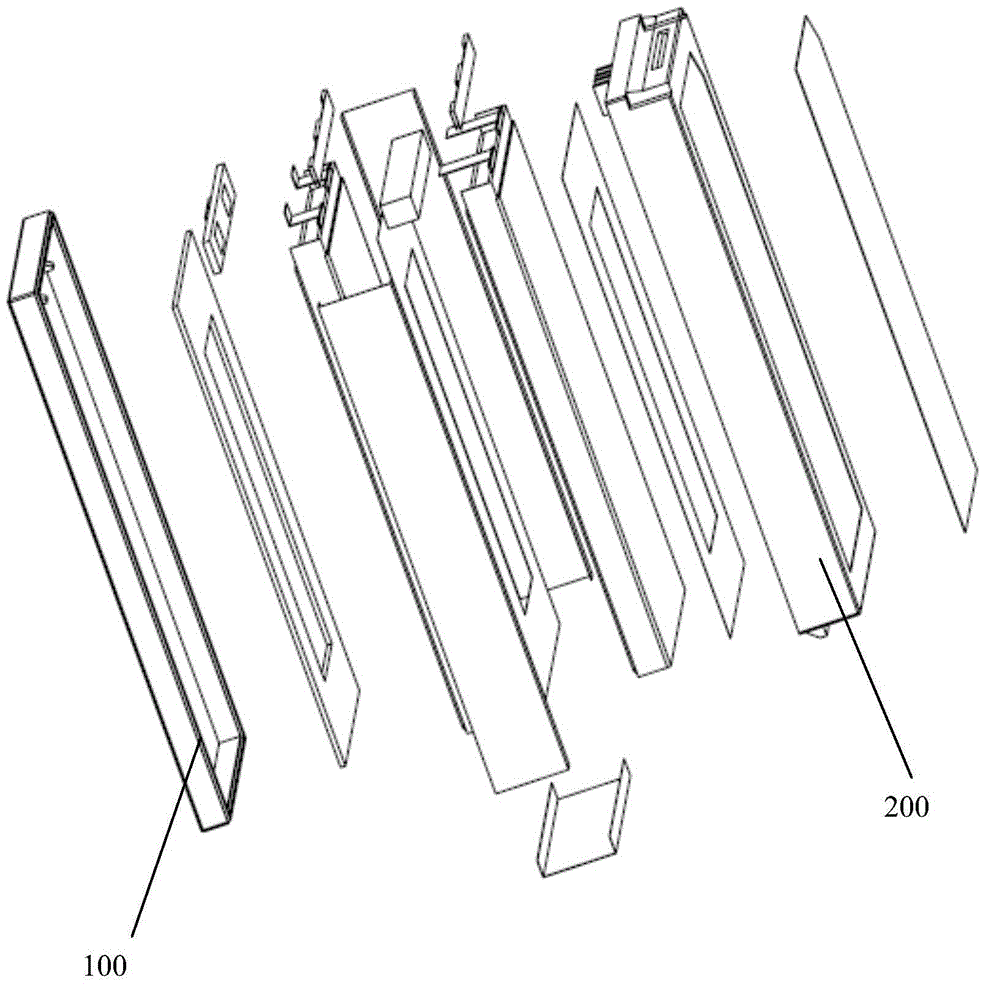

[0029] Such as Figure 2-8 As shown, the detachable polymer lithium ion battery of the present invention includes two parallel front polymer lithium ion batteries 5 and a rear polymer lithium ion battery 7, and a 0.1mm thick 0.1 mm battery cell that is fixedly connected and constitutes the battery cell accommodation chamber. An upper stainless steel sheet 1, a lower stainless steel sheet 8 with a thickness of 0.1 mm, a plastic top shell 13 and a plastic bottom shell 6, the upper stainless steel sheet and the lower stainless steel sheet include a sheet-shaped body, the two sides and the bottom of the body are respectively inward The side connection edges 104, 801 for realizing the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com