Large gear

A large-scale gear and integrated technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of unfavorable large-scale popularization, heavy weight, high risk, etc., and achieve convenient and fast welding process. The effect of saving raw materials and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

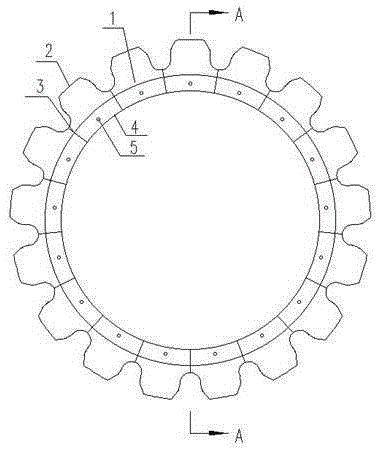

[0013] Such as figure 1 , figure 2 As shown, the present invention relates to a large-scale welded gear, including a tooth unit 1, a tooth 2, a welding spot 3, a central hole 4, and a positioning hole 5, and is characterized in that the large-scale gear has a plurality of tooth units 1 with evenly distributed welding spots 3. Composed of welding and welding, each tooth unit 1 is formed by casting, and after heat treatment and transfer processing, it is welded into one body after being positioned by the center hole 4 and the positioning hole 5. Tooth unit 1 is cast from 42GrMo. The tooth monomer 1 is heated to 850°-860° in a heat treatment furnace, then kept warm for 5 hours, and then released to air cooling. The tooth monomer is finished by processing such processes as tooth 2, center hole 4, and positioning hole 5.

[0014] When the present invention is used, each sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com