Welding method of cushion framework of left seat on back row of automobile

A welding method and cushion technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of large deformation of the cushion skeleton, unreasonable positioning of welding tooling and pressing mechanism, etc., and achieve the optimization of assembly process and welding process , Improving production efficiency and quality, and the effect of reasonable welding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

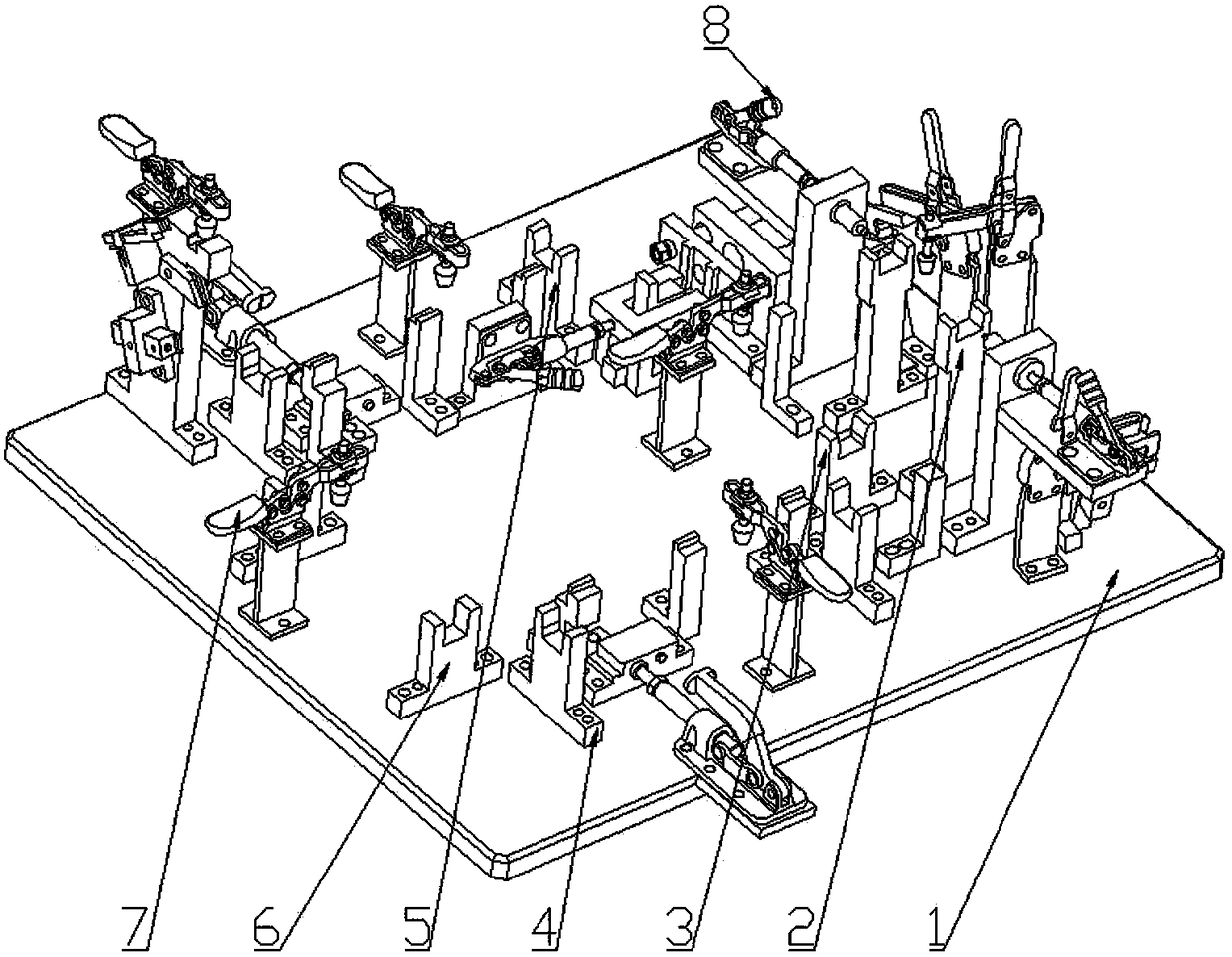

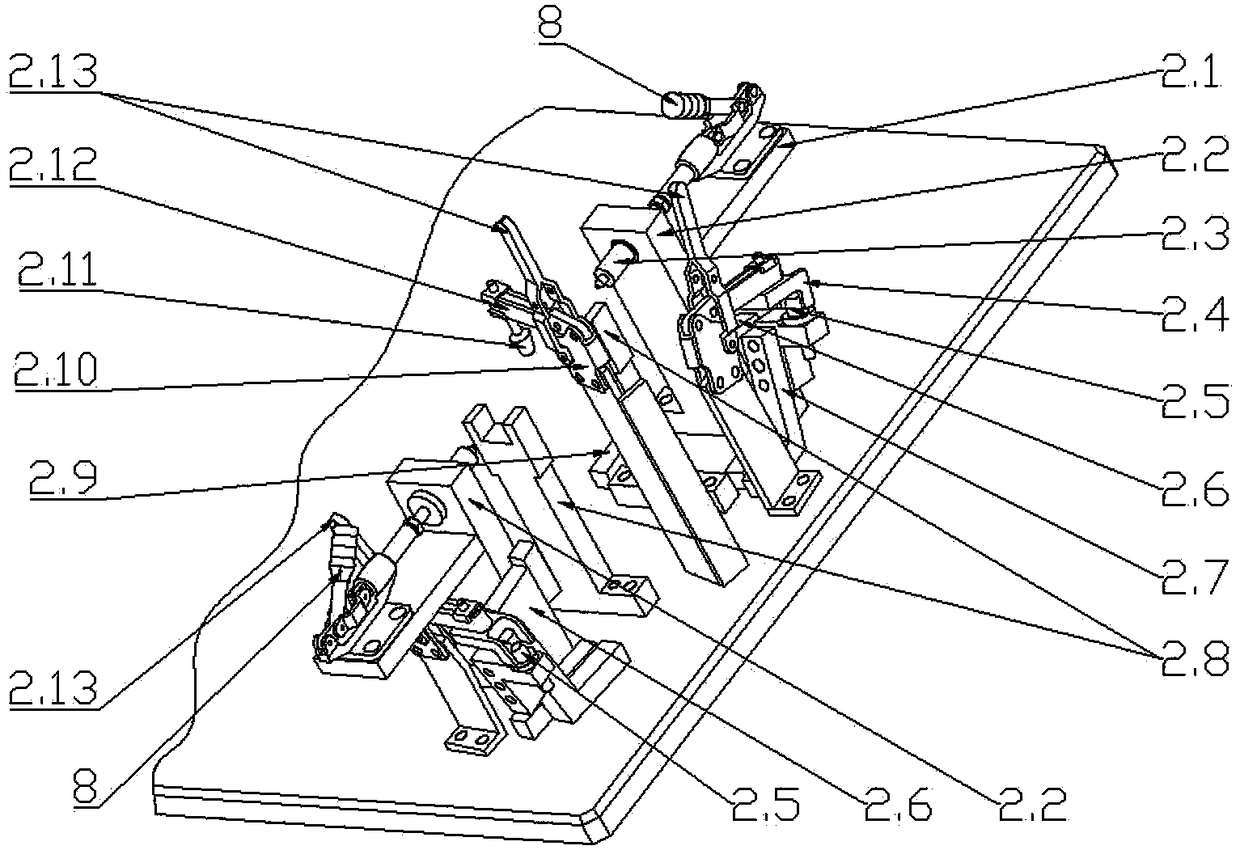

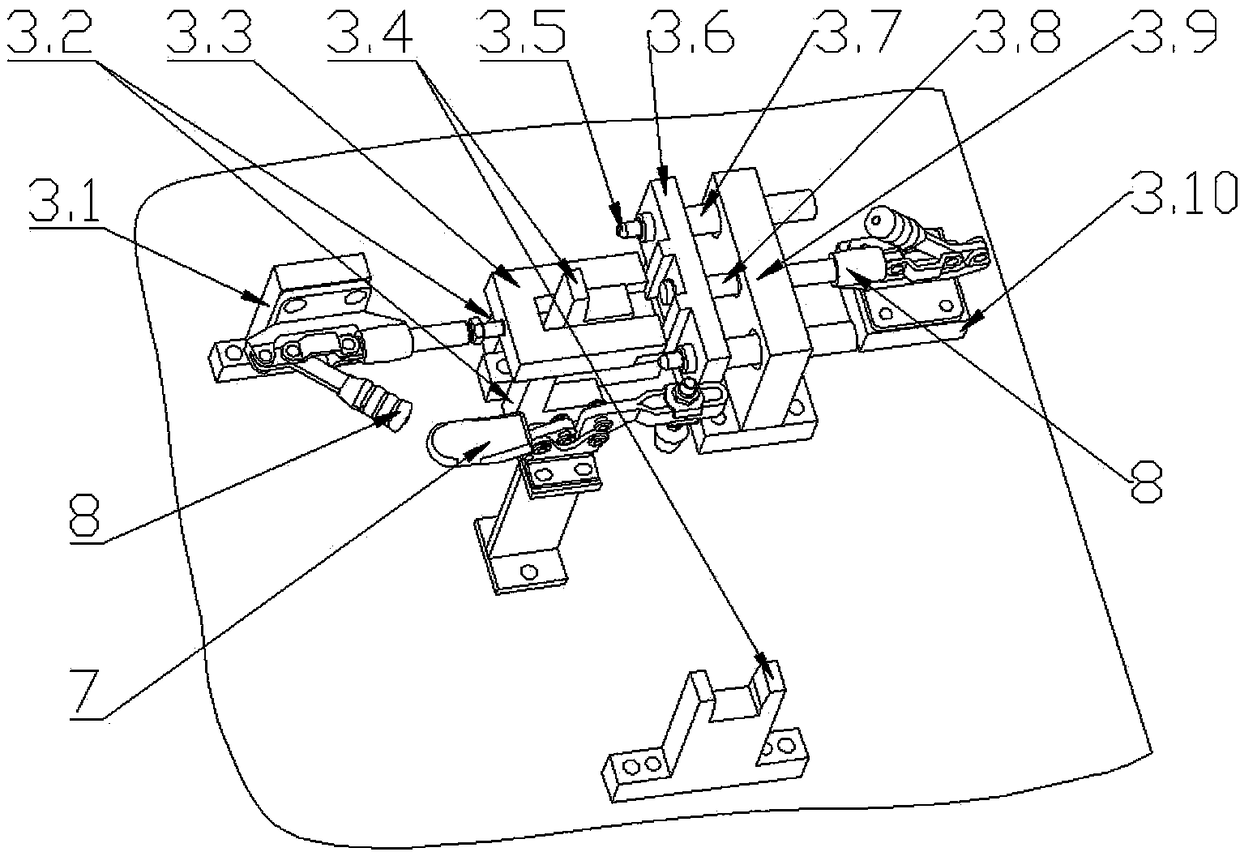

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0028] Such as Figure 8 The frame of the seat cushion on the left side of the rear row of the car is composed of the main frame (including the front horizontal tube 11, the rear horizontal tube 23, the left vertical tube 15, and the right vertical tube 27), the frame accessories (including the support plate armor 12, the snake spring Hook 13, long steel wire 14, hinge sheet metal 16, upper fixed sheet metal 17, hinge pin 18, lower fixed sheet metal 19, short steel wire 20, support plate B 21, middle steel wire 22, seat and connecting plate 24), connecting bracket (Including the left side turning sheet metal A 25, the left rear bracket 26, the support pipe 28, the left side turning sheet metal B 29, the left front bracket 30) and other parts, in order to assemble and weld these parts into a cushion skeleton that meets the technical requirements , it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com