Circuit board surface treatment method

A surface treatment, circuit board technology, applied in secondary treatment of printed circuits, improvement of metal adhesion of insulating substrates, printed circuits, etc. Good quality, good welding performance, and the effect of increasing the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

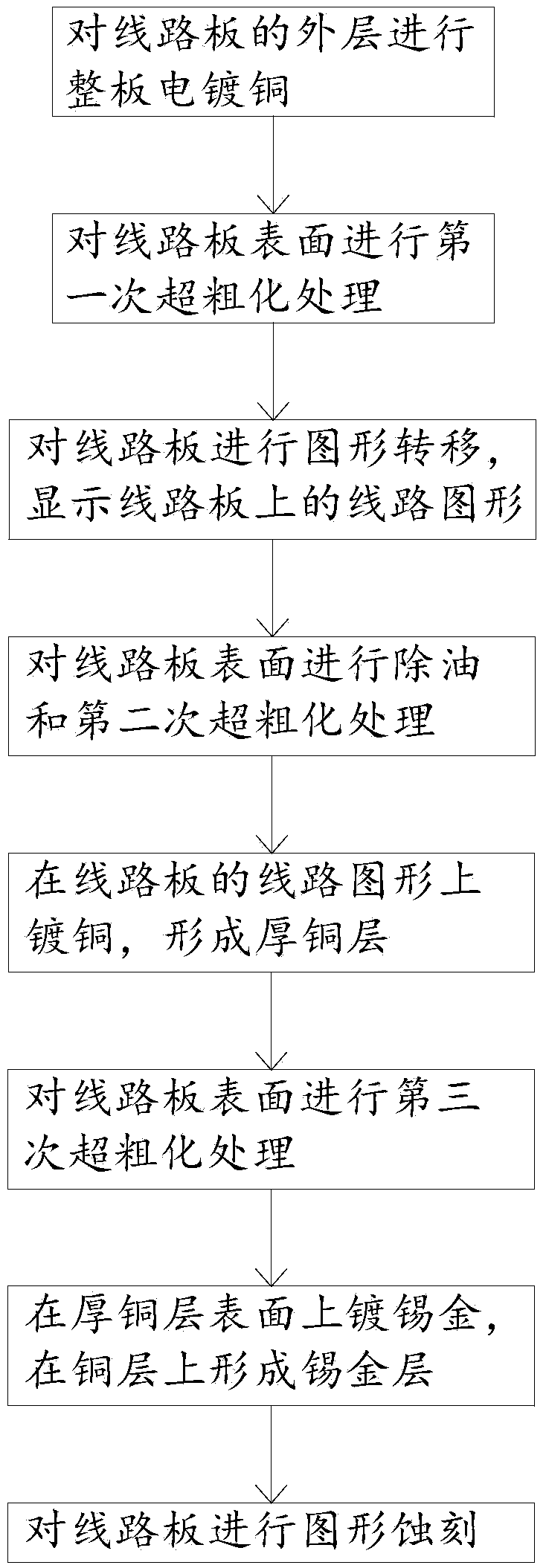

[0028] Such as figure 1 Shown, a kind of surface treatment method of circuit board is characterized in that, comprises the following steps:

[0029] Electroplate copper on the outer layer of the circuit board;

[0030] Perform the first super-roughening treatment on the surface of the circuit board;

[0031] Carry out graphics transfer to the circuit board, and display the circuit graphics on the circuit board;

[0032] Degreasing and second super-roughening treatment on the surface of the circuit board;

[0033] Plating copper on the circuit pattern of the circuit board to form a thick copper layer;

[0034] Perform the third super-roughening treatment on the surface of the circuit board;

[0035] Nickel-gold plating on the surface of the thick copper layer to form a nickel-gold layer on the thick copper layer;

[0036] Pattern etching of circuit boards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com