Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Improve melting properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing platy or lump processed cheese and cheese obtained

ActiveCN101564062AMaintain drawabilityLow heating temperatureCheese manufactureEngineeringBrowning reaction

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improves the prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD

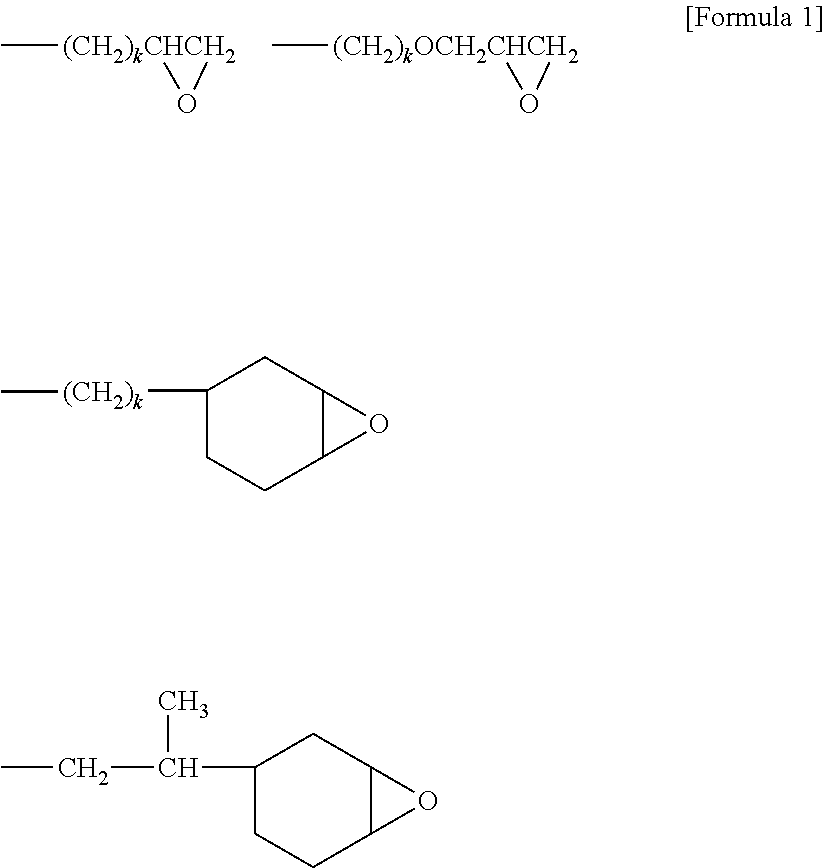

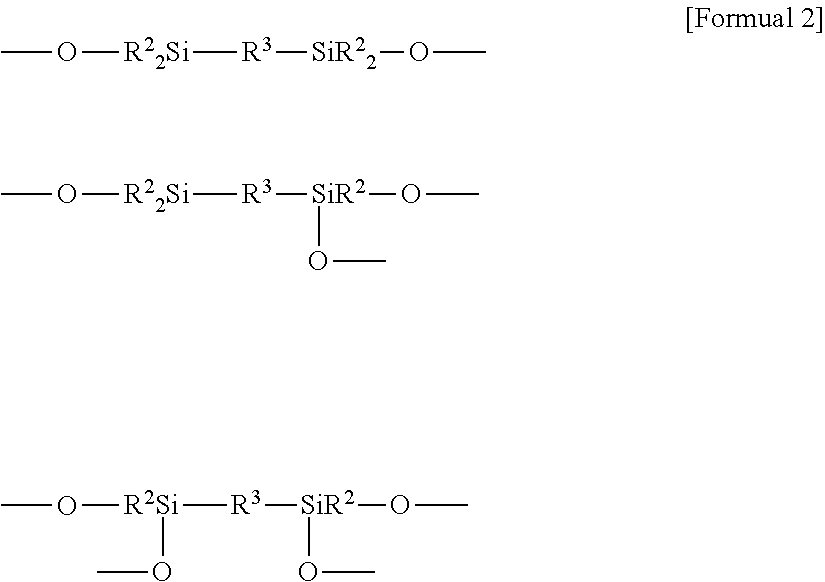

Curable organopolysiloxane composition, semiconductor sealant comprising same, and semiconductor device

ActiveUS20170355804A1Short timeGood staminaCoatingsGraft polymer adhesivesPolymer sciencePtru catalyst

Disclosed is a curable organopolysiloxane composition, comprising: (A) a curing reactive organopolysiloxane component formed by curing or semi-curing and reacting at least two or more types of organopolysiloxanes in the presence of one or more types of catalysts; and (B) a peroxide. The composition is a non-fluid at 25° C., and the melt viscosity at 100° C. is 8000 Pa·s or lower. A sealing agent comprising the curable organopolysiloxane composition and a cured product of the curable organopolysiloxane composition are also disclosed, along with a method of molding a cured product and a semiconductor device comprising the cured product.

Owner:DOW TORAY CO LTD

Method for producing polyolefin microporous membrane

InactiveCN101208379AExcellent mechanical propertiesImprove shutdown characteristicsSemi-permeable membranesMembranesPolyolefinSolvent

A method for producing a microporous polyolefin membrane by extruding a melt blend comprising a polyethylene resin, polypropylene having a mass-average molecular weight of 1 × 10 5 or more and an ethylene content of 5% by mass or less, and a membrane-forming solvent through a die, slowly cooling the resultant extrudate to form a gel-like sheet, stretching the gel-like sheet, and removing the above membrane-forming solvent, the slow-cooling speed of the extrudate being 30°C / second or less.

Owner:TONEN CHEM CORP

Free flowing glass batch

InactiveUS7494948B2Improve melting propertiesImprove uniformityCharging furnaceGlass productionGlass meltingChemistry

A process for preparing and storing moist glass-making batch is disclosed, comprising incorporating a surfactant in moist batch so that when the batch is either: a) stored at a temperature below 35° C., it remains free flowing without setting, or b) pre-heated at, or above, 100° C. before supply to a glass melting furnace, it remains free flowing without setting. The moist batch includes from 2% to 10% by weight free water and from 0.0001% to 5% by weight surfactant, which is preferably a soluble soap (for example a carboxylate having from 4 to 22 carbon atoms in its chain) that is incorporated into the batch as it is mixed. The moist batch can be stored for at least 24 hours, and it can be pre-heated to at least 150° C., and remain free flowing without setting.

Owner:PILKINGTON GROUP LTD

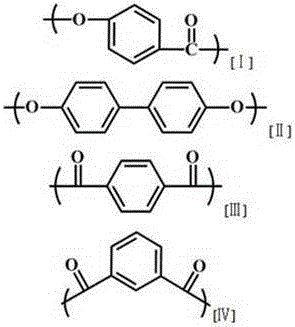

Polyurethane resin based slush molding material

InactiveCN1646590AImprove melting propertiesImprove heat resistancePedestrian/occupant safety arrangementCoatingsPolymer scienceSimple aromatic ring

Owner:SANYO CHEM IND LTD +1

Titanium alloy spectacle frame and preparation method thereof

ActiveCN107988526AImprove melting propertiesRich varietyNon-optical partsLutetiumBiocompatibility Testing

The invention discloses a titanium alloy spectacle frame and a preparation method thereof. The titanium alloy spectacle frame is characterized in that titanium alloy comprises the components of metalA, metal B, the balance titanium and inevitable impurities; the metal A is metal with the melting point higher than the melting point of Ti by a range within 600 DEG C, and the metal B is metal with amelting point lower than the melting point of Ti by a range within 200 DEG C; and the metal A comprises one kind or several kinds of platinum, zirconium and hafnium, and the metal B comprises one kind or several kinds of lutetium, palladium, erbium, thulium, scandium, yttrium, iron and cobalt. The preparation method is characterized in that the titanium alloy spectacle frame is obtained through the steps of preparing intermediate alloy, preparing the titanium alloy and producing the titanium alloy spectacle frame. The titanium alloy spectacle frame produced by the method is light in weight, is firm, is good in biocompatibility with a human body, does not contain elements such as nickel which easily causes anaphylactic reaction, is good in glossiness, conforms to the public aesthetic judgment and is good in elasticity, the comfort experience is brought to a wearer, and the problem of falling off caused by large deformation can not be caused.

Owner:永嘉姜君科技有限公司

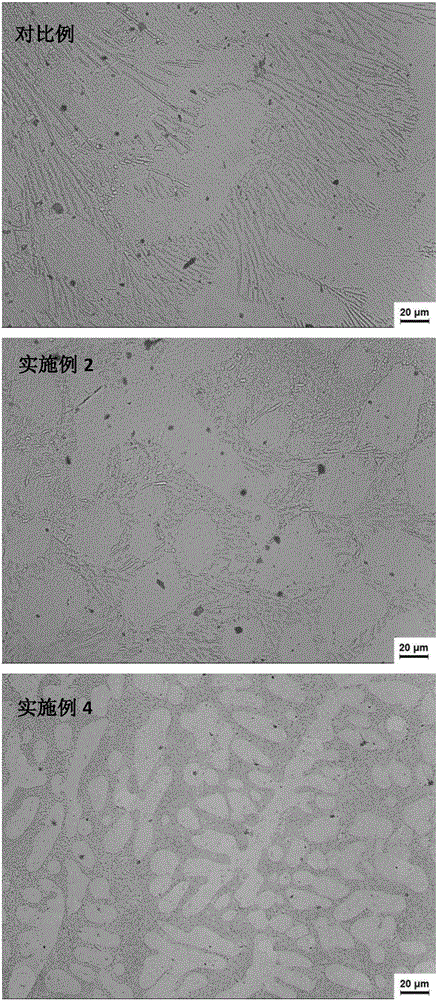

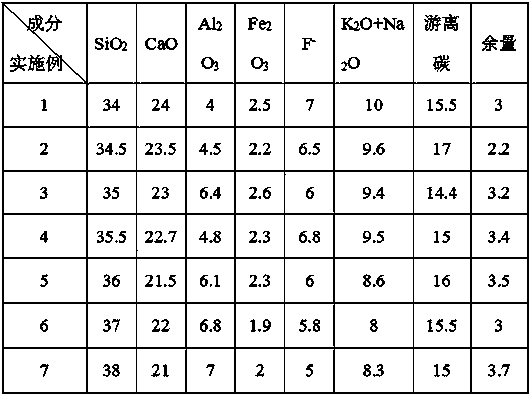

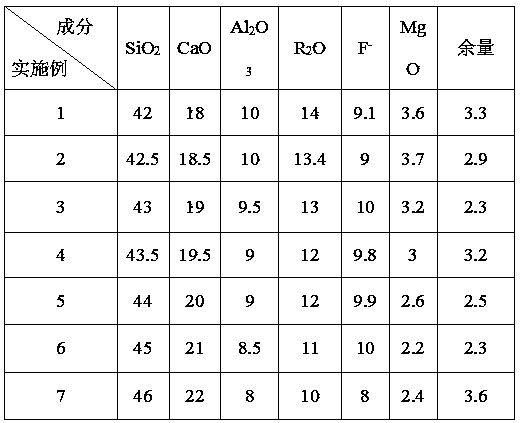

Continuous casting crystallizer protective material special for large round billet high-abrasion bearing steel

The invention discloses a continuous casting crystallizer protective material special for large round billet high-abrasion bearing steel. The protective material comprises the following components in percentage by mass: 56.0 to 64.0 percent of pre-melt, 8.0 to 12.0 percent of fine glass powder, 1.0 to 3.0 percent of sodium carbonate, 13.0 to 17.0 percent of fluorite, 2.0 to 4.0 percent of sodium fluoride, 2.0 to 6.0 percent of lithium carbonate, 1.0 to 2.5 percent of carbon black and 4.0 to 6.0 percent of re-carburizing agent. The protective material serving as the research result is melted uniformly in a crystallizer, a few slag rings are produced, the thickness of liquid slag at a normal casting speed is 10 to 12 millimeters, the consumption of the protective material for each ton of steel is 0.35 to 0.45Kg, and the cleaning-free rate of the surface of a casting blank reaches over 98 percent; and after the steel is subjected to carburization, thermal treatment, quenching and tempering, the surface hardness of the steel is 58 to 62HRC, the heart hardness of the steel is 25 to 45HRC, the surface of the steel is abrasion-resistant, and the heart of the steel has good toughness.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

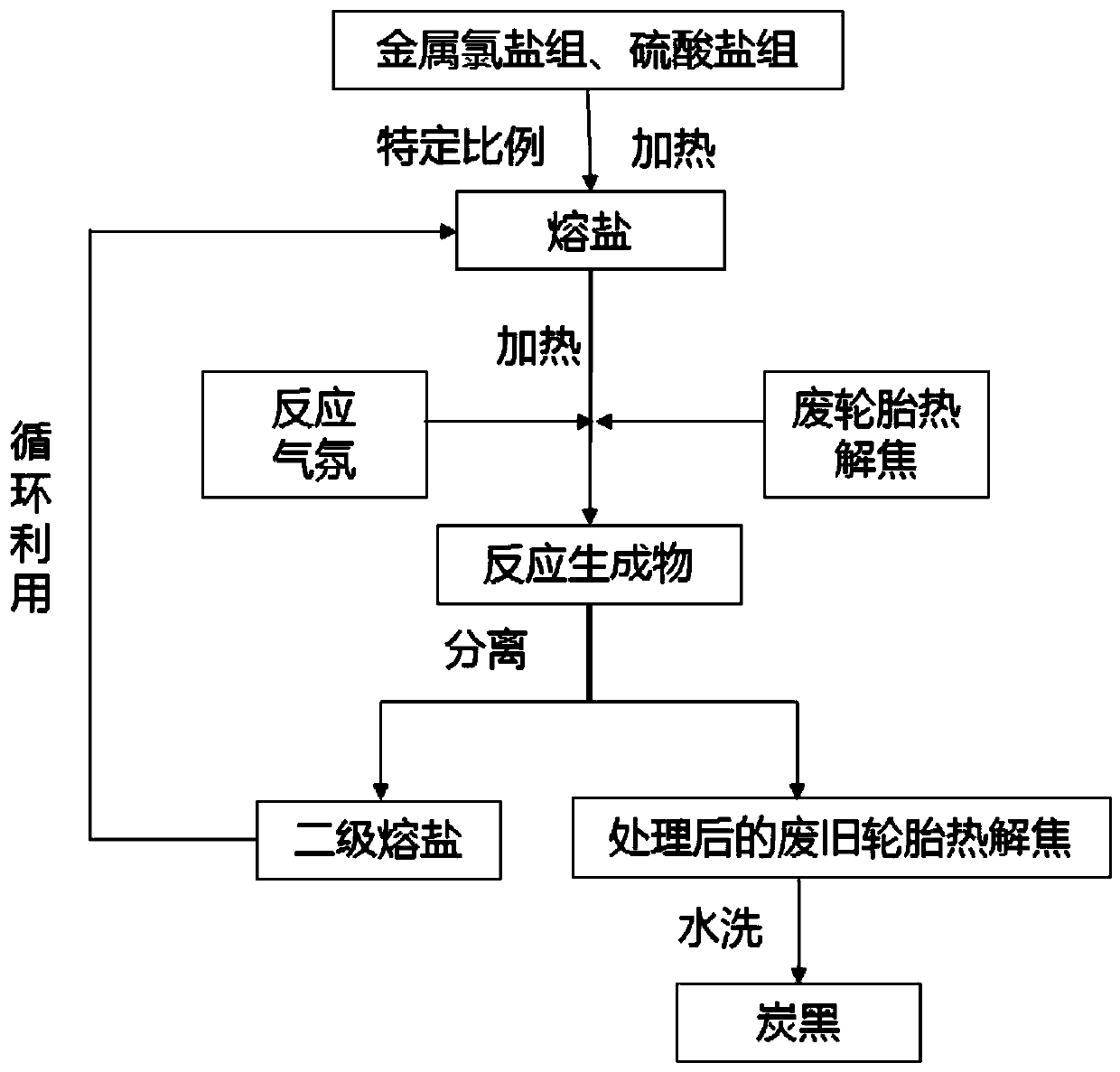

Method for preparing carbon black from pyrolysis coke of waste tire through molten salt heat treatment, and product prepared by using the same

ActiveCN110229543AEnhanced low temperature melting propertiesHigh activityPigmenting treatmentStrong acidsImpurity

The invention belongs to the technical field of resourceful utilization of organic solid wastes, and specifically discloses a method for preparing carbon black from pyrolysis coke of a waste tire through molten salt heat treatment, and a product prepared by using the same. The method comprises the following steps: heating one or two selected from the group consisting of a metal chloride salt groupand a metal sulfate salt group so as to obtain molten salt; adding the pyrolysis coke of the waste tire into the molten salt, and carrying out molten salt heat treatment under a preset reaction atmosphere; and after completion of a reaction, separating a reaction product into secondary molten salt and treated pyrolysis coke, washing treated pyrolysis coke with hot water, carrying out drying so asto obtain the carbon black, and recycling the secondary molten salt at the same time. According to the invention, by utilization of the melting characteristic of the molten salt, impurity componentsin the pyrolysis coke of the waste tire are dissolved out, so the use of strong acids and strong alkalies like nitric acid, hydrochloric acid and an alkali liquor is avoided; meanwhile, through addition of metal chloride salt, the low-temperature melting characteristic of the molten salt is reinforced; and by utilization of metal sulfate salt, acidic gases like hydrogen sulfide and hydrogen chloride are captured in situ at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel fluorine-containing siloxane fire retardant, and preparation method and application thereof

The invention relates to the technical field of plastic assistants, and concretely relates to a novel fluorine-containing siloxane fire retardant, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, uniformly mixing organosiloxane monomers, adding the obtained monomer mixture into a catalyst and emulsifier dissolved aqueous solution, and carrying out a reaction to obtain an organopolysiloxane emulsion; 2, adjusting the pH value of the organopolysiloxane emulsion by using an alkali liquid, adding a fluorine-containing styrene monomer and a copolymerization, adding an initiator, a crosslinking agent and a chain transfer agent, and carrying out a reaction to obtain an organosiloxane grafted fluorine-containing styrene polymer emulsion; and 3, diluting the polymer emulsion, adding a de-emulsifier to carry out demulsification, centrifuging the de-emulsified emulsion, and carrying out drying and crushing to prepare the novel fluorine-containing siloxane fire retardant. The novel fluorine-containing siloxane fire retardant prepared in the invention has excellent anti-dripping effect and fire-retardant property without affecting the mechanical properties of a high-molecular material polymer, and also can improve the mechanical properties and the heat resistance of matrix resin.

Owner:铨盛聚碳科技股份有限公司

Blue-green grass

InactiveUS6849566B2Improve melting propertiesReduce problemsLight protection screensPhotochemistryColoring agents

A blue-green colored glass composition includes a base portion, such as a conventional soda-lime-silica base, and major colorants. In one embodiment, the major colorants include 0.7 to 0.9 weight percent total iron (Fe2O3), 0.2 to 0.3 weight percent FeO, and 0 to 5 ppm CoO. The glass is characterized by a dominant wavelength in the range of 490 nm to 495 nm and an excitation purity in the range of 3% to 11%. The glass of the invention can be essentially free of Se.

Owner:VITRO FLAT GLASS LLC

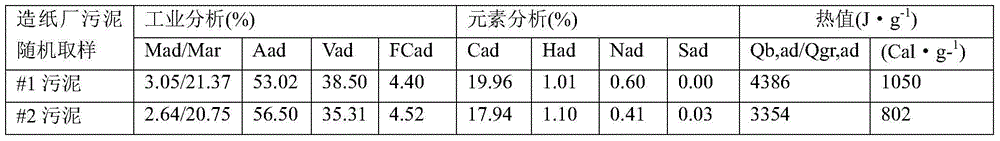

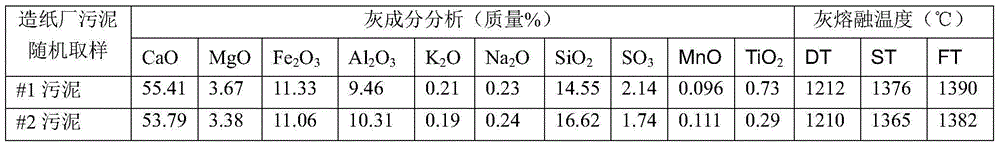

Flux for reducing fine coal gasification ash melting point temperature and use method thereof

ActiveCN104479794AImprove melting propertiesLow melting pointSolid fuelsFuel additivesChemical compositionResource utilization

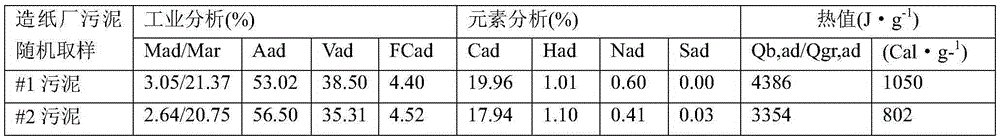

The invention discloses a flux for reducing a fine coal gasification ash melting point temperature and a use method thereof and belongs to the field of fluxes. The flux is papermaking sludge, contains organic matters, has air-dried base heat of 800-1000 kcal / kg and alkaline oxide mass content more than 50% and comprises, by mass, 40-56% of CaO, 3-12% of MgO, 3-12% of Al2O3, 9-15% of Fe2O3, 14-20% of SiO2, less than 3% of SO3, less than 0.8% of TiO2, less than 1% of each one of alkali metal oxides and a small amount of impurities. The use method of the flux comprises that when a raw material coal deformation temperature is less than 1450 DEG C, a flux use ratio is in a range of 6-15%, and when the raw material coal deformation temperature is higher than 1450 DEG C, a flux use ratio is in a range of 15-30%. The flux can effectively reduce a coal ash melting point, realize resource utilization of papermaking sludge waste and realize utilization of papermaking sludge heat.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

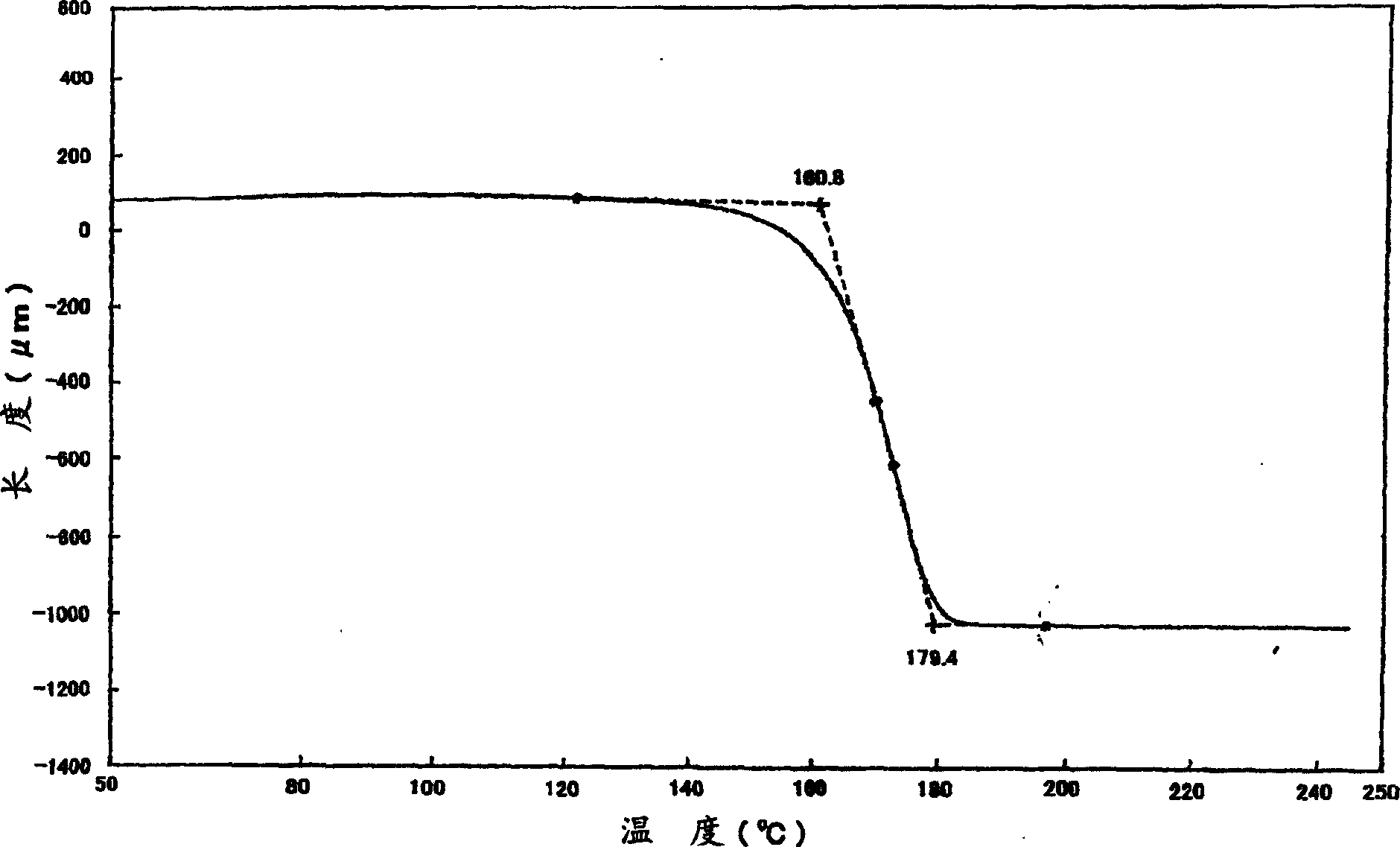

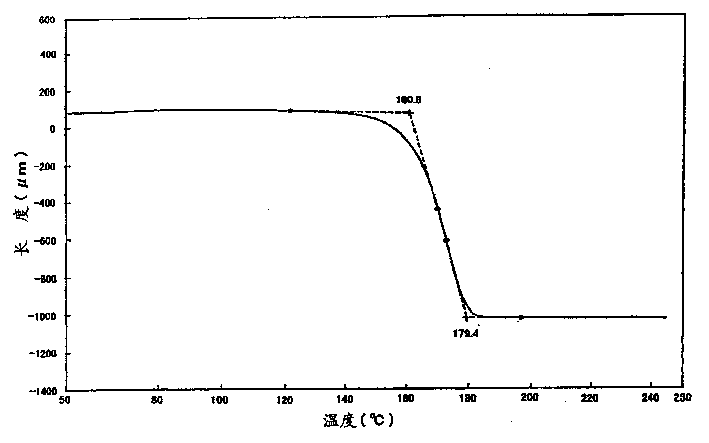

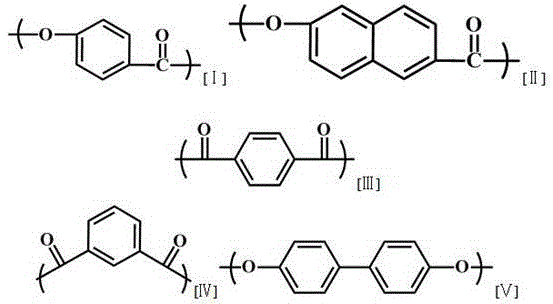

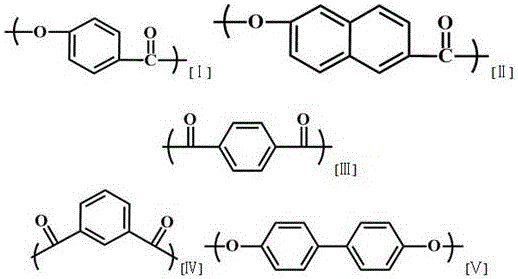

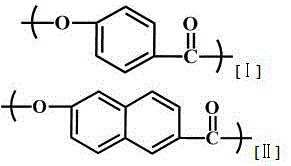

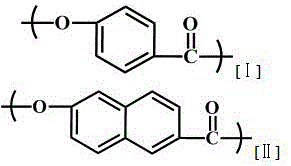

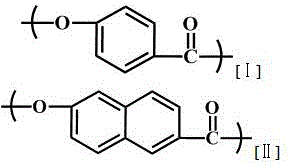

Liquid crystal polyester and its molded composition and use

ActiveCN105837803AImprove liquidityImprove melting propertiesLiquid crystal compositionsPolyesterThermomechanical analysis

The invention discloses a liquid crystal polyester and its molded composition and use. The liquid crystal polyester comprises repeated structural units [I]-[IV]. A dynamic thermomechanical analysis (DMA) test proves that the liquid crystal polyester has a storage modulus release rate delta G greater than or equal to 95.0% and less than or equal to 99.4% defined in the formula (1) of delta G=[G(-50)-G(melting point)] / G(-50)*100%. The liquid crystal polyester has a storage modulus release rate delta G greater than or equal to 95.0% and less than or equal to 99.4%. The liquid crystal polyester and the liquid crystal polyester molded composition have good fluidity and excellent melting characteristics. A small thin wall molded product has high stability and is especially suitable for a thin wall electronic product.

Owner:KINGFA SCI & TECH CO LTD

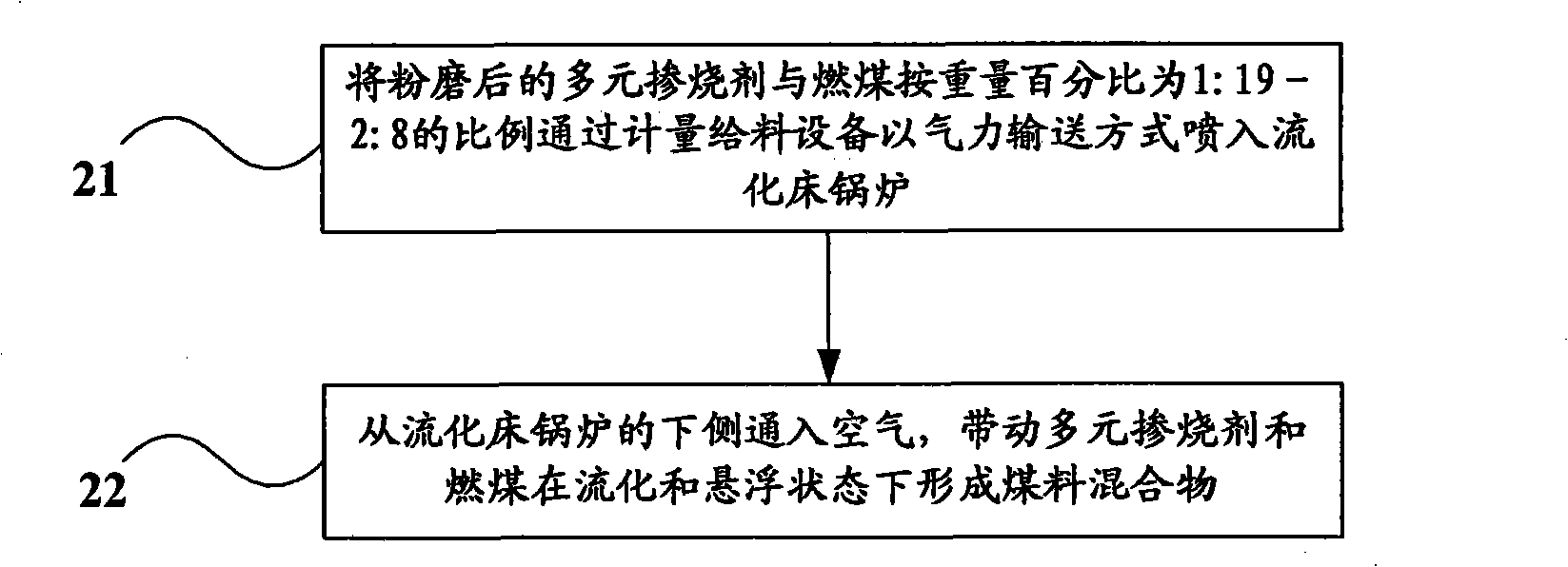

Multicomponent co-combustion agent and use method thereof

ActiveCN101314742AIncreased Strength and DurabilityLower combustion temperatureSolid fuelsSlagCoal fired

The invention relates to a multi-doped sintering agent and the usage thereof. The multi-doped sintering agent consists of a main material and a core material, wherein the main material includes one or any combination of carbide slag, soda slug, quick lime or limestone; the core material includes mineralizer, salt-melting medium and coke slag bulking agent. The usage of the multi-doped sintering agent comprises the following steps: crushing, mixing and pulverizing each component of the multi-doped sintering agent; mixing the pulverized multi-doped sintering agent with coal to form a coal mixture; burning and calcining the coal mixture in a boiler; and cooling and collecting hydraulic binding material modified ash. The multi-doped sintering agent can reduce the carbon content of fly ash and reduce the coal consumption of the boiler and can achieve high-efficiency solid desulfurization. The hydraulic binding material active ash produced after the coal burning has wide purposes, thus achieving multiple purposes of one boiler and achieving good effects of fluidized-bed combustion boiler such as environment protection, energy conservation and high-efficiency waste utilization.

Owner:中科院科技服务有限公司

Liquid crystal polyester and its molded composition and use

ActiveCN105837806AImprove liquidityImprove melting propertiesLiquid crystal compositionsPolyesterThermomechanical analysis

The invention discloses a liquid crystal polyester and its molded composition and use. The liquid crystal polyester comprises repeated structural units [I]-[IV]. A dynamic thermomechanical analysis (DMA) test proves that the liquid crystal polyester has a storage modulus release rate delta G greater than or equal to 95.0% and less than or equal to 99.5% defined in the formula (1) of delta G=[G(-50)-G(melting point)] / G(-50)*100%. The liquid crystal polyester has a storage modulus release rate delta G greater than or equal to 95.0% and less than or equal to 99.5%. The liquid crystal polyester and the liquid crystal polyester molded composition have good fluidity and excellent melting characteristics. A small thin wall molded product has high stability and is especially suitable for a thin wall electronic product.

Owner:KINGFA SCI & TECH CO LTD

A kind of flux that reduces the melting point temperature of fly coal gasification ash and its application method

ActiveCN104479794BImprove melting propertiesLow melting pointSolid fuelsFuel additivesResource utilizationAlkali metal oxide

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Sulfur control method in high-sulfur steel smelting process

ActiveCN107828937AStable and easy to createInhibit transferProcess efficiency improvementSulfurResource utilization

The invention belongs to the technical field of ferrous metallurgy, and relates to a sulfur control method in a high-sulfur steel smelting process. In the high-sulfur steel smelting process, blast furnace slag is used as synthetic slag so as to be added to a steel ladle along with steel flow, and the addition of the blast furnace slag is 5 to 8 kg per ton of steel. The production cost can be reduced, and the resource utilization rate can be increased.

Owner:SHANDONG IRON & STEEL CO LTD

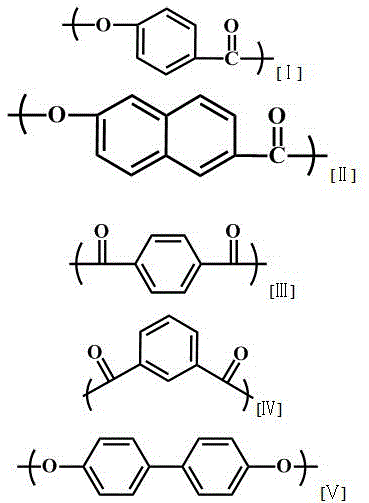

Liquid crystal polyester, molding composition composed of liquid crystal polyester and application of molding composition

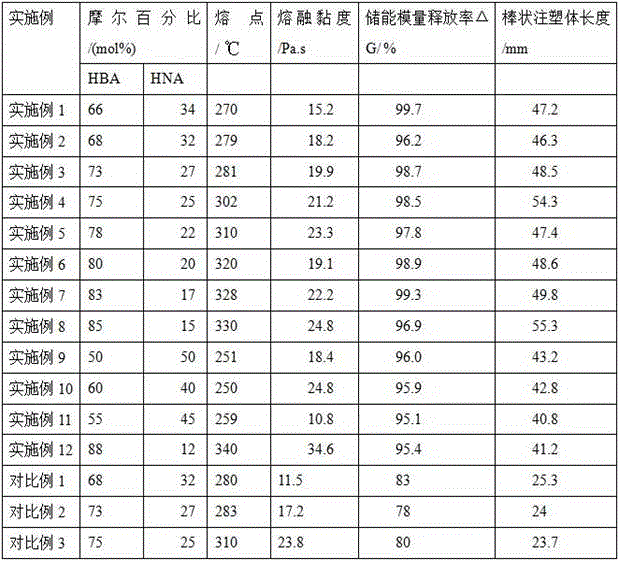

The invention discloses liquid crystal polyester, a molding composition composed of the liquid crystal polyester and an application of the molding composition. The liquid crystal polyester is composed of repetitive structural units represented by the formula I and the formula II; according to 100 mol% of the total amount of the repetitive units, the amount of the structural unit [I] derived from p-hydroxybenzoic acid is greater than or equal to 50 mol%, preferably greater than or equal to 66 mol% and less than or equal to 85 mol%; the amount of the structural unit [II] derived from 6-hydroxy-2-naphthoic acid is less than or equal to 50 mol%, preferably greater than or equal to 15 mol% and less than or equal to 34 mol%; through dynamic thermal mechanical analysis DMA testing, the liquid crystal polyester meets a condition that the energy storage modulus release rate [delta]G defined by the following formula (1) is greater than or equal to 95.0% and less than or equal to 99.7%, wherein the formula (1) is [delta]G=[G(-50)-G(melting point)] / G(-50)*100%. The liquid crystal polyester and the molding composition prepared by the liquid crystal polyester have the advantages of relatively high liquidity, excellent melting characteristics, and high forming stability of small thin-wall molding products, and are particularly suitable for use in thin-wall electronic preparation parts.

Owner:KINGFA SCI & TECH CO LTD

Method for preparing anti-oxidation coating from used lithium battery sagger

ActiveCN113321949AImprove melting propertiesReduce the amount addedCoatingsCarbide siliconSocial benefits

The invention belongs to the technical field of recycling of used refractory materials, and particularly relates to a method for preparing an anti-oxidation coating from a used lithium battery sagger. The method for preparing an anti-oxidation coating from a used lithium battery sagger comprises the following two steps of: 1, preparing a pre-melted material; and 2, crushing the pre-melted material into powder, and well mixing the powder with silicon carbide, metal silicon powder and other raw materials to obtain the anti-oxidation coating. Specifically, a pre-melted material is prepared first, namely, a used aluminum-magnesium-silicon sagger is crushed as a main component and mixed with anhydrous borax, potassium feldspar or albite, the mixture is pre-melted into slag in an electric furnace, quenching is carried out to obtain a glassy pre-melted material, and the glassy pre-melted material is crushed into pre-melted powder with the particle size of less than 30 microns; and the prepared pre-melted powder is well mixed with silicon carbide, metal silicon powder and hydroxyethyl cellulose in a mixing mill to obtain the anti-oxidation coating. According to the invention, the cost is reduced, waste resource utilization is realized, and the method has obvious social benefits and economic benefits.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

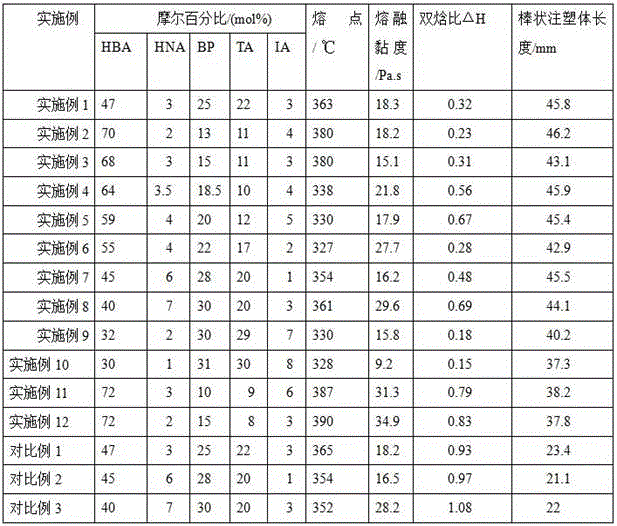

Liquid crystal polyester and its molded composition and use

The invention discloses a liquid crystal polyester and its molded composition and use. The liquid crystal polyester comprises repeated structural units [I]-[IV]. A differential scanning calorimetry (DSC) test proves that the liquid crystal polyester has a double enthalpy ratio delta H greater than or equal to 0.1 and less than or equal to 0.9 defined in the formula (1) of delta H=H(melting enthalpy) / H(crystalline enthalpy) and preferably, the double enthalpy ratio delta H is greater than or equal to 0.2 and less than or equal to 0.7. The liquid crystal polyester has a double enthalpy ratio delta H greater than or equal to 0.1 and less than or equal to 0.9. The liquid crystal polyester and the liquid crystal polyester molded composition have good fluidity and excellent melting characteristics. A small thin wall molded product has high stability and is especially suitable for a thin wall electronic product.

Owner:KINGFA SCI & TECH CO LTD

High-dimensional stability Sn-Ag-Cu solder suitable for electronic packaging

InactiveCN105834612AImprove toughnessGood electrical and thermal conductivityWelding/cutting media/materialsSoldering mediaHigh dimensionalChemical stability

The invention discloses high-dimensional stability Sn-Ag-Cu solder suitable for electronic packaging. The main component metal elements of the solder include Sn, Ag, Cu and Be. According to the solder, the excellent melting property, the excellent welding performance and the excellent mechanical property of Sn-Ag-Cu solder alloy are maintained, the elasticity modulus of a welding connector can also be remarkably improved, a welding spot is made to have high toughness, the dimensional stability is good, and the solder is particularly suitable for ultra-small interval electronic packaging. The electric conductivity and heat conductivity of the prepared welding spot can also be improved, so that the welding spot still has the excellent comprehensive service performance while bearing electric, thermal and mechanical loads and accords with the miniaturization, precision and high-performance development tendency of modern electronic components, the using reliability of the electronic products is improved, and the service life of the electronic products is prolonged. Furthermore, through one or more of Al, Ni and V, the high-temperature oxidation resistance, wettability, fluidity and high-temperature chemical stability of the solder can be further improved, the solder alloy is refined, and the mechanical property of the welding spot is improved.

Owner:CENT SOUTH UNIV +1

Preparation method of Mo-Ru brazing filler metal powder

ActiveCN112170858AImprove process performanceGood brazingWelding/cutting media/materialsSoldering mediaMetallurgyRuthenium

The invention relates to a preparation method of Mo-Ru brazing filler metal powder. The method is used for preparing the Mo-Ru brazing filler metal powder by roasting and reducing pure ruthenium powder and ammonium molybdate, and the Mo-Ru brazing filler metal powder is uniform in component, small in particle size (the particle size range is 10-100 microns, and the grain size of 90% of brazing filler metal powder particles is less than or equal to 40 microns), high in apparent density, good in melting characteristic, excellent in process characteristic, high in cost performance, and suitable for industrial mass production.

Owner:CHONGQING MATERIALS RES INST

Blue cheese product and process for preparing same

ActiveUS20110300259A1Enhance flavorImprove melt characteristicMilk preparationCheese manufactureFlavorChemistry

The present invention is directed to a cheese product having a blue cheese flavor and appearance a method of making the same. The method includes generating a coagulum comprising whey and curd from a pasteurized milk product, cutting and stirring the coagulum to release the whey from the curd, draining the whey from the curd, forming an emulsifier, adding the emulsifier to the curd, and pressing the curd into blocks. The emulsifier is preferably formed by blending oil and a paste and heating the oil and the paste. The paste preferably includes, among other ingredients, inert Penicillium roqueforti. A preferred version of the method further includes adding black pepper and ash to the curd. The resulting cheese product, unlike blue cheese, is elastic, does not crumble, and can be sliced and shredded.

Owner:NASONVILLE DAIRY

Molding material, molding method using same, method for producing molding material, and method for producing fiber-reinforced composite material

InactiveUS10023737B2Increase productivityExcellent in handleabilityCoatingsProduction rateFiber bundle

Provided is a molding material comprising a composite of 1 to 50 wt % of a continuous reinforcing fiber bundle (A) and 0.1 to 20 wt % of a poly (phenylene ether ether ketone) oligomer (B); and 30 to 98.9 wt % of a thermoplastic resin (C) adhering to the composite, wherein the component (B) has a melting point of not higher than 270° C. Also provided are a method for molding the molding material, a method for producing the molding material, and a method for producing a fiber-reinforced composite material.A molded article having high heat resistance and dynamic properties can be easily produced without impairing the economic efficiency and productivity during the process for producing a molding material. In addition, a fiber-reinforced composite material can be produced with more ease and high productivity.

Owner:TORAY IND INC

Valve steel continuous casting crystallizer functional protection material

The invention discloses a valve steel continuous casting crystallizer functional protection material. The material comprises the following raw material components including, by weight, 36.0-42.0% of pre-melt materials, 14.0-17.0% of wollastonite, 9.0-11.0% of fine glass powder, 3.0-5.0% of lithium carbonate, 7.0-9.0% of fluorite, 2.0-4.0% of sodium fluoride, 3.0-5.0% of cryolite, 10.0-12.0% of graphite carbon, 2.0-3.5% of carbon black and 2.0-3.5% of a binder. According to the valve steel continuous casting crystallizer functional protection material, the thermal insulation effect and the melting effect are guaranteed, furthermore, pulling break, slag inclusion and depression of casting blanks are effectively prevented, and the non-cleaning rate of the surfaces of the obtained casting blanks reaches up above 98%.

Owner:西峡县西保冶金材料有限公司

Continuous casting mold flux for boron containing steel

The invention belongs to the technical field of auxiliary materials for metal smelting and relates to continuous casting mold flux for boron containing steel. The continuous casting mold flux for the boron containing steel is prepared from, by weight, 3-7 parts of glass powder, 40-55 parts of premelting materials, 27-35 parts of aedelforsite, 2 parts of carbon black, 4-5 parts of graphite, 5-9 parts of sodium carbonate, 2.5-5.5 parts of sodium fluoride, 2-4 parts of bauxite, 2-5 parts of caustic calcined magnesite, 5-8 parts of boron carbide and 1.2 parts of binding agent. For crack sensitivity of the boron containing steel, selection, basicity, viscosity and melting point of raw materials of the continuous casting mold flux are controlled comprehensively, so that crack sensitivity of the boron containing steel is improved effectively, and the problems of cracks at edges of the surface of the boron containing steel is solved.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Liquid crystal polyester, molding composition composed of liquid crystal polyester and application of molding composition

ActiveCN105860036AImprove molding stabilityImprove liquidityLiquid crystal compositionsPolyesterStructural unit

The invention discloses liquid crystal polyester, a molding composition composed of the liquid crystal polyester and an application of the molding composition. The liquid crystal polyester is composed of repetitive structural units: a structural unit [I] derived from p-hydroxybenzoic acid and a structural unit [II] derived from 6-hydroxy-2-naphthoic acid; through dynamic thermal mechanical analysis DMA testing, the liquid crystal polyester meets a condition that the energy storage modulus release rate [delta]G defined by the following formula (1) is greater than or equal to 95.0% and less than or equal to 99.7%, wherein the formula (1) is [delta]G=[G(-50)-G(melting point)] / G(-50)*100%. Through differential scanning calorimetry DSC testing, the liquid crystal polyester meets a condition that the double enthalpy ratio [delta]H defined by the following formula (2) is greater than or equal to 0.05 and less than or equal to 0.9, preferably greater than or equal to 0.1 and less than or equal to 0.6, wherein the formula (2) is [delta]H=H(melting enthalpy) / H(crystallization enthalpy). The liquid crystal polyester and the molding composition prepared by the liquid crystal polyester have the advantages of relatively high liquidity, excellent melting characteristics, and high forming stability of small thin-wall molding products, and are particularly suitable for use in thin-wall electronic preparation parts.

Owner:KINGFA SCI & TECH CO LTD

Wide plastic fat composition and preparation method and application thereof to artificial butter

ActiveCN109845839AReasonable collocationEasy to digest and absorbEdible oils/fats ingredientsEdible oils/fats production/working-upChemistryPalm kernel oil

The invention discloses a wide plastic fat composition and a preparation method and application thereof to artificial butter. Raw fat comprises fat A treated through transesterification and a fat B, wherein the fat A is fat high in solid fat, the fat B is fat rich in medium-chain fatty acid, and A is one or more of palm stearin, beef tallow and mutton tallow, and the fat B is one or more of palm kernel oil, coconut oil, hydrogenated coconut oil, fractionation palm kernel oil and fractionation coconut oil. Through improvement of raw material selection and a preparation technology, the problemsof rear hardness, oral solubility, segregation and the like when the fat composition is used for the artificial butter are further improved.

Owner:广东至润油脂食品工业有限公司

A kind of mold slag for continuous casting mold for boron-containing steel

The invention belongs to the technical field of auxiliary materials for metal smelting and relates to continuous casting mold flux for boron containing steel. The continuous casting mold flux for the boron containing steel is prepared from, by weight, 3-7 parts of glass powder, 40-55 parts of premelting materials, 27-35 parts of aedelforsite, 2 parts of carbon black, 4-5 parts of graphite, 5-9 parts of sodium carbonate, 2.5-5.5 parts of sodium fluoride, 2-4 parts of bauxite, 2-5 parts of caustic calcined magnesite, 5-8 parts of boron carbide and 1.2 parts of binding agent. For crack sensitivity of the boron containing steel, selection, basicity, viscosity and melting point of raw materials of the continuous casting mold flux are controlled comprehensively, so that crack sensitivity of the boron containing steel is improved effectively, and the problems of cracks at edges of the surface of the boron containing steel is solved.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Method for preparing platy or lump processed cheese and cheese obtained

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improvesthe prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD CO LTD

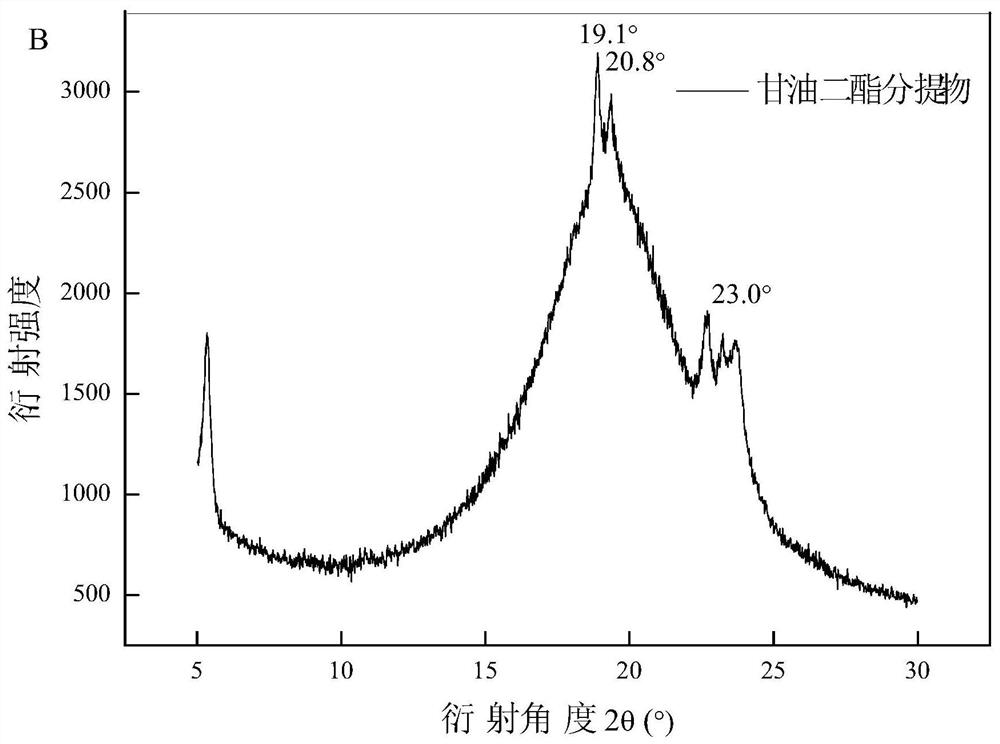

Ice cream composition and preparation method thereof

InactiveCN113133493AImprove melting propertiesSolve the technical problem of high temperature facilitation affecting the taste of foodFood freezingFood thermal treatmentDiglycerideOrganic chemistry

The invention relates to an ice cream composition and a preparation method thereof. The ice cream composition provided by the invention is characterized by comprising the following components in percentage by weight: 55-75% of water; 5-20% of milk powder; 5-25% of soybean oil-based diglyceride after fractionation; 10-18% of a sweetening agent; 0.1 to 0.5 percent of edible essence; and 0.1-0.5% of a stabilizing agent. The ice cream is high in sliding melting point, not easy to melt at room temperature, quick to melt in the mouth and low in heat.

Owner:GUANGDONG YUE S SPECIAL NUTRITION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com