Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166results about How to "Improve molding stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plunger pump type hydraulic injection moulding machine system driven by servo motor and control method thereof

The invention discloses a plunger pump type hydraulic injection moulding machine system driven by a servo motor. The system comprises an oil tank, a servo pump, a mould height motor, a mould clamping cylinder, an ejector cylinder, a movable ejection cylinder, a glue-ejecting cylinder, a glue-smelting motor and an electronic ruler measurement sensor and also comprises a computer controller, a pressure and speed comprehensive control module, a servo driver, the servo motor and a pressure sensor. The invention also discloses a control method of the plunger pump type hydraulic injection moulding machine system driven by the servo motor. In the control method, the pressure sensor and the torque control of the servo motor are adopted, the multilevel control of pressure and flow can be realized;real-time closed-loop control is adopted to control the pressure and flow during injection moulding; and in the control process, the instructions on the pressure and flow are compared with feedbacks in real time and some parameters such as the speed, pressure and current at each moment are controlled accurately, thus effectively realizing technical motions such as the mould open / closing, ejection, glue ejection and glue smelting of the injection molding machine and the closed-loop follow control of the oil cylinder. The method of the invention has the advantages of high precision, high speed and efficiency, energy-saving, environmental friend, low noise and the like.

Owner:SOUTH CHINA UNIV OF TECH

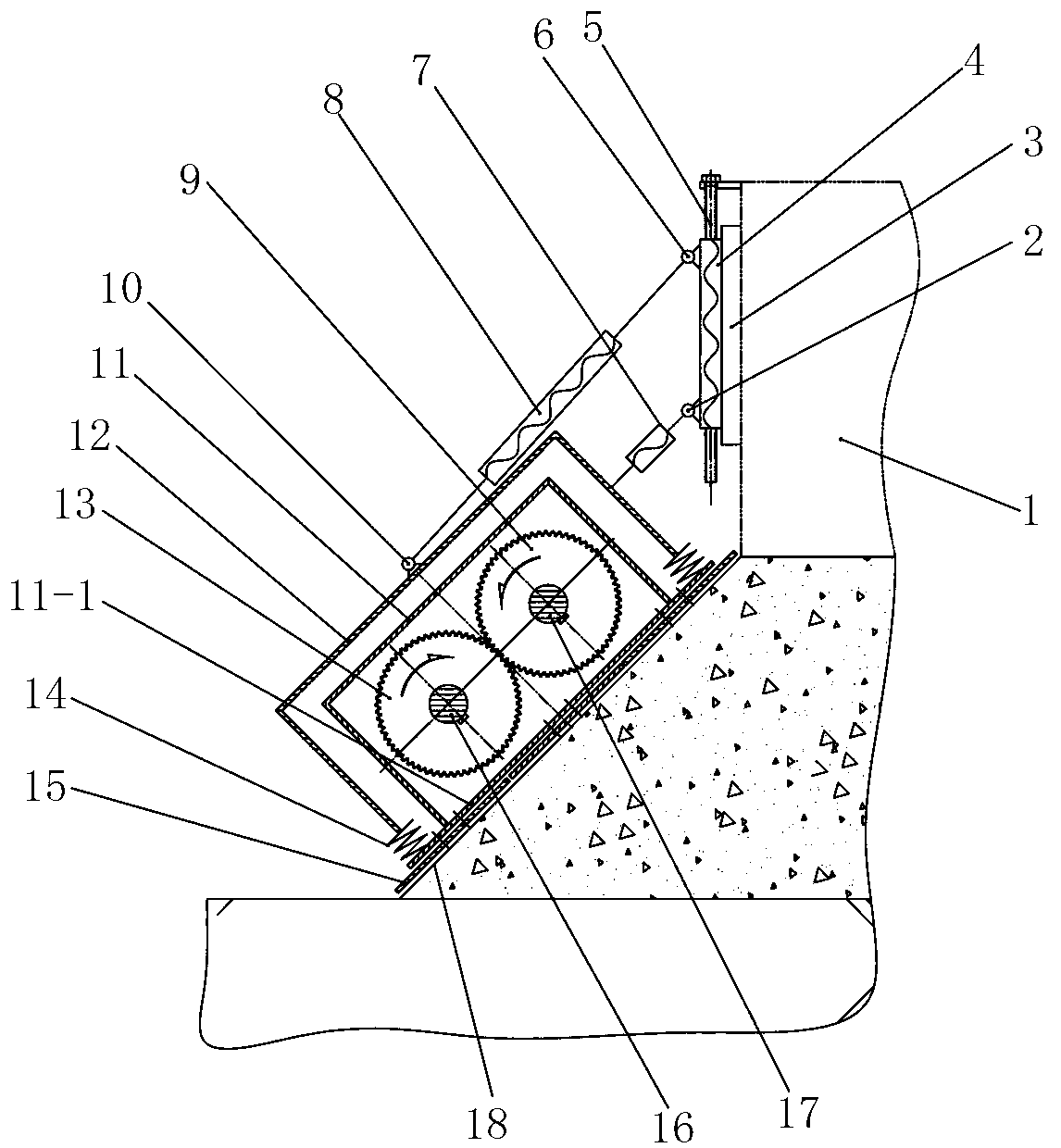

Roadbed slop vertical vibrating compacting device

The invention discloses a roadbed slop vertical vibrating compacting device which comprises a vertical vibrating mechanism aslant connected to the side wall of a working device, wherein the vertical vibrating mechanism comprises a vibrating box body, a rotating shaft I and a rotating shaft II which are mutually parallel are rotatably connected into the vibrating box body, a synchronizing wheel I is arranged on the rotating shaft I, a synchronizing gear II meshed with the synchronizing gear I is arranged on the rotating shaft II, an eccentric block I is arranged on the rotating shaft I, an eccentric block II is arranged on the rotating shaft II, a tamping plate supporting against a roadbed slope is connected to a bottom plate of the vibrating box body, and a drive device used for driving the rotating shaft I or rotating shaft II to rotate is arranged on the tamping plate. The roadbed slop vertical vibrating compacting device is capable of carrying out effective vibrating compaction on the roadbed slope, and is good in use effect, easy to operate and convenient to popularize and use.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

Polyamide/acrylonitrile-butadiene-styrene copolymer alloy and its prepn

The present invention relates to one kind of polyamide / acrylonitrile-butadiene-styrene copolymer alloy and its preparation process. The polyamide / acrylonitrile-butadiene-styrene copolymer alloy is prepared with polyamide 35-60 wt%, acrylonitrile-butadiene-styrene copolymer 8-50 wt%, compatilizer 2-10 wt%, flexibilizer 2-15 wt%, antioxidant stabilizer 0.2-2 wt%, lubricant 0.3-3 wt%, and nucleator 0.1-2 wt%. The preparation process includes weighing the materials based on the weight proportion, mixing in a high speed mixer for 1-4 min, mixing, melting and extruding in a double screw extruder, and pelletizing. The polyamide / acrylonitrile-butadiene-styrene copolymer alloy has simple processing and molding process and high performance.

Owner:SHENZHEN KEJU NEW MATERIAL

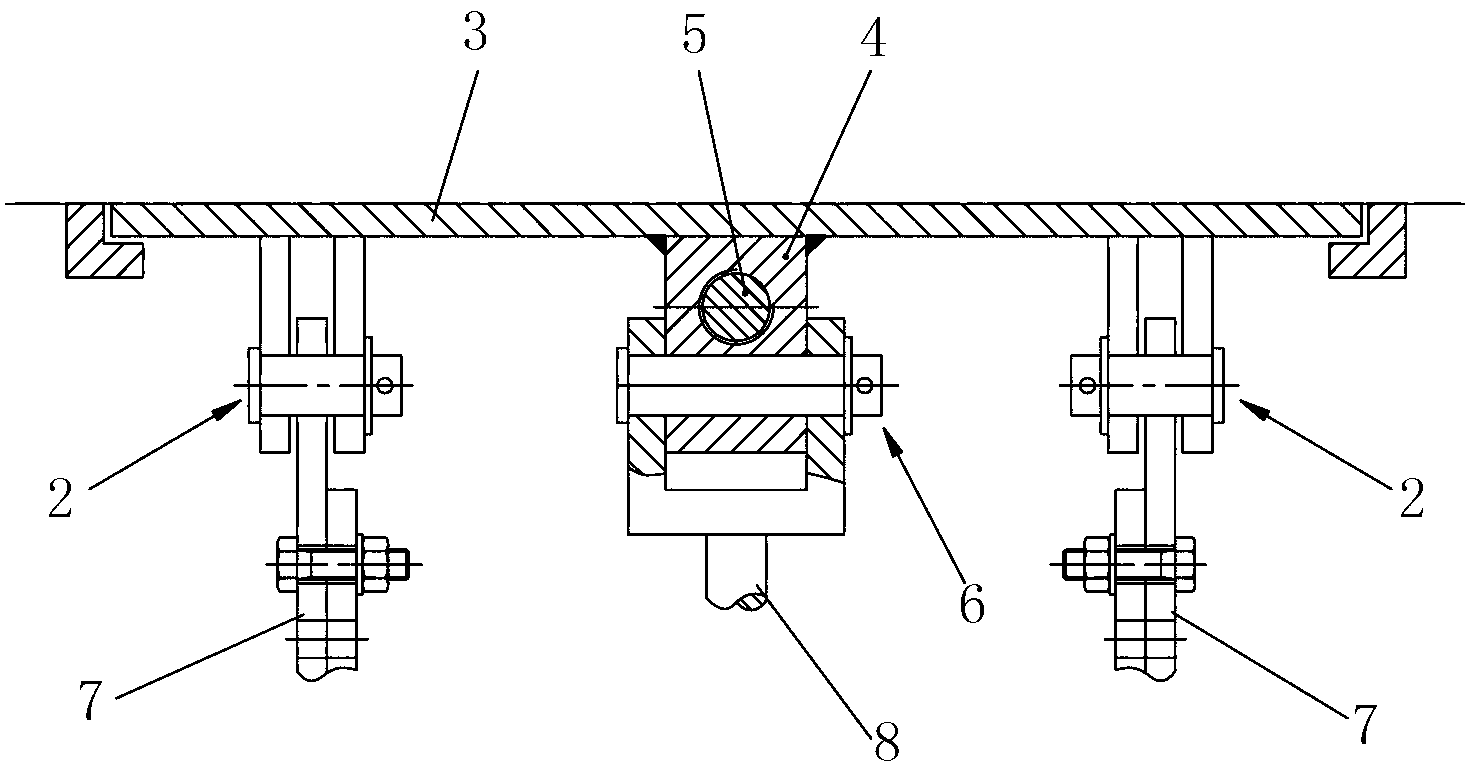

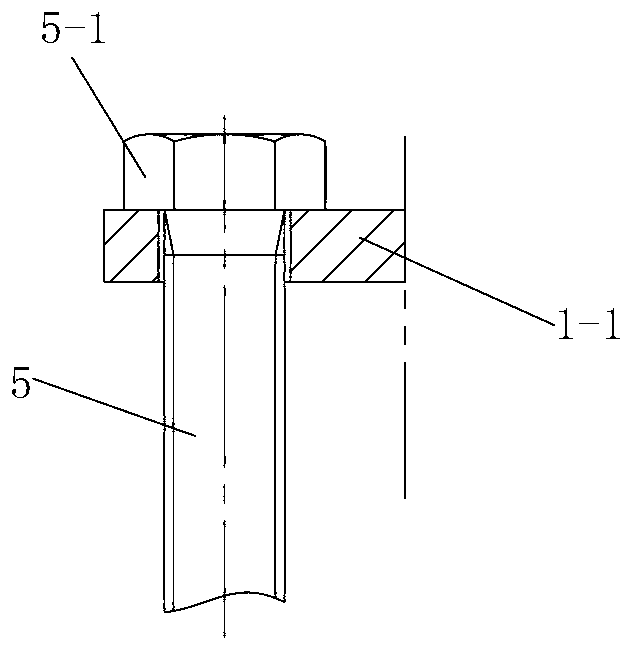

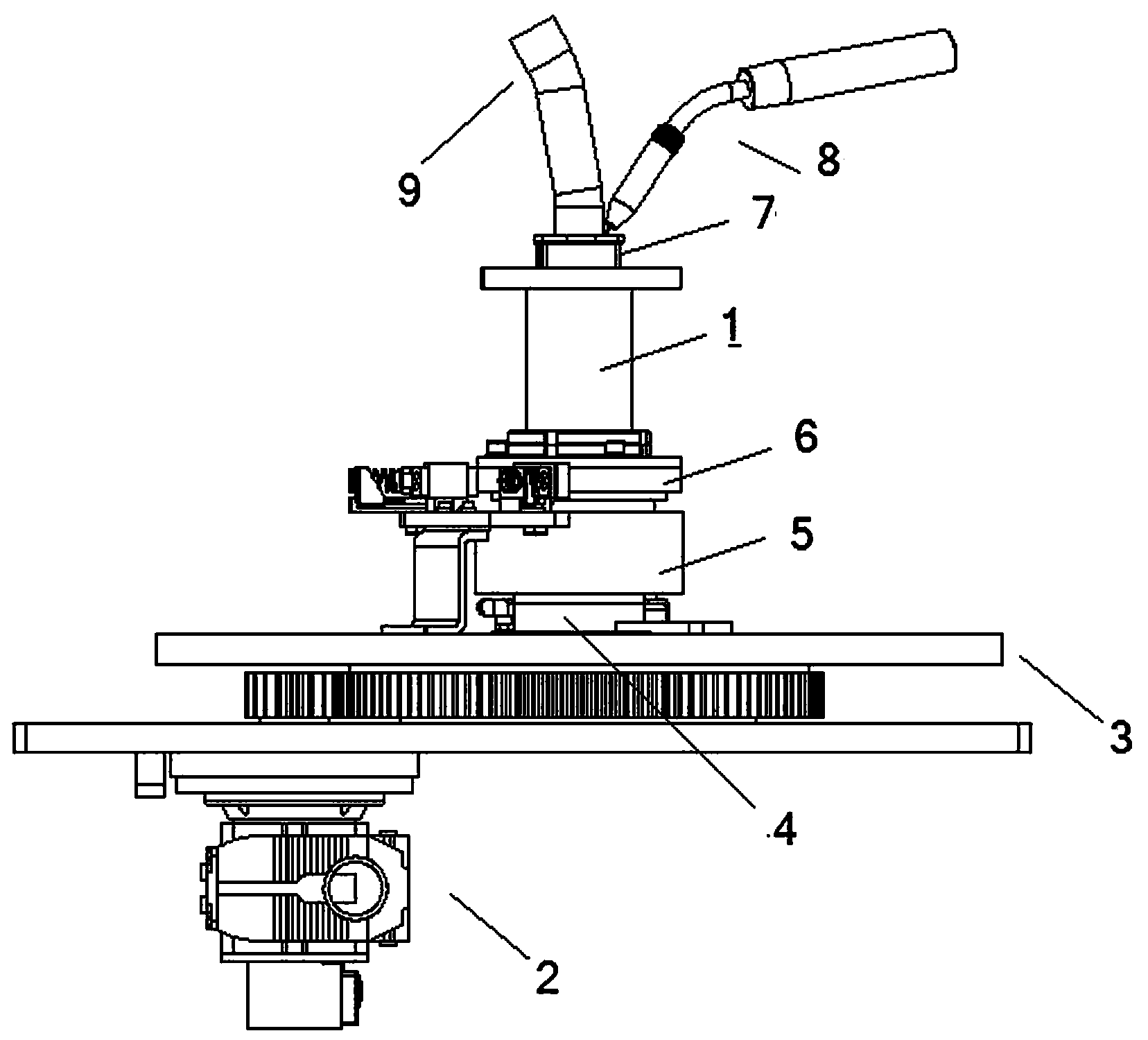

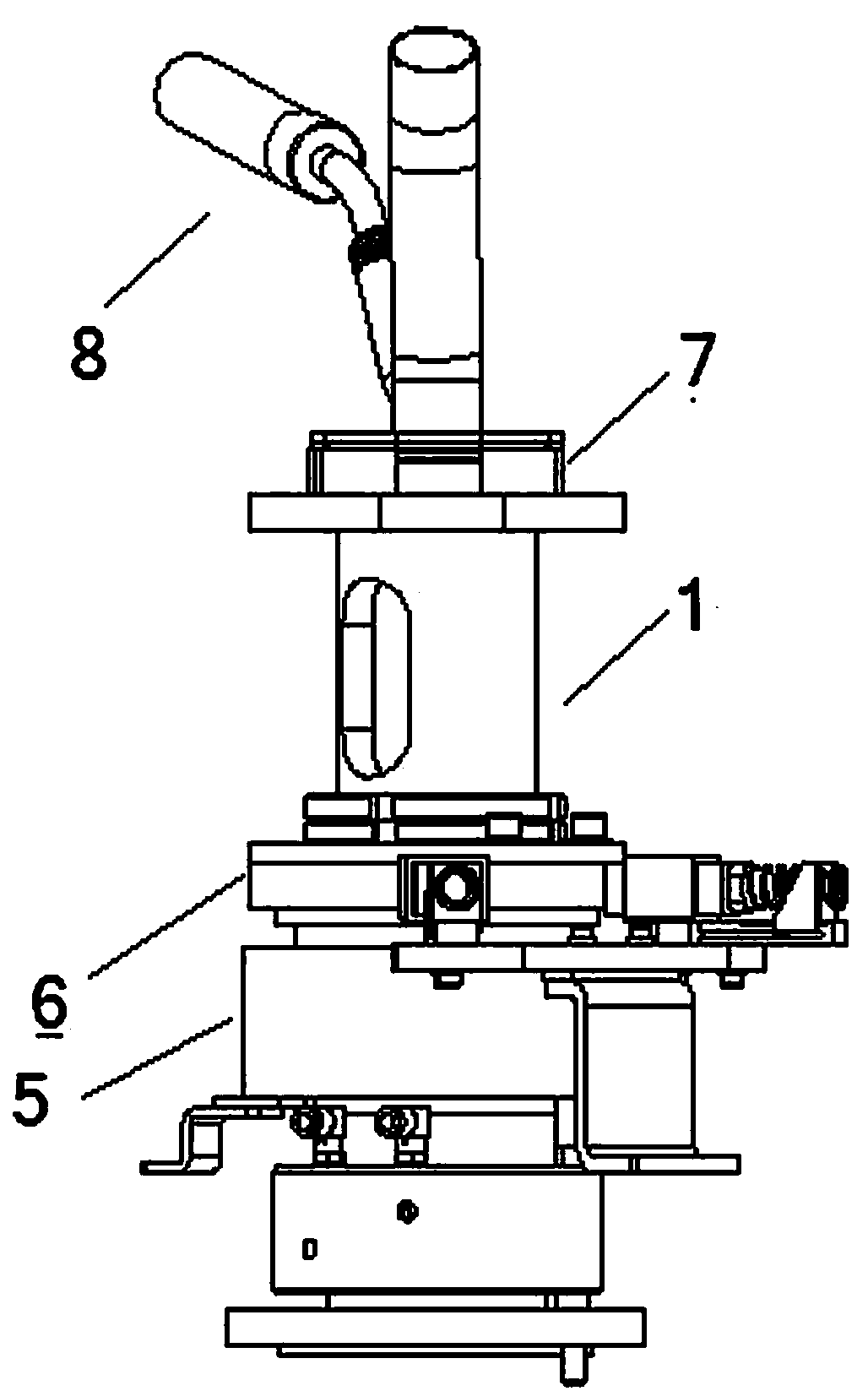

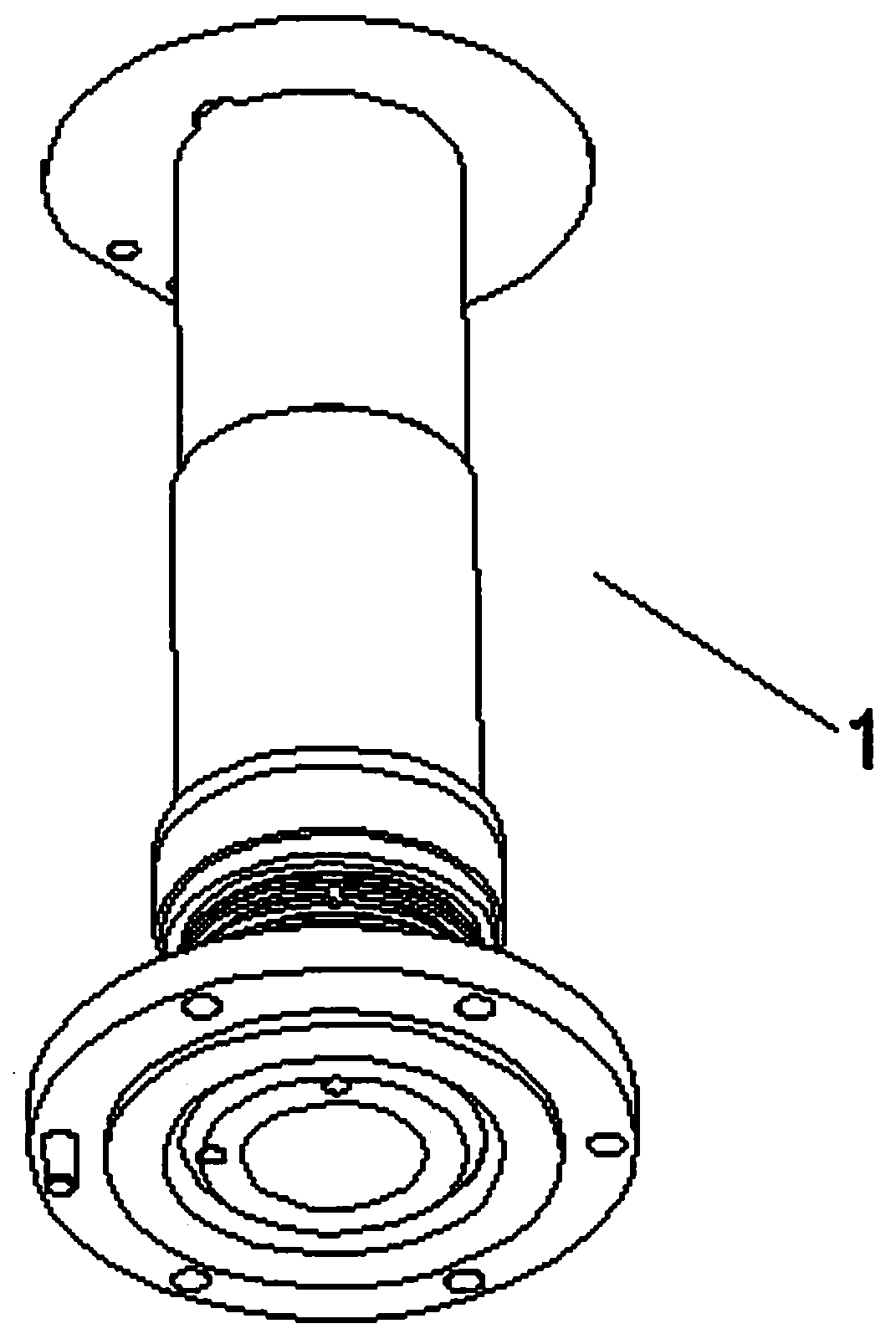

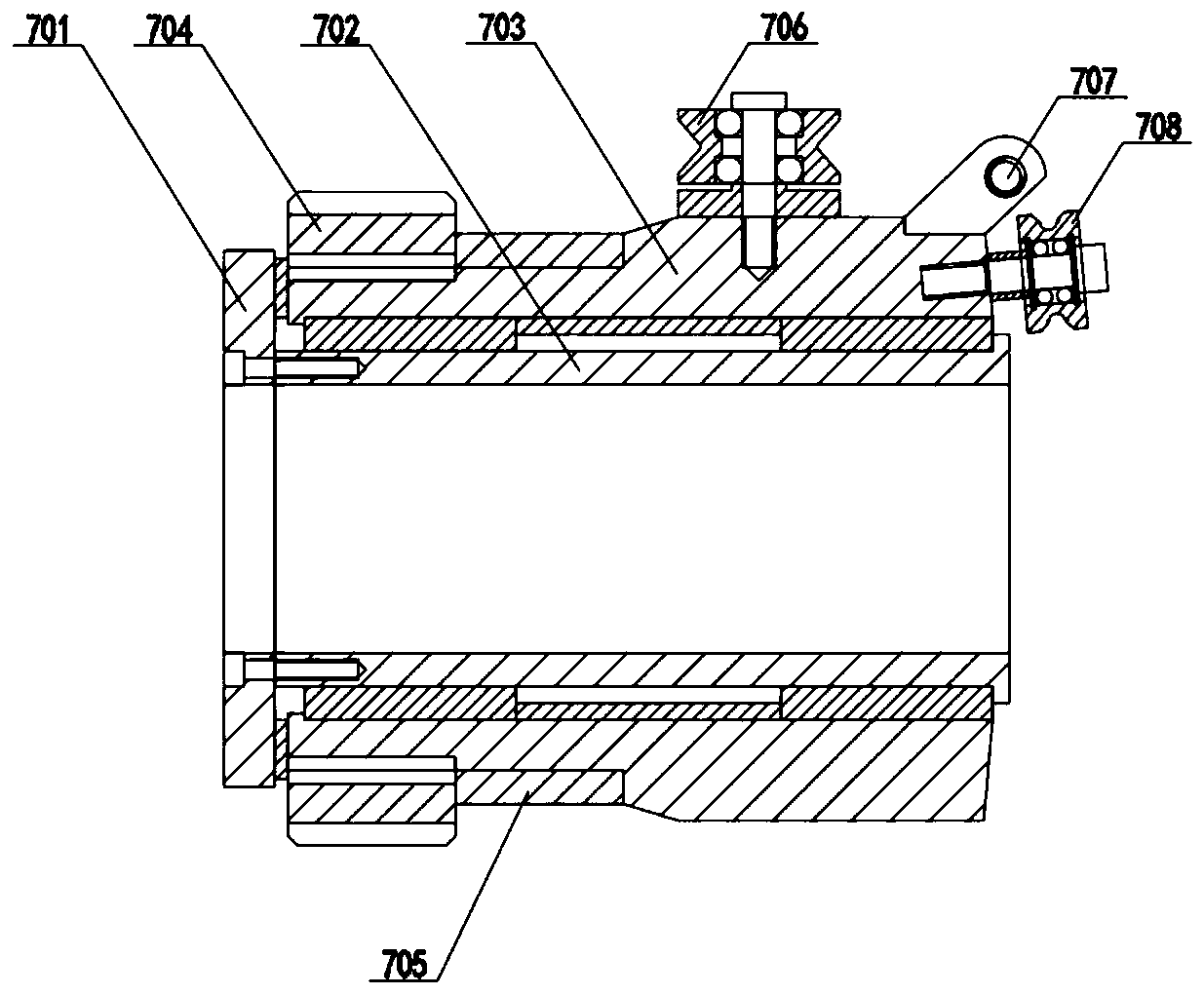

Vertical annular welding tool

ActiveCN104028884AImprove welding qualitySolve the entanglementWelding/cutting auxillary devicesElectrode holder supportersEngineeringStructural engineering

The invention discloses a vertical annular welding tool. The vertical annular welding tool comprises a rotatable platform and a hollow upright column, wherein the hollow upright column is perpendicular to the rotatable platform and sleeves the rotatable platform via a clearance; a gas guiding ring, a conductive ring and a ground wire grounding copper ring sleeve the upright column; a gas circuit, an electric control circuit and a welding ground wire are arranged in a hollow cavity of the upright column; a workpiece positioning mechanism is fixed on the upper portion of the upright column; and a wire feeding machine and a welding gun mechanism are fixed on the rotatable platform. Rotating power is provided by using a speed reducer; circuit transmission is carried out by using the conductive ring; and gas is turned on, turned off and changed over via the gas guiding ring, the welding gun can be adjusted multi-dimensionally in space, namely, the welding gun can be adjusted in the up-down direction and the left-right direction at an angle, annular welding between tubes, annular welding between a tube and a flange and annular welding between a tube and a plane can be performed, the product differentiation switching efficiency and the welding quality are improved, the welding angle and the welding speed can be freely adjusted, annular welding can be performed rotatably without limitation, workpieces do not need to rotate, and the time can be greatly saved. The vertical annular welding tool is suitable for annular welding between the tubes, annular welding between the tube and the flange and annular welding between the tube and the plane, or is suitable for welding an arc.

Owner:GREAT WALL MOTOR CO LTD

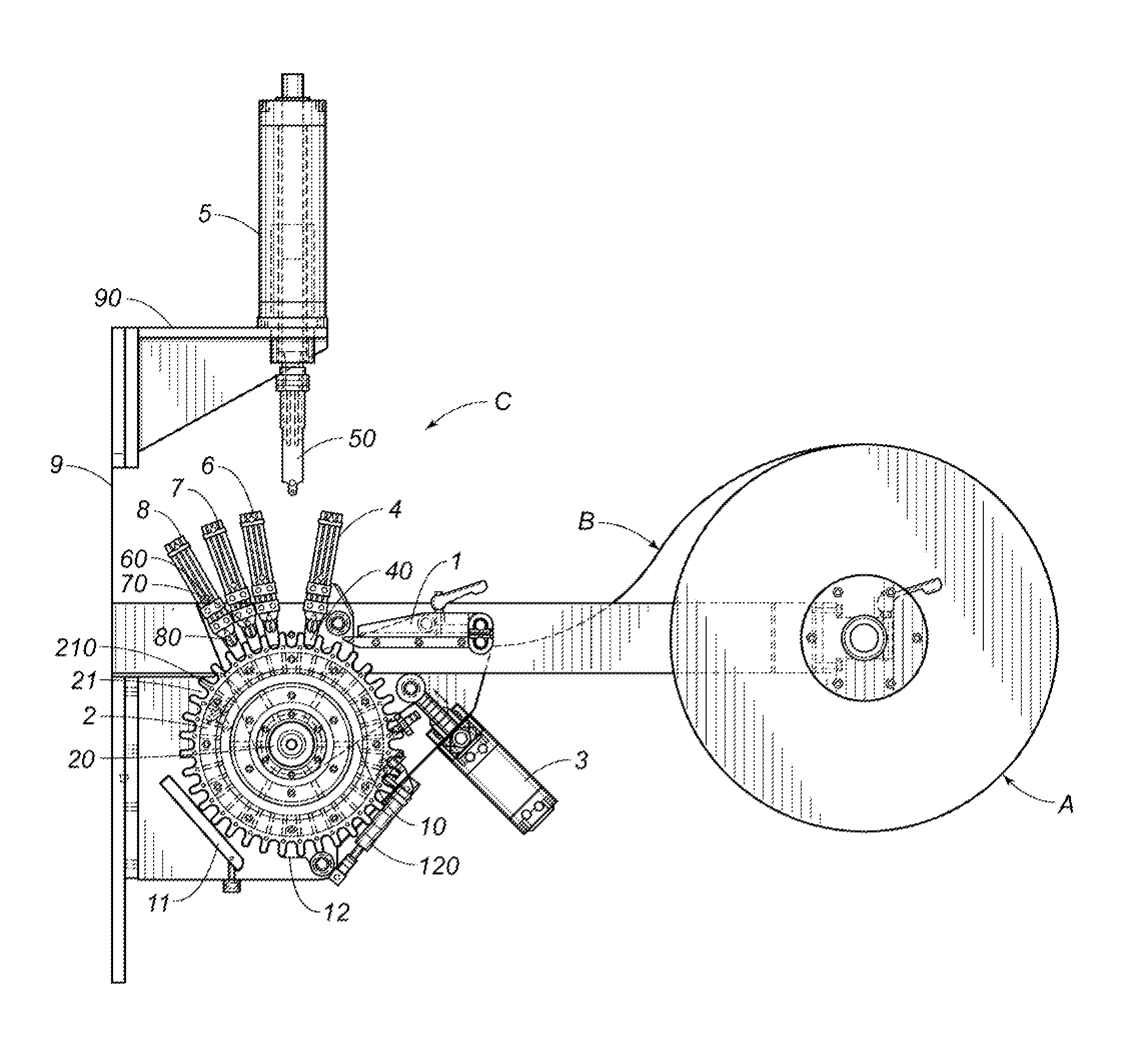

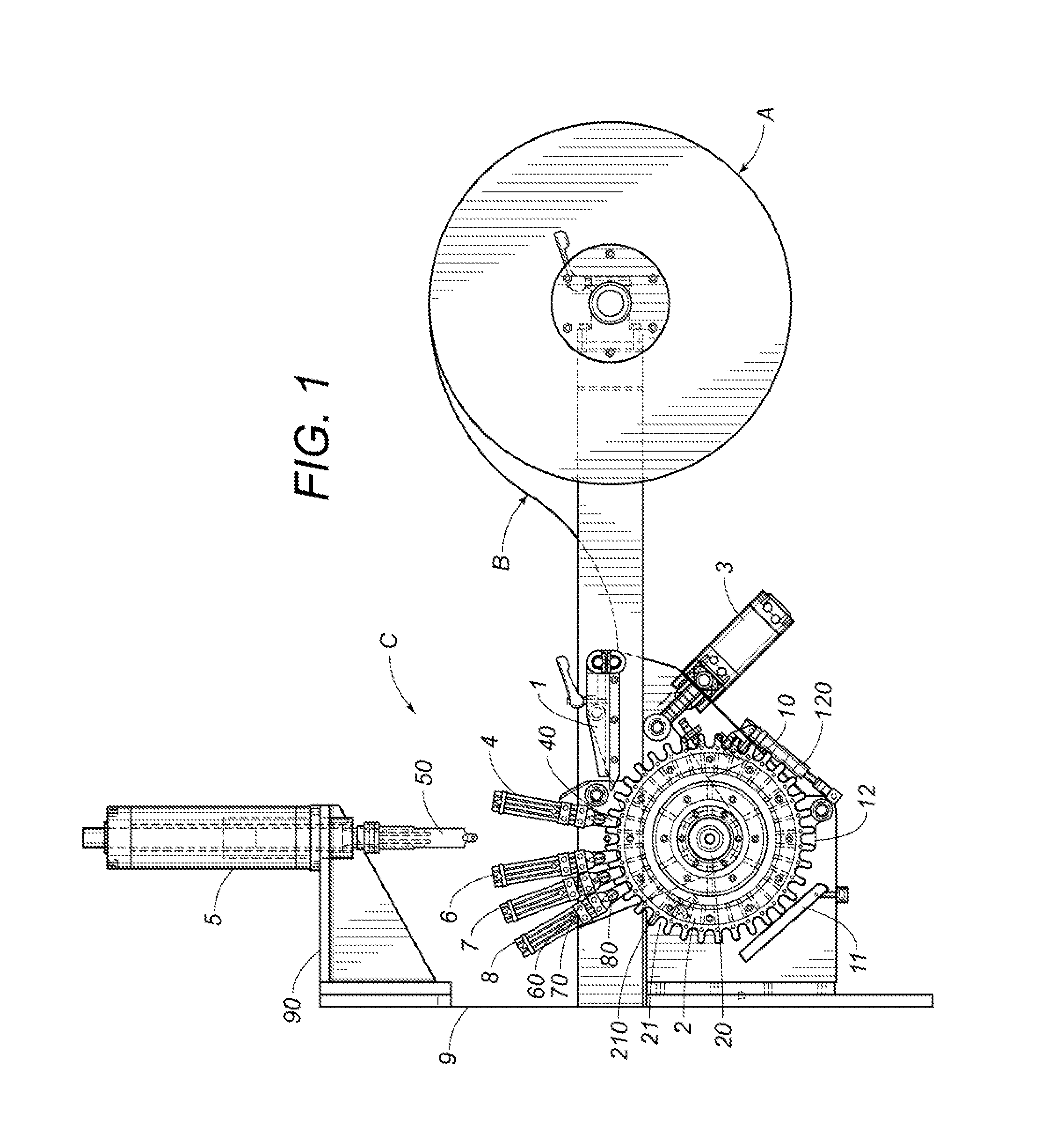

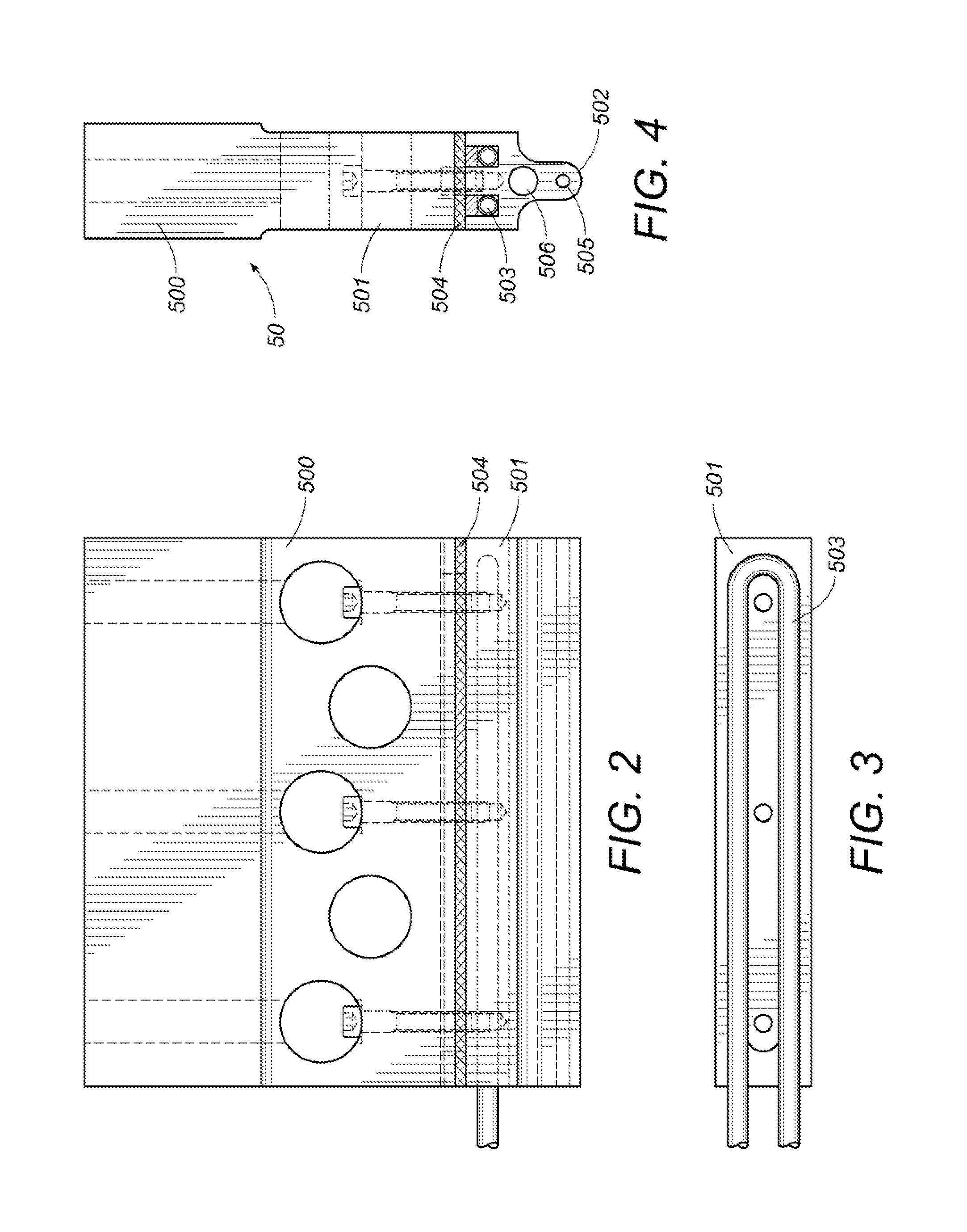

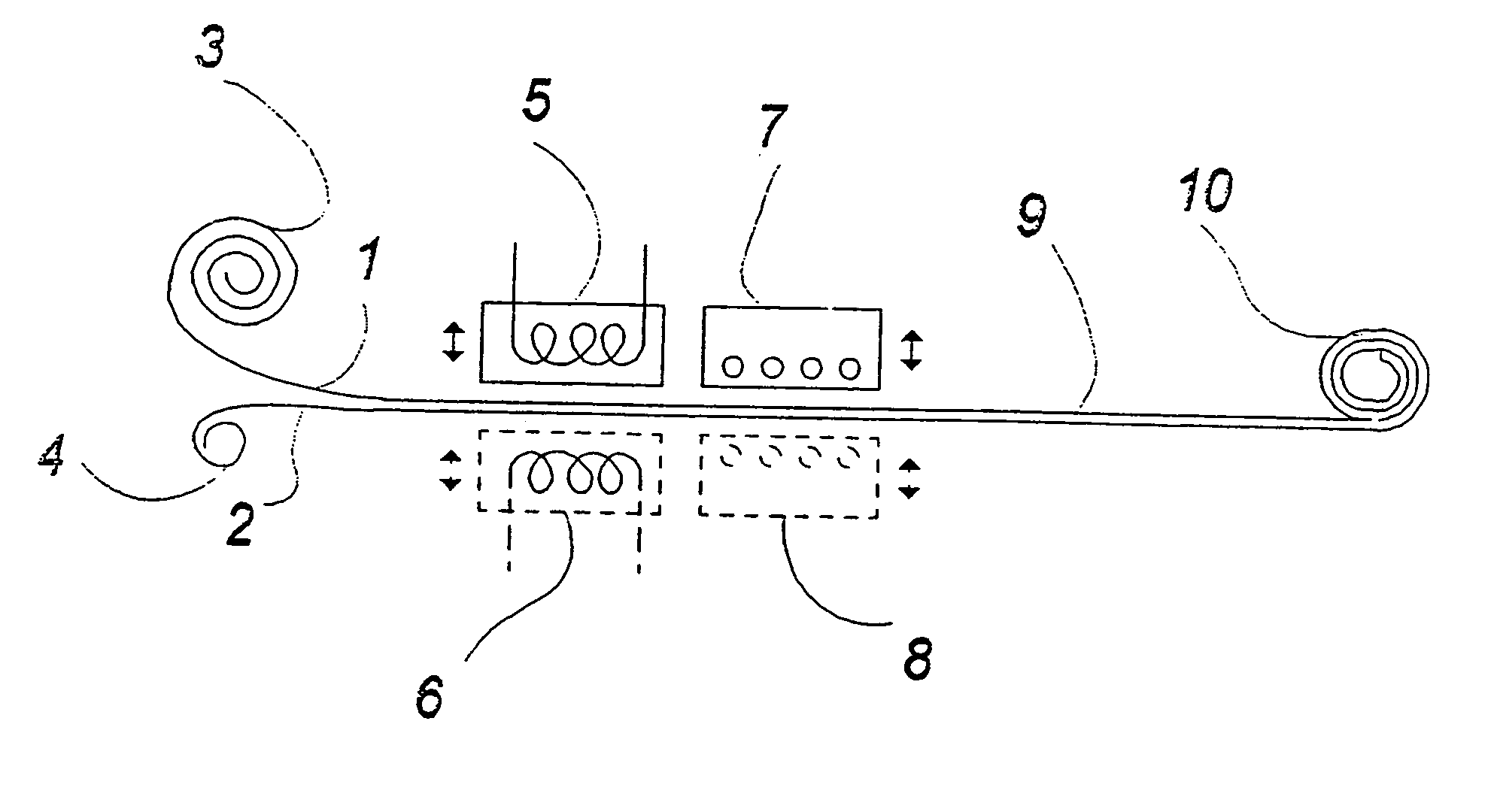

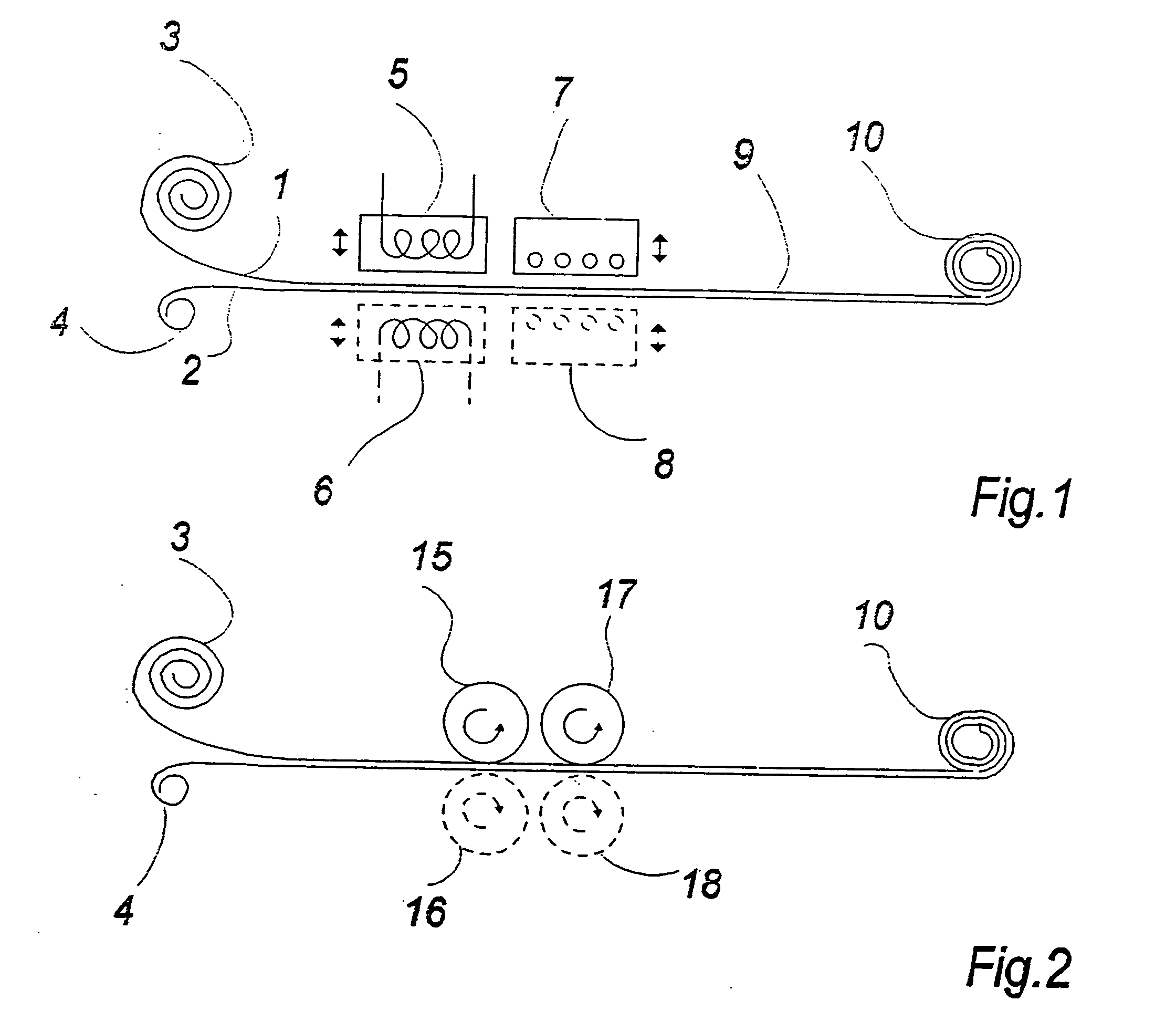

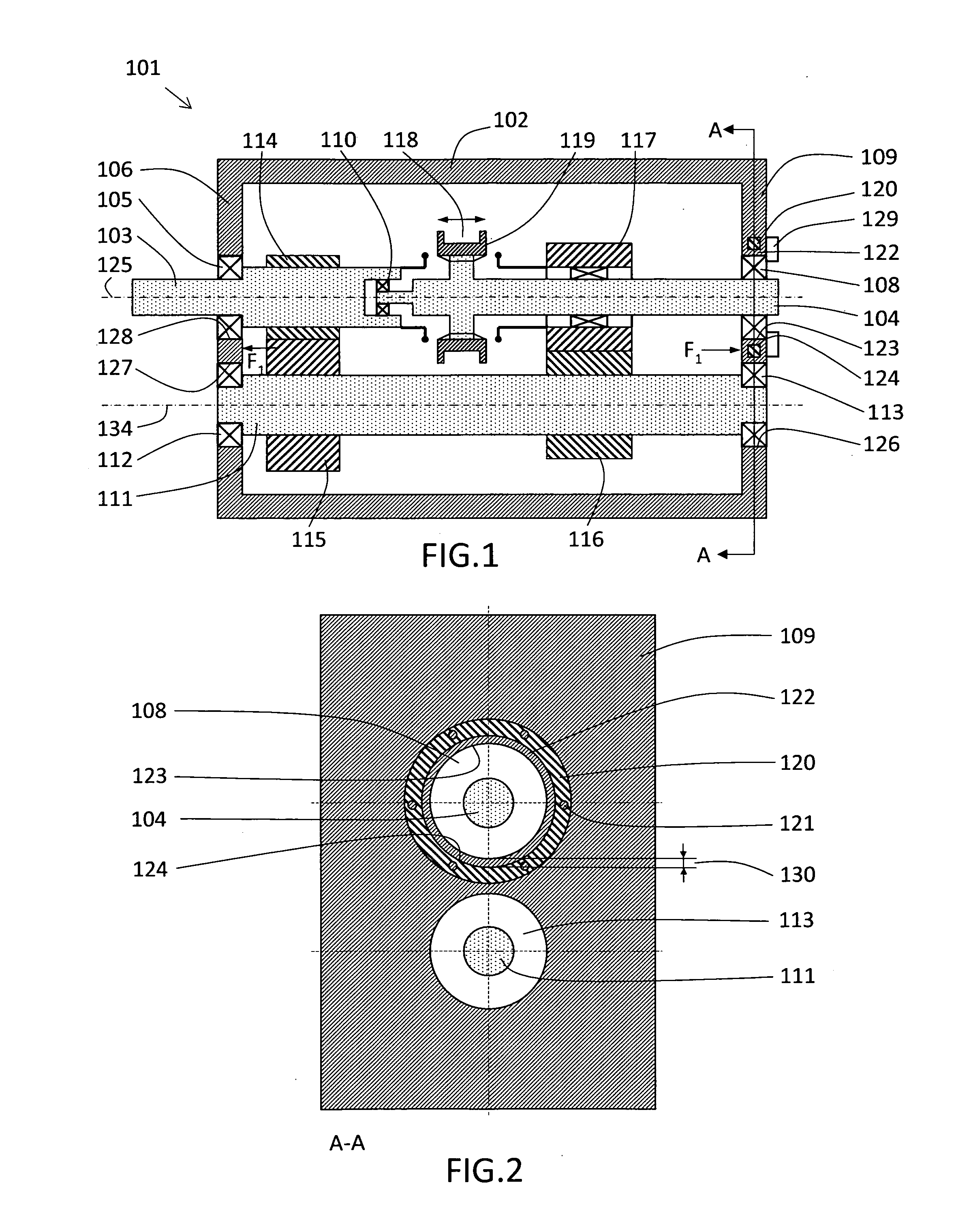

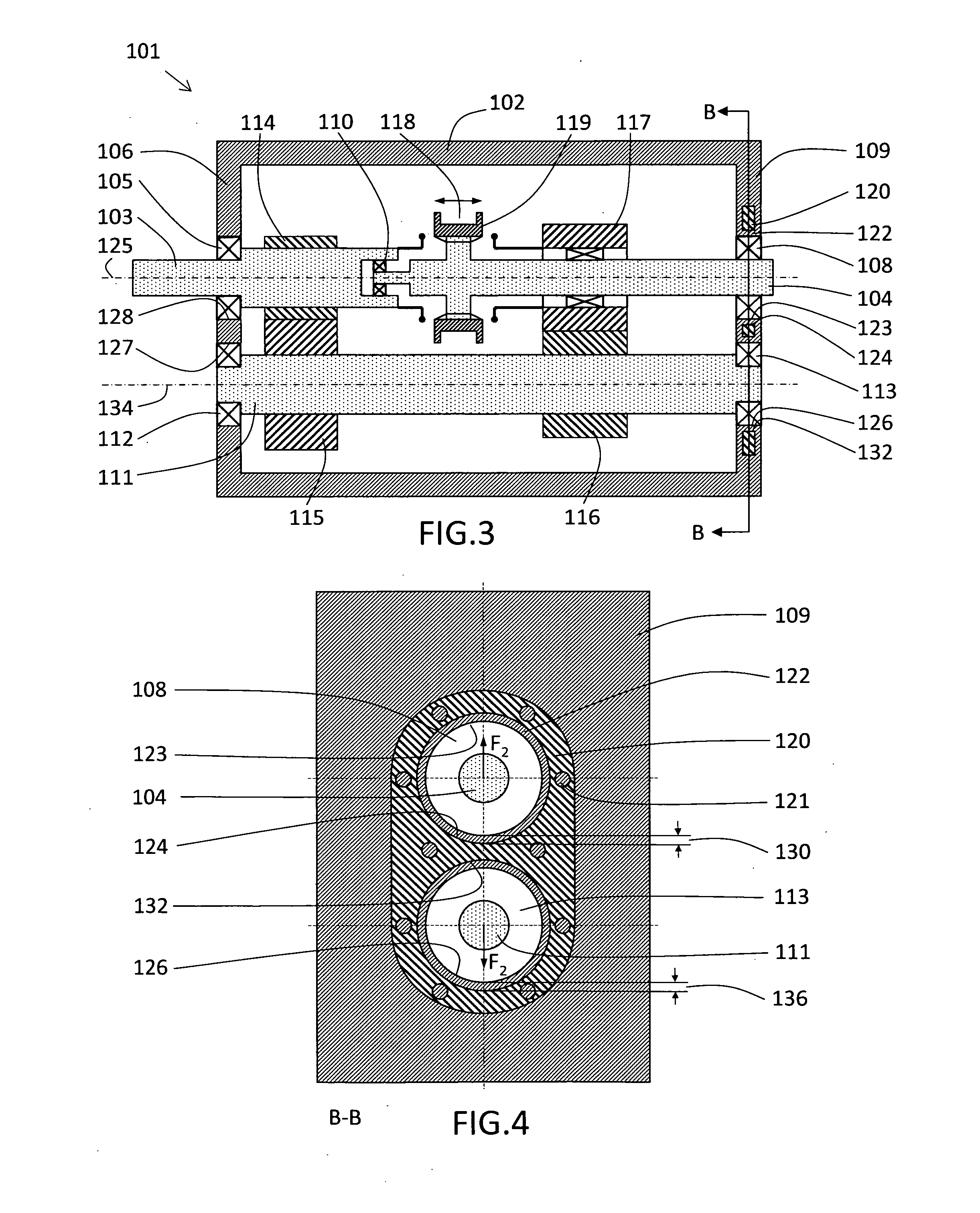

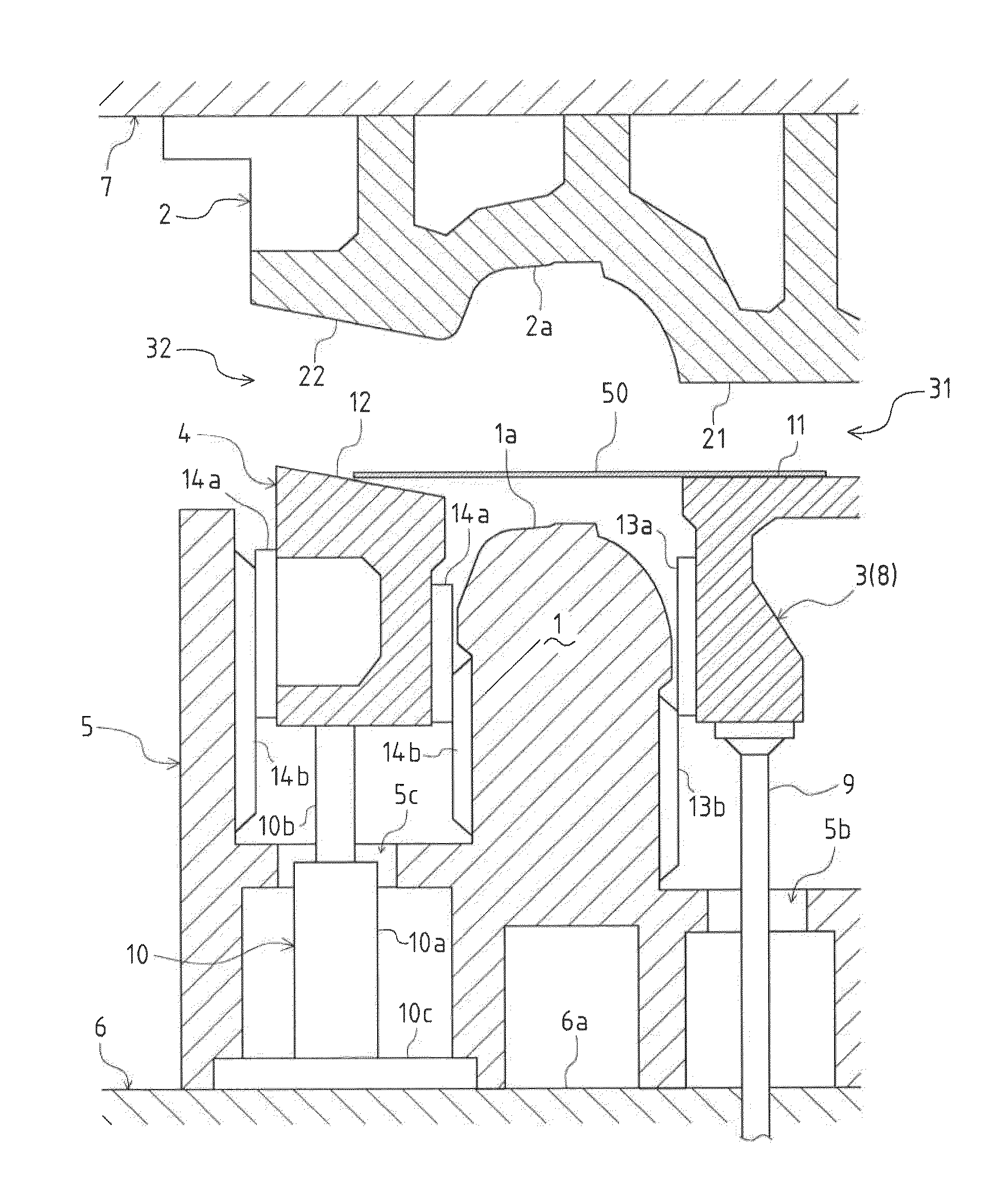

Apparatus for continuously shaping an undulating profile into a plate of polymeric material

ActiveUS7232302B2FunctionalGood production/hour capacityMechanical working/deformationLayered productsPlastic materialsClockwise

Process and apparatus for continuously and permanently shaping a plate in plastic material according to an undulated profile. The apparatus includes a guide and positioning surface of the plate; a moulding and transferral wheel, peripherally shaped according to a plurality of seats, suitable for reproducing a continuous shaped profile; and a positioning, advancement and maintenance assembly in the form of a plate, peripheral with respect to the moulding wheel, of the mobile type, respectively; counter-clockwise in synchronization with the moulding and return wheel in a position independent of the moulding wheel. The assembly includes a pre-form presser, upstream of the surface involved in the shaping, set apart by at least one first stabilization and cooling presser, a moulding presser, interposed between the pre-form presser and a cooling presser; and a possible blade for detaching the plate from the seats.

Owner:HABASIT ITALANA

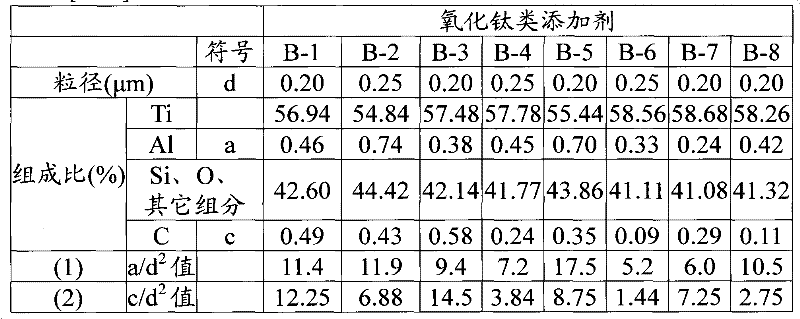

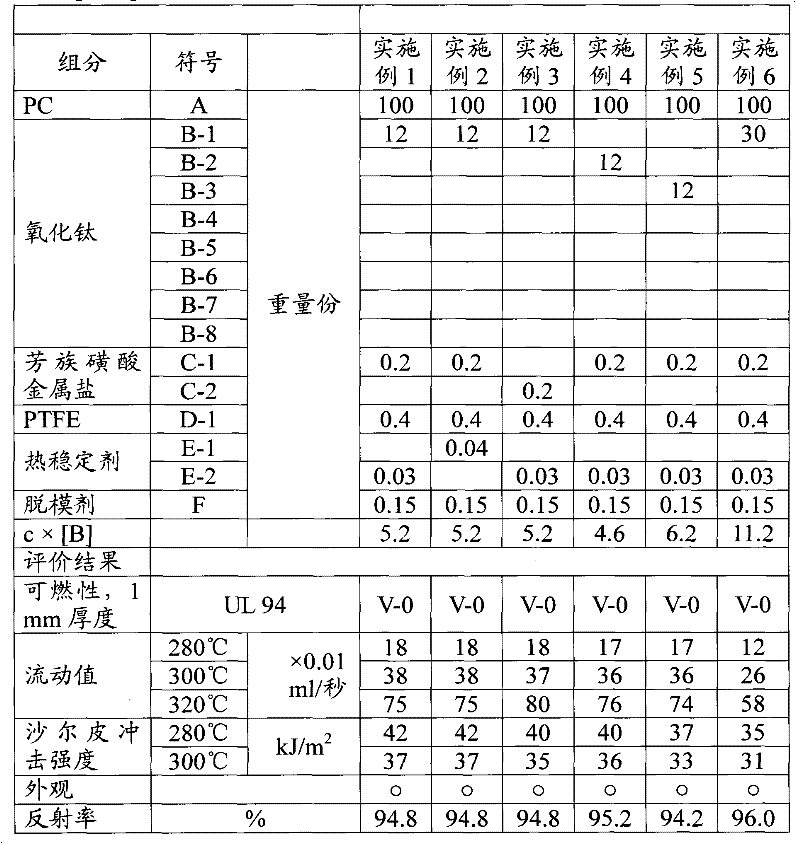

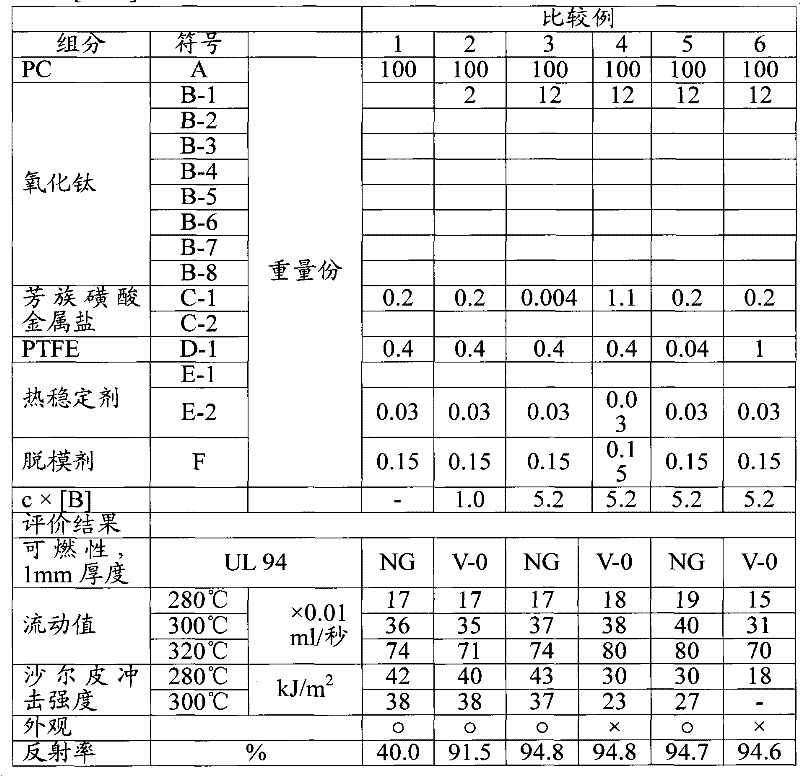

Aromatic polycarbonate resin composition, process for producing resin composition, and molded article

Disclosed is an aromatic polycarbonate composition having excellent thermal stability, excellent flame retardancy and excellent light reflectivity. Also disclosed is a light-reflecting member comprising a molded resin article produced from the aromatic polycarbonate composition. The aromatic polycarbonate resin composition is characterized by comprising 100 parts by mass of an aromatic polycarbonate resin (A), 3 to 30 parts by mass of a titanium oxide additive (B) having a surface treated with alumina and an organosiloxane, 0.05 to 0.9 part by mass of an aromatic sulfonic acid metal salt (C) and 0.01 to 1.5 parts by mass of polytetrafluoroethylene (D), wherein the content (a) (% by mass) of aluminum in the titanium oxide additive (B), the carbon content (c) (% by mass) and the average particle diameter (d) ([mu]m) of titanium oxide meet the requirements represented by formulae (1); and (2). Formula (1): 6.5 = (a / d2) = 15 Formula (2): 5 = (c / d2) = 25.

Owner:MITSUBISHI ENG PLASTICS CORP

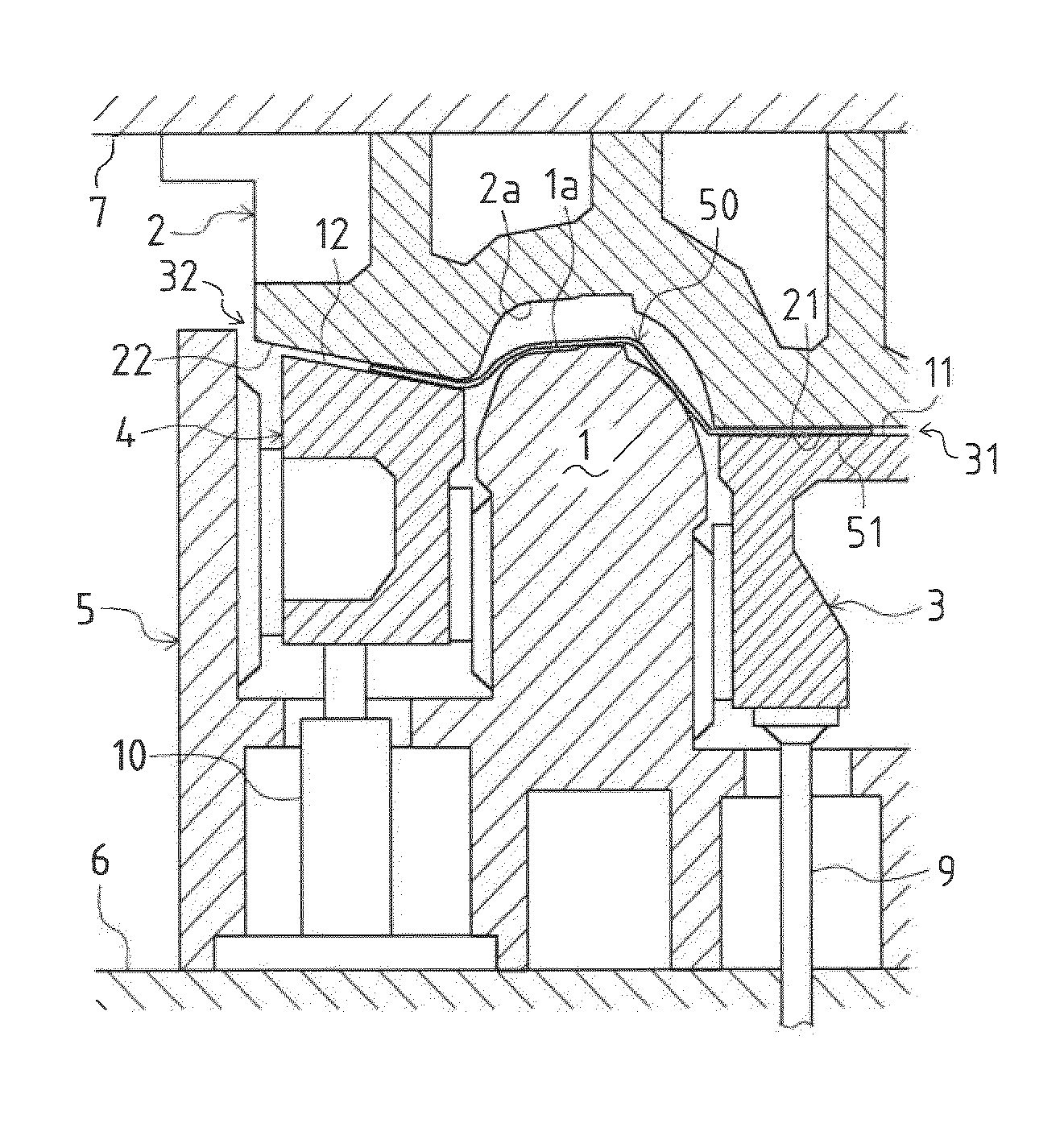

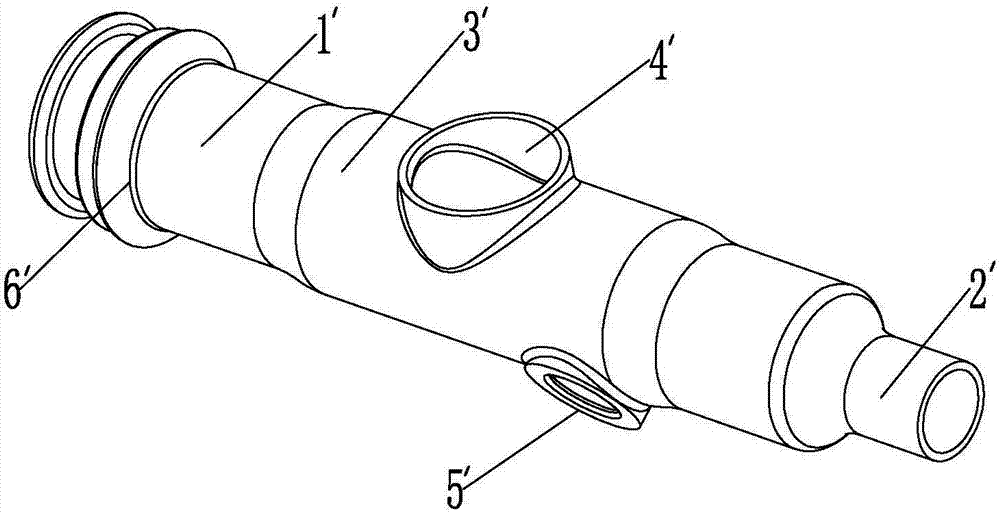

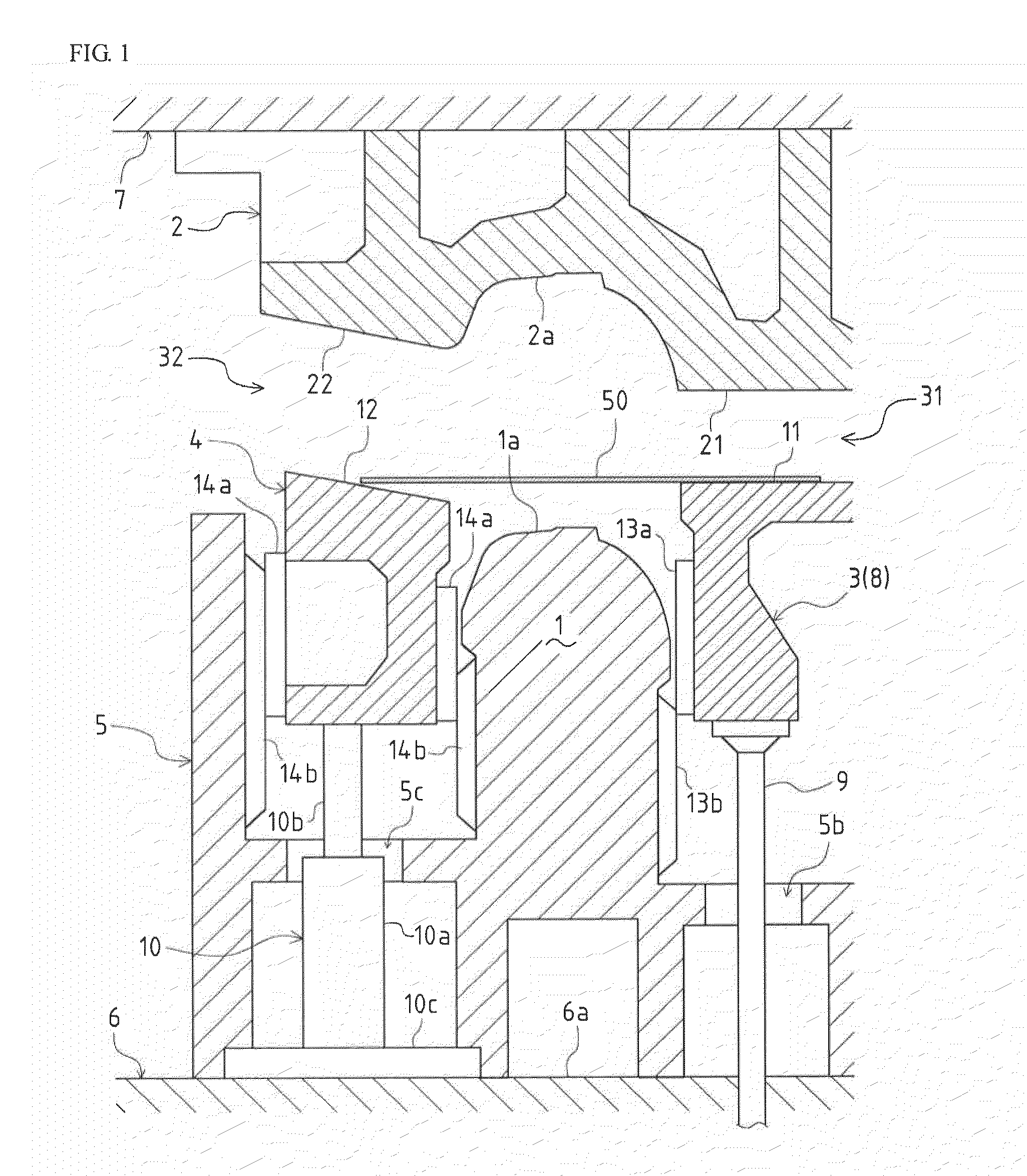

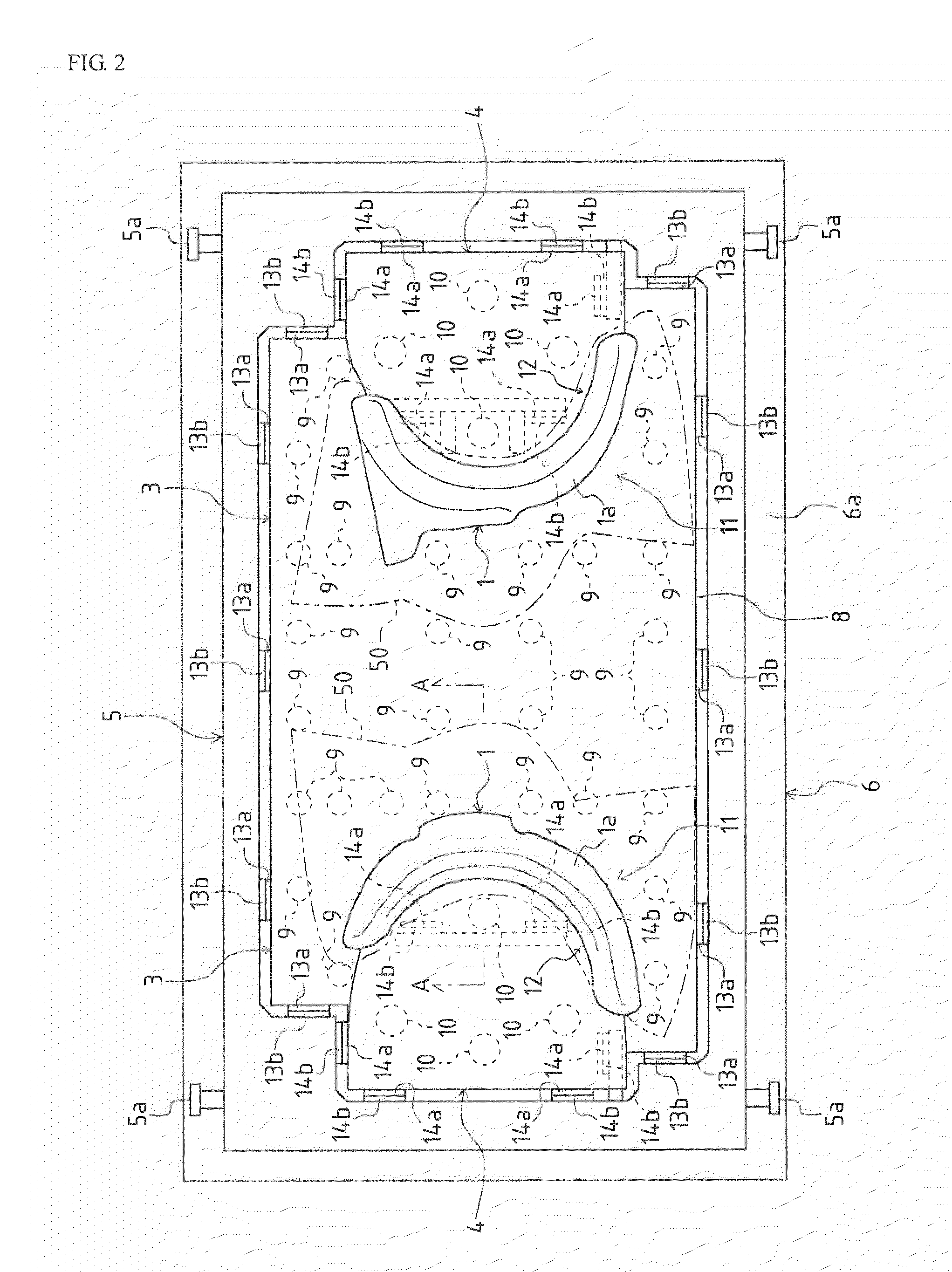

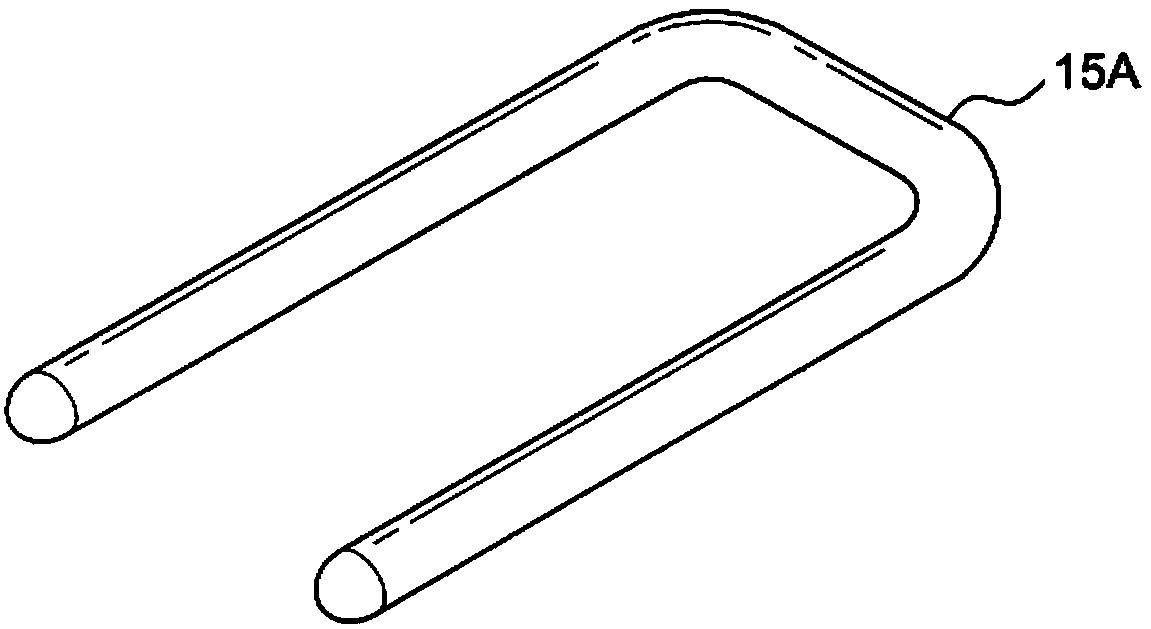

Rolling boot with transition region

ActiveUS9494199B2Improve molding stabilityReduce riskYielding couplingRotary machine partsSacroiliac jointFlange

A rolling boot comprises a first fastening region for fastening the boot to a joint casing, a second fastening region for fastening the boot to a shaft, and a fold region between the first and the second fastening region with a first fold near to the first fastening region and a second fold near to the second fastening region. The boot further comprises, between the first fastening region and the first fold, a first transition region comprising a first flange neighboring the first fastening region with a bottom. A ratio between a first minimal diameter D1, defined by the bottom of the first flange of the first transition region, and a second maximal diameter D2, defined by the first fold, where both are viewed in a longitudinal section direction along the main axis, is between approximately 1:1.01 to approximately 1:1.25.

Owner:GKN DRIVELINE INT GMBH

Production process of CIT capsule demoulding agent

The invention discloses a production process of a CIT capsule demoulding agent. The capsule demoulding agent comprises the following raw materials by weight: 63-72 portions of paraffin wax, 120-140 portions of zinc stearate, 120-130 portions of stearic acid, 50-60 portions of soybean lecithin, 5-20 portions of fatty alcohol, 40-54 portions of vegetable oil, 5-10 portions of glycerin and 12-18 portions of silicone grease. The production process is as below: first heating and evenly mixing vegetable oil, silicone grease, glycerol and fatty alcohol; then adding the mixture into a reactor containing molten paraffin wax; sequentially adding zinc stearate, stearic acid and soy lecithin, preserving, stirring and filtering; cooling the filtrate to obtain the capsule demoulding agent. The production process of CIT capsule demoulding agent provided by the invention has the advantages of easily available raw materials, simple process, convenient operation and easiness for scale production. The produced demoulding agent in improving the qualified rate of products has good effects in improve transparency and smoothness of the capsule.

Owner:ANHUI HUASHENG TECH HLDG

Metal powder core type flux-cored wire for additive manufacturing and welding method thereof

ActiveCN108672977AReduce oxygen contentImprove crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceArc stability

The invention provides a metal powder core type flux-cored wire for additive manufacturing. The metal powder core type flux-cored wire for additive manufacturing comprises carbon steel outer skin anda flux core arranged in the carbon steel outer skin. The flux core comprises the following components in percentage by mass based on total mass: 0.8-1.2% of rutile, 2-3.2% of sodium fluoride, 1-2% offerrotitanium, 0.2-0.5% of ferroboron, 0.4-0.8% of magnesium powder, 2-4% of 75# atomized ferrosilicon, 0.3-0.7% of a silicon-zirconium alloy, 3-3.8% of ferromolybdenum, 25-30% of nickel powder, 0.4-1.1% of anhydrous feldspar, 0.2-0.6% of rare earth fluoride, 2.2-3.1% of electrolytic manganese and the balance iron powder. According to the flux-cored wire, the oxygen content of a weld joint is reduced by way of combined deoxygenation of Mn-Mg-Si-Ti-Zr, and meanwhile, by adding a proper amount of minerals, the weld joint forming and arc stability is improved; by adding the iron powder, the deposition efficiency of the flux-cored wire is improved; by adding the rare earth alloy, the S content in weld joint metal is reduced and the shape of the occluded foreign substances is changed, so that the low-temperature toughness is improved, and therefore, the flux-cored wire is stable in mechanical property of melted metal, good in crack resistance and excellent in low-temperature toughness at 50DEG C below zero.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Preparation method of clove extract for base oil of flavor capsule

InactiveCN108060014AAvoid problems with insufficient dissolutionClove aromaEssential-oils/perfumesFlavorFiltration

The present invention provides a preparation method of a clove extract for base oil of a flavor capsule. The preparation method of the clove extract includes: soaking clove buds in 30-95% ethanol solution; heating the solution to reflux at a temperature of 30 to 60 DEG C, and then cooling and filtering the solution; collecting the filtrate and concentrating the filtrate under vacuum for removing the extraction solvent to obtain a clove extractum; adding octyl and decyl glycerate and Span 60, and treating the mixture by ultrasound at a frequency of 20 to 40 kHz under 30 to 60 DEG C for 0.5 to 2hours; and performing filtration to remove impurities and insolubles, and collecting the filtrate so as to obtain the clove extract. The invention provides a simple extraction method, and the obtained clove extract can be directly added into the base oil of the flavor capsule and used to prepare flavor capsules for cigarettes, and the forming stability of the clove extract is good. The flavor capsule can be added into filter tips to make cigarettes. A smoke panel test shows that the aroma of clove is strong and the aroma is rich and pure.

Owner:HUBEI CHINA TOBACCO IND

Polycarbonate/polyethylene terephthalate composite resin composition and molded article

InactiveUS20120022190A1Improve thermal stabilityHigh viscosityPolyethylene terephthalateResin-Based Composite

A polycarbonate / polyethylene terephthalate composite resin composition is provided, which contains a resin component of 100 parts by weight and contains a phosphorus thermal stabilizer of 0.01 to 0.5 parts by weight and / or a hindered phenol thermal stabilizer of 0.01 to 1 parts by weight, the resin component containing a polycarbonate resin of 95 to 30 weight % and a polyethylene terephthalate resin of 5 to 70 weight %. The polyethylene terephthalate resin contains a deactivated polycondensation catalyst. The polycarbonate / polyethylene terephthalate composite resin composition can be prevented from being deteriorated resulting from being thermally preserved.

Owner:MITSUBISHI ENG PLASTICS CORP

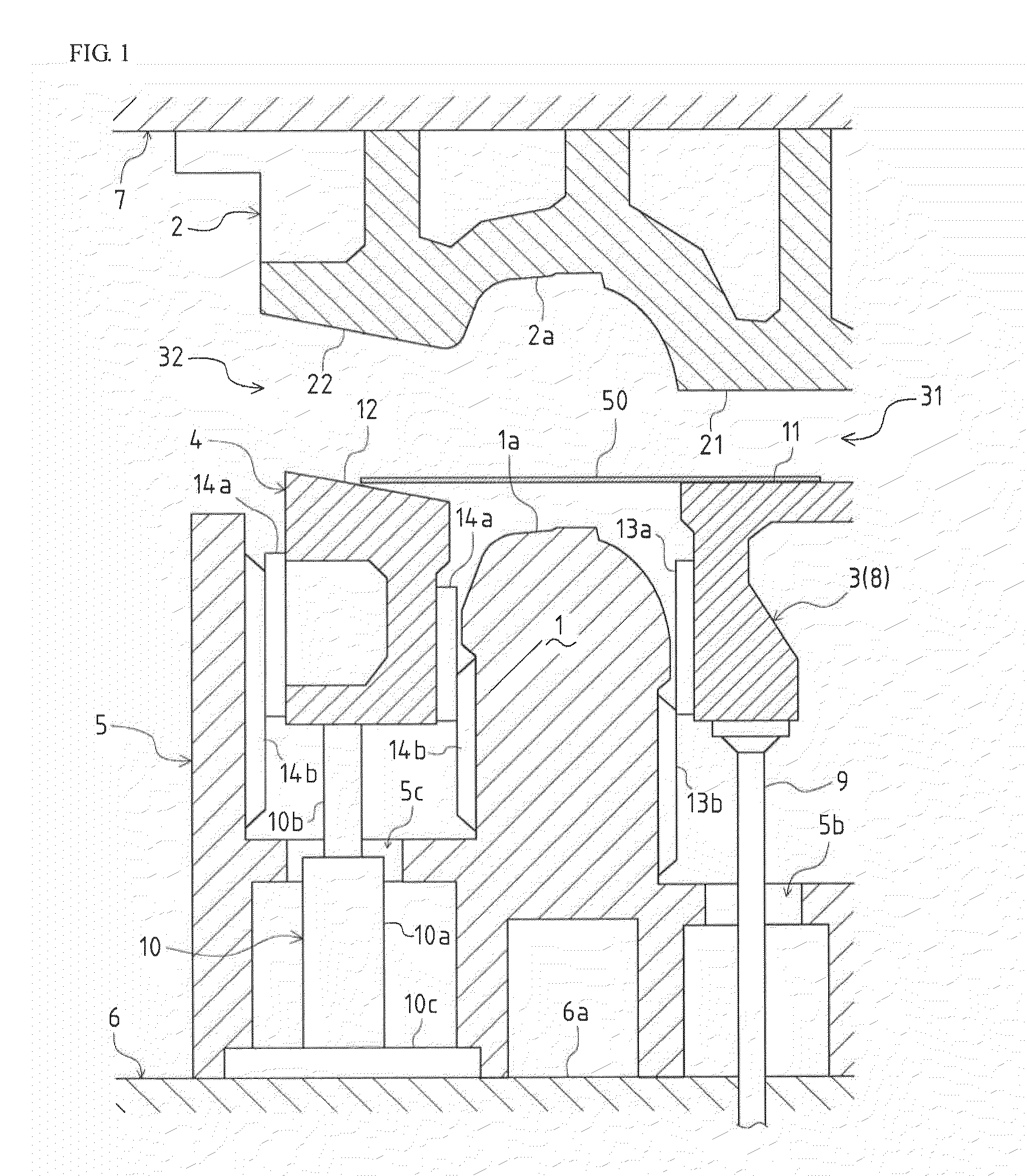

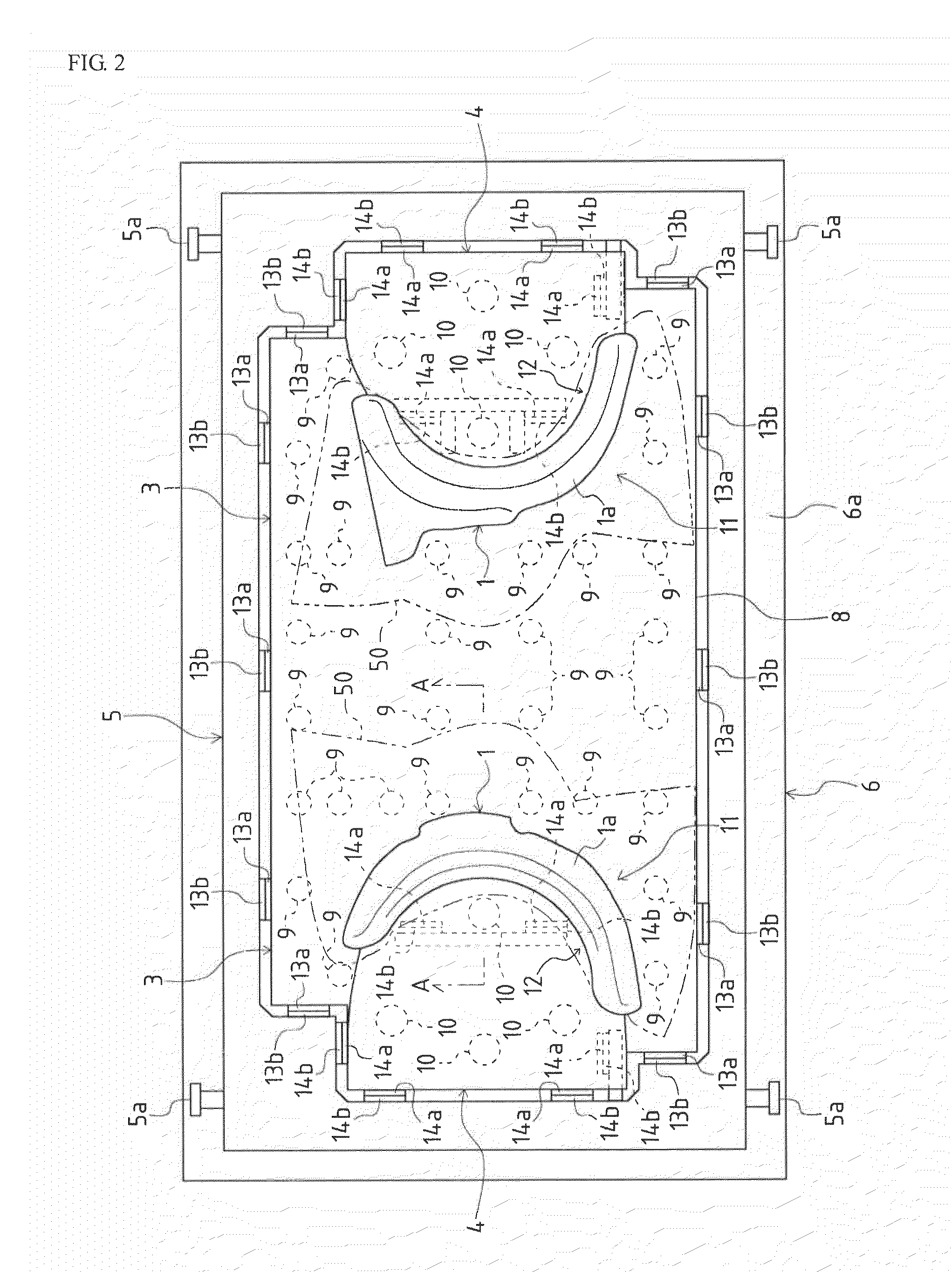

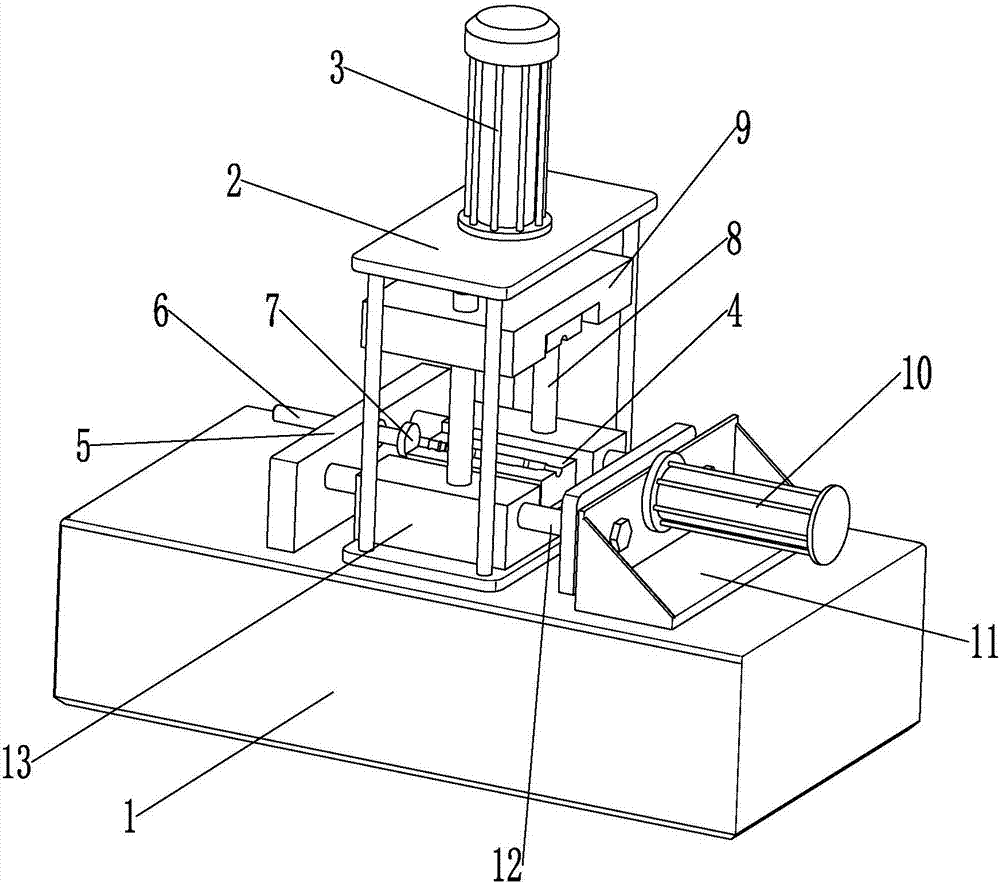

Press-processing method, and press-processing apparatus

InactiveUS20100236318A1Avoid crackingImprove molding stabilityVehicle componentsWrinkle skinCurve shape

This aims to provide a press process for drawing a plate material (50) into a predetermined shape. This press process performs a first unwrinkling treatment and a second unwrinkling treatment sequentially for unwrinkling the material (50). Between these first and second unwrinkling treatments, an introduction for deforming the material (50) is made so that the portion of the material (50) on the side to be subjected to the second unwrinkling treatment may be positioned on the side of a drawing direction with respect to the portion subjected to the first unwrinkling treatment. This first unwrinkling treatment is made on such a portion to be unwrinkled in the material (50) as is located on the side of a larger drawing depth for the predetermined shape. On the other hand, the second unwrinkling treatment is made on such a portion to be unwrinkled as is located on the side of a smaller drawing depth. The press process is advantageous for the cracks or wrinkles of the material, if the molding has a relatively complicated curve shape so that the drawing quantity (or the drawing depth) of the material to be drawn is not homogeneous, so that the press process can improve the pressing stability.

Owner:TOYOTA JIDOSHA KK

Incense flake as well as preparation method and using method thereof

InactiveCN107982562AKeep dry and feelFast dryingBiocidePest repellentsOlder peopleAdditive ingredient

The invention relates to the technical field of traditional Chinese medicine products with an incense function, in particular to an incense flake as well as a preparation method and a using method thereof. The incense flake is prepared from raw materials in parts by weight as follows: 1-10 parts of flos caryophyllata, 1-10 parts of pericarpium zanthoxyli, 1-10 parts of radix angelicae, 1-10 partsof flos magnoliae, 1-10 parts of borneol, 1-10 parts of folium artemisiae argyi, 1-10 parts of herba eupatorii, 1-10 parts of ramulus cinnamomi, 1-10 parts of fennel, 1-10 parts of rhizoma acori graminei, 1-10 parts of rhizoma atractylodis, 1-10 parts of herba menthae and 1-10 parts of agastache rugosus. The raw materials of the incense flake are traditional Chinese medicines containing volatile ingredients, are natural and harmless and have mutual compounding effect, so that the functions of the incense flake are improved, the condition of incompatibility of medicinal effects of the traditional Chinese medicines is prevented, and the incense flake has effects of resisting bacteria, cleaning air, repelling mosquitoes, relieving pressure and the like, has faint scent odor and is suitable for most environments for infants, old people, adults and the like.

Owner:深圳市卡加德科技发展有限公司

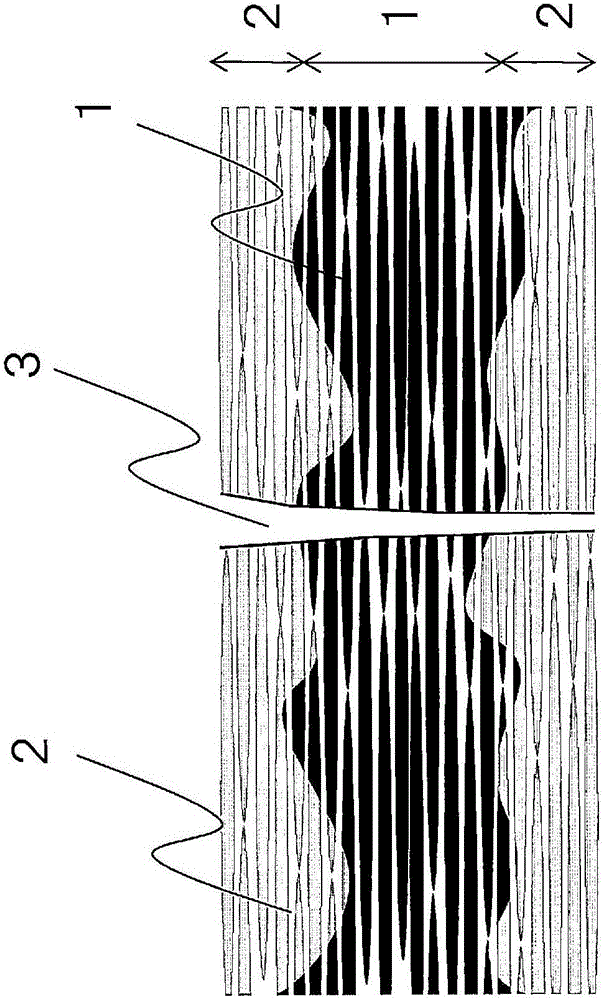

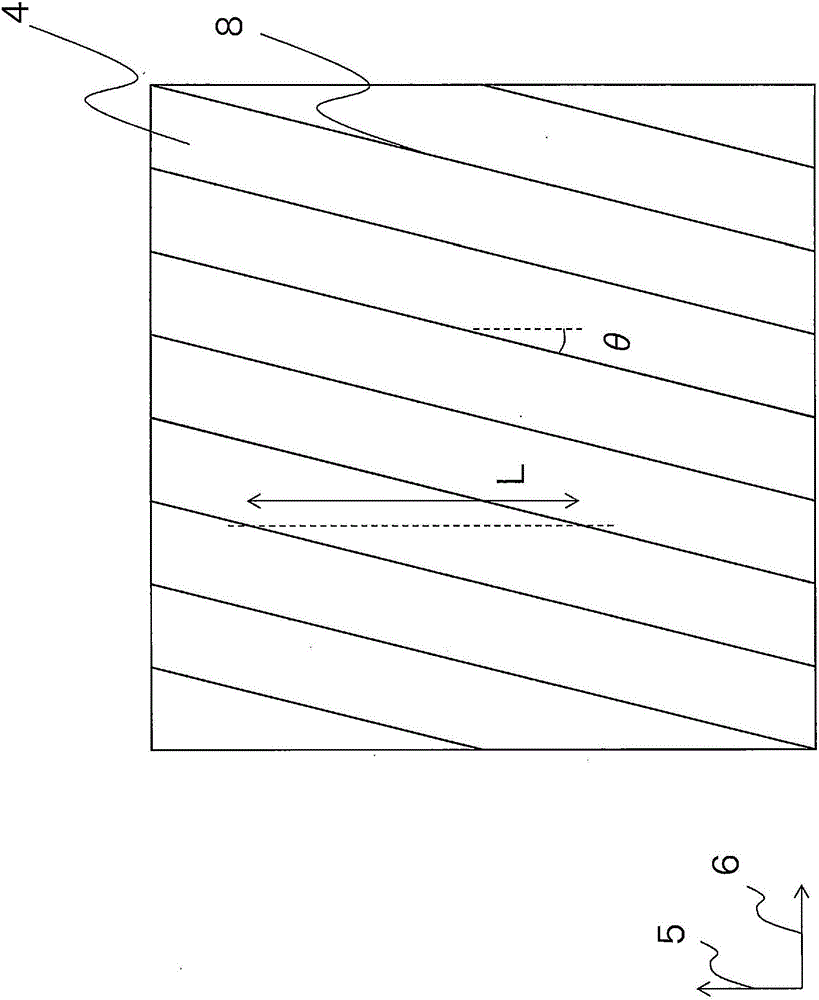

Notched pre-preg and notched pre-preg sheet

ActiveCN106715547AImprove molding stabilitySuppression of molding defects that reduce strengthSynthetic resin layered productsPaper/cardboard layered productsWrinkle skinLow pressure molding

The purpose of the present invention is to provide: an intermediate substrate that has excellent handleability and followability for complex shapes, and also achieves good yield, excellent mechanical properties and low variation thereof, as well as excellent dimensional stability as a result of strength-reducing moulding defects, such as wrinkles and voids, occurring less readily when used in a fibre-reinforced plastic, even with low-pressure moulding; and a method for manufacturing a fibre-reinforced plastic, the intermediate substrate being used in said method. This pre-preg, which has a layer that contains reinforcing fibres impregnated with a resin composition, is characterised by: being a notched pre-preg; the rate of impregnation by the resin composition in the pre-preg being within a prescribed range; comprising reinforcing fibres, at least a portion of which is of a prescribed fibre length due to a plurality of notches; and having a reinforcing-fibre volume content Vf that is within a prescribed range.

Owner:TORAY IND INC

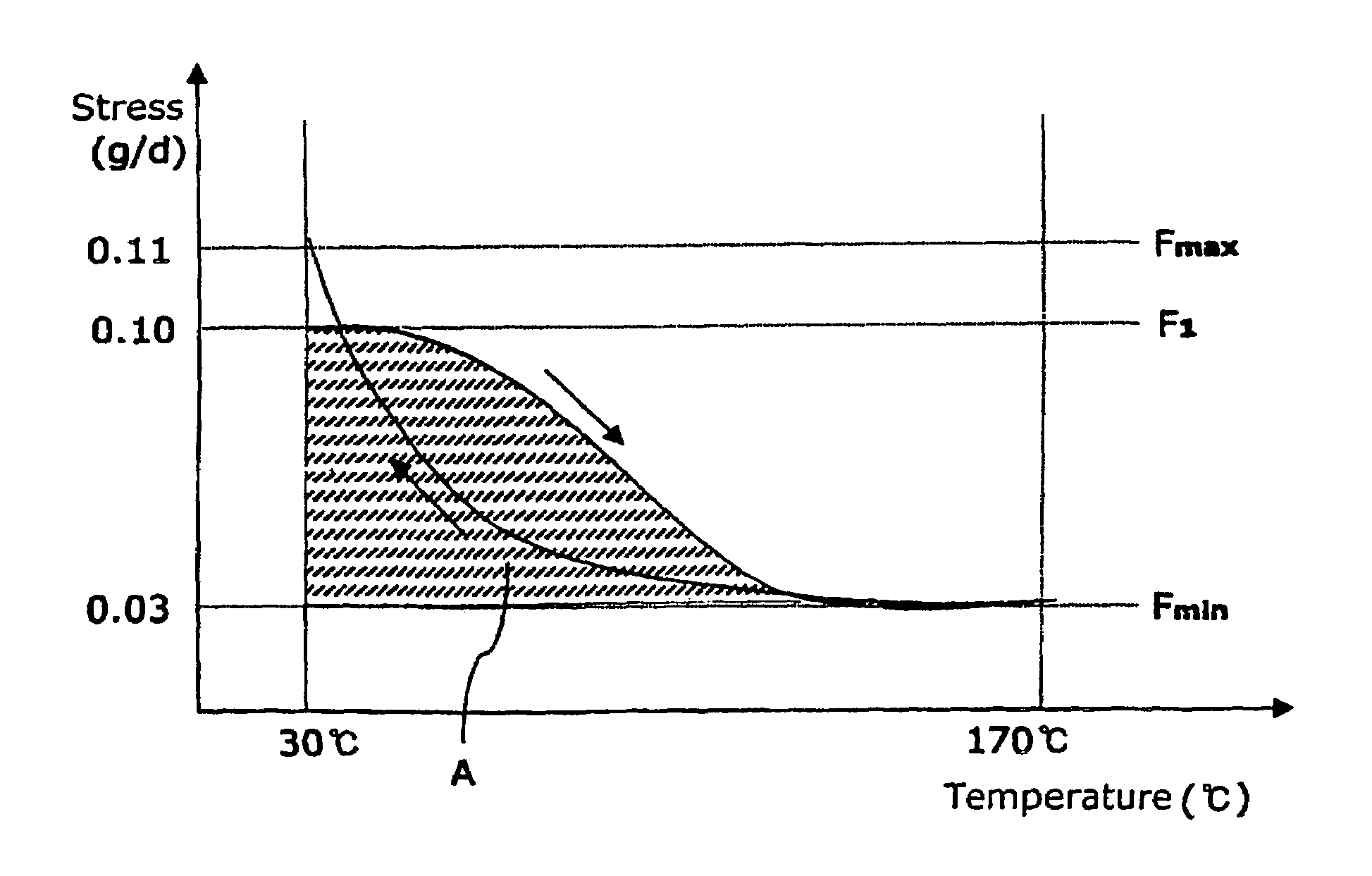

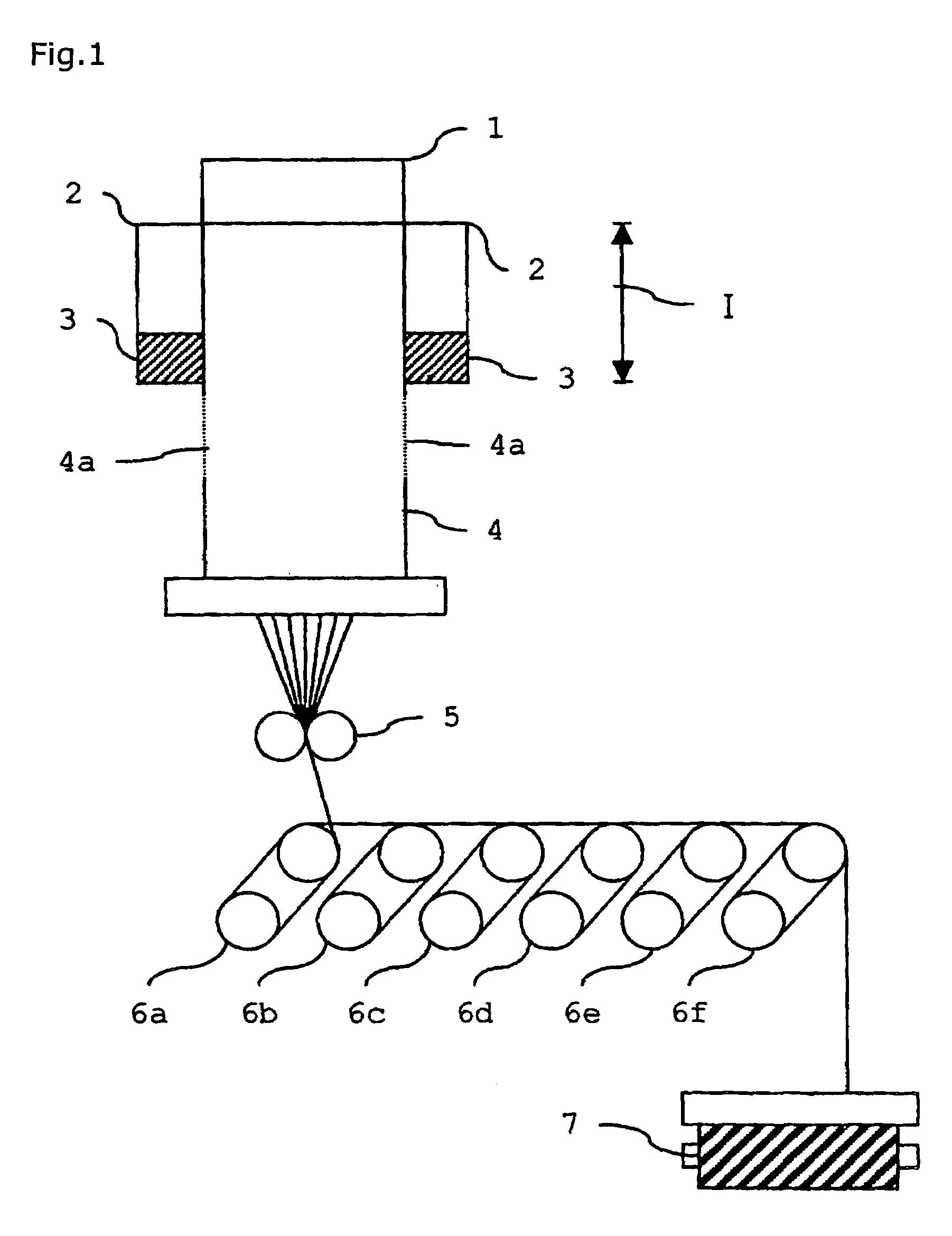

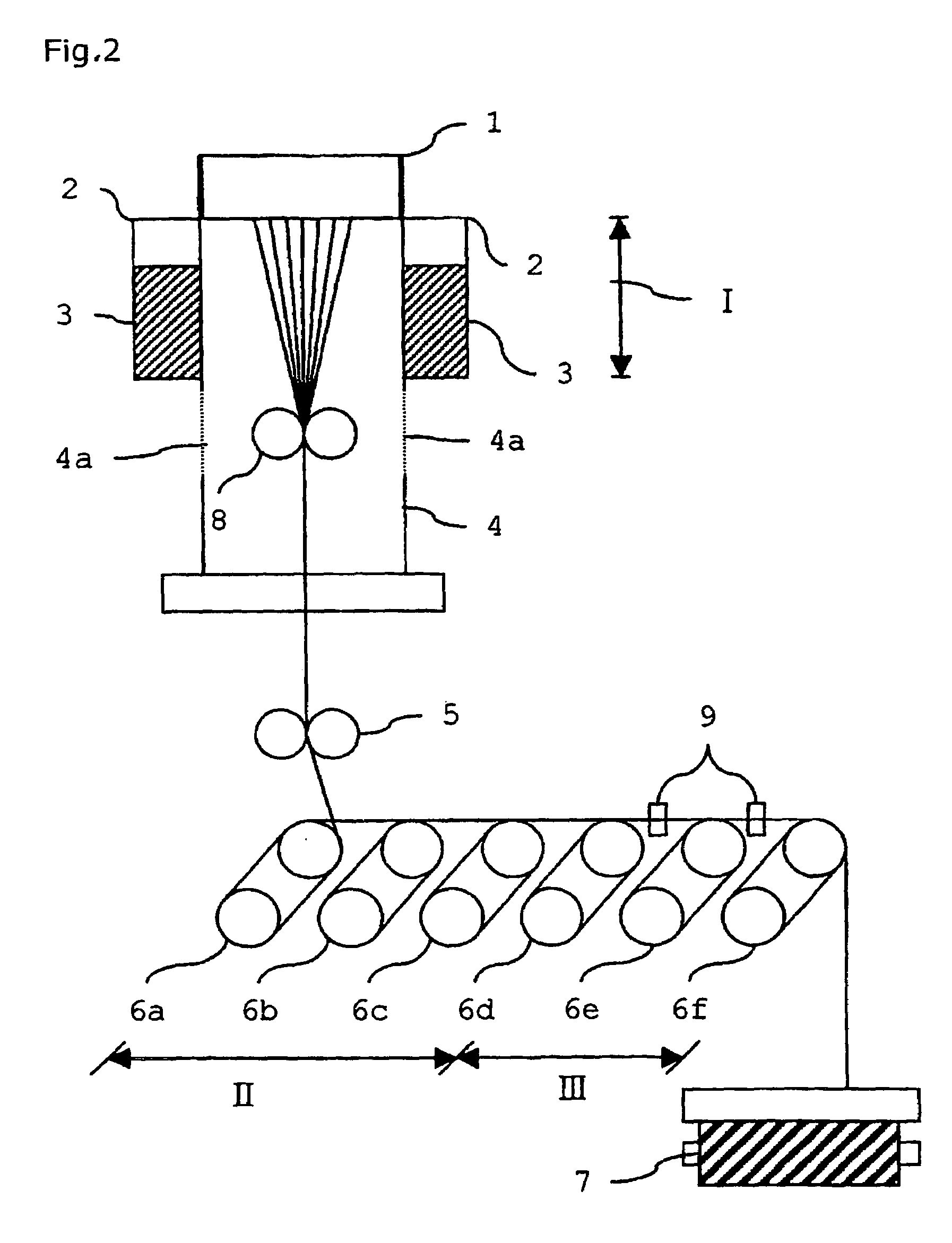

High strength low shrinkage polyester drawn yarn, and a process of preparing for the same

InactiveUS7198843B2Minimize form changeLow rate of changeSynthetic resin layered productsYarnYarnPolyester

The present invention discloses a high strength low shrinkage polyester drawn yarn used as industrial yarns and a process or producing the same. The strength low shrinkage polyester drawn yarn has a thermal relaxation stress change ratio of 5 to 100% and a thermal relaxation stress area ratio of 50 to 140% on a thermal relaxation and shrinkage stress curve with a final temperature set to 170% C. The process for producing a high strength low shrinkage polyester drawn yam by a direct spin draw (DSD) process in which a quenching delay region I is mounted, wherein the high strength low shrinkage polyester drawn yarn is produced in such methods that a spinning oil is attached to the yarn being spun with an oiling apparatus 8 mounted at the position 500 to 1,500 mm below from the lower bottom surface of the insulating board 3, the relaxation stress of the yarn is controlled with one or tow tension guides 9 mounted between Godet rollers of a relaxation region III, or both oiling apparatus 8 and tension guides 9 are mounted.

Owner:KOLON IND INC

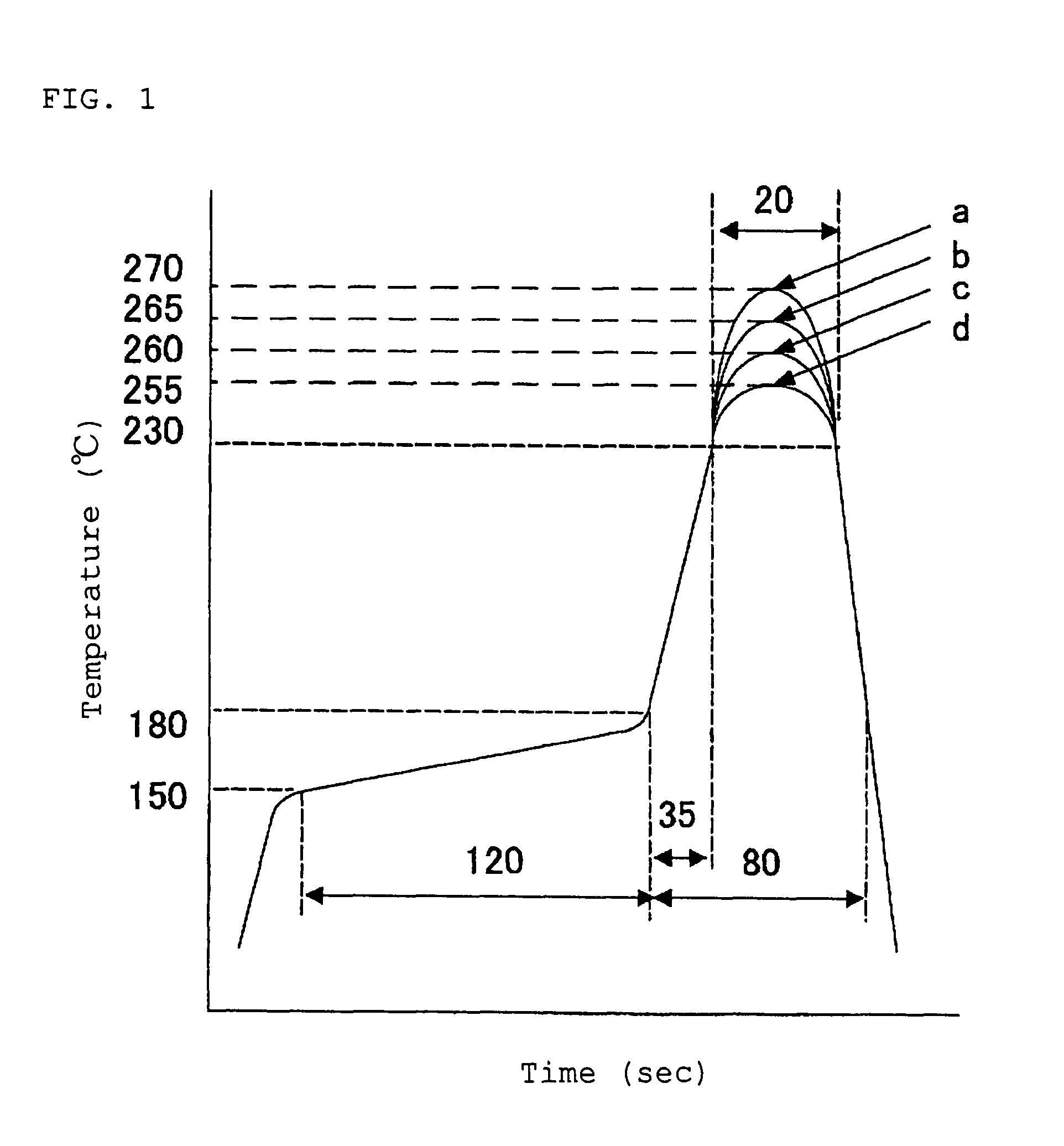

Flame-retardant polyamide composition

InactiveUS7816438B2Excellent in incombustibilityExcellent in propertiesAnti-corrosive paintsPolymer scienceAntimony compounds

To provide a polyamide resin composition which inhibits generation of a gas, formation of decomposition products and discoloration of molded articles even under high molding temperature conditions, is excellent in incombustibility and toughness, and heat resistance in a reflow soldering step being required for surface mounting. The present invention provides a flame-retardant polyamide composition comprising 20 to 80% by mass of polyamide (A), 5 to 40% by mass of a flame retardant (B), 0.01 to 0.45% by mass of an antimony compound (C) and 0.5 to 10% by mass of a salt of zinc or calcium (D).

Owner:MITSUI CHEM INC

Method for manufacturing a composite material

InactiveUS20050164581A1Improve molding stabilityReduce Shrinkage ProblemsLamination ancillary operationsLayered product treatmentMetallurgyHigh pressure

The invention relates to a method of manufacture of a composite product including at least one layer of reinforced woven material and at least one layer of PTFE foil or ePTFE foil, where the foil or foils are laminated together with the layer or layers of woven material under the use of heating and pressurizing, where the composite material subsequently is cooled to a fully or partly fixed state. According to a preferred embodiment the composite is fixated by means of one or two cooperating pressure surfaces under a relative high pressure. By the invention a form stable composite material having a considerable enhanced E-modulus is achieved.

Owner:KE BURGMANN

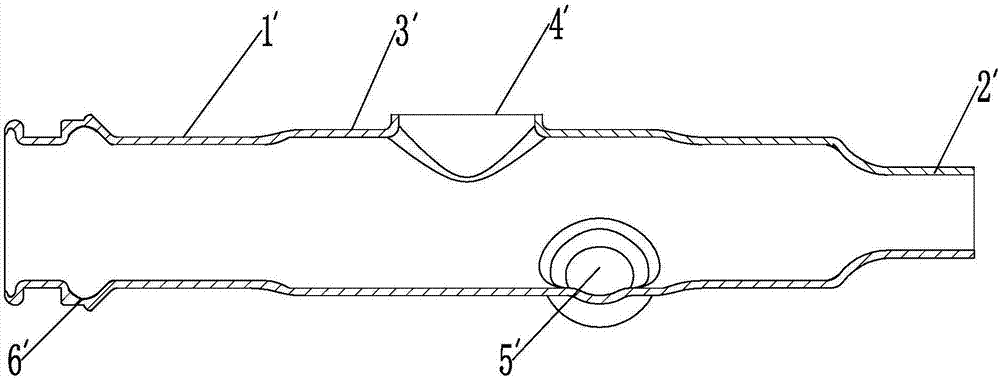

Automobile pipe port forming equipment and port forking method thereof

The invention discloses automobile pipe port forming equipment and a port forking method thereof. The key point of the technical scheme is that the automobile pipe port forming equipment comprises a rack, a die frame, a forming die and a top pressure mechanism, wherein the die frame is fixedly mounted on the rack; a die mounting cavity for mounting the forming die is formed in the die frame; the forming die comprises an upper die and a lower die which are correspondingly arranged up and down, a lifting driving mechanism for driving the upper die to do lifting motion and a mandrel; the mandrel comprises a bulging block and a step shaft; the diameter of a small-diameter section of the step shaft is less than the inner diameter of a reducing section of an automobile pipe; the diameter of a large-diameter section of the step shaft corresponds to the inner diameter of a pipe body of the automobile pipe; the bulging block is a cylinder; one end of the bulging block is fixedly connected with the end surface of the large-diameter section of the mandrel; and the top pressure mechanism comprises a fixed ejector block and a movable ejector block which are relatively arranged at two ends of a die cavity of the forming die, and a top pressure driving assembly for driving the movable ejector block to do relative motion to the fixed ejector block. The problems of low efficiency and relatively high cost of the existing automobile pipe during pipe end forming machining are solved.

Owner:宁波嘉天汽车管件有限公司

Multi-ratio gearbox housing

ActiveUS20140157954A1Reducing thermal radial expansionIncreased heat generationGearboxesGear lubrication/coolingEngineeringMechanical engineering

A multi-ratio gearbox housing for a vehicle is made of light metal material and includes a first bearing seat having a cylindrical inner surface, and a reinforcement member having a first cylindrical inner surface surrounding the first bearing seat for reducing thermal radial expansion of the first bearing seat, the reinforcement member being of a material the coefficient of thermal expansion of which is less than the coefficient of thermal expansion of the light metal material of the housing. The reinforcing member is a cast-in insert arranged in the housing, and a radial distance between the first cylindrical inner surface and the cylindrical inner surface of the first bearing seat is substantially constant along circumferential lines of the first bearing seat, facilitating improved form stability of the cylindrical inner surface of the first bearing seat over the temperature operating range of the housing.

Owner:VOLVO LASTVAGNAR AB

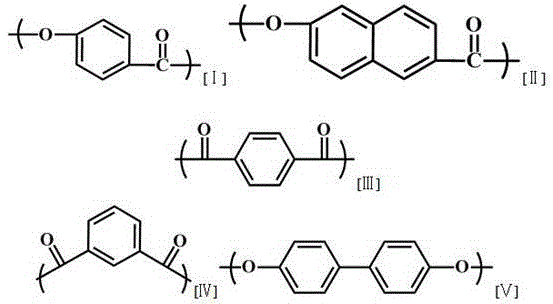

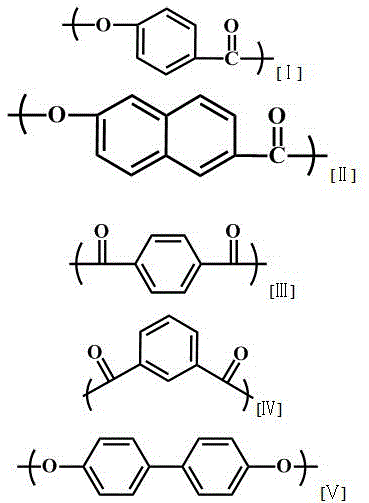

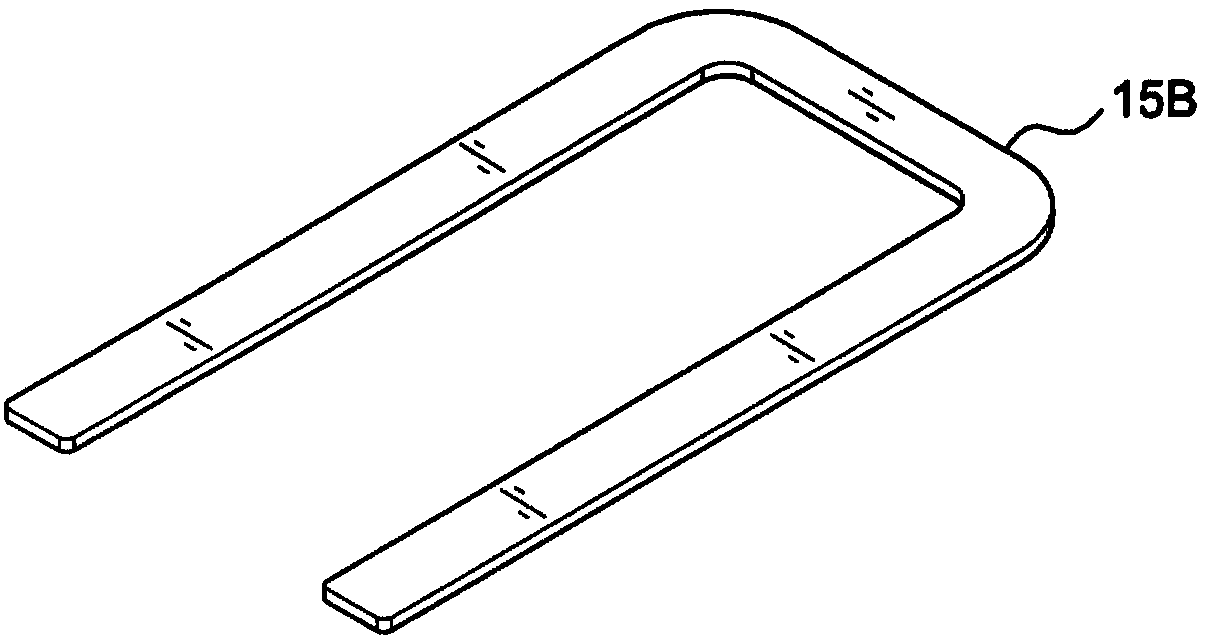

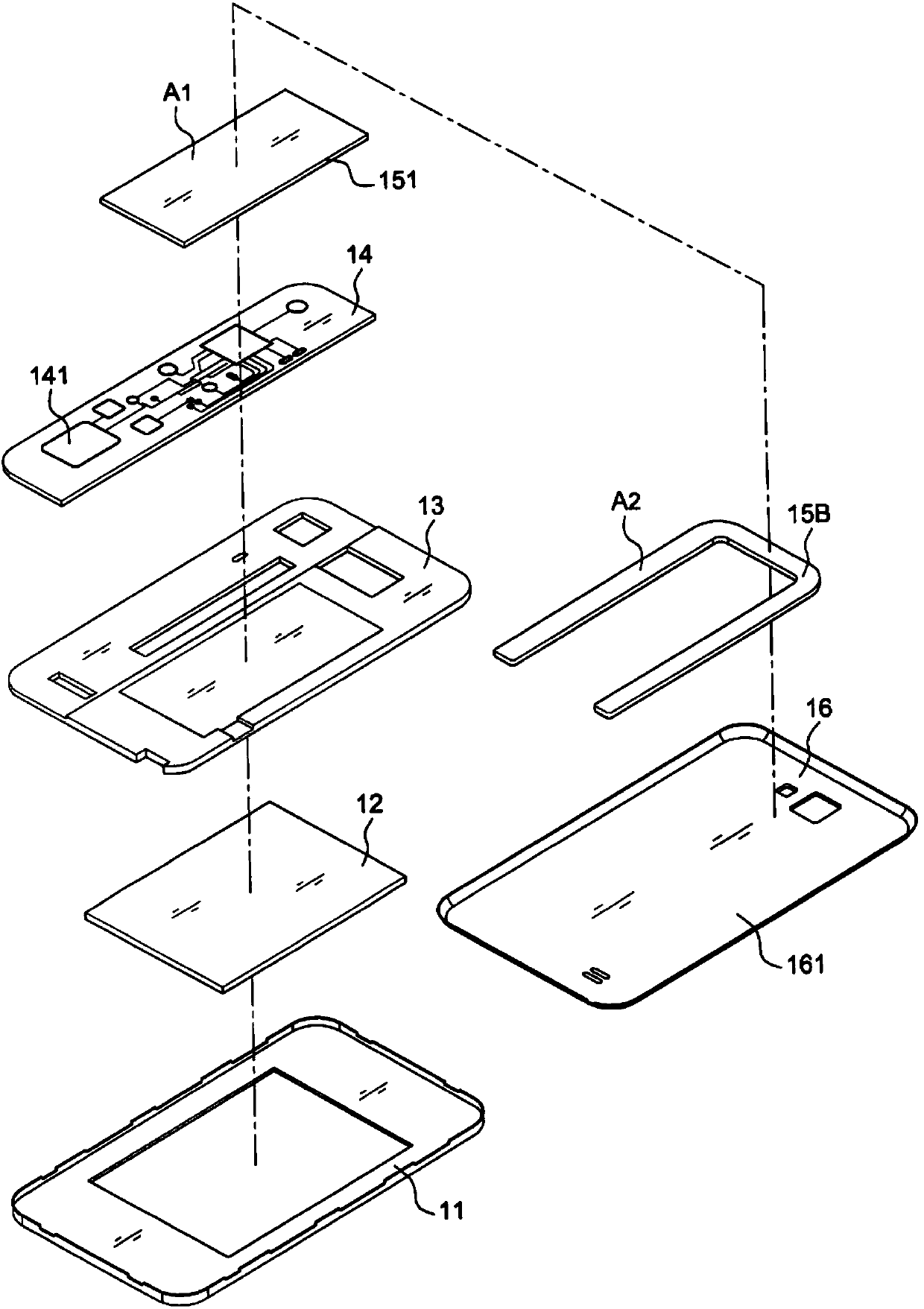

Liquid crystal polyester and its molded composition and use

ActiveCN105837803AImprove liquidityImprove melting propertiesLiquid crystal compositionsPolyesterThermomechanical analysis

The invention discloses a liquid crystal polyester and its molded composition and use. The liquid crystal polyester comprises repeated structural units [I]-[IV]. A dynamic thermomechanical analysis (DMA) test proves that the liquid crystal polyester has a storage modulus release rate delta G greater than or equal to 95.0% and less than or equal to 99.4% defined in the formula (1) of delta G=[G(-50)-G(melting point)] / G(-50)*100%. The liquid crystal polyester has a storage modulus release rate delta G greater than or equal to 95.0% and less than or equal to 99.4%. The liquid crystal polyester and the liquid crystal polyester molded composition have good fluidity and excellent melting characteristics. A small thin wall molded product has high stability and is especially suitable for a thin wall electronic product.

Owner:KINGFA SCI & TECH CO LTD

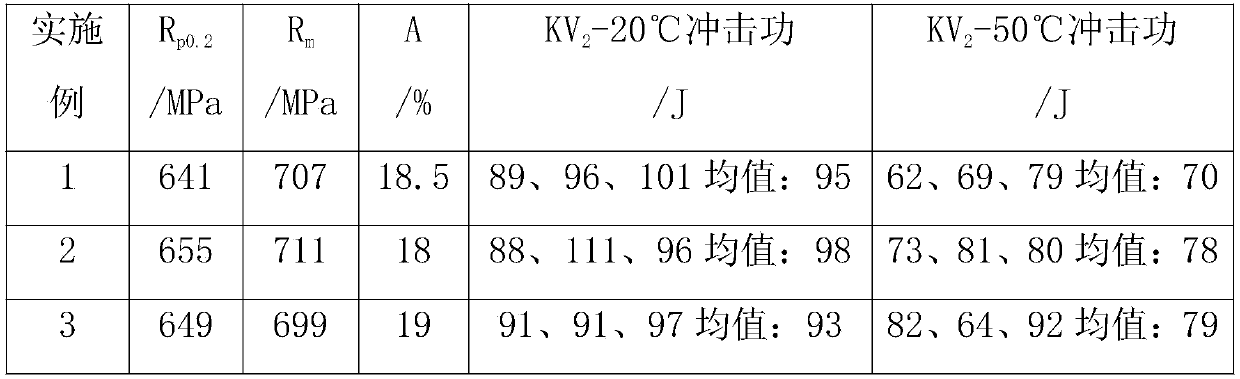

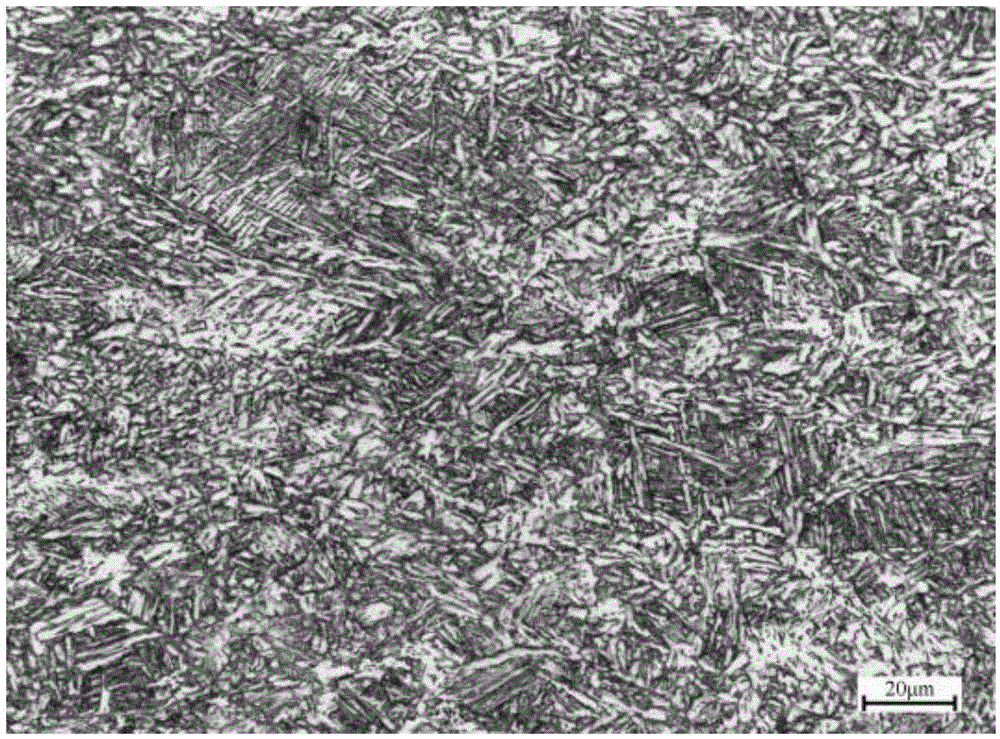

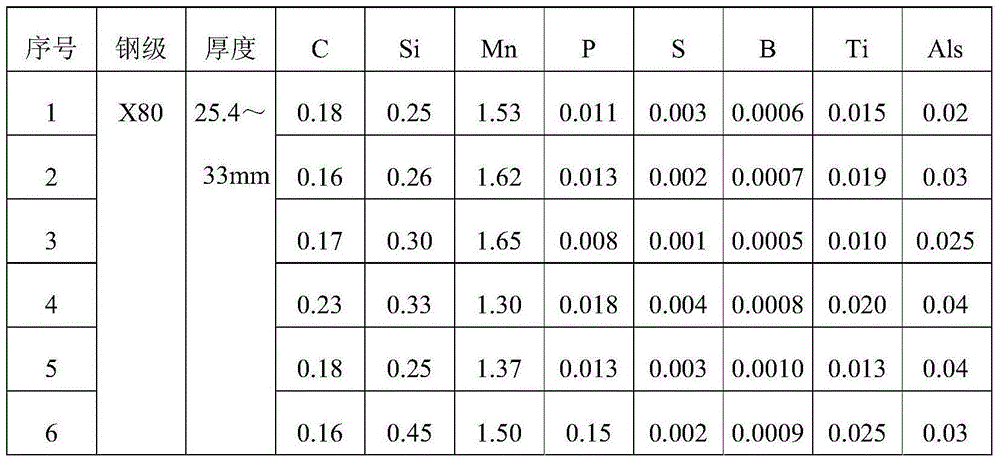

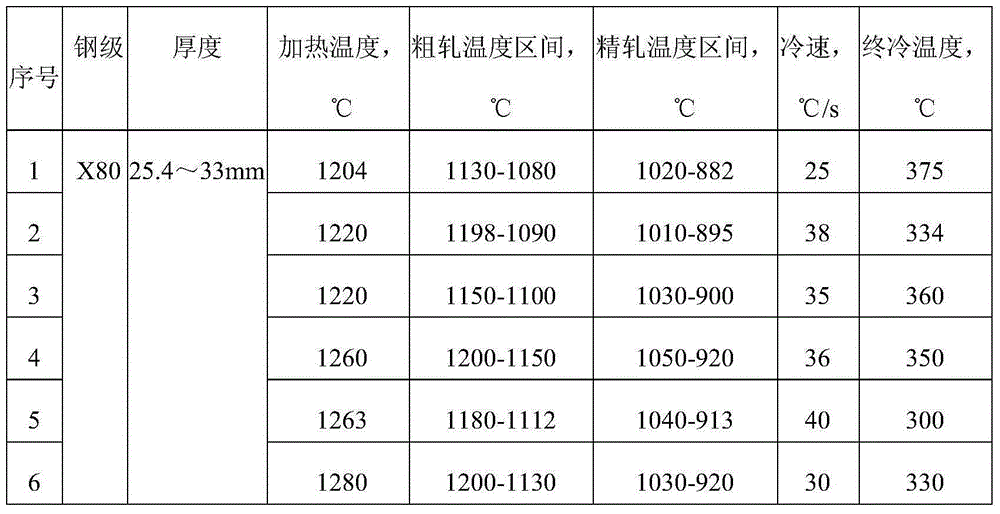

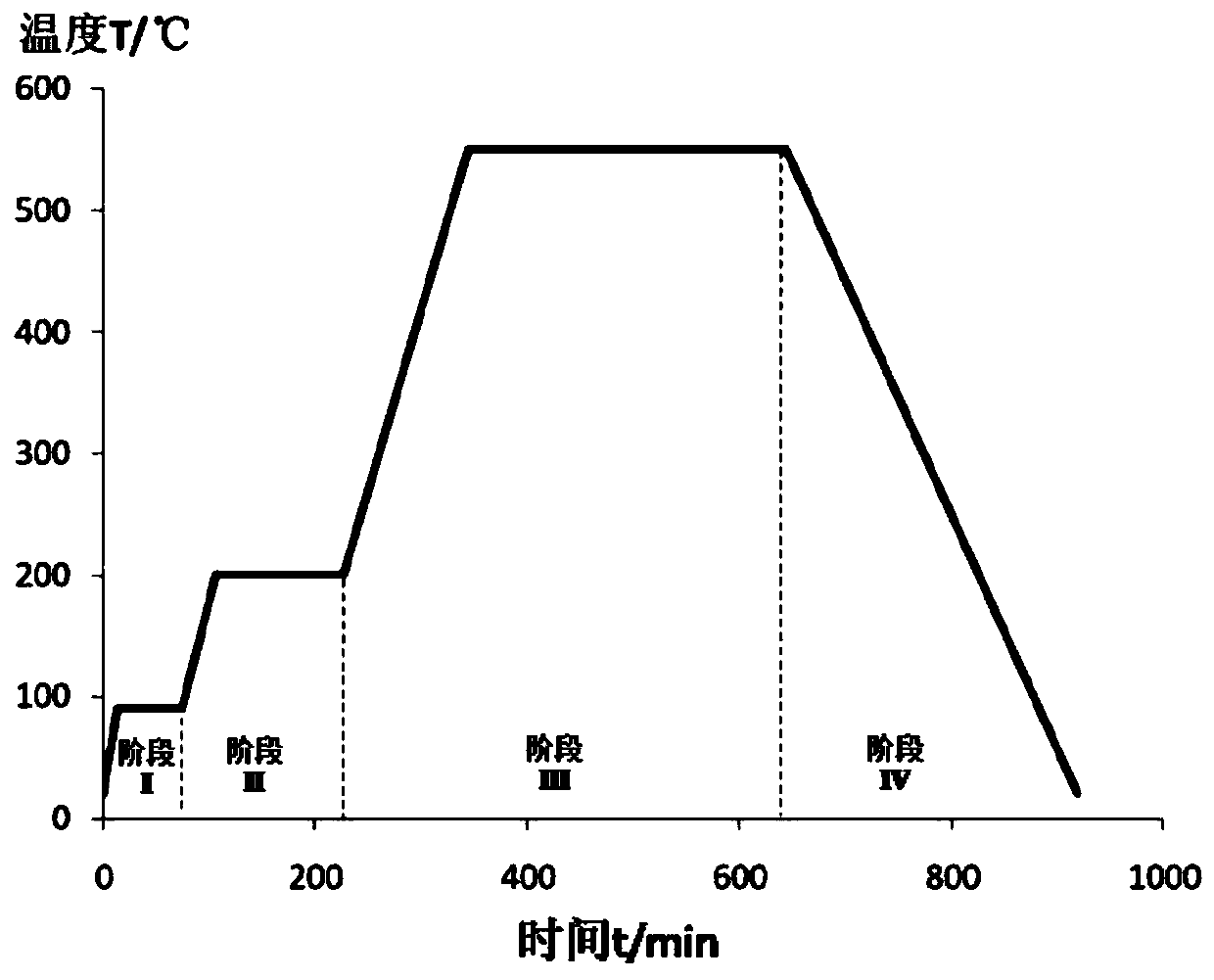

Hot-rolled flat plate for X80 high-wear-resistant hot-bending elbows and production method of hot-rolled flat plate

InactiveCN106480369AReasonable design of ingredientsReduce manufacturing costCooling temperatureSteel plates

The invention provides a hot-rolled flat plate for X80 high-wear-resistant hot-bending elbows and a production method of the hot-rolled flat plate. The hot-rolled flat plate comprises the following raw components by weight: 0.16% to 0.23% of C, 0.25 % to 0.45% of Si, 1.30% to 1.65% of Mn, 0.008% to 0.025% of Ti, 0.015% to 0.06% of Al, 0 to 0.020% of P, 0 to 0.004% of S, 0.0005% to 0.0010% of B, and the balance Fe and unavoidable impurities. According to the production method, rolling adopts the controlled rolling and controlled cooling technology, the slab heating temperature is 1200 to 1280 DEG C, the rough rolling temperature is 1080 to 1200 DEG C, the finish rolling temperature is 880 to 1050 DEG C, the cooling speed after rolling is 25 to 40 DEG C / s, the finish cooling temperature is 300 to 375 DEG C, and then air cooling is carried out. Due to adoption of the hot-rolled flat plate and the production method, the production cost is lowered by about 15%; and the steel plate is easy to mold at high temperature, and high in hardness at room temperature, and has good molding stability and abrasion resistance.

Owner:ANGANG STEEL CO LTD

Method for preparing ozone catalyst by step-type gradient heating calcining method and application thereof

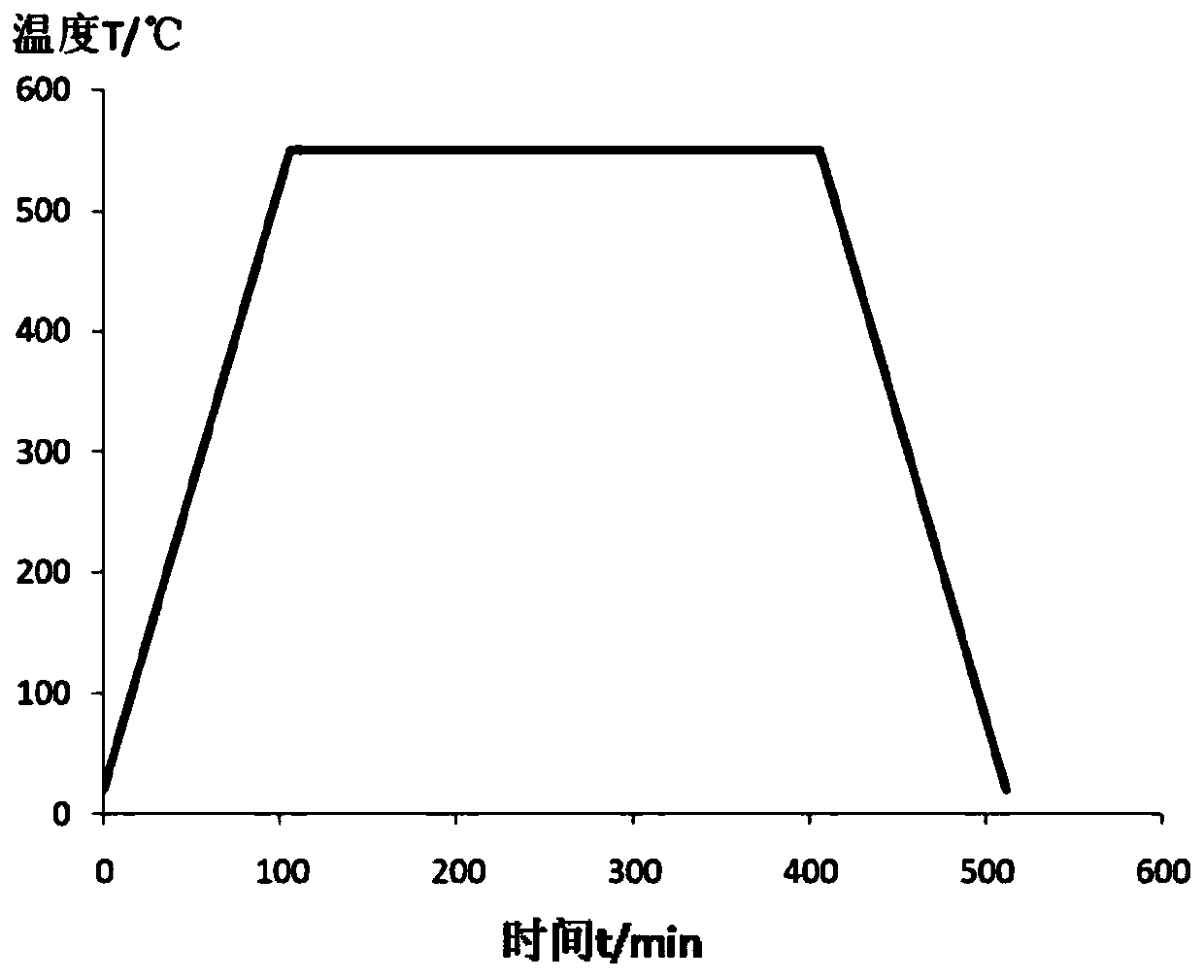

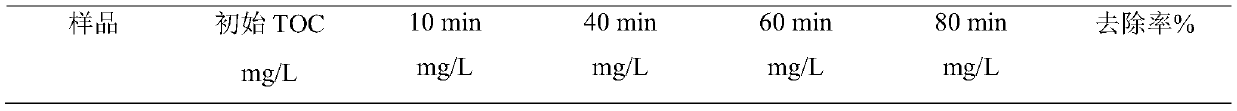

ActiveCN109718749AHigh removal rateGood catalyticWater contaminantsCatalyst activation/preparationWastewaterChemistry

The invention discloses a method for preparing an ozone catalyst by a stepped gradient heating calcining method and application thereof, and belongs to the field of environment-friendly materials. Themethod comprises the following steps: adding water into an aluminum-based precursor material, and uniformly stirring so as to obtain an active precursor material; drying the active precursor materialto obtain an active material; and roasting the active material to obtain the ozone catalyst, wherein the roasting method is a program step type gradient heating calcining method. According to the method disclosed by the invention, the efficiency of removing TOC from the ozone catalyst in the wastewater can be effectively improved, the catalyst is prepared by adopting the method, the steps are simple, the control is easy, and the mass production of the high-efficiency ozone catalyst is facilitated.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

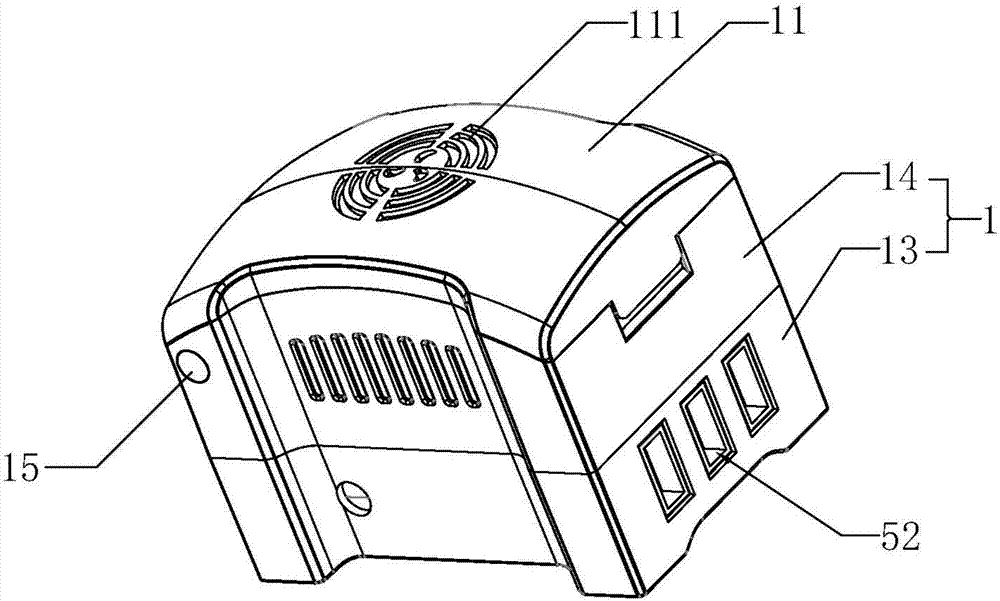

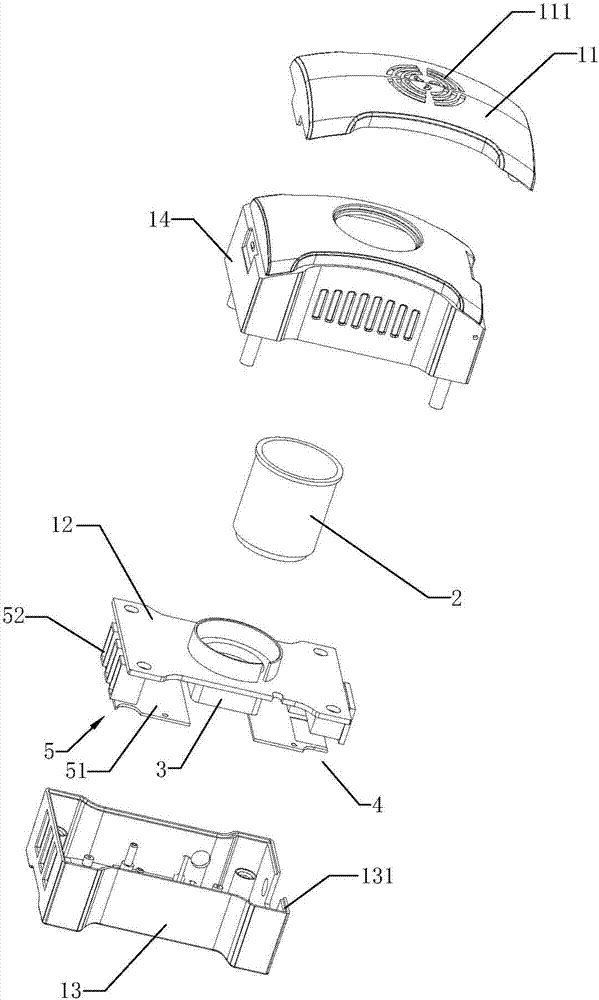

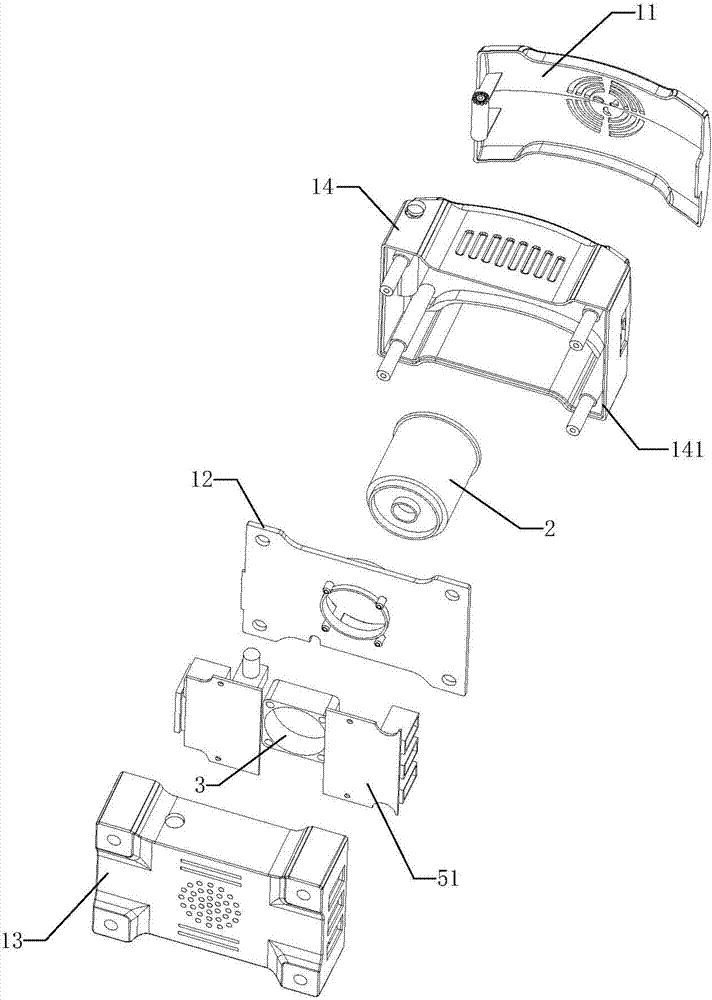

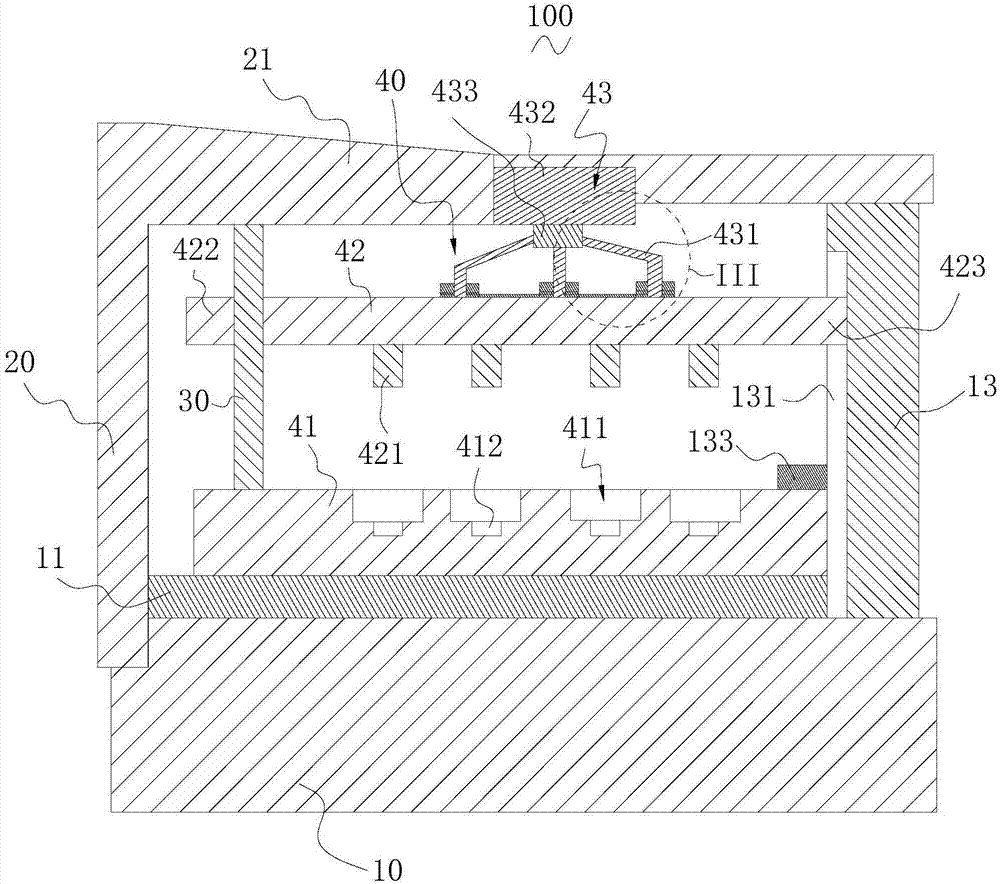

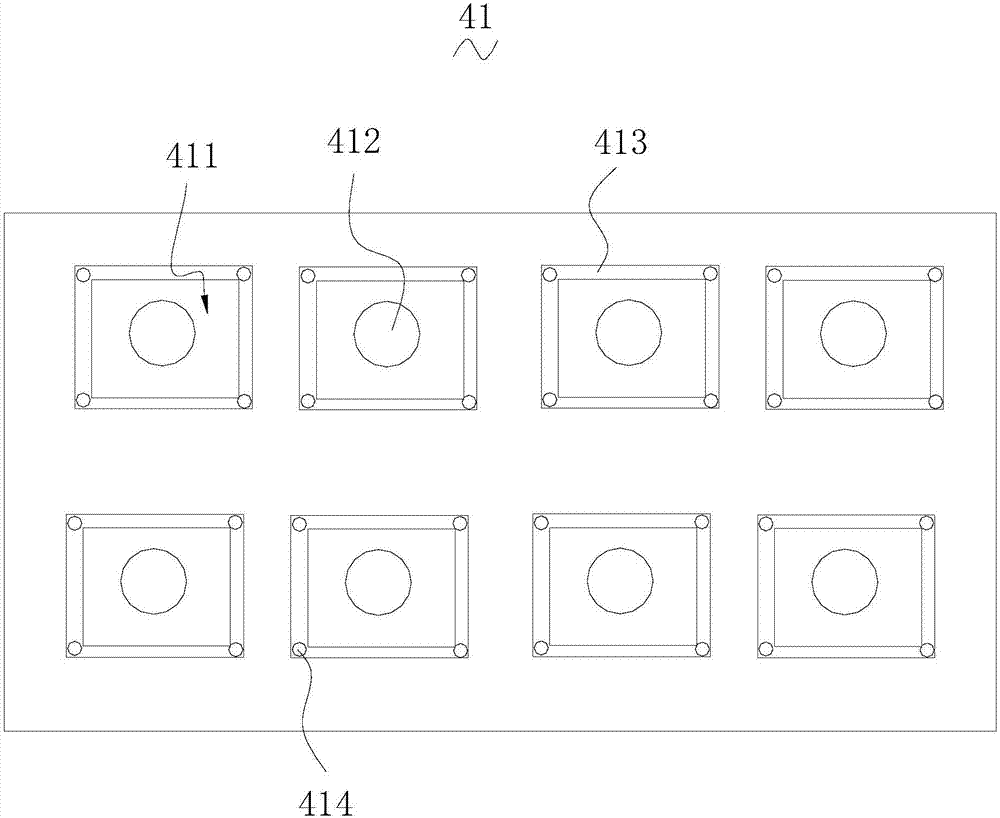

Mold pressing device

InactiveCN107030183AImprove the uniformity of forceImprove molding stabilityShaping toolsPerforating toolsEngineeringMechanical engineering

Owner:惠州市里斯科技有限公司

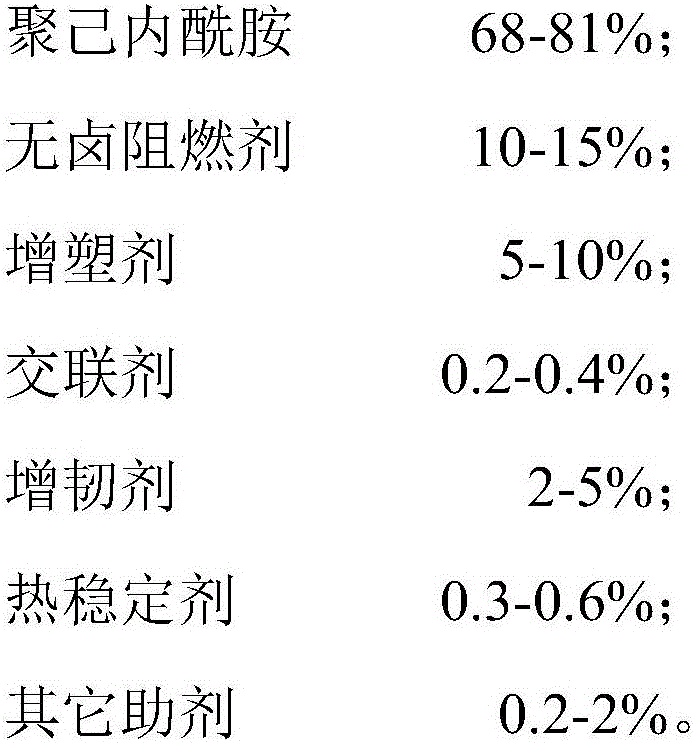

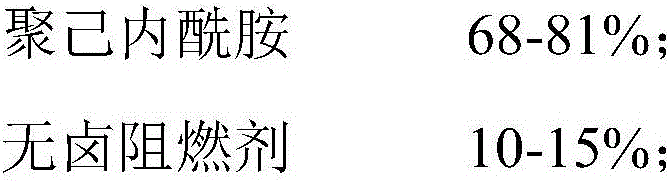

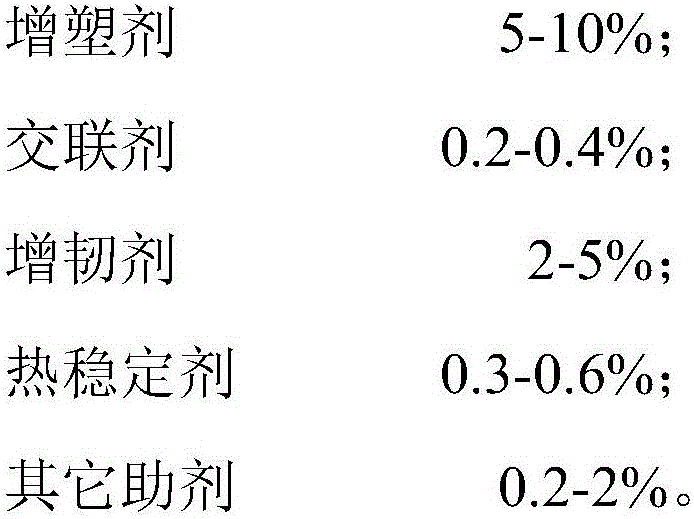

Bellows material and production method thereof

The invention belongs to the technical field of macromolecular materials and particularly relates to a bellows material and a production method thereof; the bellows material comprises, by total weight of 100%, 68-81% of polycaprolactam, 10-15% of halogen-free flame retardant, 5-10% of a plasticizer, 0.2-0.4% of a crosslinking agent, 2-5% of a toughener, 0.3-0.6% of a thermostabilizer, and 0.2-2% of other aids. Through modifying effects of the plasticizer, the halogen-free flame retardant, the crosslinking agent, the toughener and the thermostabilizer and the synergy of the components within the specific content range, the bellows material provided herein is given excellent flexibility, flame retardancy and thermostability, as well as excellent forming stability, and has significantly better effects than those of the prior art.

Owner:ANHUI KEJU NEW MATERIALS

Press-processing method, and press-processing apparatus

InactiveUS8850864B2Avoid crackingImprove molding stabilityForging press detailsForging press drivesEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

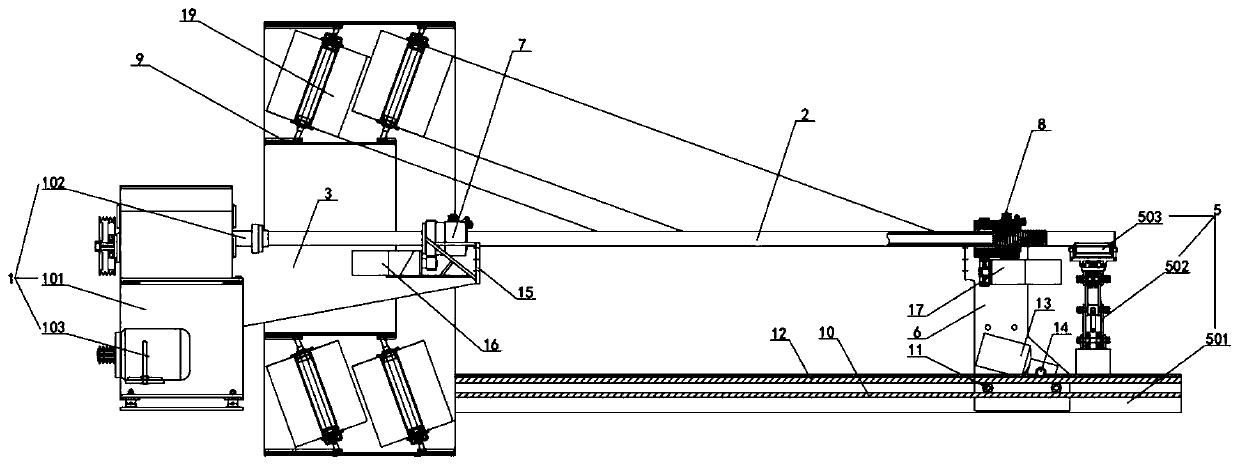

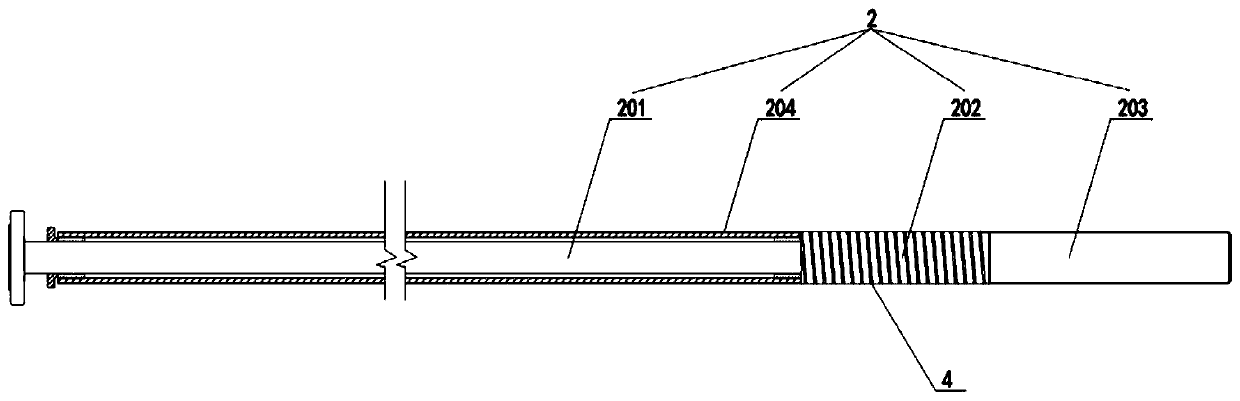

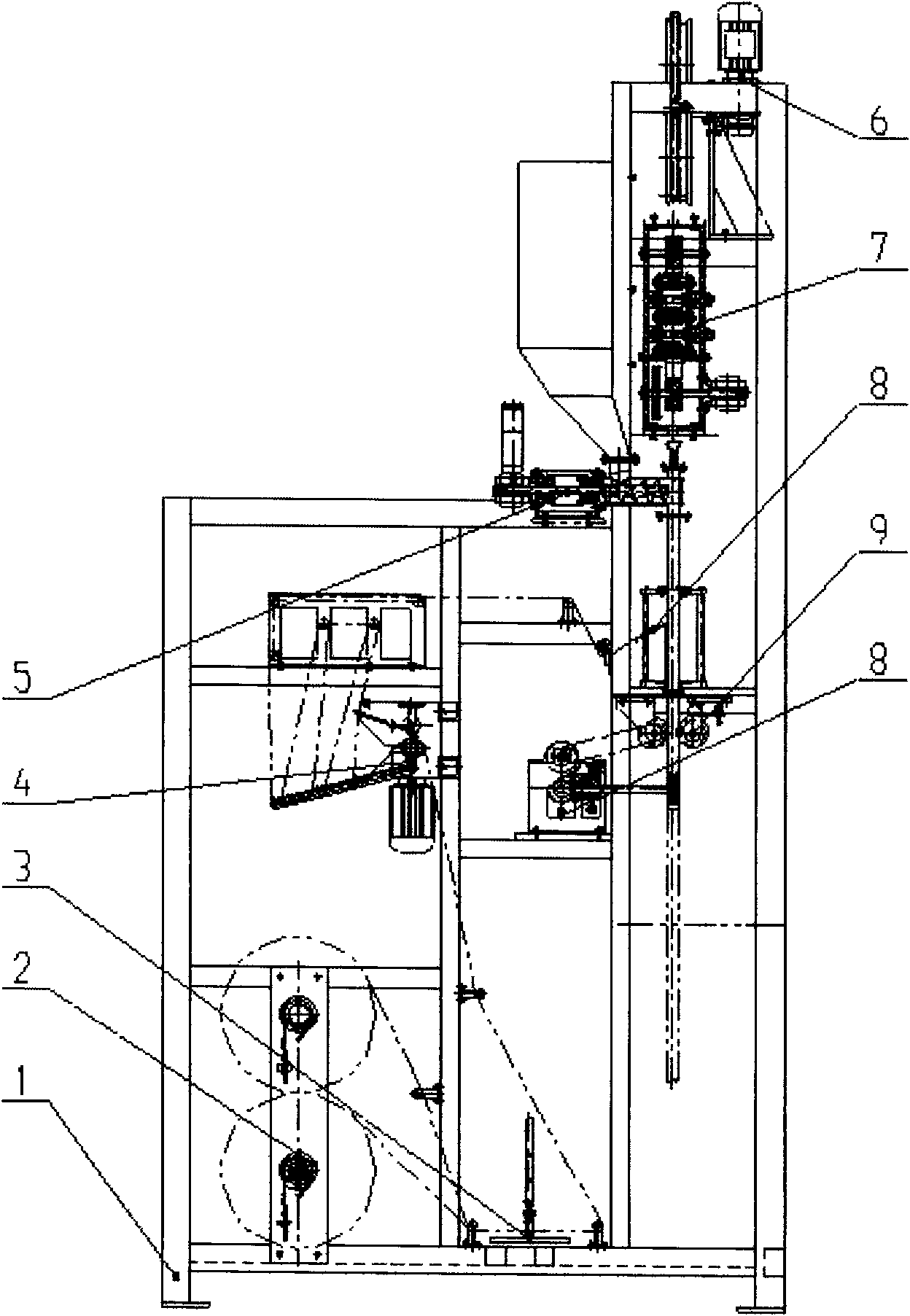

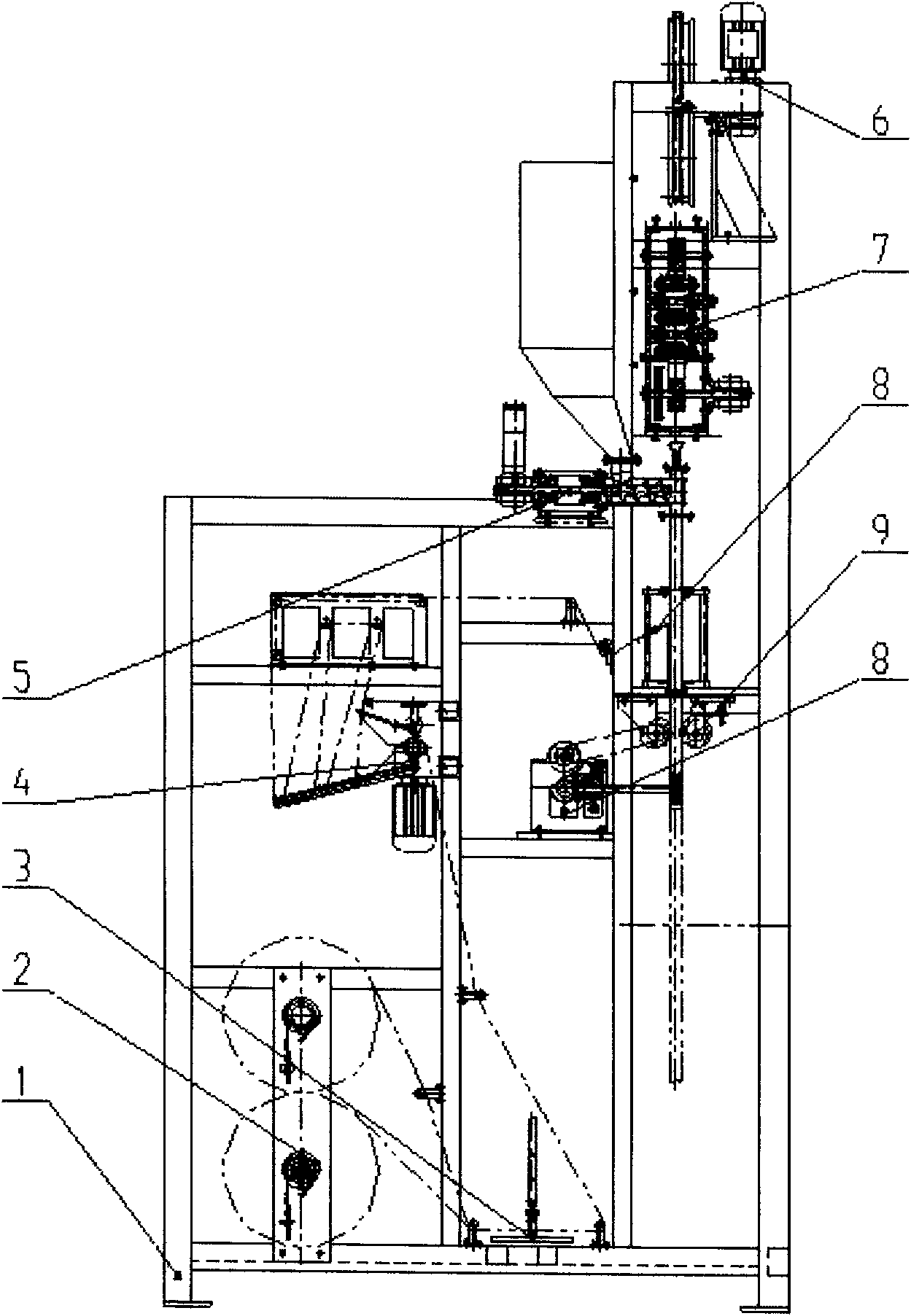

Full-automatic composite hose making machine

PendingCN111516281AOff-pipe implementationAdapt to production needsTubular articlesStructural engineeringMechanical engineering

The invention relates to a full-automatic composite hose making machine. The full-automatic composite hose making machine comprises a core rod driving mechanism, a core rod mechanism, a supporting mechanism, an inner steel wire winding mechanism, an outer steel wire winding mechanism and a cloth film winding mechanism, wherein the core rod driving mechanism comprises a mounting base, and an innersteel wire winding mechanism mounting plate is fixedly arranged on the front portion of the mounting base; the core rod mechanism is arranged on the front side of the mounting base, the core rod mechanism comprises a core rod body in transmission connection with the core rod driving mechanism, the front end of the core rod body is fixedly connected with a tube removing core rod, and the tube removing core rod is provided with a tube removing thread; the supporting mechanism is arranged below the front side of the core rod body and comprises a bottom support, and an outer steel wire winding mechanism mounting plate is movably mounted on the bottom support; the inner steel wire winding mechanism is detachably arranged on the inner steel wire winding mechanism mounting plate; the outer steelwire winding mechanism is fixedly arranged on the outer steel wire winding mechanism mounting plate; and the cloth film winding mechanism is rotationally arranged at the rear end of the core rod body.According to the full-automatic composite hose making machine, the composite hose can be continuously prepared, and the forming stability of the composite hose can be effectively improved.

Owner:厦门市卓励石化设备有限公司 +1

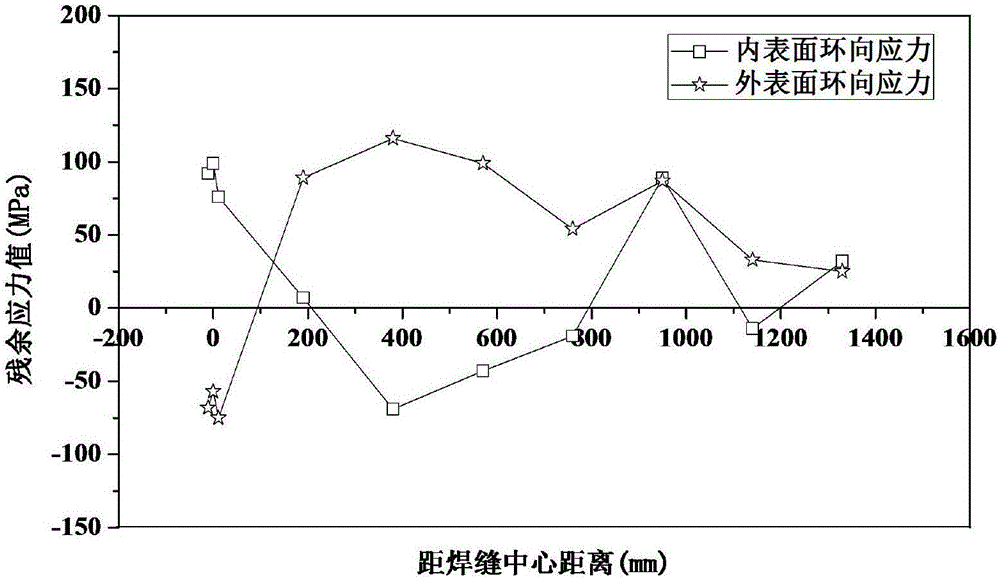

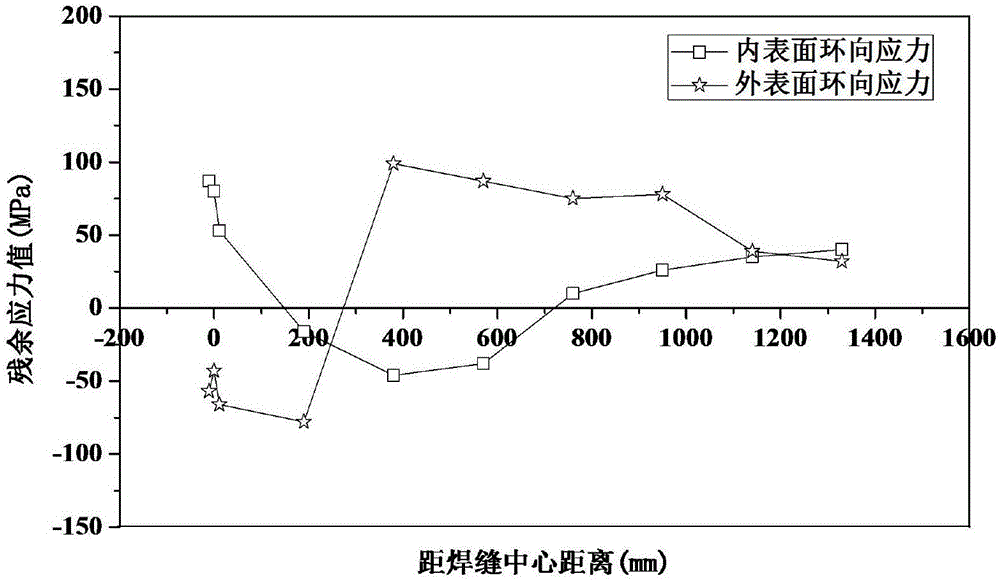

Method for manufacturing X 90 grade pipeline steel large-diameter thick-wall spiral submerged-arc welding pipe

The invention discloses a method for manufacturing an X 90 grade pipeline steel large-diameter thick-wall spiral submerged-arc welding pipe. The method comprises the following working procedures: uncoiling, flattening, edge milling, forming, welding, pipe end expanding, X-ray continuous detection, static hydrostatic testing, weld joint and base metal ultrasonic flaw detection, pipe end chamfering, pipe end shooting and finished product inspection; the welding working procedure comprises inside and outside prewelding, finish inside and outside welding; through reasonably selecting welding parameters, a weld joint and base metal can transit smoothly to reduce or eliminate undercut, and the weld joint has excellent mechanical property and ensures obdurability match of the welding pipe and a welded joint; while the pipe end expanding working procedure is carried out, an automatic spiral submerged-arc welding pipe perimeter measuring device is adopted to measure the perimeter in real time, so that real-time measurement and monitoring on the welding pipe perimeter during the forming process are realized, and precise geometric dimensioning of the welding pipe is ensured.

Owner:BAOJI PETROLEUM STEEL PIPE

Flat film-type cooling device

PendingCN107660099AGuaranteed reliabilityImprove molding stabilityCooling/ventilation/heating modificationsHeat sinkCooling fluid

The invention discloses a flat film-type cooling device, which comprises an upper metal cooling layer, a lower metal cooling layer and a resin layer, wherein the upper metal cooling layer is a flat body and the thickness is 0.01-0.20mm; the lower metal cooling layer is a flat body, the thickness is 0.01-0.20mm, and the lower metal cooling layer corresponds to the upper metal cooling layer; the resin layer is located between the upper metal cooling layer and the lower metal cooling layer and is arranged into a film micro-pipe with a heat pipe pattern; an upper film surface and a lower film surface of the film micro-pipe are combined with the lower surface of the upper metal cooling layer and the upper surface of the lower metal cooling layer separately; and a cooling fluid can be stored into the film micro-pipe to form the flat film-type cooling device formed by compounding the micro-pipe and cooling fins.

Owner:M VICTORY SPECIFIC MATERIAL

Laser-etched polypropylene modified material and preparation method thereof

The invention relates to a laser-etched polypropylene modified material and a preparation method thereof. The laser-etched polypropylene modified material is prepared from the following components: 62to 92.8 percent of polypropylene, 5 to 30 percent of talcum powder, 1 to 5 percent of laser-etching master batch, 0.1 to 0.5 percent of coupling agent, 0.5 to 1 percent of lubricant, 0.5 to 1 percentof dispersant and 0.1 to 0.5 percent of antioxidant. A technology comprises the following steps: firstly, adding all component materials into a mixing barrel according to the ratio and uniformly mixing; then adding a mixture into a double-screw extruder and mixing, wherein first-section extrusion temperature and second-section extrusion temperature of the double-screw extruder are 170 to 180 DEGC, extrusion temperature of other sections is 190 to 230 DEG C and the total staying time of reactants in the double-screw extruder is 3 to 8min; finally, after extruding the obtained material, cooling and dicing to obtain the needed laser-etched polypropylene modified material. The material provided by the invention is used on new energy source automobiles at present and the work of printing, spraying paint and the like on original products is omitted; meanwhile, the environment protection problem caused by links including paint spraying and the like are solved; the material provided by the invention is adaptive to requirements on the development of the times and has a wide application prospect.

Owner:苏州晋圣博高分子材料科技有限公司

Cable production equipment

InactiveCN102254624ASimple and compact structureGood molding stabilityCable/conductor manufactureMaterial supplyEngineering

The invention relates to cable production equipment. According to the cable production equipment, three processes, i.e., package material conveying, carbon powder conveying and cable conveying, are mutually independent; the synchronous and ordered control of the three processes is completed by using a CAN (Controller Area Network)open bus control technology; an installation mode of two rolls of rolled material is adopted in a package material supply mechanism to realize the advance in-place placement of a standby package material, and therefore, the time is saved; the application of a crawler-type traction mechanism combined with a servo motor is adopted in a cable forming and traction mechanism so that the cable traction speed is stable, the forming position is accurate, and the traction pull is stable; a packaging and forming mechanism is used for carrying out stable turndown forming on the package material by applying a cylindrical turndown former so that the attractive appearance and the reliability of packaging and forming are ensured; a profile modeling traction wheel mechanism, an appropriate tension mechanism and the control of the servo motor are adopted by a gluing and grinding mechanism and a forming and traction mechanism, so that the advantages of stable forming speed, even forming tension, attractive appearance of gluing and grinding and firmness and reliability in gluing are achieved by the package material. The cable production equipment has the advantages of simple and compact structure, good forming stability and wide application range.

Owner:LIGHT INDAL XIAN MECHANIC DESIGN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com