Hot-rolled flat plate for X80 high-wear-resistant hot-bending elbows and production method of hot-rolled flat plate

A wear-resistant, hot-bending technology, which is applied in the field of high-pressure manufacturing of steel for hot-bending pipes and hot-rolled flat plates for large-diameter oil and gas pipelines, can solve problems such as poor wear resistance, many alloy elements, and production costs. Advanced problems, to achieve the effects of reasonable composition design, high hardness, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

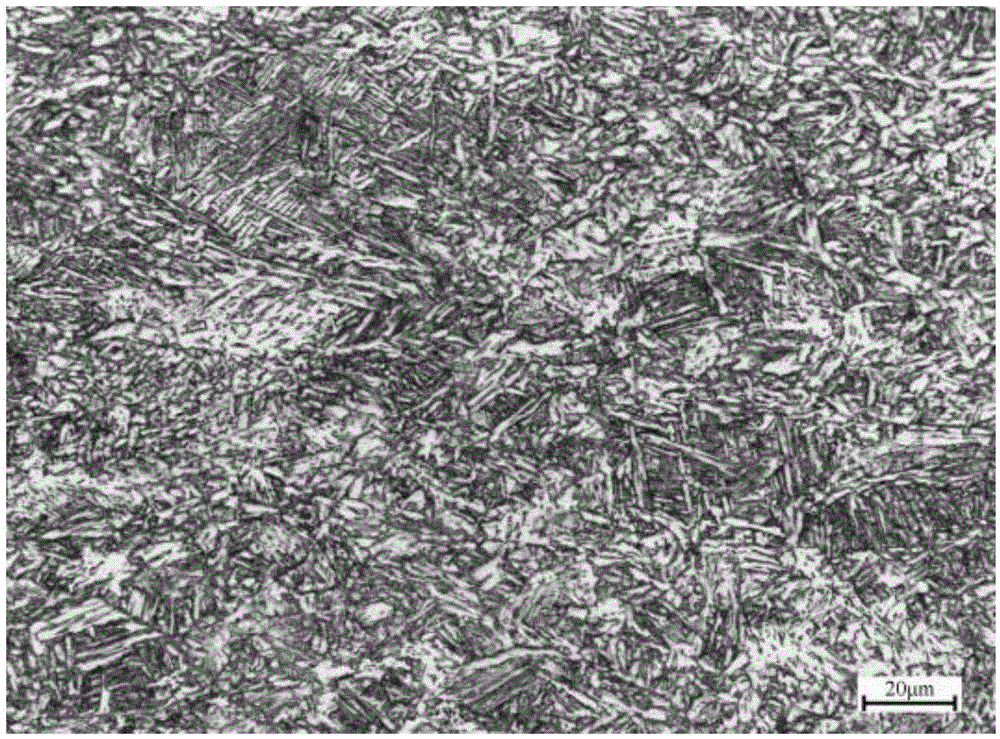

Image

Examples

Embodiment Construction

[0025] Below by embodiment the present invention will be further described.

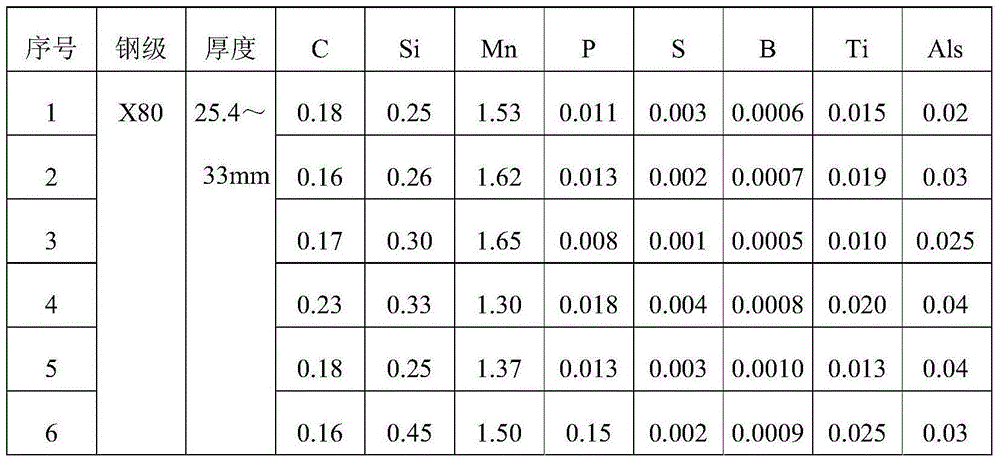

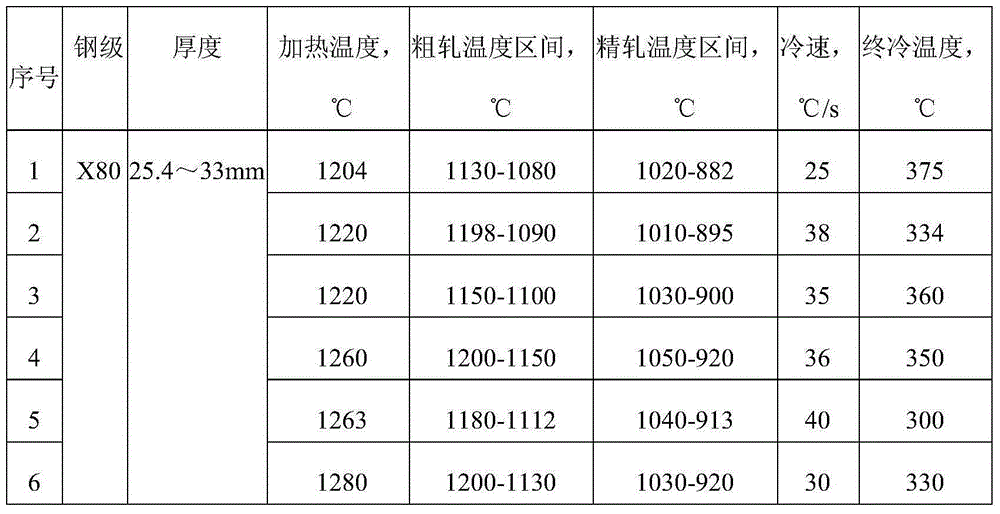

[0026] In the embodiment of the present invention, smelting, out-of-furnace refining, continuous casting, rolling, and cooling are carried out according to the composition ratio of the technical proposal. The composition of the steel of the embodiment of the present invention is shown in Table 1. The rolling process parameters of the steel in the embodiment of the present invention are shown in Table 2. The performance of the steel of the embodiment of the present invention is shown in Table 3. The performance of the steel of the embodiment of the present invention after simmering is shown in Table 4.

[0027] Table 1 Composition (wt %) of the embodiment steel of the present invention

[0028]

[0029] The rolling process parameter of table 2 embodiment steel of the present invention

[0030]

[0031] The performance of table 3 embodiment steel of the present invention

[0032]

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com