Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Meet the requirements of corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

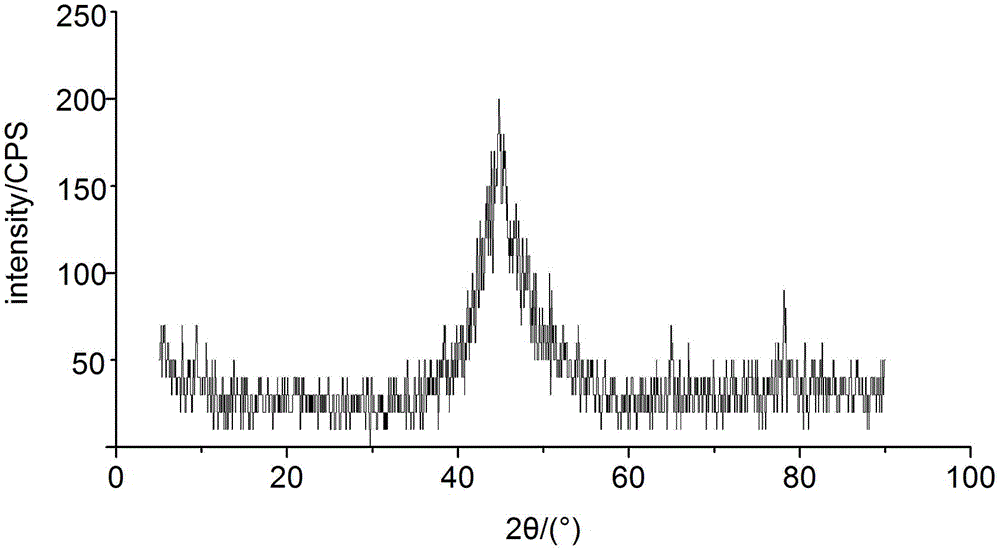

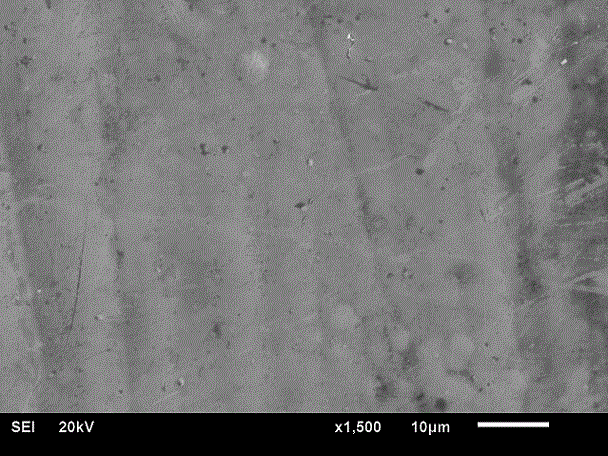

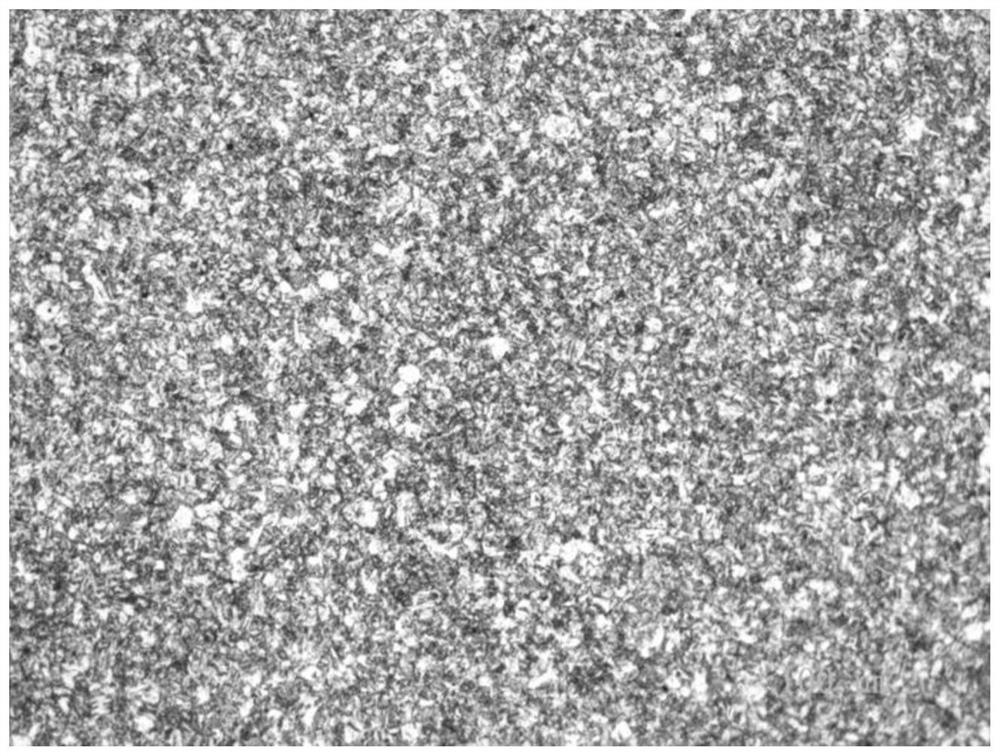

Ultrahigh-strength martensitic stainless steel and preparation method thereof

ActiveCN106906429AImprove mechanical propertiesImprove corrosion resistanceMartensitic stainless steelIngot

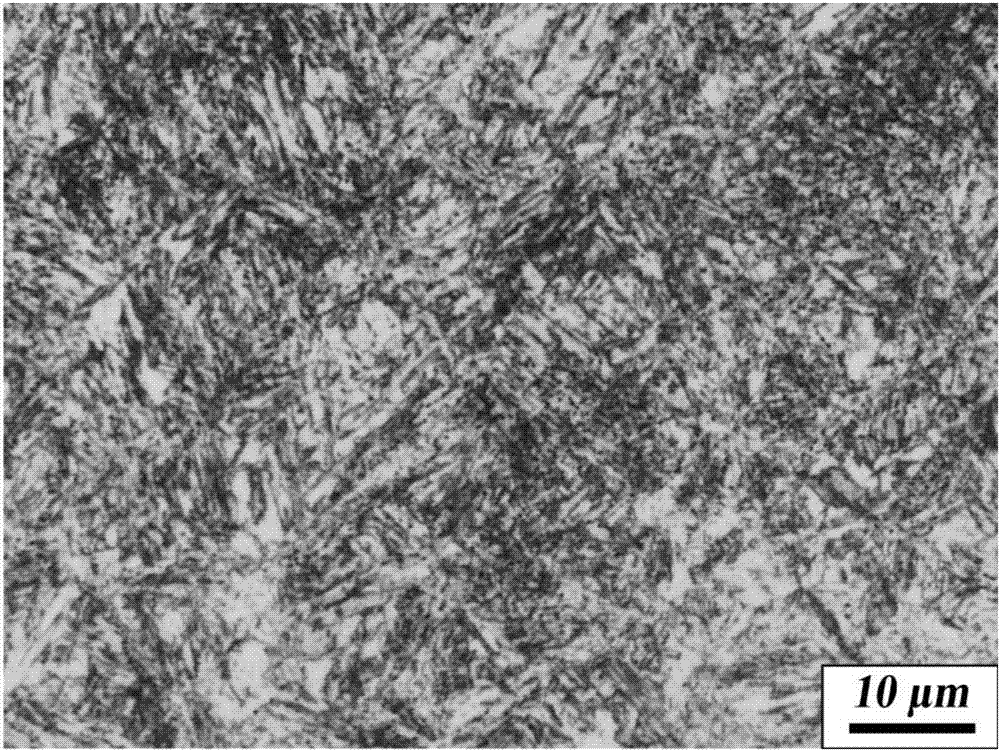

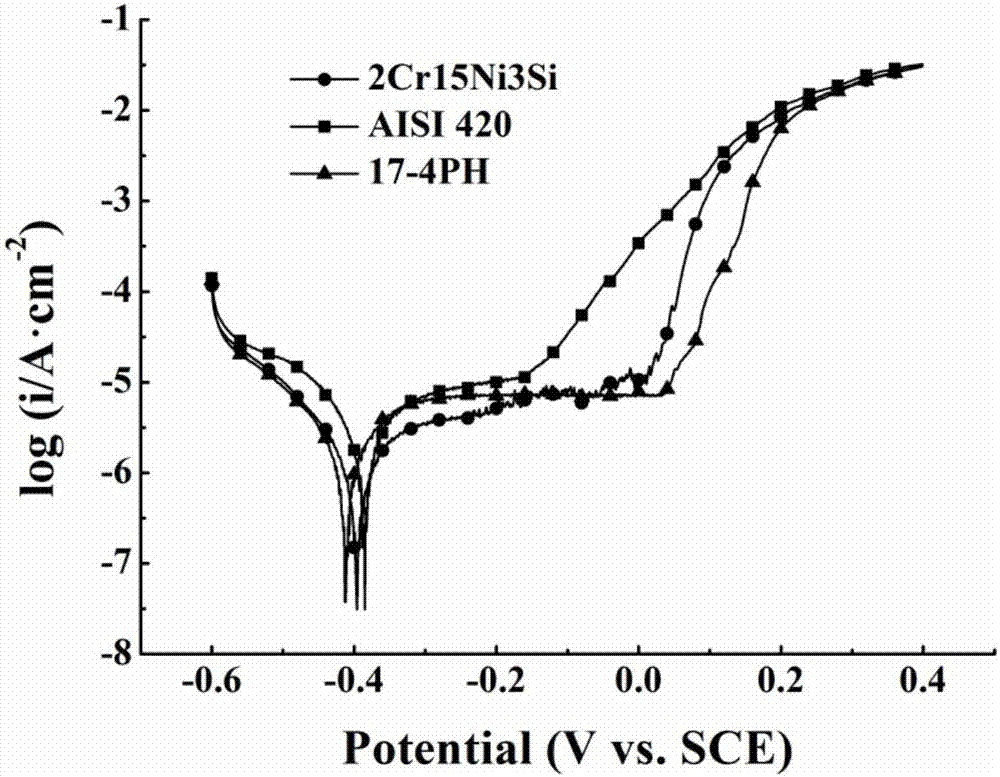

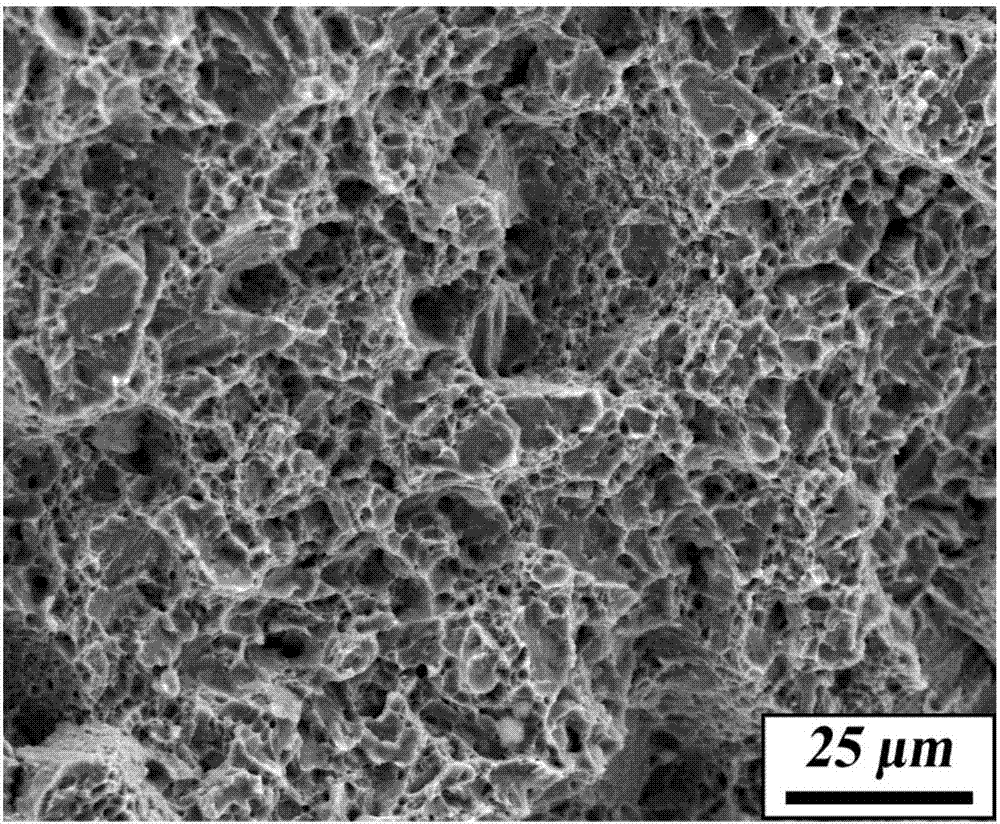

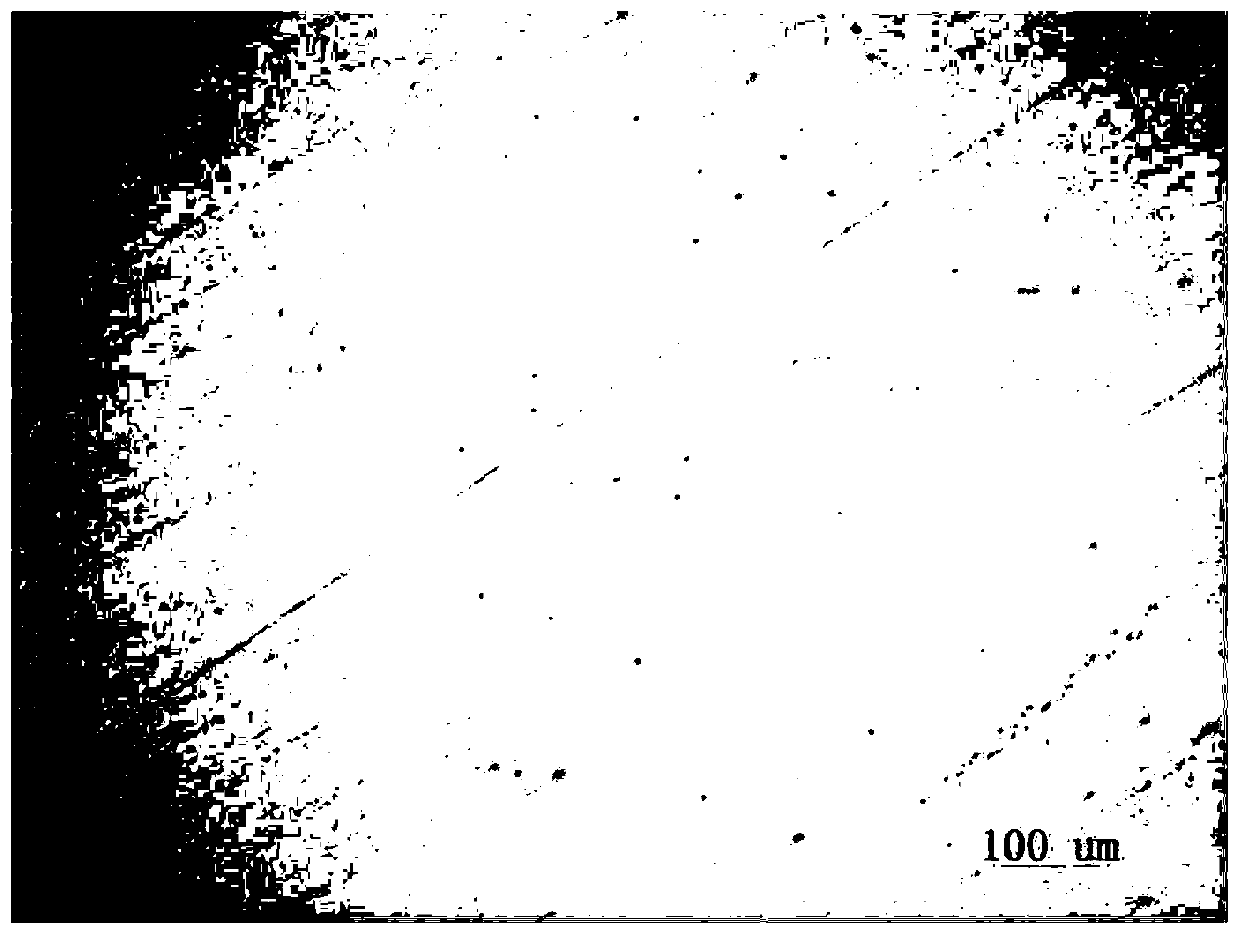

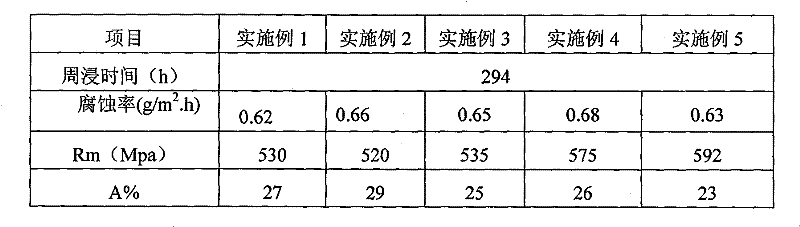

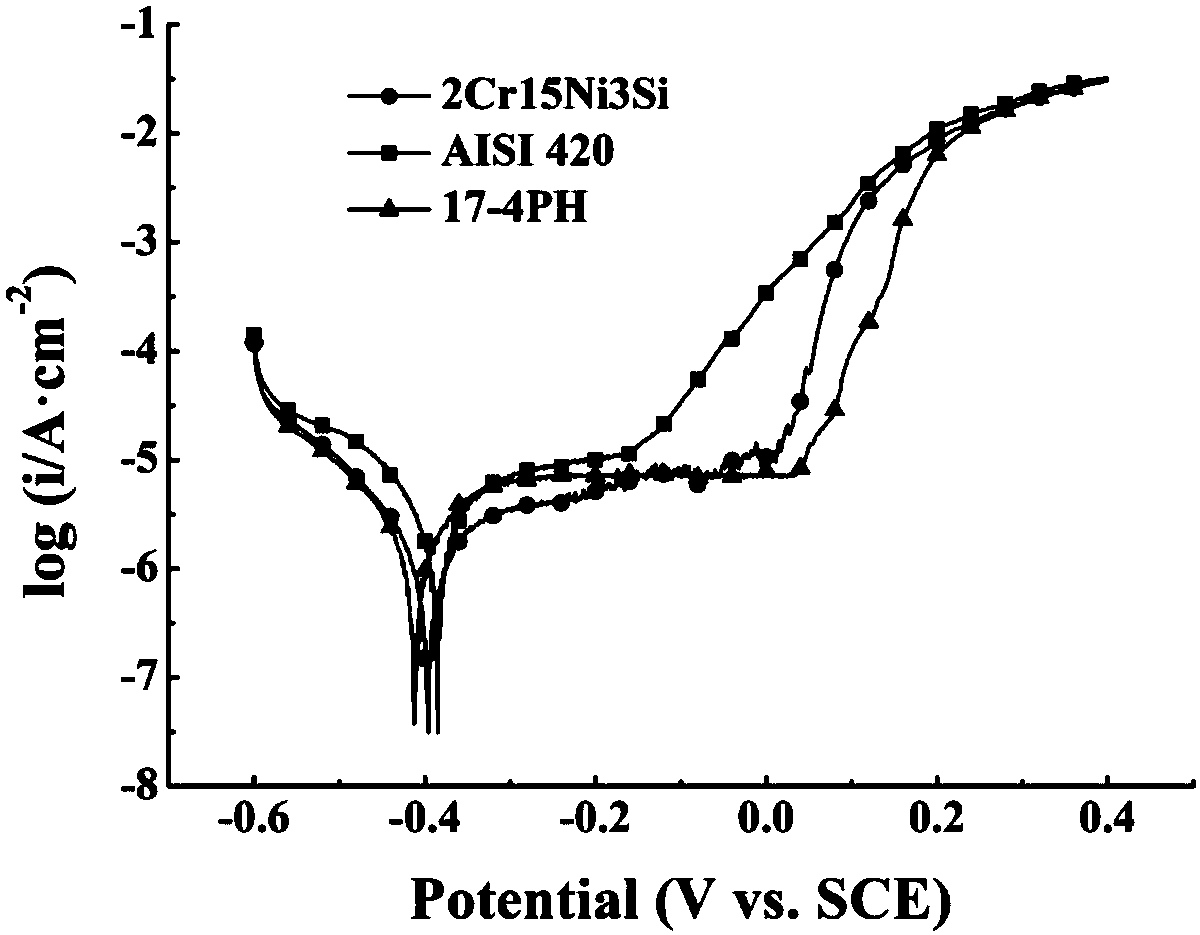

The invention discloses ultrahigh-strength martensitic stainless steel and a preparation method thereof. The ultrahigh-strength martensitic stainless steel is high in yield strength, high in tensile strength, good in ductility and good in impact toughness. The preparation method comprises the steps as follows: Step 1, a raw material is prepared from stainless steel components in percentage by weight according to the burnt value, is smelted in the vacuum environment and is poured to form a steel ingot; the steel ingot is prepared from components in percentage by weight as follows: 0.10%-0.25% of C, 11.0%-17.0% of Cr, 0.5%-2.0% of Mn, 1.1%-3.0% of Si, 0.1%-4.0% of Ni, 0.1%-0.3% of Cu, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance of Fe and inevitable impurity elements; Step 2, forging of the steel ingot is started at 1,050-1,200 DEG C, the finish forging temperature ranges from 880 DEG C to 920 DEG C, the forging ratio is larger than or equal to 5, and air cooling is performed after forging; Step 3, a forging is subjected to heat preservation at 950-1,050 DEG C for 2-4 h, is subjected to water quenching and then is tempered at 200-300 DEG C for 2-4 h, and the ultrahigh-strength martensitic stainless steel is obtained after natural cooling.

Owner:XI AN JIAOTONG UNIV

Corrosion resistant cupronickel alloy material for plate heat exchanger and processing technique thereof

ActiveCN101100715AMeet the requirements of corrosion resistanceLow costPlate heat exchangerCupronickel

A corrosion-proof German silver band for plate heat exchanger and its production are both disclosed herewith. It contains (wt%): Ni 9.0-11.0, Mn 0.5-1.0, Fe 1.0-1.8, Ce 0.05-0.2, and waste Cu alloy with Cu balanced, and with impurity not more than 0.7. It is produced by: weighing, smelting, casting, hot rolling, end-surface milling, primary rolling, inter-annealing, cold rolling, inter-annealing, edge cutting, pre-rolling, inter-rolling, fine rolling, final annealing, surface treating, cutting, and packing. It is of size (0.4-8.5mm)X(300-1000mm)X(500-3000mm), performance of Rm not less than 320MPa, A11.3 not less than 30%, Hv1 not less than 85, grain 0.015-0.045mm, and Ra larger than 0.2um without scratches, and can meet demands of PHE and bactericidal washing machine.

Owner:中铝洛阳铜加工有限公司

Corrosion resistant brass alloy material for plate heat exchanger and processing technique thereof

A corrosion-proof brass band for plate heat exchanger and its production are both disclosed herewith. It contains (wt%): Cn 76-79, Al 1.0-3.5, Ni 0.3-1.5, B 0.002-0.015, As 0.01-0.1, Ce 0.05-0.2, and balanced with Zn, and with impurity not more than 0.3. It is produced by: weighing, smelting, casting, hot rolling, end-surface milling, primary rolling, inter-annealing, cold rolling, inter-annealing, edge cutting, pre-rolling, inter-rolling, fine rolling, final annealing, surface treating, cutting, and packing. It is of size (0.4-8.5mm)X(300-1000mm)X(500-3000mm), performance of Rm not less than 410MPa, A11.3 not less than 40%, Hv1 not less than 90, grain 0.010-0.030mm, and Ra larger than 0.2um without scratches.

Owner:中铝洛阳铜加工有限公司

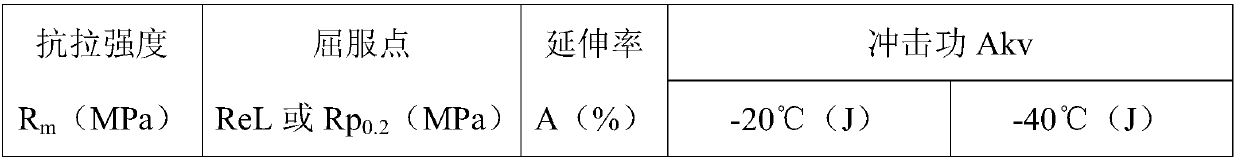

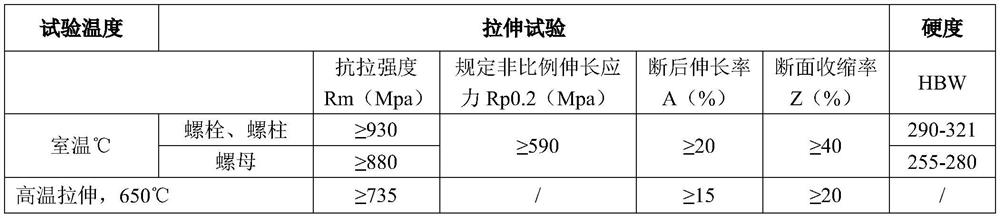

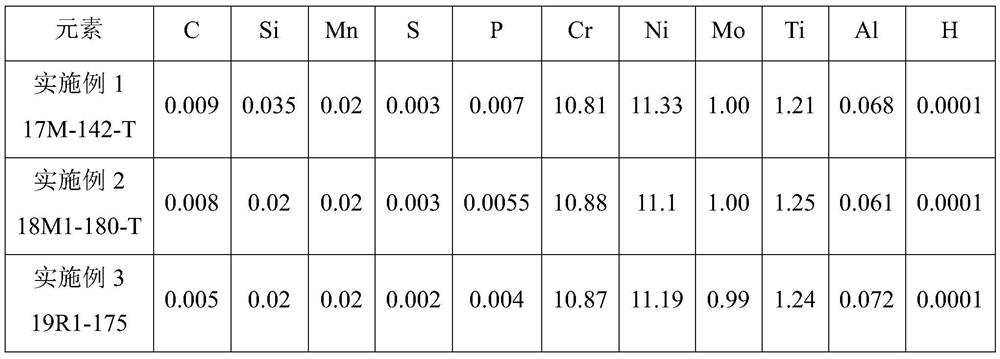

Anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for fastener, and manufacturing method thereof

ActiveCN111218618AIncrease chromium contentImprove hydrogen embrittlement resistanceMetallic materialsSS - Stainless steel

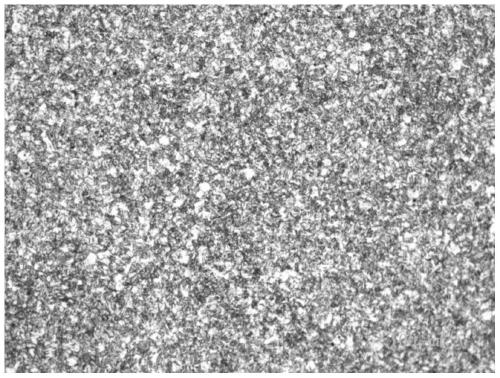

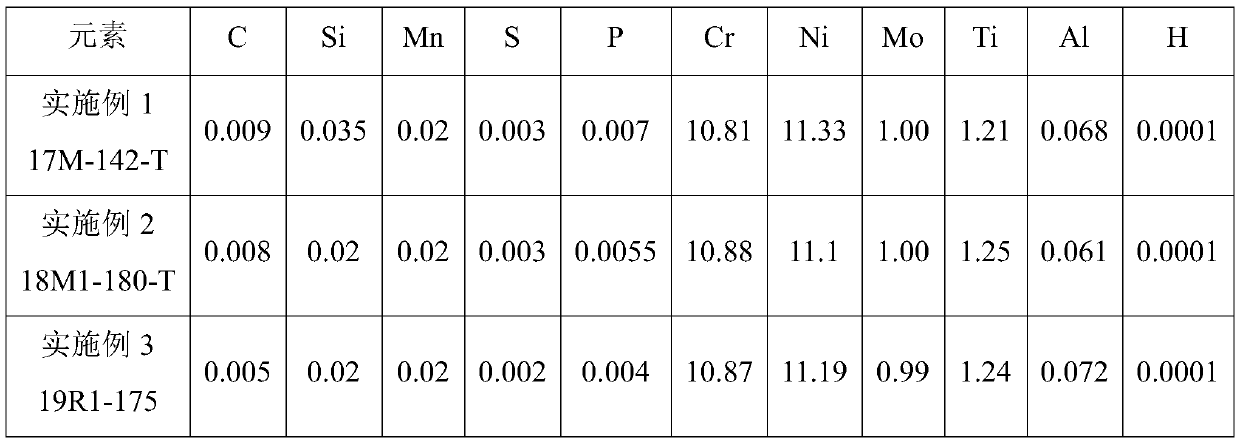

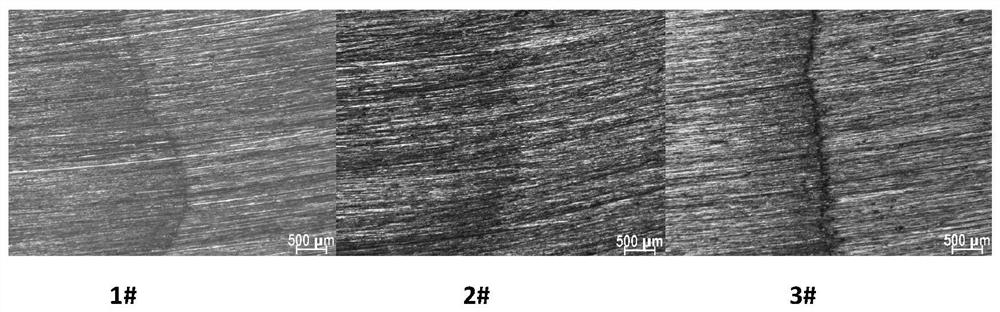

The invention relates to an anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for a fastener, and a manufacturing method thereof, belongs to the technical field of metal materials, and solves the problem of low matching degree of anti-hydrogen embrittlement property and high toughness of a fastener used in an aerospace environment. The anti-hydrogen embrittlement, high-strength and high-toughness stainless steel bar for the fastener comprises the following elements in mass fraction: 0.0001%-0.01% of C, 0%-0.10% of Si, 0.01%-0.15% of Mn, 0%-0.005% of S, 0%-0.015%of P, 10.50%-12.50% of Cr, 10.70%-11.50% of Ni, 0.75%-1.25% of Mo, 1.20%-1.70% of Ti, 0%-0.10% of Al, not greater than 1.5ppm of H, and the balance iron and inevitable impurities. The stainless steelbar meeting the comprehensive performance of high strength, high toughness and anti-hydrogen embrittlement property simultaneously is prepared, and the use requirement of the fastener making contactwith a corrosive medium and used for the aerospace environment is met.

Owner:CENT IRON & STEEL RES INST

Compound passivating fluid for mechanical zinc coating

InactiveCN102864447AImprove passivation effectMeet the requirements of corrosion resistancePolyurea/polyurethane coatingsMetallic material coating processesCompound (substance)Solvent

The invention belongs to the technical field of metal surface treatment and specifically relates to a compound passivating fluid for a mechanical zinc coating. The compound passivating fluid comprises a component A and a component B, wherein the component A is waterborne polyurethane, of which the weight percent is 8-18% in the compound passivating fluid; the component B is an inorganic passivator, of which the weight percent is 2.4-1.5% in the compound passivating fluid; and the balance is deionized water. The pH value of the compound passivating fluid is adjusted to 6-9 by using the sulfuric acid with the mass fraction of 98%. The compound passivating fluid has a better passivating function to a mechanical zinc coating workpiece; the environmental pollution caused by hexavalent chromium is avoided; a formed film is bright and transparent, is durable and excellent in flexibility, has a certain mechanical property, is excellent in water and chemical solvent resistance and is long in salt mist resisting time. The coating has the advantages of self-repairing function, high stability, low cost, simple preparation process and simple use method.

Owner:SHANDONG UNIV OF TECH

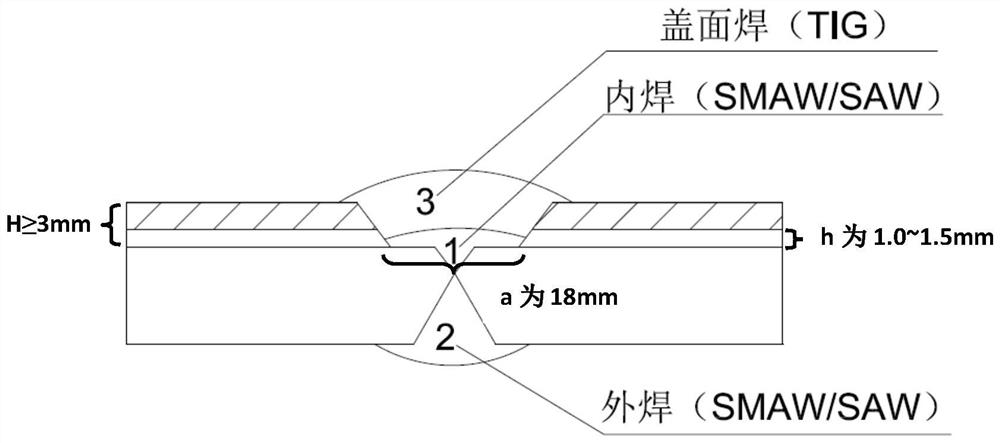

Nickel-based high-corrosion-resistance composite steel pipe welding method

InactiveCN111659980AGuaranteed toughnessMeet the requirements of corrosion resistanceArc welding apparatusMechanical propertyPipe welding

The invention discloses a nickel-based high-corrosion-resistance composite steel pipe welding method. According to the welding method, through reasonable groove design, an N08825 / L450MS composite steel pipe is welded through base layer positioned welding and double-face SAW welding or double-face SMAW welding and cladding TIG welding, the welding efficiency is improved, the mechanical property ofa welding joint is matched with that of base metal, the requirement for the corrosion resistance of the welding joint is met while the toughness of the welding joint is guaranteed, and meanwhile the working efficiency can be improved. Tests show that by the adoption of the welding method, various mechanical properties of the welded joint can meet the standard requirements. Intergranular corrosion,pitting corrosion and HIC corrosion tests are carried out on the composite pipe welding joint, the intergranular corrosion rate and the pitting corrosion rate both meet the standard requirements, andcracks do not appear in the HIC tests.

Owner:NANJING IRON & STEEL CO LTD

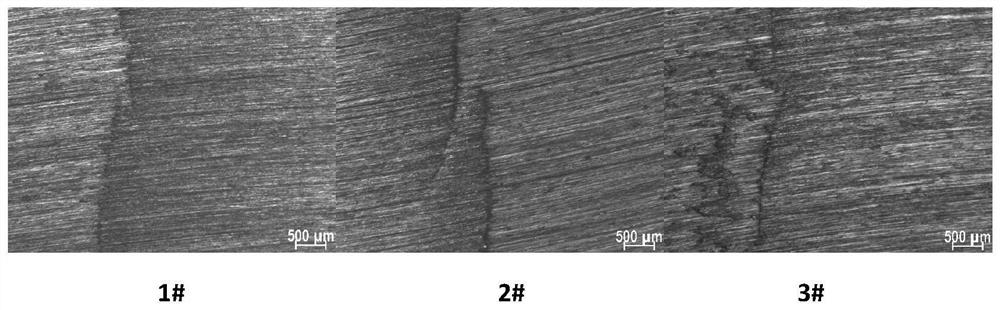

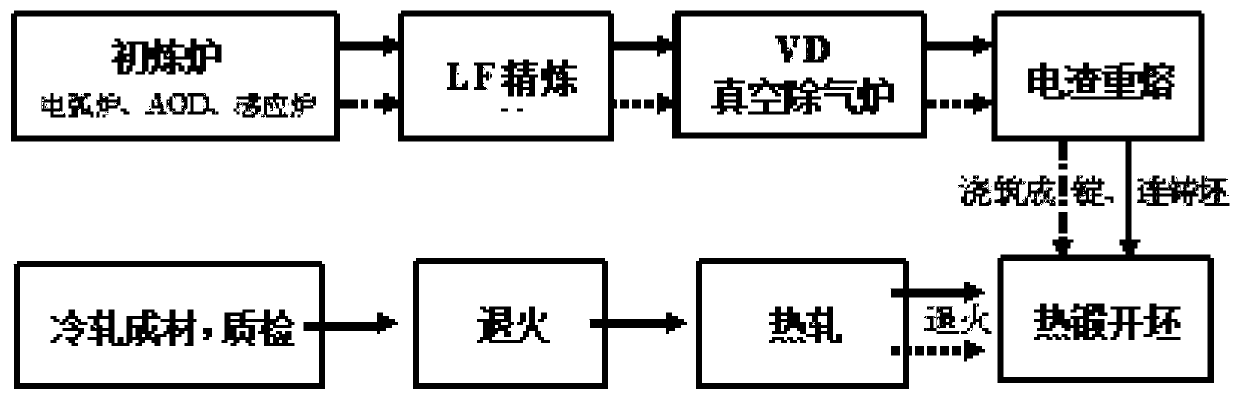

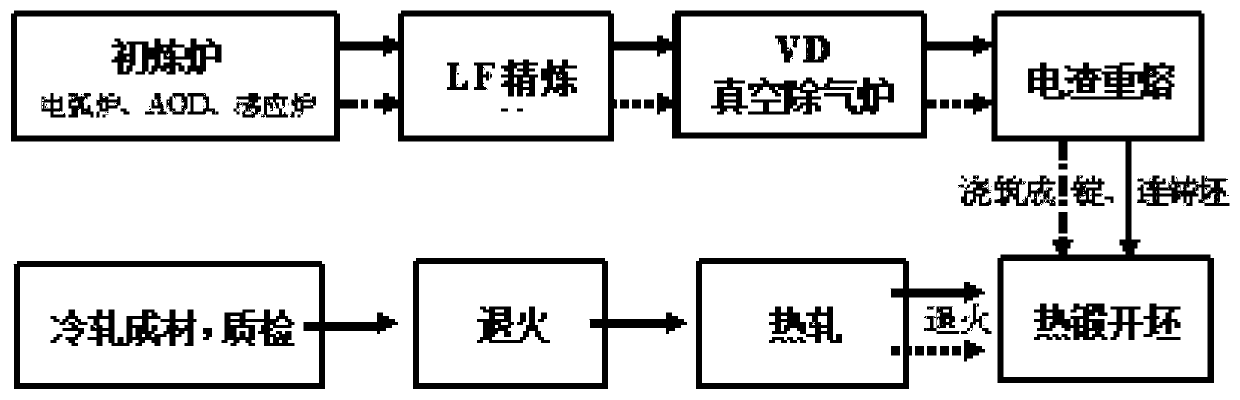

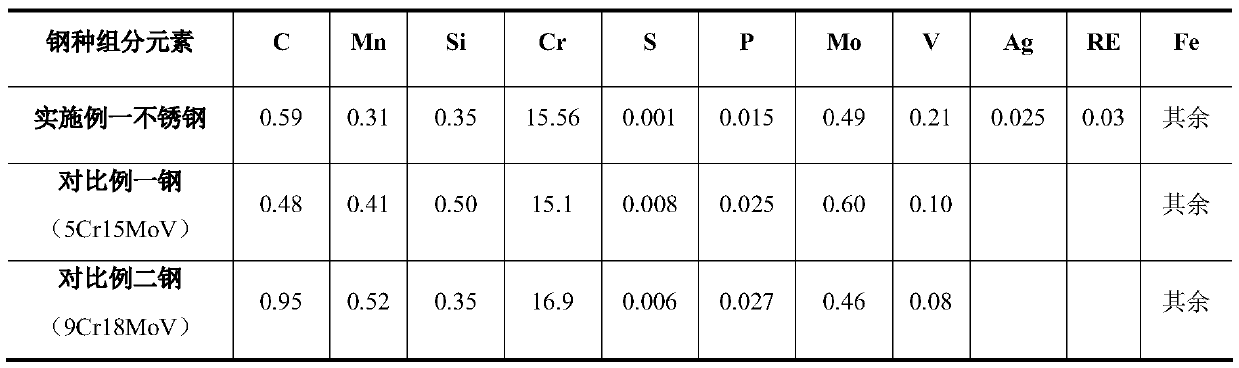

High-strength high-corrosion-resistance anti-microbial stainless steel and preparation method thereof

InactiveCN109972040AImproves strength and hardnessImprove hardenabilityElectric furnaceProcess efficiency improvementRare-earth elementCorrosion resistant

The invention discloses high-strength high-corrosion-resistance anti-microbial stainless steel and a preparation method of the high-strength high-corrosion-resistance anti-microbial stainless steel. The stainless steel has high performance, particularly high antibacterial property, high safety, ultra-high strength, high corrosion resistance, high wear resistance and good toughness. Compared with existing stainless steel for cutters, the high-strength high-corrosion-resistance anti-microbial stainless steel has the advantages of high hardness, high corrosion resistance, good antibacterial property and the like. Compared with steel for existing cutters, the content of carbon and chromium is adjusted in components, the silver element and the rare earth element are added, so that the materialhas high hardness and sharpness besides corrosion resistance and antibacterial property, the requirements of consumers can be met, and the grade of the cutters is improved. The steel has the high hardness of 56.0-60.0HRC, high pitting corrosion resistance and salt fog resistance. The steel is applicable to tools such as kitchen knives, scissors and the like, and can also be applied public facilities, household appliances and medical appliances.

Owner:SHANGHAI UNIV

Pneumatic valve actuator

PendingCN108087610AImprove corrosion resistanceImprove rigidityOperating means/releasing devices for valvesRotational axisPneumatic valve

The invention relates to a pneumatic valve actuator. The pneumatic valve actuator comprises an air cylinder assembly, a piston assembly, a drive output assembly, an end cover assembly and a spring return assembly, wherein the air cylinder assembly comprises an air cylinder; the piston assembly comprises two pistons which are symmetrically arranged left and right; the two pistons are oppositely arranged in the horizontal direction; the two pistons are arranged in an inner cavity of a cylinder body main shaft of the air cylinder; the drive output assembly comprises a rotary shaft and an output insert; the output insert is arranged in a central through hole of the rotary shaft in a limiting mode, and rotates along with the rotary shaft; the drive output assembly is arranged in the air cylinder; a rack section part of the rotary shaft is in engaged and power connection with first racks of two pistons of the piston assembly; the end cover assembly comprises two end covers; the two end covers are separately mounted on the air cylinder from left and right ends; the spring return assembly comprises 2n springs; and the two groups of the springs are separately arranged between the end coverat one side inside the air cylinder and the corresponding piston to elastically support the corresponding piston. The actuator can operate for a long time under a high-corrosion special working condition.

Owner:JIANGSU HUASHENG PLASTIC

Application of a diamond-like film on the impeller

InactiveCN102261347ANo deformationMeet the normal working environmentPump componentsPumpsImpellerDiamond-like carbon

The invention relates to a fan, in particular to the application of a diamond-like film on an impeller. The diamond-like carbon film is used as a coating, which is plated on the flow channel of the impeller. The present invention adopts the omni-directional plasma injection method on the inner wall of the irregular shape such as the impeller, and coats the diamond-like film on the inner wall of the irregular shape, so that the inner surface of the irregular shape can be uniformly realized, and avoids the influence of some conventional surface heat treatment on the shape of the product, etc. Restriction, and the uniform coating of DLC film inside the impeller flow channel can effectively improve the service life and efficiency of the impeller while avoiding the problem of regular online cleaning.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

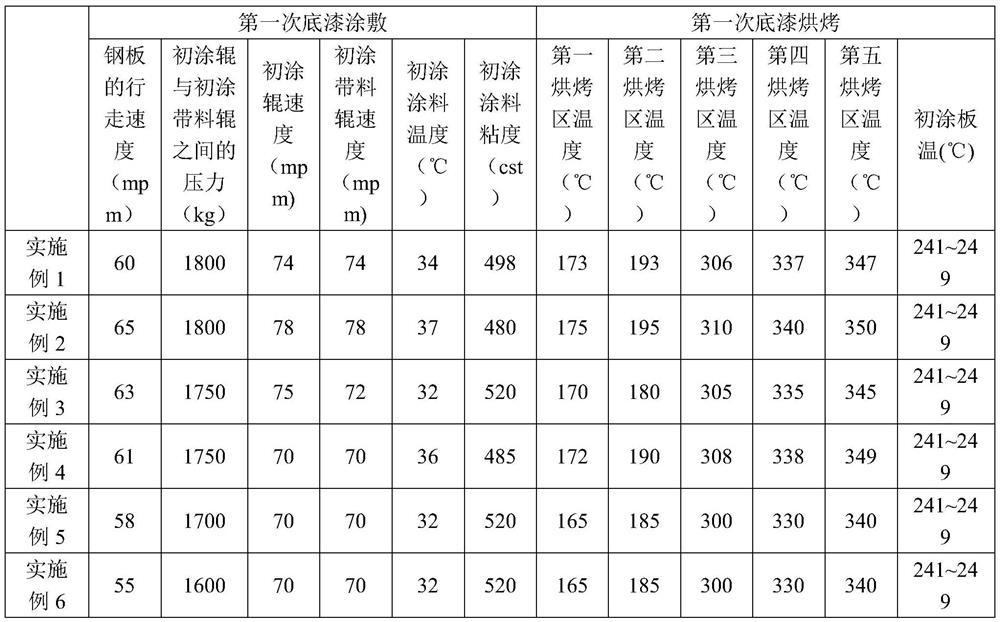

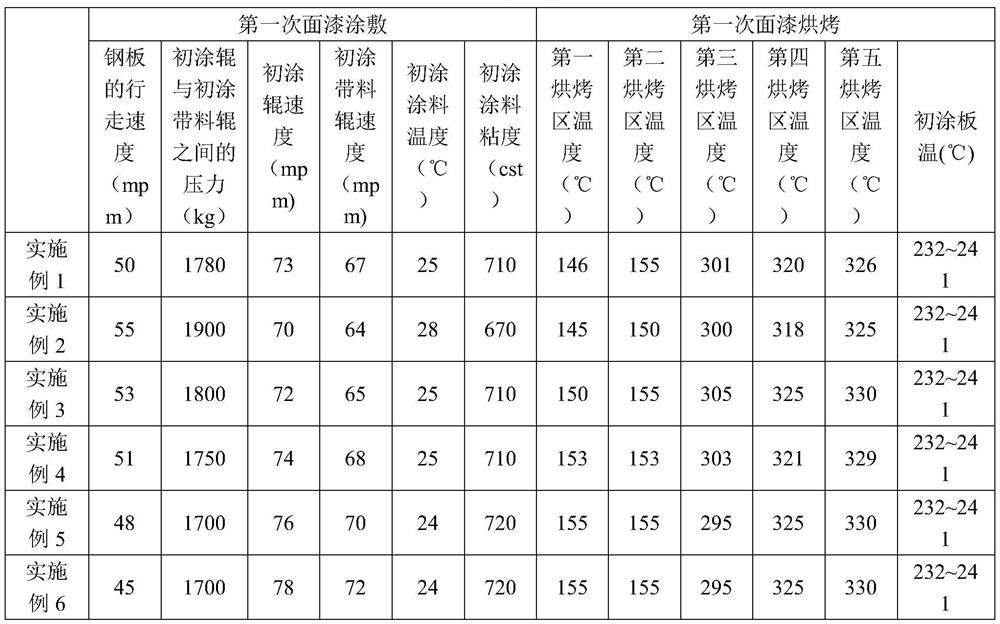

Roller coating process of an ultra-thick coating color-coated steel plate

InactiveCN111822297AIncrease coating thicknessMeet the requirements of corrosion resistancePretreated surfacesSpecial surfacesCoatingSteel plates

The invention discloses a roller coating process of an ultra-thick coating color-coated steel plate. The roller coating process comprises at least two primer coating steps and at least two finish paint coating steps. In the first primer coating step, the pressure between a primary coating roller and a primary coating material roller is controlled to be 1600-1800kg. After the first primer coating step, the steel plate is baked by a baking oven, the interior of the baking oven is divided into a first baking area, a second baking area, a third baking area, a fourth baking area and a fifth bakingarea in sequence in the moving direction of the steel pipe, wherein the baking temperature in each baking area is sequentially increased. In the second primer coating step, the pressure between a finish coating roller and a finish coating material roller is controlled to be 1600-1800kg. After the second primer coating step, the steel plate is baked by the baking oven. The moving speed of the steelplate is controlled within 55-65mpm in the first primer coating step, the second primer coating step and baking steps afterwards.

Owner:BAOSHAN IRON & STEEL CO LTD

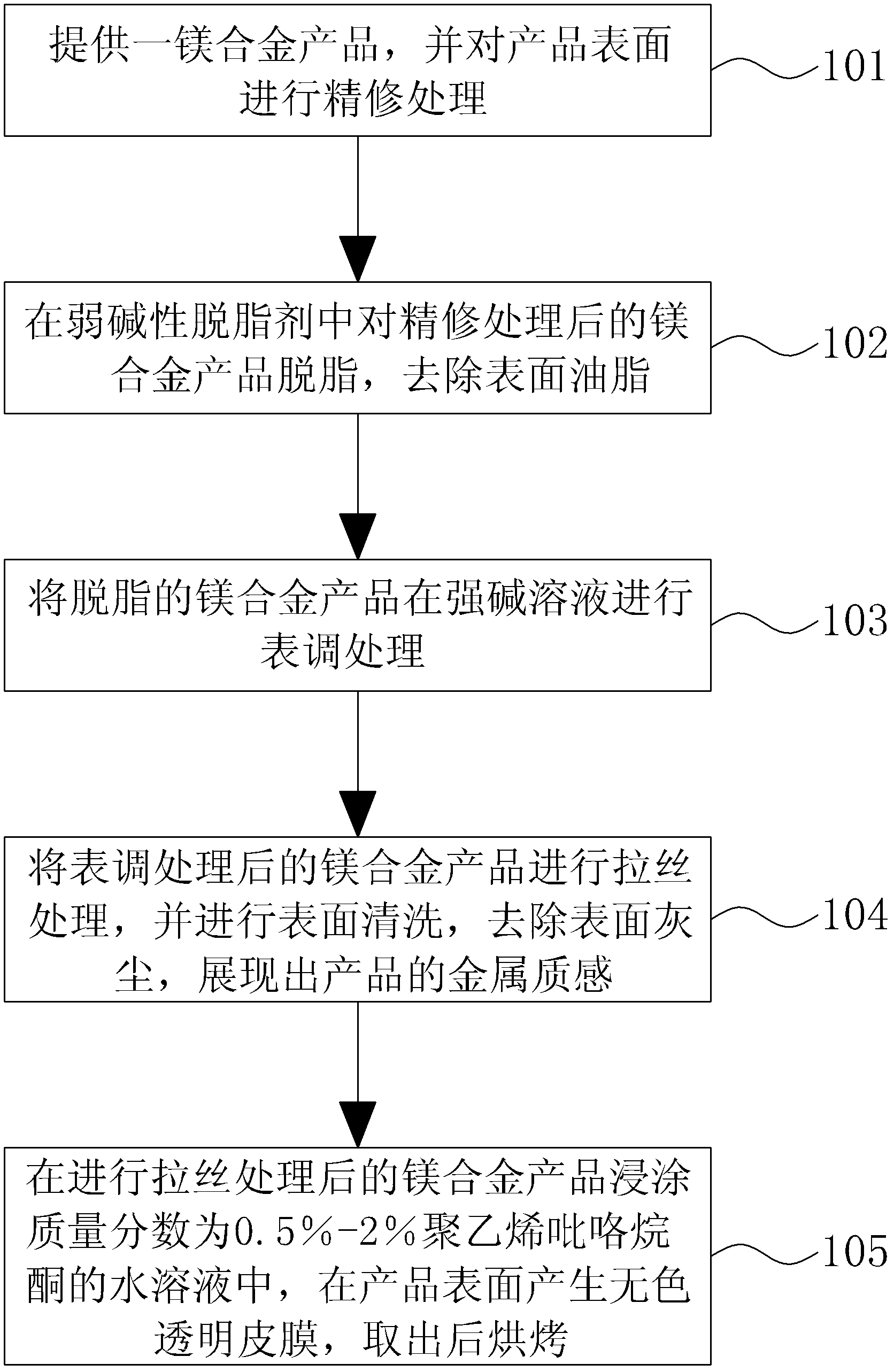

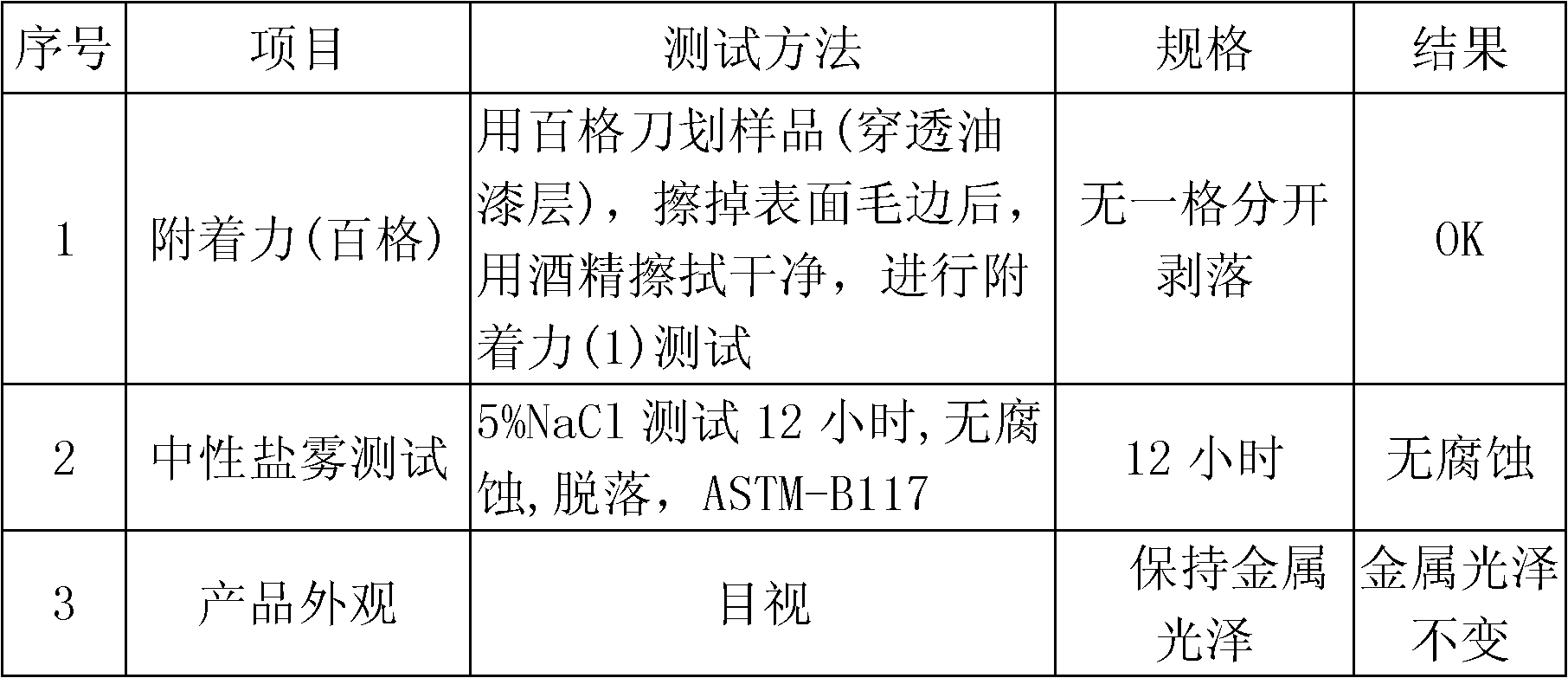

Method for manufacturing magnesium alloy colorless transparent film and product with the same

ActiveCN103121005AShow metal textureMeet the requirements of corrosion resistancePretreated surfacesSpecial surfacesSurface conditionsDip-coating

The invention discloses a method for manufacturing a magnesium alloy colorless transparent film and a product with the same. The method includes the following steps: providing a magnesium alloy product, and finishing the product surface; degreasing the finished magnesium alloy product in an alkalescent degreasant and removing surface grease; carrying out surface conditioning on the degreased magnesium alloy product in strong aqueous alkali; carrying out brushed treatment on the surface-conditioned magnesium alloy product, cleaning the surface, removing surface dust, and showing metal texture of the product; dip-coating the brushed magnesium alloy product in aqueous solution of polyvinylpyrrolidone with the mass fraction of 0.5-2%, generating the colorless transparent film on the product surface, taking out the film and then drying and warming the film by the fire. The product with is the one obtained after being processed with the method. Therefore, metal texture of the brushed magnesium alloy workpiece can be shown, and the requirement for corrosion resistance is also met.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

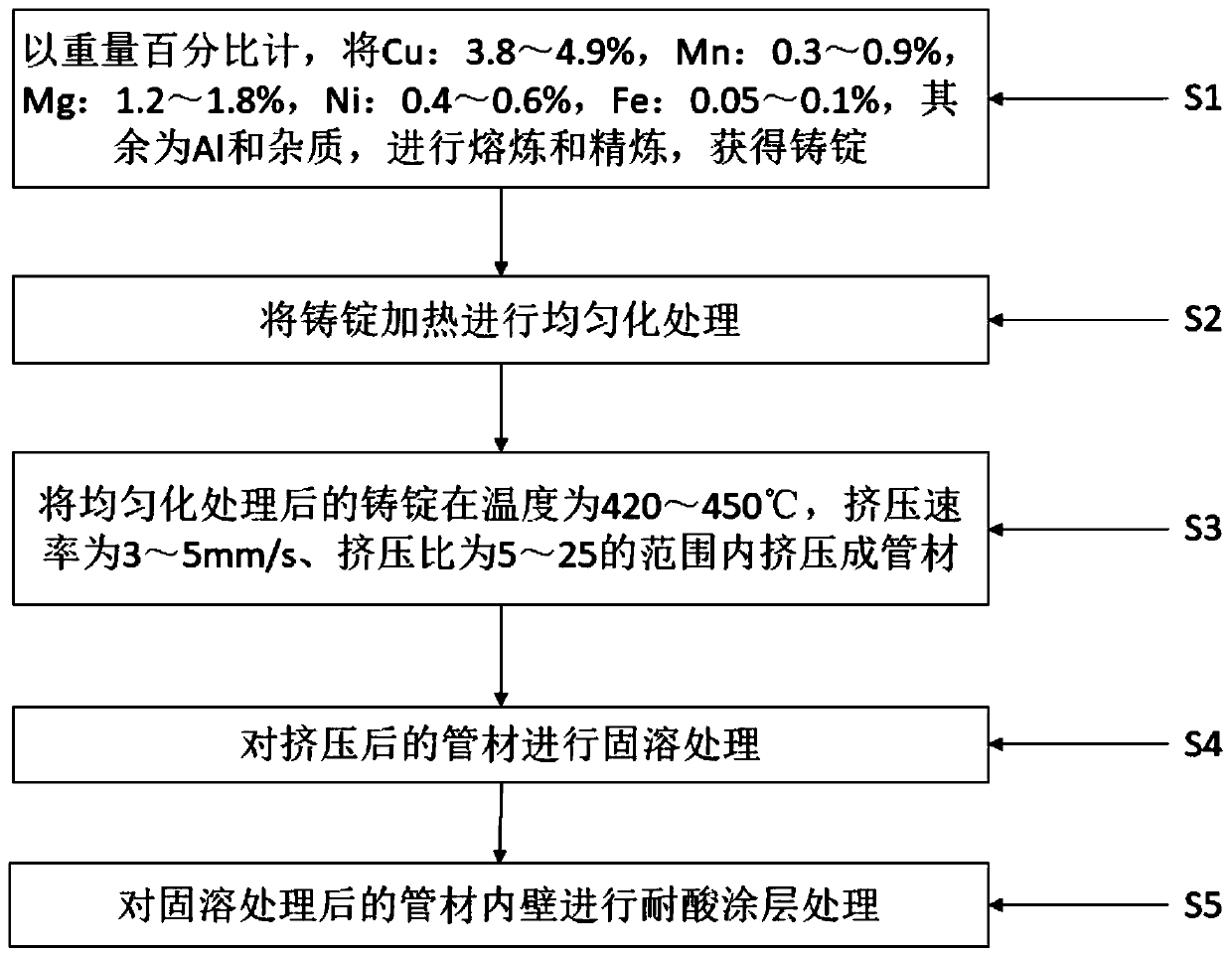

Soluble acid-resistant aluminum alloy oil pipe, preparation method thereof and aluminum alloy thereof

ActiveCN110699581AMeet the requirements of corrosion resistanceMeet strength requirementsLiquid surface applicatorsDrilling rodsSolution treatmentIngot

The invention discloses a soluble acid-resistant aluminum alloy oil pipe, a preparation method thereof and aluminum alloy thereof. The oil pipe comprises an oil pipe material and an acid-resistant coating on the inner wall of the pipe material, wherein the oil pipe material is made of aluminum alloy; and the aluminum alloy comprises the following components in percentage by weight: 3.8 to 4.9% ofCu, 0.3 to 0.9% of Mn, 1.2 to 1.8% of Mg, 0.4 to 0.6% of Ni, 0.05 to 0.1% of Fe and the balance Al and impurities. The preparation method for the pipe material comprises the following steps of: smelting and refining the components to obtain a cast ingot; heating the cast ingot for homogenization treatment; extruding the homogenized cast ingot into the pipe material; performing solution treatment on the extruded pipe material; and finally, performing acid-resistant coating treatment on the inner wall of the pipe material subjected to the solution treatment. The oil pipe material can be dissolved in formation water, so that the task of fishing the oil pipe after production can be completely avoided; the inner wall of the pipe material is acid-resistant, so that the problem of corrosion, breakage and separation of the pipe wall is solved; and the oil pipe can be used as a pipeline for conveying acid liquor, and the strength meets the strength requirements of oil well formation and operation.

Owner:优模(上海)新材料科技有限公司

High-toughness gas-electric vertical welding flux-cored wire for corrosion-resistant cot steel and preparation method thereof

ActiveCN105234588BImprove corrosion resistanceEasy constructionWelding/cutting media/materialsSoldering mediaElectrolysisManganese

The invention discloses a high-toughness electrogas vertical welding flux-cored wire matched with corrosion-resistant COT steel and a preparation method thereof. The high-toughness electrogas vertical welding flux-cored wire comprises a low-carbon steel sheath and a flux core wrapped in the low-carbon steel sheath, wherein the flux core is prepared from the following components: 0.32-0.33 weight part of copper powder, 0.06-0.07 weight part of tungsten powder, 0.07 weight part of antimony powder, 0.58-0.6 weight part of calcium fluoride, 0.55-0.85 weight part of sodium carbonate, 0.4 weight part of potassium carbonate, 0.08 weight part of aluminum powder, 1.3-1.7 weight parts of electrolytic manganese, 0.3-0.4 weight part of silicon iron, 0.55-0.7 weight part of nickel powder and 18-19 weight parts of iron powder. Compared with the prior art, through the organic preparation of the components of the flux core and the matching of the flux core and the low-carbon steel sheath, the electrogas vertical welding flux-cored wire has good corrosion resistance, a good welding process property and good physical and chemical properties.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

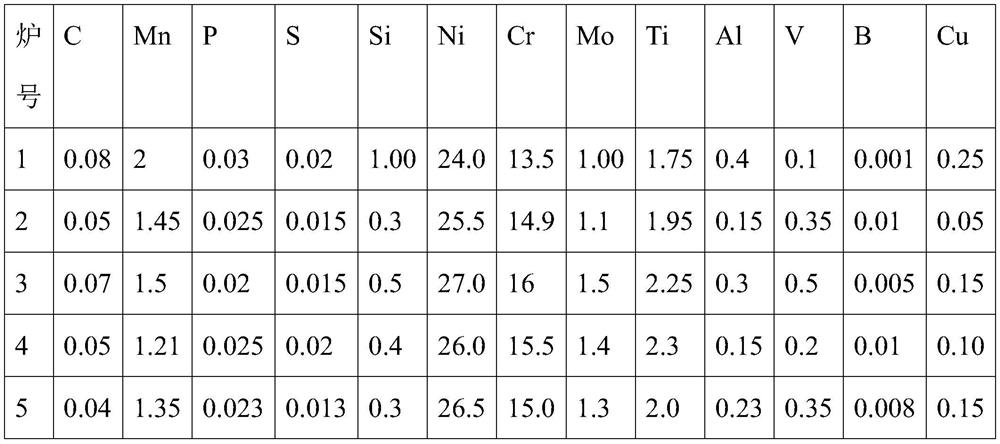

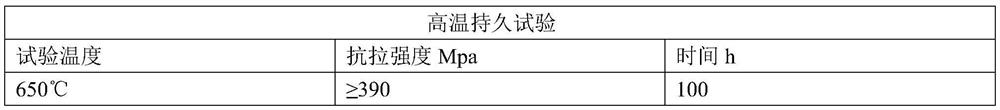

Fastener for aviation and preparation method of fastener

InactiveCN112760575AHigh temperature strengthImprove stabilityIncreasing energy efficiencyAviationHardness

The invention provides a fastener for aviation and a preparation method of the fastener. Design components of raw materials comprise, by weight percent, not larger than 0.08% of C, not larger than 2.0% of Mn, not larger than 0.03% of P, not larger than 0.02% of S, not larger than 1.0% of Si, 24.0%-27.0% of Ni, 13.5%-16.0% of Cr, 1.0%-1.5% of Mo, 1.75%-2.3% of Ti, not larger than 0.4% of Al, 0.1%-0.5% of V, 0.001%-0.010% of B, not larger than 0.25% of Cu and the balance Fe. The fastener not only has good strength and hardness, but also has good high-temperature corrosion resistance, good processing property and high thermal strength, and can completely meet the requirements of the force-bearing part fastener for aviation for materials.

Owner:江苏新核合金科技有限公司

Substitutive treatment agent for metal surface phosphating and preparation method thereof

The invention discloses a substitutive treatment agent for metal surface phosphating and a preparation method thereof, and relates to the metal surface treatment technology. The substitutive treatment agent for phosphating consists of the following components of: gamma-APS, anhydrous alcohol, fluozirconate and de-ionized water, wherein the substitutive treatment agent for phosphating consisting of the components is a silane and nanoceramic composite film; the preparation method for the silane and nanoceramic composite film which consists of the components and is used for pre-treating the metal surface comprises the following steps of: rinsing with hot water; degreasing in advance; rinsing for the first time; rinsing for the second time; rinsing for the third time; performing phosphate-free conversion; rinsing a straight bar; rinsing for the fourth time; rinsing for the fifth time; and finishing the preparation. The substitutive treatment agent and the preparation method have the advantages that: the silane and nanoceramic composite film does not rust in 48 hours after being formed on the metal surface of a cold rolled steel sheet and the like and naturally cooled so as to meet the requirement on corrosion resistance in the production process; and meanwhile, the composite silane film has high bonding force with polyester coating layers, the cross-cut test for the adhesion reaches the first grade, the comprehensive impact resistance reaches 50cm / kg, the bending resistance is less than 1mm, and the salt spray test is more than or equal to 500 hours.

Owner:ANHUI WEILAI SURFACE TECH

An environment-friendly aluminum alloy rapid electroless nickel-phosphorus additive

ActiveCN104561948BMeet the requirements of corrosion resistanceRapid depositionLiquid/solution decomposition chemical coatingElectroless nickelPotassium

Owner:哈尔滨三泳金属表面技术有限公司

Composite passivation solution for mechanical zinc coating

InactiveCN102864447BImprove passivation effectMeet the requirements of corrosion resistancePolyurea/polyurethane coatingsMetallic material coating processesSolventZinc

The invention belongs to the technical field of metal surface treatment and specifically relates to a compound passivating fluid for a mechanical zinc coating. The compound passivating fluid comprises a component A and a component B, wherein the component A is waterborne polyurethane, of which the weight percent is 8-18% in the compound passivating fluid; the component B is an inorganic passivator, of which the weight percent is 2.4-1.5% in the compound passivating fluid; and the balance is deionized water. The pH value of the compound passivating fluid is adjusted to 6-9 by using the sulfuric acid with the mass fraction of 98%. The compound passivating fluid has a better passivating function to a mechanical zinc coating workpiece; the environmental pollution caused by hexavalent chromium is avoided; a formed film is bright and transparent, is durable and excellent in flexibility, has a certain mechanical property, is excellent in water and chemical solvent resistance and is long in salt mist resisting time. The coating has the advantages of self-repairing function, high stability, low cost, simple preparation process and simple use method.

Owner:SHANDONG UNIV OF TECH

Anti-hydrogen embrittlement, high-strength stainless steel bar for fasteners and method of manufacturing the same

ActiveCN111218618BIncrease chromium contentImprove hydrogen embrittlement resistanceMetallic materialsSS - Stainless steel

The invention relates to an anti-hydrogen embrittlement, high-strength and tough stainless steel rod used for fasteners and a manufacturing method thereof, which belongs to the technical field of metal materials and solves the problem of anti-hydrogen embrittlement, high-strength stainless steel rods used in aerospace environments. The toughness and tight matching are not high. A hydrogen embrittlement-resistant, high-strength and tough stainless steel bar used for fasteners, the mass fraction of each element in the stainless steel bar is C: 0.0001-0.01%, Si: 0-0.10%, Mn: 0.01-0.15%, S: 0~0.005%, P: 0~0.015%, Cr: 10.50%~12.50%, Ni: 10.70%~11.50%, Mo: 0.75%~1.25%, Ti: 1.20%~1.70%, Al: 0~0.10% , H≤1.5ppm, the rest is iron and unavoidable impurities. A stainless steel bar with comprehensive properties of high strength, high toughness and hydrogen embrittlement resistance is prepared, which meets the requirements for fasteners used in aerospace environments exposed to corrosive media.

Owner:CENT IRON & STEEL RES INST

A kind of phosphorus-free metal surface treatment agent and using method thereof

The invention relates to a nonphosphorus metal surface treatment agent and a use method of the nonphosphorus metal surface treatment agent. The nonphosphorus metal surface treatment agent consists of the following ingredients in part by weight: 5 to 20 parts of nanometer zirconium dioxide dispersing liquid with the concentration being 28 percent, 6 to 30 parts of hydrofluoric acid, 3 to 15 parts of propylene glycol, 6 to 20 parts of octavinyl polyhedral oligomeric silsesquioxane, 3 to 20 parts of acetic acid, 0.03 to 0.5 part of rare earth cerium salt, 1 to 5 parts of sodium hydroxide and 50 to 76 parts of deionized water. The nonphosphorus metal surface treatment agent has the advantages that a nanometer silane inorganic conversion film can be formed on the metal surface after the treatment on the metal. The nonphosphorus metal surface treatment agent belongs to a replacing product of the traditional phosphorizing liquid, no phosphor and no heavy metal are contained, the nonphosphorus metal surface treatment agent can work at room temperature and can be used for surface pre-treatment of various metals, the rusting phenomenon cannot be generated in 48 hours after the nanometer silane inorganic conversion film is formed on the metal surfaces of cold rolled steel plates and the like, and is then blown to be dry, and the requirement of corrosion resistance performance in the production work procedures is met.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

High-strength galvanized building floor steel and preparation method thereof

PendingCN112375972AHigh yield strengthMeet the requirements of corrosion resistanceChemical compositionFloor slab

The invention belongs to the technical field of steel plate preparation, and particularly relates to high-strength galvanized building floor steel. The steel comprises the chemical components including, by weight percentage, 0.03-0.15% of C, 0.1-0.3% of Si, 1.00-1.50% of Mn, 0.30-0.35% of Alt, 0.01-0.012% of Ti, 0.5-0.6% of Cr, 0.01-0.05% of Ni, less than or equal to 0.02% of S, less than or equalto 0.01% of P, less than or equal to 0.03% of N and the balance of Fe and inevitable impurities. According to the steel, Ni, Ti and Cr are added, the requirement for corrosion resisting performance is met, the yield strength of the steel is improved to 400 MPa, the tensile strength is 1000 MPa or above, and the ballistic work at the temperature of subzero 50 DEG C is 85-90 J.

Owner:威海红光金属材料有限公司

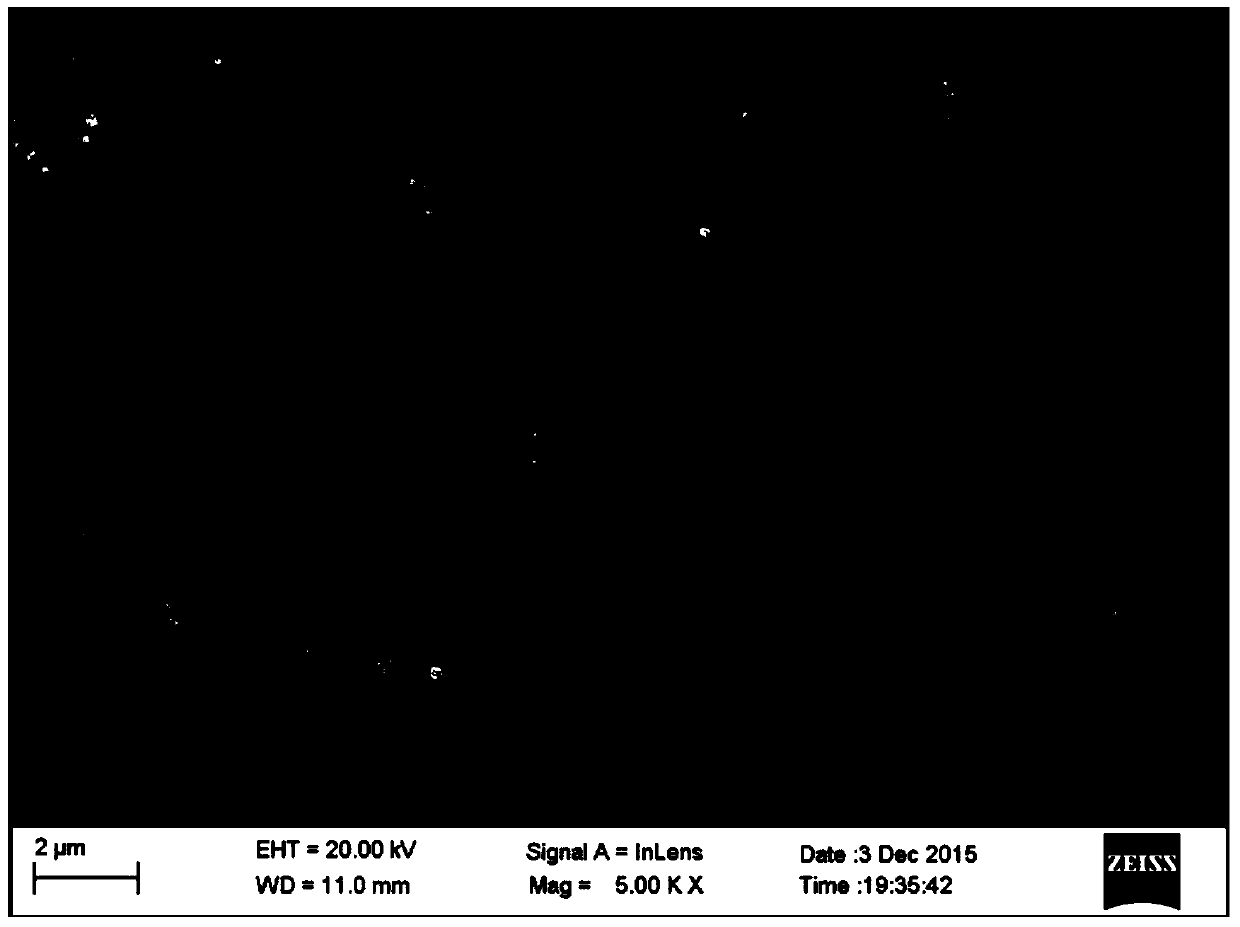

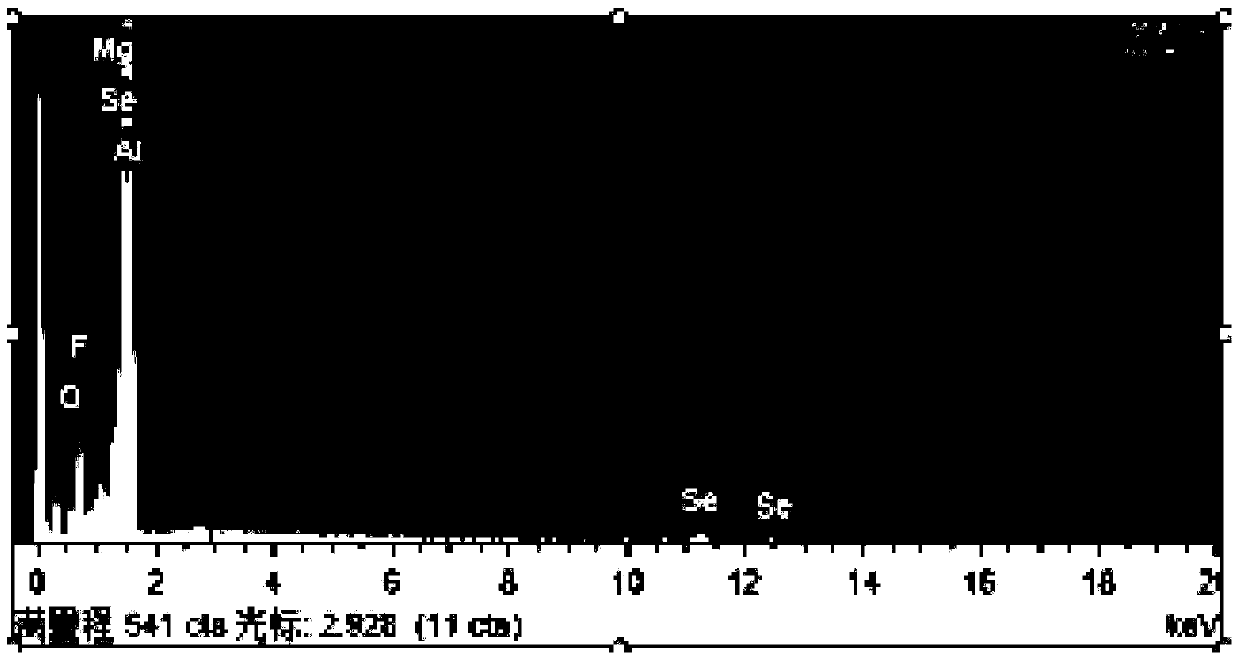

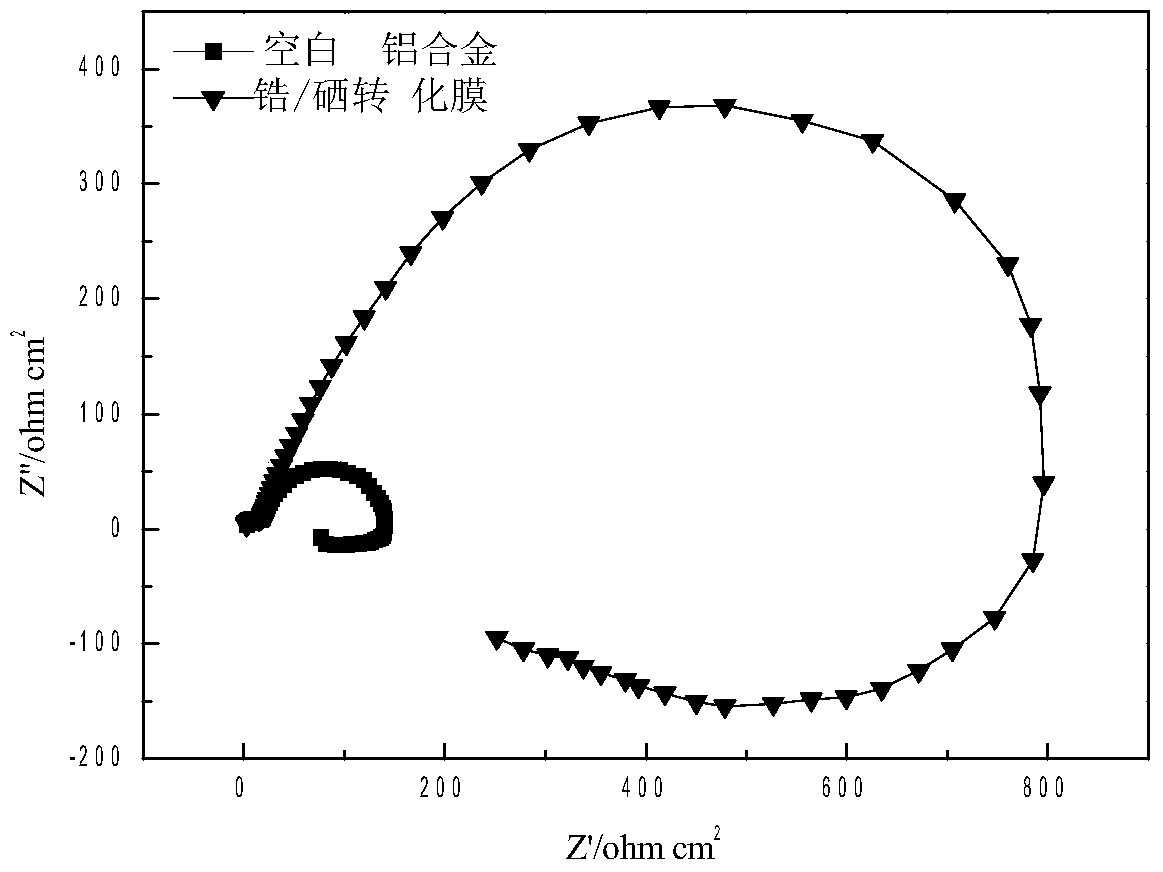

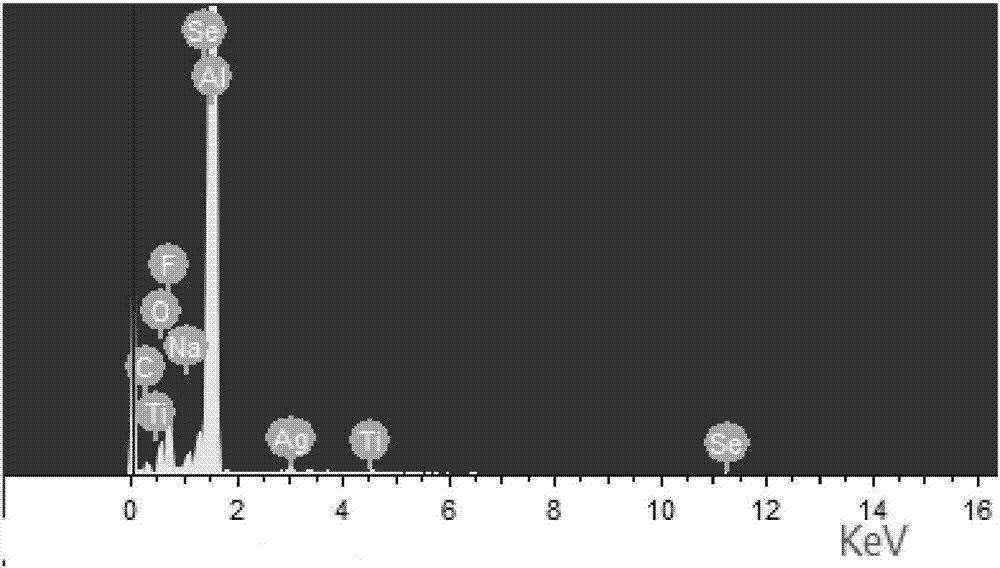

A method for preparing zirconium/selenium composite conversion film on the surface of aluminum alloy

ActiveCN105543824BIncreased self-corrosion potentialImprove corrosion resistanceMetallic material coating processesSelenateOrganic acid

The invention provides a method for preparing a zirconium-selenium composite conversion film on the surface of aluminum alloy. The method is mainly characterized by comprising the steps of preparing film formation liquid, wherein each liter of film formation liquid is composed of 0.1-5 g of zirconate, 0.1-10 g of selenium type oxide or selenate, 0.1-15 g of organic acid, 0.1-10 g of auxiliary oxidizing agents, 0.1-15 g of film formation accelerants and the balance deionized water; carrying out degreasing treatment and activating treatment on the pre-ground aluminum alloy, placing the aluminum alloy into the film formation liquid with the temperature ranging from 10 DEG C to 60 DEG C for conversion treatment for 5-30 minutes, then taking out the aluminum alloy, washing the aluminum alloy through distilled water, air-drying the aluminum alloy and finally obtaining the zirconium-selenium colorful composite conversion film on the surface of aluminum alloy. The method has the advantages that the operation is simple, the cost is low, the composite conversion film high in uniformity and excellent in compactness can be formed, the corrosion resistance of the aluminum alloy is improved, the environmental friendliness is high, and production is easy.

Owner:YANSHAN UNIV

Pre-coating and bottom-coating integrated medicament for color-coated sheet, preparation method of pre-coating and bottom-coating integrated medicament, color-coated sheet and production method thereof

ActiveCN114874691ARich and fullShort processAnti-corrosive paintsPolyurea/polyurethane coatingsChemistrySilane coupling

The invention discloses a pre-primer combination agent for a color-coated sheet, a preparation method of the pre-primer combination agent, the color-coated sheet and a production method of the color-coated sheet. The pre-primer combination agent for the color-coated sheet comprises the following raw materials in percentage by weight: 20-30% of water-based resin; 0.5%-1.0% of a curing agent; 5%-10% of a silane coupling agent; 2%-4% of an inorganic corrosion inhibitor; 0.1%-0.3% of a complexing agent; 0.5%-1.5% of a friction modifier; 1%-4% of a polyvinyl alcohol solution; by using the pre-primer integrated medicament for the color-coated sheet provided by the invention, a passivation pretreatment process and a primer coating process can be integrated, an obtained coating can have the functions of a passivation layer and a primer layer at the same time, and the home appliance color-coated sheet produced by using the pre-primer integrated medicament has excellent corrosion resistance, oil stain resistance and chemical resistance; and the use requirements of household appliances can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

Alkaline soil corrosion-resistant steel for hot-rolled U-shaped steel sheet pile and manufacture method thereof

InactiveCN101818306BAccelerated corrosionMeet the requirements of corrosion resistanceManufacturing convertersMetal rolling arrangementsChemical compositionSlag

The invention relates to a manufacture method of alkaline soil corrosion-resistant steel for a hot-rolled U-shaped steel sheet pile. The manufacture method comprises the steps of: smelting in a converter and refining; controlling the chemical composition and the weight percentage of the molten steel after refining as follows: 0.15-0.26% of C, 0.8-1.4% of Mn, 0.10-0.6% of Si, less than or equal to 0.020% of S, less than or equal to 0.02% of P, 0.2-0.5% of Cu, 0.1-0,25% of Ni, and the balance Fe and unavoidable impurities; controlling the alkalinity R of final slag to be at 2-5; continually casting; controlling the depth that a long water opening is inserted into a crystallizer to be at 100-300mm; heating a continually-cast blank at 1050-1150 DEG C; and rolling, wherein the rolling temperature is 1020-1100 DEG C, and the rolling is performed under the melting point temperature of the copper less than 1083 DEG C. The alkaline soil corrosion-resistant steel can not generate the phenomena of steel water overturning and slag entrapment when being cast, has good alkaline soil corrosion resistance, and meets the requirement of the corrosion resistance of the hot-rolled steel sheet pile when being used in the alkaline soil.

Owner:武钢集团有限公司

A kind of ultra-high strength martensitic stainless steel and its preparation method

ActiveCN106906429BImprove mechanical propertiesImprove corrosion resistanceMartensitic stainless steelIngot

The invention discloses ultrahigh-strength martensitic stainless steel and a preparation method thereof. The ultrahigh-strength martensitic stainless steel is high in yield strength, high in tensile strength, good in ductility and good in impact toughness. The preparation method comprises the steps as follows: Step 1, a raw material is prepared from stainless steel components in percentage by weight according to the burnt value, is smelted in the vacuum environment and is poured to form a steel ingot; the steel ingot is prepared from components in percentage by weight as follows: 0.10%-0.25% of C, 11.0%-17.0% of Cr, 0.5%-2.0% of Mn, 1.1%-3.0% of Si, 0.1%-4.0% of Ni, 0.1%-0.3% of Cu, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance of Fe and inevitable impurity elements; Step 2, forging of the steel ingot is started at 1,050-1,200 DEG C, the finish forging temperature ranges from 880 DEG C to 920 DEG C, the forging ratio is larger than or equal to 5, and air cooling is performed after forging; Step 3, a forging is subjected to heat preservation at 950-1,050 DEG C for 2-4 h, is subjected to water quenching and then is tempered at 200-300 DEG C for 2-4 h, and the ultrahigh-strength martensitic stainless steel is obtained after natural cooling.

Owner:XI AN JIAOTONG UNIV

A bimetal wear-resistant seamless composite steel pipe and its preparation method

ActiveCN103697244BHigh hardnessSolve the problem of impact resistanceFurnace typesRigid pipesWear resistantWear resistance

The invention discloses a bimetallic wear-resisting seamless composite steel tube. The bimetallic wear-resisting seamless composite steel tube is characterized by comprising an inner steel tube and an outer steel tube which is metallurgically bonded on the inner steel tube, wherein the outer steel tube is made of a 304 stainless steel material, and the inner steel tube is made of a 9Cr18MoVNb material. The bimetallic wear-resisting seamless composite steel tube is simple in structure and low in cost, and also can satisfy the requirement on corrosion resistance and wear resistance, thereby being suitable for popularization and application.

Owner:SICHUAN XINDING NEW MATERIALS

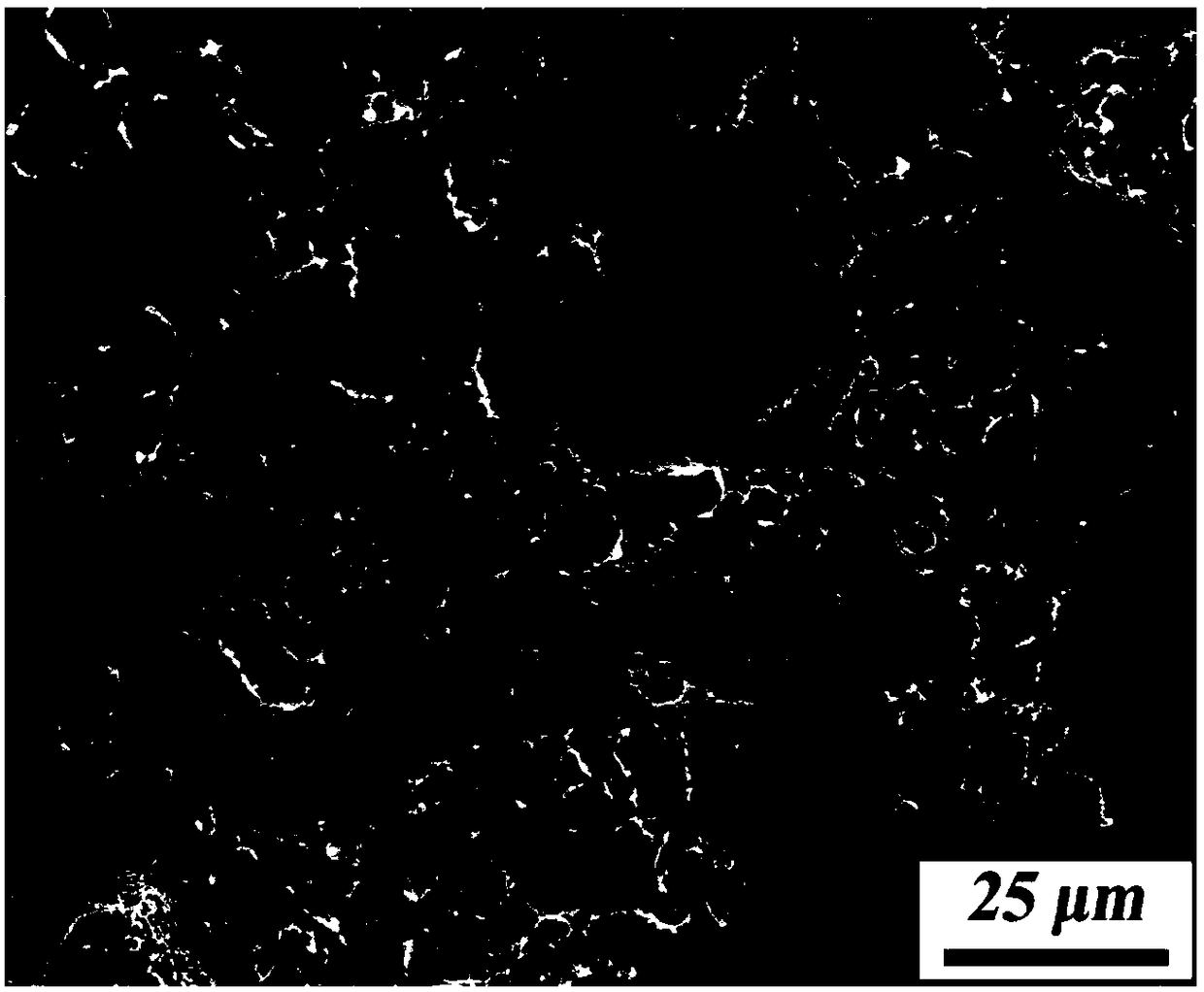

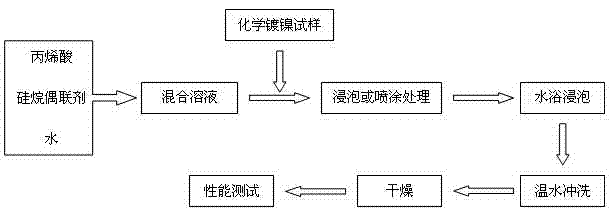

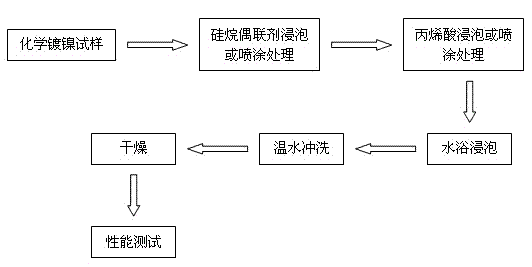

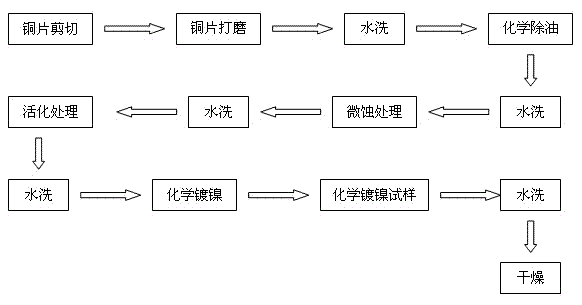

Hole-sealing agent for chemical nickel plating layer and hole-sealing treatment process thereof

ActiveCN102212803BImprove corrosion resistanceMeet the requirements of corrosion resistanceLiquid/solution decomposition chemical coatingOrganic filmThermal treatment

The invention discloses a hole-sealing agent for a chemical nickel plating layer and a hole-sealing treatment process thereof. The hole-sealing agent is prepared from the following materials in percentage by volume: 90-98% of acrylic acid, 1-9% of silane coupling agent and 1-9% of water. The hole-sealing treatment process of the hole-sealing agent for a chemical nickel plating layer comprises thefollowing steps: soaking or spraying the hole-sealing agent onto the chemical nickel plating layer to enable the hole-sealing agent to be uniformly distributed on the surface of the chemical nickel plating layer; selecting water of 70-90 DEG C to carry out appropriate heating treatment on the chemical nickel plating layer, wherein the heating treatment time is 1-5 minutes; and selecting water of 30-45 DEG C to rinse the chemical nickel plating layer, and then carrying out blow-drying. After the hole-sealing treatment of the hole-sealing agent for a chemical nickel plating layer, a well combined organic film can be formed on the surface of the chemical nickel plating layer, so that the porosity of the chemical nickel plating layer is remarkably reduced, the corrosion resistance is obviously enhanced, and the conductivity and appearance of the chemical nickel plating layer are not affected.

Owner:深圳明阳电路科技股份有限公司

Aluminum alloy micro-arc oxidation electrolyte, method and product thereof

InactiveCN111118571ASolve surface roughnessSolve the problem of large pore sizeAnodisationElectrolytic agentMicro arc oxidation

The invention relates to the technical field of micro-arc oxidation, in particular to an aluminum alloy micro-arc oxidation electrolyte, a method and a product thereof. The aluminum alloy micro-arc oxidation electrolyte is prepared from the components: 5-30g / L of water-soluble phosphate, 1-10g / L of alkali metal hydroxide and 5-30g / L of citrate, and a solvent is deionized water. Compared with the prior art, the formula of die-casting aluminum micro-arc oxidation electrolyte can solve the problems of rough surface, large micropore diameter and poor corrosion resistance of a micro-arc oxidation film prepared by an existing electrolyte. The micropore diameter of the prepared micro-arc oxidation film is only 0.5-2[mu]m, the requirements of aluminum alloy micro-arc oxidation for corrosion resistance can be met, and the surface of the film is more smooth.

Owner:华孚精密科技(马鞍山)有限公司

A method for preparing titanium/selenium colorful composite conversion film on the surface of aluminum alloy

ActiveCN105543823BIncreased self-corrosion potentialImprove corrosion resistanceMetallic material coating processesSelenateEnvironmental resistance

The invention discloses a method for preparing a titanium / selenium multicolour composite conversion film on the surface of an aluminium alloy. The method mainly comprises the following steps: preparing film-forming solution according to a ratio that per cubic litre of the film-forming solution contains 0.1-5g of titanates, 0.1-8g of selenium oxides or selenates, 0.1-10g of organic acids, 0.1-10g of an auxiliary oxidant, 0.1-8g of a film-forming accelerant and the balance deionized water, and carrying out degreasing and activating treatments on pre-grinded aluminium alloy; placing the aluminium alloy in the film-forming solution at 10-60 DEG C and carrying out conversion treatment for 5-30min, then taking out the aluminium alloy and cleaning the aluminium alloy with distilled water, blow-drying the aluminium alloy by natural wind and then obtaining the Ti-Se multicolour composite conversion film on the surface of the aluminium alloy. The method disclosed by the invention is low in cost, simple to operate, capable of improving the corrosion resistance of the aluminium alloy, quite high in environmental value, and easy to produce.

Owner:YANSHAN UNIV

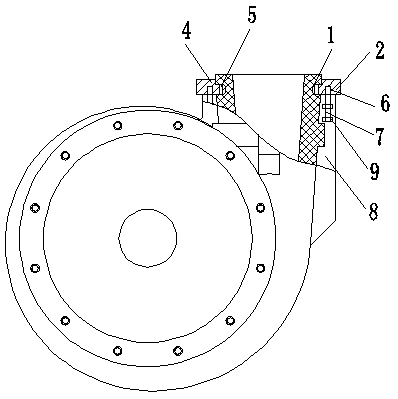

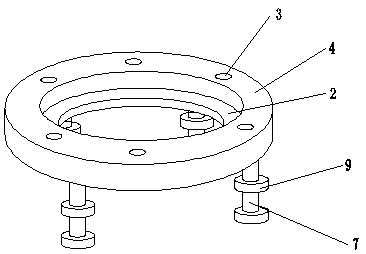

Inlet/outlet unit of high-strength and corrosion-resistant pump formed by two materials through die pressing

InactiveCN111271321AMeet strength requirementsMeet the requirements of corrosion resistancePump componentsPumpsUltimate tensile strengthCorrosion resistant

The invention discloses an inlet / outlet unit of a high-strength and corrosion-resistant pump formed by two materials through die pressing. An orifice of the pump is made of plastic and is an inlet and / or an outlet, an annular groove is formed in the outer side of the orifice, a metal flange is arranged in the annular groove, part of the metal flange is located in the annular groove, and the otherpart of the metal flange is located outside the annular groove, a plurality of flange holes are formed in the area located outside the annular groove, and the metal flange and the orifice are formed by die pressing. The inlet / outlet unit can not only meet the corrosion-resistant requirement, but also can meet the strength requirement, is formed by die pressing once and has high formation efficiency.

Owner:宜兴市盛达泵阀有限公司

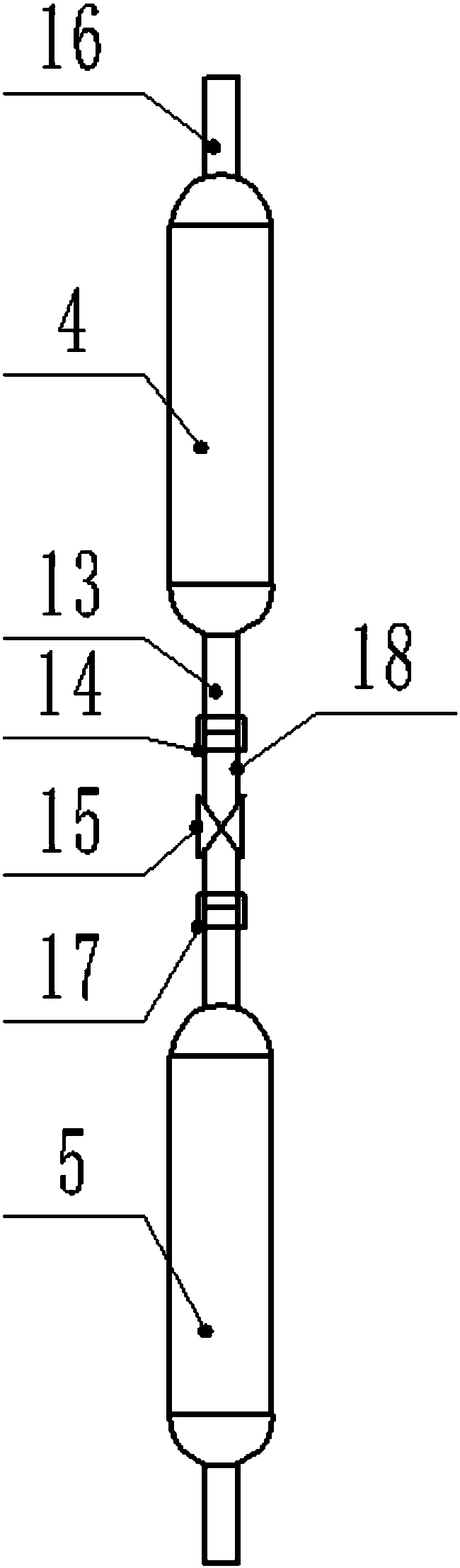

Device for recovering and treating photoelectric material pickling waste liquid

InactiveCN108543507AMeet the requirements of corrosion resistanceLow costSilicaSulfur compoundsLiquid wasteEvaporation

The invention discloses a device for recovering and treating a photoelectric material pickling waste liquid. The device comprises an evaporator, the shell side of the evaporator is connected with theshell side of a preheater, the liquid outlet of the evaporator is imterconnected with the liquid inlet of a separator, the liquid outlet of the separator is interconnected with the liquid inlet of a steam saturator, the liquid outlet of the steam saturator is interconnected with the liquid inlet of a first-stage acid absorption tank, the liquid outlet of the first-stage acid absorption tank is interconnected with the liquid inlet of a second-stage acid absorption tank, the liquid outlet of the second-stage acid absorption tank is interconnected with the liquid inlet of a condenser, the liquidoutlet of the condenser is interconnected with the liquid inlet of a gas-liquid separation tank, and the liquid outlet of the gas-liquid separation tank is interconnected with the liquid inlet of a concentrate condenser. The device meets the requirements of anticorrosion, is economical and reasonable, reduces the device cost, and also has the advantages of high evaporation efficiency, continuousness and stability in production, simplicity in operation, low treatment cost and obvious environmental protection benefits.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com