Pre-coating and bottom-coating integrated medicament for color-coated sheet, preparation method of pre-coating and bottom-coating integrated medicament, color-coated sheet and production method thereof

A technology of color-coated boards and medicaments, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve quality problems and other problems, achieve the effect of enriching the sense of fullness and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

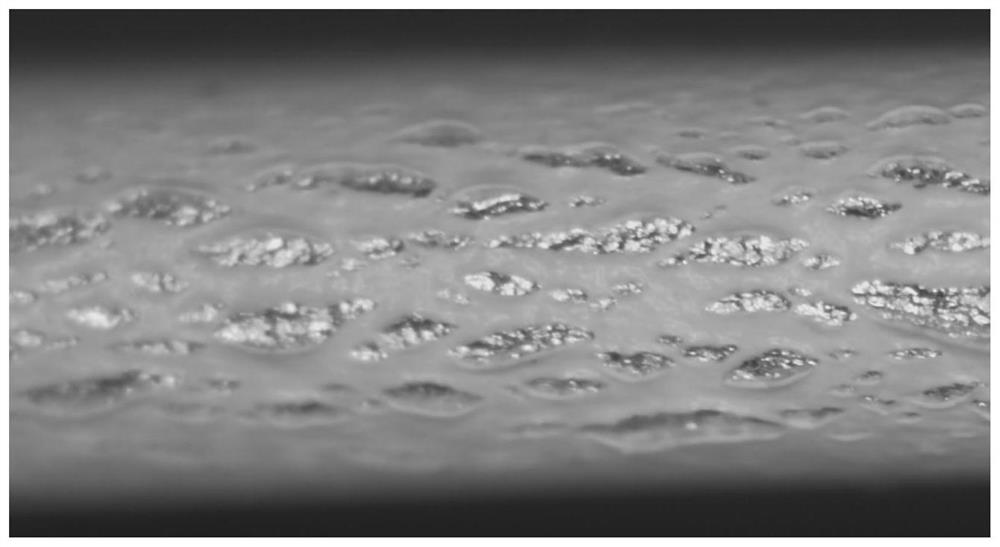

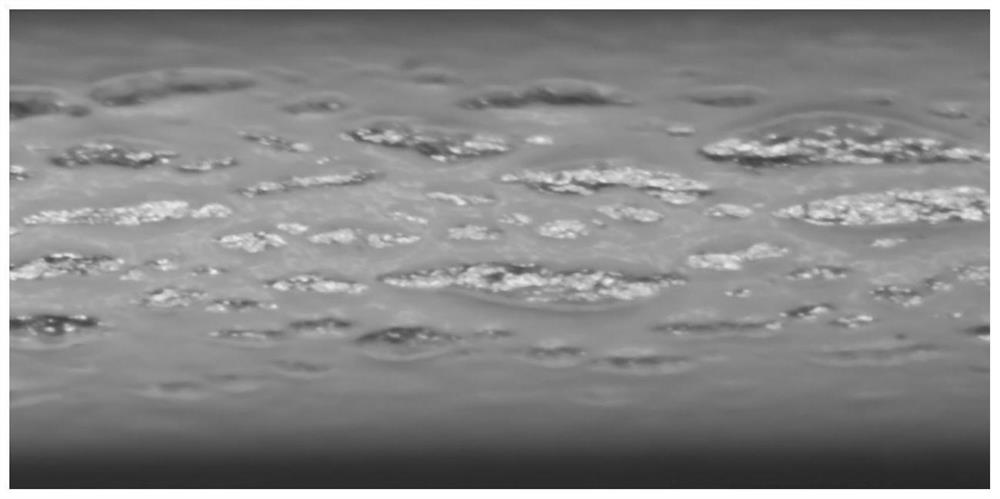

Image

Examples

Embodiment 1

[0087] A preparation method of a pre-bottom-integrated medicament for color-coated boards, comprising the following steps:

[0088] (1) Add 7.0g of vinyltriethoxysilane to 10g of 8% ethanol aqueous solution, after 30min, add 2.0g of fluorotitanic acid and 2.0g of fluorozirconic acid, and add 0.15g of hydrogen peroxide, put it on a high-speed stirrer Stir for 30min, and the stirring speed is 500r / min to obtain mixed solution 1;

[0089] (2) Add 10g of water-soluble polyurethane resin and 10g of water-soluble acrylic resin to 10g of 8% ethanol aqueous solution, stir evenly, then add 0.6g of ethylenediamine, stir on a high-speed mixer for 20min, and the stirring speed is 1200r / min, get the mixture two;

[0090] (3) Weigh 1g of dialkyldithiophosphoric acid-modified nano-silica, 1g of adhesion promoter TEGOAddBond LTH and 1.5g of 10% polyvinyl alcohol hydrolyzate, and condensed and refluxed at 75°C for 30min to obtain mixed solution three ;

[0091] (4) adding above-mentioned mi...

Embodiment 2

[0095] A preparation method of a pre-bottom-integrated medicament for color-coated boards, comprising the following steps:

[0096] (1) Add 7.0g of vinyltris(β-methoxyethoxy)silane to 10g of 7% ethanol aqueous solution, after 30min, add 1.5g of fluorotitanic acid and 1.5g of fluorozirconic acid, and add 0.15g of hydrogen peroxide, Put it on a high-speed stirrer and stir for 30min, and the stirring speed is 500r / min to obtain a mixed solution 1;

[0097](2) Add 11g of water-soluble polyurethane resin and 11g of water-soluble acrylic resin to 10g of 7% ethanol aqueous solution, stir evenly, and then add 0.5g of ethylenediamine and diethylenetriamine according to the mass ratio of 2:3 to mix and cure and put it on a high-speed stirrer to stir for 20min, and the stirring speed is 1200r / min to obtain mixed solution II;

[0098] (3) Weigh 0.8g of dialkyldithiophosphoric acid-modified nano-silica, 1.5g of adhesion promoter TEGOAddBond LTH and 2.5g of 10% polyvinyl alcohol hydrolyzat...

Embodiment 3

[0103] A preparation method of a pre-bottom-integrated medicament for color-coated boards, comprising the following steps:

[0104] (1) Add 3.5g vinyltriethoxysilane and 3.5g vinyltris(β-methoxyethoxy)silane to 10g 6% ethanol aqueous solution, after 30min, add 1.8g fluorotitanic acid and 1.8g fluorine Zirconic acid, add 0.15g hydrogen peroxide, put it on a high-speed stirrer and stir for 30min, and the stirring speed is 500r / min to obtain a mixed solution 1;

[0105] (2) Add 12g water-soluble epoxy resin and 12g water-soluble acrylic resin to 10g 6% ethanol aqueous solution diluent, stir evenly, then add 0.7g by mass ratio of ethylenediamine, diethylenetriamine and triethylenetetramine The mixed curing agent of 1:1:1 was placed on a high-speed agitator and stirred for 20 minutes, and the stirring speed was 1200r / min to obtain mixed solution II;

[0106] (3) Weigh 0.8g of dialkyldithiophosphoric acid-modified nano-molybdenum disulfide, 1.8g of adhesion promoter TEGOAddBond LTH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com