Functional blend oil and preparation method thereof

A technology for blending oils and functions, applied in edible oil/fat, food science, applications, etc., can solve the problems of high cost, incomplete extraction, time-consuming and labor-intensive walnut oil, etc., achieve rich nutrients, low price, and promote blood circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

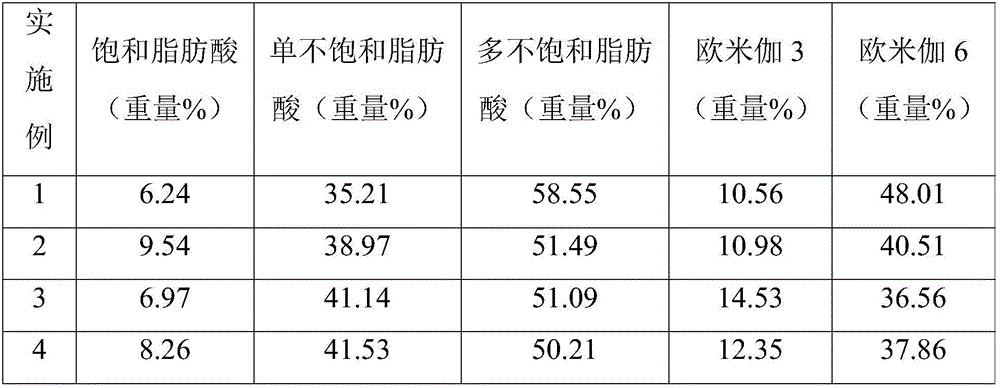

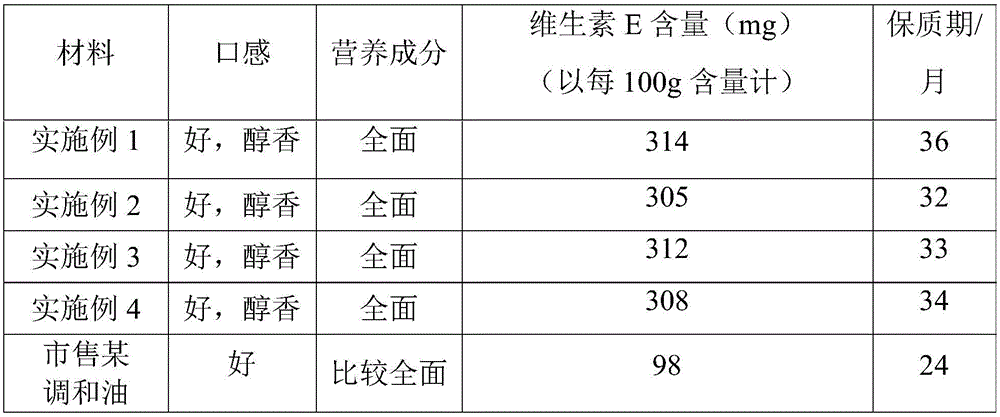

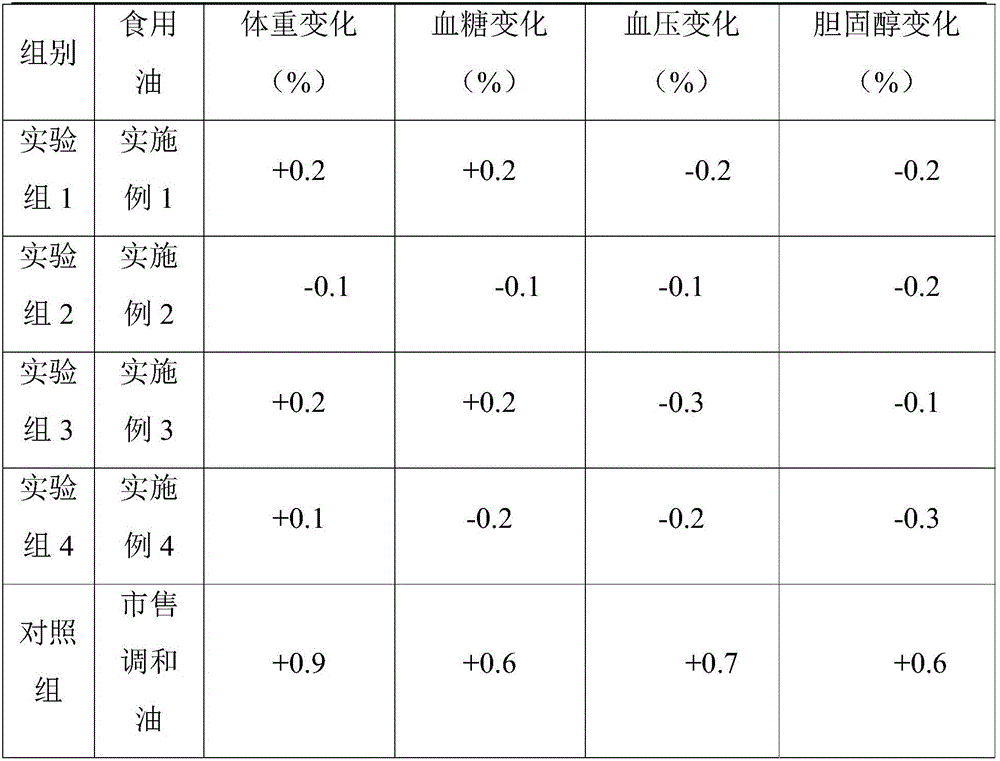

Examples

Embodiment 1

[0038] 1) Prepare raw materials according to the components in parts by weight: 500kg of linseed, 300kg of sesame, 300kg of sunflower seed, 150kg of perilla, 150kg of cinnamon, and 150kg of rosemary;

[0039] 2) Use a cleaning sieve to clean the flaxseeds, sesame seeds, sunflower seeds, and perilla of the above weight to make the impurity rate less than 0.1%, and use a shelling separator to remove the shells so that the shell kernel rate is less than 0.5%. The shell content rate is less than 1%, then use a dryer to dry at 90-100°C for 60 minutes, and then use a crusher to break into 6-8 pieces; use a cleaning sieve to clean the impurities of cinnamon and rosemary with the above weight and dry them in the shade;

[0040] 3) The flaxseeds, sesame seeds, sunflower seeds, and perilla crushed in step (2) are pressed at a temperature of 62° C. by a twin-screw oil press to obtain pressed cake I and crude oil I;

[0041] 4) Grind the shade-dried cinnamon and rosemary in step (2) into po...

Embodiment 2

[0045] 1) Prepare raw materials according to the components in parts by weight: 300kg of linseed, 100kg of sesame, 100kg of sunflower seed, 50kg of perilla, 50kg of cinnamon, and 50kg of rosemary;

[0046] 2) Use a cleaning sieve to clean the flaxseeds, sesame seeds, sunflower seeds, and perilla of the above weight to make the impurity rate less than 0.1%, and use a shelling separator to remove the shells so that the shell kernel rate is less than 0.5%. The shell content rate is less than 1%, then use a dryer to dry at 90-100°C for 60 minutes, and then use a crusher to break into 6-8 pieces; use a cleaning sieve to clean the impurities of cinnamon and rosemary with the above weight and dry them in the shade;

[0047] 3) The flaxseeds, sesame seeds, sunflower seeds, and perilla crushed in step (2) are pressed at a temperature of 68° C. by a twin-screw oil press to obtain pressed cake I and crude oil I;

[0048] 4) Grind the shade-dried cinnamon and rosemary in step (2) into pow...

Embodiment 3

[0052] 1) Prepare raw materials according to the components in parts by weight: 400kg of linseed, 200kg of sesame, 200kg of sunflower seed, 100kg of perilla, 100kg of cinnamon, and 100kg of rosemary;

[0053] 2) Use a cleaning sieve to clean the flaxseeds, sesame seeds, sunflower seeds, and perilla of the above weight to make the impurity rate less than 0.1%, and use a shelling separator to remove the shells so that the shell kernel rate is less than 0.5%. The shell content rate is less than 1%, then use a dryer to dry at 90-100°C for 60 minutes, and then use a crusher to break into 6-8 pieces; use a cleaning sieve to clean the impurities of cinnamon and rosemary with the above weight and dry them in the shade;

[0054] 3) The flaxseeds, sesame seeds, sunflower seeds, and perilla crushed in step (2) are pressed at a temperature of 65° C. by a twin-screw oil press to obtain pressed cake I and crude oil I;

[0055] 4) Grind the shade-dried cinnamon and rosemary in step (2) into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com