Anti-hydrogen embrittlement, high-strength stainless steel bar for fasteners and method of manufacturing the same

A technology of tough stainless steel and stainless steel rods, which is applied in the field of metal material preparation, can solve the problems of plasticity and toughness decline, and achieve the effect of improving the performance of hydrogen embrittlement resistance, easy metallurgy level, and meeting the requirements of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

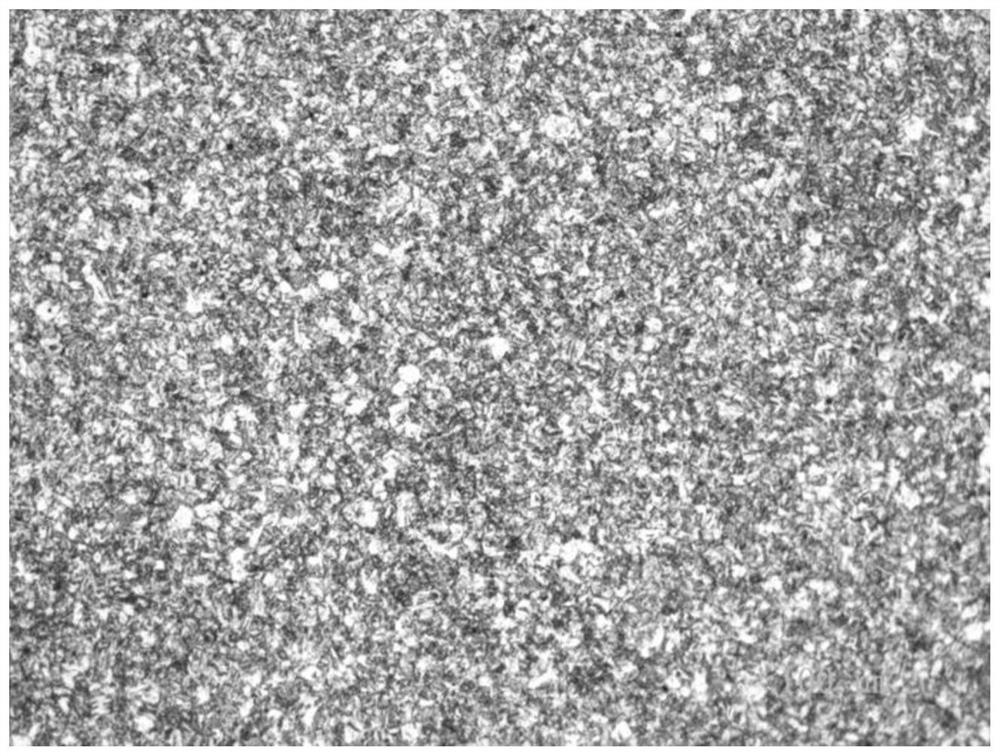

Image

Examples

Embodiment 1

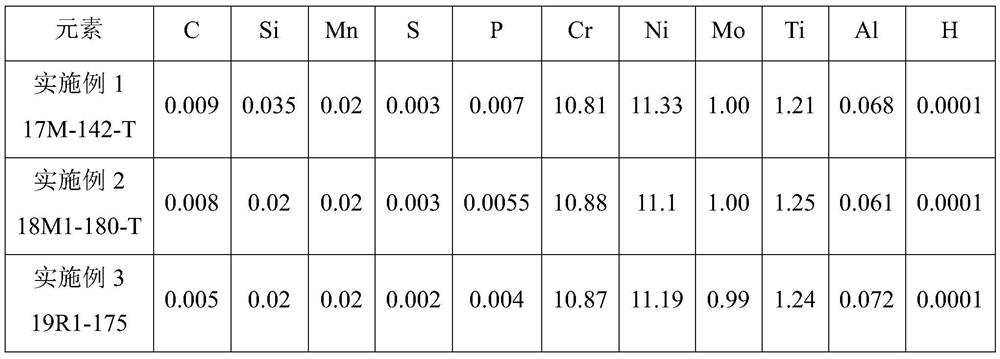

[0061] A 6-ton vacuum induction furnace is used to smelt the steel of the invention after iron washing in the forehearth. A 6-ton vacuum consumable remelting furnace is used for refining, and the vacuum degree of the vacuum induction furnace and the vacuum consumable remelting furnace is 0.01Pa. The chemical composition of the head and tail of the consumable ingot was analyzed, see Table 1.

[0062] After the consumable ingot is homogenized at 1200°C for 24 hours, the billet is opened to 140 square meters by a 4T electro-hydraulic hammer, and the billet is opened by a 750KG air hammer to 55 square meters. Rolled to Φ10mm billet, after softening treatment at 920°C, heat preservation for 40min, and air cooling, one cold drawing with 10% deformation to form Φ9mm, and then annealed at 670°C, heat preservation for 5h, air cooling, and polished to Φ8. 5mm bar. The bar is subjected to high-temperature solution treatment at 950°C×30min, oil cooling, cryogenic treatment at -78°C×13h,...

Embodiment 2

[0064] A 6-ton vacuum induction furnace is used to smelt the steel of the invention after iron washing in the forehearth. A 6-ton vacuum consumable remelting furnace is used for refining. The vacuum degree of vacuum induction furnace and vacuum consumable remelting furnace is 0.1Pa. The chemical composition of the head and tail of the consumable ingot was analyzed, see Table 1.

[0065] After the consumable ingot is homogenized at 1250°C for 24 hours, the billet is opened to 80 square meters by a 4T electro-hydraulic hammer, and the billet is opened by a 750KG air hammer to 59 square meters. Rolled to Φ25mm billet, after softening treatment at 920°C, heat preservation for 2 hours, and air cooling, one-time deformation of cold drawing forming Φ17mm, and then annealing at 670°C, heat preservation for 6 hours, air cooling, and polished into Φ16mm bars. The bar is subjected to high-temperature solution treatment at 900°C×40min, oil cooling, cryogenic treatment at -78°C×13h, retu...

Embodiment 3

[0067] A 6-ton vacuum induction furnace is used to smelt the steel of the invention after iron washing in the forehearth. A 6-ton vacuum consumable remelting furnace is used for refining. The vacuum degree of vacuum induction furnace and vacuum consumable remelting furnace is 0.1Pa. The chemical composition of the head and tail of the consumable ingot was analyzed, see Table 1.

[0068]After the consumable ingot is homogenized at 1150°C for 36 hours, it is opened to 100 square meters by a 4T electro-hydraulic hammer, and the billet is opened by a 750KG air hammer to 55 square meters. Rolled to Φ10mm billet, after softening treatment at 980℃, heat preservation for 40min, and air cooling, cold drawing of Φ7mm for secondary deformation, and then annealing at 690℃, heat preservation for 3h, air cooling, and polished into Φ6.5mm rod material. The rods are subjected to high-temperature solution treatment at 850°C×2h, oil cooling, cryogenic treatment at -85°C×12h, returning to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com