Soluble acid-resistant aluminum alloy oil pipe, preparation method thereof and aluminum alloy thereof

A technology of aluminum alloy and tubing, applied in the direction of drill pipe, casing, manufacturing tools, etc., can solve the problems of tubing failure, delay of production well commissioning time, workover costs, sidetracking processing difficulties, etc., so as to avoid the task of salvaging tubing, Reduce the difficulty and cost of operation and meet the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

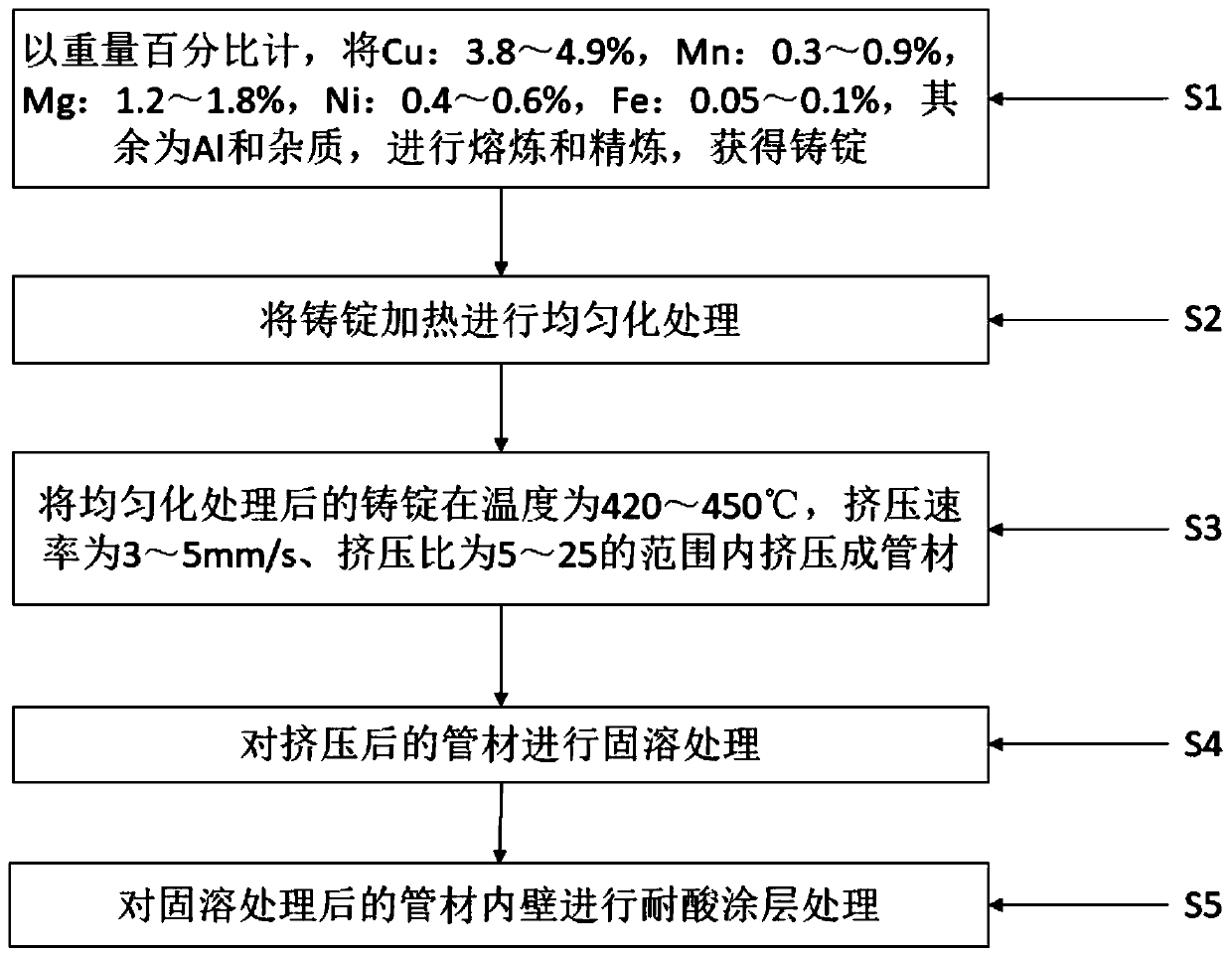

[0038] see figure 1 , the present invention also provides a preparation method of a soluble acid-resistant aluminum alloy oil pipe, comprising the following steps:

[0039] S1: In terms of weight percentage, Cu: 3.8-4.9%, Mn: 0.3-0.9%, Mg: 1.2-1.8%, Ni: 0.4-0.6%, Fe: 0.05-0.1%, and the rest are Al and impurities. Smelting and refining to obtain ingots;

[0040] S2: Heating the ingot for homogenization treatment, improving the crystal structure inside the alloy, eliminating casting stress and reducing segregation;

[0041] S3: extruding the homogenized ingot into a pipe at a temperature of 420-450°C, an extrusion rate of 3-5mm / s, and an extrusion ratio of 5-25;

[0042] S4: performing solution treatment on the extruded pipe;

[0043] S5: Perform acid-resistant coating treatment on the inner wall of the pipe after solution treatment.

[0044] The aluminum alloy oil pipe provided by the present invention includes a soluble pipe material and an acid-resistant coating on the inne...

Embodiment 1

[0064] This embodiment provides a soluble acid-resistant aluminum alloy for oil pipes, its chemical composition includes: Cu: 3.85%, Mn: 0.65%, Mg: 1.6%, Ni: 0.5%, Fe: 0.08%, The remaining components are Al and unavoidable impurities, and the Si content of the impurities is not more than 0.1% of the total weight of the aluminum alloy.

[0065] The manufacturing process steps of the above-mentioned soluble acid-resistant aluminum alloy tubing are as follows: the above-mentioned raw materials are smelted and refined outside the furnace and then cast to obtain ingots, and the ingots are heated to 450°C in a heating furnace for homogenization treatment, and the holding time is 6 hours; casting The extrusion temperature of the ingot is 435°C, the extrusion ratio is 18.3, and the extrusion speed is 3mm / s; the solution treatment temperature is 360°C, and the holding time is 3 hours.

[0066] The inner wall of the pipe after solid solution treatment is subjected to the following elect...

Embodiment 2

[0076] The present invention is an aluminum alloy for soluble acid-resistant aluminum alloy oil pipe, its chemical composition includes: Cu: 4.28%, Mn: 0.86%, Mg: 1.45%, Ni: 0.6%, Fe: 0.06%, and other components in weight percentage It is Al and inevitable impurity Si, and the content of impurity Si is not more than 0.1% of the total weight of the aluminum alloy.

[0077] The manufacturing process steps of the above-mentioned soluble acid-resistant aluminum alloy tubing are as follows: the above-mentioned raw materials are smelted and refined outside the furnace and cast to obtain ingots, and the ingots are heated to 435°C in the heating furnace for homogenization treatment, and the holding time is 7 hours; casting The extrusion temperature of the ingot is 425°C, the extrusion ratio is 16, and the extrusion speed is 5mm / s; the solution treatment temperature is 360°C, and the holding time is 3.5 hours.

[0078] The inner wall of the pipe after solid solution treatment is subjecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com