High-strength high-corrosion-resistance anti-microbial stainless steel and preparation method thereof

A high-corrosion-resistant, high-strength technology, used in the fields of high-strength stainless steel and its preparation, stainless steel and its preparation, and new stainless steel materials, can solve the problem of reducing mechanical properties and corrosion resistance, affecting sharpness and wear resistance, and not having antibacterial properties And other problems, to achieve the effect of improving processing performance, improving pitting corrosion resistance and salt spray corrosion resistance, and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

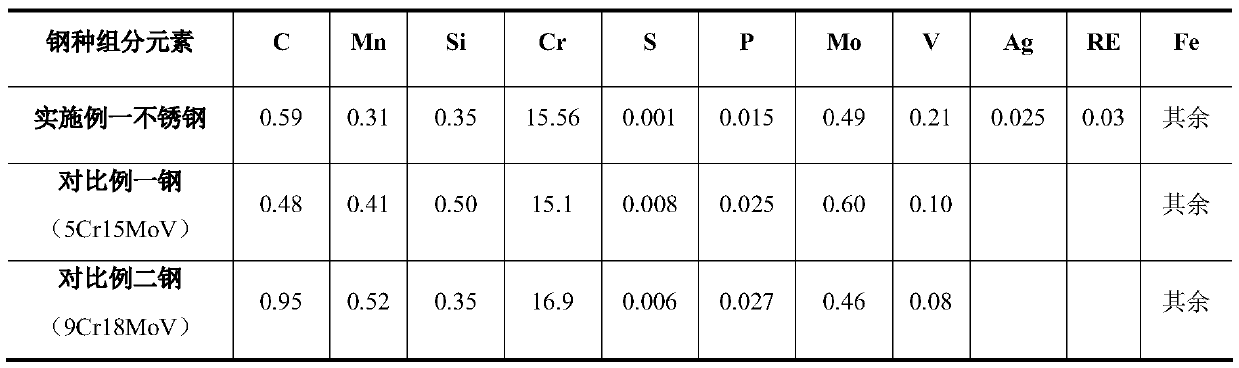

[0041] In this embodiment, a high-strength, high-corrosion-resistant and antibacterial stainless steel for knives has a chemical composition as shown in Table 1.

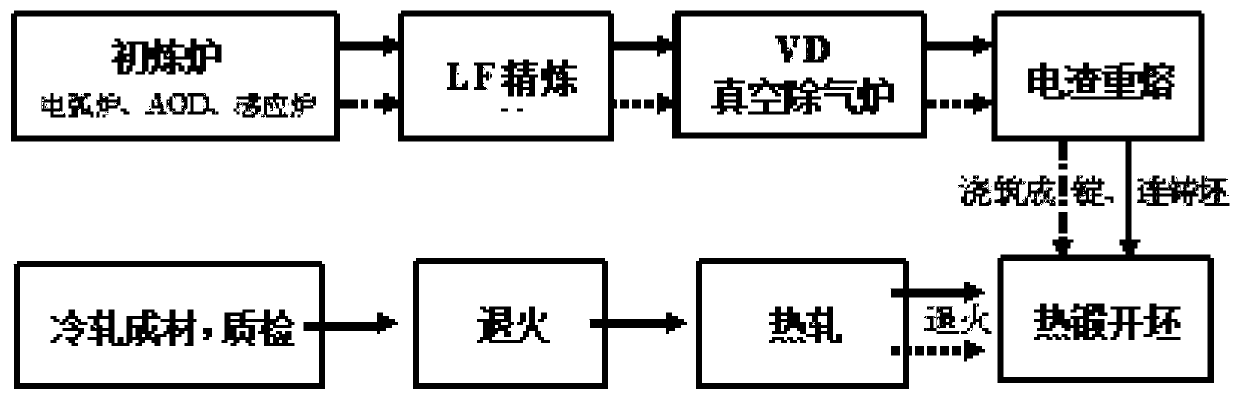

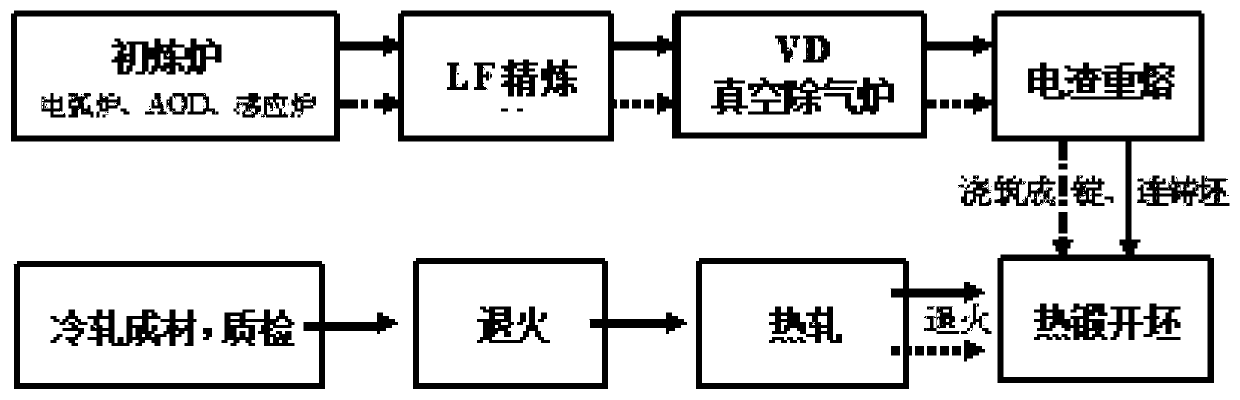

[0042] In this example, see figure 1 , the preparation method of stainless steel for high-strength, high-corrosion-resistant and antibacterial cutting tools of the present embodiment comprises the following steps:

[0043] a. Weigh the raw materials according to the prepared target stainless steel component mass percentage with the composition of Table 1:

[0044] C: 0.59%, Si: 0.35%, S: 0.001%, P: 0.015%, Mn: 0.31%, Mo: 0.49%, Cr: 15.56%, V: 0.21%, Ag: 0.025%, Ce: 0.03, the rest partly iron and unavoidable impurities;

[0045] b. The raw materials taken in the step a are smelted in an electric furnace, refined outside the furnace of the LF process, VD vacuum degassing, electroslag remelting, forging, hot rolling, and cold rolling to obtain the required thickness. Stainless steel plate; after forging, hot rolling...

Embodiment 2

[0076] This embodiment is basically the same as Embodiment 1, especially in that:

[0077] In this embodiment, a high-strength antibacterial stainless steel for cutting tools, its chemical composition is shown in Table 7.

[0078] In this embodiment, the method for preparing stainless steel for high-strength and tough antibacterial knives in this embodiment includes the following steps:

[0079] a. Weigh the raw materials according to the prepared target stainless steel component mass percentage with the composition of Table 5:

[0080] C: 0.70%, Si: 0.40%, S: 0.001%, P: 0.015%, Mn: 0.6%, Mo: 1.0%, Cr: 16.5%, V: 0.5%, Ag: 0.1%, Ce: 0.05, the rest partly iron and unavoidable impurities;

[0081] b. The raw materials taken in the step a are smelted in an electric furnace, refined outside the furnace of the LF process, VD vacuum degassing, electroslag remelting, forging, hot rolling, and cold rolling to obtain the required thickness. Stainless steel plate; after forging, hot r...

Embodiment 3

[0083] This embodiment is basically the same as the previous embodiment, and the special features are:

[0084] In this embodiment, a high-strength antibacterial stainless steel for cutting tools, its chemical composition is shown in Table 7.

[0085] In this embodiment, the method for preparing stainless steel for high-strength and tough antibacterial knives in this embodiment includes the following steps:

[0086] a. Weigh the raw materials according to the prepared target stainless steel component mass percentage with the composition of Table 5:

[0087] C: 0.50%, Si: 0.30%, S: 0.020%, P: 0.020%, Mn: 0.6%, Mo: 0.1%, Cr: 14.5%, V: 0.1%, Ag: 0.1%, La: 0.05, the rest partly iron and unavoidable impurities;

[0088] b. The raw materials taken in the step a are smelted in an electric furnace, refined outside the furnace of the LF process, VD vacuum degassing, electroslag remelting, forging, hot rolling, and cold rolling to obtain the required thickness. Stainless steel plate;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com