Steel for acid soil corrosion-resistant hot rolling U-shaped steel sheet pile and production method thereof

A technology of soil corrosion and acid resistance, which is applied in the direction of temperature control, etc., to achieve the effect of simple production process, favorable promotion and excellent corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

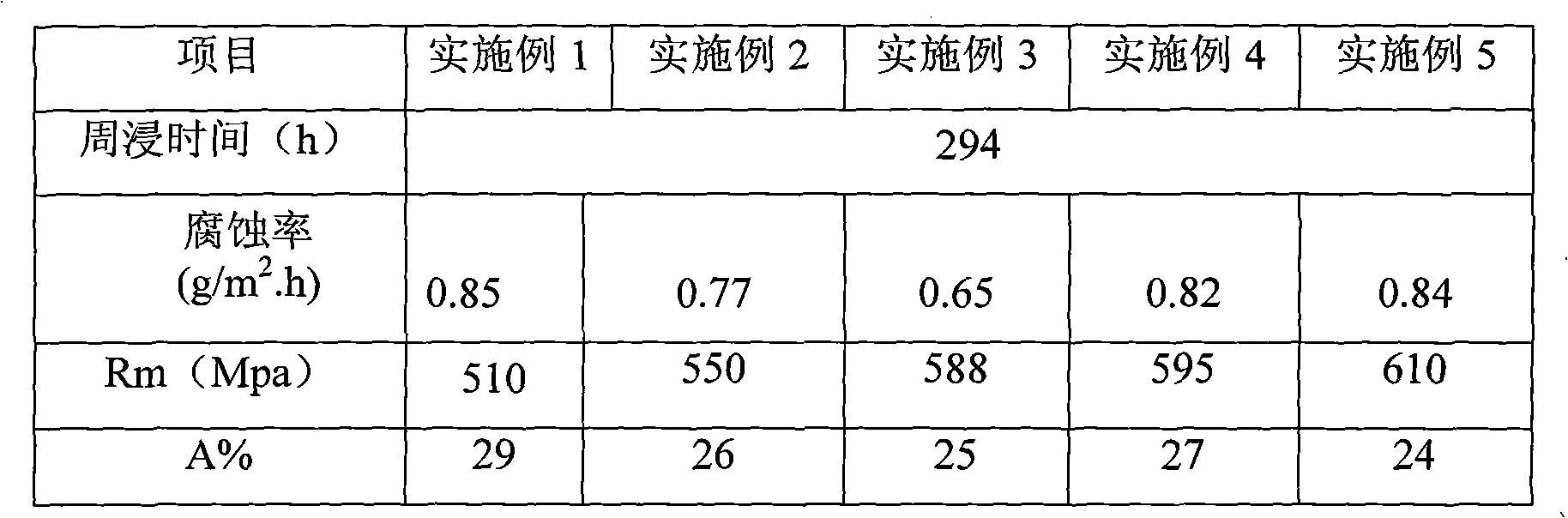

Examples

Embodiment 1

[0025] Steel for hot-rolled U-shaped steel sheet piles resistant to acid soil corrosion, its chemical composition and weight percentage are: C 0.13%, Mn0.6%, Si 0.10%, S0.02%, P0.02%, Cr 0.5%, Mo 0.15%, the rest is Fe and unavoidable impurities.

[0026] A method for producing steel for hot-rolled U-shaped steel sheet piles resistant to acidic soil corrosion, the steps of which are:

[0027] 1) Smelting: adopt a deoxidation process with a weight percentage of [Al]<0.005%, add lime at a time of 10 kg / ton of steel at the beginning of the furnace for mixed flushing, and the thickness of the slag on the liquid surface is 6 mm;

[0028] 2) Continuous casting: control the pouring temperature at 1570°C to 1575°C, control the superheat of continuous casting at 15°C, casting speed at 1.0 m / min, control the thickness of the mold powder at the liquid level at 2 mm, and cool the mold and the secondary cooling section The amount of water can be controlled according to the requirements of ...

Embodiment 2

[0033] Steel for hot-rolled U-shaped steel sheet piles resistant to acidic soil corrosion, its chemical composition and weight percentage are: C 0.172%, Mn0.85%, Si 0.21%, S0.0198%, P0.0196%, Cr 0.6%, Mo 0.185%, the rest is Fe and unavoidable impurities.

[0034] A method for producing steel for hot-rolled U-shaped steel sheet piles resistant to acidic soil corrosion, the steps of which are:

[0035] 1) Smelting: adopt a deoxidation process with a weight percentage of [Al]<0.005%, add lime at a time of 15 kg / ton of steel at the beginning of the furnace for mixed flushing, and the thickness of the slag on the liquid surface is 8 mm;

[0036] 2) Continuous casting: control the pouring temperature at 1576°C to 1580°C, control the superheat of continuous casting at 20°C, cast at a speed of 1.5 m / min, control the thickness of mold flux on the liquid surface at 3 mm, and cool the mold and the secondary cooling section The amount of water can be controlled according to the requireme...

Embodiment 3

[0041] Steel for hot-rolled U-shaped steel sheet piles resistant to acidic soil corrosion, its chemical composition and weight percentage are: C 0.21%, Mn1.25%, Si 0.35%, S0.0195%, P0.0194%, Cr 0.81%, Mo 0.2%, the rest is Fe and unavoidable impurities.

[0042] A method for producing steel for hot-rolled U-shaped steel sheet piles resistant to acidic soil corrosion, the steps of which are:

[0043] 1) Carry out smelting: adopt the deoxidation process of [Al]<0.005% by weight, add lime at a time at 20 kg / ton of steel at the beginning of the furnace for mixed flushing, and the thickness of the steel slag on the liquid surface is 10 mm;

[0044] 2) Conduct continuous casting: control the pouring temperature at 1575°C to 1580°C, control the superheat of continuous casting at 28°C, cast at 2.0 m / min, control the thickness of the mold flux on the liquid surface at 4.0 mm, and cool the mold and the secondary cooling section The amount of water can be controlled according to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com