Bellows material and production method thereof

A corrugated pipe and raw material technology, which is applied in the field of corrugated pipe materials and its preparation, can solve the problems of stability, flexibility, high temperature aging resistance, poor low temperature impact resistance, and environmental protection. The conditions are easy to control, excellent flexibility, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Correspondingly, in another aspect, the embodiment of the present invention also provides a method for preparing a bellows material. The method comprises the steps of:

[0026] S01: Weigh the raw materials of each component according to the above bellows material formula;

[0027] S02: Stir and mix the ingredients of the above-mentioned raw materials, and then melt and extrude them to obtain bellows materials.

[0028] The preparation method of the bellows material has simple process, easy control of conditions and high efficiency, and is very suitable for industrial production. The corrugated pipe material made by this method has excellent flexibility, flame retardancy, thermal stability and molding stability.

[0029] Specifically, in the above step S02, the stirring and mixing time is 5-20 minutes; the melt extrusion is carried out in a twin-screw extruder, and the operating parameters of the twin-screw extruder are: the length-to-diameter ratio of the screw is 28-...

Embodiment 1

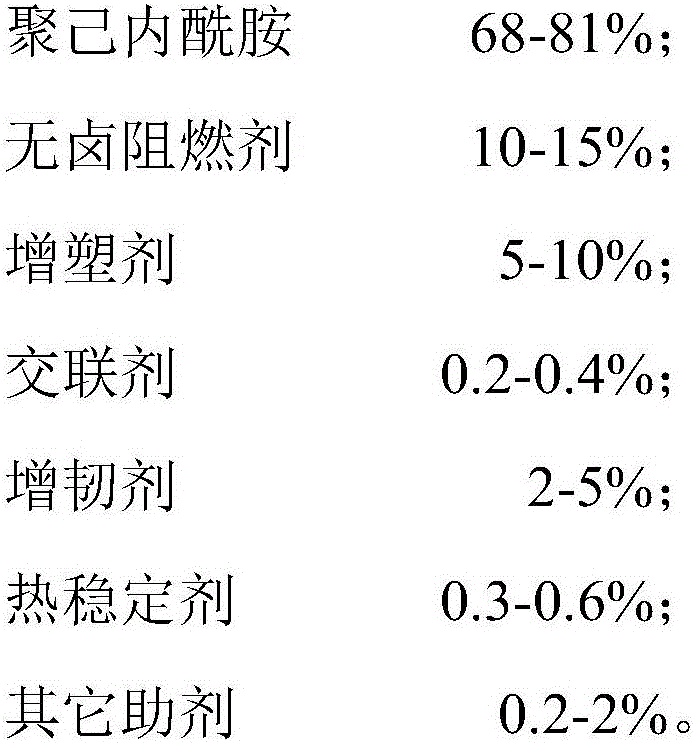

[0032] A corrugated pipe material, which includes the components in mass percentage as shown in Table 1.

[0033] The preparation method of above-mentioned automobile water tank material is as follows:

[0034] S11: Weigh each component raw material respectively according to the above-mentioned formula of automobile water tank material;

[0035] S12: Pass the ingredients and raw materials in the above step S11 through a parallel co-rotating twin-screw extruder to obtain an automobile water tank material.

[0036]In the above step S12: Stir and mix all the components except the short glass fiber evenly, and then granulate the mixture through a parallel twin-screw extruder with an aspect ratio of 25-40, while the short glass fiber is fed through the side join in. The operating parameters of the parallel co-rotating twin-screw extruder are: the temperature in the first zone is 100-180°C; the temperature in the second, third, and fourth zones is 260-280°C; 240°C; main engine sp...

Embodiment 2

[0038] A corrugated pipe material, which includes the components in mass percentage as shown in Table 1.

[0039] The preparation method of above-mentioned automobile water tank material is as follows:

[0040] S21: Weigh each component raw material respectively according to the formula of the above-mentioned automobile water tank material;

[0041] S22: Pass the ingredients and raw materials in the above step S21 through a parallel co-rotating twin-screw extruder to obtain an automobile water tank material.

[0042] In the above step S22: Stir and mix all components except the short glass fiber evenly, and then granulate the mixture through a parallel twin-screw extruder with an aspect ratio of 25-40, while the short glass fiber is fed through the side join in. The operating parameters of the parallel co-rotating twin-screw extruder are: the temperature in the first zone is 100-180°C; the temperature in the second, third, and fourth zones is 260-280°C; 240°C; main engine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com