Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Increased heat generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

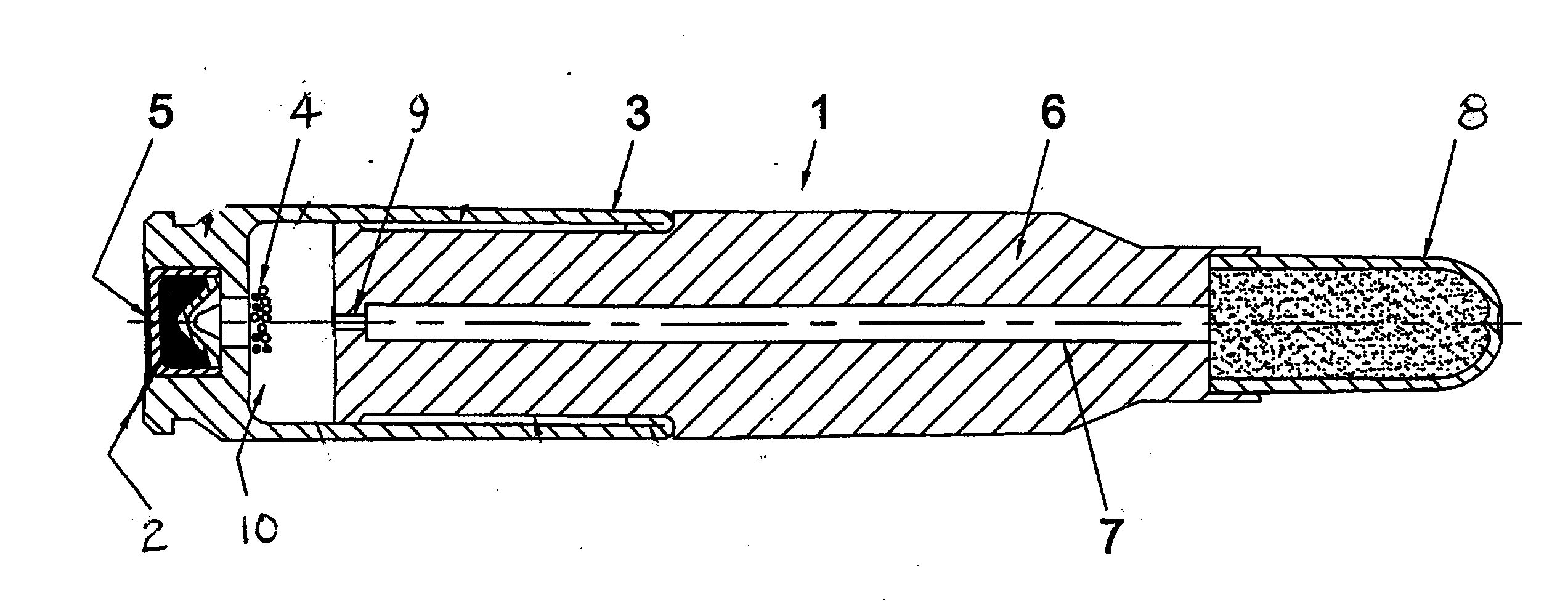

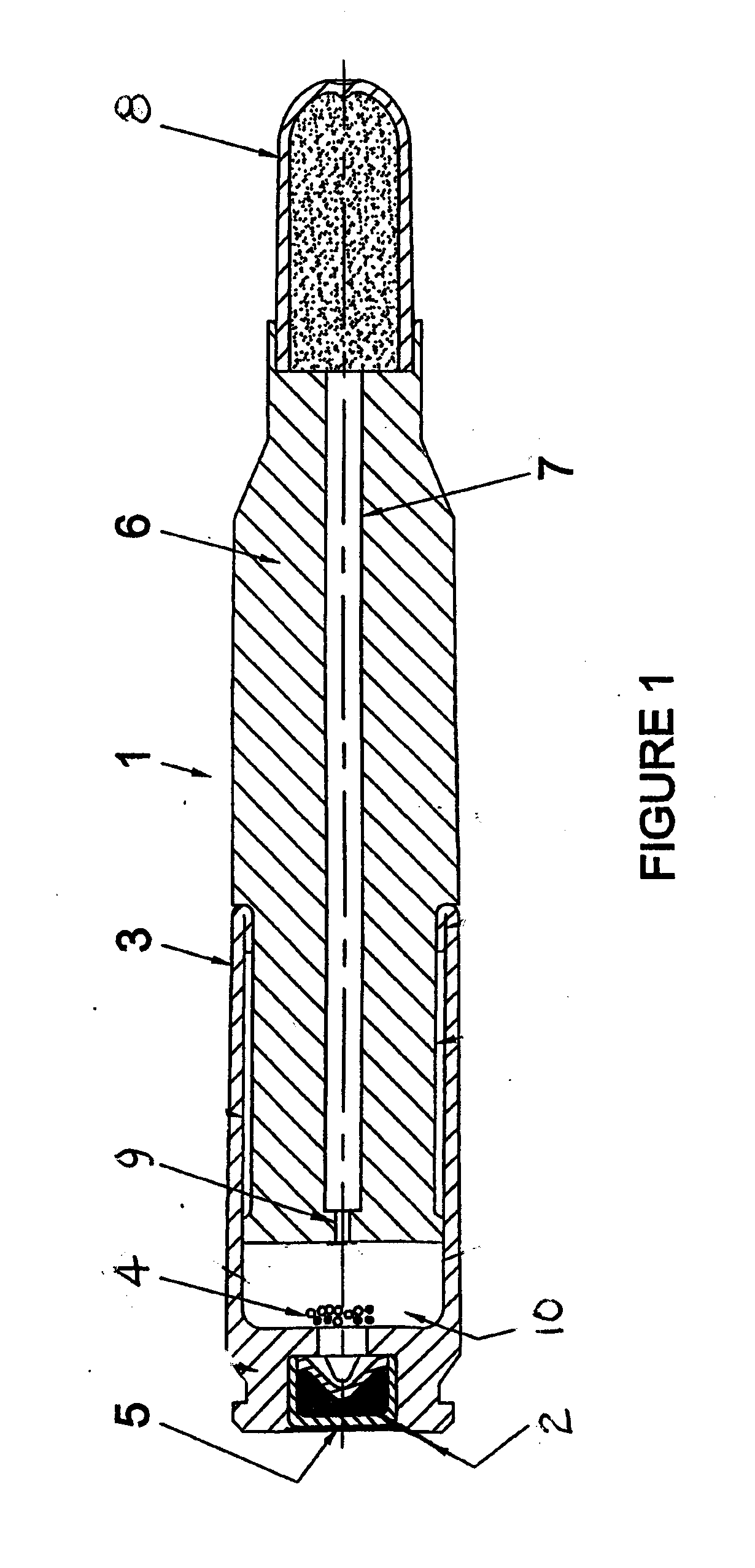

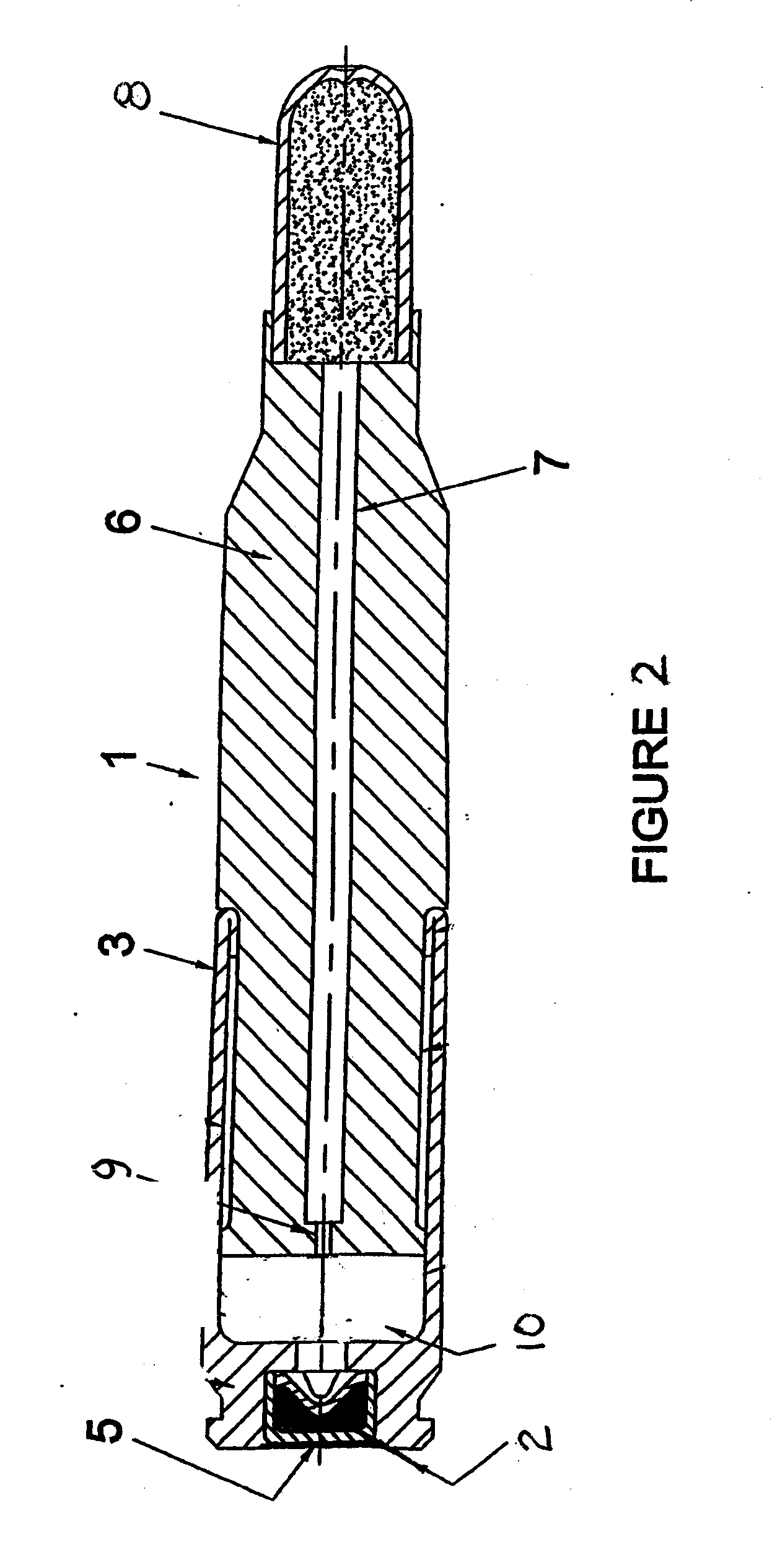

Low toxicity primer compositions for reduced energy ammunition

InactiveUS20100300319A1Increased heat generationHigh sensitivityAmmunition projectilesShotgun ammunitionToxic materialOxidizing agent

A primer composition with reduced toxicity suited for reduced-energy ammunition comprises bismuth (III) oxide as the principal oxidizer and contains a portion of propellant composition mixed therein. This composition may also be used in a cartridge which is otherwise substantially free of any other propellant compound and preferably produces a residue which is substantially free of toxic substances.

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA VALLEYFIELD INC

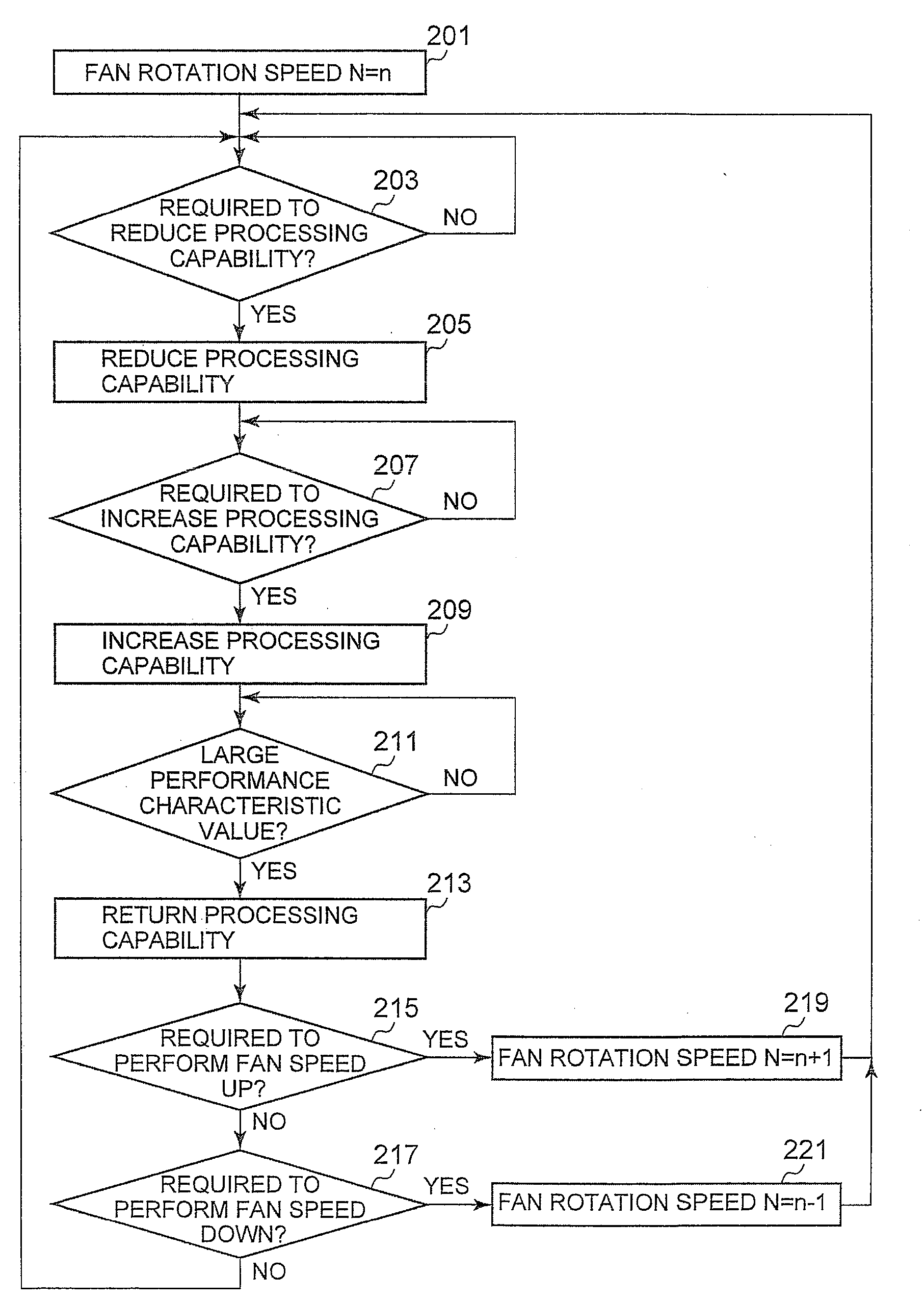

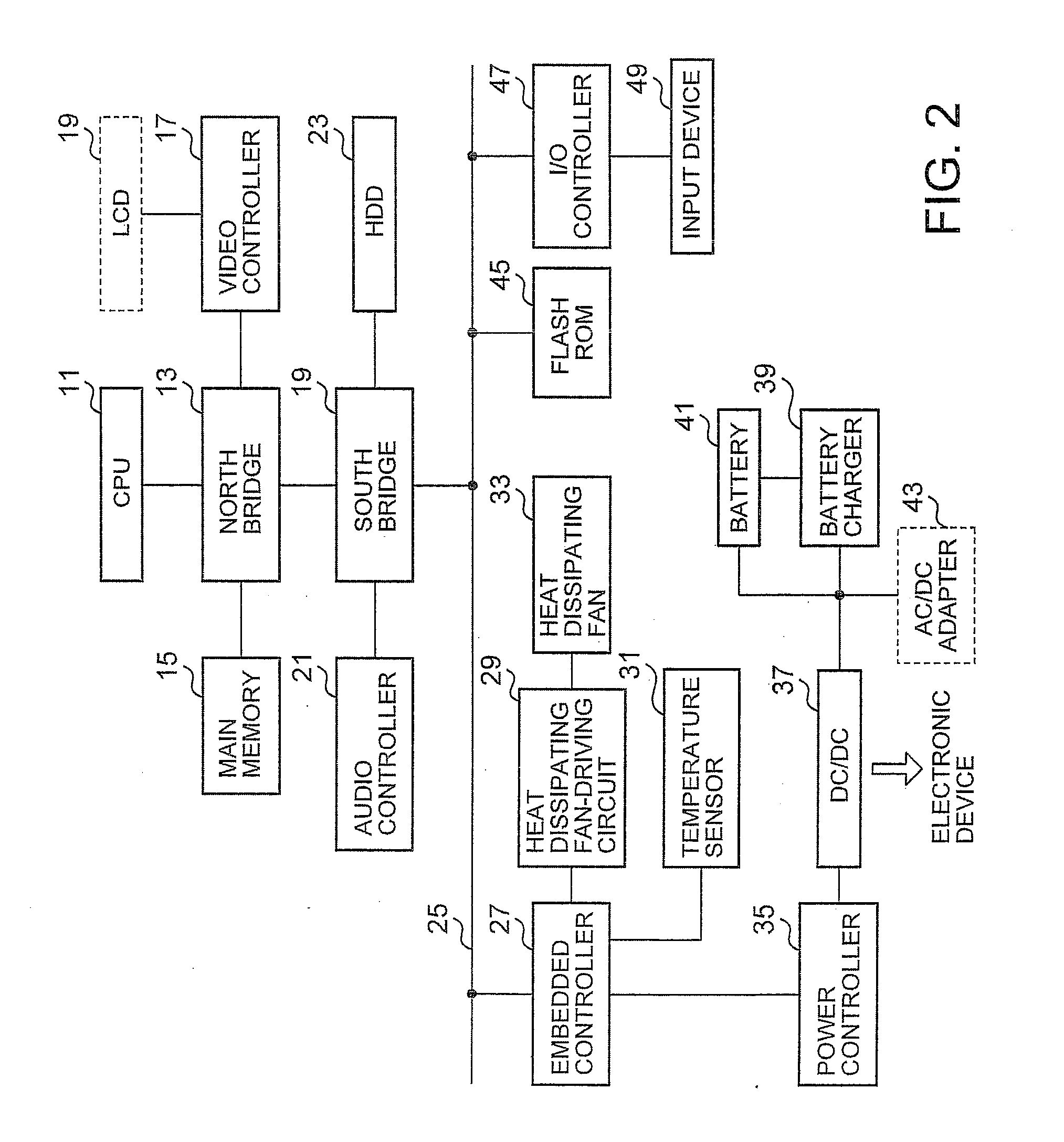

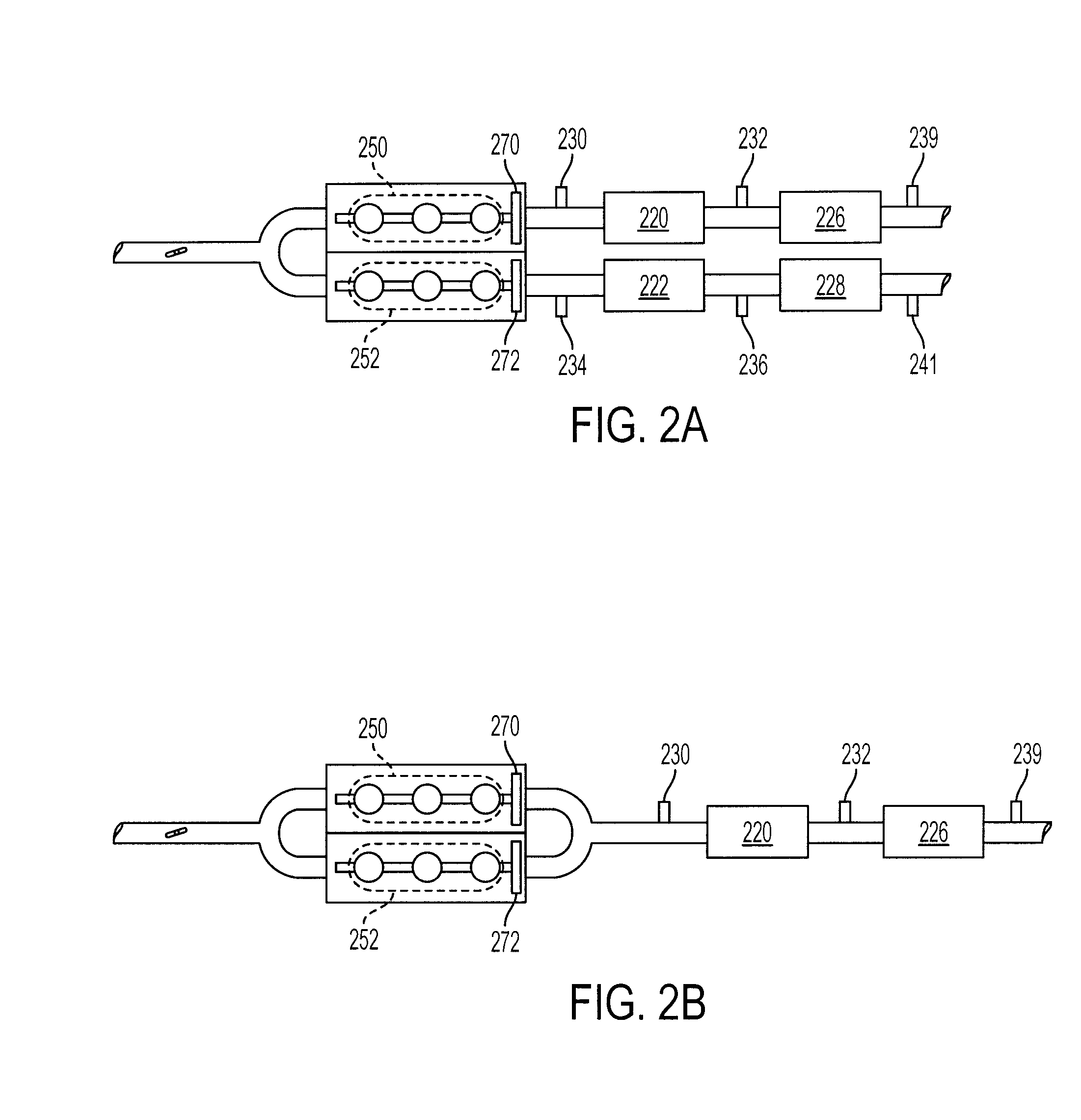

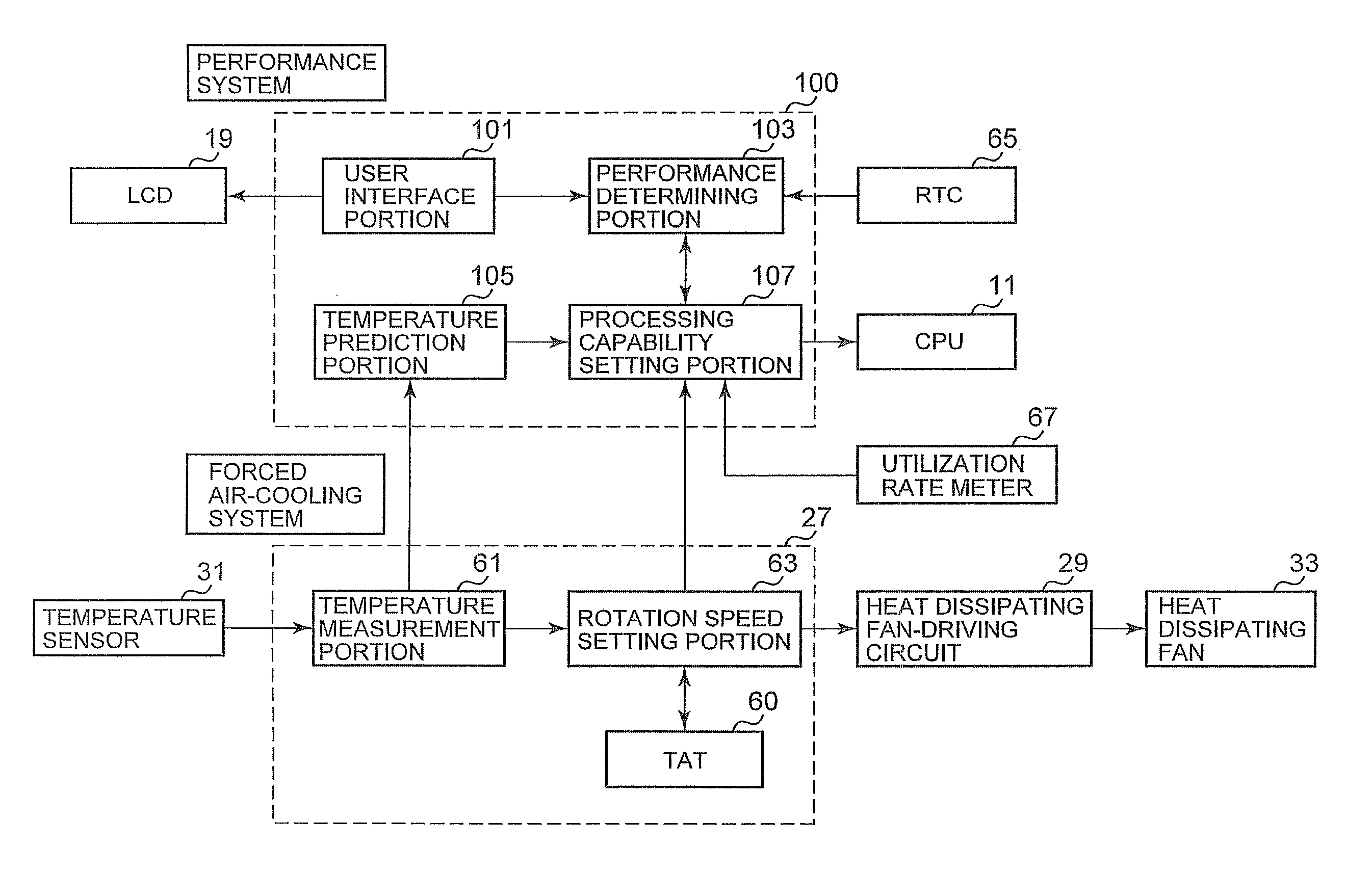

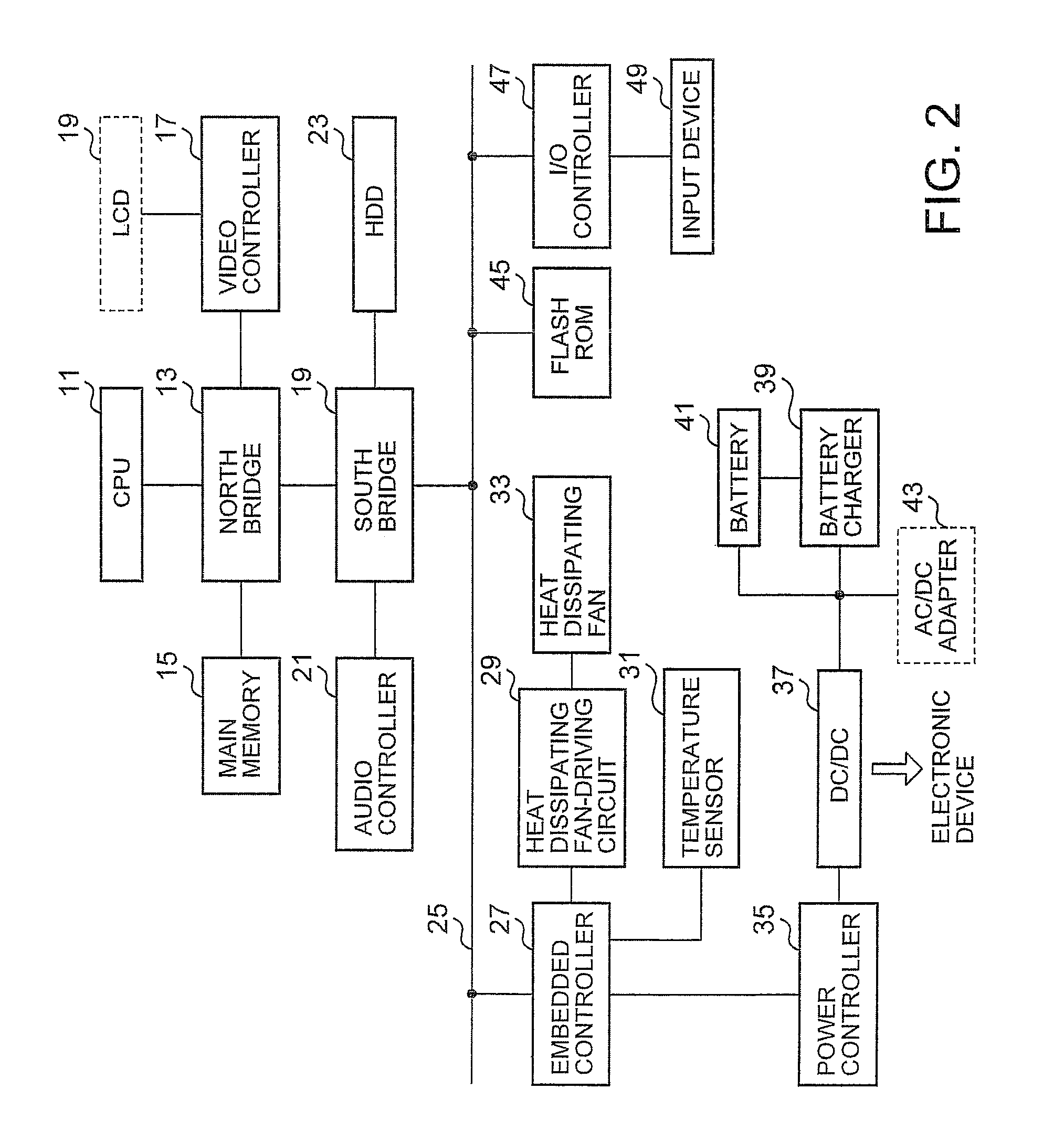

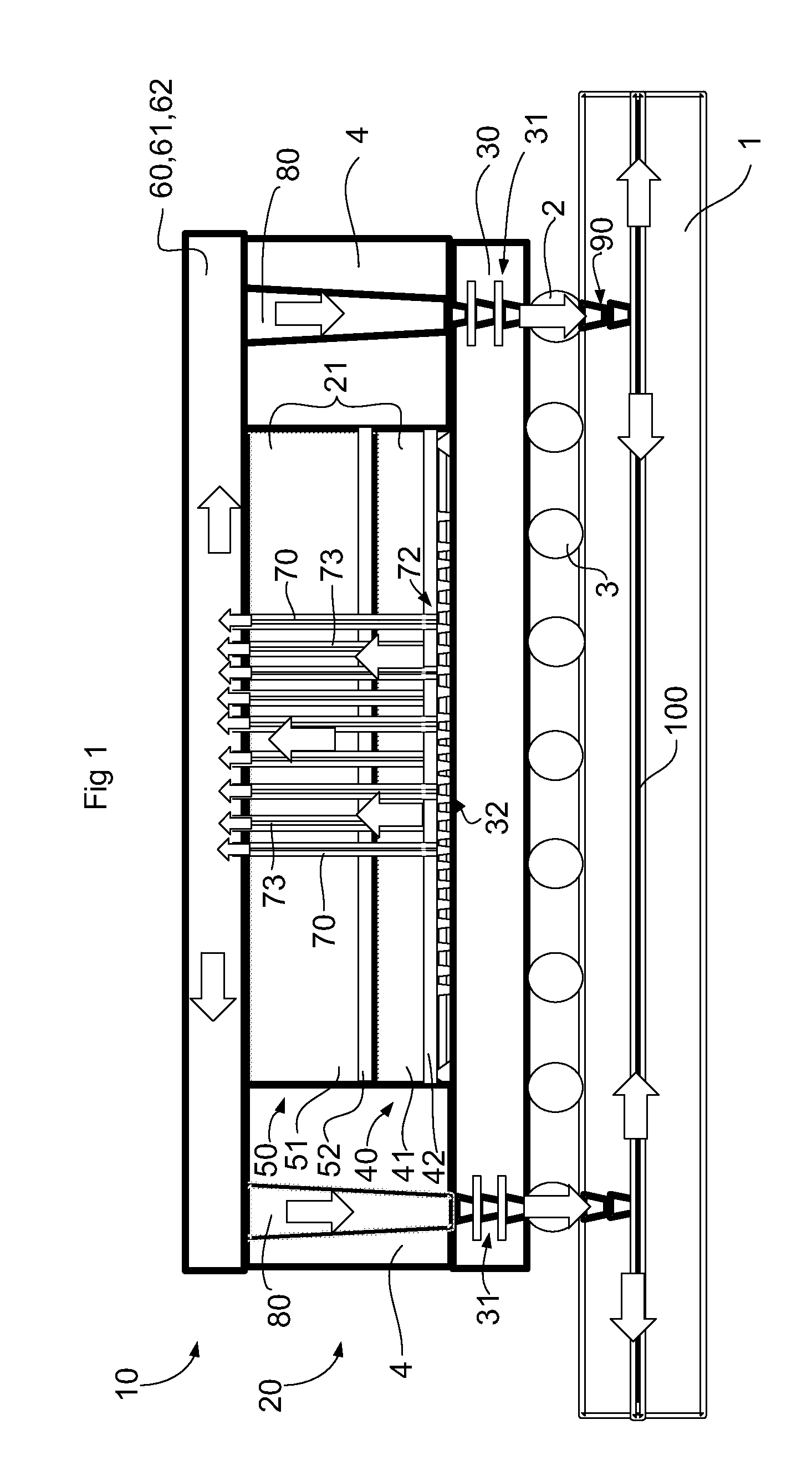

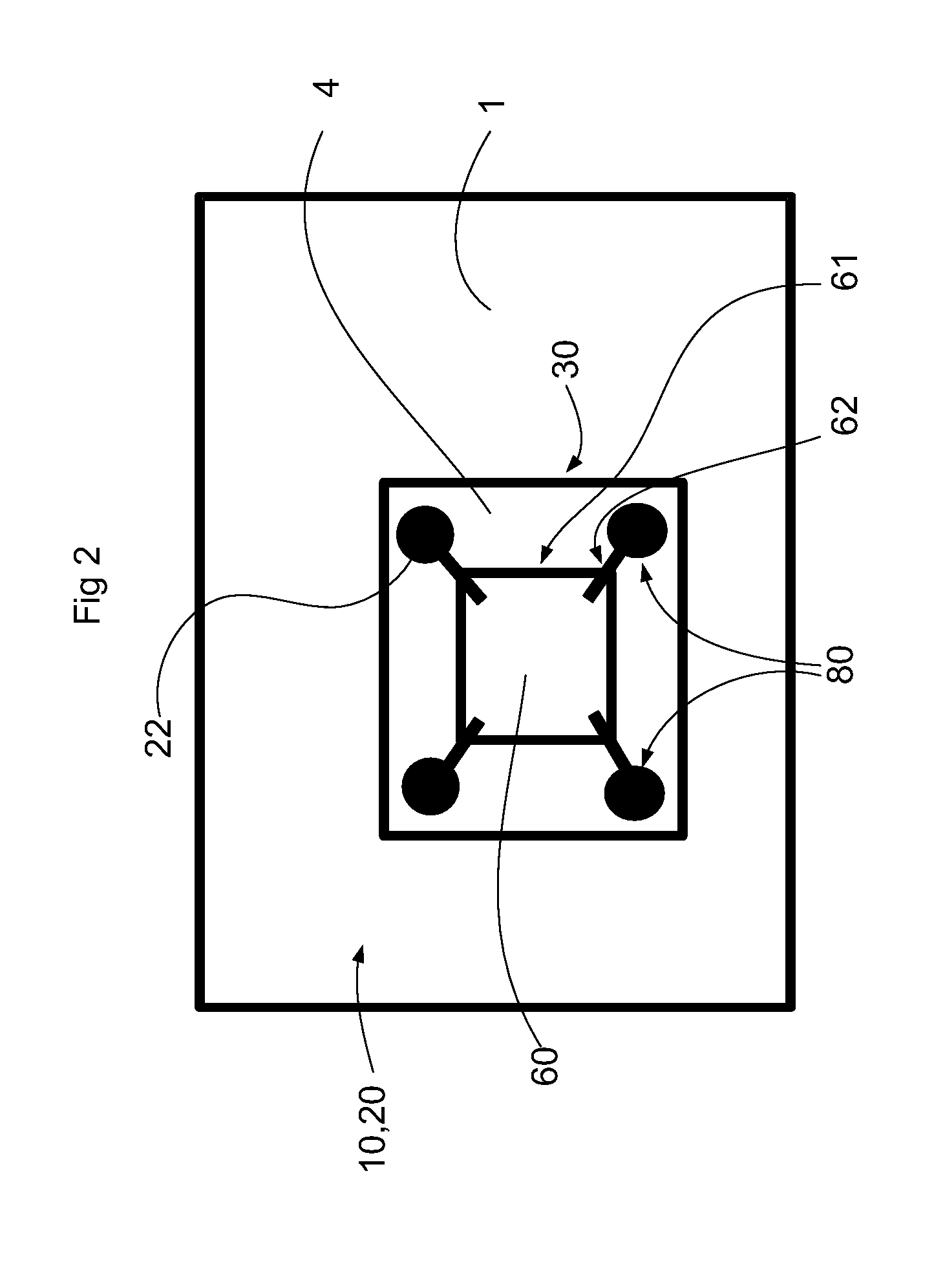

Heat Dissipation System for Computers

ActiveUS20100030395A1Maximizing levelEasy to handleThermometer detailsEnergy efficient ICTEngineeringThreshold temperature

A heat dissipation system within a housing of a computer is disclosed. The heat dissipation system includes a heat dissipating fan, a temperature sensor, a rotation speed setting portion, and a performance control portion. The rotation speed setting portion is configured to change a rotation speed of the heat dissipating fan in a stepwise manner based on a threshold temperature and a measurement temperature measured by the temperature sensor. The performance control portion is configured to temporarily reduce the processing capability of a processor within the computer in response to a determination that the measurement temperature has exceeded the threshold temperature during a predetermined period of time.

Owner:LENOVO PC INT

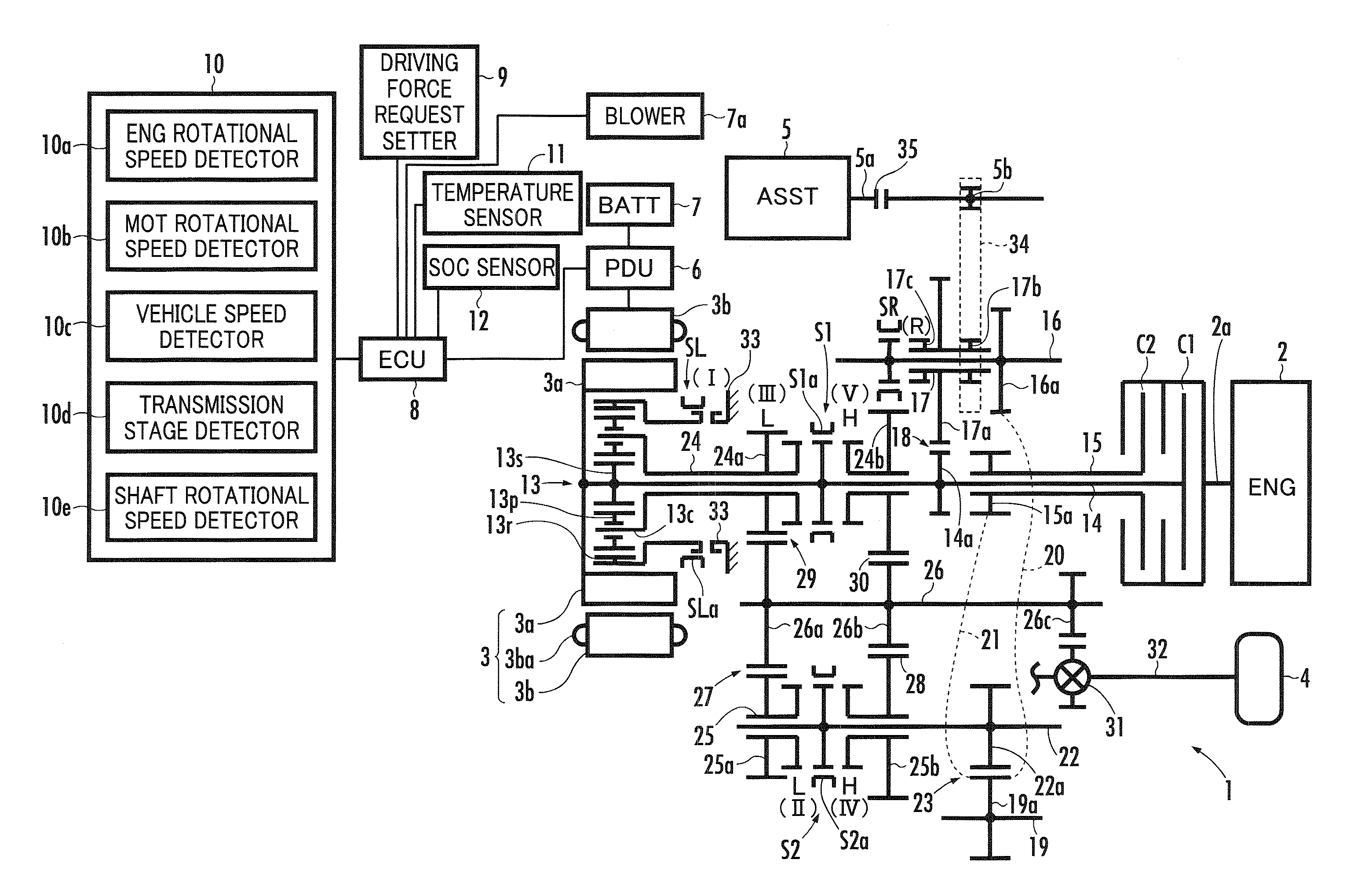

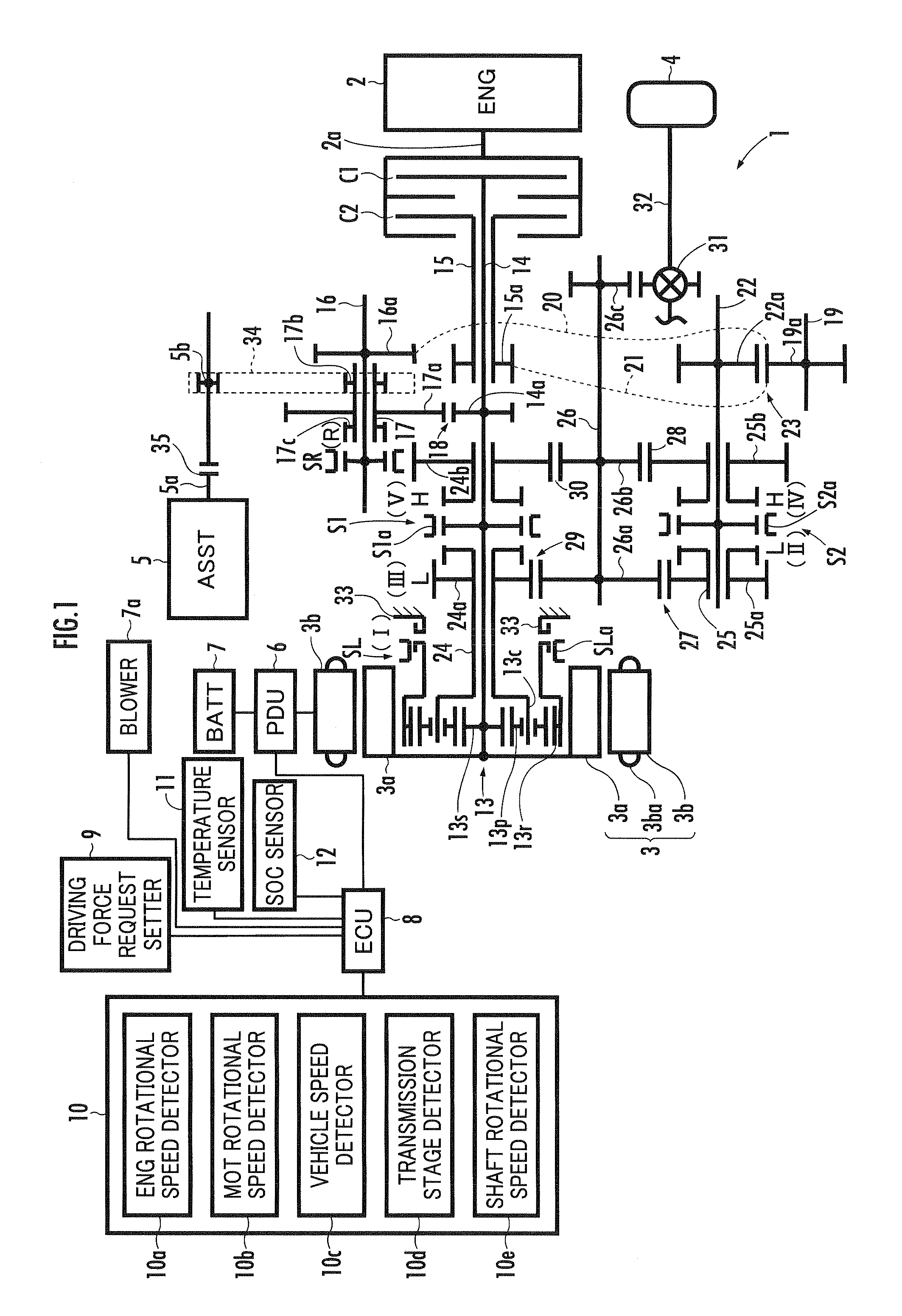

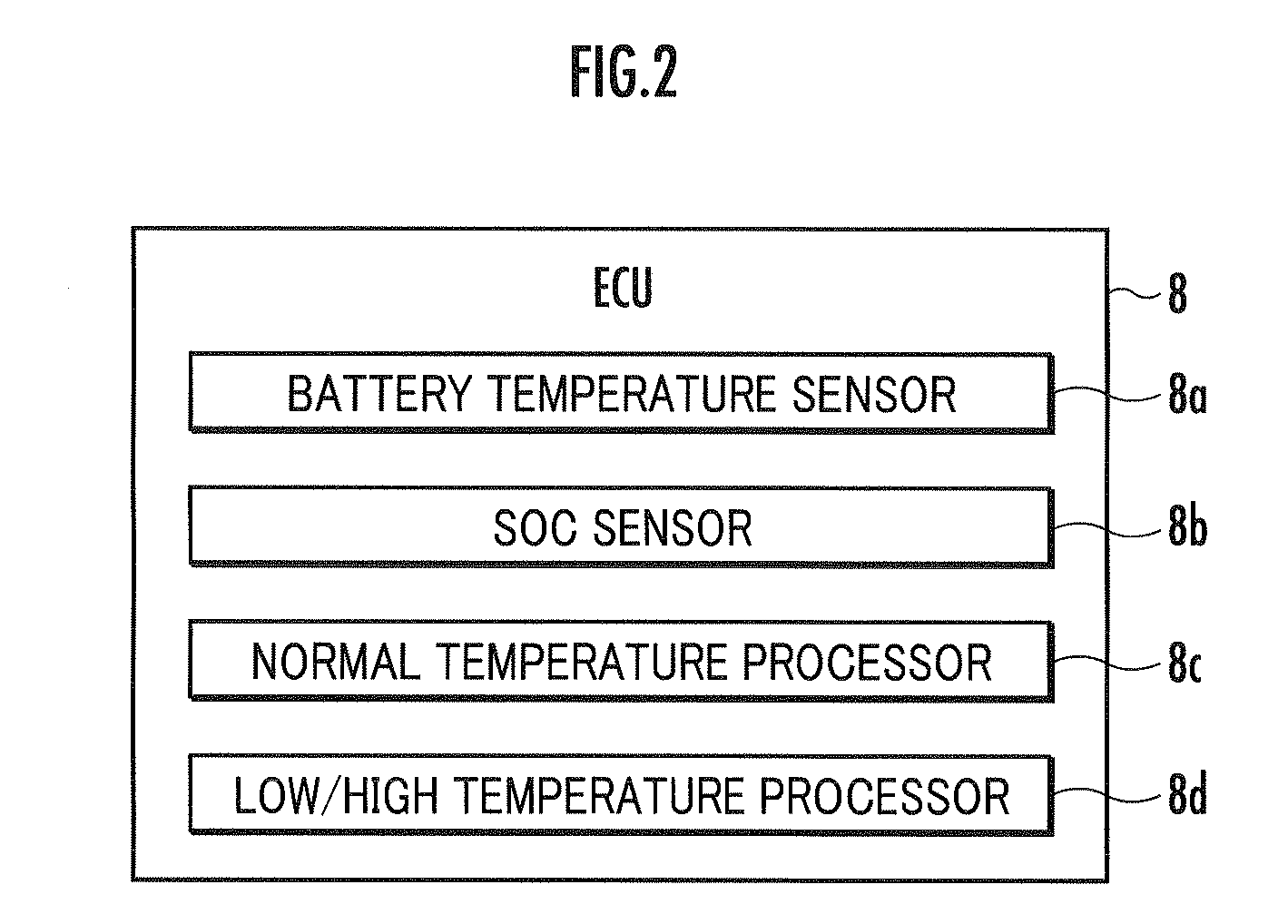

Hybrid vehicle

ActiveUS20120245781A1Increase delayImprove gear shifting responsivenessAuxillary drivesElectric devicesDrive wheelIntermediate stage

A transmission has a first transmission group which is capable of transmitting motive power from an electric motor and / or an engine to driven wheels and which is provided with a plurality of transmission stages having different transmission ratios and a second transmission group capable of transmitting motive power from the engine to the driven wheels. If the temperature of a battery detected by a temperature sensor is below a first predetermined temperature or a second predetermined temperature or higher, then an ECU sets the transmission stage of the first transmission group at an intermediate stage and carries out control so as to travel at an intermediate stage of the second transmission group which is adjacent to the intermediate stage of the first transmission group.

Owner:HONDA MOTOR CO LTD

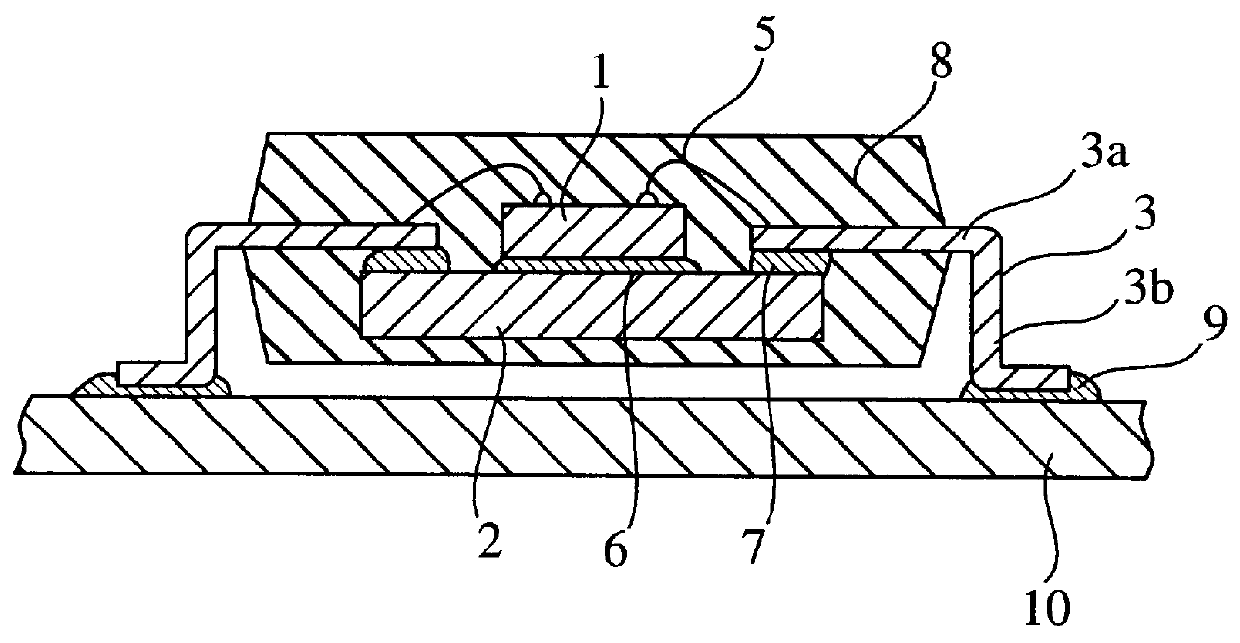

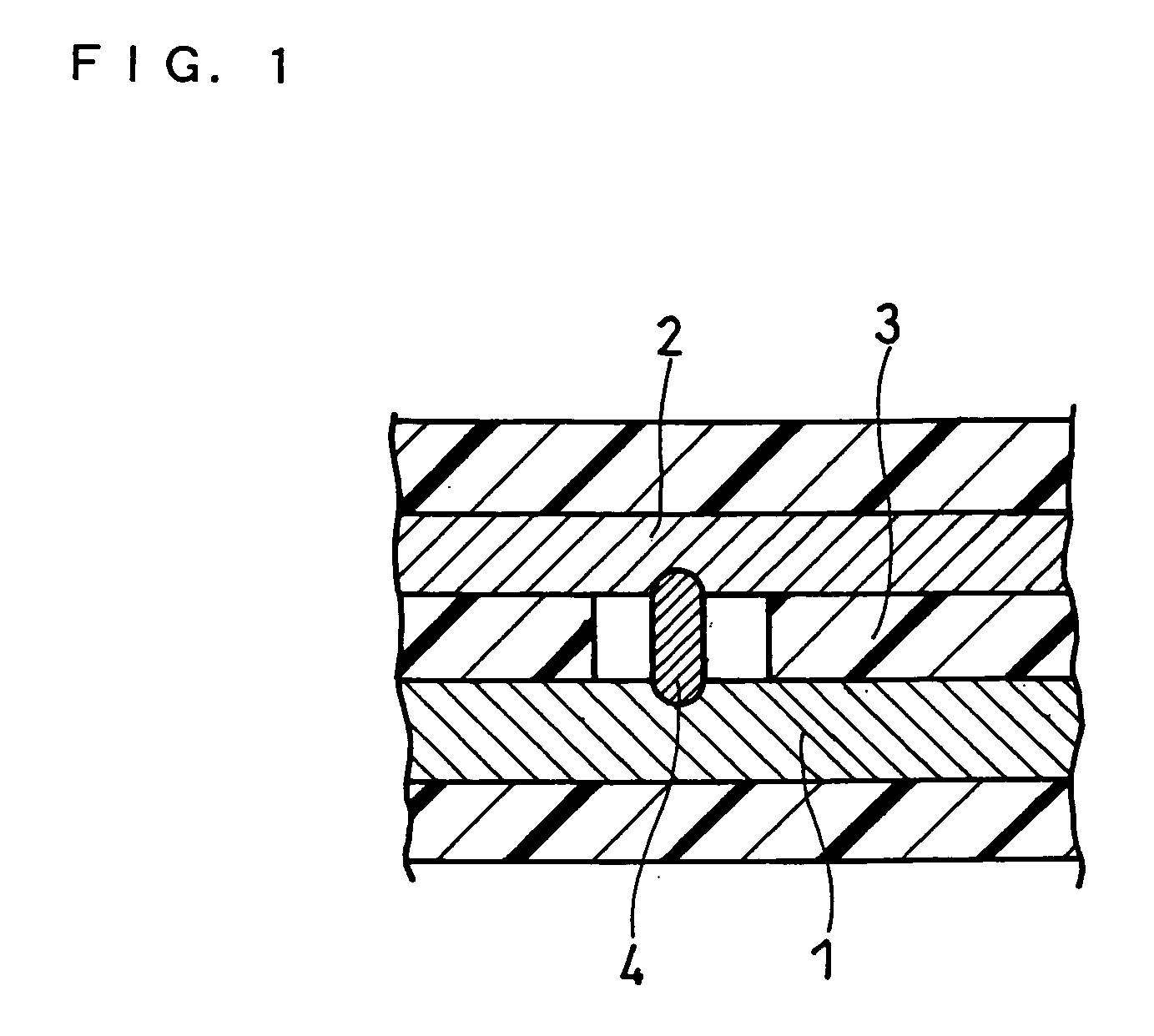

Thermal package wth heat slug for die stacks

InactiveUS20130277821A1Improve cooling effectImproved thermal connectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor assembly comprises a package, which in turn comprises at least one substrate, a first die stacked onto the substrate, at least one further die stacked onto the first die, at least one heat spreader in the package, and TSV:s extending through the stacked dies. The ends of the TSV:s are exposed at the further die.

Owner:SONY MOBILE COMM INC +1

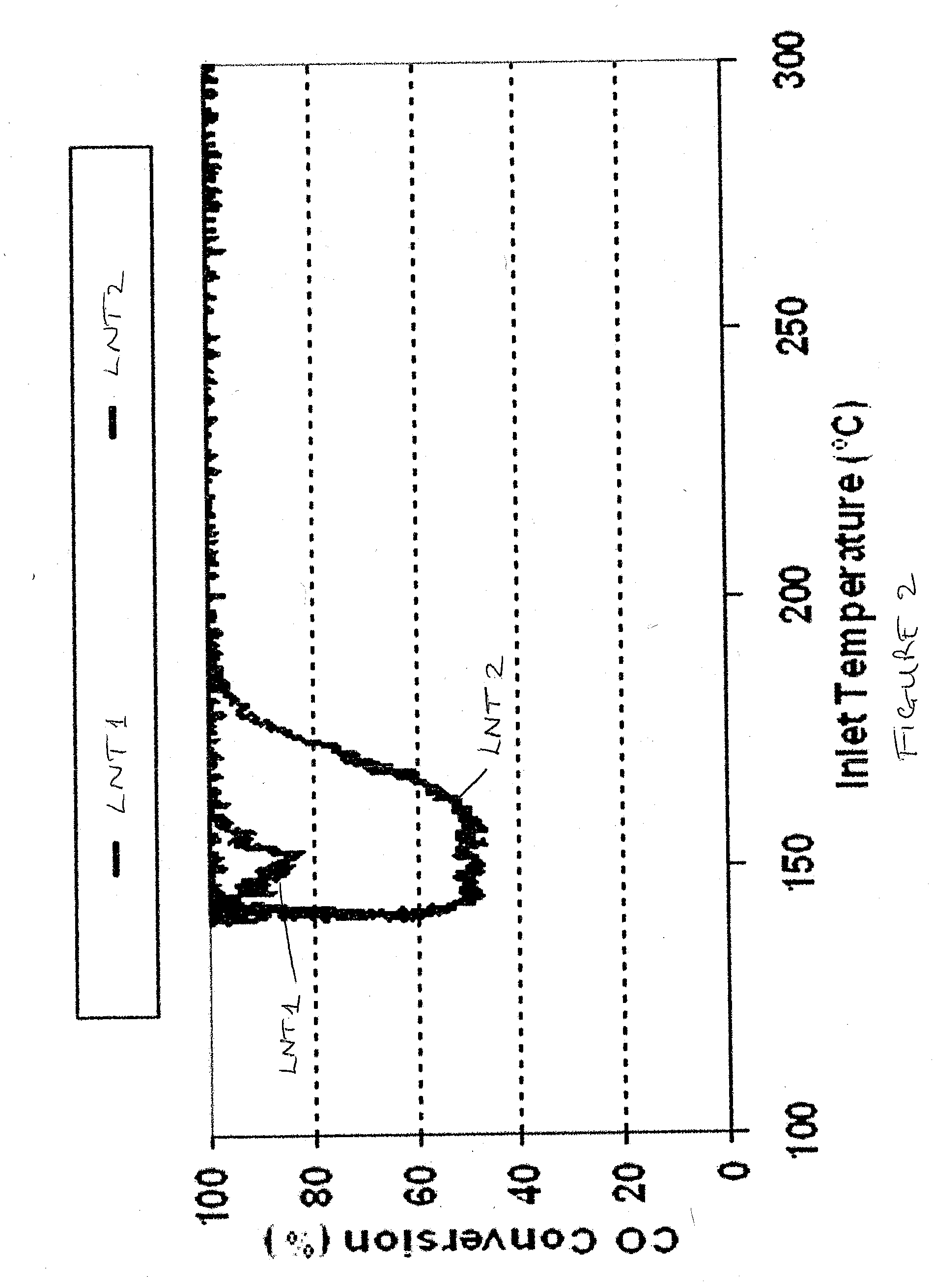

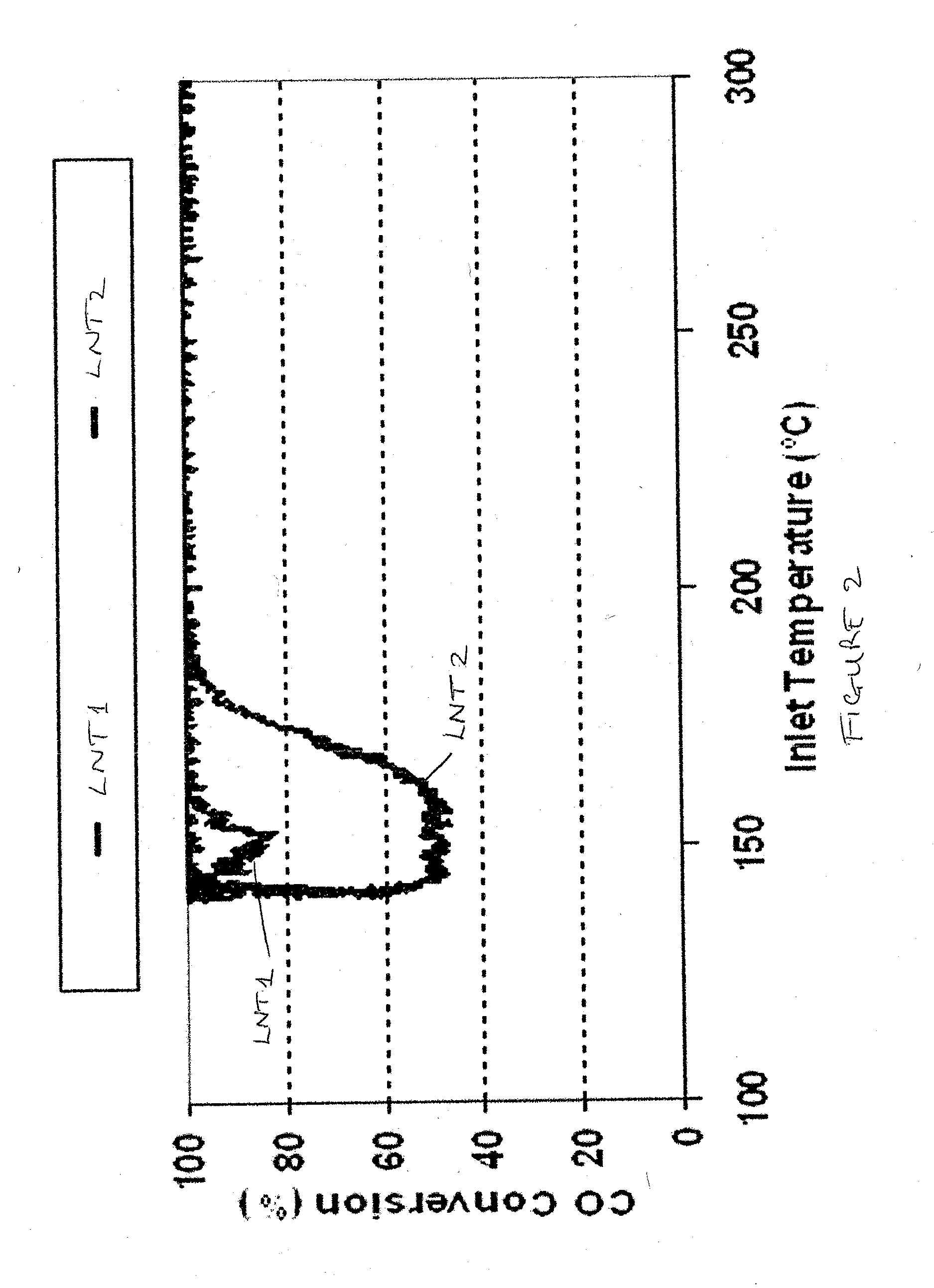

NOx TRAP

InactiveUS20110154807A1Improve heat generationEfficient releaseGas treatmentInternal combustion piston enginesCeriumInternal combustion engine

A NOx trap comprises components comprising at least one platinum group metal, at least one NOx storage material and bulk ceria or a bulk cerium-containing mixed oxide deposited uniformly in a first layer on a honeycombed substrate monolith, the components in the first layer having a first, upstream, zone having increased activity relative to a second, downstream zone for oxidising hydrocarbons and carbon monoxide, and a second, downstream, zone having increased activity to generate heat during a desulphation event, relative to the first zone, wherein the second zone comprises a dispersion of rare earth oxide, wherein the rare earth oxide loading in the second zone is greater than the loading in the first zone. An exhaust system for a lean burn internal combustion engine, a vehicle comprising a lean burn internal combustion engine and the exhaust system and methods of making the NOx trap are also disclosed.

Owner:JOHNSON MATTHEY PLC

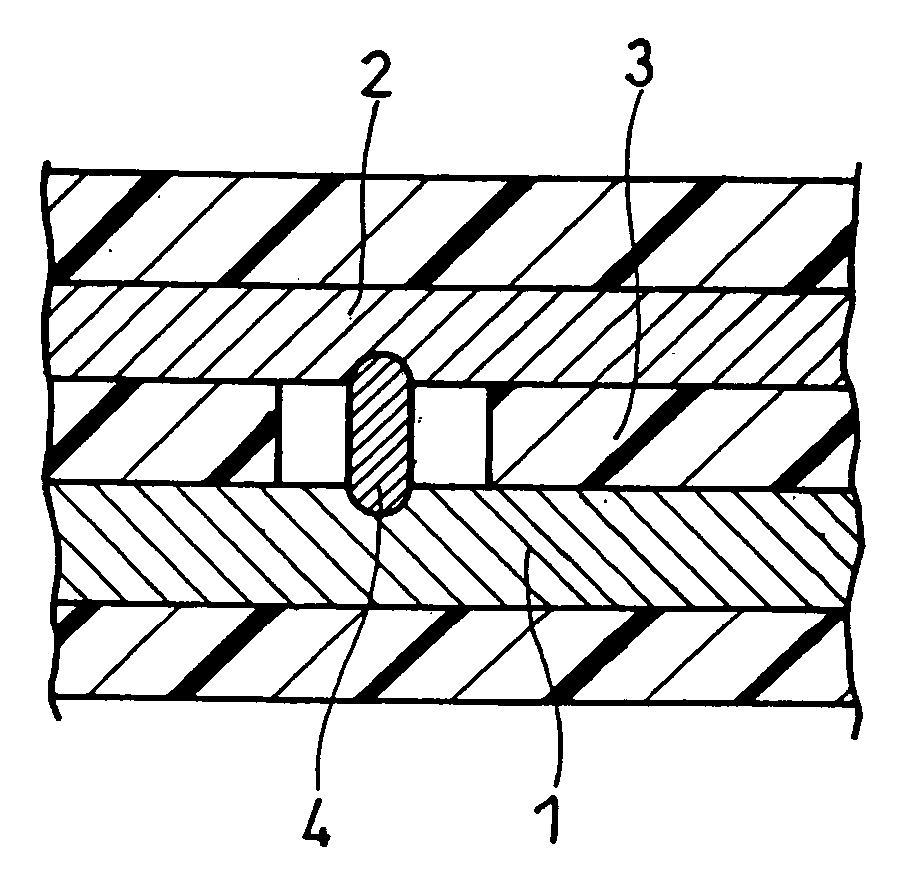

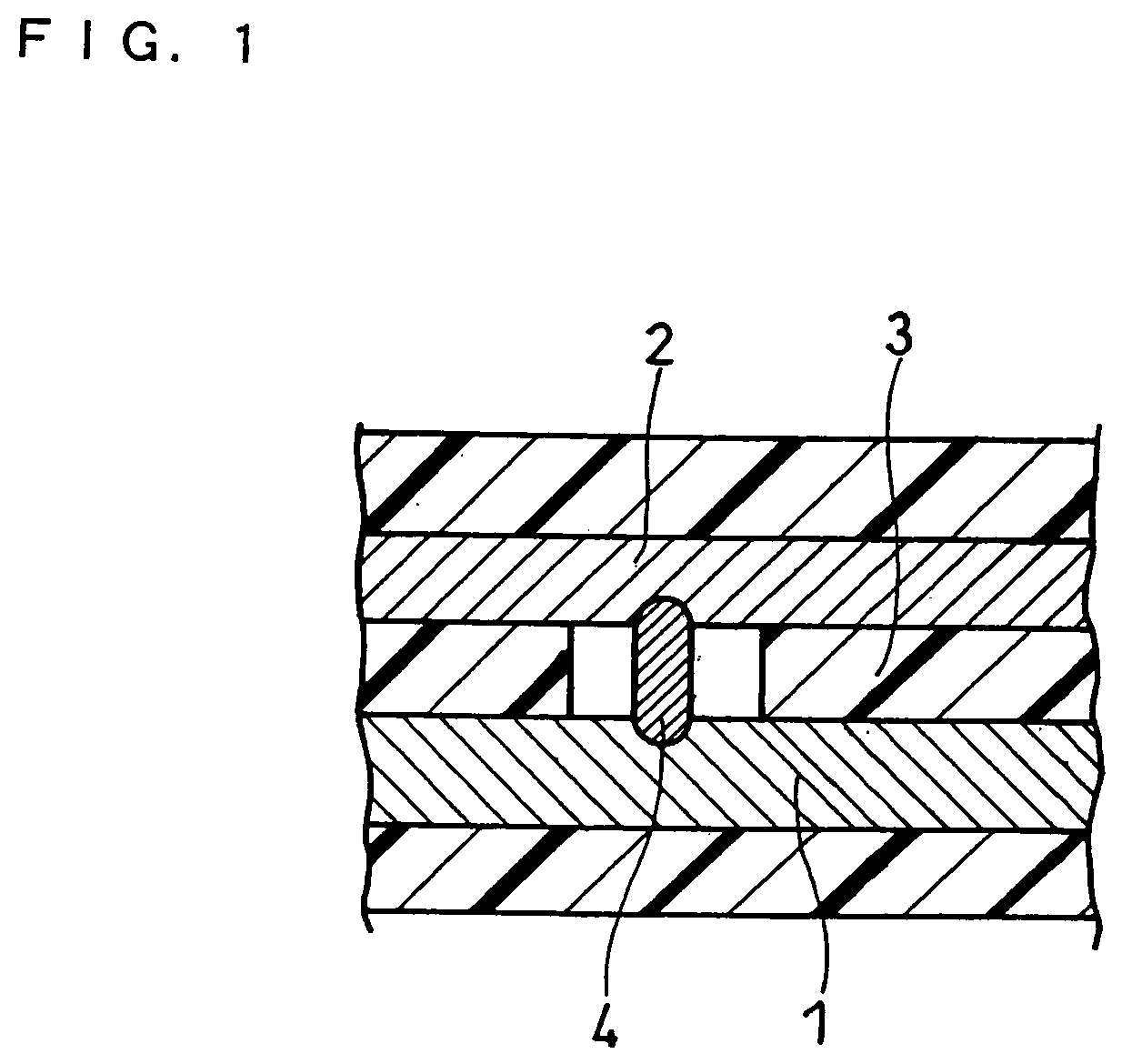

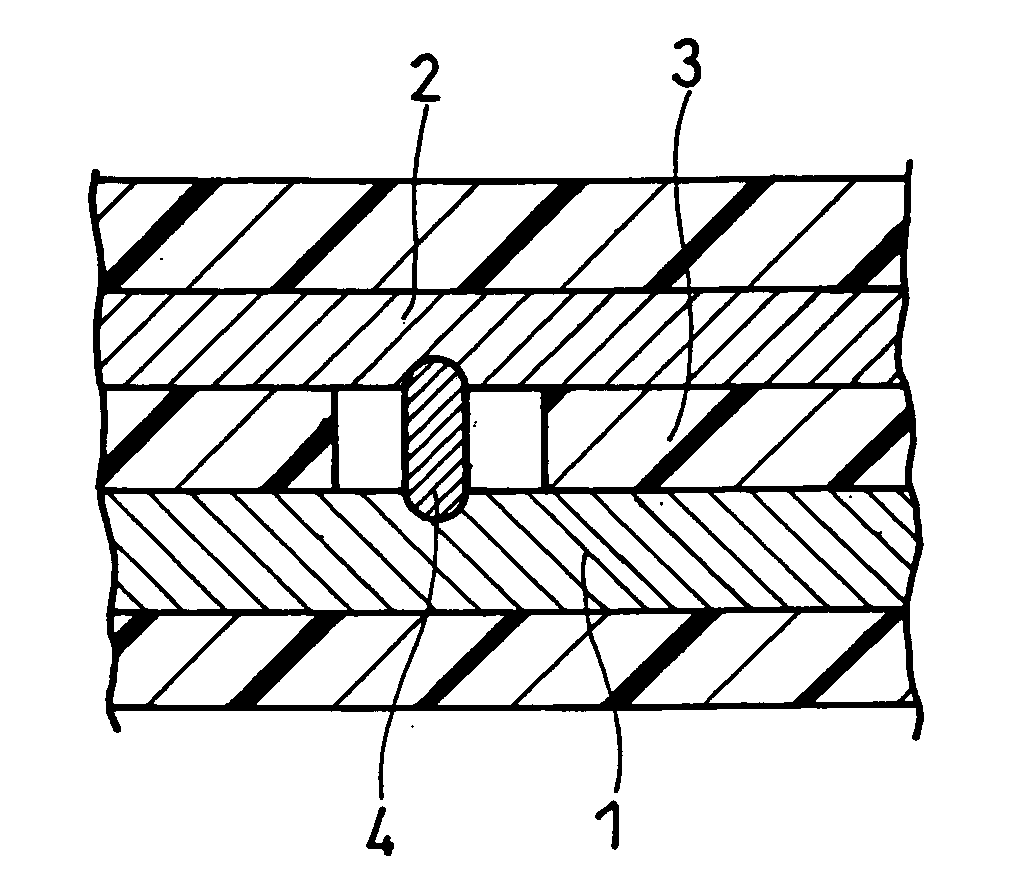

Method for producing a heat spreader and semiconductor device with a heat spreader

InactiveUS6032362AImprove cooling effectSmall differenceSemiconductor/solid-state device detailsSolid-state devicesMetal sheetCopper

A heat spreader for a semiconductor device is constituted by an integral laminate of alternatingly stacked and diffusion-bonded Fe-Ni alloy sheets and copper-group metal sheets, the laminate having a one-directional stripe pattern of the Fe-Ni alloy sheets and the copper-group metal sheets, which appears on a planar surface on which a silicon chip is disposed. It is produced by (a) alternatingly stacking Fe-Ni alloy sheets and copper-group metal sheets, (b) hot isostatic-pressing the resulting stack of the metal sheets to form a slab, (c) rolling the slab vertically to the laminating direction of the metal sheets to form an integrated stripe-pattern laminate, and (d) cutting the integrated stripe-pattern laminate to a predetermined shape.

Owner:HITACHI METALS LTD +1

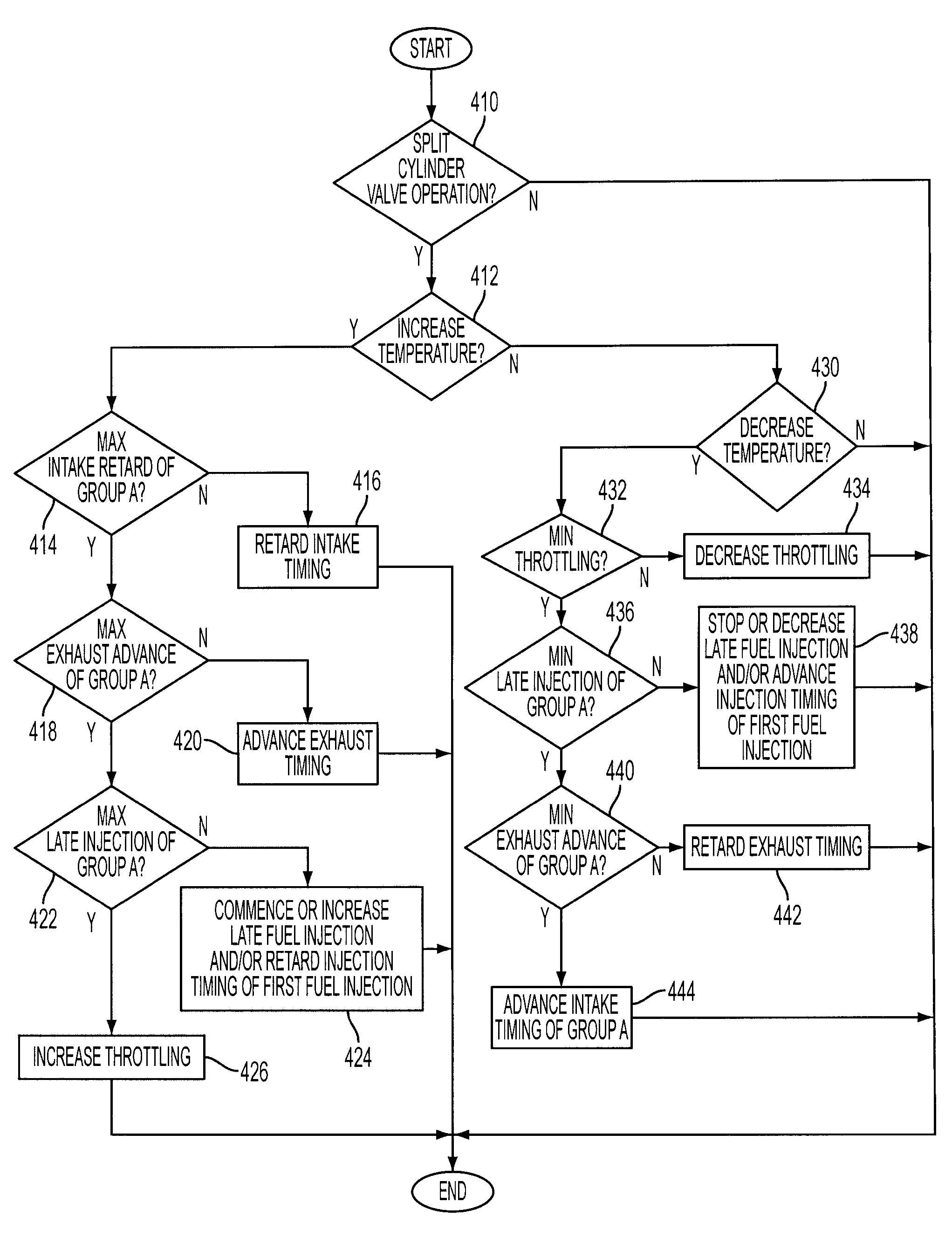

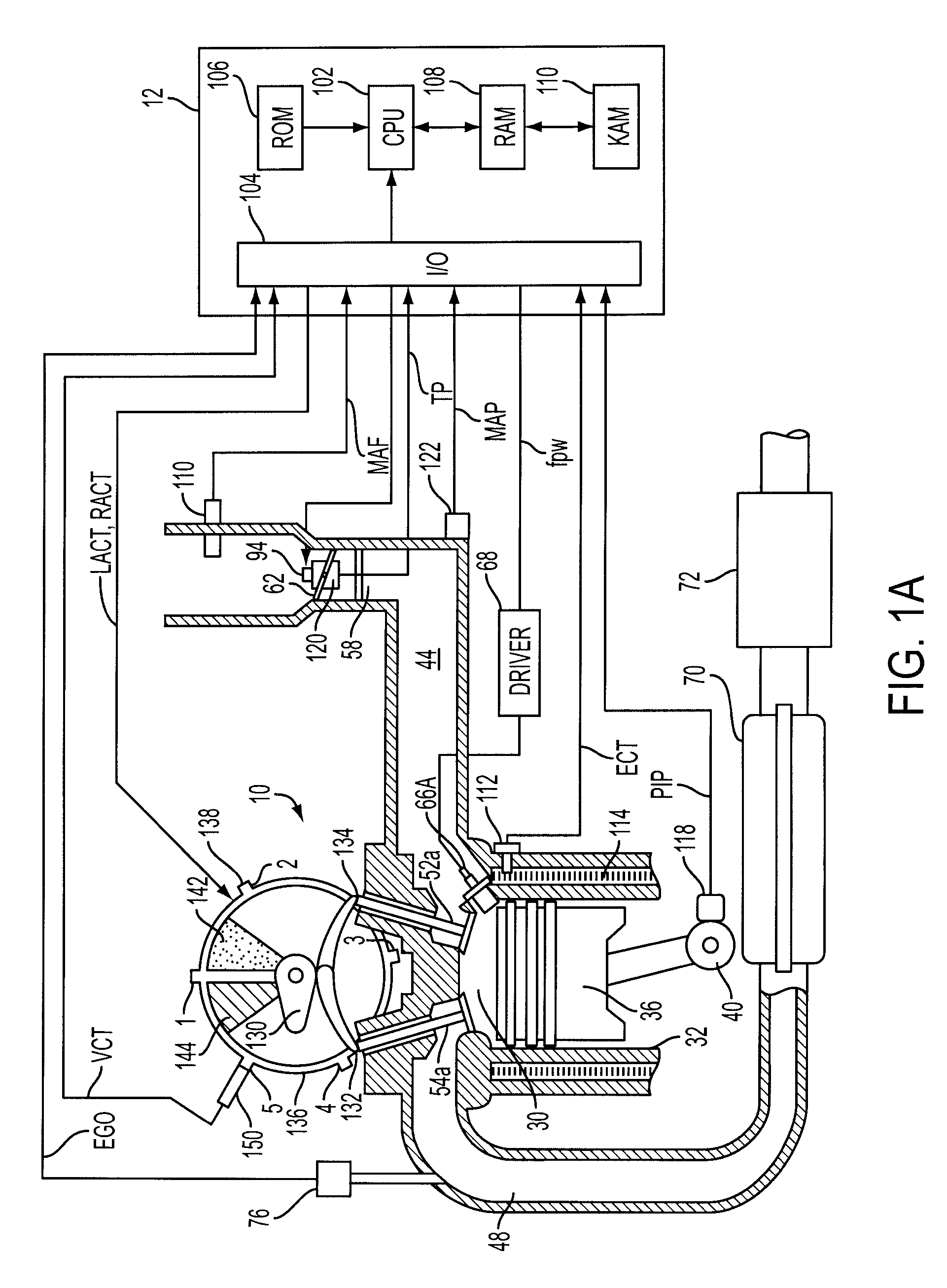

Diesel engine with differential cylinder group operation

InactiveUS7246595B1Less torqueIncreasing throttlingValve arrangementsElectrical controlCombustionExhaust valve

A method for controlling operation of a diesel engine having a plurality of cylinders, the engine including a first group of cylinders and a second group of cylinders, the method comprising of operating the first group of cylinders with a first intake and exhaust valve timing, the first group of cylinders inducting air and performing diesel compression ignition combustion of injected fuel; and operating the second group of cylinders with a second intake and exhaust valve timing, the second group of cylinders inducting air and performing diesel compression ignition combustion of injected fuel, wherein said second intake valve timing is retarded compared to said first intake valve timing or said second exhaust valve timing is advanced compared to said first exhaust valve timing.

Owner:FORD GLOBAL TECH LLC

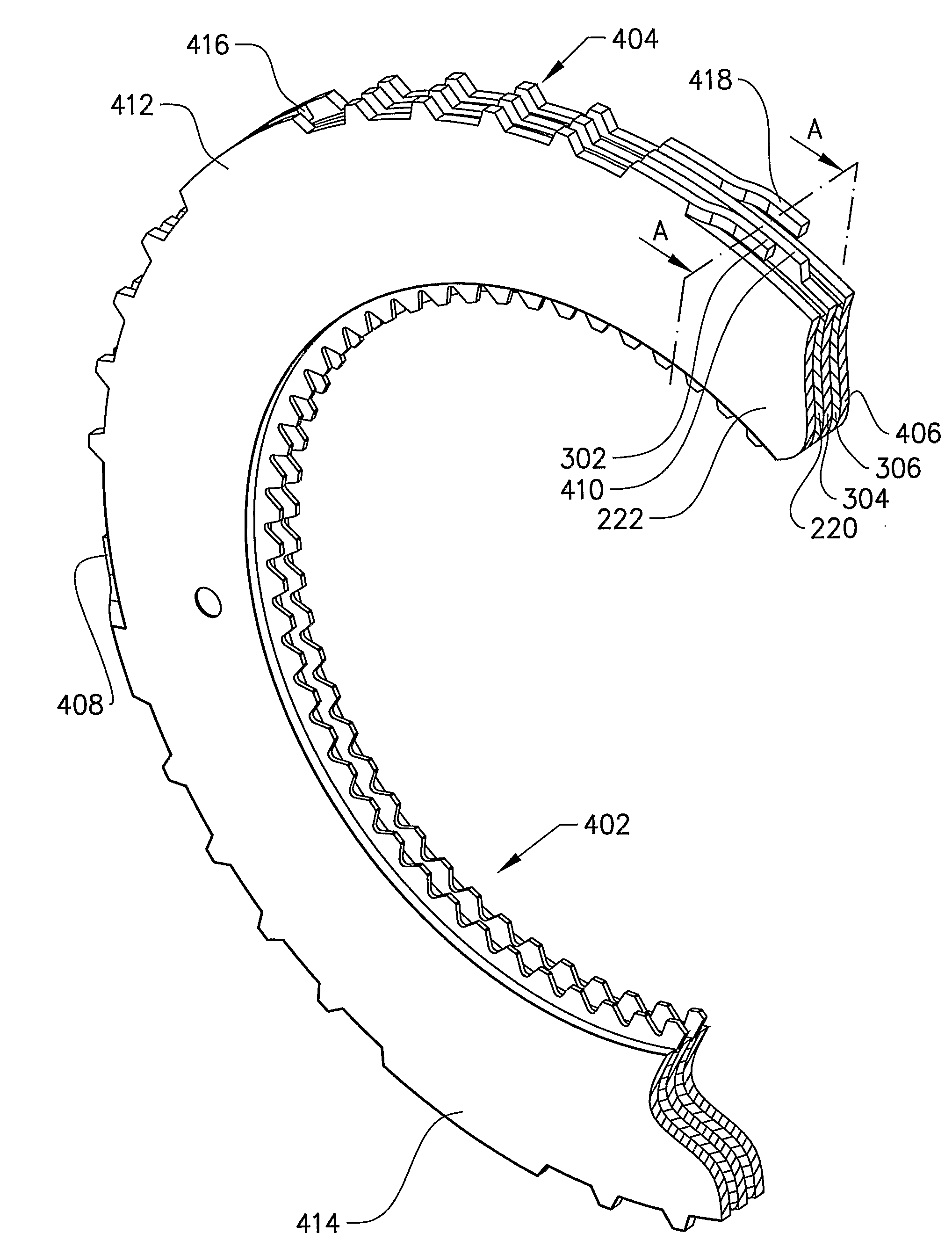

Lithium secondary battery

InactiveUS20060286438A1Increase energy densityImprove securityCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringLithium-ion battery

A lithium secondary battery including: an electrode group, a non-aqueous electrolyte and a battery case housing the electrode group and the non-aqueous electrolyte, the electrode group including a positive electrode, a negative electrode and a separator layer interposed between the positive electrode and the negative electrode, wherein an end-of-charge voltage and an end-of-discharge voltage are set in such a manner that the electrode group has an energy density of not less than 700 Wh / L, the separator layer includes a porous heat-resistant layer, and a short circuit area A produced when an internal short circuit has occurred between the positive electrode and the negative electrode, and a reduced area B of the porous heat-resistant layer that is produced by heat generation satisfy 1≦(A+B) / A≧10.

Owner:PANASONIC CORP

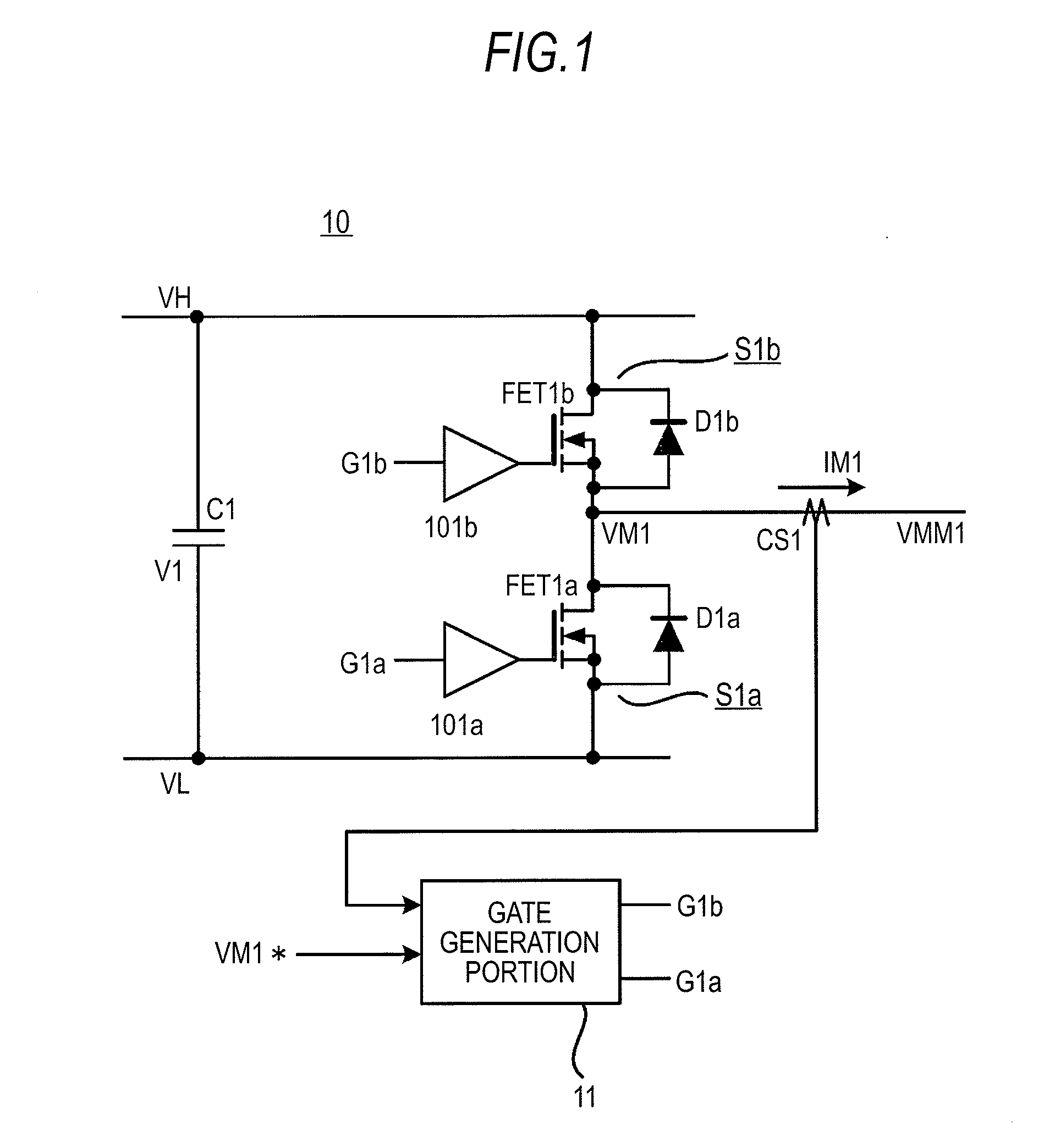

Power converter

ActiveUS20130002227A1Improve heat generationLow heat generationEfficient power electronics conversionAc-dc conversionPower flowCurrent sensor

A power converter has one set of two semiconductor switches performing switching actions, each of which is formed of an FET and a free wheel diode connected in anti-parallel to the FET, and a smoothing capacitor, and convers power by complementary switching actions of the FETs in the semiconductor switches. The power converter is provided with a current sensor that detects a direction of a current flowing through the semiconductor switches and a gate generation portion that skips ON signals of PWM gate signals of the semiconductor switches when the direction of the current flowing through the semiconductor switches is negative.

Owner:MITSUBISHI ELECTRIC CORP

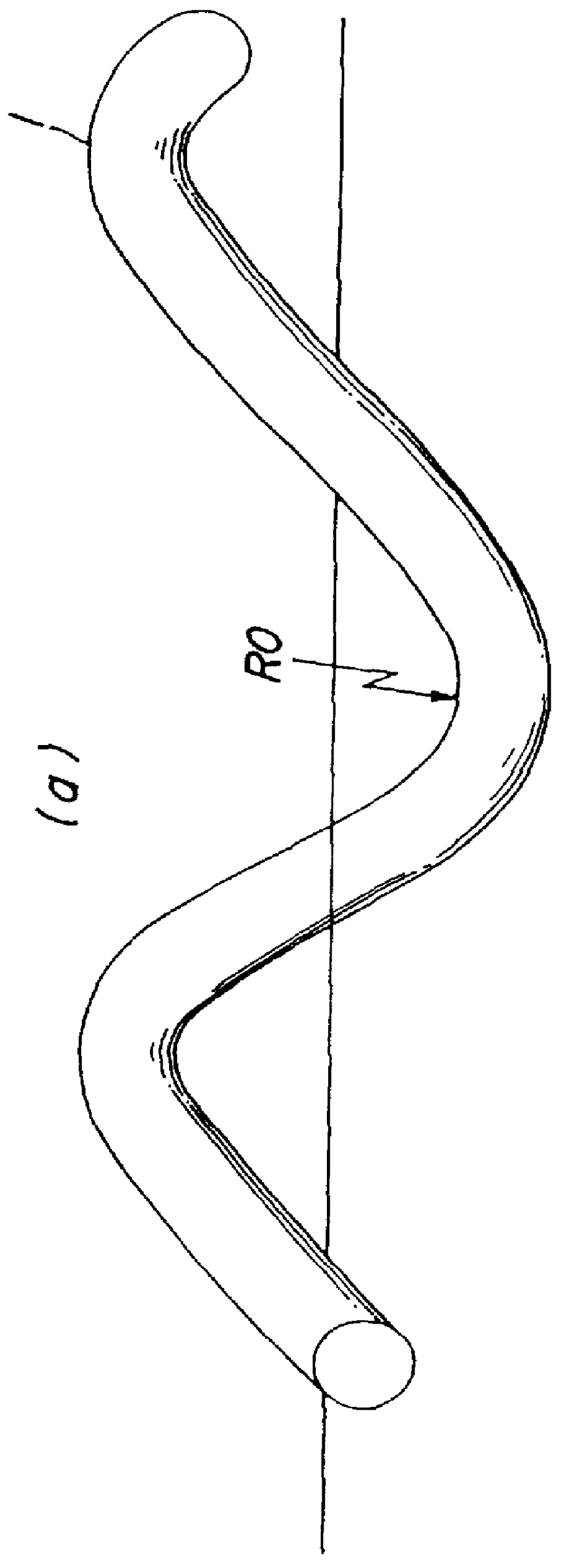

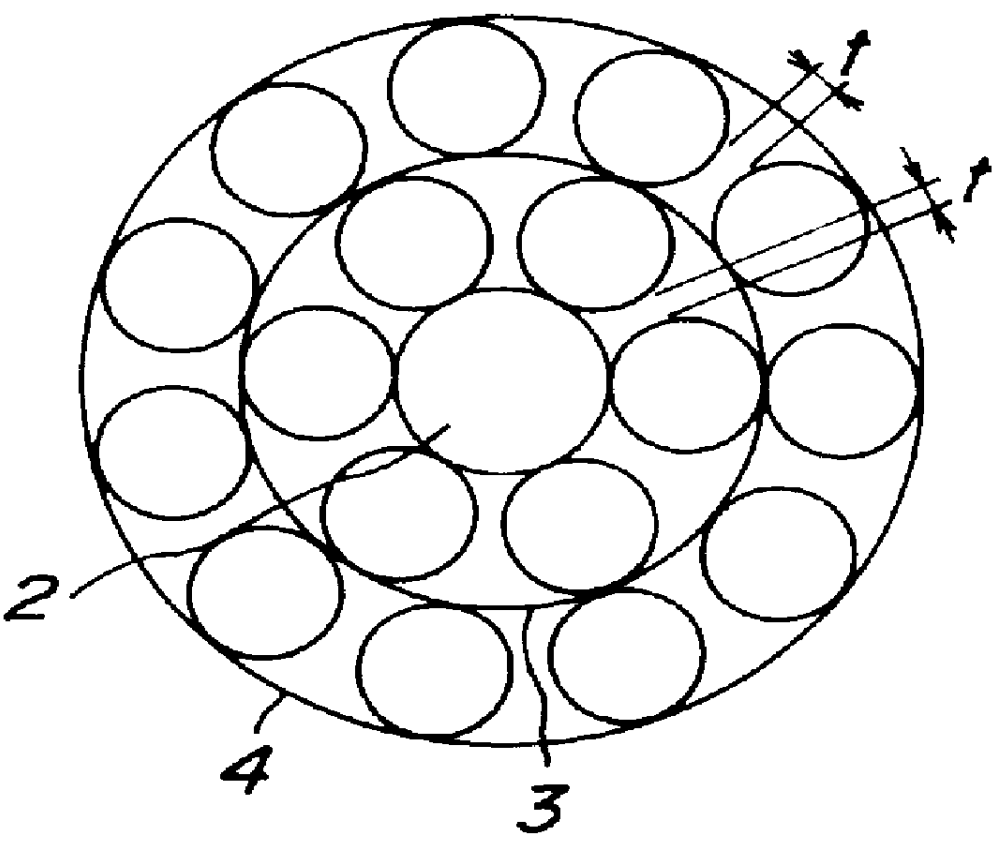

Corrosion resistant steel cords and pneumatic tires reinforced with same

InactiveUS6102095ALowering of resistance to corrosion fatigueHigh tensile strengthPneumatic tyre reinforcementsYarnSurface layerMetallurgy

PCT No. PCT / JP97 / 01338 Sec. 371 Date Nov. 24, 1997 Sec. 102(e) Date Nov. 24, 1997 PCT Filed Apr. 18, 1997 PCT Pub. No. WO97 / 39176 PCT Pub. Date Oct. 23, 1997A corrosion resistant steel cord for reinforcing rubber articles, particularly a belt and / or carcass of a pneumatic tire, has a residual compressive stress inside the twisting helix of each steel filament such that a ratio R1 / R0 is less than one, where R0 is the radius of curvature of a helix in each helically formed steel filament obtained by untwisting of the cord and R1 is the radius of curvature of the helix after removal of a surface layer from the inside of the helix in the steel filament. The steel filaments have a tensile strength of 4,000-4,800 N / mm2. The cord does not have a wrapping wire around its outer peripheral surface and has either a single twisted construction obtained by twisting 3 to 6 steel filaments in an open structure having a space between adjacent filaments or a two-layer twisted construction obtained by surrounding a core of n=1-4 steel filaments with a sheath of n+(2-6) steel filaments in a rubber penetration structure having a space between adjacent filaments of the sheath or a three-layer twisted construction obtained by surrounding a core of a single steel filament with a first sheath of m=3-6 steel filaments and a second sheath of m+(2-6) steel filaments in a rubber penetration structure having a space between adjacent filaments of each sheath.

Owner:BRIDGESTONE CORP +1

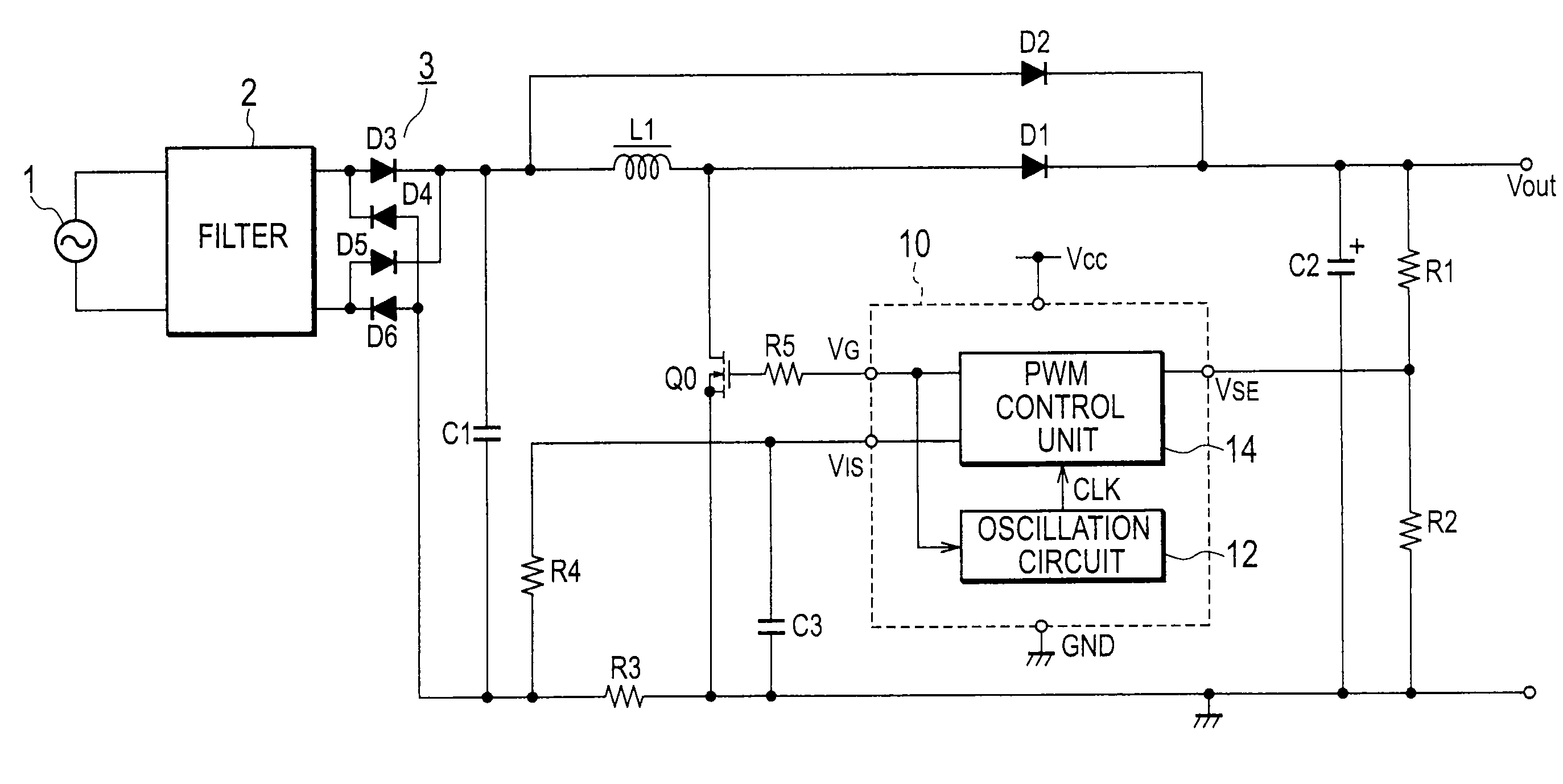

Power factor correction circuit

InactiveUS20100118576A1Diffusing generated noiseImprove efficiencyAc-dc conversion without reversalEfficient power electronics conversionEngineeringPower factor correction circuits

A power factor correction circuit includes a rectifier 3 to rectify an AC voltage of an AC power source 1, a first series circuit connected in parallel with an output of the rectifier and having a step-up reactor L1 and a switching element Q0 that are connected in series, a second series circuit connected in parallel with the switching element and having a rectifying diode D1 and a smoothing capacitor C2 that are connected in series, an oscillation circuit 12 to generate a clock signal CLK having a predetermined oscillation frequency, and a control circuit 10 to generate, at the period of the clock signal generated by the oscillation circuit and according to a voltage value of the smoothing capacitor, a drive signal for driving the switching element. The oscillation circuit changes the predetermined frequency according to the drive signal for the switching element.

Owner:SANKEN ELECTRIC CO LTD

Heat dissipation system for computers

ActiveUS8150561B2Maximizing levelEasy to handleThermometer detailsEnergy efficient ICTEngineeringThreshold temperature

A heat dissipation system within a housing of a computer is disclosed. The heat dissipation system includes a heat dissipating fan, a temperature sensor, a rotation speed setting portion, and a performance control portion. The rotation speed setting portion is configured to change a rotation speed of the heat dissipating fan in a stepwise manner based on a threshold temperature and a measurement temperature measured by the temperature sensor. The performance control portion is configured to temporarily reduce the processing capability of a processor within the computer in response to a determination that the measurement temperature has exceeded the threshold temperature during a predetermined period of time.

Owner:LENOVO PC INT

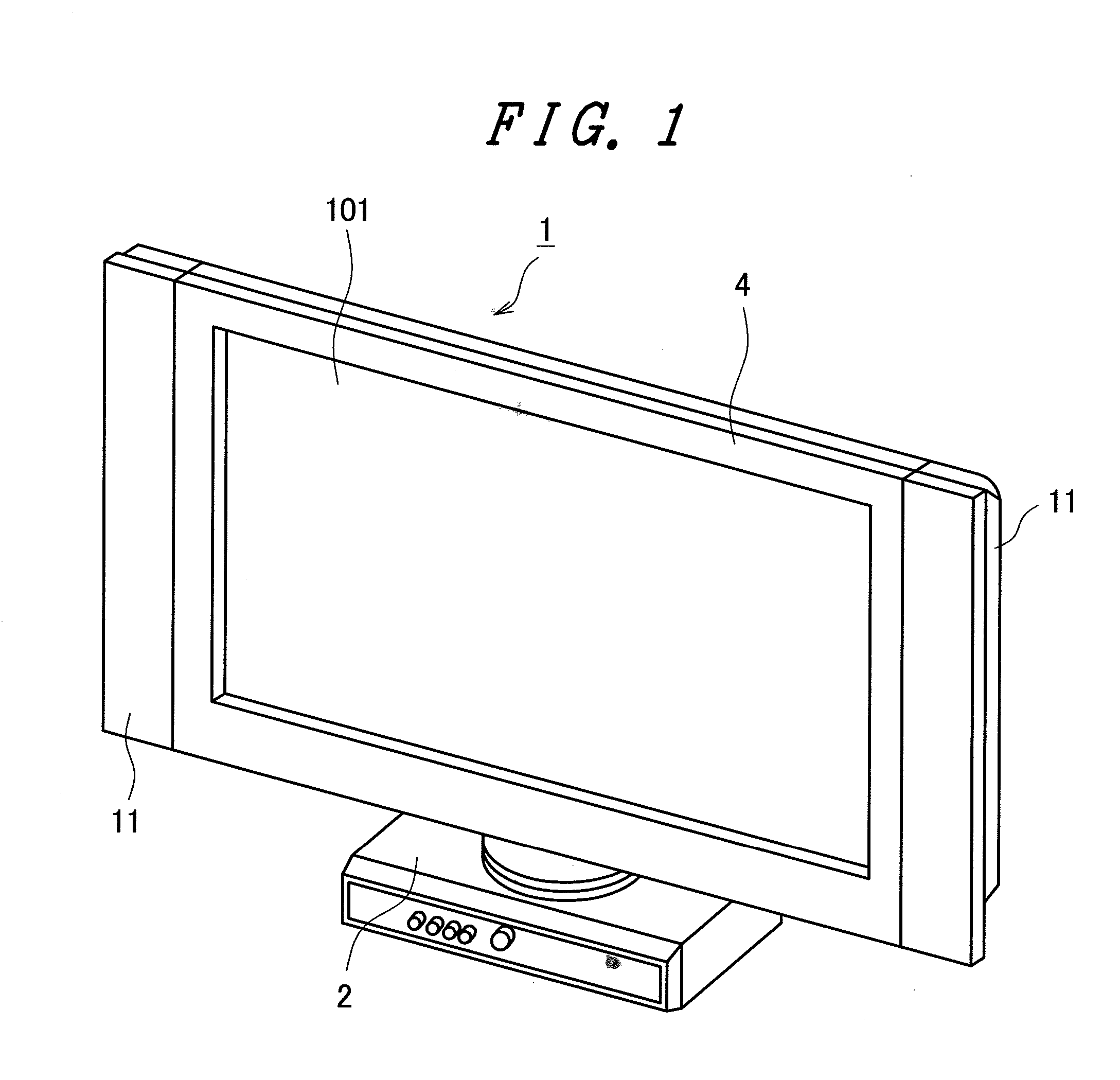

Display Device

InactiveUS20070216670A1High bulk densityEasy loadingCathode-ray tube indicatorsElectrical apparatus contructional detailsDisplay deviceEngineering

The present invention ensures the efficient radiation of heat of a flat display panel without increasing a space outside a display screen of the flat display panel. A periphery of a reinforcing member adhered to a back surface of the flat display panel is folded in an L-shape and a driver IC is brought into contact with the folded portion.

Owner:HITACHI DISPLAYS

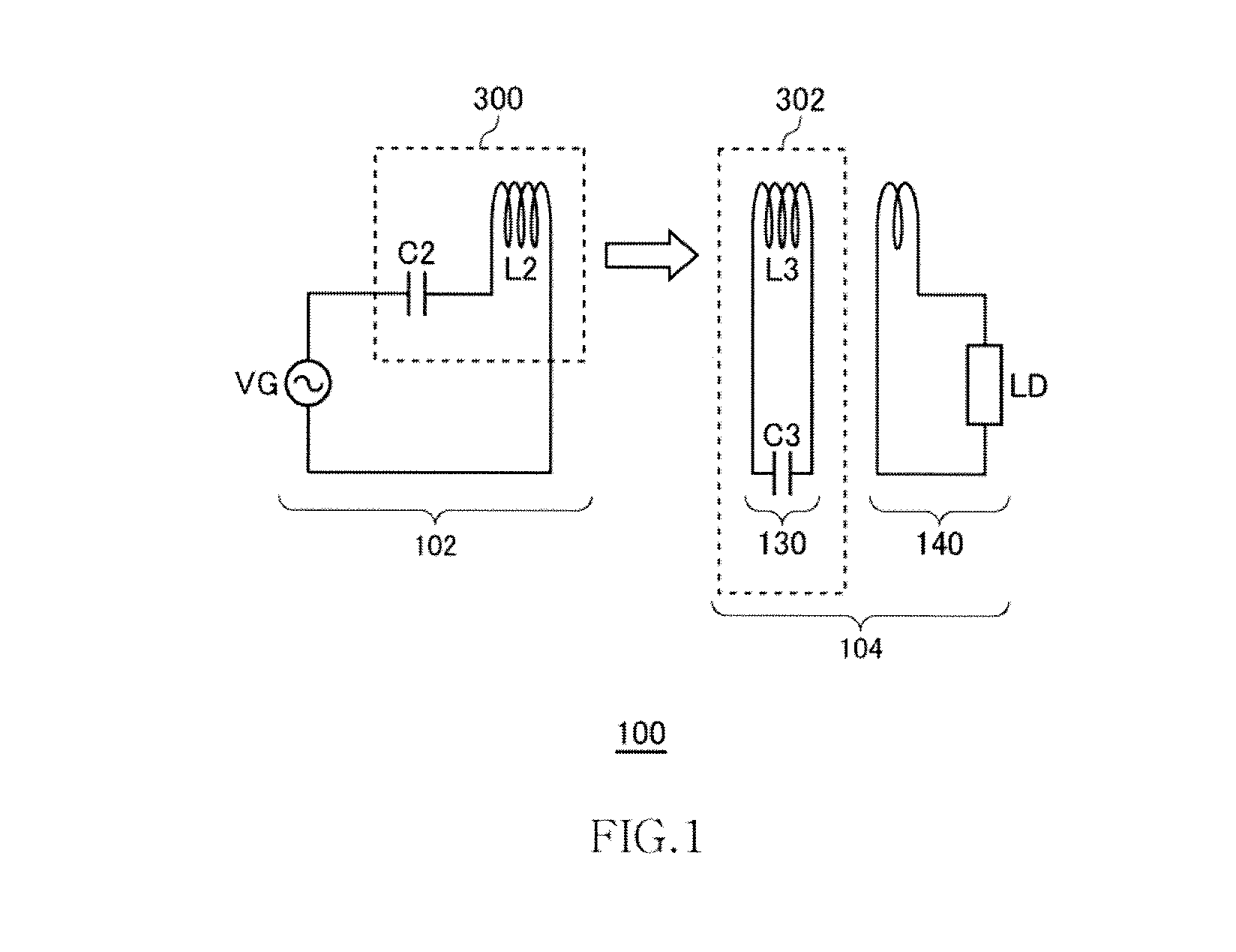

Wireless power receiver and wireless power transmission system

ActiveUS20120248882A1Easily and effectively radiateSimple processElectromagnetic wave systemTransformersElectric forceLoad circuit

Power is fed from a feeding coil to a receiving coil L3 by magnetic resonance. The receiving coil L3 and a capacitor C3 are connected in series to constitute a receiving coil circuit. A loading coil L4 electromagnetically coupled to the receiving coil L3 is connected to a load through a rectification circuit 142 to constitute a loading circuit. Placing the rectification circuit 142 on a first flat plate electrode 132 of the capacitor C3 allows heat generated from the rectification circuit 142 to escape to the first flat plate electrode 132.

Owner:TDK CORPARATION

Lithium secondary battery

ActiveUS20060286439A1Increase energy densityImprove securityCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringLithium-ion battery

A lithium secondary battery including: an electrode group, a non-aqueous electrolyte and a battery case housing the electrode group and the non-aqueous electrolyte, the electrode group including a positive electrode, a negative electrode and a separator layer interposed between the positive electrode and the negative electrode, wherein an end-of-charge voltage and an end-of-discharge voltage are set in such a manner that the electrode group has an energy density of not less than 700 Wh / L, the separator layer includes a porous heat-resistant layer, and a short circuit area A produced when an internal short circuit has occurred between the positive electrode and the negative electrode, and a reduced area B of the porous heat-resistant layer that is produced by heat generation satisfy 1≦(A+B) / A≦10.

Owner:PANASONIC CORP

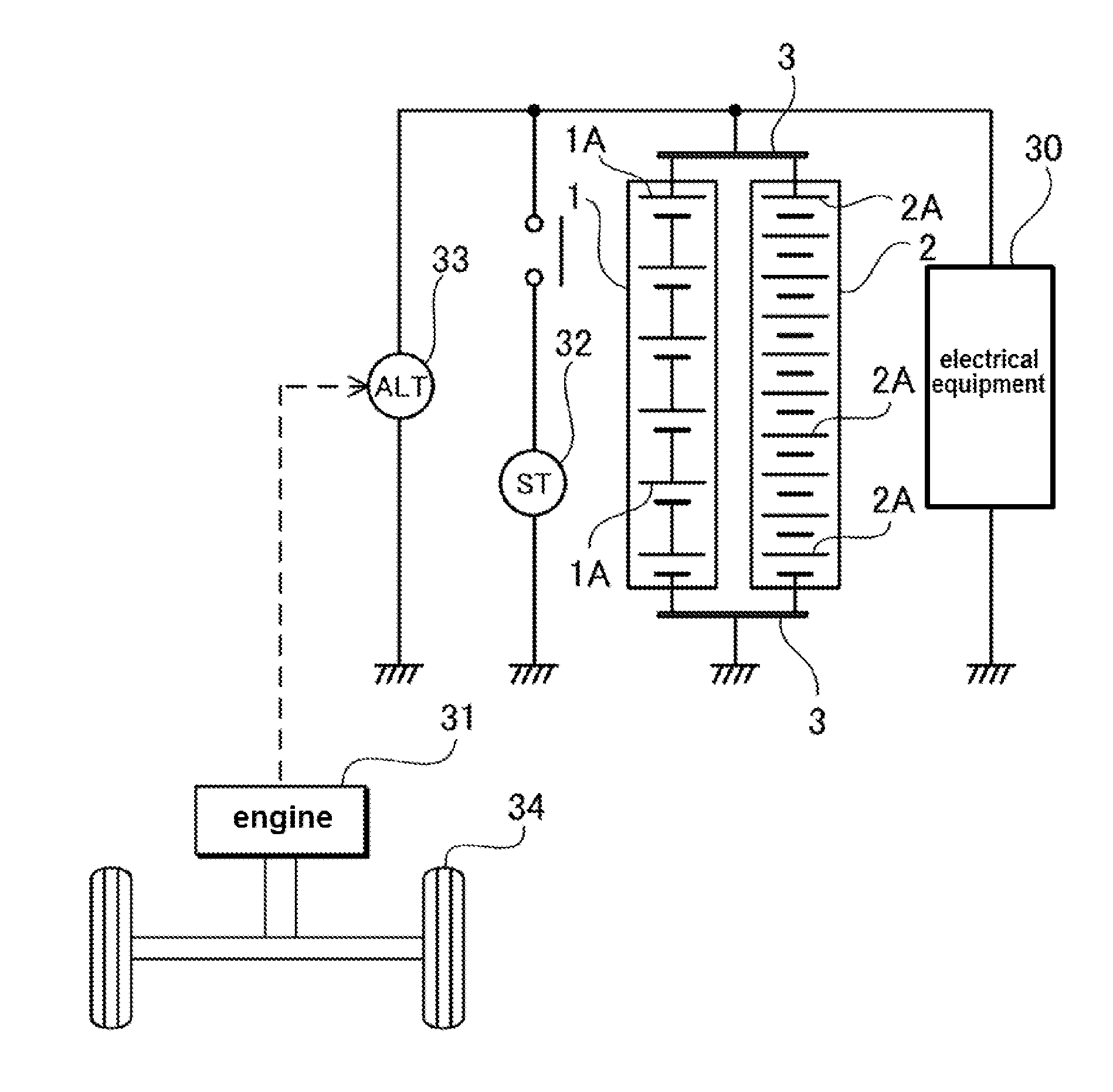

Power supply device for vehicle performing regenerative braking

ActiveUS20150298557A1Efficiently charged with regenerative generation powerLow costPower to auxillary motorsPropulsion by batteries/cellsRegenerative brakeEngineering

A power supply device comprises a lead-acid battery disposing a plurality of cells in a battery case of a rectangular parallelepiped shape having a pair of facing walls and a pair of end surface walls at the circumference of a rectangular bottom surface plate, and a power storage device connected in parallel to the lead-acid battery. The power storage device has a larger storage capacity by regenerative braking than that of the lead-acid battery, and the power storage device has an external case having a heat radiation plate disposed in a thermally connected state to the facing wall of the lead-acid battery, and the heat radiation plate is thermally connected to the facing wall of the lead-acid battery.

Owner:SANYO ELECTRIC CO LTD

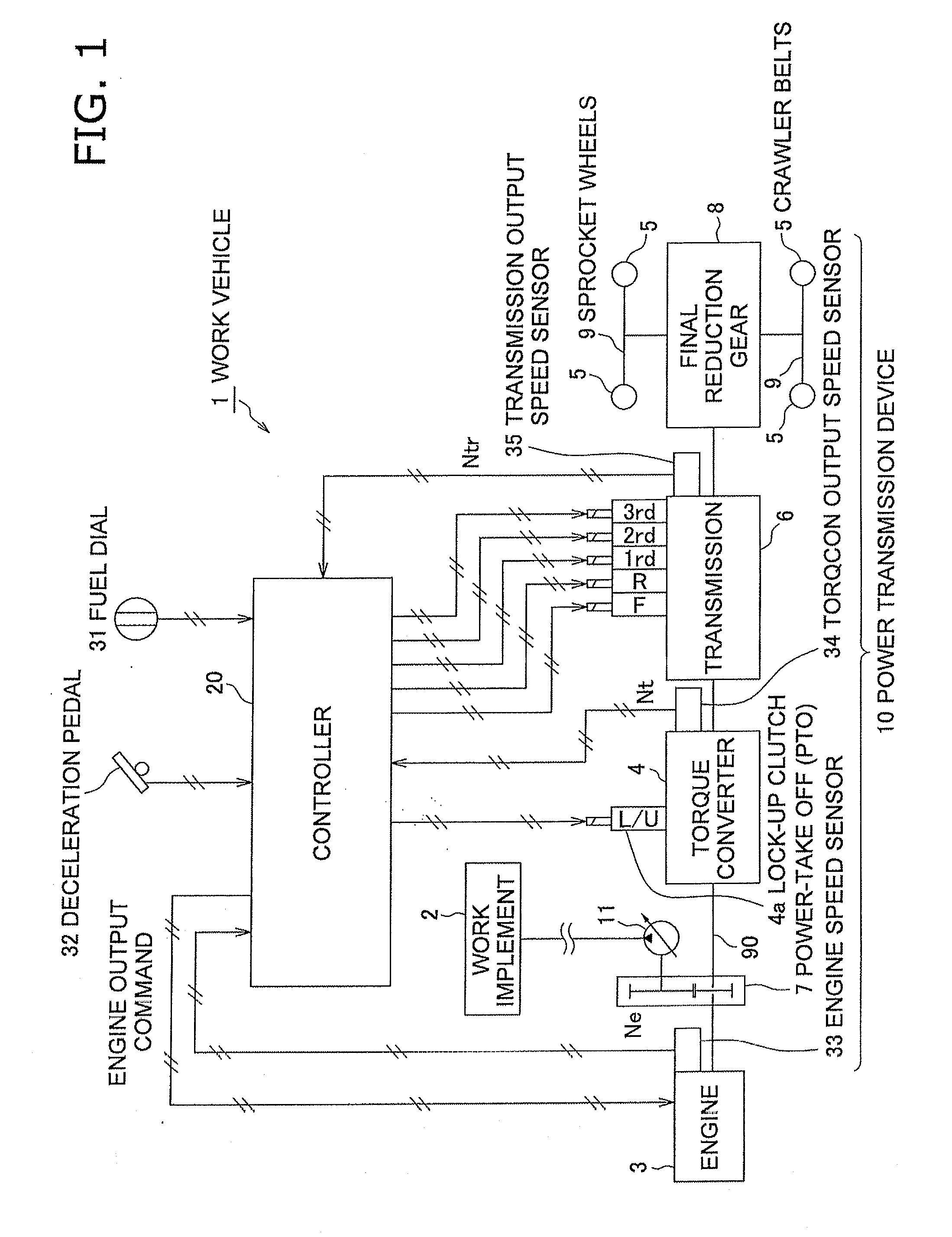

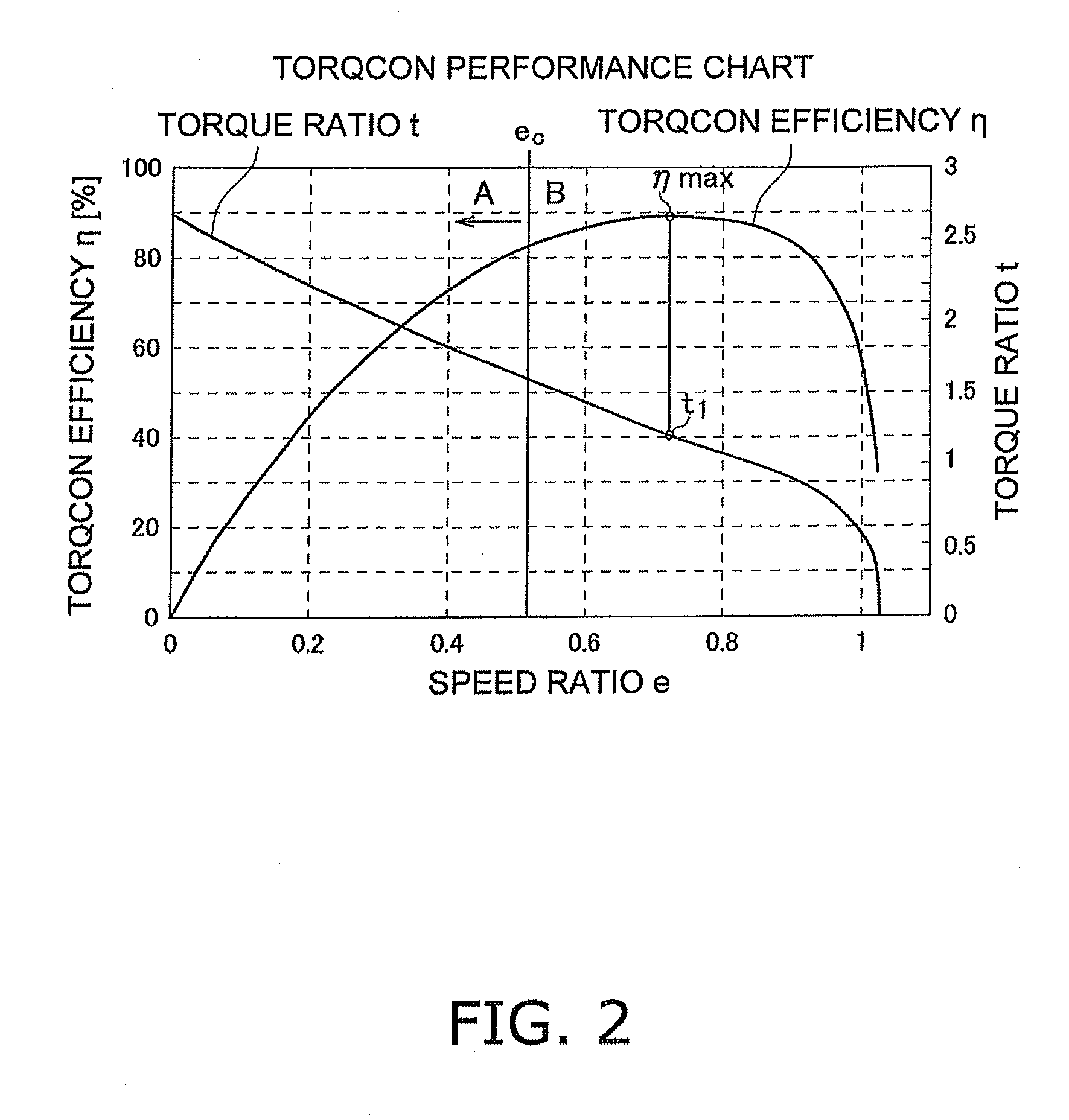

Working vehicle engine output control system and method

ActiveUS20110040458A1Engine output decreaseLow efficiencyAnalogue computers for trafficVehicle sub-unit featuresControl systemMaximum efficiency

An engine output control system is for a work vehicle composed of an engine, a travel device and a power transmission unit, the power transmission unit including a torque converter and transmitting an output of the engine to the travel device via the torque converter. The engine output control system includes a speed ratio computation portion and an engine output reduction control portion. The speed ratio computation portion is configured and arranged to compute a speed ratio of the torque converter. The engine output reduction control portion is configured and arranged to reduce an output torque of the engine without changing a target speed of the engine when the computed speed ratio is equal to or less than a speed ratio threshold set in advance. The speed ratio threshold is a speed ratio at which a torque ratio of the torque converter is greater than a torque ratio corresponding to a maximum efficiency.

Owner:KOMATSU LTD

NOx TRAP

InactiveUS20170043322A1Increased heat generationEfficient releaseGas treatmentInternal combustion piston enginesCeriumInternal combustion engine

A NOx trap comprises components comprising at least one platinum group metal, at least one NOx storage material and bulk ceria or a bulk cerium-containing mixed oxide deposited uniformly in a first layer on a honeycombed substrate monolith, the components in the first layer having a first, upstream, zone having increased activity relative to a second, downstream zone for oxidising hydrocarbons and carbon monoxide, and a second, downstream, zone having increased activity to generate heat during a desulphation event, relative to the first zone, wherein the second zone comprises a dispersion of rare earth oxide, wherein the rare earth oxide loading in the second zone is greater than the loading in the first zone. An exhaust system for a lean burn internal combustion engine, a vehicle comprising a lean burn internal combustion engine and the exhaust system and methods of making the NOx trap are also disclosed.

Owner:JOHNSON MATTHEY PLC

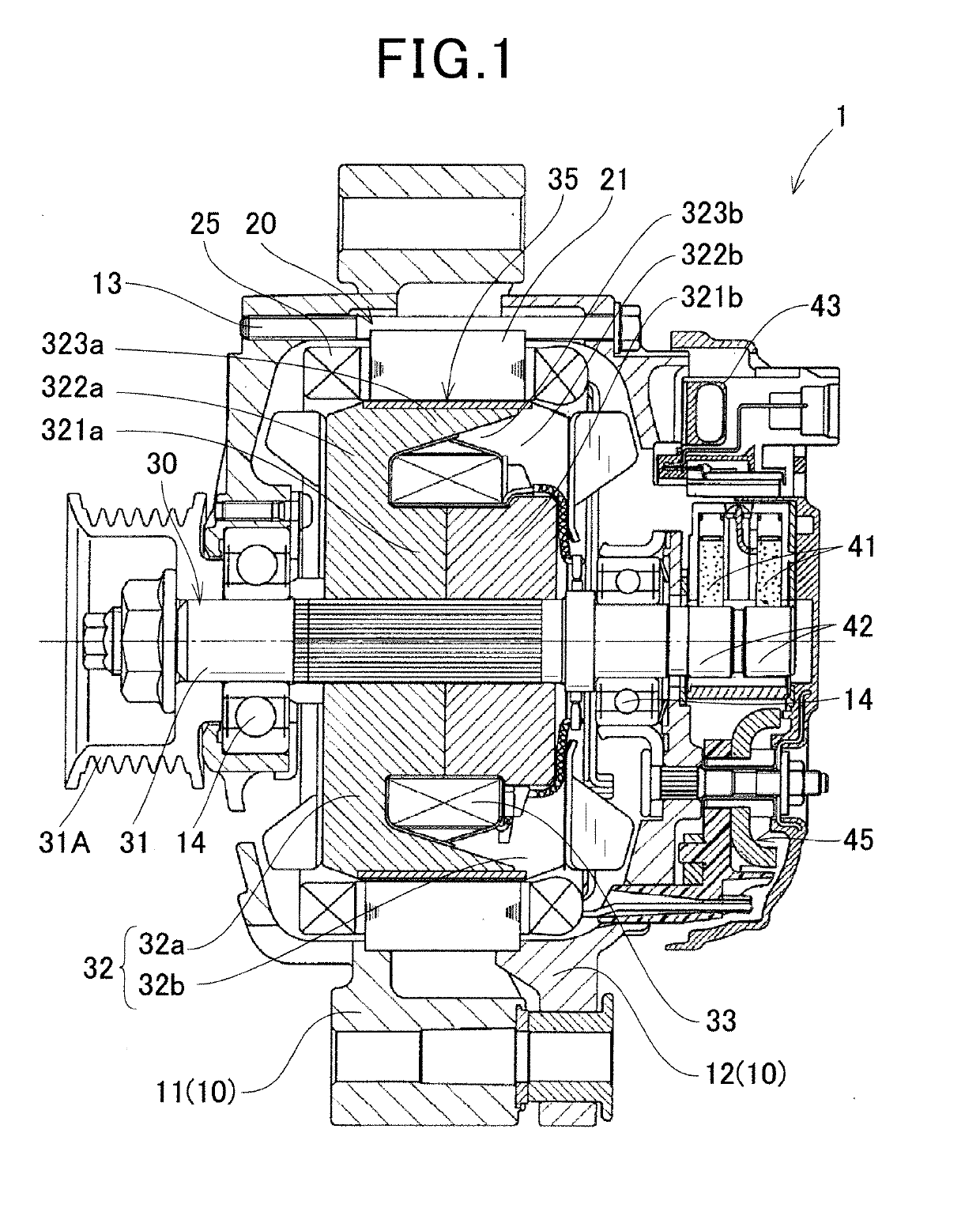

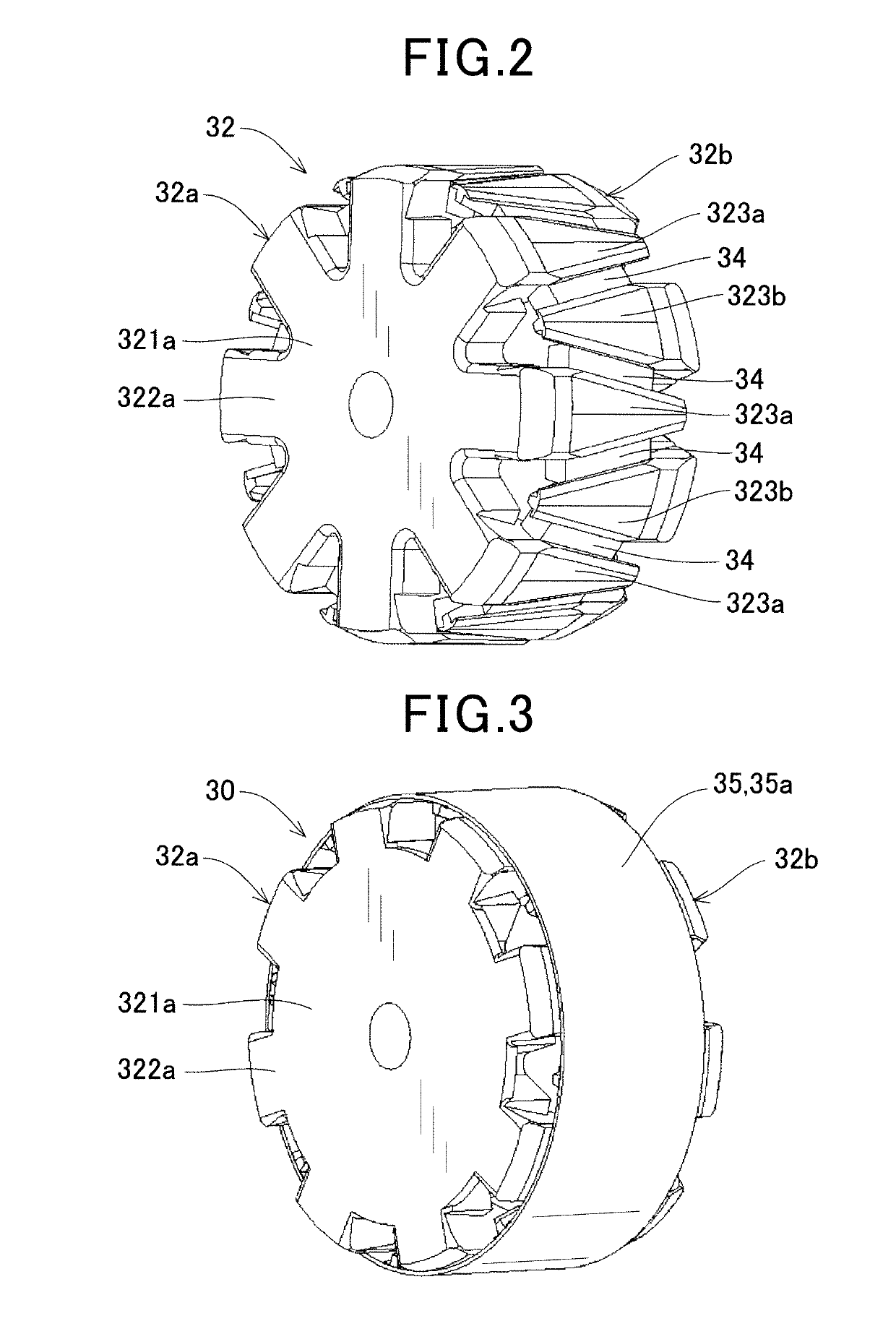

Rotating electric machine

ActiveUS20190157954A1Lower capability requirementsIncrease productionSynchronous machine detailsMagnetic circuitMagnetomotive forceElectric machine

A rotor of a rotating electric machine includes a field core having a cylindrical boss portion, and a plurality of claw-shaped magnetic pole portions that are arranged on the outer side of the boss portion and form poles of alternately different polarities in the circumferential direction, a field winding that is wound around the outer periphery of the boss portion and generates a magnetomotive force by energization, a permanent magnet disposed between the circumferentially adjacent claw-shaped magnetic pole portions so as to have its easy axis of magnetization oriented in the circumferential direction and have its polarity coincide with the polarity of the claw-shaped magnetic pole portions which alternately appears by excitation, and a magnetic flux short circuit member having a short circuit portion that magnetically connects the claw-shaped magnetic pole portions circumferentially arranged to have different polarities.

Owner:DENSO CORP

Methods and systems for improving hybrid vehicle cooling

ActiveUS20150360675A1Reduce capacityReduce the possibilityHybrid vehiclesDigital data processing detailsHybrid vehicleElectric generator

Systems and methods for improving hybrid vehicle cooling are presented. In one example, an electric pump may supply transmission fluid to a transmission and a driveline integrated starter / generator to cool, operate, and lubricate driveline components. The electric pump may be selectively operated to conserve energy and to supply driveline cooling when driveline cooling may be desirable.

Owner:FORD GLOBAL TECH LLC

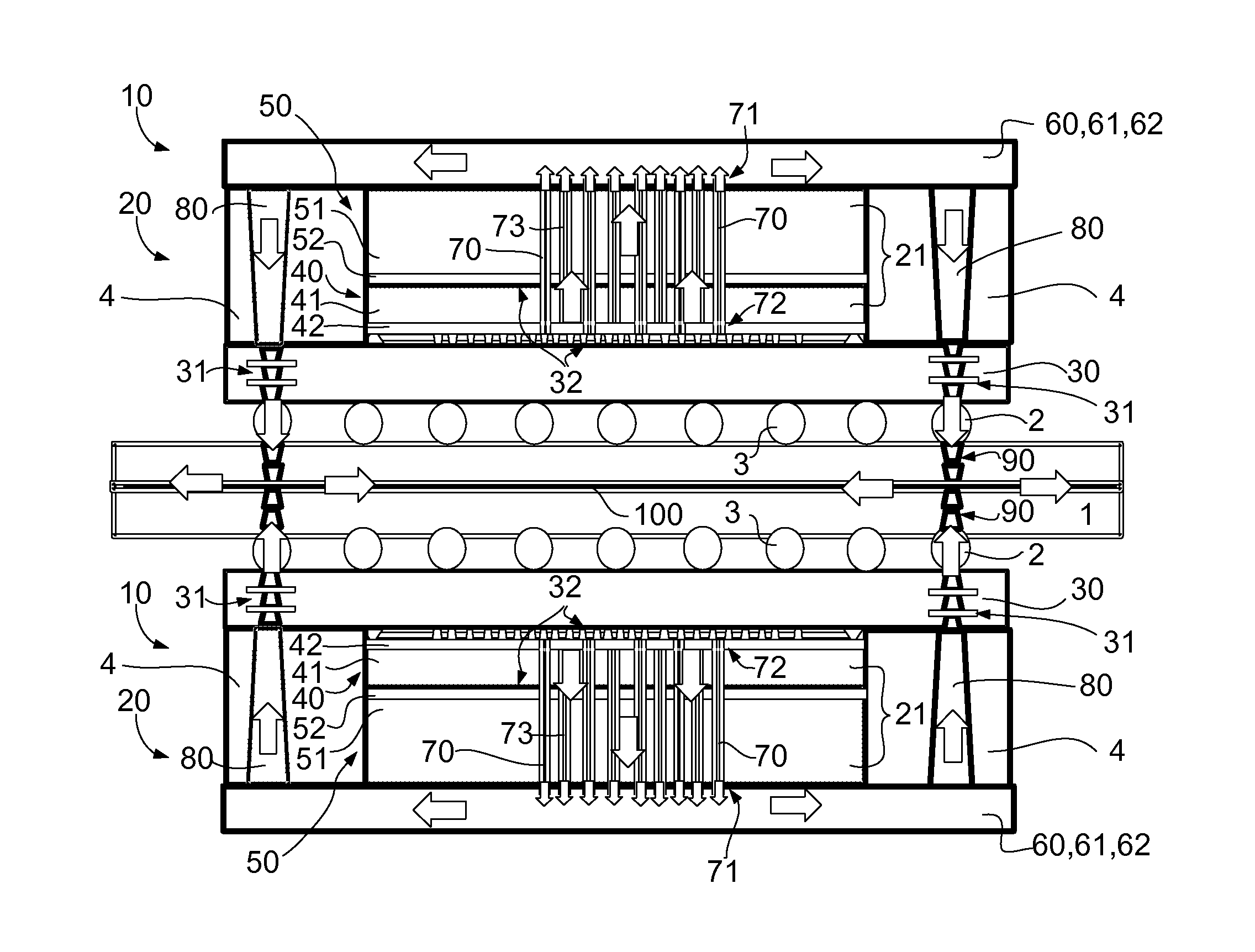

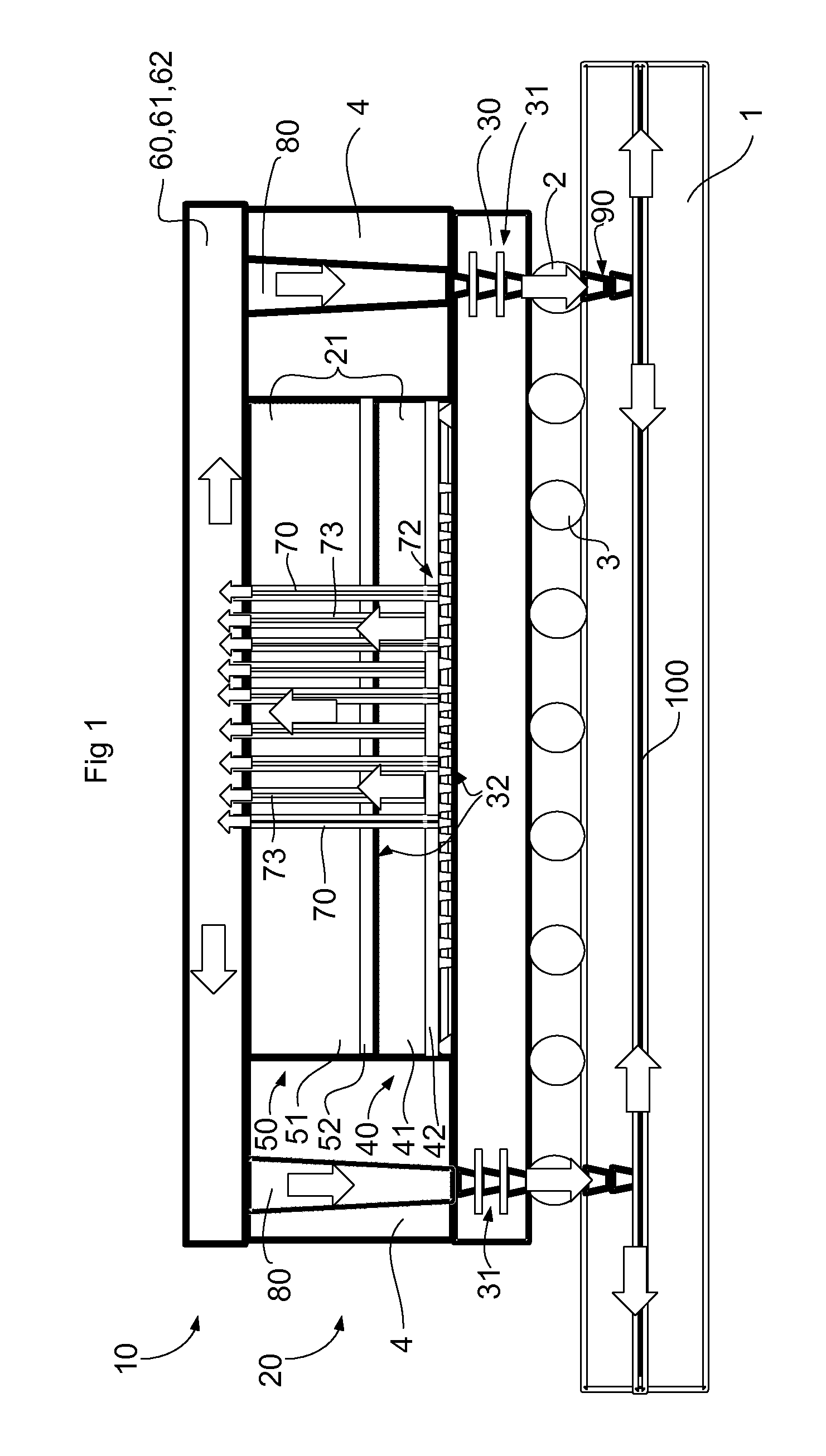

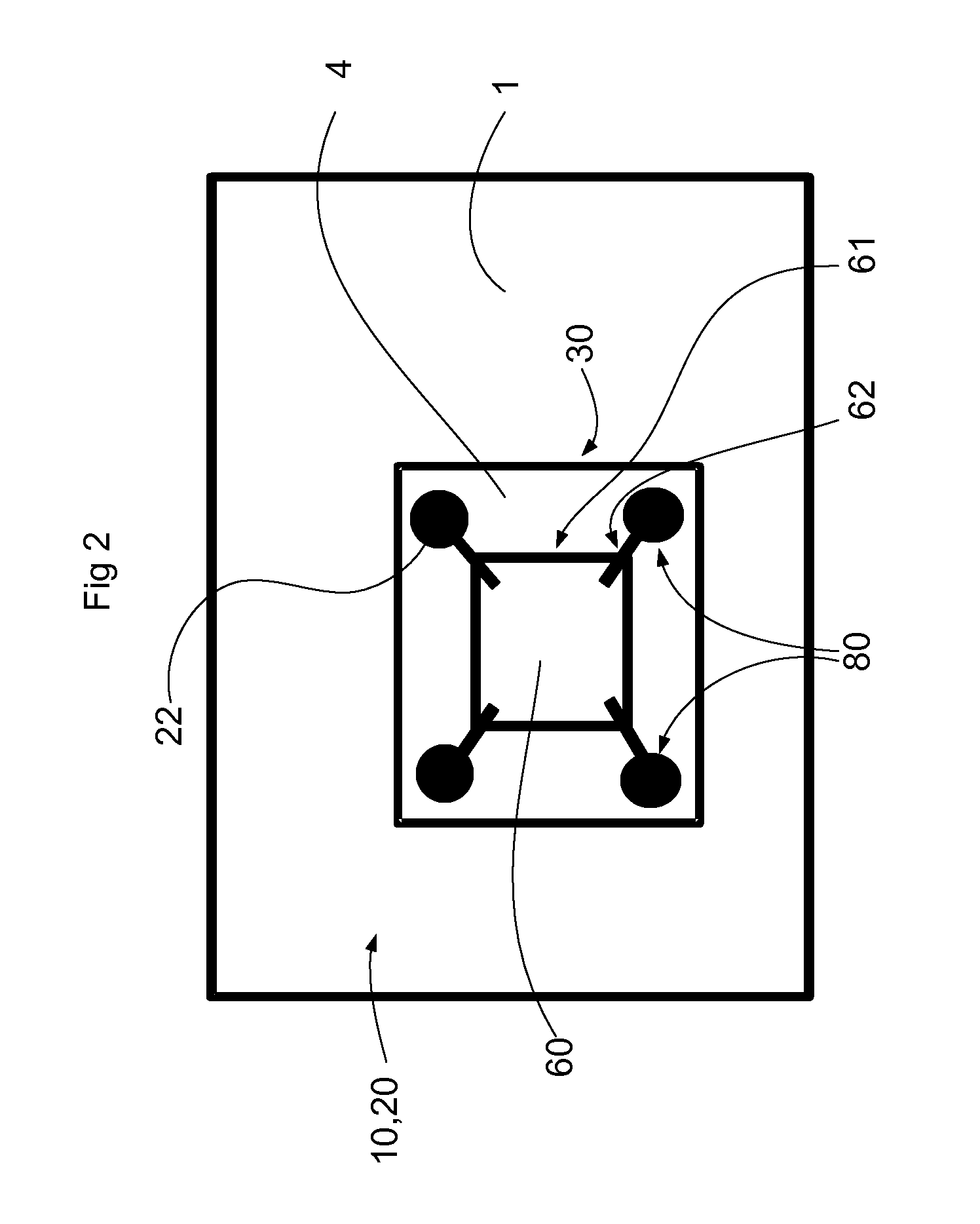

Wheel brake for a vehicle and a vehicle comprising the wheel brake

InactiveUS20090101458A1Reduce material costsSave spaceAxially engaging brakesBraking discsMechanical engineering

A wheel brake for a vehicle including a brake disc unit adapted to brake the rotation of a rotation element, which is adapted to be drivingly connected to the wheel . The brake disc unit includes a first set of discs and a second set of discs arranged in an alternating manner in an axial direction. The discs in the first disc set are adapted to be rotationally rigidly connected to the rotation element. The brake disc unit includes at least one separator element, which is adapted to keep a sufficient distance between two adjacent discs of one of the disc sets for an intermediate disc from the other disc set to rotate at least substantially freely relative to the spaced discs when the brake disc unit is in a deactivated condition.

Owner:VOLVO CONSTR EQUIP

Organic light emitting diode display

ActiveUS20140145171A1Reduce contact resistanceImprove heat generationStatic indicating devicesSolid-state devicesDisplay deviceLight-emitting diode

Disclosed is an organic light emitting diode display including: a pixel unit including an organic light emitting diode for displaying an image; and a periphery surrounding the pixel unit. The periphery includes a gate common voltage line formed on the substrate and receiving a common voltage from an external circuit, an interlayer insulating layer covering the gate common voltage line and including a common voltage contact hole for exposing a part of the gate common voltage line, a data common voltage line formed on the interlayer insulating layer and contacting the gate common voltage line through the common voltage contact hole, and a plurality of protrusions provided in the common voltage contact hole and formed on the substrate.

Owner:SAMSUNG DISPLAY CO LTD

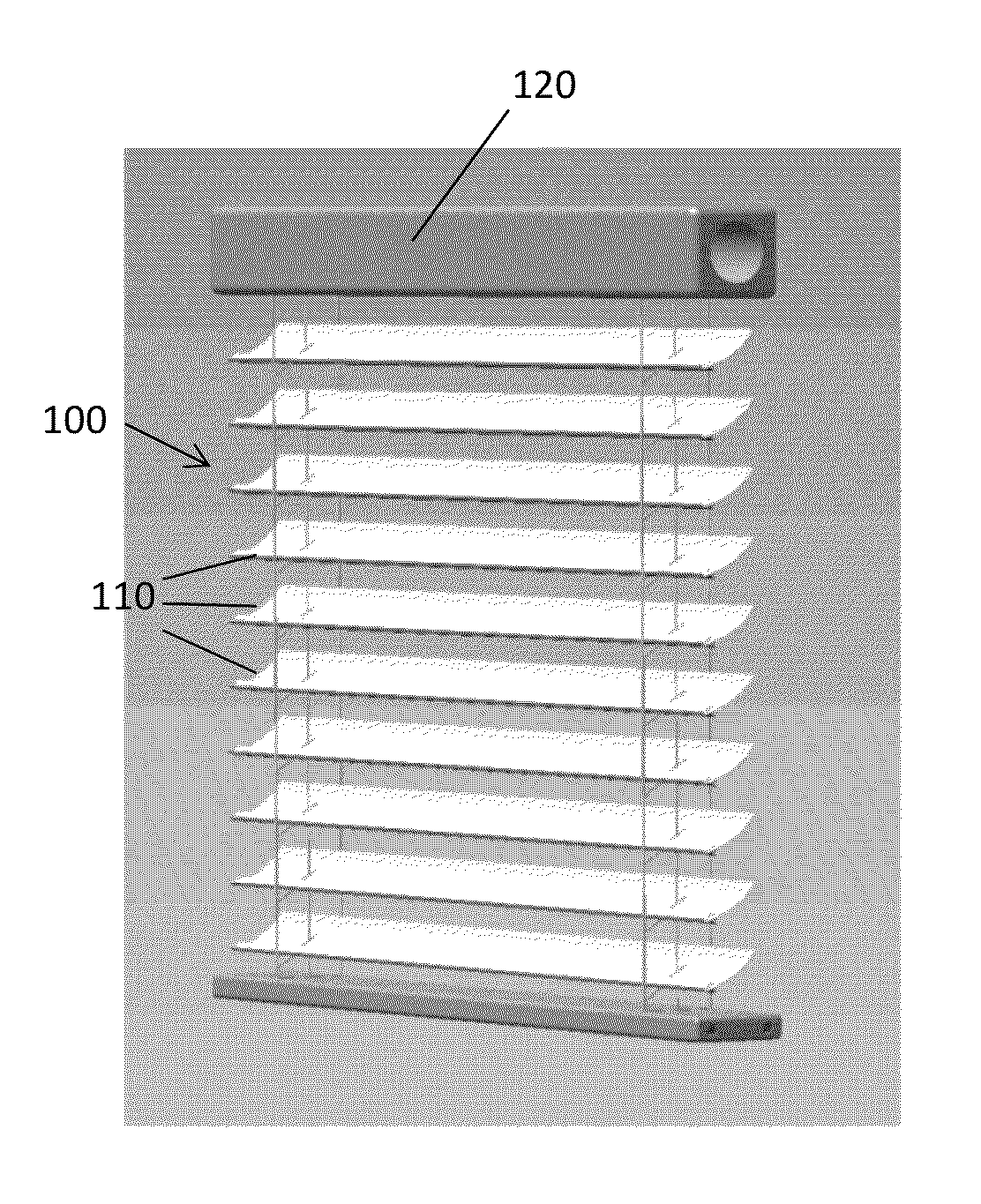

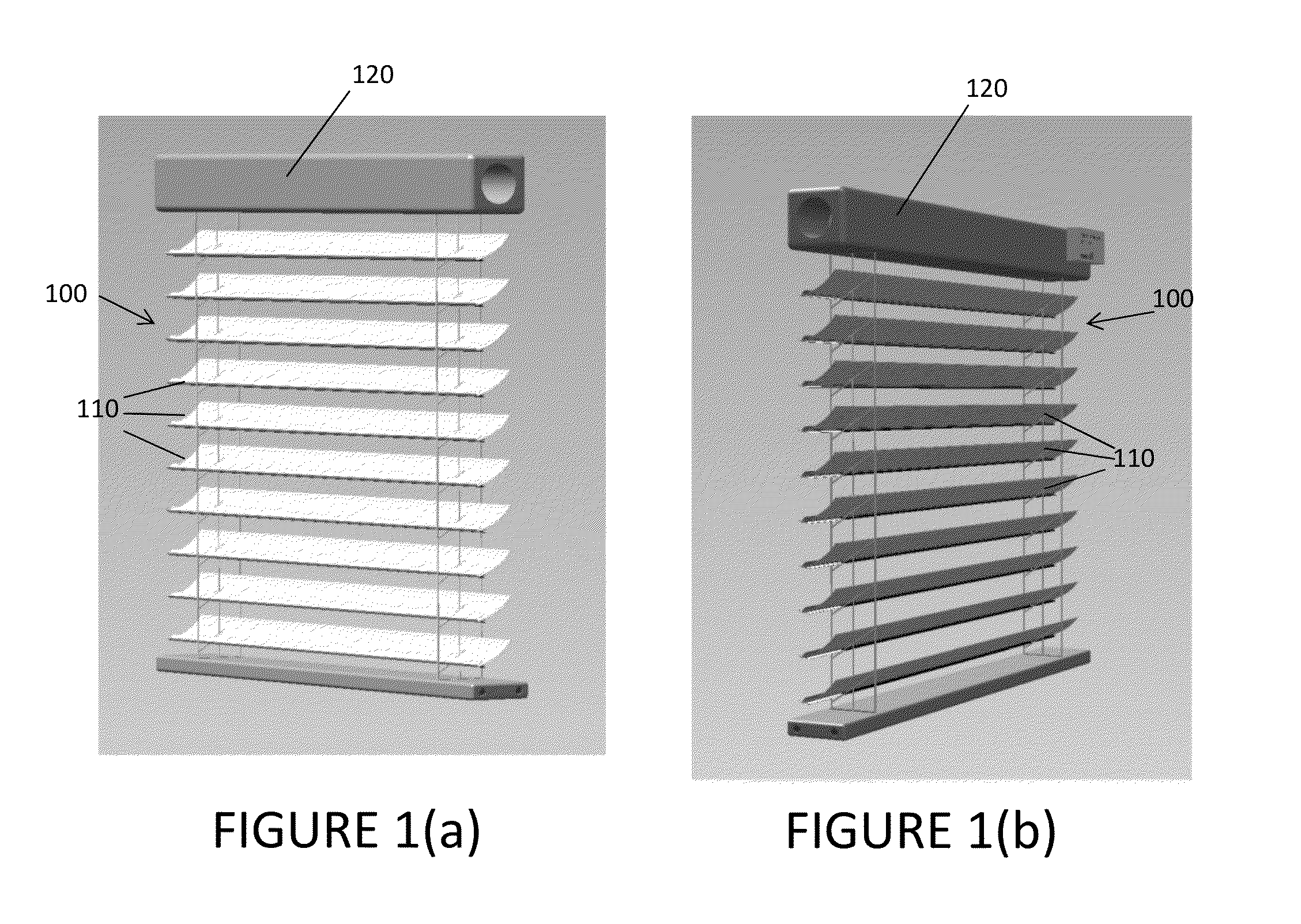

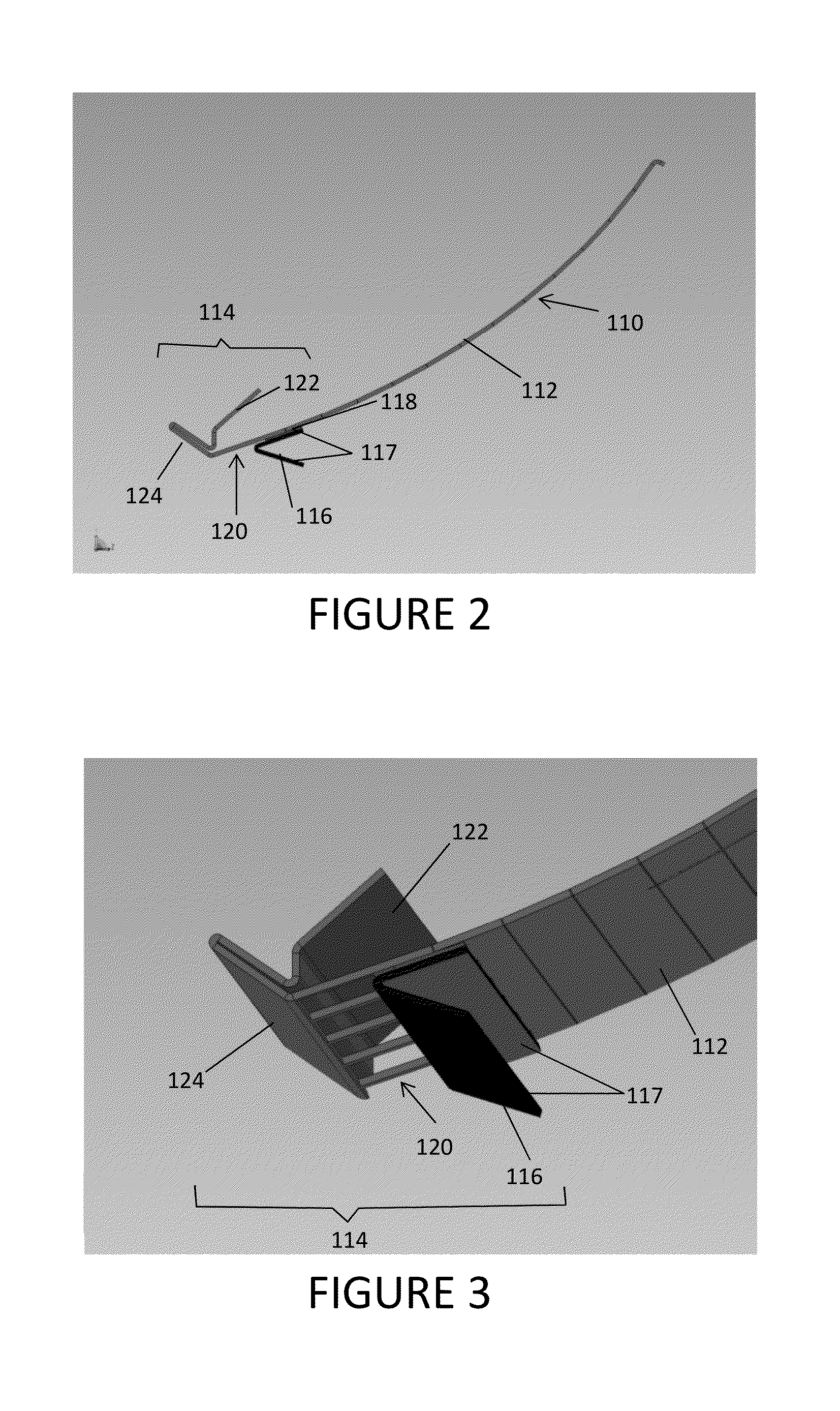

Window Blind Solar Energy Management System

InactiveUS20130250422A1Energy saveLow temperature of airDoor/window protective devicesCondensersLouverEngineering

Disclosed is a window blind solar energy management system for capturing solar energy to manage illumination and temperature within a defined space. Blinds comprising curved louvers are hung from the internal frame of a window, each louver having a concave, highly reflecting specular mirrored surface that focuses incoming solar beam radiation onto a thin area on the back of the adjacent louver. The angle of the louvers is adjusted by an integral automatic controller so that the thin strip of light can be focused on one or two of three regions on the back of the adjacent louver which are designed to either reflect, absorb, or reject the incoming light.

Owner:MBC VENTURES INC

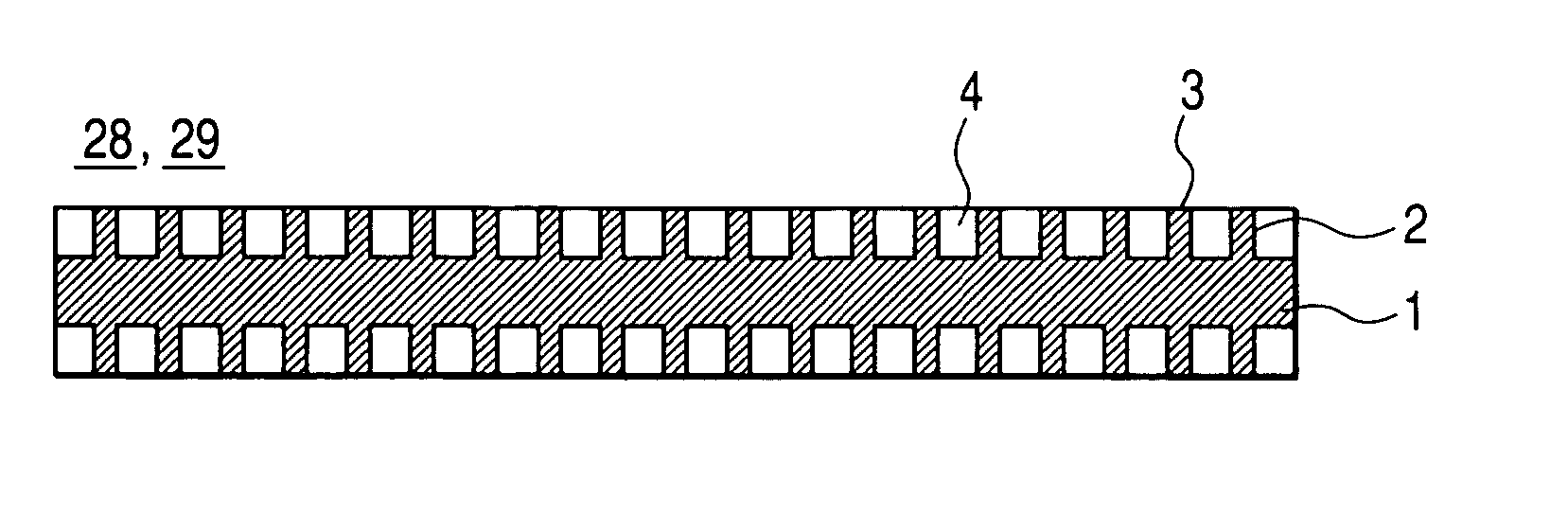

Electrically conductive adhesive sheet, method of manufacturing the same, and electric power conversion equipment

InactiveUS20050147839A1Preferable contact reliabilityImprove contact reliabilityPrinted circuit assemblingLayered productsMetallic foilElectricity

In order to solve the issue mentioned above, the present invention is featured in electrically conductive adhesive sheet: wherein the substrate 1 which composes electrically, thermally, or electrically and thermally conducting paths in a direction along the plane of the sheet is formed of metallic foil having a coefficient of thermal expansion between the coefficient of thermal expansion of one of at least two bonded members and the coefficient of thermal expansion of another one of the bonded members. In accordance with the present invention adopting the composition mentioned above, a stress applied to the protrusion layer 2, which composes electrically, thermally, or both electrically and thermally conducting paths between the substrate 1 and the bonded members by difference in thermal expansion, can be moderated.

Owner:HITACHI LTD

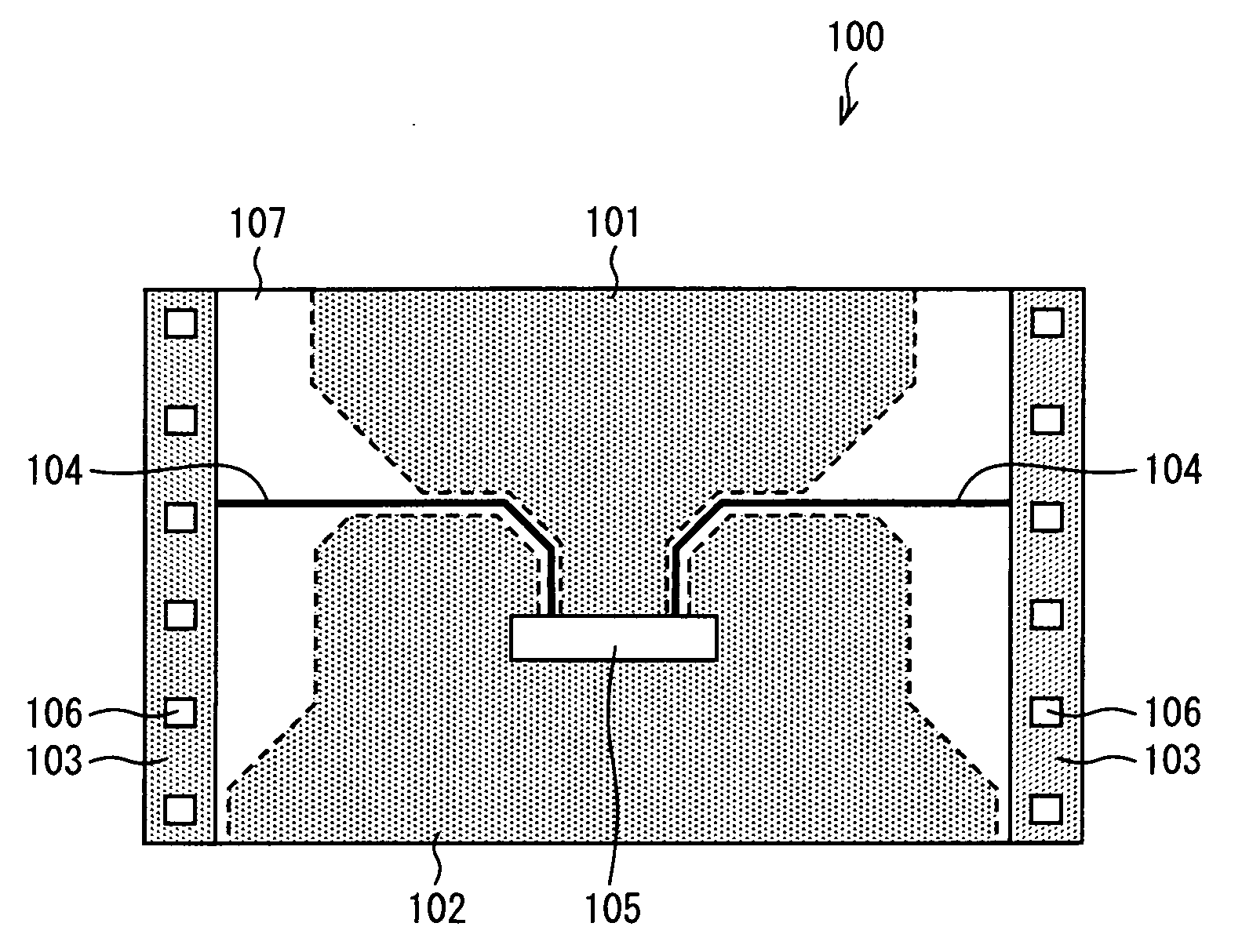

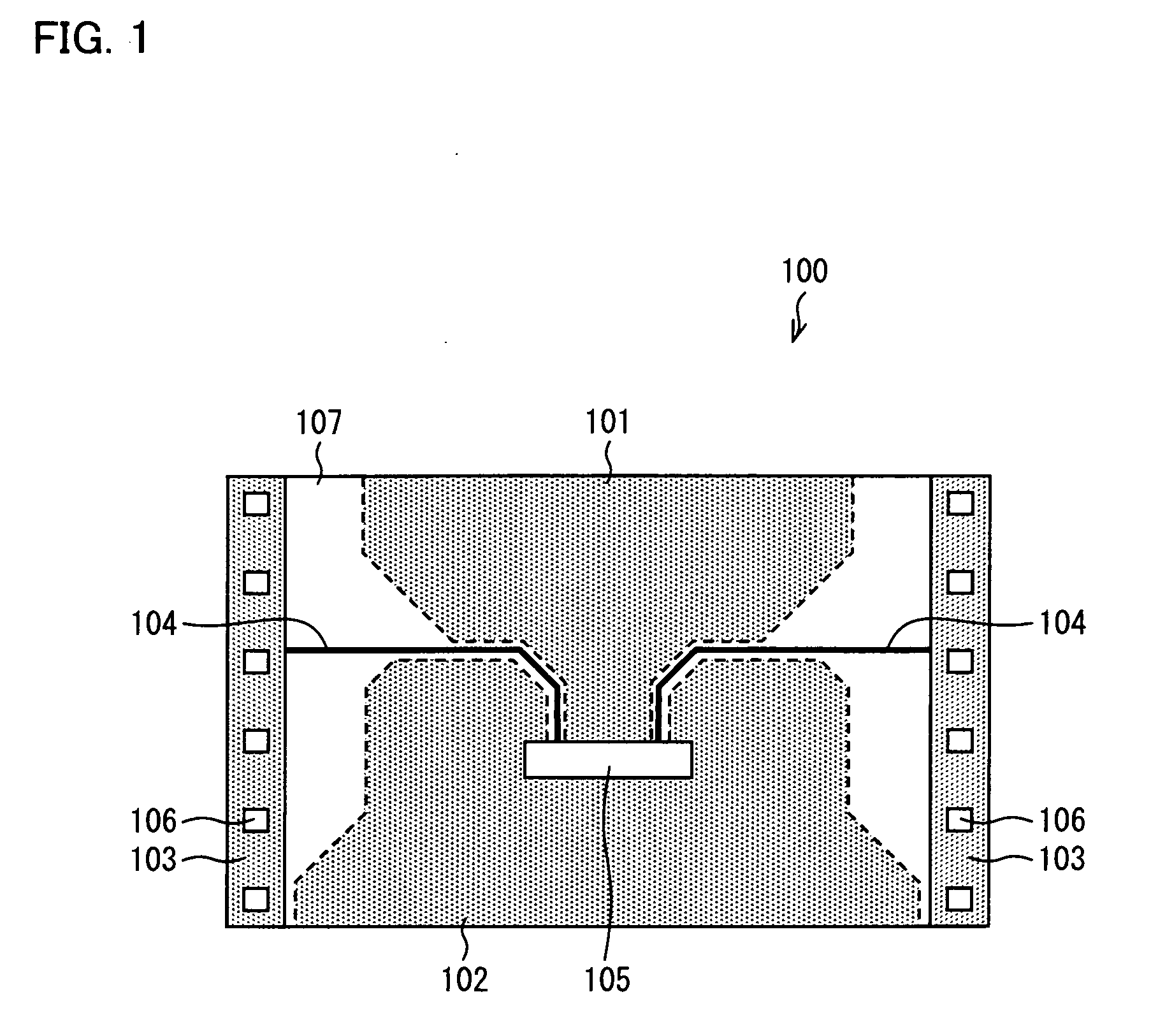

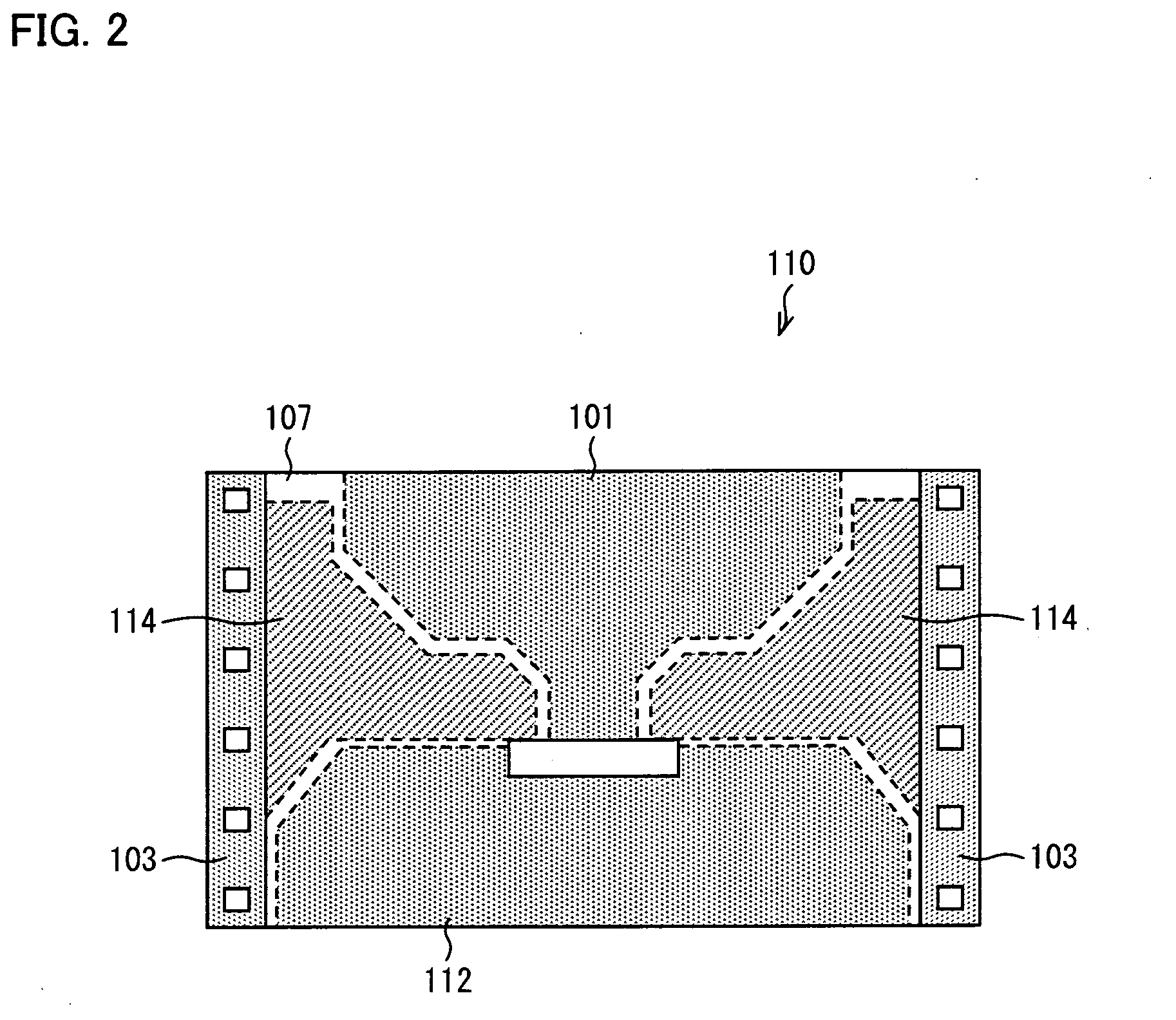

Source driver, method for manufacturing same, and liquid crystal module

ActiveUS20100302474A1Advantageous in heat dissipation propertyCost reductionSemiconductor/solid-state device detailsPrinted circuit aspectsCopper foilSprocket

In at least one embodiment, a source driver of a film package type, includes: a film substrate; a semiconductor chip on a surface of the film substrate, the semiconductor chip having a plurality of terminals each of which is connectable to an external member, the plurality of terminals including input terminals, output terminals, and third terminals; an input terminal wiring region for receiving first wiring lines which are connected to the input terminals, respectively, the input terminal region being provided on the surface of the film substrate; an output terminal wiring region for receiving second wiring lines which are connected to the output terminals, respectively, the output terminal wiring region being provided on the surface of the film substrate; and sprocket portions at opposite ends of the film substrate, each of the sprocket portions having a copper foil on the surface, and a string of holes, the input terminal wiring region and the output terminal wiring region being provided so as to extend toward opposite ends having no sprocket portion, respectively, the source driver further including a heat conducting patterns for connecting the third terminals, each of which is connected to neither any one of the plurality of first wiring lines nor any one of the plurality of second wiring lines, to the copper foils of the sprocket portions, respectively, the heat conducting patterns being provided on the surface of the film substrate. This makes it possible to provide a source driver, a method for manufacturing the source driver, and a liquid crystal module, each of which can increase a heat dissipation amount.

Owner:SHENZHEN TOREY MICROELECTRONIC TECH CO LTD

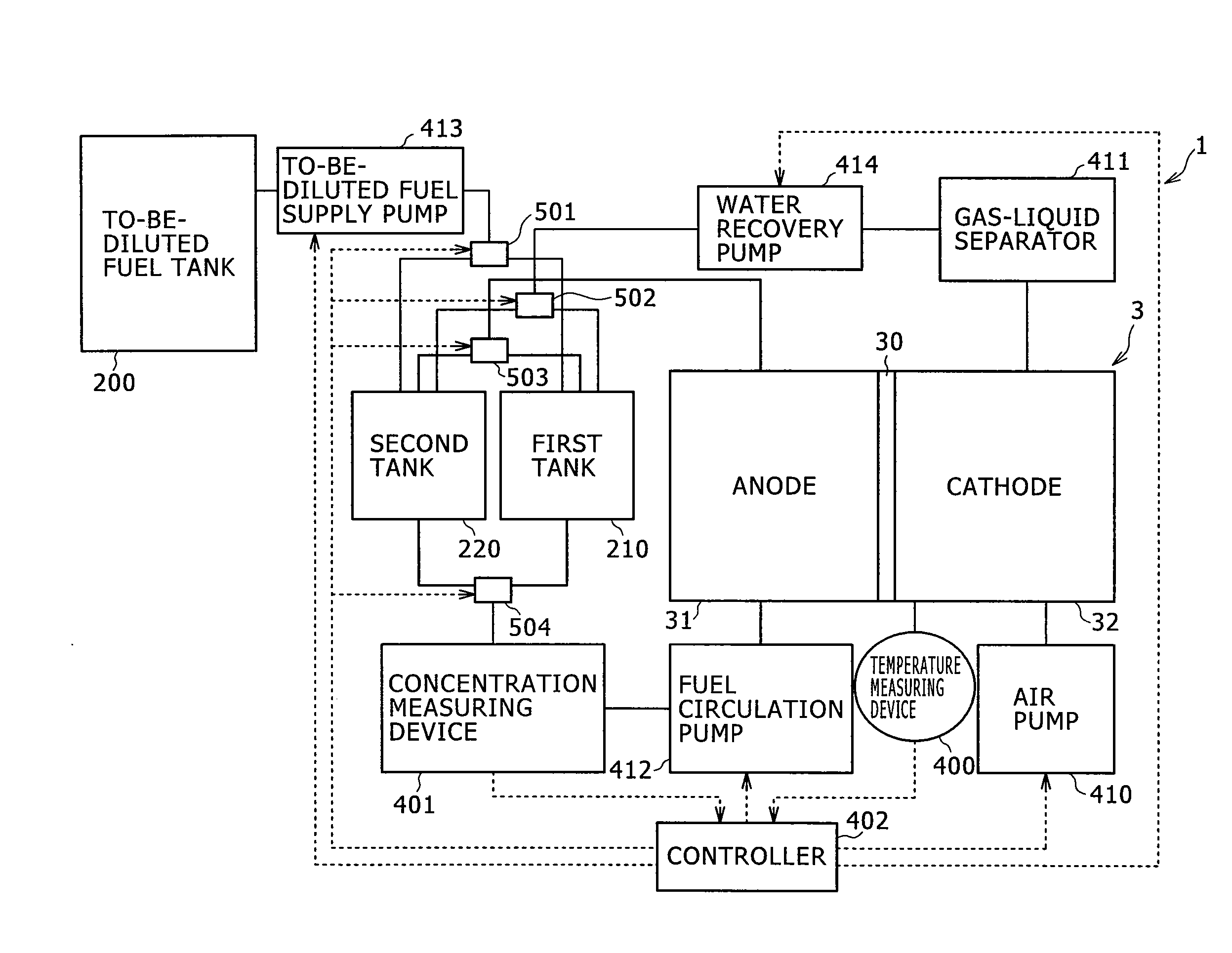

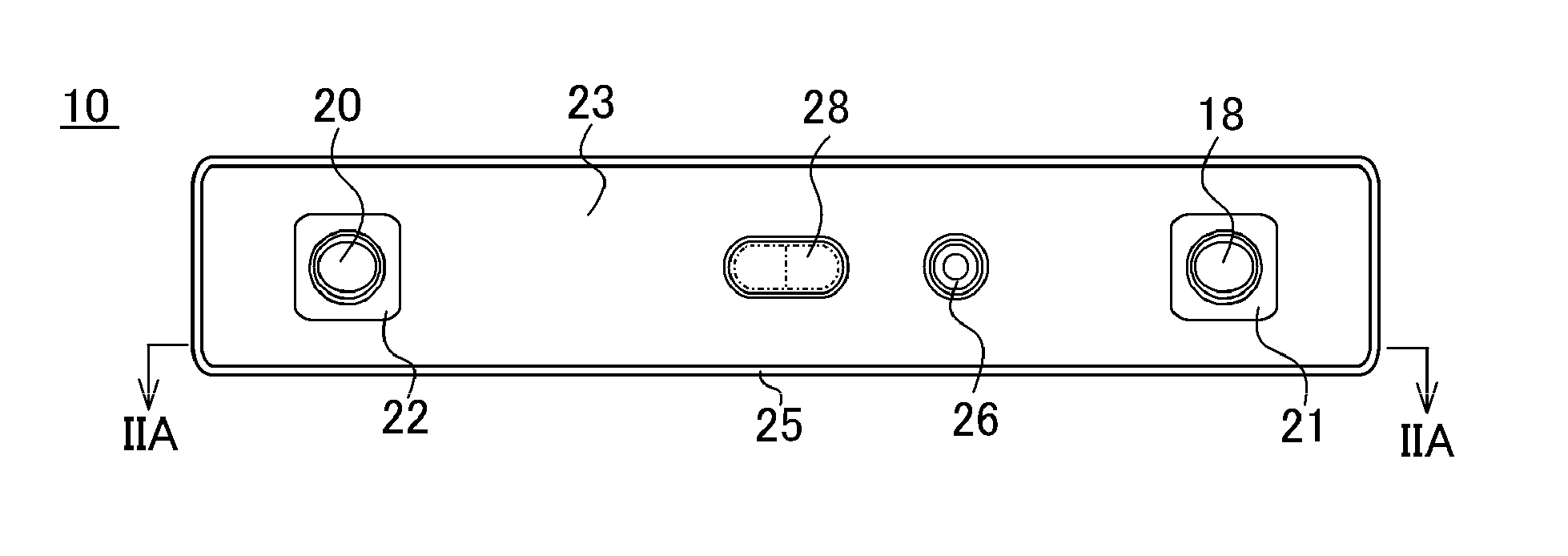

Fuel cell system and fuel cell starting method

InactiveUS20070212581A1Shorten the time periodIncrease temperatureReactant parameters controlWater management in fuel cellsHigh concentrationFuel cells

It is an object of the present invention to provide a system in which a fuel cell can be operated by use of a fuel having a constantly optimum concentration. It is another object of the present invention to shorten the time taken in starting a fuel cell. A low-concentration fuel for performing mainly a power generation reaction and a high-concentration fuel for performing mainly the power generation reaction and a reaction for raising the temperature of a power generation cell are stored respectively in separate storage vessels, whereby the fuel supplied to a negative electrode can be instantaneously changed over according to the temperature of the power generation cell. This makes it possible to perform an operation at a constantly optimum fuel concentration. In addition, since it is possible to raise the temperature of the power generation cell in a short time, it is possible to reduce the capacity of an auxiliary battery used when the temperature of the power generation cell is low, and to reduce the fuel cell system in size.

Owner:SONY CORP

Nonaqueous electrolyte secondary battery

InactiveUS20140045022A1Improve output characteristicsImproved heat release characteristicFinal product manufactureWound/folded electrode electrodesLithiumElectrolyte

In a prismatic nonaqueous electrolyte secondary battery, a flat winding electrode assembly and a nonaqueous electrolyte are housed in a prismatic outer body. A positive electrode includes a positive electrode substrate exposed portion formed along the longitudinal direction. A negative electrode includes a negative electrode substrate exposed portion formed along the longitudinal direction. The nonaqueous electrolyte contains a lithium salt having an oxalate complex as an anion at the time of making the nonaqueous electrolyte secondary battery. The area of the negative electrode substrate exposed portion is 700 cm2 or more. The area of the positive electrode substrate exposed portion is 500 cm2 or more. The area of the negative electrode substrate exposed portion is larger than the area of the positive electrode substrate exposed portion. The prismatic nonaqueous electrolyte secondary battery above can provide a nonaqueous electrolyte secondary battery that has excellent cycling characteristics and excellent reliability.

Owner:SANYO ELECTRIC CO LTD

Method and apparatus of growing silicon single crystal and silicon wafer fabricated thereby

ActiveUS20060137599A1Eliminate failure problemsQuality improvementPolycrystalline material growthBy zone-melting liquidsCzochralski methodSingle crystal

Disclosed is a metod of fabrication of high quality silicon single crystal at high growth rate. The method grows silicon single crystal from silicon melt by Czochralski method, wherein the silicon single crystal is grown according to conditions that the silicon melt has an axial temperature gradient determined according to an equation, {(ΔTmax−ΔTmin) / ΔTmin}×100≦10, wherein ΔTmax is a maximum axial temperature gradient of the silicon melt and ΔTmin is a minimum axial temperature gradient of the silicon melt, when the axial temperature gradient is measured along an axis parallel to a radial direction of the silicon single crystal.

Owner:LG SILTRON

Thermal package with heat slug for die stacks

InactiveUS9129929B2Reduce impactImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:SONY MOBILE COMM AB +1

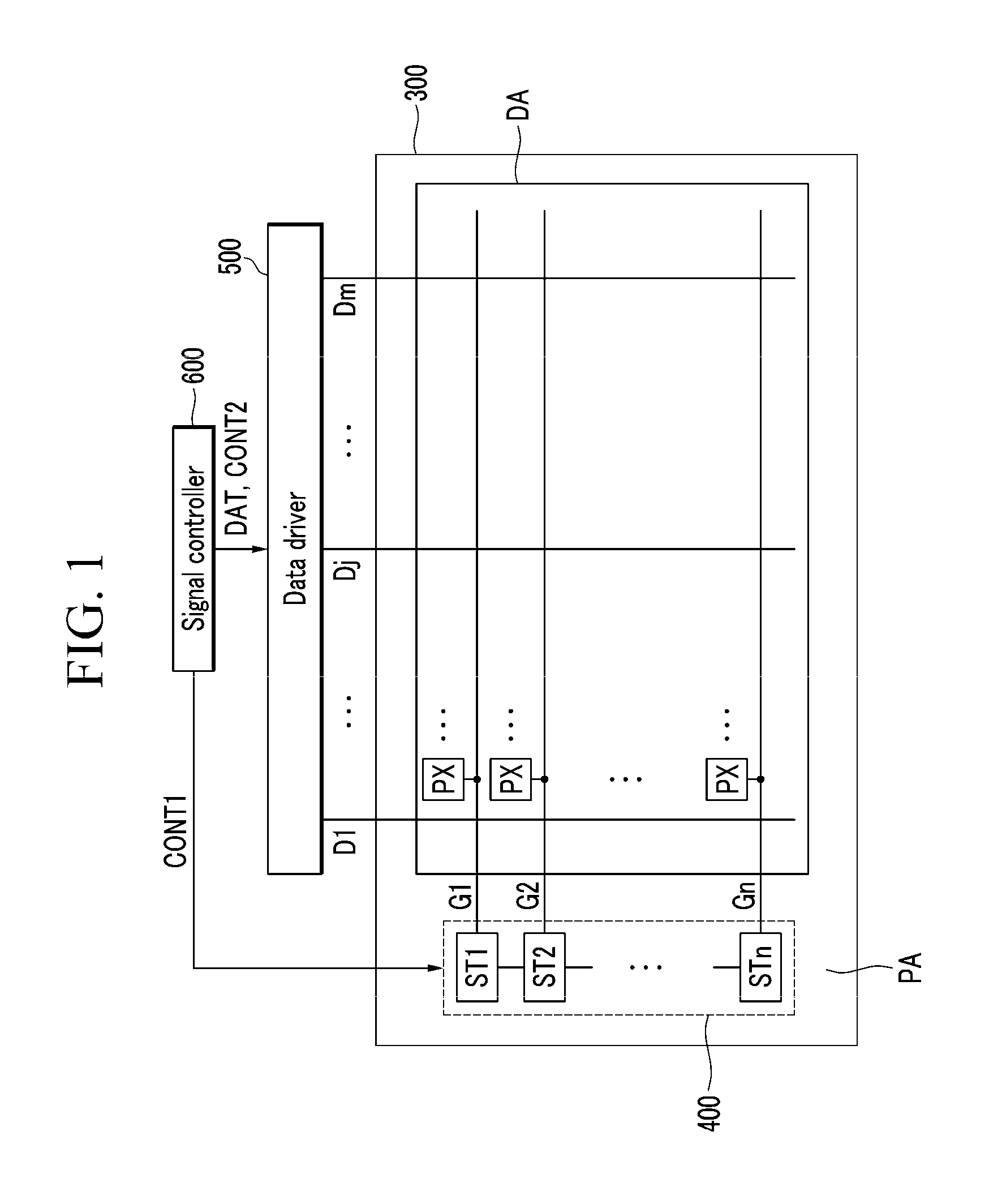

Display device

ActiveUS20150194444A1Avoid problemsReduce overlapStatic indicating devicesSolid-state devicesDisplay deviceGate driver

Provided is a display device, more particularly, a display device including a gate driver. The display device includes: a plurality of pixels; a plurality of gate lines connected to the plurality of pixels; a gate driver including a plurality of stages outputting gate signals to the plurality of gate lines; a clock signal wiring transferring a clock signal to the gate driver; a voltage wiring transferring an off voltage to the gate driver; in which the clock signal wiring is positioned at a first side of the gate driver, and the voltage wiring is positioned at a second side facing the first side of the gate driver.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com