Flat film-type cooling device

A heat dissipation device and thin-film technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as reducing thermal disturbance of mobile electronic devices, improve manufacturing convenience, and improve assembly quality efficiency and maintain reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

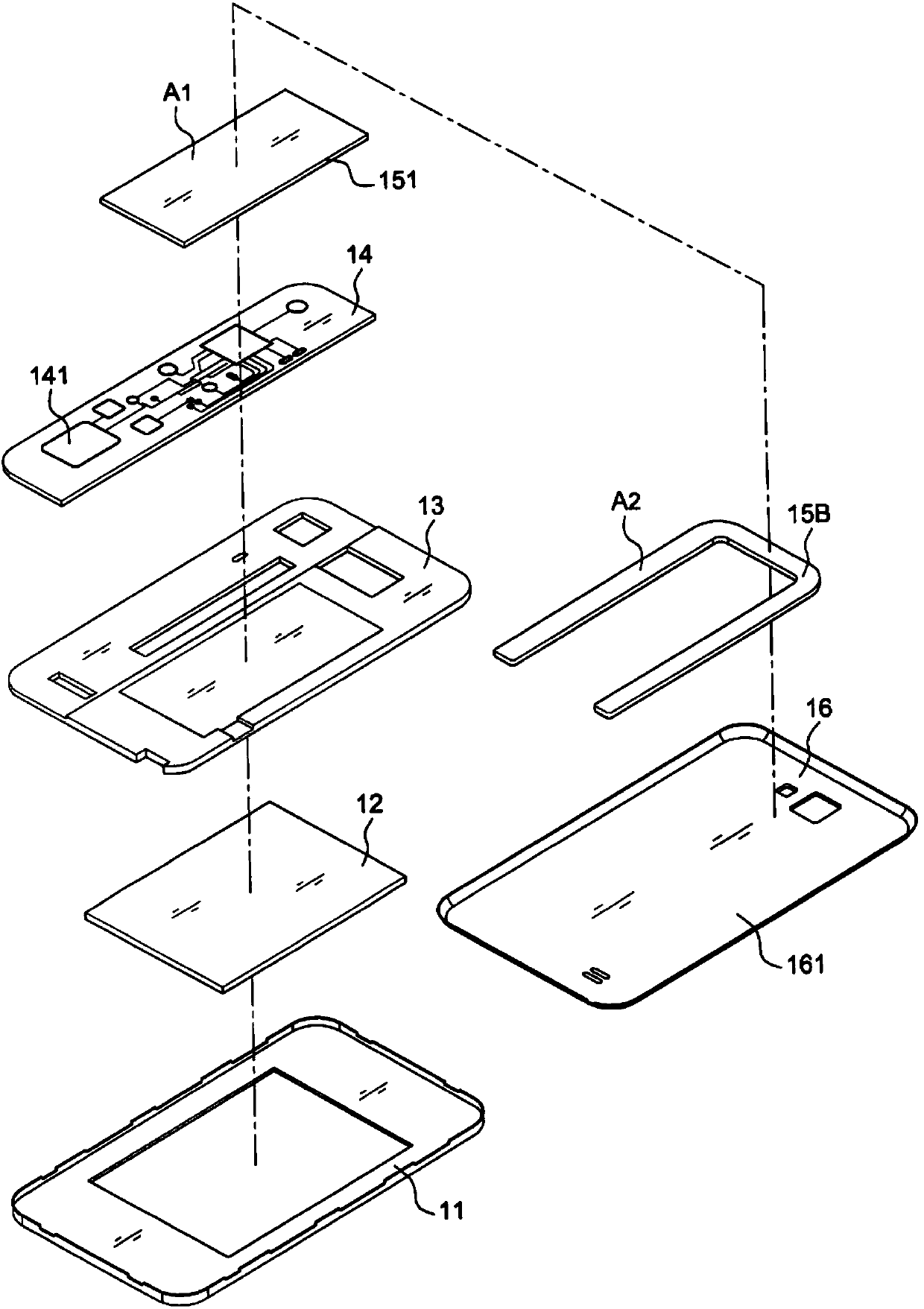

[0048] First, see Figure 3 ~ Figure 9 As shown, a preferred embodiment of a flat film heat dissipation device 20 of the present invention includes: an upper metal heat dissipation layer 21, which is a flat body, and its thickness is 0.01-0.20 mm; a lower metal heat dissipation layer 22, which is a flat body , and its thickness is 0.01 ~ 0.20mm, and corresponds to the upper metal heat dissipation layer 21, in this embodiment, the upper metal heat dissipation layer 21 and the lower metal heat dissipation layer 22 are made of gold, silver, copper, titanium, aluminum, stainless steel The metal, the alloy of the metal, or one of the alloys of multiple metal combinations. In another embodiment, the upper metal heat dissipation layer 21 and the lower metal heat dissipation layer 22 are made of silicon carbide, aluminum oxide, silicon wafer, graphite ene, polymer-containing temperature equalizing or heat-dissipating coating, but not limited thereto.

[0049] A resin layer 23 is loca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com