Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "High shear modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

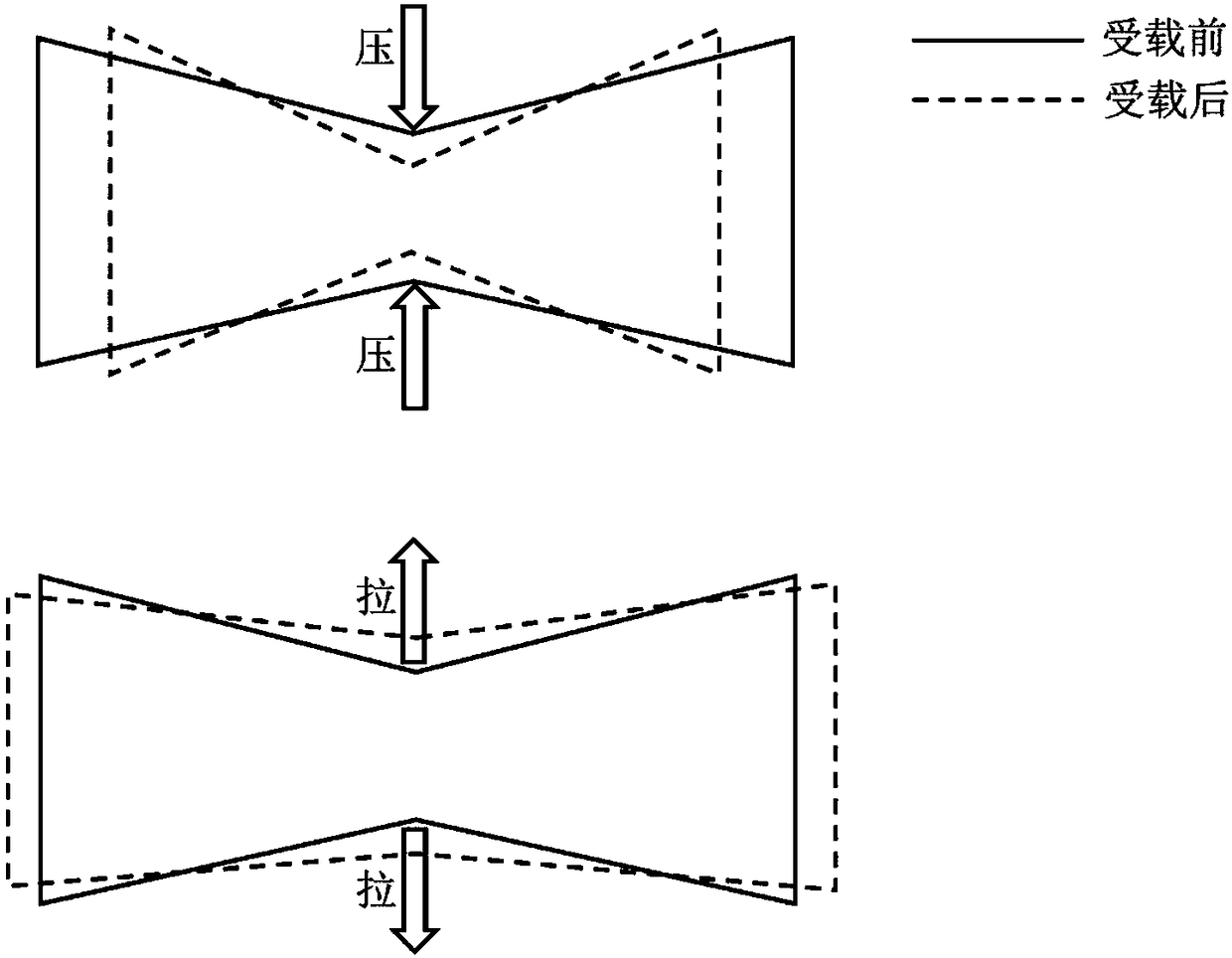

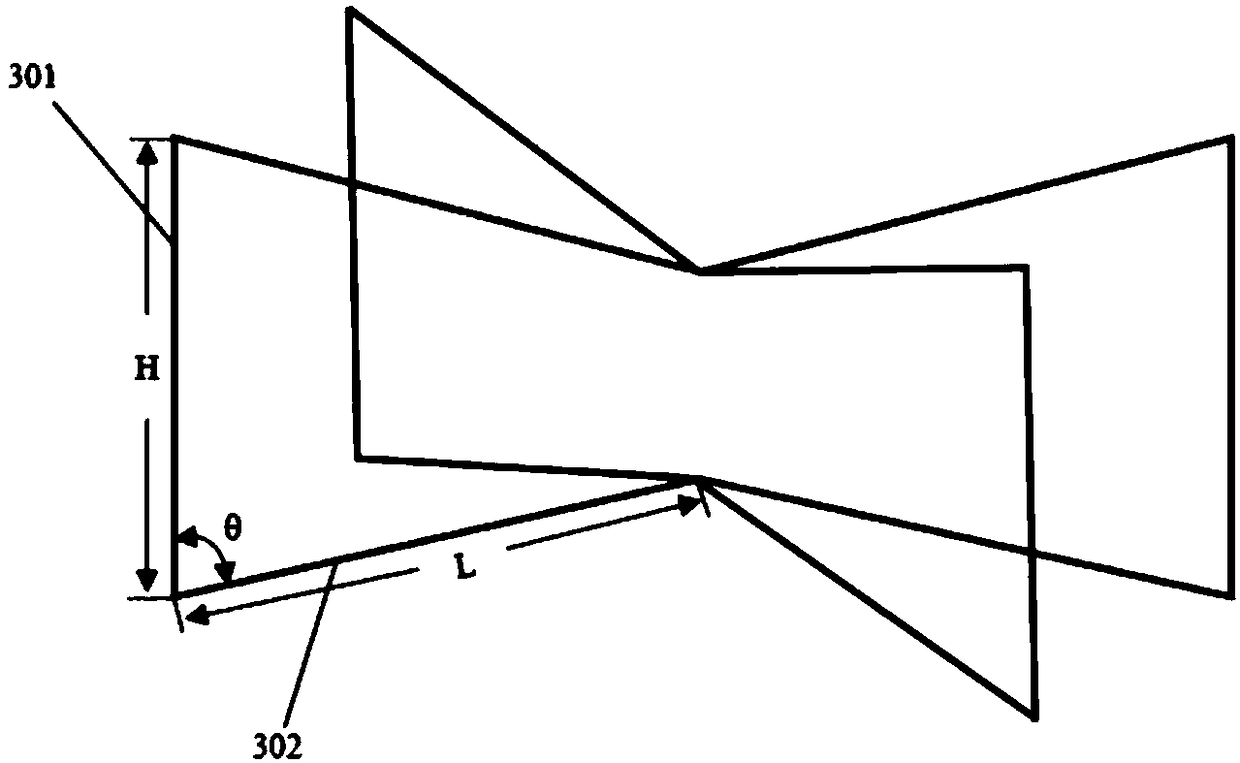

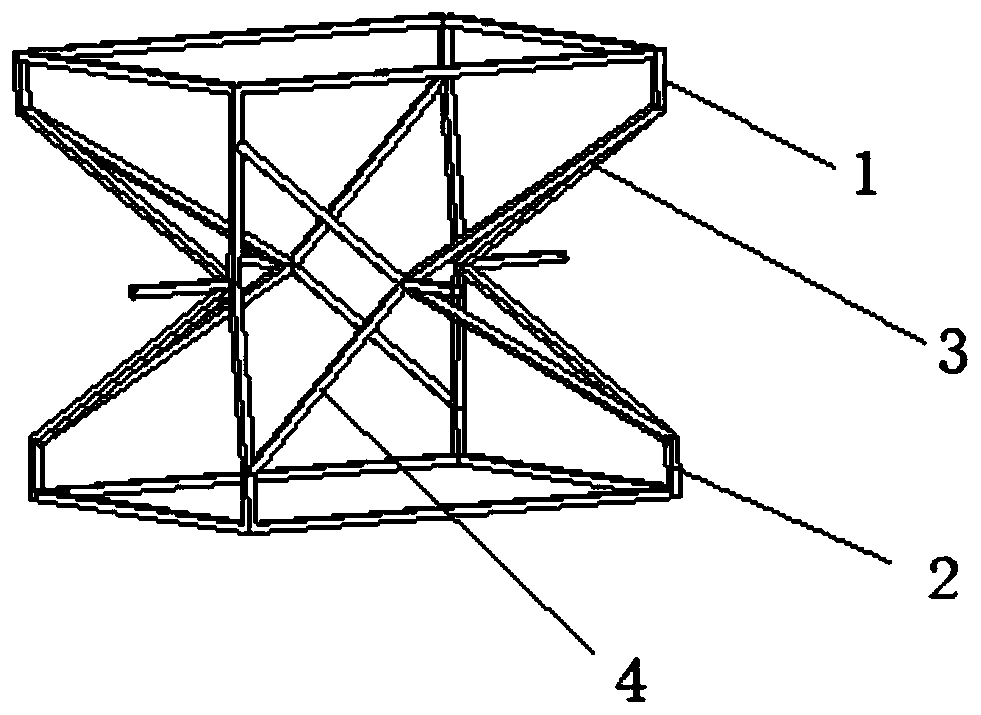

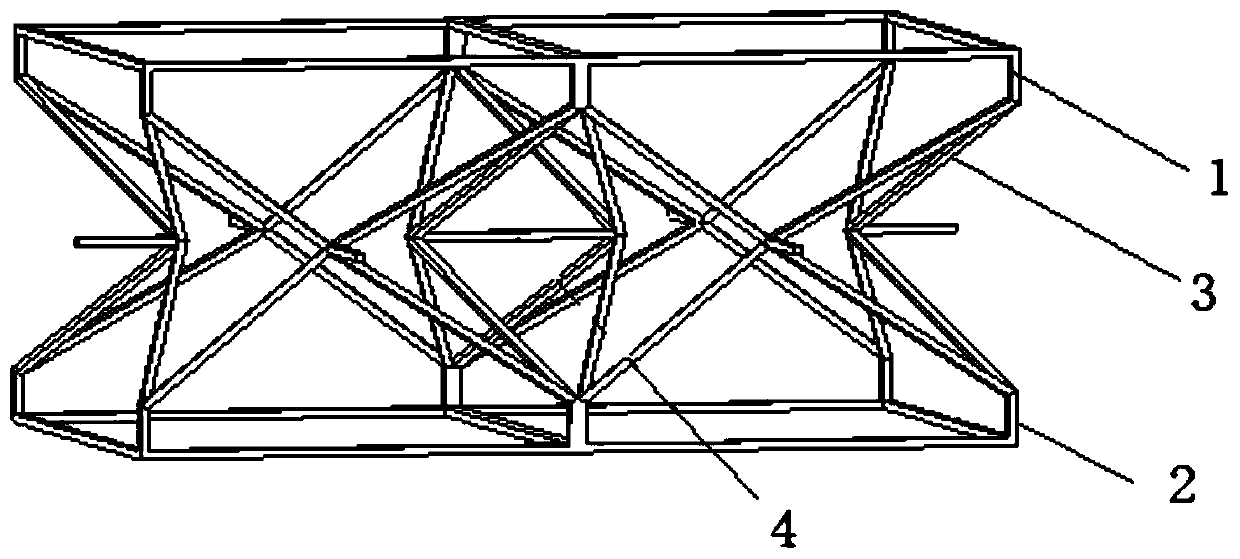

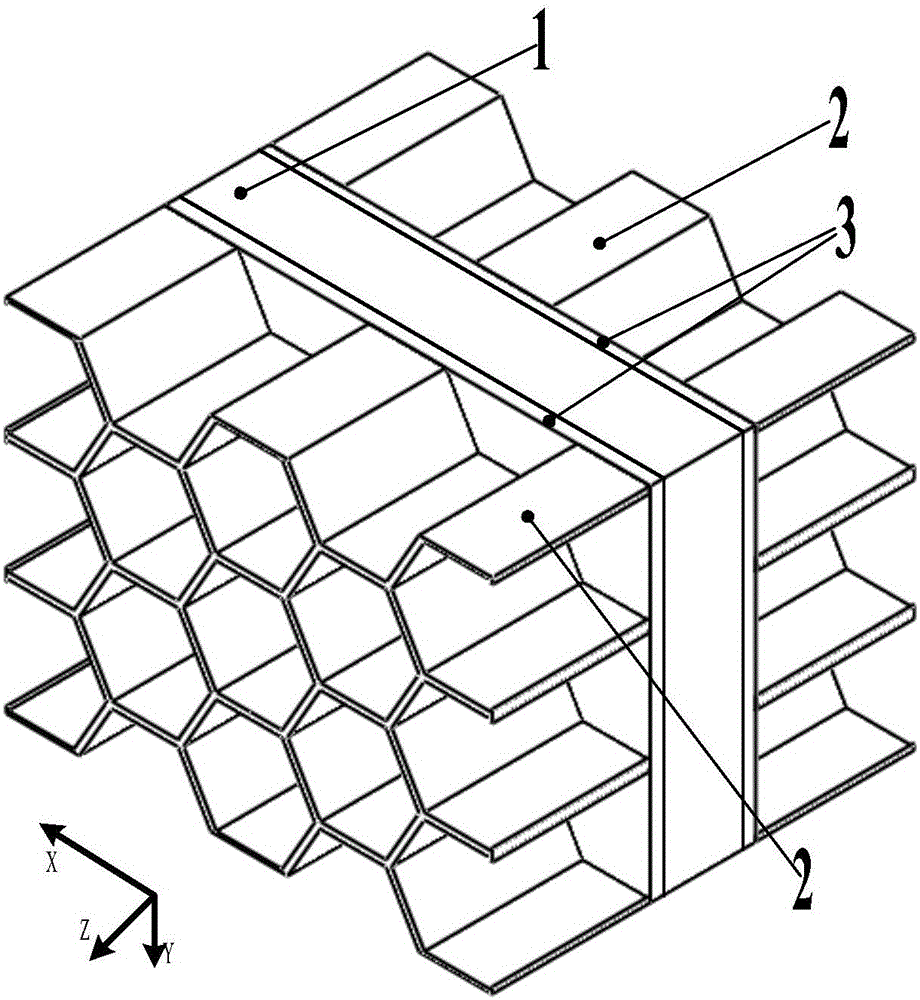

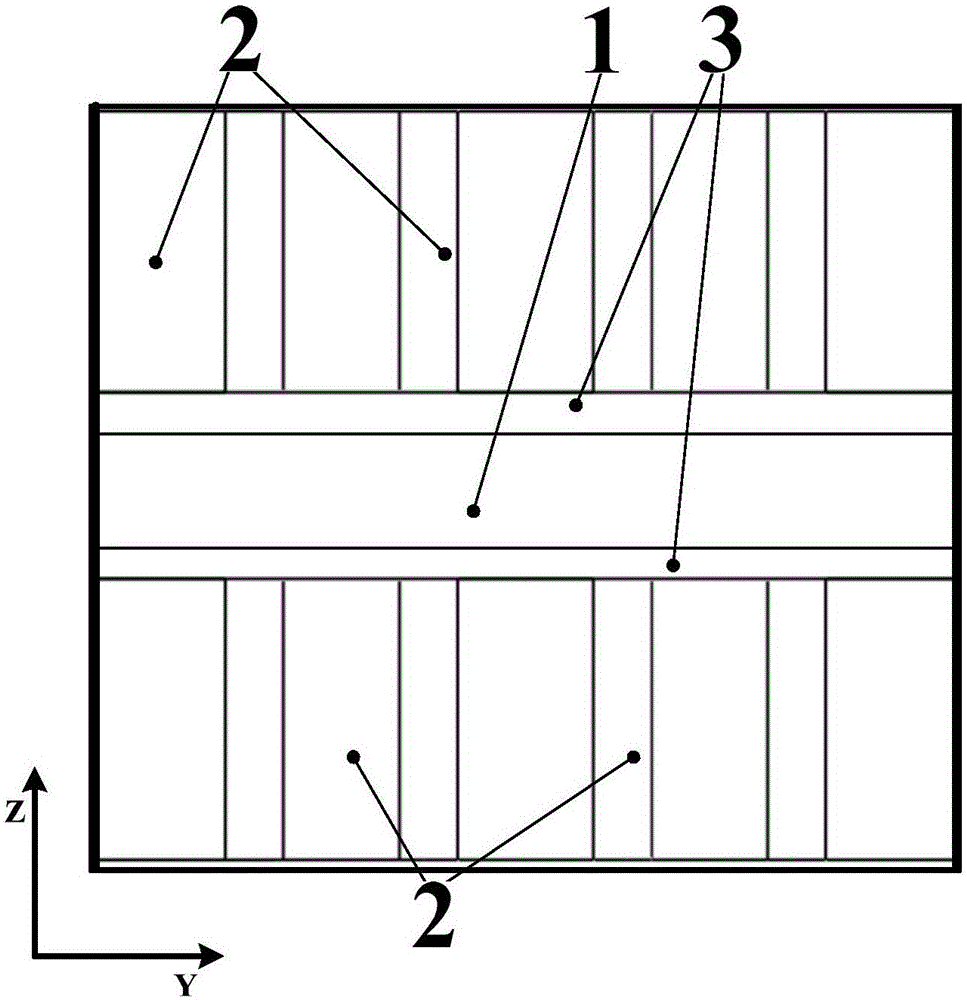

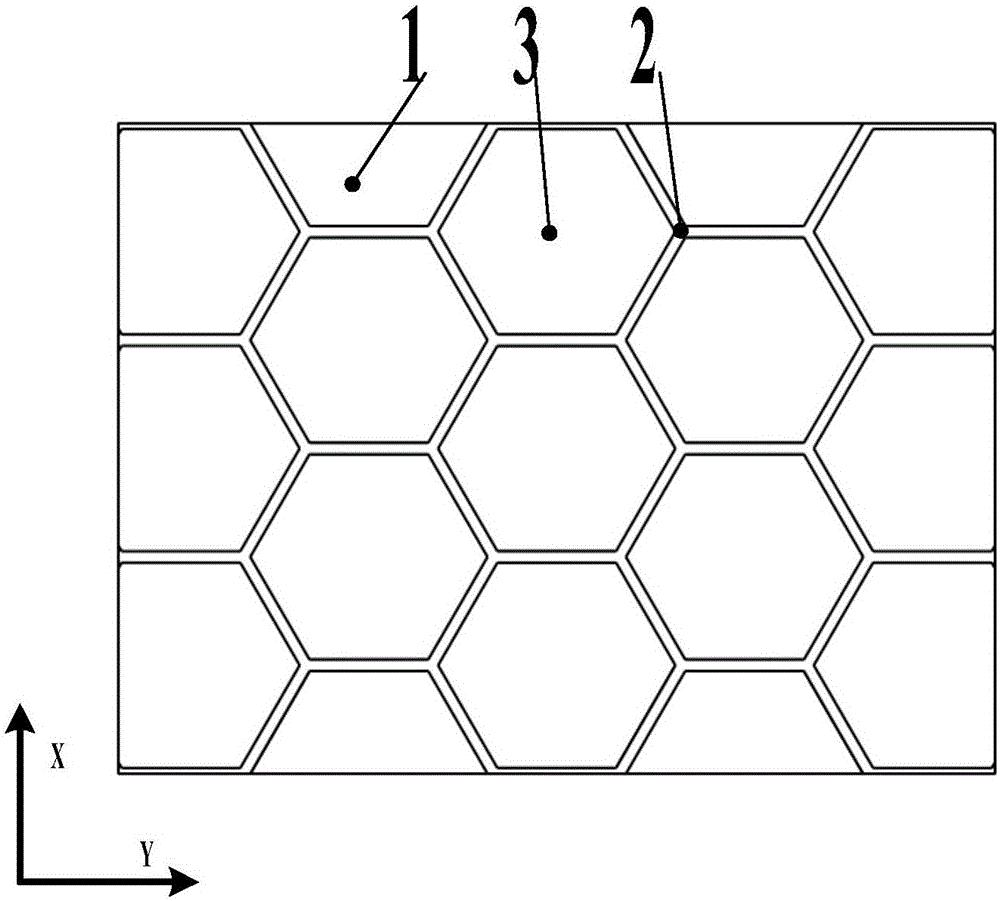

Negative poisson ratio structural component based on inner sunken hexagonal unit

PendingCN108082102AGood resilience toughness and fracture resistanceHigh strengthBumpersSustainable transportationSupporting cellElastic modulus

The invention discloses a negative poisson ratio structural component based on an inner sunken hexagonal multi-cell unit. The negative poisson ratio structural component comprises a plurality of unitcell structures, each of the unit cell structures consists of two inner sunken hexagons, the inner sunken hexagons are in a left-right symmetric dovetail shape, and every two inner sunken hexagons arearranged in an orthogonal mode and intersect at two concave angle apexes to form a complete unit cell structure; the multiple unit cell structures are connected with each other horizontally in both directions by sharing one support cell arm, and are extended in the horizontal direction to form a continuous unit layer; and a plurality of unit layers are connected with each other in the vertical direction by sharing curved ribs to form a multi-layered cross-aligned inner sunken honeycomb-shaped three-dimensional negative poisson ratio structure. According to the negative poisson ratio structural component based on the inner sunken hexagonal multi-cell unit, a significant negative poisson ratio effect is achieved, higher elastic modulus, shear modulus and storage modulus can be generated when loaded, better rebound toughness and fracture resistance are achieved and improved with the enhancement of the negative poisson ratio effect.

Owner:NANJING UNIV OF SCI & TECH

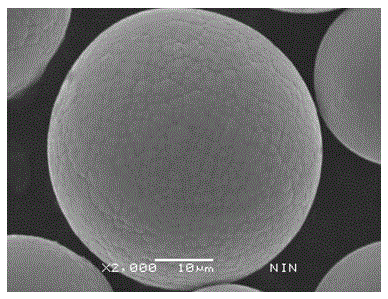

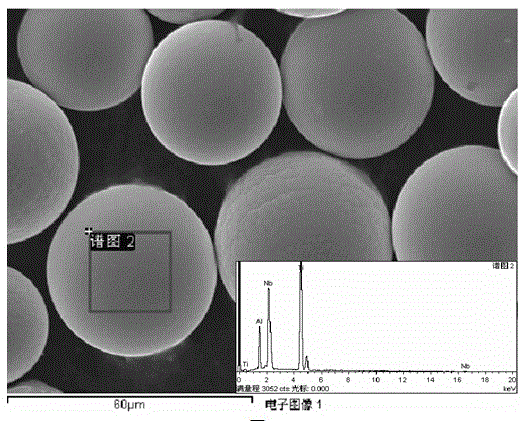

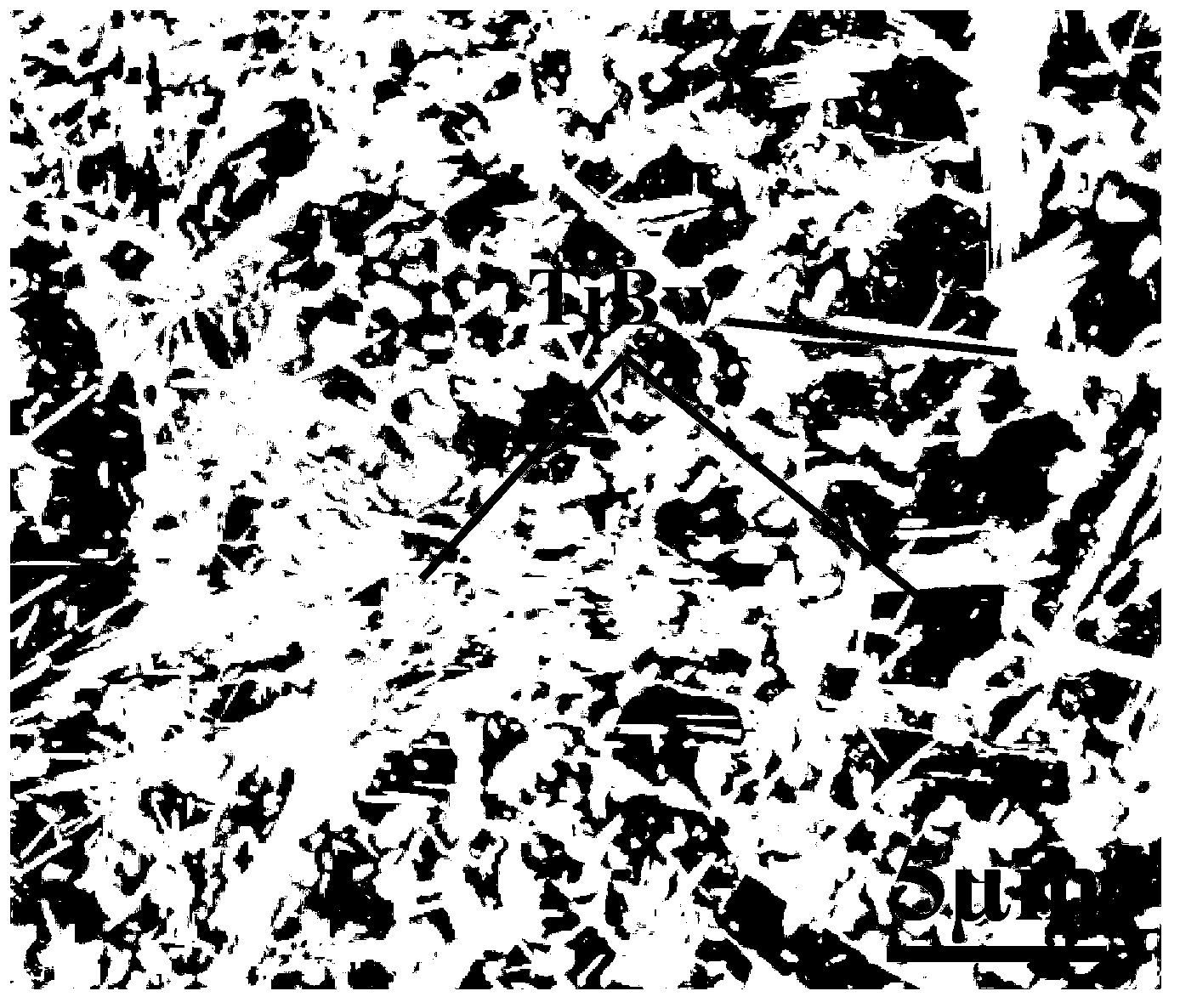

Preparing method for ultra-fine high-purity Ti2AlNb alloy powder

ActiveCN105537603AHigh purityHigh sphericityTransportation and packagingMetal-working apparatusAlloyUltra fine

The invention provides a preparing method for ultra-fine high-purity Ti2AlNb alloy powder. The preparing method comprises the following steps that 1, components of a Ti2AlNb base alloy are used as ingredients and smelted into a Ti2AlNb alloy bar; 2, finish turning is carried out on the smelted Ti2AlNb alloy bar, the diameter of a processed electrode bar ranges from 10 mm to 100 mm, and the length ranges from 100 mm to 1000 mm; 3, the electrode bar is loaded into a reaction chamber, the reaction chamber is vacuumized, and helium or argon or helium and argon mixed gas is introduced into the reaction chamber; 4, plasma gun powder of PREP powder manufacturing equipment ranges from 100 kW to 300 kW, a plasma torch comprises a tungsten cathode and a copper anode, the electrode bar is not used as an electrode, the end of the electrode bar is heated to be melted uniformly, atomized drops are tossed out from the end of the electrode bar, the drops are cooled fast in an inert gas environment to form spherical particles, and the spherical particles drop into a bottom collector of the reaction chamber; 5, prepared Ti2AlNb alloy powder is screened and packaged in the inert gas protection environment; 6, the Ti2AlNb alloy powder prepared through the method has the advantages of being ultra-fine, high in purity, high in spherical degree and low in oxygen content.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

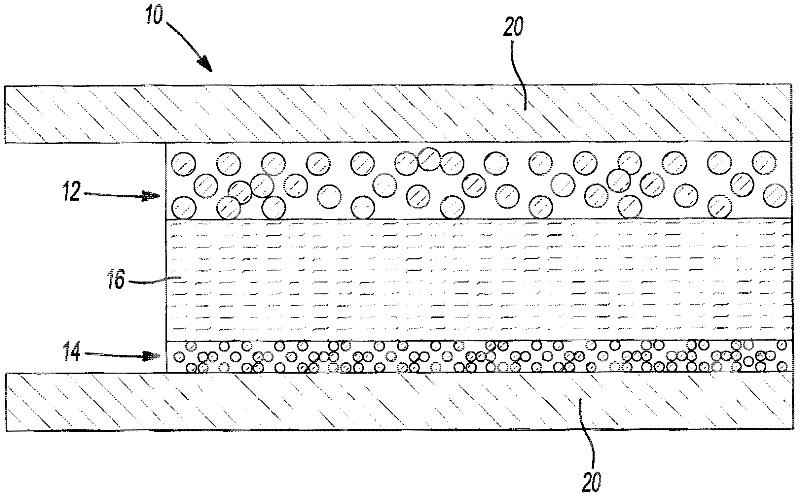

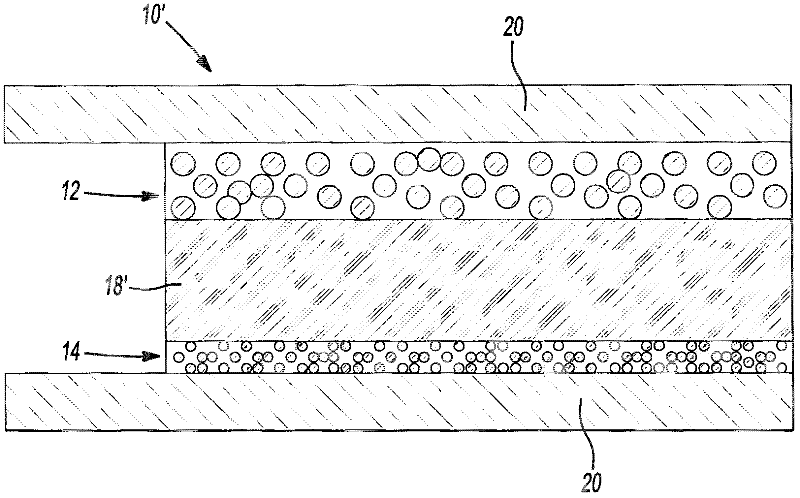

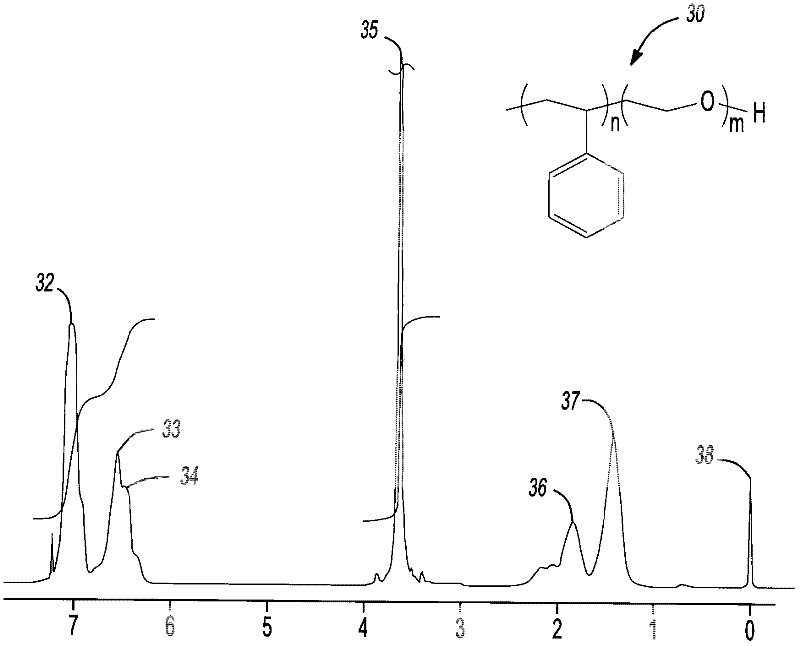

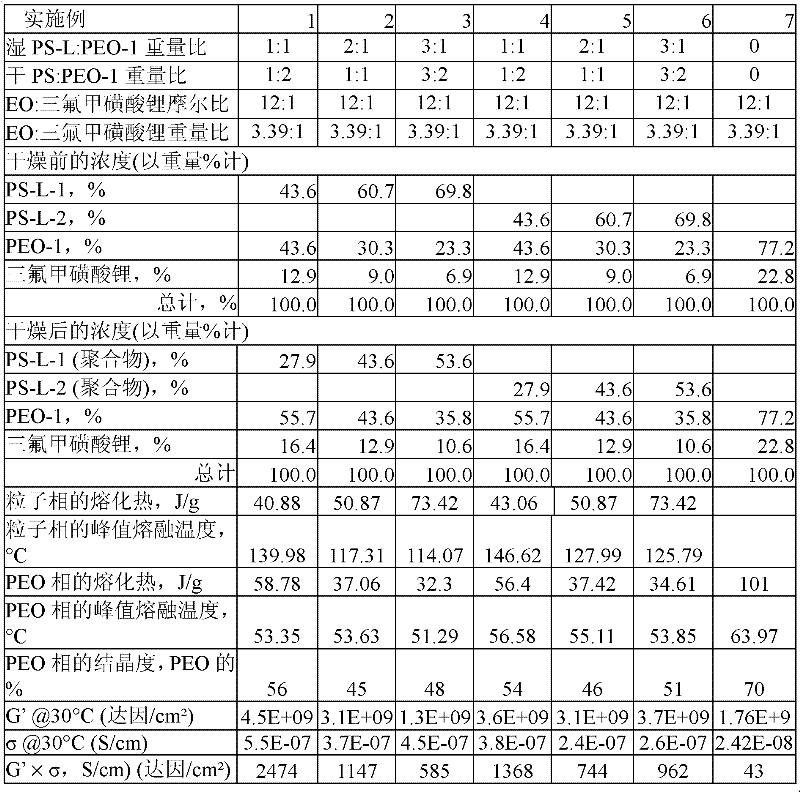

Highly conductive polymer electrolytes and secondary batteries including the same

InactiveCN102318125AHigh melting temperatureHigh glass transition temperatureFinal product manufactureElectrolytesPolymer electrolytesShear modulus

The present invention is directed to novel block copolymers and to novel polymeric electrolyte compositions, such as solid polymer electrolytes that comprises a block copolymer including a first block having a glass transition temperature greater than about 6O DEG C or a melting temperature greater than about 60 DEG C, and a second block including a polyalkoxide. The polymer electrolyte composition preferably has a shear modulus, G', measured at 1 rad / sec and about 30 DEG C and a conductivity, s, measured at about 30 DEG C, such that i) G'- s is greater than about 200 (S / cm)(dynes / cm2); and ii) G' is from about 104 to about 1010 dynes / cm2.

Owner:DOW GLOBAL TECH LLC

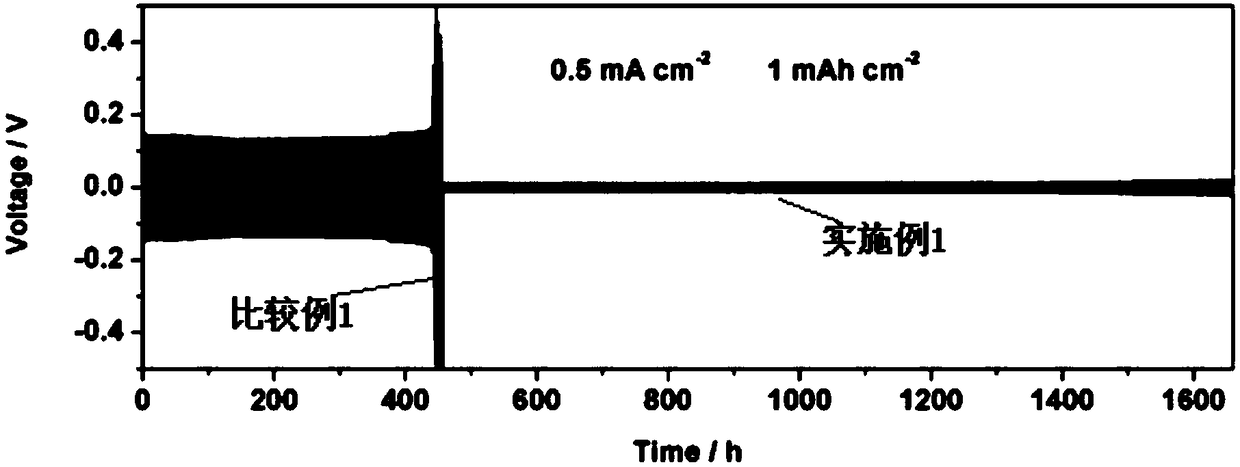

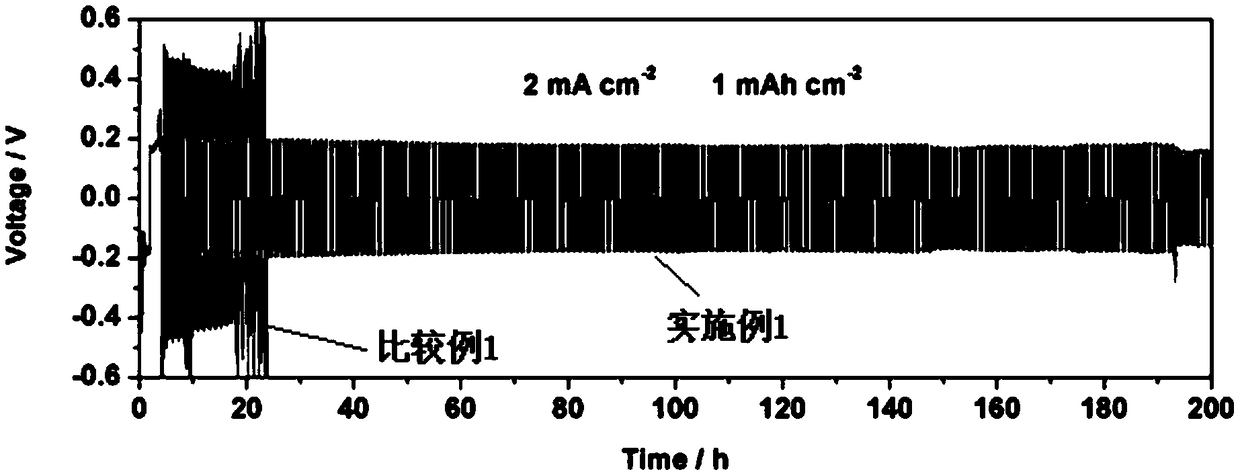

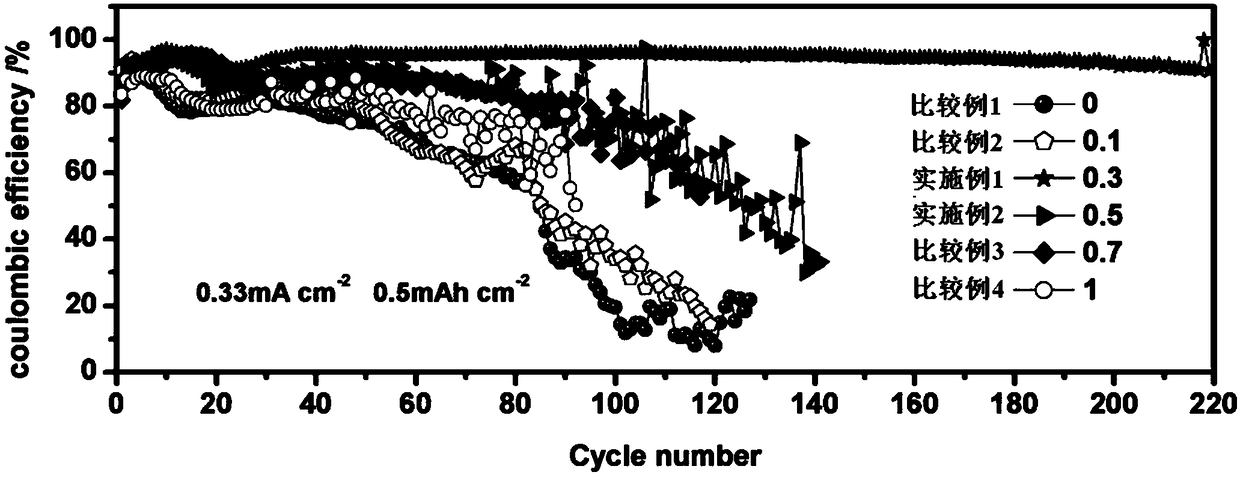

Lithium metal battery electrolyte and lithium metal battery

ActiveCN109494406AFree from corrosionImprove securitySecondary cells servicing/maintenanceOrganic electrolytesOrganic solventLithium metal

The invention provides a lithium metal battery electrolyte. The lithium metal battery electrolyte is composed of lithium salt, additives and non-aqueous solvent, wherein the additives are one or moreselected from NaBOB, NaTFSI, NaFSI, NaPF6, NaBF4, (C3H3NaO2)n, Na2SO4, Mg(FSI)2, Mg(TFSI)2, KFSI and KTFSI, and the concentration of the additives of the lithium metal battery electrolyte is 0.2-0.5 mol / L; the non-aqueous solvent is one or more selected from carbonate organic solvent, phosphate organic solvent and ether organic solvent. The lithium metal battery electrolyte can form an SEI (solidelectrolyte interface) layer on the surface of a metal lithium negative electrode during a constant current charging and discharging process to improve the safety performance, the utilization rate andthe cycling stability of a lithium metal battery. The invention also provides the lithium metal battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

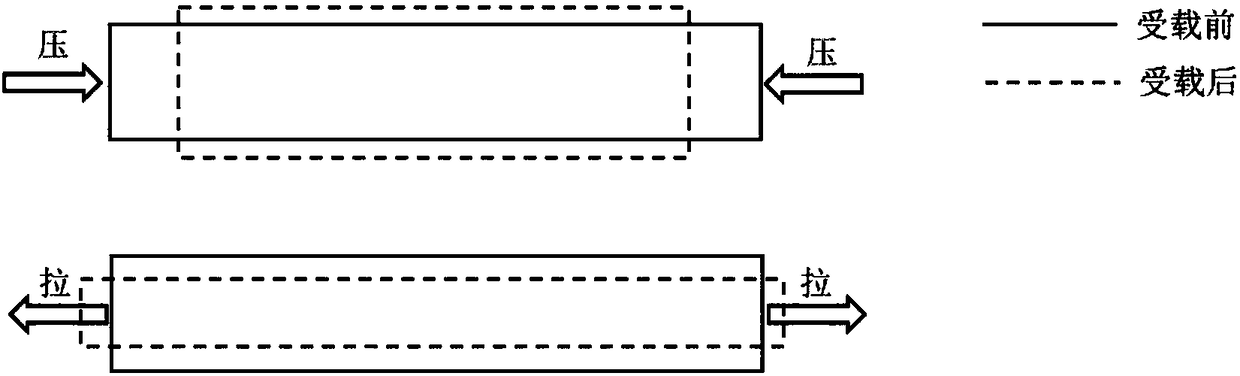

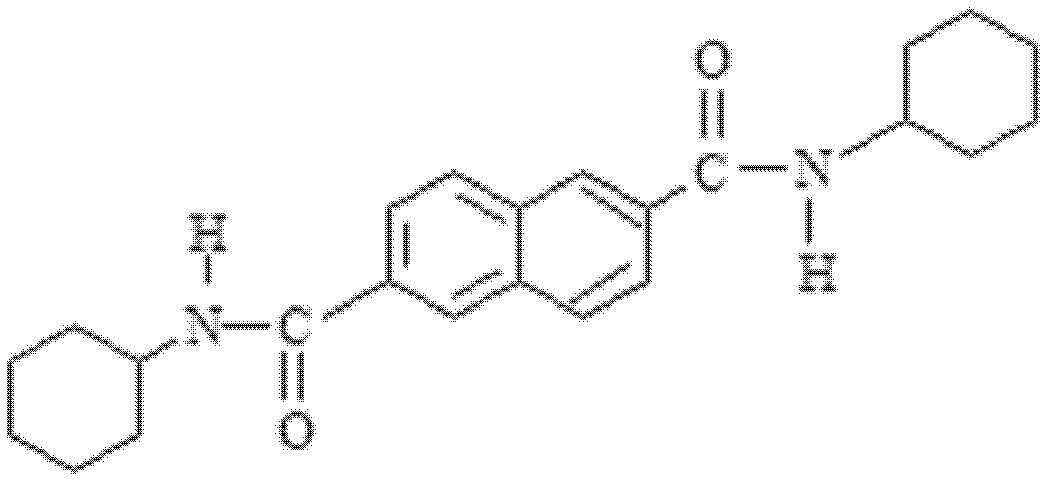

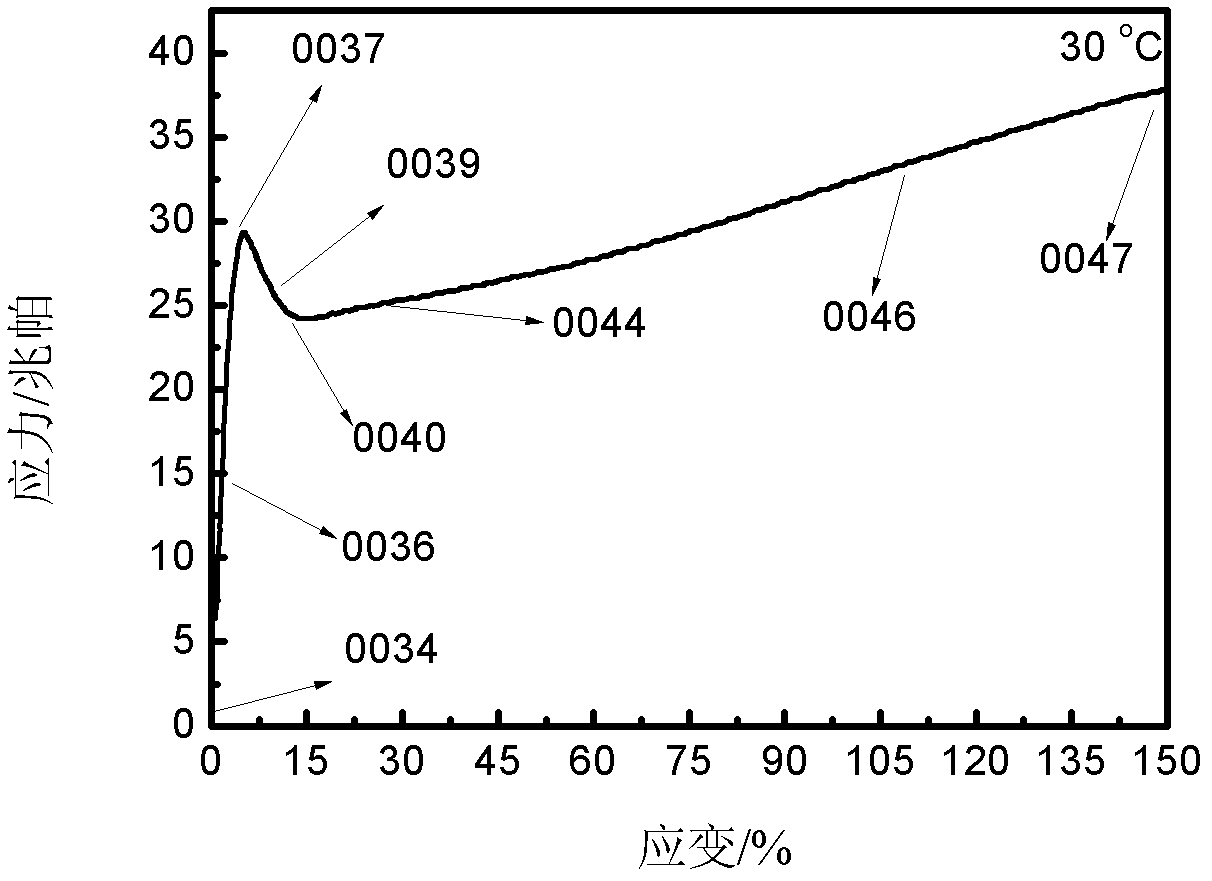

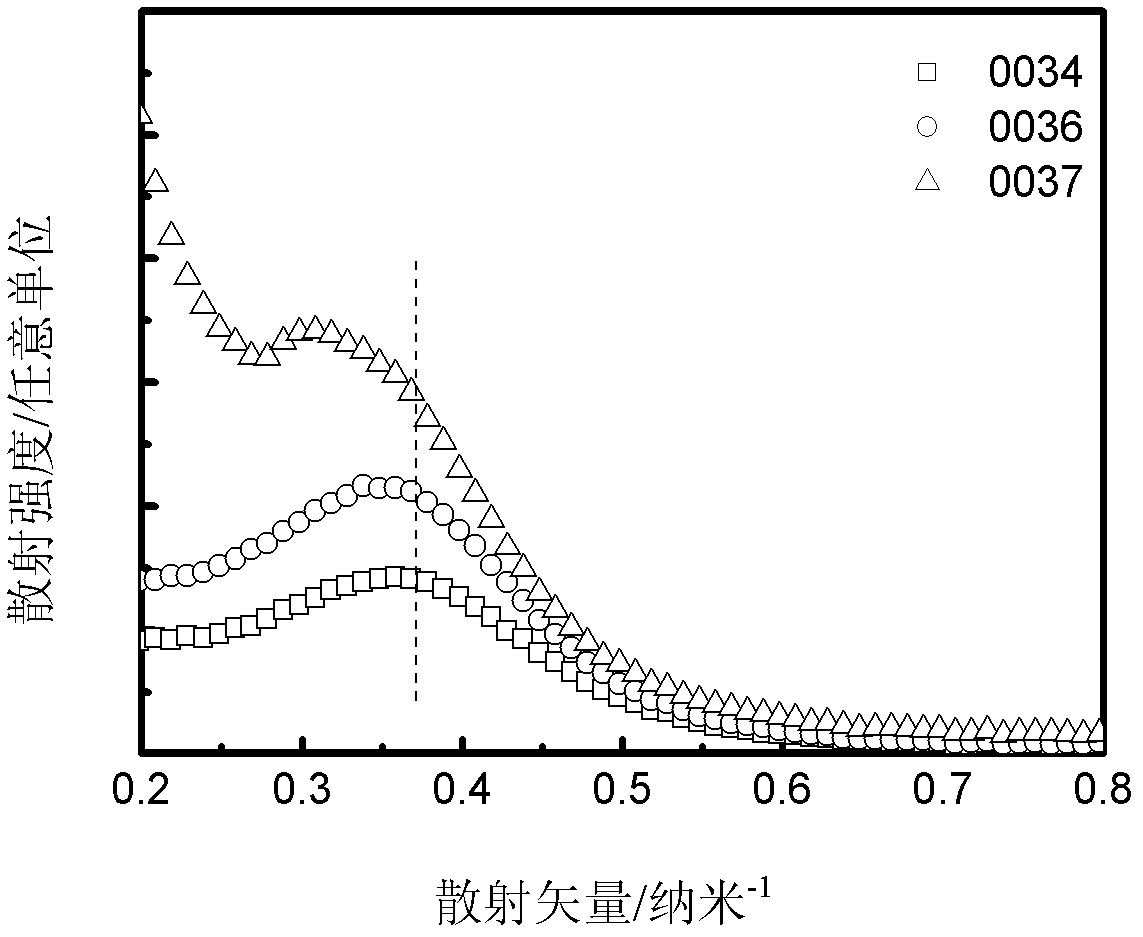

Beta crystal polypropylene tensile expandable material and preparation method thereof

InactiveCN102352069AHigh mechanical strengthReduce prone defectsPolymer scienceManufactured material

The invention discloses a beta crystal polypropylene tensile expandable material and a preparation method thereof. N,N'-dicyclohexyl-2,6-naphthalenedicarboxamide (DCNDCA) is used as a single beta crystal nucleating agent of isotactic polypropylene, and the adding amount of the DCNDCA is more than 0 and not more than 2 percent of the mass of the isotactic polypropylene. The nucleating agent and the isotactic polypropylene are blended by multiple modes of melt blending, solution blending and the like, so that the nucleating agent is uniformly dispersed in the polypropylene material. The material shows tensile expandable property in a certain strain range; and the tensile expandable property of the material is conveniently and flexibly controlled by formation control of polypropylene beta crystal, so that an alternative raw material with flexibility, convenience for making and high economical efficiency, isotropy and mechanical strength is provided for design and manufacture of more tensile expandable material products, the category of the domestic tensile expandable material is enriched, and support is provided for wider application of the tensile expandable material.

Owner:TIANJIN UNIV

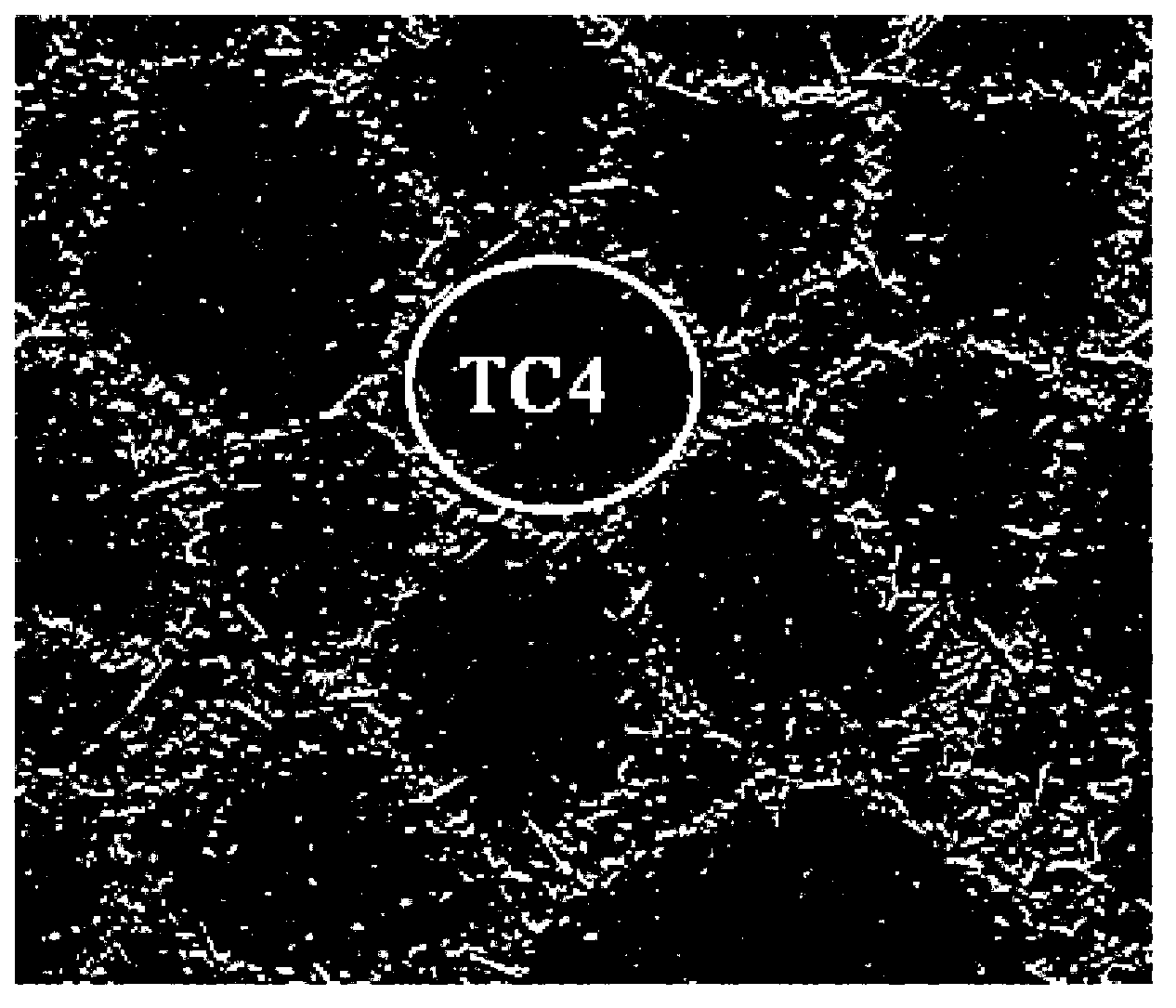

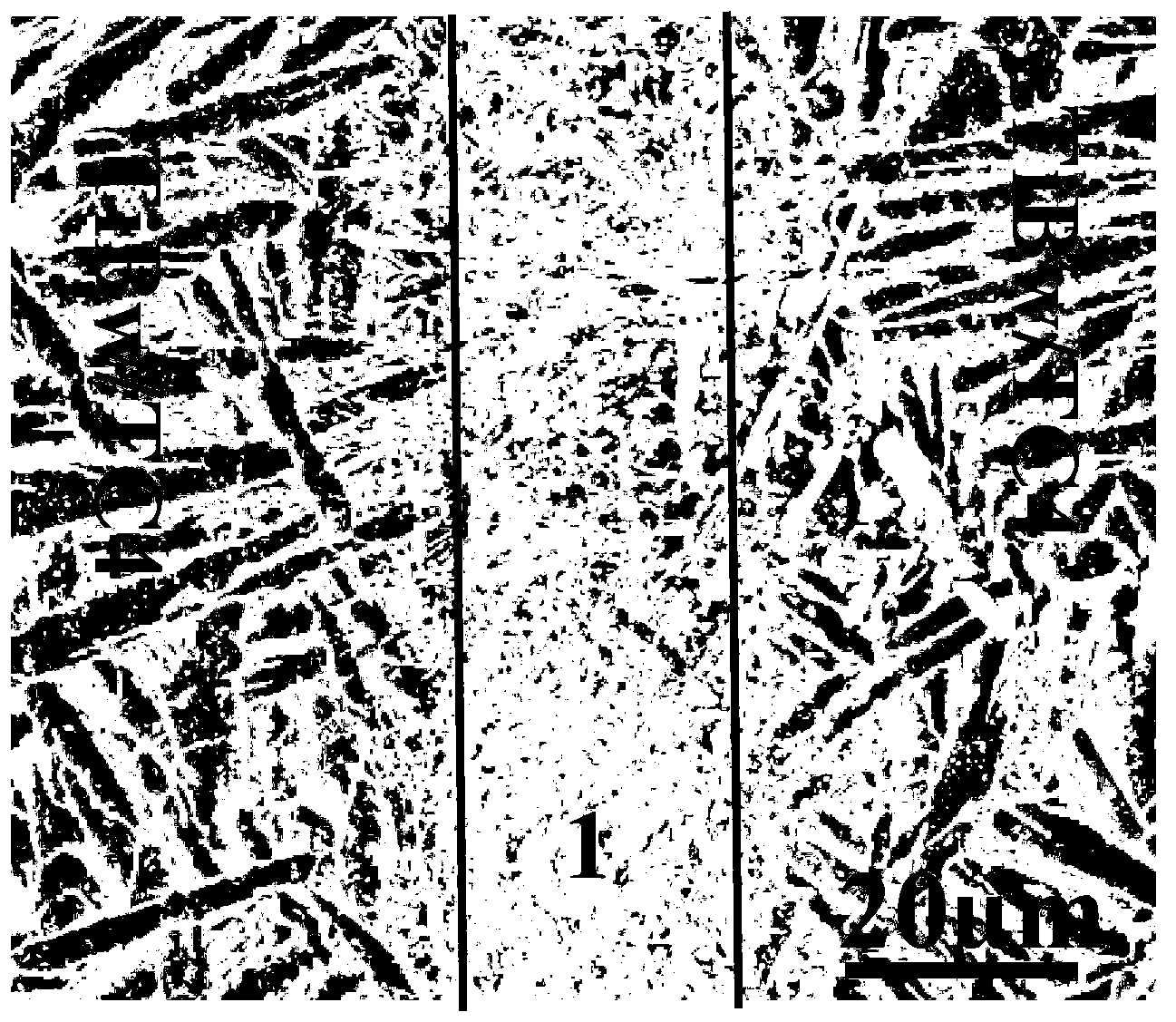

Composite soldering material, preparation method thereof and method of using composite soldering material to solder TiBw/TC4 titanium-based composite material

ActiveCN103264235AActive connectionHigh temperature strengthWelding/cutting media/materialsSoldering mediaTitanium matrix compositesTitanium

The invention relates to a composite soldering material, a preparation method thereof and a method of using the composite soldering material to solder a TiBw / TC4 titanium-based composite material, and aims at solving the problem that joints with high high-temperature strength are difficult to obtain by using a single soldering material to solder the titanium-based composite material. The composite soldering material is prepared by uniformly coating TiB2 particles on the surface of TiZrCuNi amorphous foil by binder. The soldering method includes: 1, grinding a base material; 2, cleaning the base material; and 3, soldering. By adopting the composite soldering material prepared by the method, effective connection of the TiBw / TC4 titanium-based composite material can be realized, and a connecting joint has high high-temperature strength. The composite soldering material prepared by the method is used for soldering the TiBw / TC4 titanium-based composite material.

Owner:HARBIN INST OF TECH

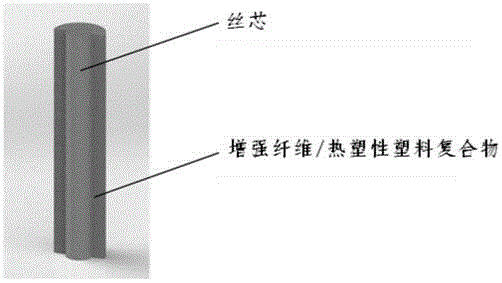

Composite fiber material for FDM technology and preparation method of composite fiber material

InactiveCN104141179AImprove adhesionHigh shear modulusFilament/thread formingConjugated synthetic polymer artificial filamentsMolten stateFiber

The invention discloses a composite fiber material for the FDM technology. The composite fiber material comprises a fiber core and thermoplastic plastic wrapping the outer layer of the fiber core. The fiber core is glass fiber or carbon fiber or a metal wire, and the diameter of the fiber core ranges from 5 micrometers to 20 micrometers. The diameter of the fiber material ranges from 20 micrometers to 50 micrometers. The thermoplastic plastic wrapping the outer layer of the fiber core contains 5-30%wt of reinforcing fiber with the diameter of 0.1 micrometer to 1 micrometer and the length smaller than or equal to 1 mm. A method for preparing the composite fiber material includes the steps of firstly, heating the thermoplastic plastic to the molten state; secondly, adding the reinforcing fiber into the molten plastic and evenly mixing the reinforcing fiber with the molten plastic; thirdly, evenly attaching the mixed melt to the surface of the fiber core through a fiber sending mechanism; fourthly, obtaining the composite fiber material with the diameter of 20 micrometers to 50 micrometers through extruding and sizing. The short reinforcing fiber and the fiber core are added to the thermoplastic plastic, and therefore the attaching effect between interfaces of the molten fiber material can be enhanced, axial connection strength of all layers of a printed piece is enhanced, and the independent tensile strength of each layer in the radial direction can be improved as well.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

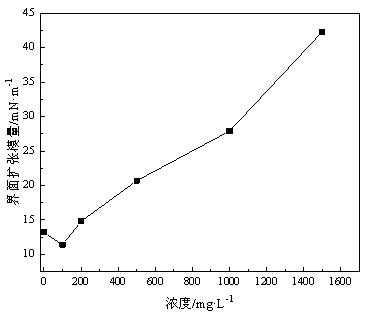

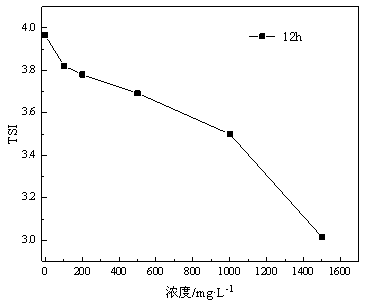

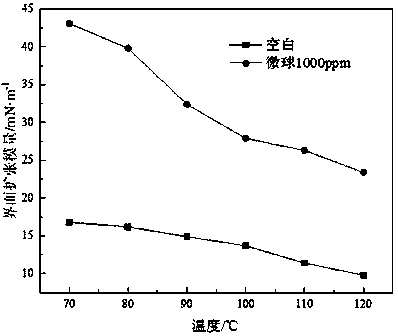

Polyacrylamide microsphere system and preparation method and application thereof

The invention relates to a microemulsion system and a preparation method thereof, in particular to a polyacrylamide microsphere system and a preparation method and application thereof. The microspheresystem is prepared through an emulsion polymerization reaction under the action of a composite initiator. The emulsion system comprises the following components in percentage by mass: 10%-60% of a monomer, 0.1%-3% of an organic salt, 3%-20% of an emulsifier, 0.01%-2% of a co-emulsifier, 0.01%-1% of a cross-linking agent, 0.001%-0.5% of an initiator, 0.001%-1% of a polymerization auxiliary agent,10%-70% of deionized water and 10%-50% of a non-polar solvent. The polymer microsphere system is used as an interface enhancer for emulsion flooding, can effectively improve the expansion modulus andshear modulus of an emulsion interface, and enhances emulsion stability; and after compounding polymer microspheres and a surfactant, a very good fluidity control effect is obtained and the profile control and flooding capacity of emulsion flooding is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

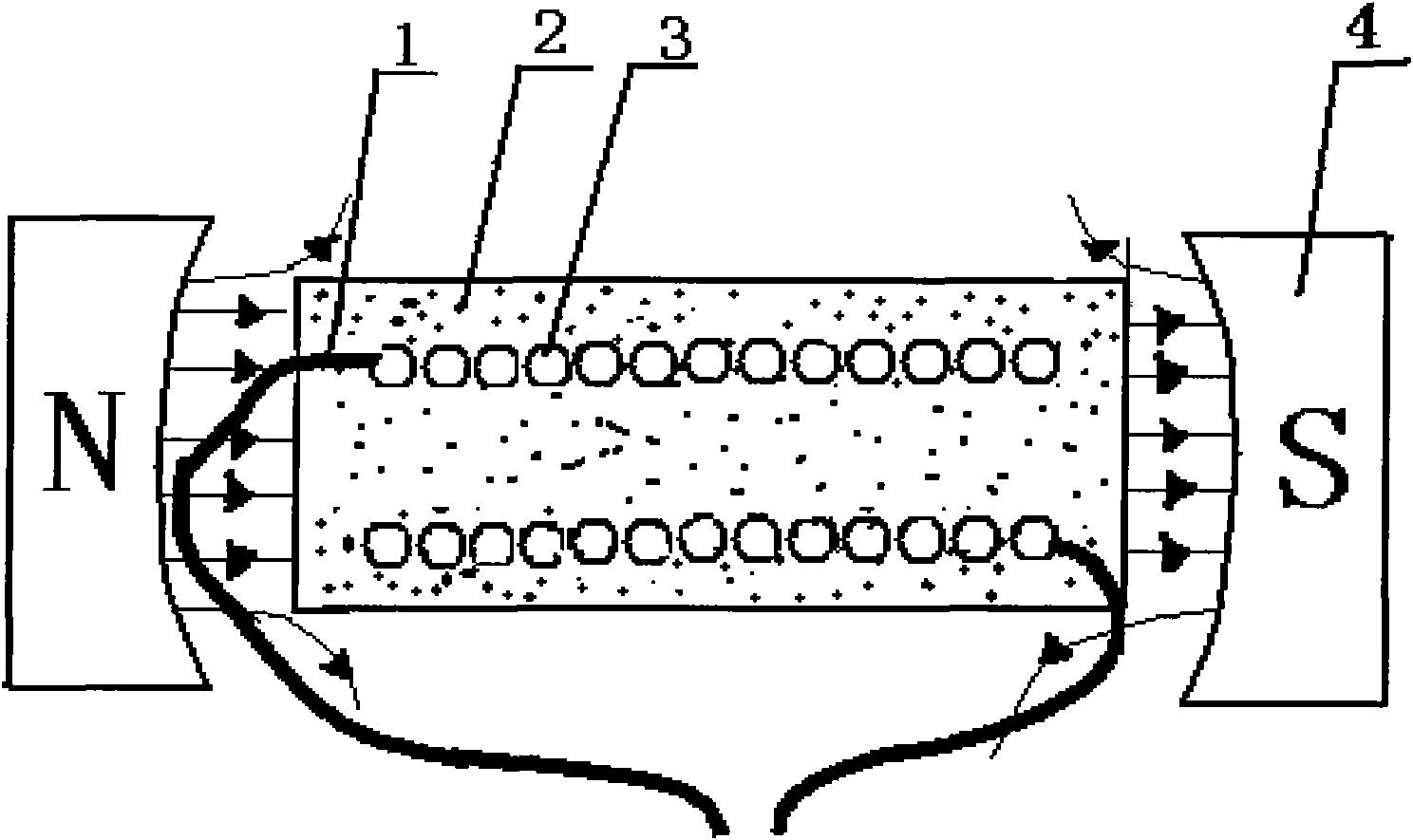

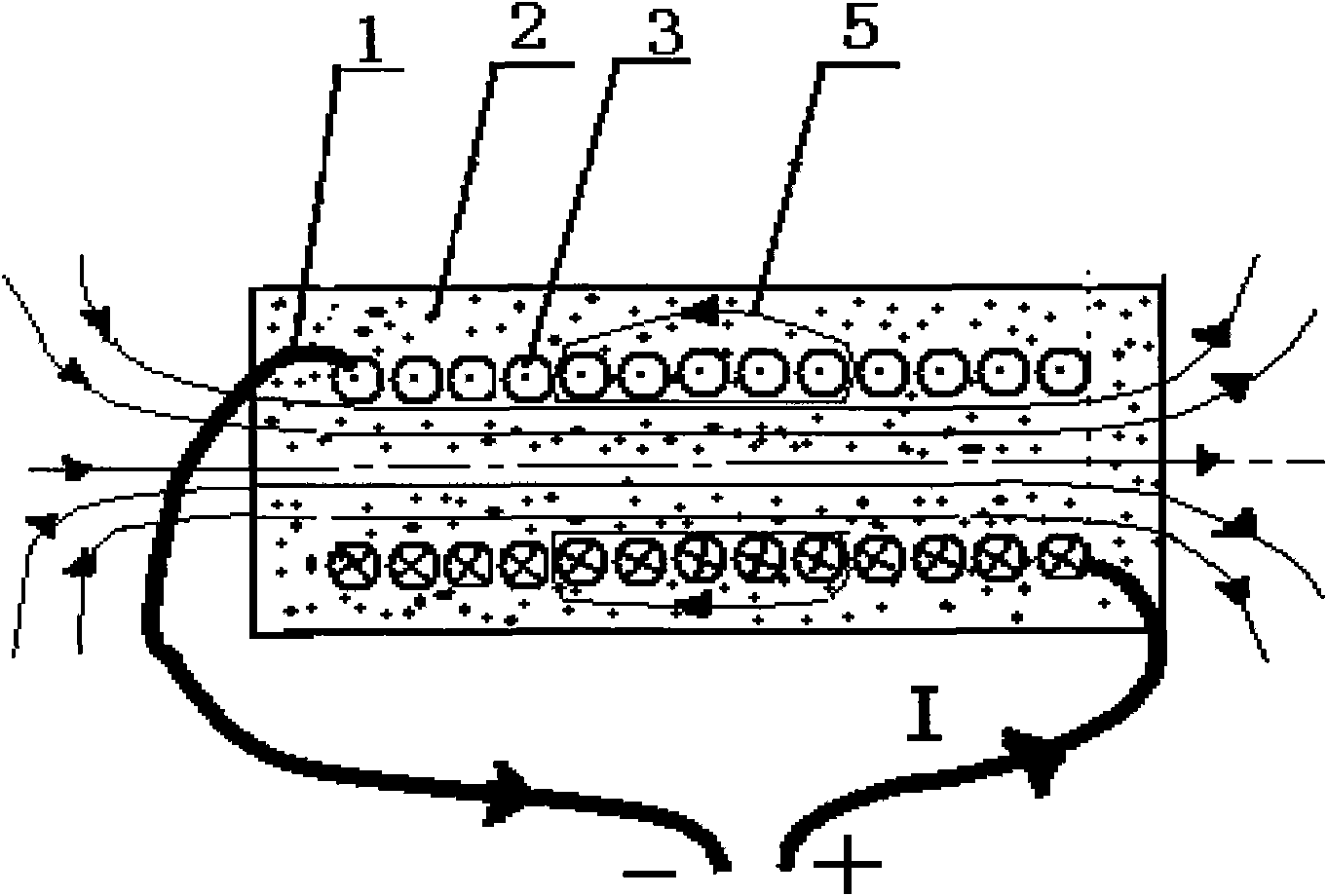

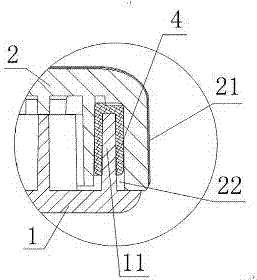

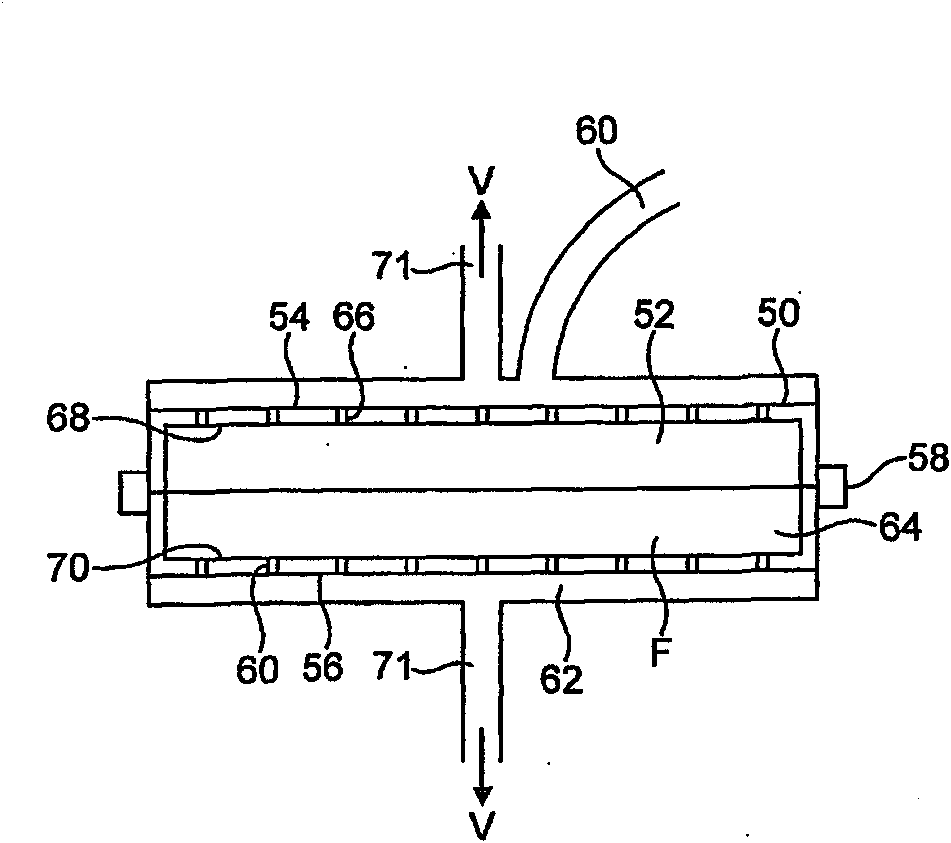

Compound structure formed by implementing magnet exciting coil in magnetorheological elastomer

InactiveCN101615468AIncrease profitAvoid Flux LeakageNon-rotating vibration suppressionMagnetic liquidsElastomerShear modulus

The invention provides a compound structure formed by implementing a magnet exciting coil in a magnetorheological elastomer. The structure mainly comprises the magnetorheological elastomer and the magnet exciting coil, wherein the magnet exciting coil is implemented in the magnetorheological elastomer; the magnet exciting coil is fixed in a mould when the magnetorheological elastomer is produced, uniformly mixed raw materials of the magnetorheological elastomer are injected into the mould, the raw materials of the magnetorheological elastomer, under the action of an external magnetic field, are slowly solidified, the magnet exciting coil is integrally compounded in the materials of the magnetorheological elastomer, and the electrification head of the magnet exciting coil is kept out. The structure has the technical scheme that under the circumstance of electrification, a conductive coil can generate a magnetic field in the coil due to the electromagnetic induction effect, and corresponding magnetic lines of force of the magnetic field respectively penetrate through the magnetorheological elastomer; and by constantly changing exciting currents in the coil, the magnetic-induced shear modulus of the elastomer can be controlled, and a magnetorheological elastomer actuator can be regulated, thereby eliminating various shocks and vibrations during the implementation of projects.

Owner:CHONGQING UNIV

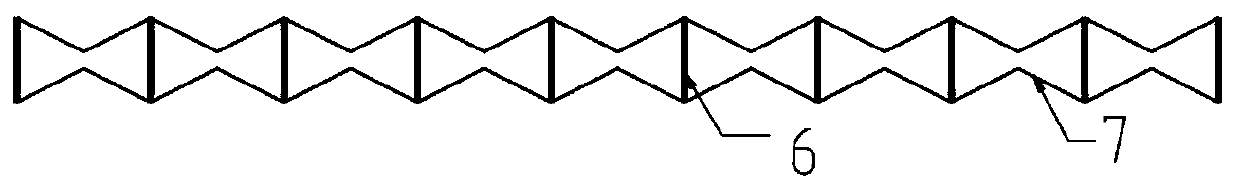

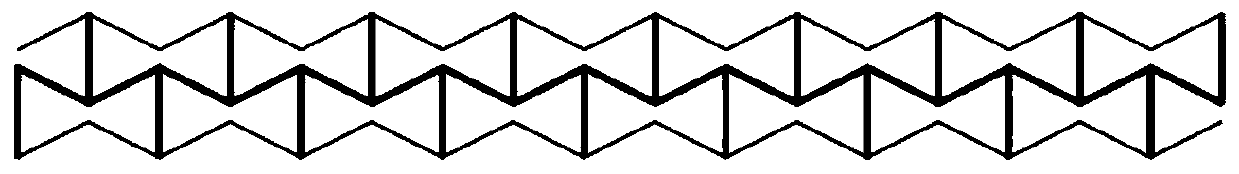

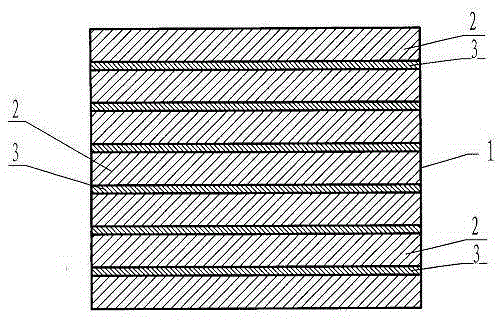

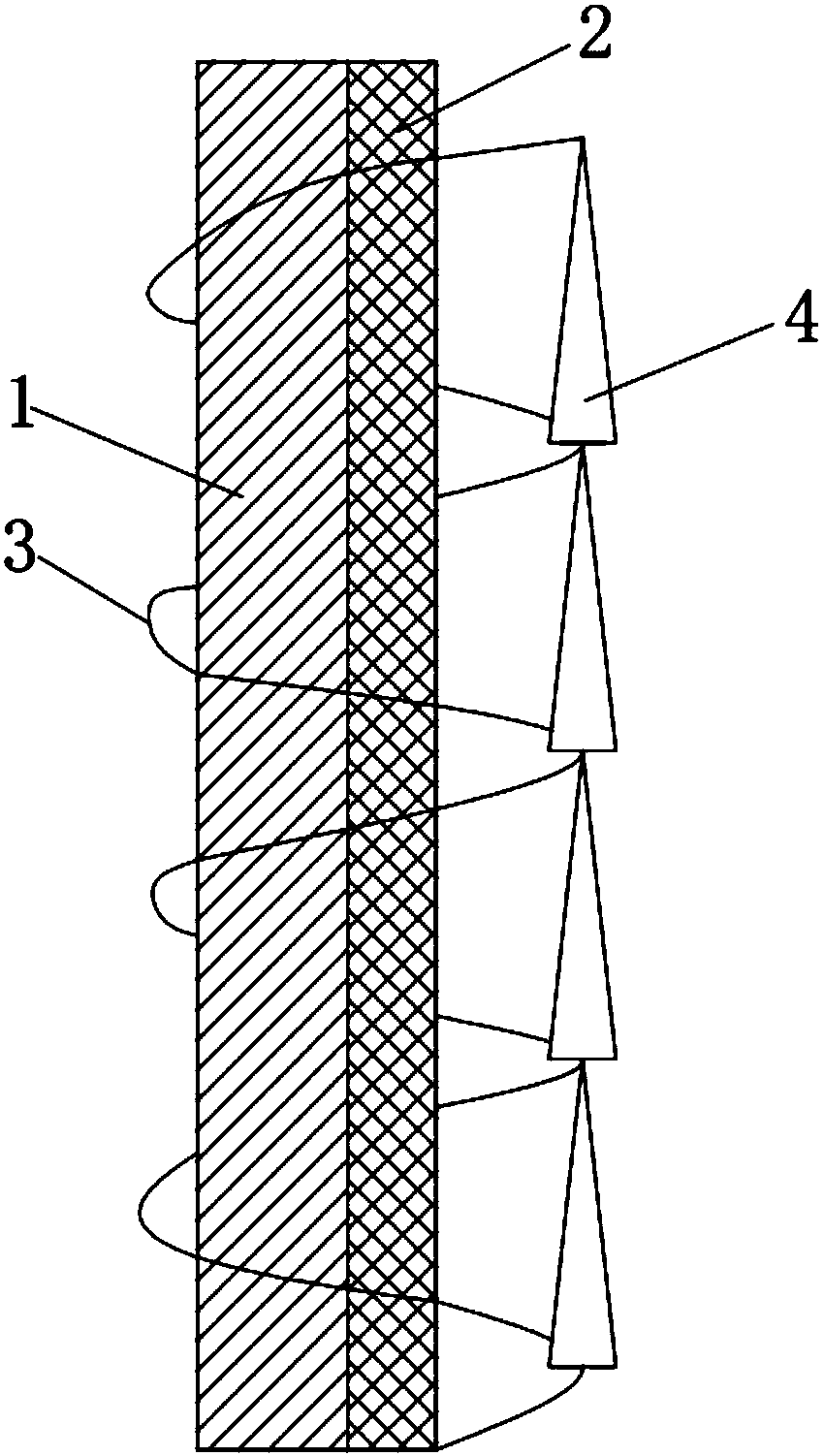

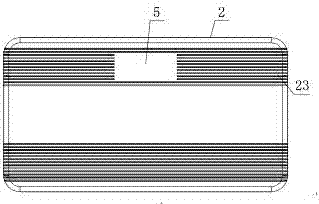

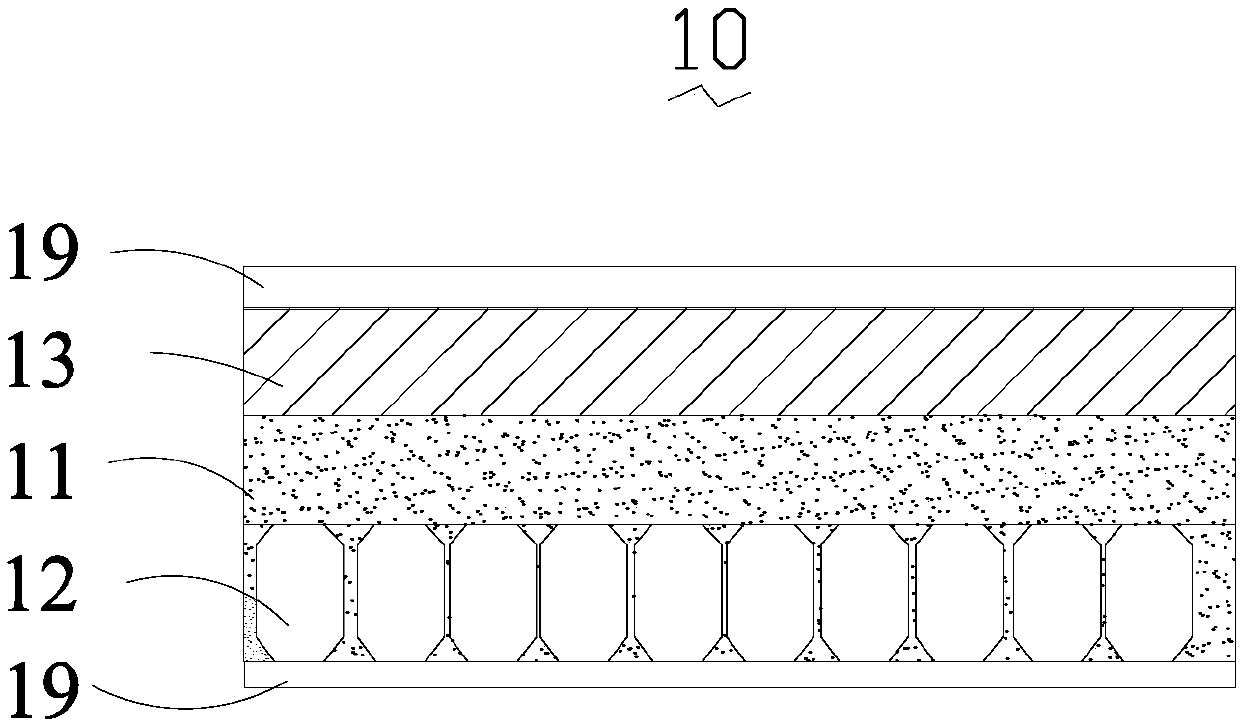

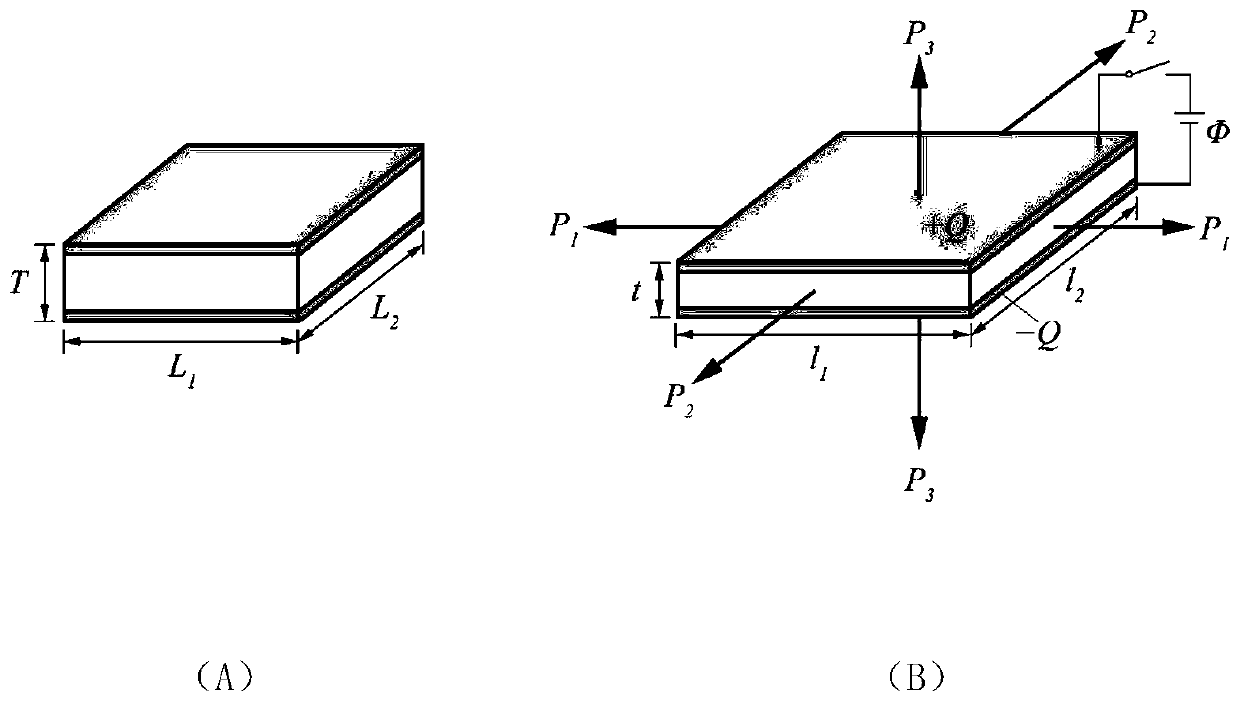

3D printing structure composite material laminboard with negative Poisson's ratio effect and processing method of laminboard

PendingCN110744873AGood physical and mechanical propertiesHigh shear modulusAdditive manufacturing apparatusLamination ancillary operationsSquare ShapeMechanical properties of carbon nanotubes

The invention discloses a 3D printing structure composite material laminboard with a negative Poisson's ratio effect and a processing method of the laminboard. The 3D printing structure composite material laminboard comprises an upper surface layer, a lower surface layer and a middle core material layer; the upper surface layer and the lower surface layer are made of a composite material formed bycuring fiber cloth and resin, the middle core material layer is a negative Poisson's ratio structure layer through 3D printing, and the structure layer is bonded with the upper surface layer and thelower surface layer through a bonding agent; the negative Poisson's ratio structure layer is formed by arraying negative Poisson's ratio units and connecting the negative Poisson's ratio units throughmiddle rod pieces, the rod pieces are of inwards-concave structures with the auxetic compression negative Poisson's ratio effect, and the cross sections of the rod pieces are square or circular. Thecomposite material laminboard can be used as a surface layer of a sandwich structure, and plays roles in protecting a core material and improving the overall mechanical property; the composite material laminboard also can be used as an anti-collision surface layer for bridges, buildings and the like. And the upper surface layer and the lower surface layer can also be filled with foam to serve as sound insulation plates to achieve the sound insulation effect.

Owner:NANJING UNIV OF TECH

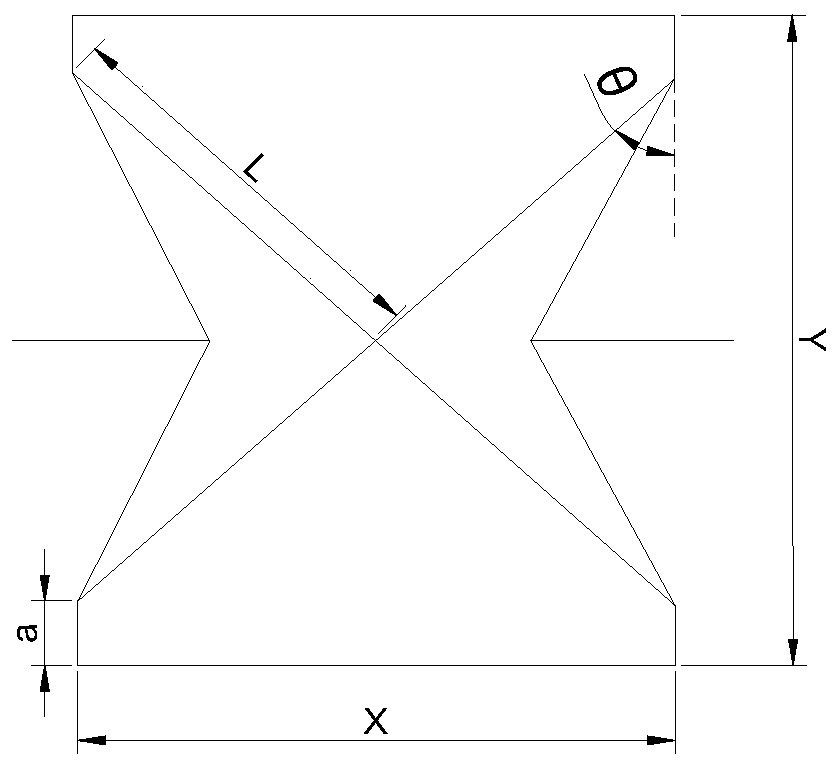

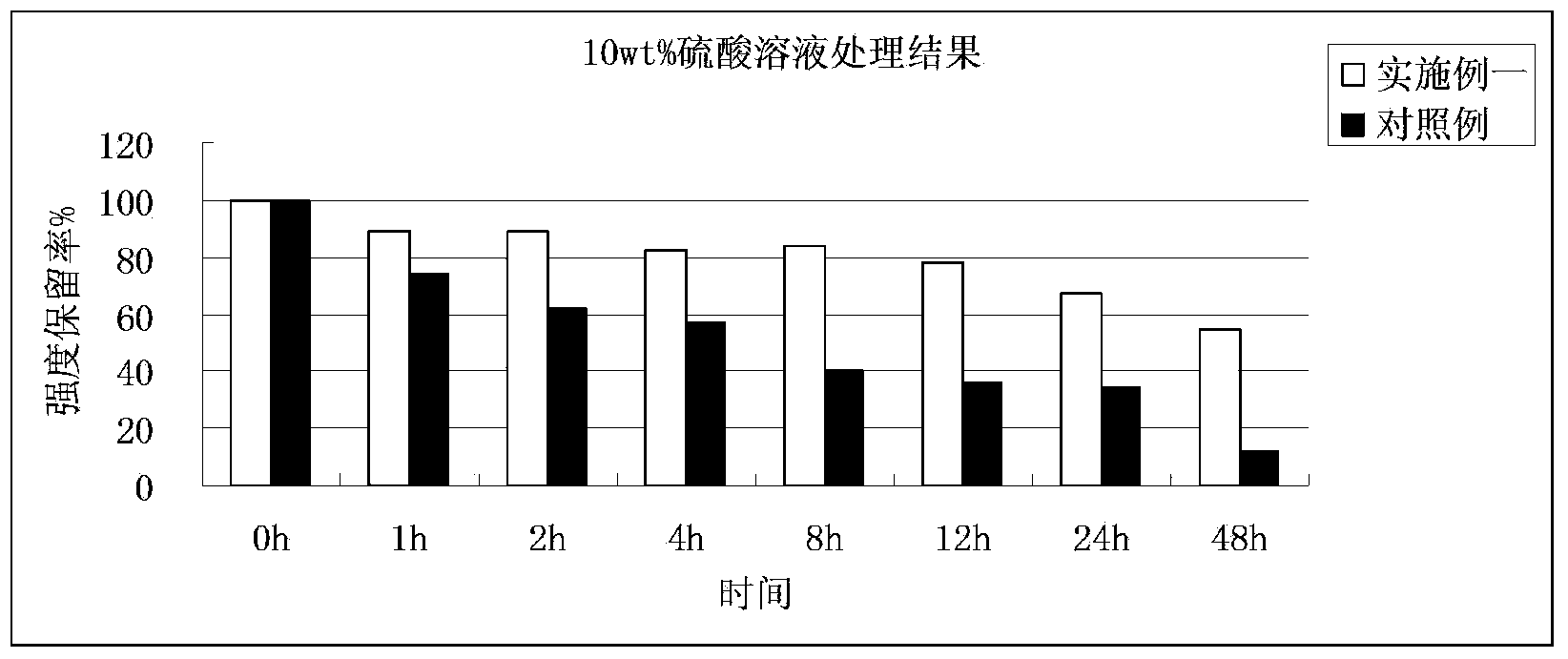

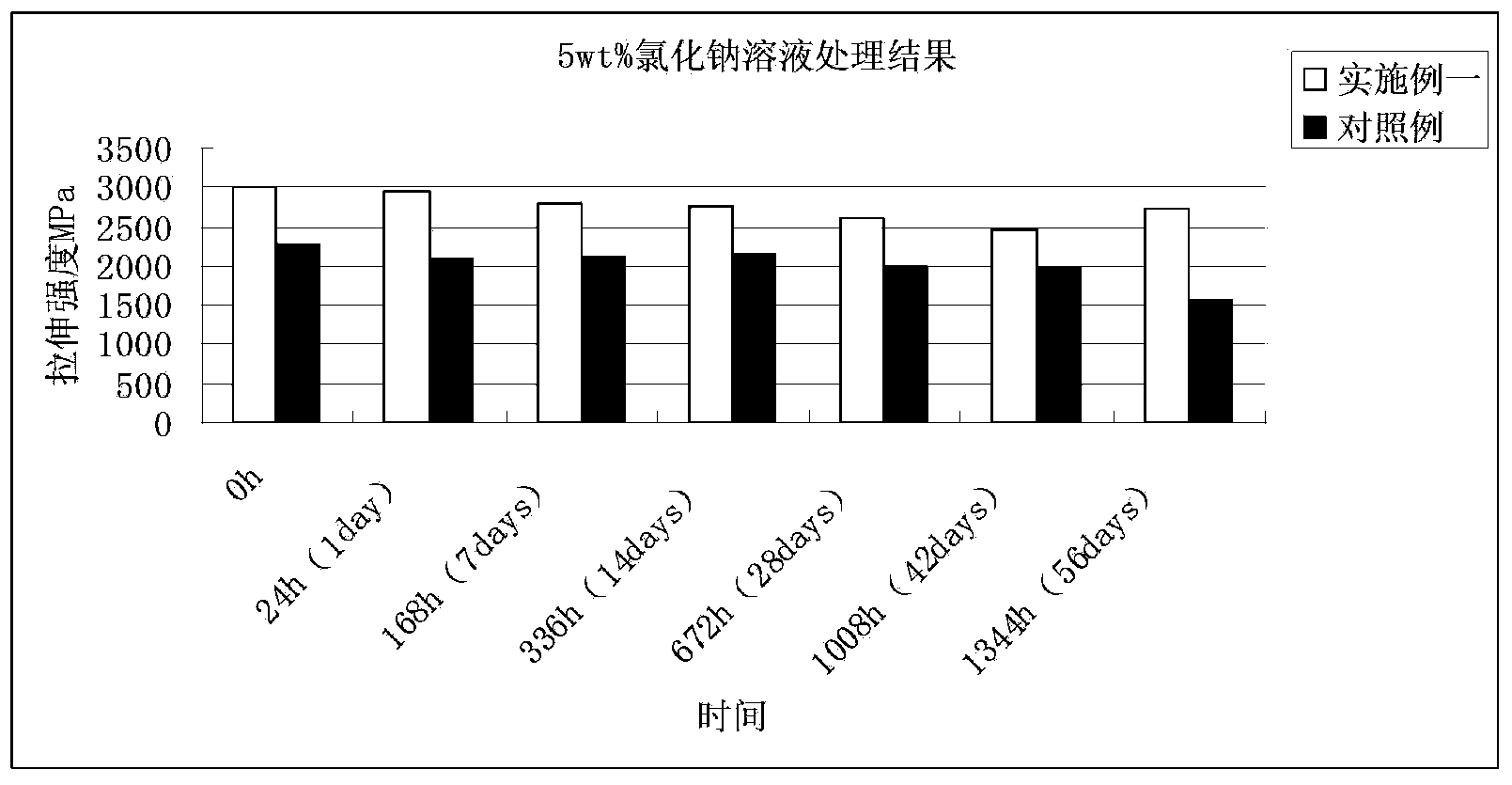

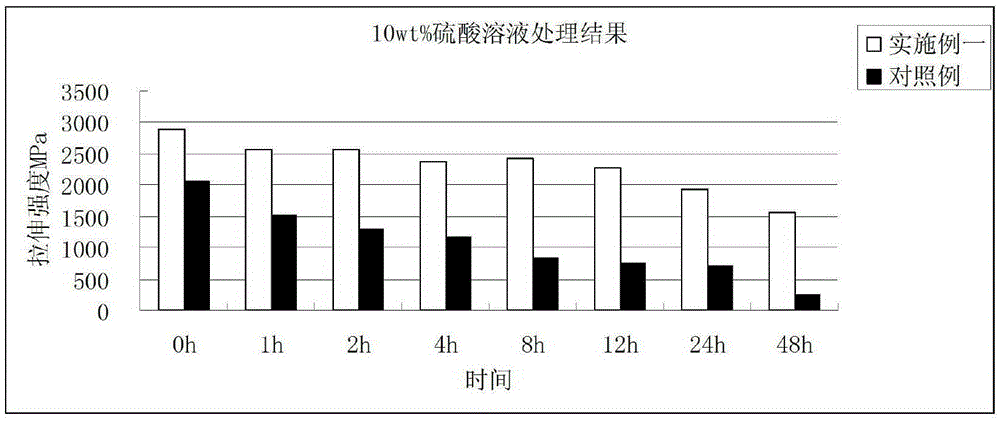

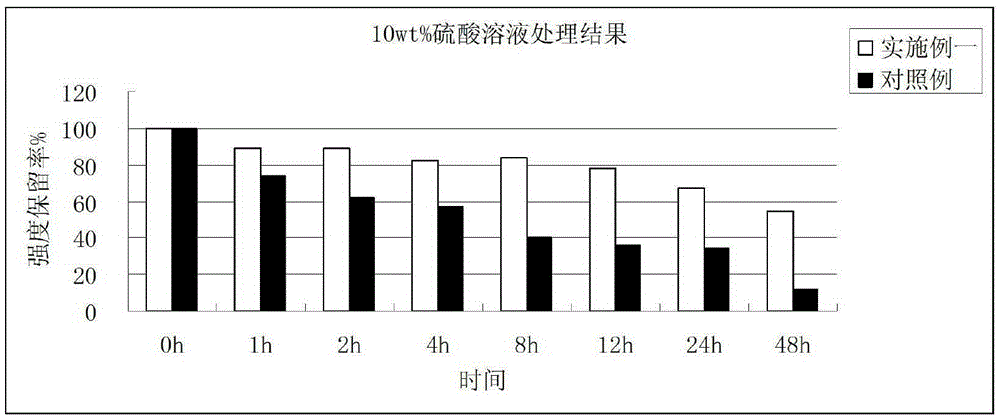

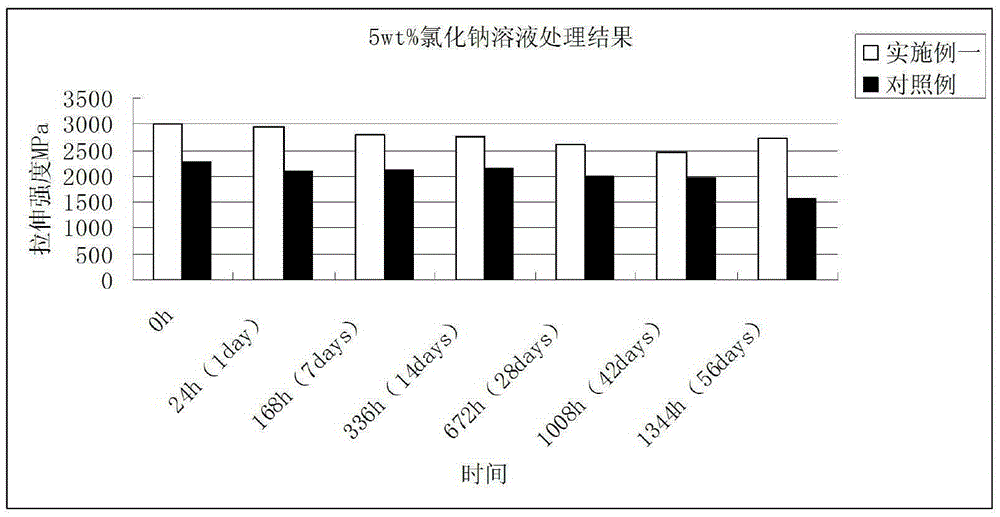

Corrosion-resistant high-strength high-modulus fiber and fabric prepared from fiber

The invention discloses a corrosion-resistant high-strength high-modulus fiber and a fabric prepared from the fiber. The corrosion-resistant high-strength high-modulus fiber consists of the following components in percentage by mass: 55%-65% of SiO2, 12%-18% of Al2O3, 8%-14% of MgO, 5%-13% of CaO, 0.2%-1% of Li2O, 1%-2% of TiO2 and the balance of impurities. The fabric obtained by the fiber disclosed by the invention has high strength, high elastic modulus, high shear modulus, long-term temperature resistance and corrosion resistance, and difficulty in ageing. Moreover, the composite material product does not have a room temperature creep phenomenon. A high-strength high-modulus compound impregnating compound for wiredrawing is directly coated on yarns to prepare a high-strength high-modulus fabric which can be directly compounded with resin, and does not need after-treatment. The organization structure of the glass fiber fabric is preferably twill weave or satin weave, and is suitable for various post-processing processes such as manual pasting or vacuum auxiliary forming.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

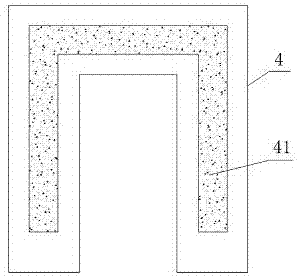

Sound insulation and noise reduction composite material and preparation method thereof

ActiveCN111114020AImprove sound insulation and noise reduction performanceHigh shear modulusLamination ancillary operationsSynthetic resin layered productsLoad resistanceSi substrate

The invention relates to the field of material science, and in particular, relates to a sound insulation and noise reduction composite material and a preparation method thereof. The sound insulation and noise reduction composite material comprises a base plate, a top plate and a sandwich layer located between the base plate and the top plate, wherein the sandwich layer is provided with a negativePoisson's ratio unit; the negative Poisson's ratio unit is mainly formed by alternately stacking and bonding a first negative Poisson's ratio unit and a second negative Poisson's ratio unit made of two different materials and having concave hexagonal structures. The sound insulation composite material has the negative Poisson's ratio unit, the sound insulation and noise reduction performance of the material can be improved, meanwhile, the shear modulus, the fracture resistance, the resilience toughness and the load resistance of the material are improved, and the application range of the material is greatly expanded.

Owner:上海众汇泡沫铝材有限公司

Polygon structure composite acoustic board based on negative mass

InactiveCN105109147AHigh specific strengthHigh specific stiffnessSynthetic resin layered productsMetal layered productsEpoxyNegative mass

The invention discloses a polygon structure composite acoustic board based on the negative mass. The board comprises polygon structure layers which have the negative mass effect in the Z direction, the polygon structure layers are bonded to the two sides of an intermediate layer through bonding layers, so that an integral whole is formed, the intermediate layer is made of ethylene-vinyl acetate copolymer, silicone rubber or latex, the bonding layers are made of two-component epoxy resin adhesive, and the polygon structure layers are made of aluminum alloy or other light-weight alloy materials and metal materials. By means of the polygon structure layers of the negative mass effect, the integral structure is high in specific strength, specific rigidity and shear modulus, impact-resistant and heat-insulative, the good low-frequency sound absorption performance is achieved, what is more important, the surface density of the integral structure is low, the structure is simple, the board has the advantages of being easy to process and manufacture and convenient to achieve, the whole performance of equipment is not affected, and meanwhile requirements of vibration damping and noise reduction can be met.

Owner:XI AN JIAOTONG UNIV

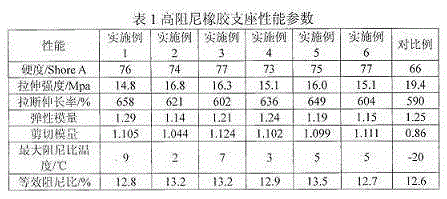

Wide-temperature range high-damping rubber bearer and preparation technology thereof

The invention belongs to the technical field of a rubber bearer and discloses a wide-temperature range high-damping rubber bearer and a preparation technology thereof. The wide-temperature range high-damping rubber bearer comprises, by mass, 70-90 parts of natural rubber, 10-30 parts of styrene-butadiene rubber, 10-60 parts of high styrene resin, 4-10 parts of an activator, 50-80 parts of super abrasion furnace black, 5-20 parts of tripoli, 10-30 parts of ultrafine Illite-smectite clay powder, 15-30 parts of calcium carbonate, 10-30 parts of machine oil, 1.5-2.5 parts of a vulcanizing agent and 1.4-3.5 parts of a promoter. The wide-temperature range high-damping rubber bearer utilizes high styrene resin to replace petroleum resin in the traditional high-damping bearer, increases a vitrification point area and widens a damping temperature. Through reasonable matching of inorganic filling material types and use amounts, a damping ratio of the high-damping rubber bearer is improved and shear modulus and elastic modulus of the bearer are balanced.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

Ultrahigh molecular-weight polyethylene fiber braided fabric for field protection

The invention discloses an ultrahigh molecular-weight polyethylene fiber braided fabric for field protection. The ultrahigh molecular-weight polyethylene fiber braided fabric for field protection comprises a composite layer, and polyurethane lines which are knitted around the composite layer, wherein the composite layer is prepared by compounding ultrahigh molecular-weight polyethylene fiber layers and carbon fiber layers; a plurality of knitting blocks which are knitted through the polyurethane lines are arranged on one side of the composite layer; the surface of the braided fabric is coatedwith a high-temperature-resistant nano coating; the ultrahigh molecular-weight polyethylene fiber layer is subjected to surface treatment, namely, polyethylene chain of the ultrahigh molecular-weightpolyethylene fiber layer is grafted with an acrylic acid monomer and acrylonitrile, and the grafted acrylonitrile is subjected to amidoximation and then is chelated with metal ions. The braided fabricwhich is of a three-dimensional structure is high in intensity, high in elastic modulus, high in shearing modulus, high in long-term high-temperature resistance and corrosion resistance, outstandingin abrasion resistance, and hard to age; meanwhile, the modified ultrahigh molecular-weight polyethylene fibers are high in moisture absorption, breathability, flame retarding performance and antibacterial performance.

Owner:成都天府轨谷科技有限公司

Polymer electrolytes including porous organic particles

InactiveCN102318124AHigh melting temperatureHigh glass transition temperatureSolid electrolytesLi-accumulatorsShear modulusPolymer electrolytes

Owner:DOW GLOBAL TECH LLC

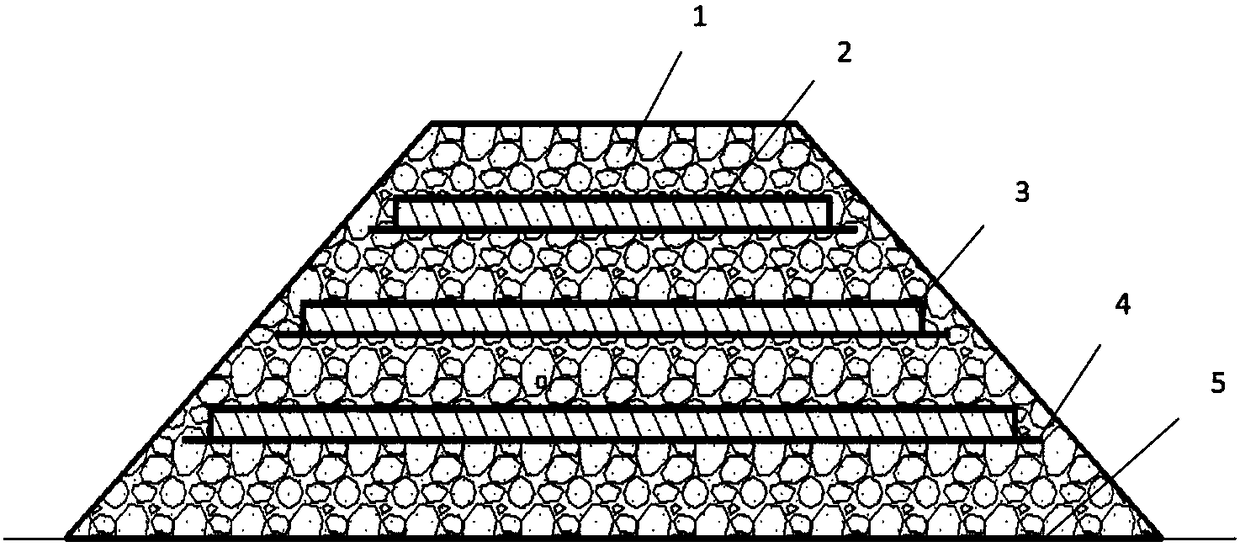

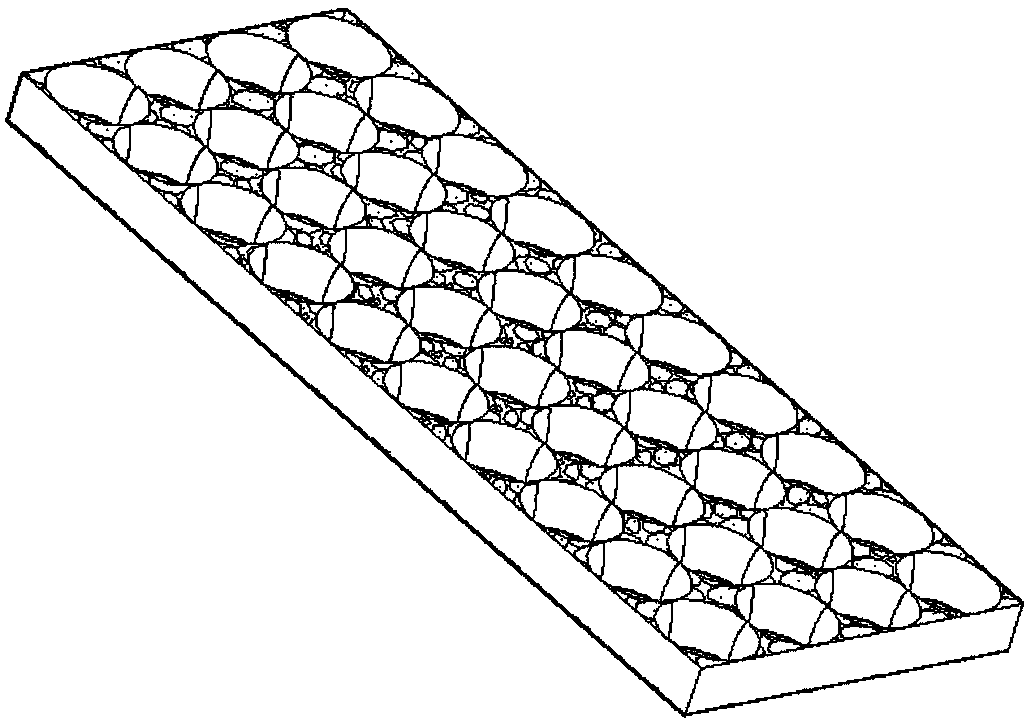

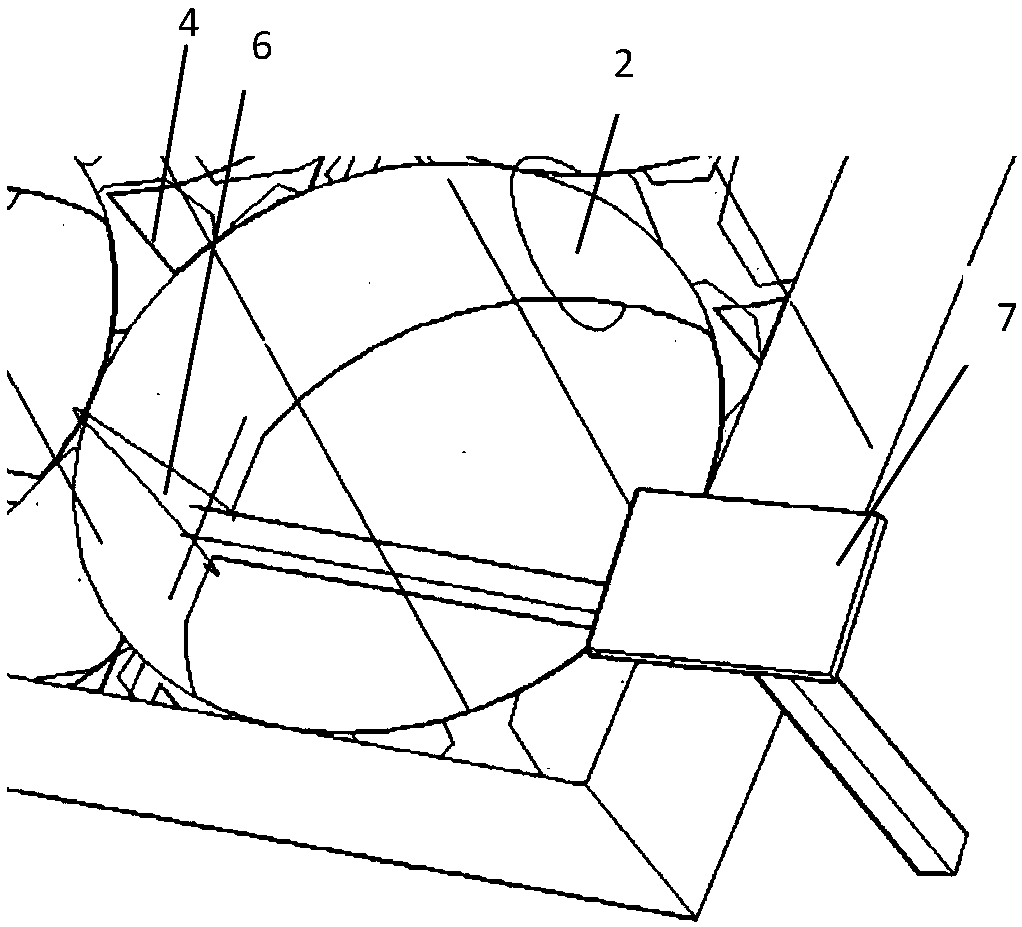

Doped construction waste integrated reinforced rib damping roadbed and construction technical method thereof

The invention provides a doped construction waste integrated reinforced rib damping roadbed. The doped construction waste integrated reinforced rib damping roadbed comprises a cushion layer laid on the roadbed, a plurality of reinforced rib structural layers and roadbed fillers, wherein the reinforced rib structural layers are laid at intervals from bottom to top, and each reinforced rib structural layer comprises a plurality of waste plastic bottles, a two-way geogrid and reinforced rib structural fillers. The waste plastic bottles are bound to the two-way geogrid, the waste plastic bottles and gaps are filled with the reinforced rib structure fillers, the reinforced structural fillers is compacted in layers, and the reinforced structural fillers is a mixture of used tire chips and sand mixture which are blended according to the optimum mix proportion. The cushion layer and the roadbed fillers are both a mixture of construction waste and sand mixture. The bearing capacity and seismicperformance of the roadbed are improved, at the same time, inherent resources, namely, the construction waste, the waste plastic bottles and used tires are recycled and reused, the ecological environment is improved, the greenhouse effect is reduced, the cost is lower, and the doped construction waste integrated reinforced rib damping roadbed has a wide application prospect.

Owner:HUBEI UNIV OF TECH

Multi-functional weighing scale

InactiveCN107345831AOvercome the defect that it cannot be used in wet places and is easily damagedAvoid gatheringWeighing apparatus detailsSpecial purpose weighing apparatusEngineeringPressure sensor

The invention relates to a multi-functional weighing scale. The multi-functional weighing scale comprises a bottom shell, an upper cover and an electronic function module set; the center of the bottom shell is recessed downwards to form an accommodating cavity; the center of the upper cover is recessed upwards to form an accommodating cavity; the bottom shell is covered with the upper cover; the electronic function module set is arranged in the accommodating cavities of the bottom shell and the upper cover; four foot bases are uniformly arranged on the bottom surface of the bottom shell; the foot bases are wrapped with waterproof sleeves for preventing liquid from entering the accommodating cavity of the bottom shell; pressure sensors are arranged in the foot bases and are used for sensing pressure; a sealing strip is arranged between the bottom shell and the upper cover; the sealing strip is tightly pressed between the bottom shell and the upper cover so as to seal the bottom shell and the upper cover; the bottom surface of the bottom shell is provided with a drug box, through holes being evenly distributed at the surface of the drug box; and anti-cockroach drugs are arranged in the drug box. The multi-functional weighing scale of the invention has an extremely strong anti-cockroach function, so that cockroaches can be prevented from gathering and breeding on the weighing scale.

Owner:冯杏华

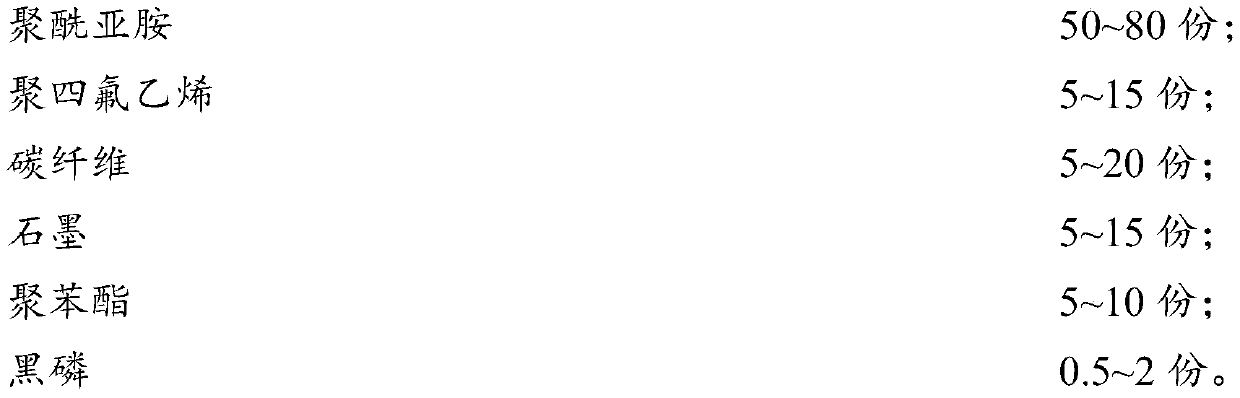

Black phosphorus modified polyimide composite material, and preparation method and application thereof

ActiveCN109880365AThe wear surface is uniform andWear surface smoothOther chemical processesElastic modulusPolytetrafluoroethylene

The invention relates to the technical field of composite materials, and provides a black phosphorus modified polyimide composite material, a preparation method thereof, and an application of the black phosphorus modified polyimide composite material as a friction material. The black phosphorus modified polyimide composite material comprises, by mass, 50-80 parts of polyimide, 5-15 parts of polytetrafluoroethylene, 5-20 parts of carbon fibers, 5-15 parts of graphite, 5-10 parts of polyphenyl ester and 0.5-2 parts of black phosphorus. Results of embodiments in the invention show that the hardness (Shore D) of the black phosphorus modified polyimide composite material obtained in the invention is equal to or more than 85, the wear extent is equal to or less than 0.001 g / h, the elastic modulus is equal to or more than 9.5 GPa, the glass transition temperature is equal to or more than 260 DEG C, and the composite material has excellent performances.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solid electrolyte and lithium battery cell with same, and lithium battery

InactiveCN109935898AGood interface adhesionEnhanced surface contactFinal product manufactureLi-accumulatorsSolid state electrolyteShear modulus

The invention relates to the field of lithium batteries, in particular to a solid electrolyte and a lithium battery cell with the solid electrolyte, and a lithium battery. The solid electrolyte includes LiMF<x>H<12-x>, wherein M is B, Ga, Al or a combination thereof. Compared with the existing solid electrolyte, a compound with F atoms has larger molecular volume, and thus can provide largerspace for the Li+ and improve the migration capability of lithium ions. Furthermore, the M-F bond can form a stable structure, so that the solid electrolyte can have high electrochemical window and flexibility, and the structural stability and cycle performance can be improved when lithium ions migrate rapidly. Based on the structural characteristics, the solid electrolyte can have higher shear modulus and Young's modulus.

Owner:成都大超科技有限公司

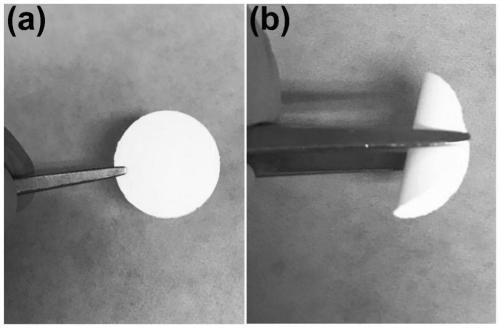

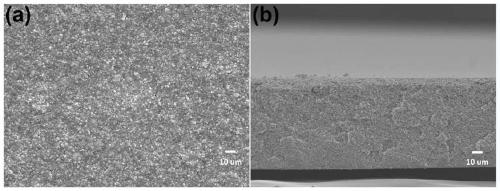

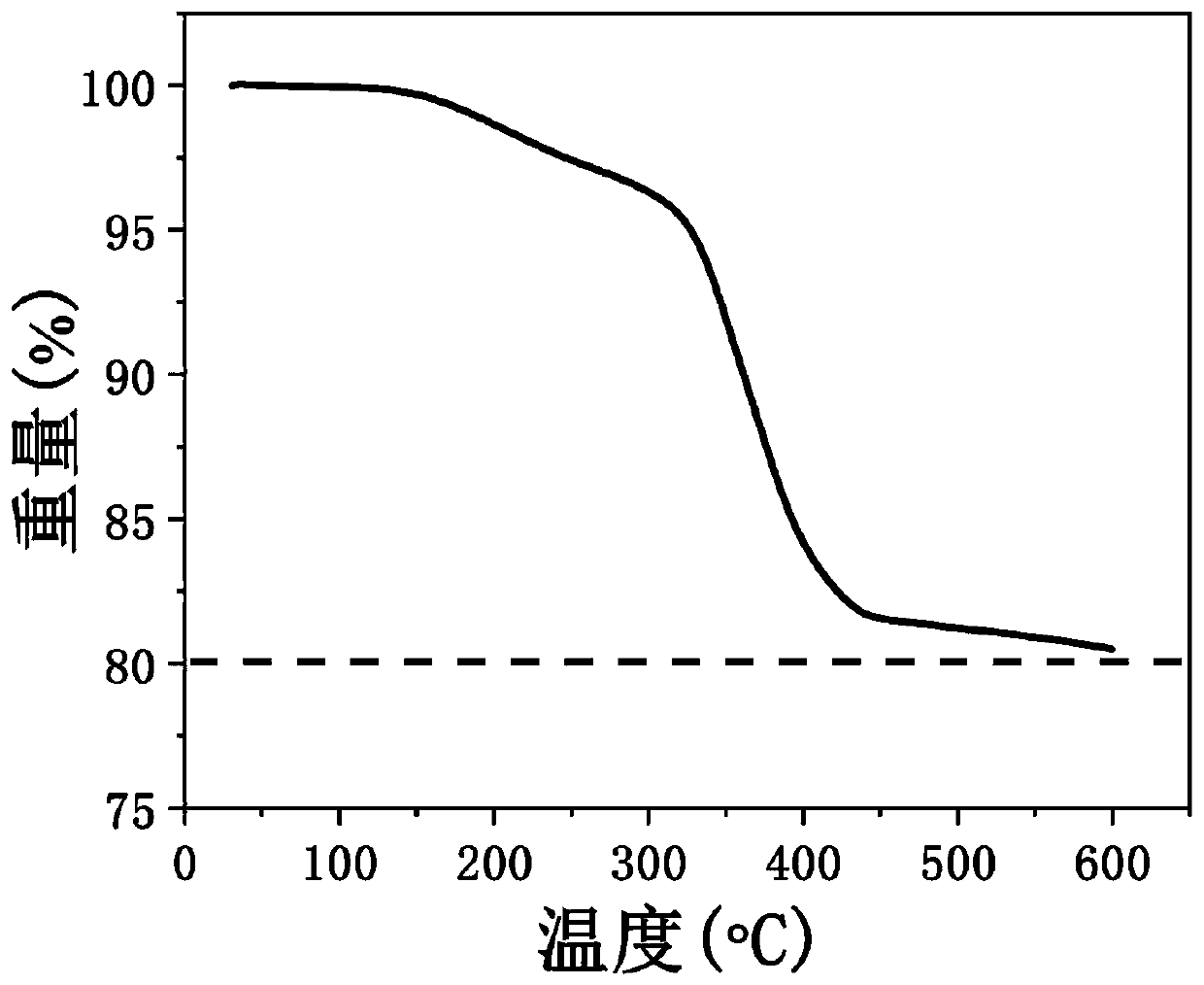

High-ceramic-content composite solid electrolyte, and preparation method thereof

PendingCN111509290ASimple manufacturing methodIncrease productionSolid electrolytesFinal product manufacturePhysical chemistrySlurry

The invention relates to the field of electrochemical energy storage, particularly to a composite solid electrolyte with high ceramic content, and a preparation method thereof. The composite solid electrolyte comprises the following components: perovskite type solid electrolyte LLTO, PAN and a lithium salt, wherein the mass fraction of LLTO is 60-85%. The preparation method comprises the followingsteps: preparing LLTO powder with an average particle size of 0.01-50 microns; mixing the LLTO powder with PAN and the lithium salt, adding an N,N-dimethylformamide solvent, and carrying out ball milling (or stirring or ultrasonic treatment) to obtain slurry; and finally coating a clean glass plate with the obtained slurry by adopting a casting molding method, and heating and drying in a vacuum drying oven to obtain the composite solid electrolyte. The composite solid electrolyte disclosed by the invention has the advantages of high lithium ion conductivity (0.1-5 mScm<-1>), good flexibility,simple preparation method and the like, and is suitable for the fields of lithium ion batteries, flow batteries and the like.

Owner:THE HONG KONG UNIV OF SCI & TECH

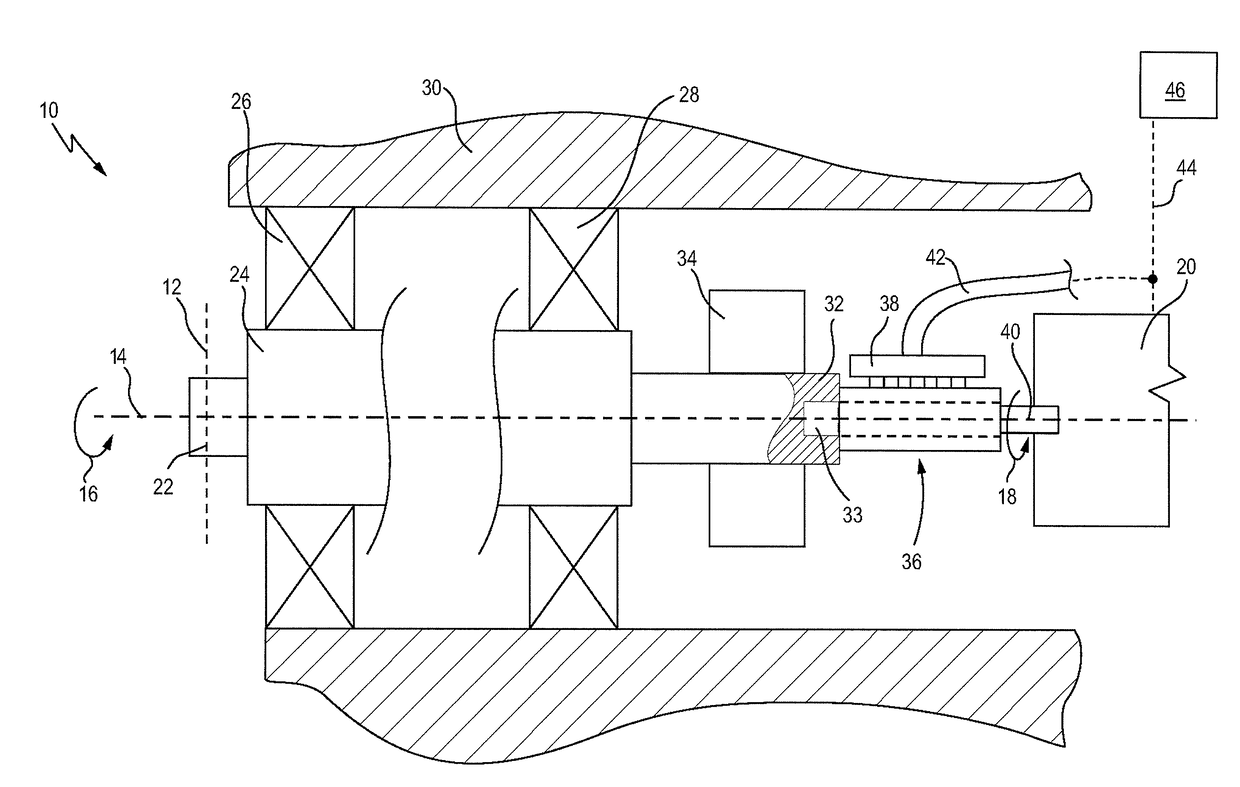

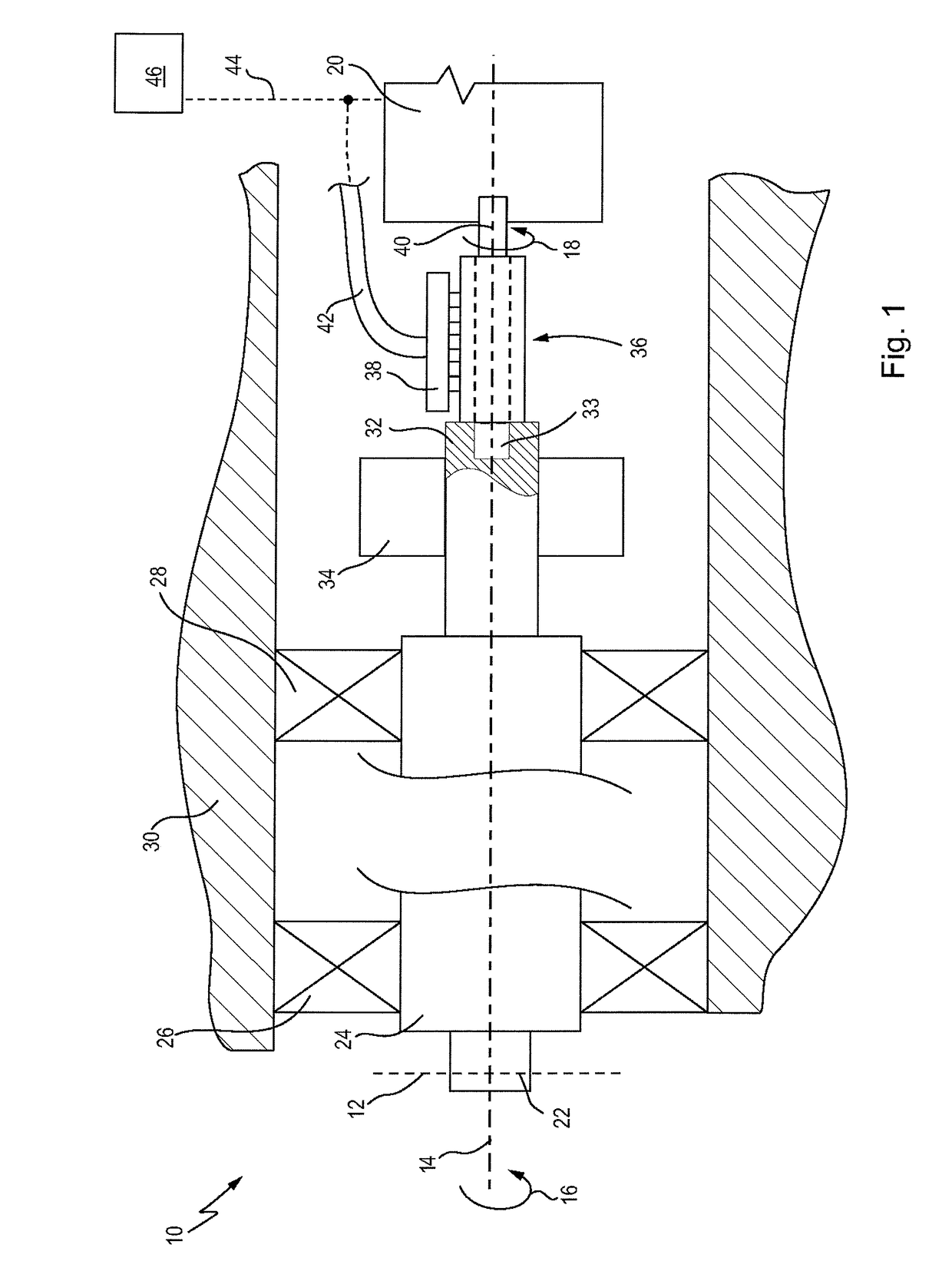

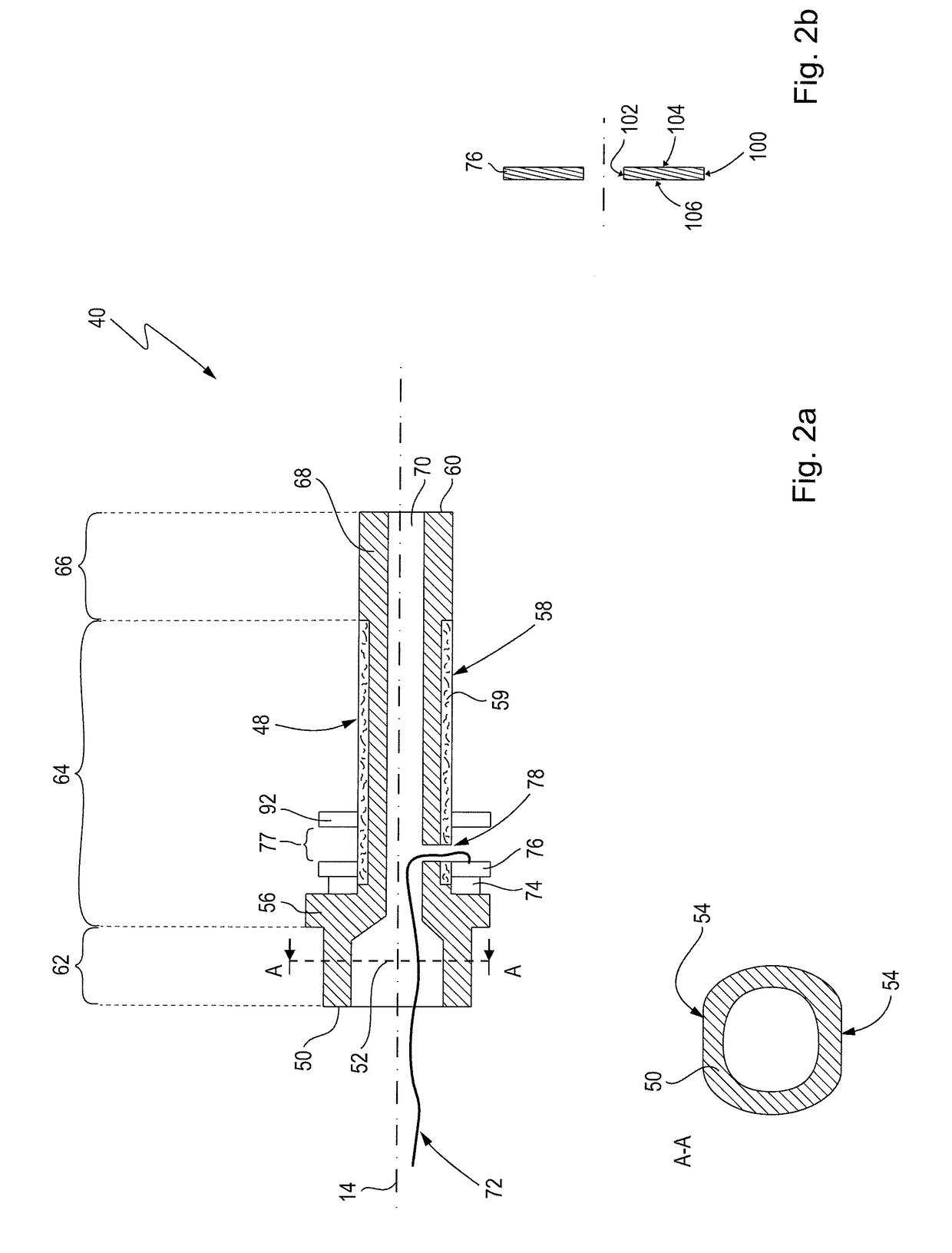

Rotor arrangement for a slip ring assembly and rotary coupling arrangement comprising a rotor arrangement of this kind

ActiveUS20170271833A1Avoid influenceSmall installation spaceRotary current collectorTesting/measuring connectorsCouplingSlip ring

A rotor arrangement for a slip ring assembly, comprising a shaft element and at least one contact ring. The shaft element is at least partially in the form of a hollow shaft with a hollow interior and a casing wall. The shaft element has a middle section and each contact ring is arranged on the shaft element in the middle section and is electrically insulated from the shaft element by means of an insulation. The middle section has at least one cutout through the insulation and the casing wall into the interior. Each contact ring is connected to a cable element which is guided through one of the at least one cutout into the interior. The shaft element has a first end section with an outer circumferential cross section for the rotationally fixed coupling. Furthermore, a rotary coupling arrangement comprising a rotor arrangement of this kind is proposed.

Owner:CARL ZEISS IND MESSTECHN GMBH

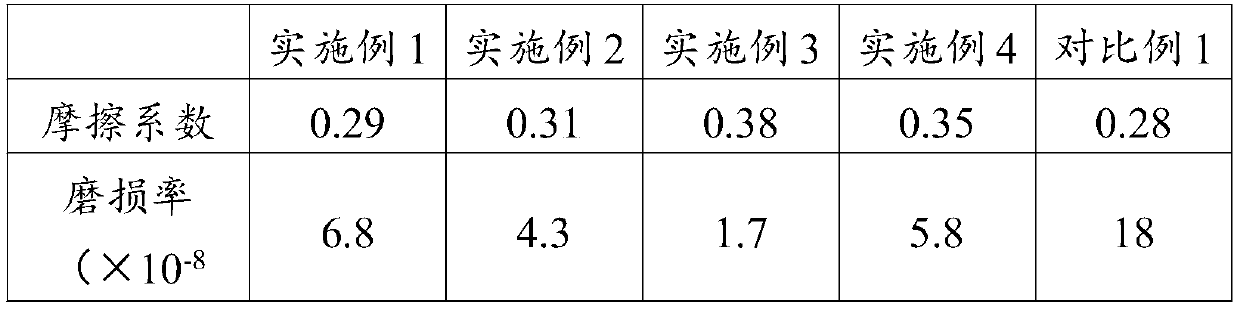

A kind of black phosphorus modified polyimide composite material and its preparation method and application

ActiveCN109880365BHigh shear modulusImprove notch resistanceOther chemical processesFiberCarbon fibers

The invention relates to the technical field of composite materials, and provides a black phosphorus modified polyimide composite material, a preparation method thereof, and an application of the black phosphorus modified polyimide composite material as a friction material. The black phosphorus modified polyimide composite material comprises, by mass, 50-80 parts of polyimide, 5-15 parts of polytetrafluoroethylene, 5-20 parts of carbon fibers, 5-15 parts of graphite, 5-10 parts of polyphenyl ester and 0.5-2 parts of black phosphorus. Results of embodiments in the invention show that the hardness (Shore D) of the black phosphorus modified polyimide composite material obtained in the invention is equal to or more than 85, the wear extent is equal to or less than 0.001 g / h, the elastic modulus is equal to or more than 9.5 GPa, the glass transition temperature is equal to or more than 260 DEG C, and the composite material has excellent performances.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

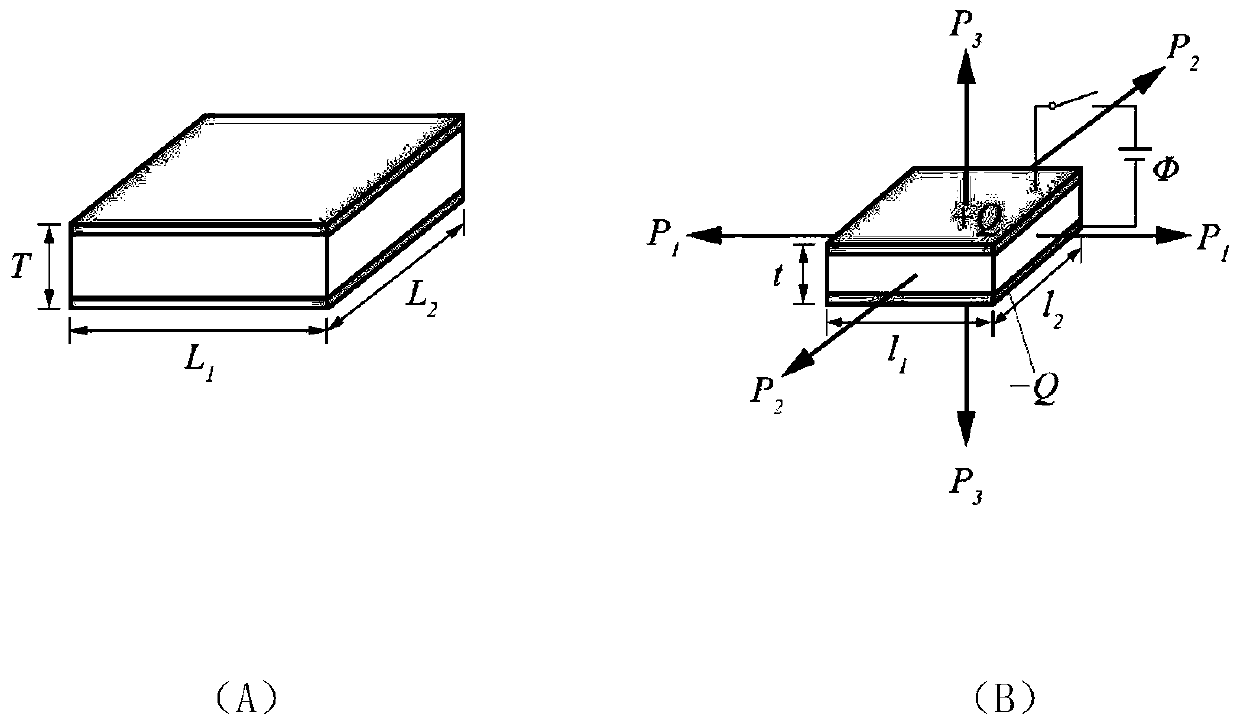

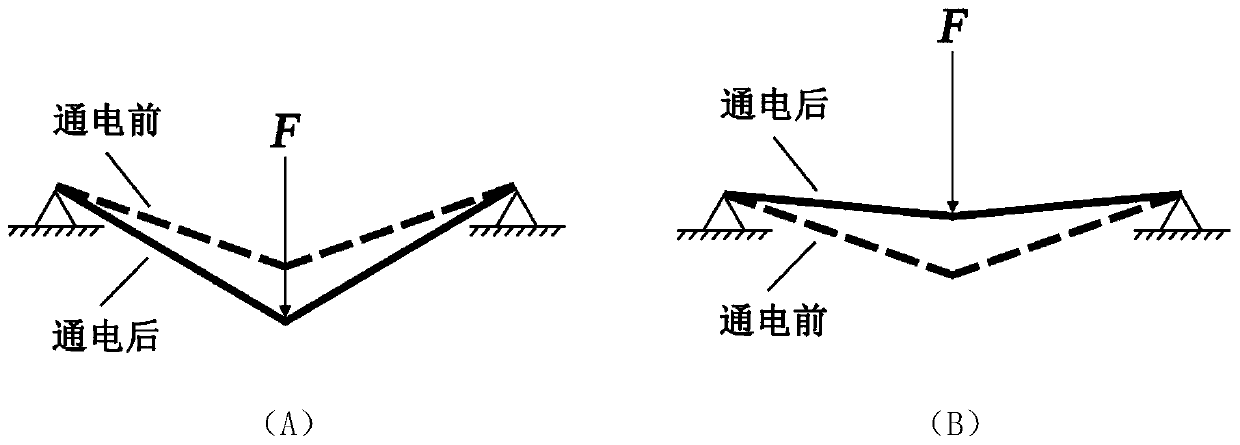

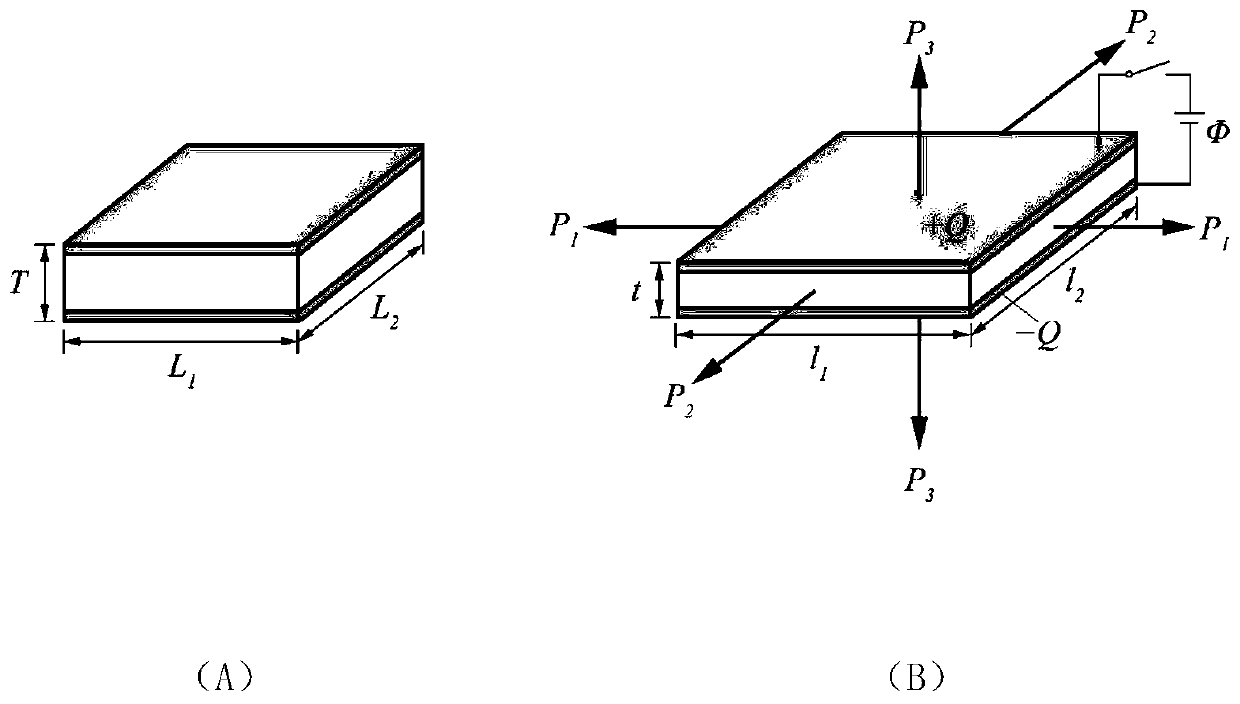

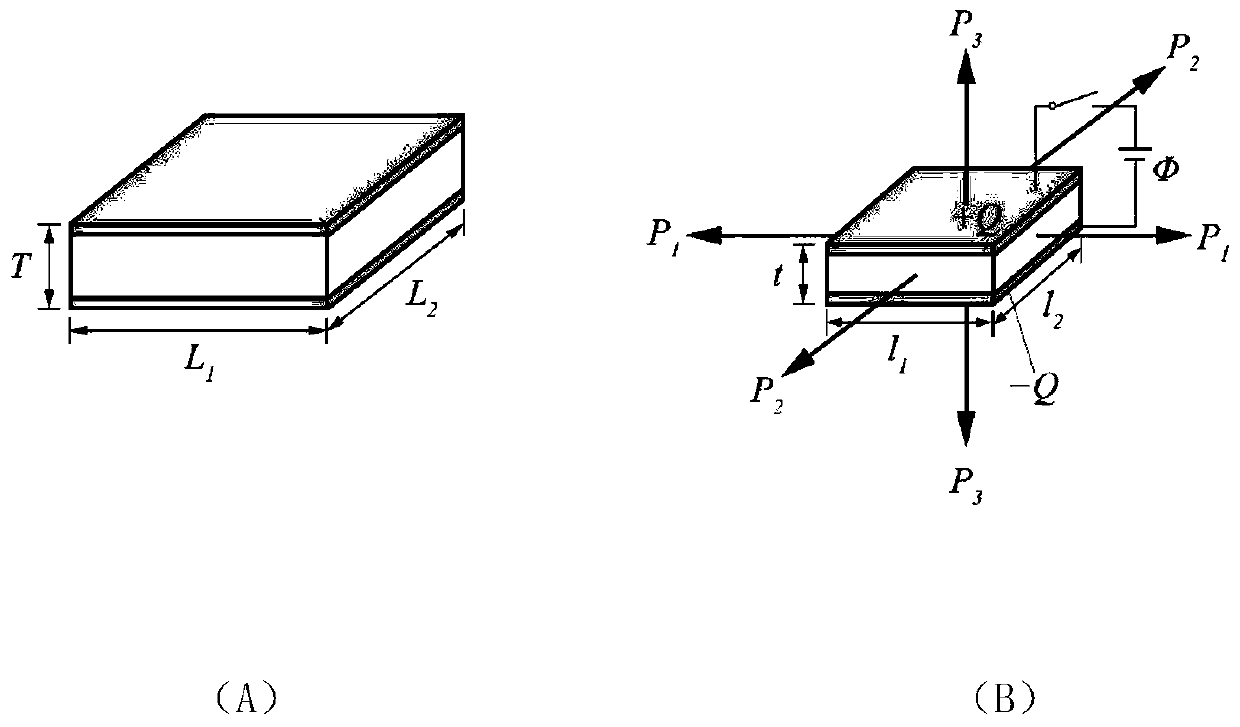

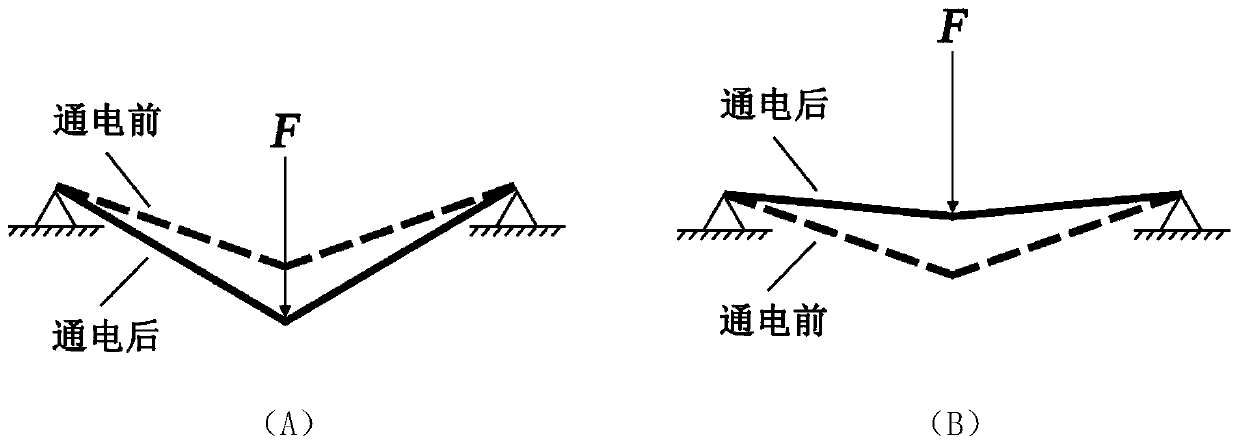

Negative poisson ratio dielectric elastic body-based novel electrical active polymer

ActiveCN109787502AReduce areaHigh shear modulusElectrostatic generators/motorsActive polymerInstability

The invention discloses a negative poisson ratio dielectric elastic body-based novel electrical active polymer. The negative poisson ratio dielectric elastic body-based novel electrical active polymercomprises an elastic film and flexible electrodes, wherein the flexible electrodes are arranged at two sides of the elastic film, the flexible electrodes at the two sides of the elastic film are uniformly coated on an upper surface and a lower surface of the elastic film, the thicknesses of the flexible electrodes are smaller than the thickness of the elastic film, the Young modulus of the flexible electrodes is smaller than the Young modulus of the elastic film, and the flexible electrodes are respectively used for connecting a positive electrode and a negative electrode of an external voltage. When voltages are applied to the flexible electrodes at the two sides, the elastic film contracts simultaneously along a thickness direction, a length direction and a width direction, the volume is reduced, the density, the rigidity and the bearing capability of the material are improved, the failure limit of mechanical damage, electric breakdown and electromechanical coupling instability is improved, so that the negative poisson ratio dielectric elastic body-based novel electrical active polymer has more excellent electromechanical performance compared with a traditional dielectric electrical active polymer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of copper-tantalum composite wire with high strength and high conductivity

The invention discloses a preparation method of a copper-tantalum composite wire with high strength and high conductivity. The method comprises the steps of (1) overlapping a pure tantalum foil and ananaerobic copper foil, jointly winding on a central copper rod, and forming a densely arranged winding copper foil-tantalum foil composite; (2) loading the copper foil-tantalum foil composite into acopper sleeve body, vacuum seal welding, and carrying out isostatic cool pressing treatment and hot extrusion processing, so as to obtain an extrusion composite rod; (3) drawing to obtain a compositecore rod; (4) after sizing and cutting, straightening and acid pickling, loading a multi-core bundle into a copper pipe, carrying out hot extrusion and drawing processing, and cooperating with intermediate annealing, so as to obtain the copper-tantalum composite wire with high strength and high conductivity. According to the preparation method of the copper-tantalum composite wire with high strength and high conductivity provided by the invention, the copper foil and the tantalum foil are selected as raw materials, so that the plastic deformation degree of tantalum is greatly reduced, a Cu / Tainterface is remarkably increased, the advantages of the high shear modulus and the high strength of the tantalum are fully played, the mechanical property of the wire is further improved, and the copper-tantalum composite wire with high strength and high conductivity can be applicable to a high field pulse magnet.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

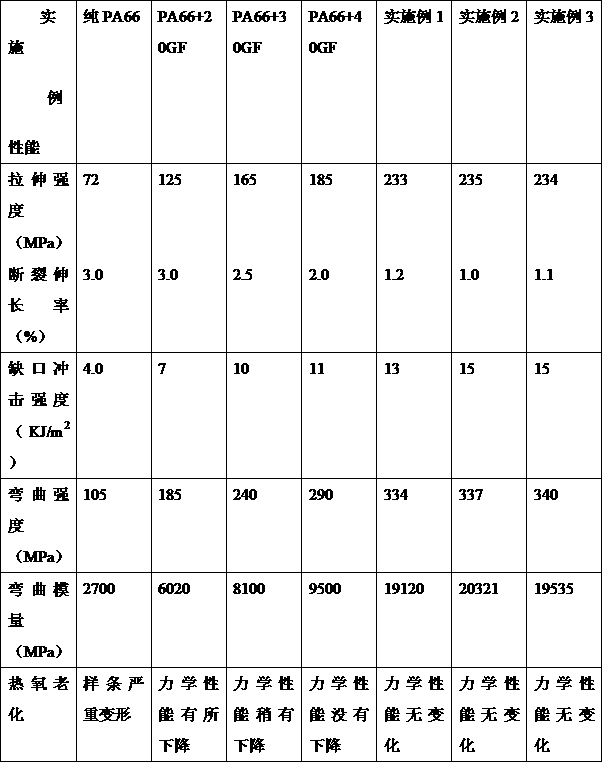

High-content glass fibre-enhanced nylon 66 composite material and preparation method thereof

InactiveCN108219451AFast crystallizationImprove interfacial adhesionAntioxidantSilicon carbide nanotubes

The invention relates to a high-content glass fibre-enhanced nylon 66 composite material and a preparation method thereof, and belongs to the field of high polymer materials. The composite material isprepared from the following components in percentage by mass: 31.9 to 38 percent of nylon 66, 58 to 62 percent of alkaline-free glass fibres, 2 to 5 percent of a compatilizer, 0.3 to 0.5 percent of amain antioxidant, 0.3 to 0.5 percent of an auxiliary antioxidant and 0.5 to 1.0 percent of a lubricating agent, wherein the surfaces of the alkaline-free glass fibres are coated with an enhancement layer; the enhancement layer is made of carbon nano-tubes or silicon carbide nano-tubes which are extruded and granulated by using a twin-screw extruder. The composite material provided by the invention is high in glass fibre content; the mechanical properties and the physical properties of the composite material are improved; moreover, the surfaces of the alkaline-free glass fibres are coated withthe nano-tubes; the compatibility of the alkaline-free glass fibres and the nylon 66 is increased by selecting suitable lengths and diameters of the glass fibres and the molecular weight of the nylon66; the defect that the appearance of the material becomes poor along with the increment of the content of the glass fibres filled in the nylon in the past is overcome.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

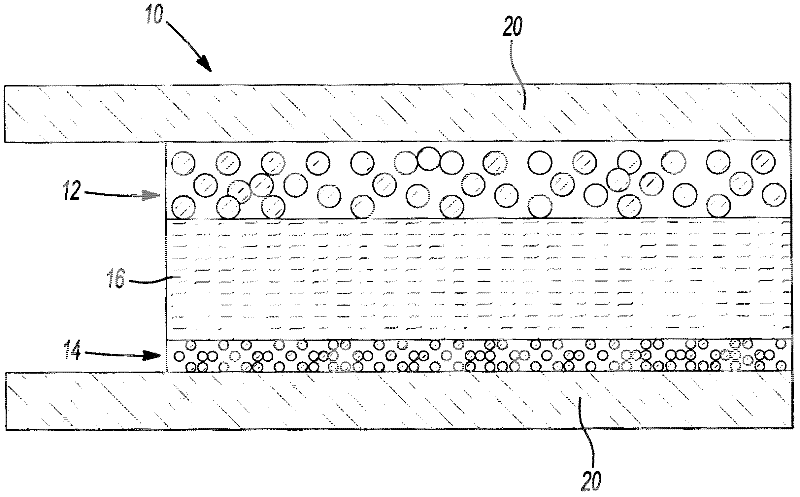

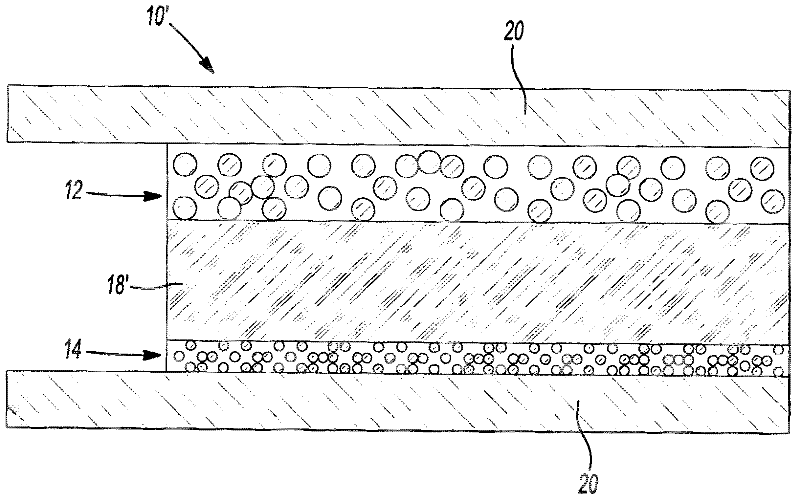

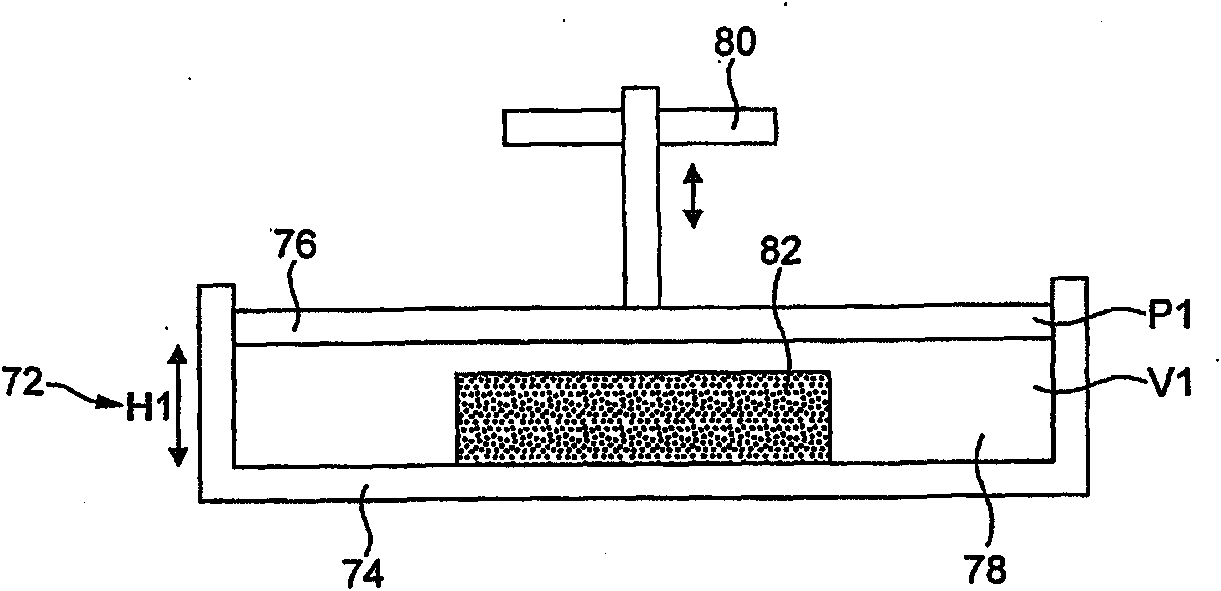

Structural foam and manufacture thereof

InactiveCN102066074AImproved static mechanical propertiesImprove mechanical propertiesThin material handlingMaterials scienceDirectional anisotropy

The present invention discloses a method of manufacturing a foam body having an anisotropic cell structure, the method comprising the steps of: expanding a polymer at an elevated temperature to form an initial foam body; and cooling the initial foam body under a negative pressure. There is also provided a method of manufacturing a foam body having an anisotropic cell structure, the method comprising the steps of: (a) in a first expansion step, expanding a foamable polymer composition substantially isotropically to form an initial foam body having an isotropic cell structure; and (b) in a second expansion step, expanding the initial foam body anisotropically in a selected direction under a negative pressure which applies an expanding force in the selected direction to provide a final foam body having an anisotropic cell structure. Apparatus for the methods are also disclosed.

Owner:GURIT (UK) LTD

Electromechanical response estimation method of novel electroactive polymer

InactiveCN109728743AImprove carrying capacityExpand the scope of applicationPiezoelectric/electrostriction/magnetostriction machinesEngineeringEstimation methods

The invention discloses an electromechanical response estimation of a novel electroactive polymer. The novel electroactive polymer comprises an elastic membrane and flexible electrodes at the two sides of the elastic membrane, the flexible electrodes are uniformly coated on the upper and lower surfaces of the elastic membrane, the thickness of the electrodes is lower than that of the elastic membrane, the young modulus of the electrodes is lower than that of the elastic membrane, and the flexible electrodes are connected with anode and cathode of an external voltage respectively. The elastic membrane is of a dielectric elastomer material of a negative Poisson's ratio, the material is prepared by applying compression force in three orthogonal directions to a porous dielectric elastomer material when the porous material is heated to the temperature slightly higher than the heat softening temperature range. Via the method, the novel electroactive polymer has a higher electromechanical performance than a traditional dielectric electroactive polymer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

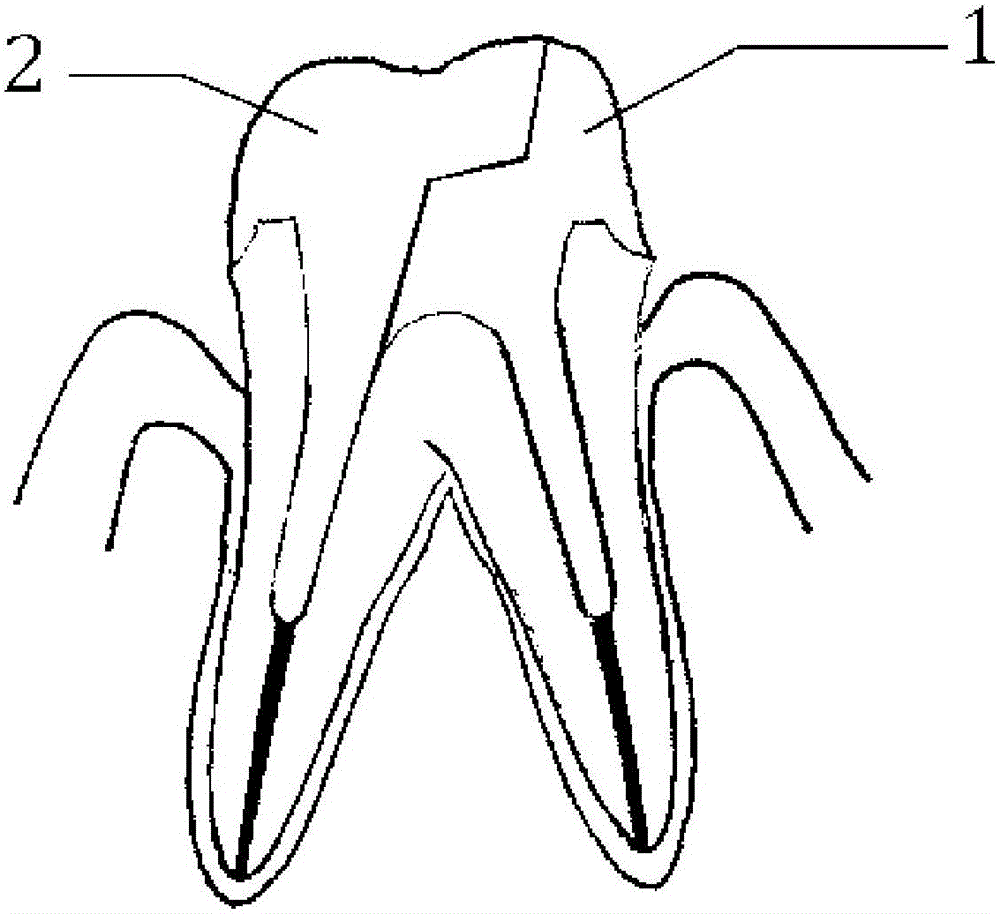

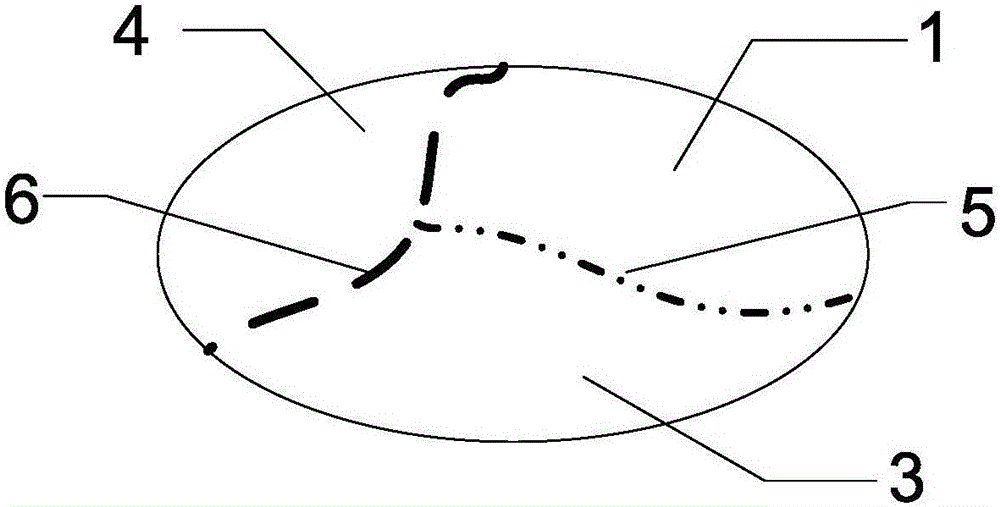

Chimeric post-core body, and preparation method and application thereof

InactiveCN105852999AReduce stress concentrationGood biocompatibilityDental prostheticsEngineeringRoot canal

The invention discloses a chiseled post core body and its preparation method and application. The chiseled post core body is formed by interfitting a main post core and an auxiliary post core, and the main post core and the auxiliary post core are both composed of a post and The core at the top of the post is integrally formed; the cores are fitted with each other, and the longitudinal joint surface between the cores is parallel to the post of the auxiliary post core. The invention divides the post and core into two or three parts into root canals with different directions, enhances the retention force of the post and core through friction force and locking effect, and improves the fracture resistance of teeth, and is especially suitable for multiple canals with non-parallel posterior teeth Restoration of residual roots and crowns.

Owner:ZHEJIANG UNIV

Corrosion-resistant high-strength high-modulus fiber and fabric prepared therefrom

The invention discloses a corrosion-resistant high-strength high-modulus fiber and a fabric prepared therefrom. The corrosion-resistant high-strength high-modulus fiber is composed of the following components: SiO2: 55-65%, Al2O3: 12-18%, MgO: 8 ~14%, CaO: 5~13%, Li2O: 0.2~1%, TiO2: 1~2%, and the balance is impurities, and the stated percentages are mass percentages. The fabric obtained in the present invention has high strength, high elastic modulus, high shear modulus, long-term temperature resistance, good corrosion resistance, and is not easy to age, and there is no room temperature creep phenomenon in composite material products; high-strength and high-modulus compound sizing agent for wire drawing Directly coated with raw silk, after making high-strength and high-modulus fabric, it can be directly compounded with resin, and the fabric does not need to be post-treated; the structure of the glass fiber fabric of the present invention is preferably twill or satin, suitable for various post-processing such as hand lay-up or vacuum-assisted molding. processing technology.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com