3D printing structure composite material laminboard with negative Poisson's ratio effect and processing method of laminboard

A negative Poisson's ratio, 3D printing technology, applied in the direction of additive processing, chemical instruments and methods, synthetic resin layered products, etc., can solve the difficulty of negative Poisson's ratio structure selection, limited use of core materials, high processing difficulty, etc. problems, achieve good mechanical properties, increase shear modulus, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation plan

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

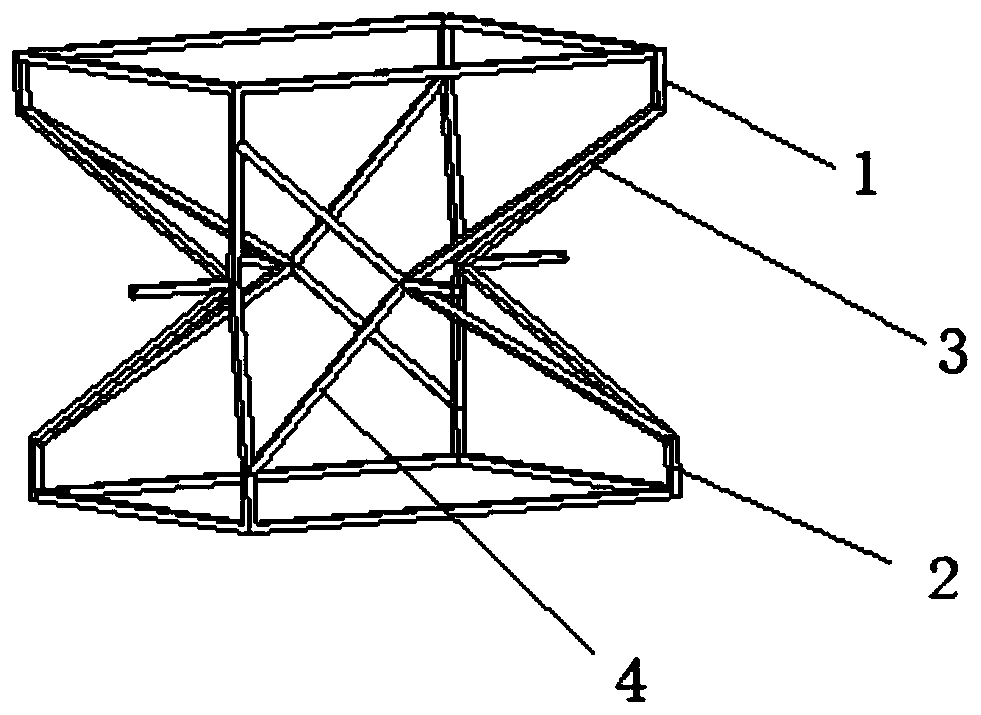

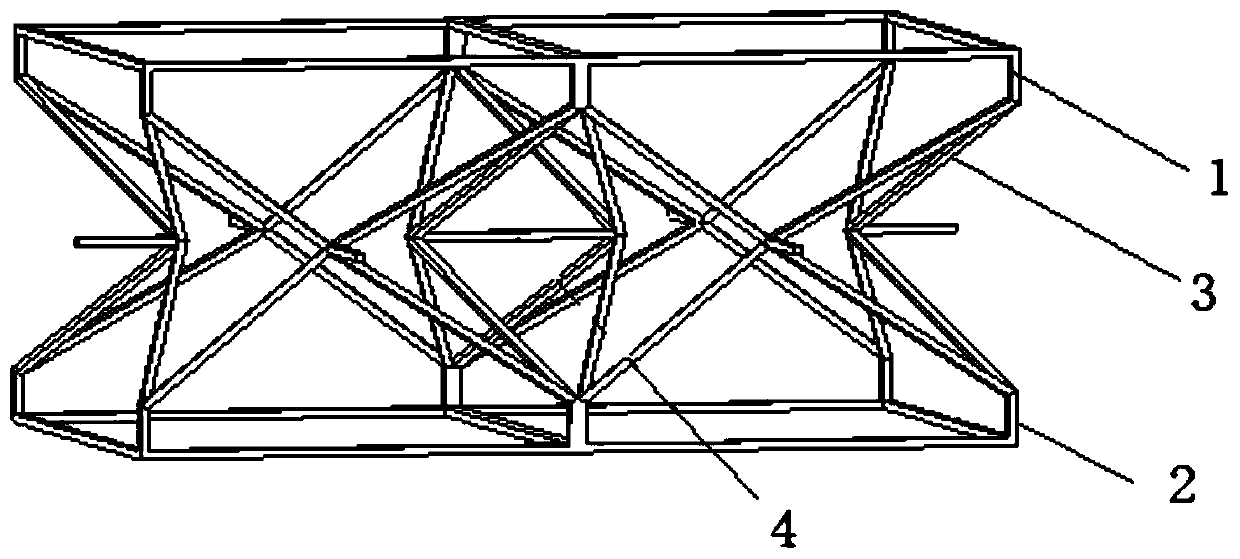

[0041] Such as Figure 1-7 As shown, a 3D printed structural composite sandwich panel with negative Poisson's ratio effect, including upper layer 1, lower layer 2 and middle core material layer 3;

[0042] The upper layer 1 and the lower layer 2 are composite materials made of fiber cloth and resin cured, and the middle core material layer 3 is a negative Poisson's ratio structural layer printed by 3D, and the structural layer is bonded to the upper layer through an adhesive. , the lower layers are bonded together;

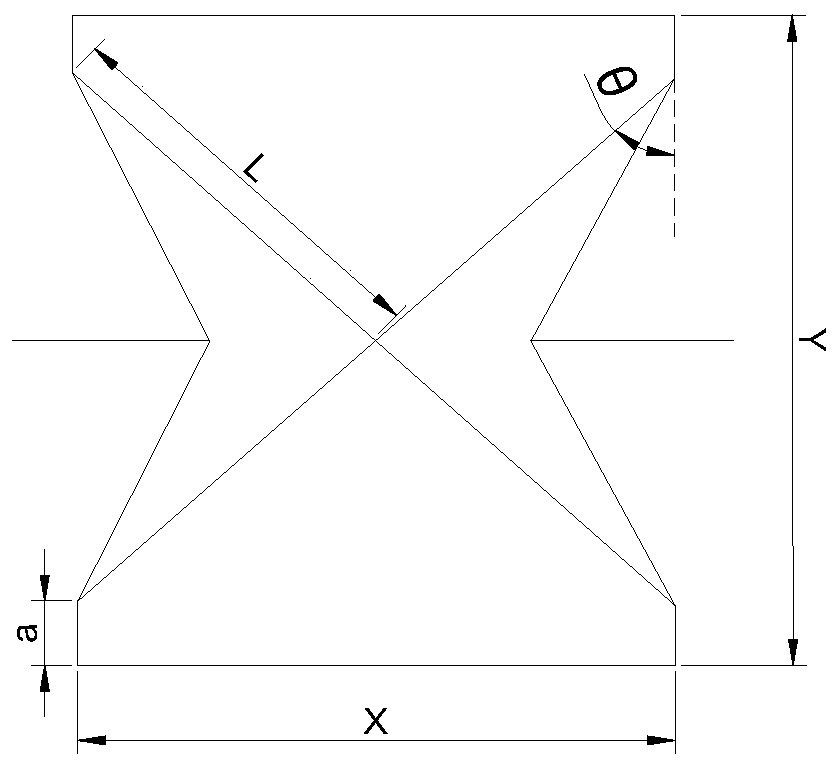

[0043] The negative Poisson's ratio structural layer is formed by connecting an array of negative Poisson's ratio units and the middle rod 4, and the rod 4 is a concave structure with a negative Poisson's ratio effect of auxetic compression, The section of the rod 4 is square or circular;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com