Polymer electrolytes including porous organic particles

A polymer and electrolyte technology, applied in the field of multi-phase materials, can solve the problems of not obtaining the electrical conductivity of the battery pack, insufficient mechanical properties, and unstable efforts, and achieve efficient ion mobility, good mechanical properties, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

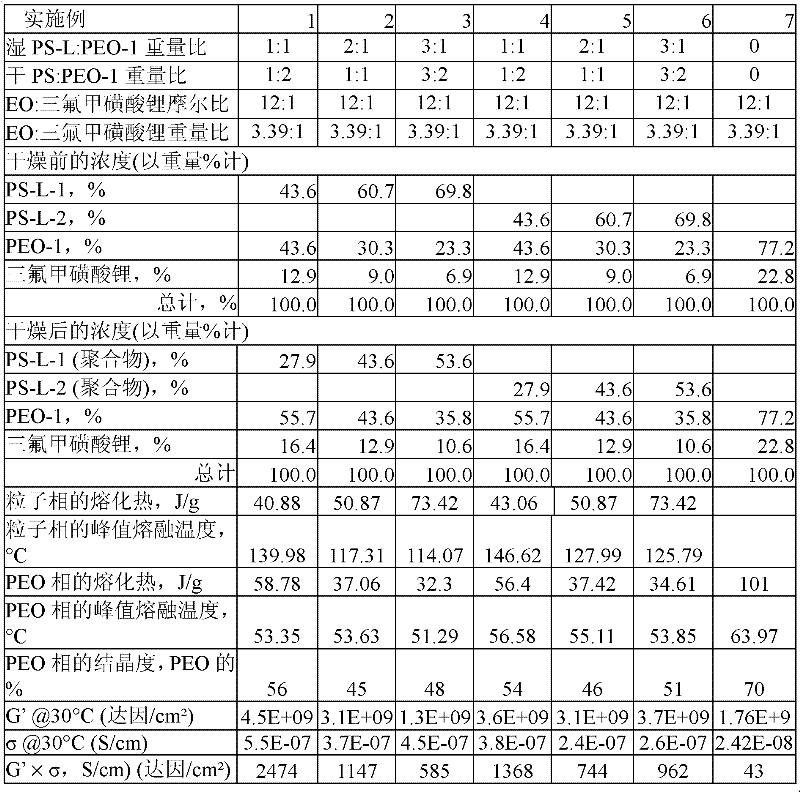

[0119] 43.6 wt% PS-L-1, 43.6 wt% PEO-1 and 12.8 wt% lithium triflate were combined in a beaker with enough deionized water to dissolve the PEO. The mixture was mixed overnight at a temperature of about 25°C. The mixing temperature was kept below the glass transition temperature of the polymers in the PS-L-1 latex. Continue mixing until the PEO-1 is dissolved and the solution is uniform. The solution was then dried at room temperature using a continuous stream of nitrogen gas to remove water. Drying was accomplished under vacuum at room temperature to remove residual water. After drying, the composition contained a molar ratio of oxirane groups (EO) on polyethylene oxide to lithium (ie, on lithium triflate) of about 12:1.

Embodiment 2-6

[0121] Examples 2, 3, 4, 5 and 6 were prepared using a procedure similar to that in Example 1 using the concentrations given in Table 2. The concentration of lithium triflate is selected such that the molar ratio of oxygen (ie, ethylene oxide) to lithium (ie, lithium triflate) is about 12:1. Example 2 and Example 3 were prepared at a weight ratio of PS-L-1:PEO-1 of about 2:1 and about 3:1, respectively. Examples 4, 5 and 6 were prepared using PS-L-2 instead of PS-L-1. Example 4, Example 5, and Example 6 were prepared at PS-L-2:PEO-1 weight ratios of about 1:1, about 2:1, and about 3:1, respectively.

[0122] As shown in Table 2, Comparative Example 7 was prepared by mixing PEO-1 with lithium triflate at a temperature higher than the melting temperature of PEO-1.

[0123] Examples containing propylene carbonate solvent were prepared by dissolving PEO in deionized water to form a PEO solution, and mixing the PEO solution with latex (which contained about 50% polymer and about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com