High-ceramic-content composite solid electrolyte, and preparation method thereof

A technology of solid electrolyte and high-temperature solid-phase method, which is applied in the field of electrochemical energy storage, can solve the problems that the electrical conductivity cannot meet the practical standard, the lithium metal dendrite cannot be suppressed, and the shear modulus is low, and the preparation of The method is simple and fast, and the effect of improving inhibition and flexibility is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

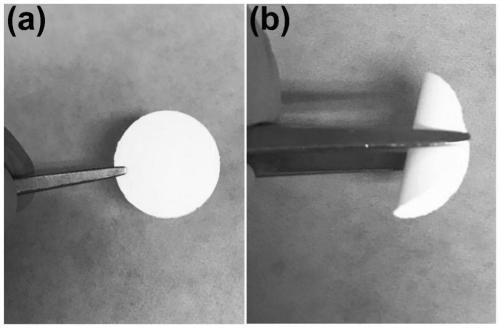

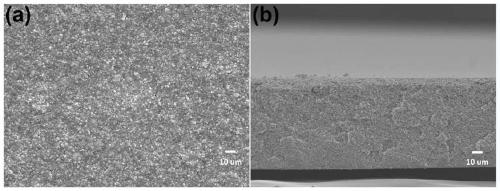

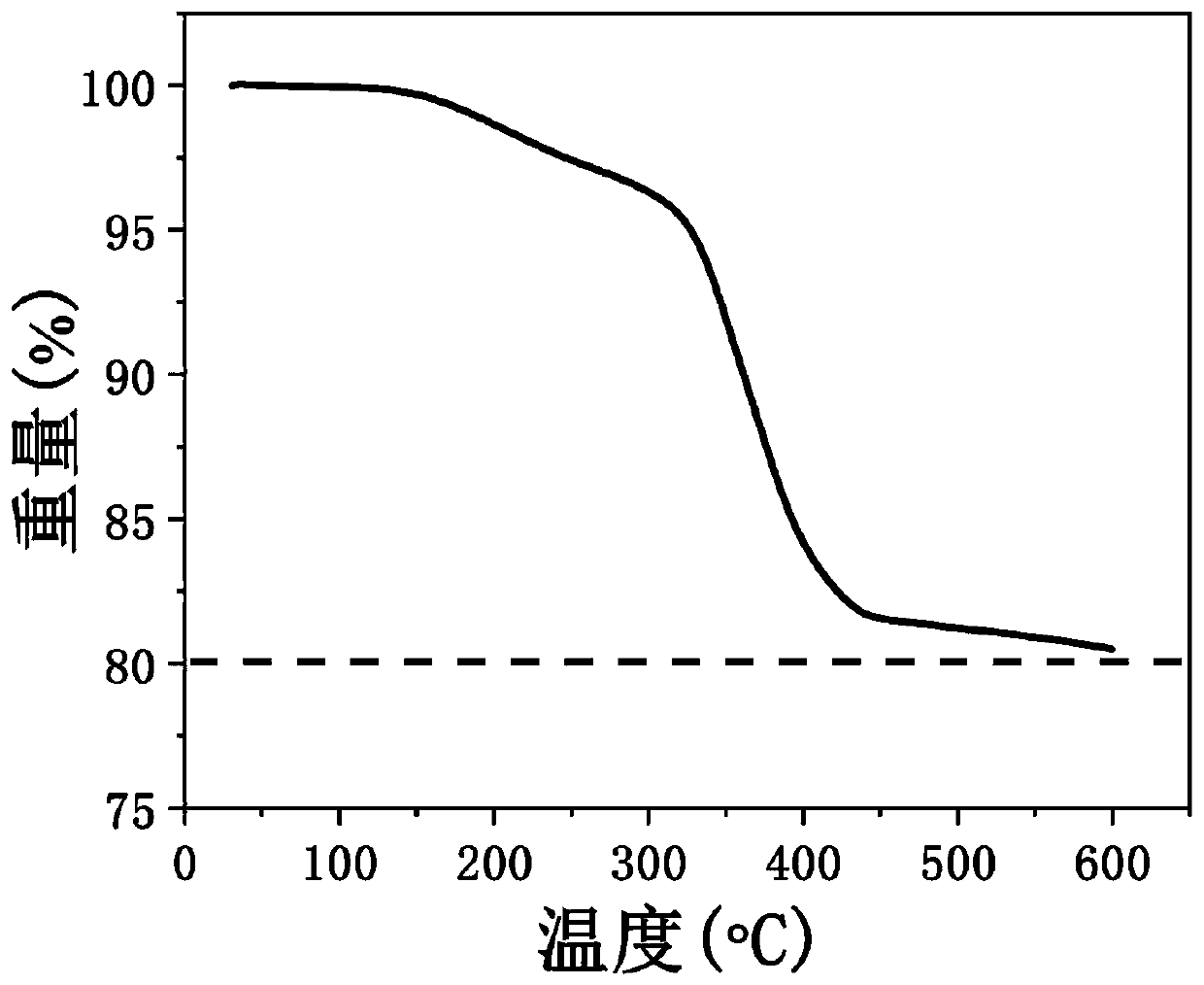

[0032] In the specific implementation process, the composition of the high ceramic content composite solid electrolyte of the present invention is a perovskite solid electrolyte Polyacrylonitrile (PAN) and lithium salts such as lithium perchlorate (LiClO 4 ) or lithium bistrifluoromethanesulfonimide (LiTFSI)), wherein the mass fraction of LLTO is controlled between 60 to 85%, and the mass ratio of PAN to lithium salt is 1:0.01 to 1:10 (preferably 1: 0.3~1:0.5). Its preparation method includes the following steps: first prepare LLTO by high-temperature solid-phase method, ball mill for 0.5-200 hours (preferably 20-60 hours) to reduce its particle size, and obtain LLTO with an average particle size of 0.01-50 μm (preferably 0.01-0.1 μm). LLTO powder; then the LLTO powder with PAN and LiClO 4 Mix according to the required mass ratio, and add a certain volume of N,N-dimethylformamide (DMF) solvent (N,N-dimethylformamide (DMF) and polyacrylonitrile (PAN) The mass ratio is 1:1~1...

Embodiment 1

[0036] In this example, the specific preparation process of the high ceramic content composite solid electrolyte is as follows:

[0037] Take by weighing 3.511g lithium carbonate (Li 2 CO 3 ), 21.894g lanthanum oxide (La 2 o 3 ) and 19.168g titanium oxide (TiO 2) was placed in a 250ml ball mill jar, 100ml of ethanol was added, and then ball milled at a speed of 400rpm for 48h. After the obtained sample was dried, it was placed in a corundum crucible, and pre-fired at 900°C for 12h, and the heating and cooling rate was 3°C / min. The obtained powder was first hand-milled in a mortar for 30 minutes, then placed in a 250 ml ball mill jar, added with 120 ml of ethanol, ball milled at 400 rpm for 48 hours, and then dried. The precursor powder was placed in a high-temperature box furnace, and sintered at 1210°C for 16 hours, and the heating and cooling rates were both 1°C / min. The obtained perovskite solid electrolyte Li 0.33 La 0.557 TiO 3 (LLTO) was first hand-ground in a m...

Embodiment 2

[0042] In this example, the specific preparation process of the high ceramic content composite solid electrolyte is as follows:

[0043] For solid electrolyte Take x=0.05, weigh Li according to the stoichiometric ratio 2 CO 3 (30% excess), TiO 2 and La 2 o 3 Mixed, sintered at 1260°C for 20h, and then ball milled for 100h to obtain LLTO powder with a particle size of about 0.07μm. According to LLTO, PAN and LiClO 4 The mass ratio is 0.7:0.075:0.15. The three materials are weighed and mixed, and then DMF solvent (30 times the mass of PAN) is added. After ball milling at 300rpm for 30h, the precursor slurry of high ceramic content composite solid electrolyte is prepared. The obtained precursor slurry was coated on a clean glass plate by tape casting method, and placed in a vacuum drying oven to heat and dry, then evacuated, and kept at 60°C for 12 hours to obtain a precursor for preparing a composite solid electrolyte with high ceramic content slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com