Corrosion-resistant high-strength high-modulus fiber and fabric prepared from fiber

A high-strength, high-modulus, corrosion-resistant technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of low elastic modulus, low shear modulus, room temperature creep, etc., achieve high elastic modulus, shear High modulus, not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

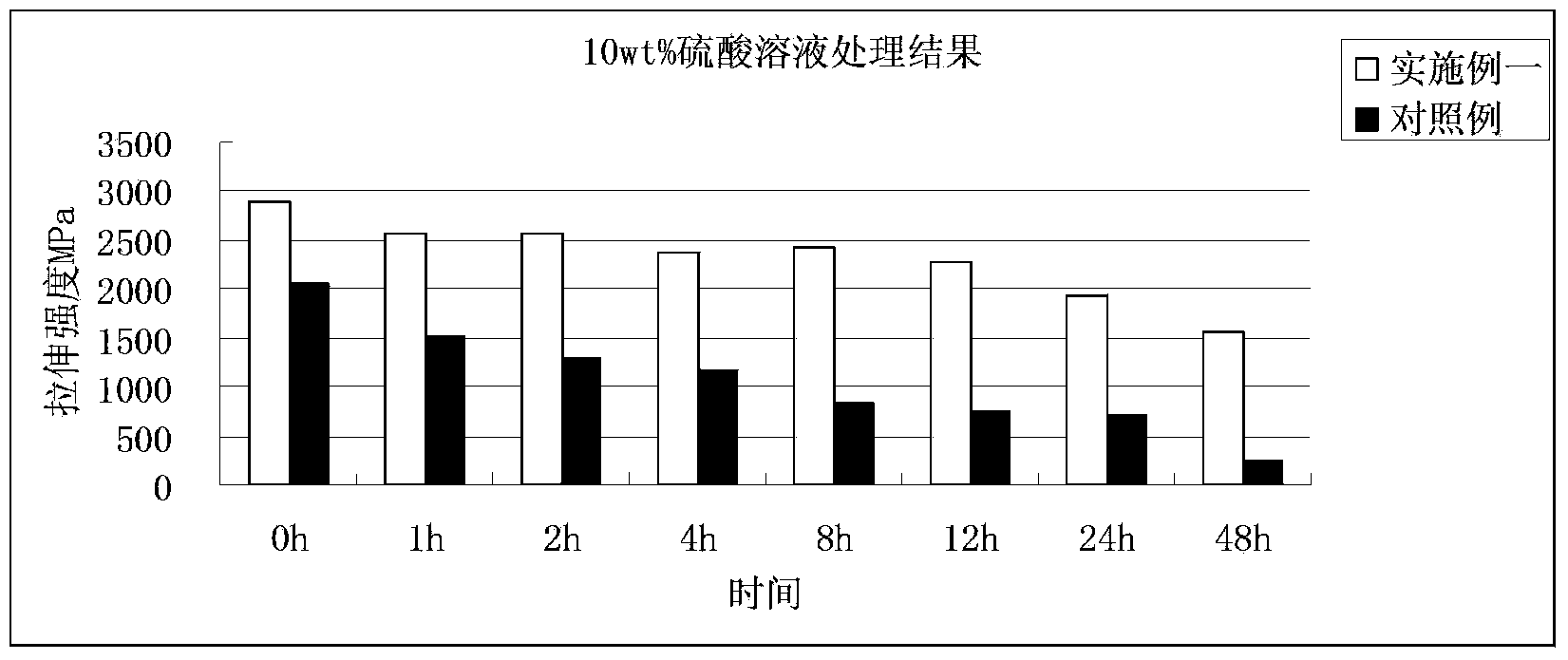

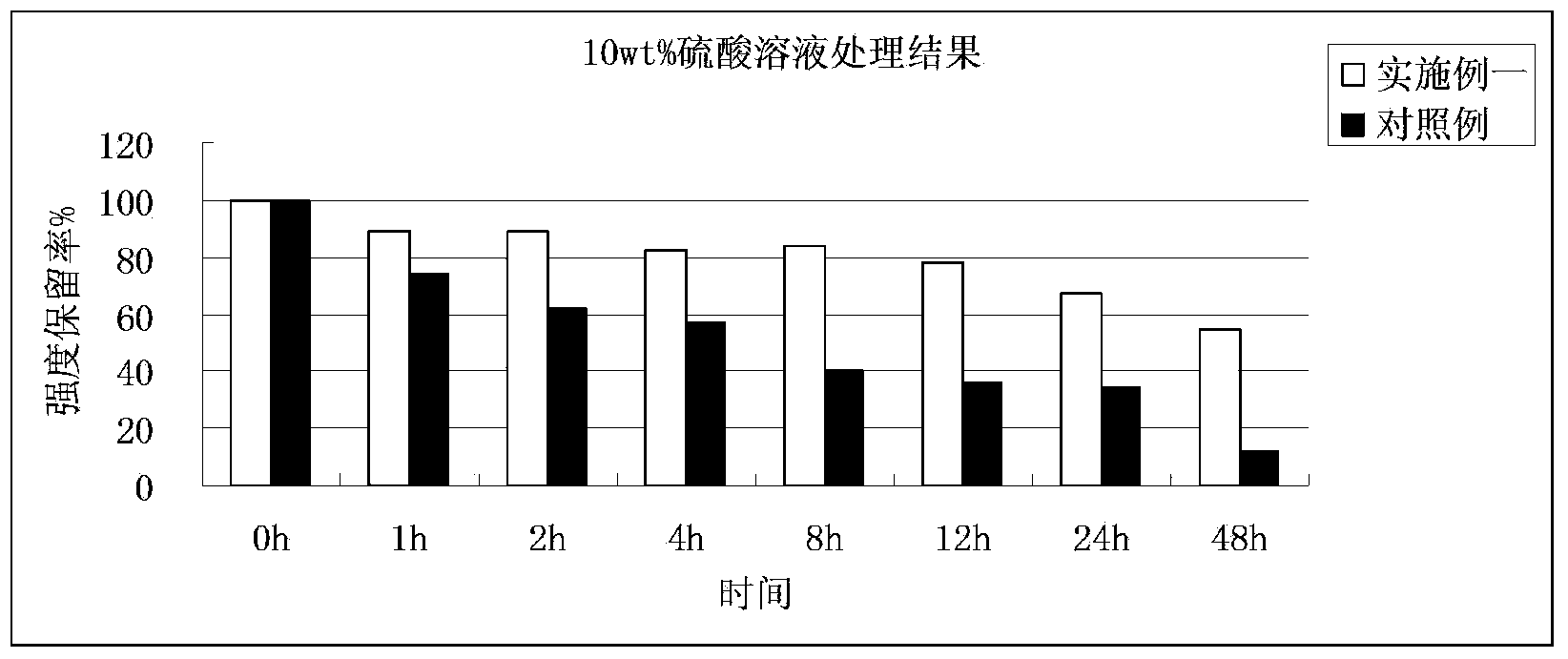

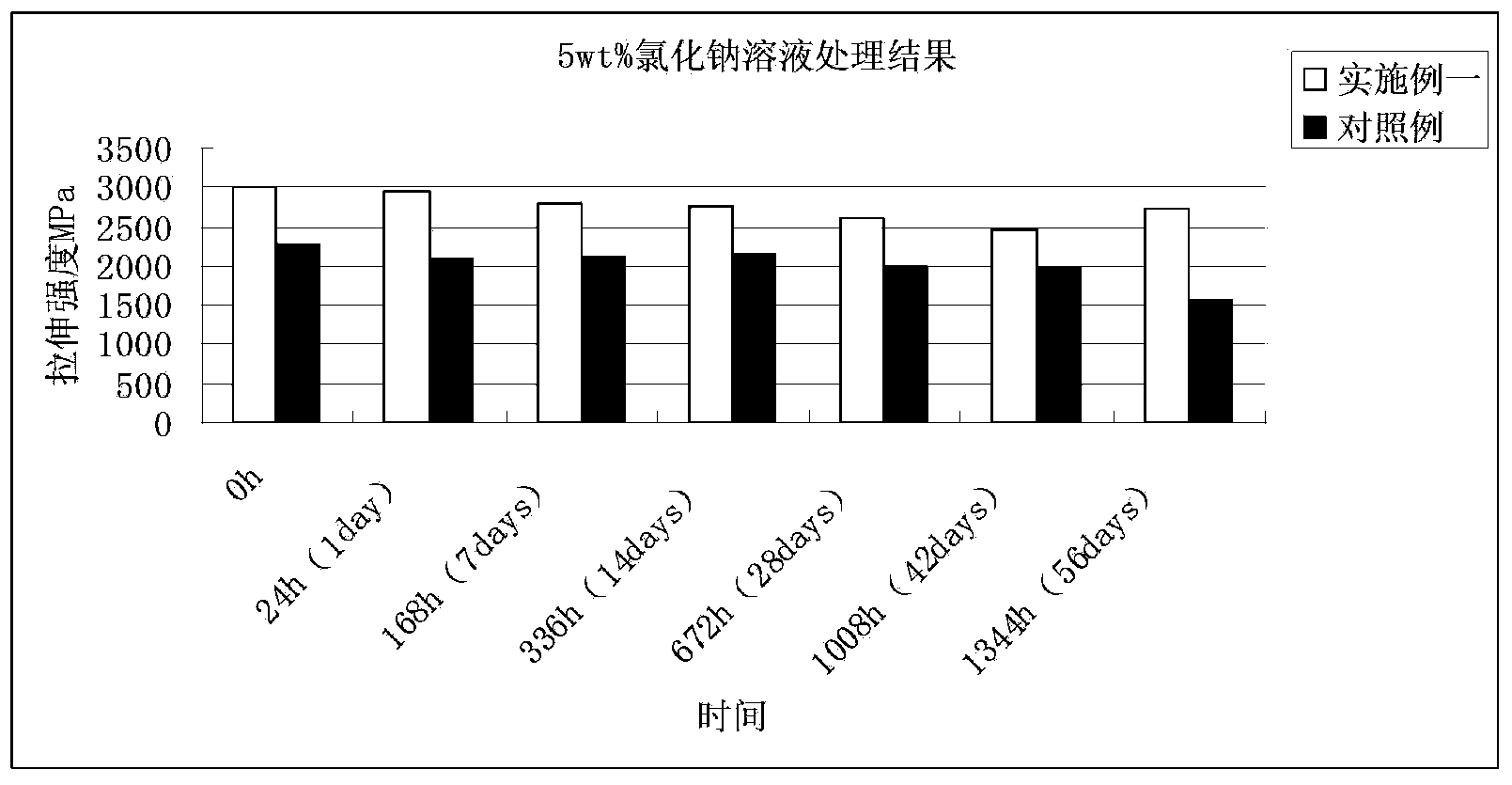

[0033] The raw material components of glass fiber are listed in Table 1. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a 24tex strand. 72tex warp yarns and weft yarns are produced through untwisting and twisting processes, and the formula of the high-strength and high-modulus compound sizing agent used is shown in Table 2 (when using, the components are mixed to obtain final product); the warp yarns are warped and worn. Synthesize the warp head; use a rapier loom to weave according to the two-up and two-down twill weaving process, and the surface weight is 220g / m 2 Corrosion-resistant high-strength high-modulus fiberglass fabric. The fabric structure is twill. Embodiment one in the accompanying drawings refers to the present embodiment 1.

[0034] Table 1

[0035] Recipe Components Proportion, mass% SiO 2 63.6 al 2 o 3 16 MgO 9 CaO 8 Li 2 o 0.5 TiO 2 2 Impurities (N...

Embodiment 2

[0039] The raw material components of glass fiber are listed in Table 3. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a 24tex strand. 72tex warp yarn and weft yarn are produced through untwisting and twisting process, and the formula of the high-strength and high-modulus compound sizing agent used is shown in Table 4 (when using, mix each component to get final product); Synthesize the warp head; use a rapier loom to weave according to the two-up and two-down twill weaving process, and the surface weight is 220g / m 2 Corrosion-resistant high-strength high-modulus fiberglass fabric. The weave structure is satin.

[0040] table 3

[0041]

[0042]

[0043] Table 4

[0044]

Embodiment 3

[0046] The raw material components of glass fiber are listed in Table 5. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a 24tex strand. The 72tex warp and weft yarns are produced through the untwisting and twisting process. The formula of the high-strength and high-modulus compound sizing agent used is shown in Table 6 (when using, the components are mixed to obtain final product); Synthesize the warp head; use a rapier loom to weave according to the two-up and two-down twill weaving process, and the surface weight is 220g / m 2 Corrosion-resistant high-strength high-modulus fiberglass fabric. The fabric structure is twill.

[0047] table 5

[0048] Recipe Components Proportion, mass%

[0049] SiO 2 58 Al 2 o 3 15 MgO 14 CaO 10 Li 2 o 1 TiO 2 1.5 Impurities (Na 2 O: Fe 2 o 3 : ZrO 2 =1:3:1 (mass ratio)) 0.5 Acid resistance 10% sulfuric acid solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com