Compound structure formed by implementing magnet exciting coil in magnetorheological elastomer

A magnetorheological elastomer and excitation coil technology, applied in the field of magnetorheological materials, can solve the problems of reducing the magnetorheological effect of magnetorheological elastomers, bulky structure, and reduced magnetic induction intensity, and achieve simple structure and low production cost Low, high shear modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

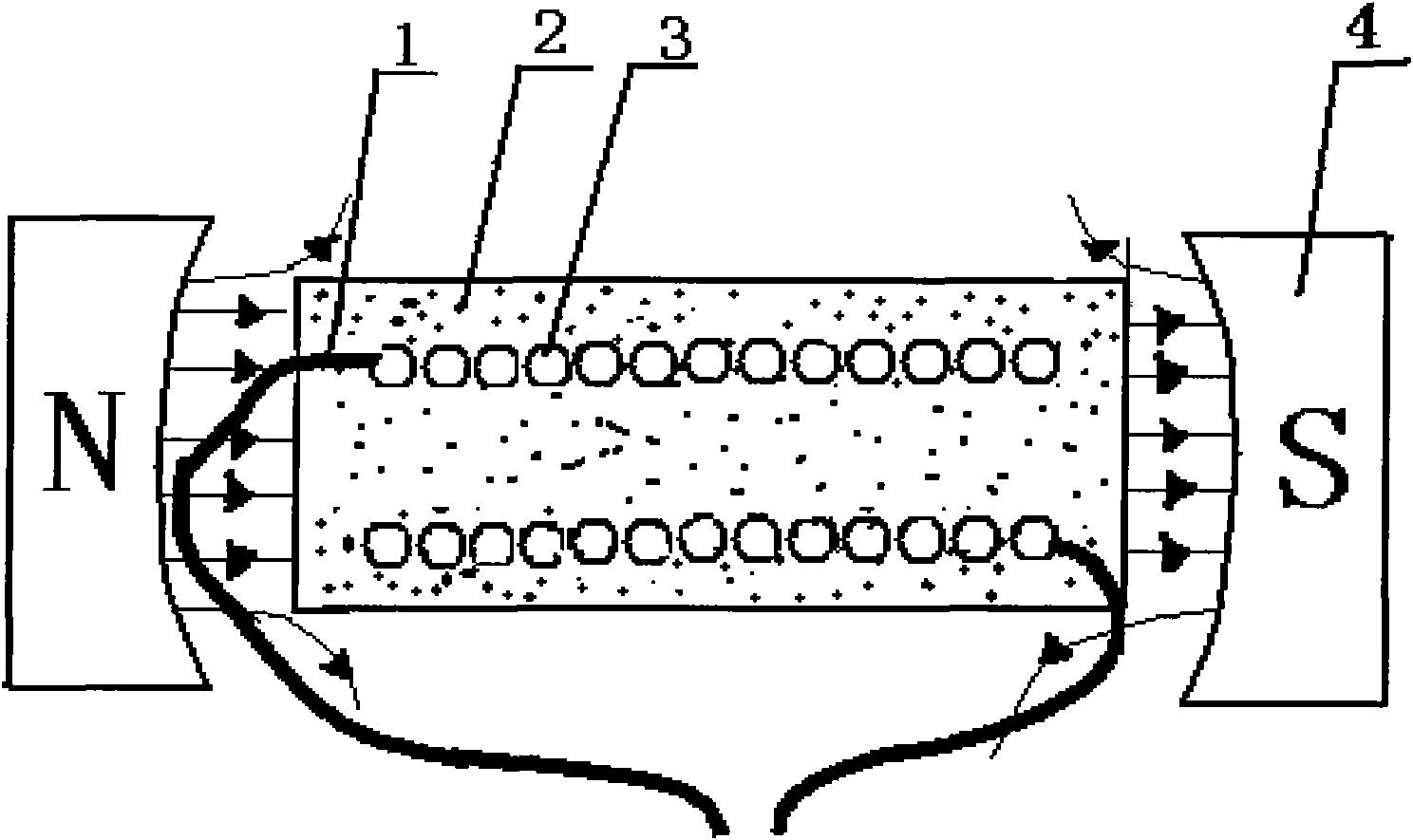

[0014] First, fix the excitation coil 3 in the mold, and mix the liquid polymer and ferromagnetic particles uniformly; then inject the mixture into the mold, and the ferromagnetic particles will be randomly distributed; finally, add permanent magnets to the structure. The constant magnetic field generated by the magnet 4 causes it to slowly solidify at a certain temperature. At this time, the magnetic field will cause the ferromagnetic particles to form complex structures such as chains. During the solidification process, the excitation coil 3 will interact with the base material and chain magnetic particles. The structure is tightly combined and remains unchanged after curing. The excitation coil 3 is integrally compounded inside the magnetorheological elastomer 2 material, and the excitation coil energization joint 1 is left, the structure is as figure 1 Shown.

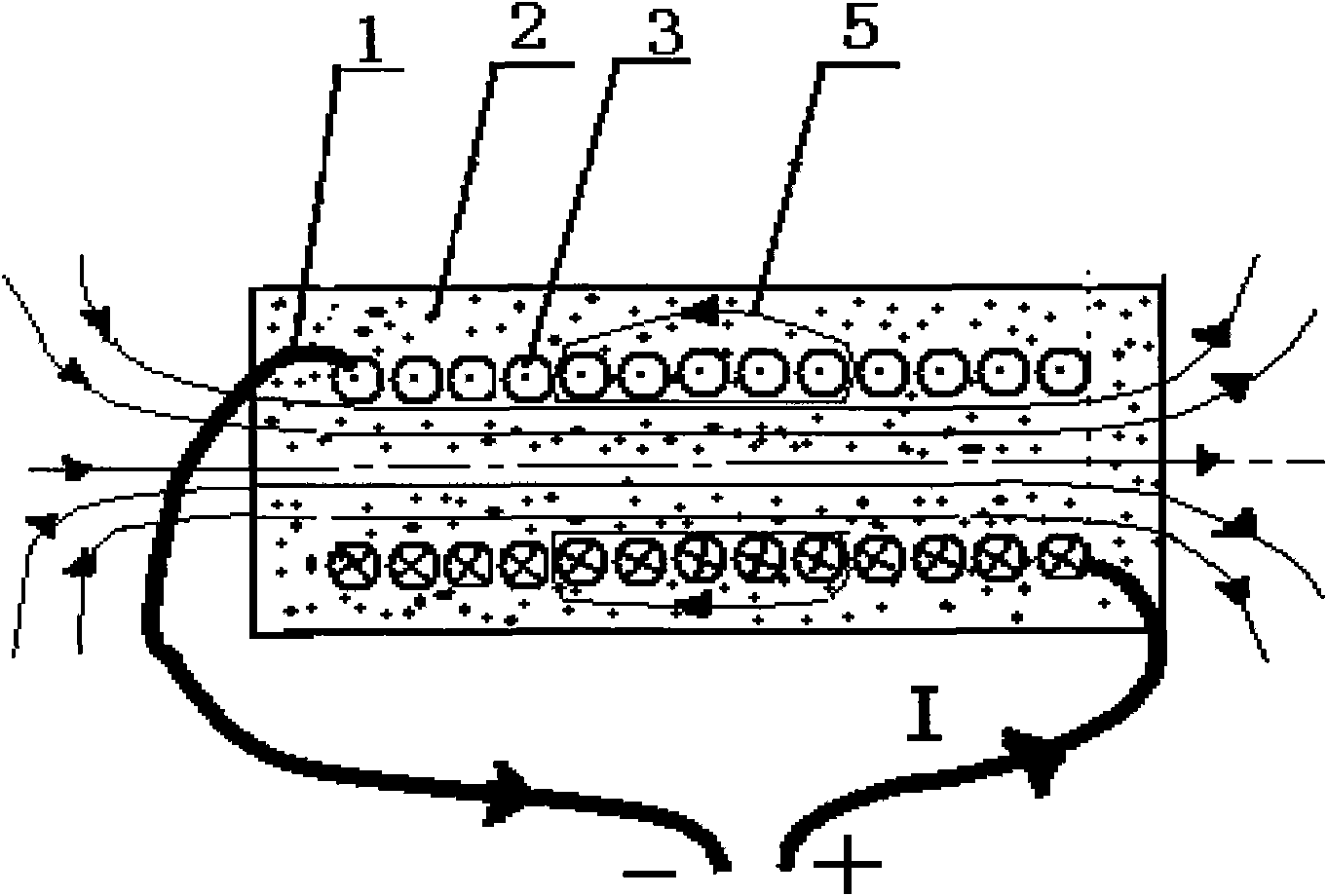

[0015] During production, it is best to arrange the excitation coil 3 in the middle position of the magnetorheologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com