Sound insulation and noise reduction composite material and preparation method thereof

A composite material and noise reduction technology, applied in the field of materials, can solve problems such as insufficient stiffness and thermal performance, and achieve the effects of improving shear modulus, easy manufacturing, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

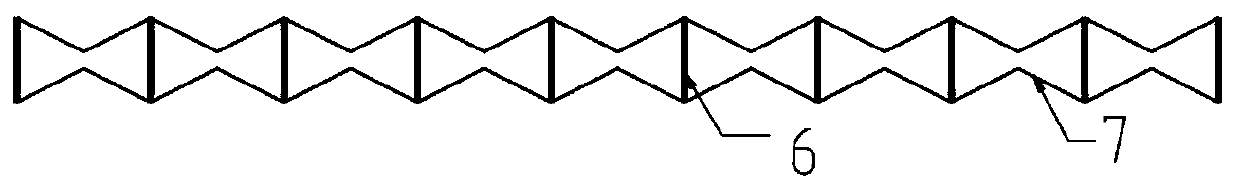

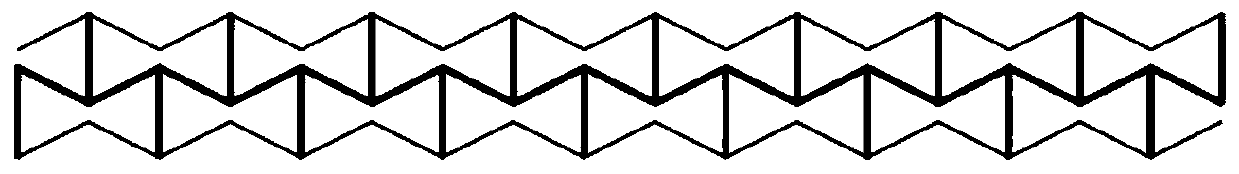

[0038] like figure 1 As shown, this embodiment provides a sound-insulating and noise-reducing composite material, including a base plate 1, a top plate 2, and a sandwich layer 3 between the base plate 1 and the top plate 2, and the sandwich layer 3 has a negative Poisson’s ratio unit 4 . Described negative Poisson's ratio unit 4 comprises the first negative Poisson's ratio unit and the second negative Poisson's ratio unit, and described first negative Poisson's ratio unit and the second negative Poisson's ratio unit all have several same-sized inner concave hexagonal structure; figure 2 shows a schematic cross-sectional view of the first negative Poisson's ratio unit and the second negative Poisson's ratio unit with the same structure, and in the schematic diagram, the first negative Poisson's ratio unit and the second negative Poisson's ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com