Wide-temperature range high-damping rubber bearer and preparation technology thereof

A rubber bearing and high damping technology, which is applied in the field of high damping rubber bearings, can solve the problems of sub-zero, limited rubber damping effect, and inability to be in the best use state at room temperature, so as to achieve the effect of improving the damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

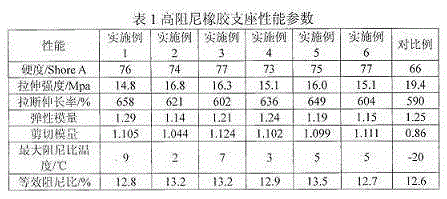

Examples

Embodiment 1

[0048]The preparation process of the wide temperature range high damping rubber bearing of the present invention comprises the following steps:

[0049] The first step of mixing

[0050] Mix 70 parts by weight of natural rubber in an internal mixer for 30 seconds, add 4 parts by weight of active agent, 50 parts by weight of carbon black and 10 parts by weight of engine oil in turn, and when the temperature rises to 80 ° C, put in 30 parts by weight of styrene-butadiene rubber, 60 parts by weight Parts by weight of high styrene resin, 30 parts by weight of iridescent mixed-layer clay, 5 parts by weight of silica and 15 parts by weight of precipitated calcium carbonate, until the temperature rises to 160 ° C for debinding;

[0051] After standing at room temperature for 8 hours, add 2.5 parts by weight of vulcanizing agent and 1.4 parts by weight of accelerator in the internal mixer, and mix well to obtain a rubber compound;

[0052] Second step vulcanization

[0053] The stif...

Embodiment 2

[0055] The preparation process of the wide temperature range high damping rubber bearing of the present invention comprises the following steps:

[0056] The first step of mixing

[0057] Mix 90 parts by weight of natural rubber in an internal mixer for 60 seconds, add 10 parts by weight of active agent, 80 parts by weight of carbon black and 30 parts by weight of engine oil in sequence, and when the temperature rises to 100 °C, put in 10 parts by weight of styrene-butadiene rubber, 10 parts by weight of Parts by weight of high styrene resin, 10 parts by weight of imonite mixed layer clay, 20 parts by weight of silica and 30 parts by weight of precipitated calcium carbonate, until the temperature rises to 140 ° C for debinding;

[0058] After standing at room temperature for 16 hours, add 1.5 parts by weight of vulcanizing agent and 3.5 parts by weight of accelerator in the internal mixer, and mix evenly to obtain a rubber compound;

[0059] Second step vulcanization

[0060...

Embodiment 3

[0062] The preparation process of the wide temperature range high damping rubber bearing of the present invention comprises the following steps:

[0063] The first step of mixing

[0064] Mix 80 parts by weight of natural rubber in an internal mixer for 50 seconds, then add 3 parts by weight of zinc oxide, 3 parts by weight of stearic acid, 65 parts by weight of carbon black and 20 parts by weight of engine oil. When the temperature rises to 90°C, put in 20 Parts by weight of styrene-butadiene rubber, 35 parts by weight of high styrene resin, 25 parts by weight of imonite mixed layer clay, 12 parts by weight of silica and 22 parts by weight of precipitated calcium carbonate, until the temperature rises to 150 ° C for debinding;

[0065] After standing at room temperature for 10 hours, add 2 parts by weight of vulcanizing agent, 0.6 parts by weight of benzothiazole disulfide and 2.0 parts by weight of N-cyclohexyl-2-benzothiazole sulfenamide in the internal mixer, and mix well ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com