Lithium metal battery electrolyte and lithium metal battery

A lithium metal battery and electrolyte technology, applied in the field of lithium ion batteries, can solve problems such as complex operation, low room temperature conductivity of the electrolyte, and difficulty in manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention has no special restrictions on the preparation method of the electrolyte. Before the vegetation is covered, the lithium salt additive and the non-lithium salt are kept fully dry, and the non-aqueous solvent is dehydrated by molecular sieves for more than 24 hours. After the above pretreatment is completed, the above three The raw materials are mixed to obtain an electrolyte solution.

[0040] The present invention also provides a lithium metal battery, comprising a positive electrode, a negative electrode and an electrolyte;

[0041] The negative electrode is lithium metal;

[0042] The electrolyte is the above-mentioned electrolyte for lithium metal batteries.

[0043] In the present invention, there is no special limitation on the type of the positive electrode in the lithium metal battery, and the positive electrode of the lithium metal battery commonly used by those skilled in the art can be used.

[0044] The invention provides an electrolyt...

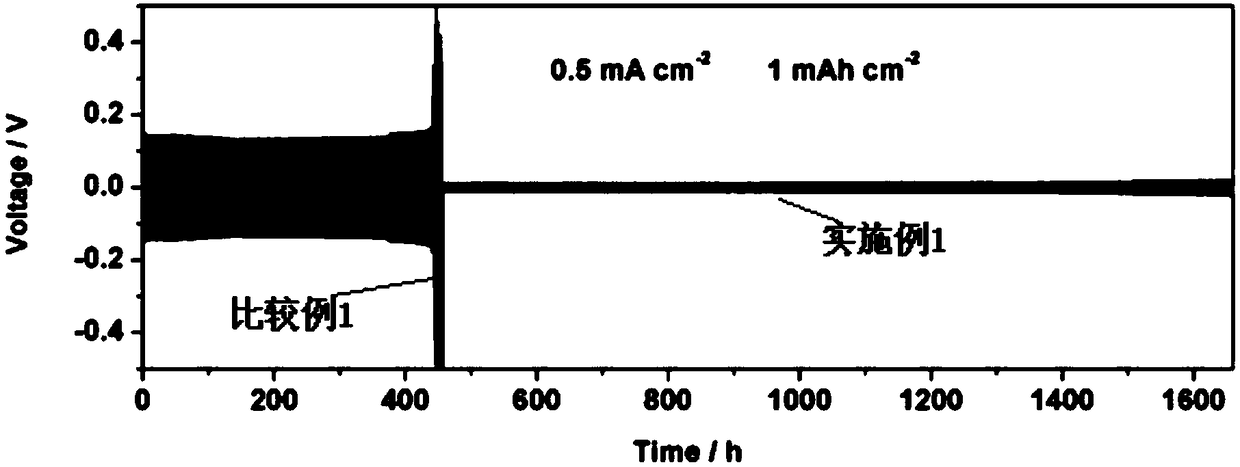

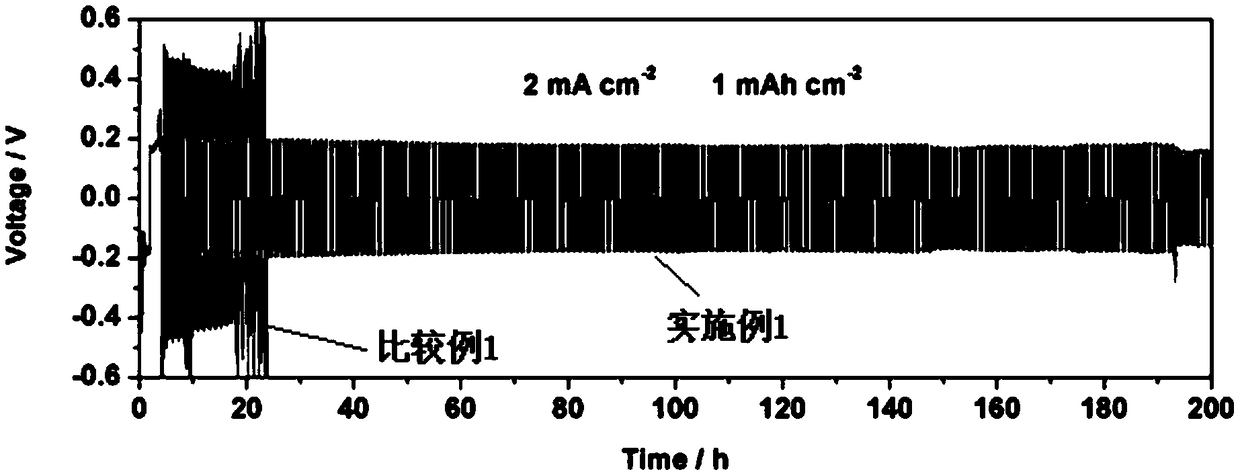

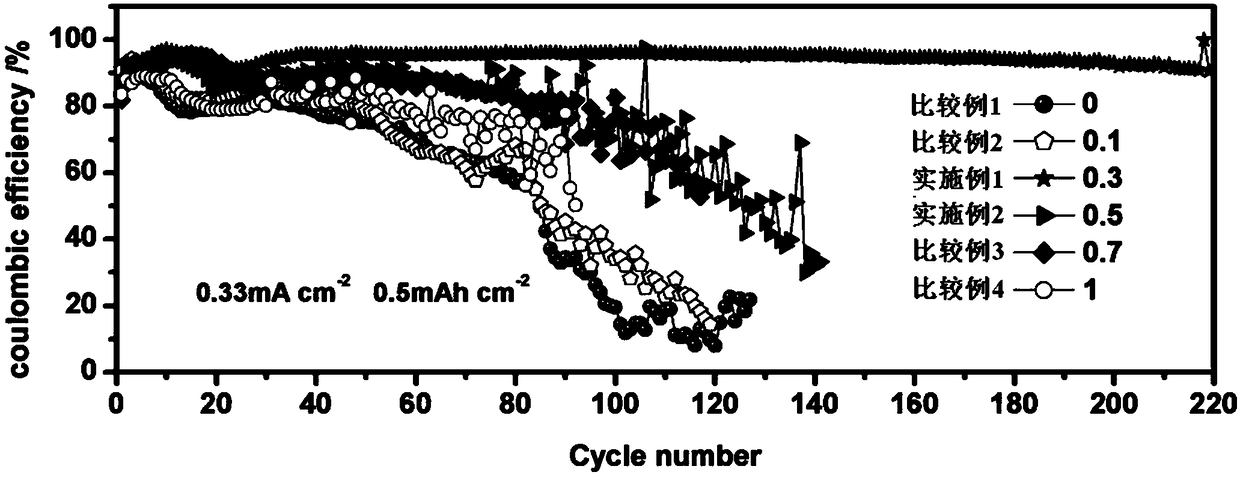

Embodiment 1

[0047] The electrolyte with the following formula is: 1mol / L LiTFSI, 0.3mol / L NaFSI, and the non-aqueous solvent is dimethyl ether (DME) and ethylene glycol methylene ether (DOL) with a volume ratio of 1:1.

[0048] Metal lithium is used as the negative electrode, and the above-mentioned electrolyte solution is assembled into a lithium-lithium symmetrical battery and a lithium-copper battery respectively.

Embodiment 2

[0050] The electrolyte and the lithium metal battery were obtained according to the formula and materials in Example 1, except that 0.5 mol / L NaFSI was used in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com