Wear-resistant and anticorrosive polyethersulfone coating, and preparation method and application thereof

A technology of anti-corrosion coatings and polyethersulfone, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of anti-corrosion, wear-resistant performance decline, incompatibility between anti-corrosion performance and wear-resistant performance, and cumbersome spraying process, etc. Good strength, good chemical resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 18 grams of N-methylpyrrolidone, 18 grams of N,N-dimethylacetamide, 22 grams of toluene, and 12 grams of butanone to form a composite solvent, and dissolve 15 grams of polyethersulfone resin in Composite solvent, adding 6 grams of polytetrafluoroethylene resin micropowder and 3 grams of silicon carbide micropowder with a particle size of 0.5 microns into the solution of polyethersulfone, stirred for 15 minutes at a linear speed of 15 m / s, and then sanded for 2 hours to obtain Polyethersulfone wear-resistant and anti-corrosion coating. The logarithmic reduced viscosity of the polyethersulfone resin is between 0.31 and 0.37; the particle diameter of the polytetrafluoroethylene resin powder is within 10 microns.

[0025] The polyethersulfone wear-resistant multifunctional coating was applied to the sandblasted steel plate by air spraying method, baked at 100°C for 30 minutes, cured at 360°C for 10 minutes and cooled to room temperature for testing.

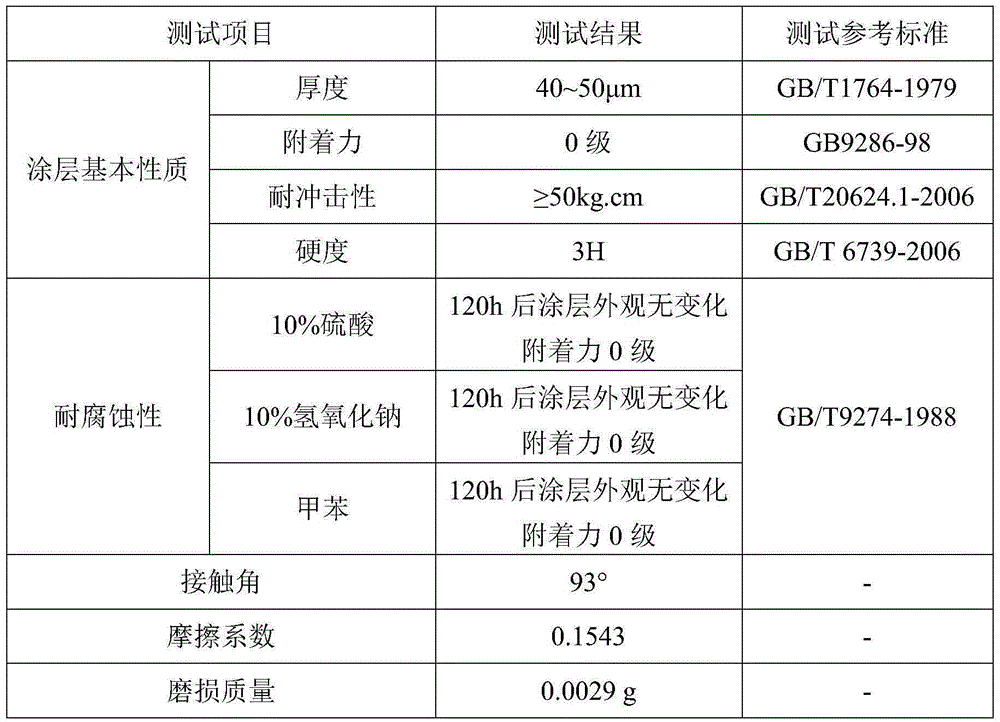

[0026] Coating pe...

Embodiment 2

[0029] Mix 28 grams of N-methylpyrrolidone, 28 grams of N,N-dimethylacetamide, 9 grams of toluene, and 5 grams of butanone to form a composite solvent, and dissolve 21 grams of polyethersulfone resin in Composite solvent, adding 6 grams of polytetrafluoroethylene resin micropowder and 9 grams of silicon carbide micropowder with a particle size of 30 microns to the solution of polyethersulfone, stirred for 30 minutes at a linear speed of 15 m / s, and then sanded for 6 hours to obtain Polyethersulfone wear-resistant and anti-corrosion coating. The logarithmic reduced viscosity of the polyethersulfone resin is between 0.31 and 0.37; the particle diameter of the polytetrafluoroethylene resin powder is within 10 microns.

[0030] The polyethersulfone wear-resistant and anti-corrosion coating was applied to the sandblasted steel plate by air spraying method, baked at 120°C for 60 minutes, cured at 390°C for 15 minutes and cooled to room temperature for testing.

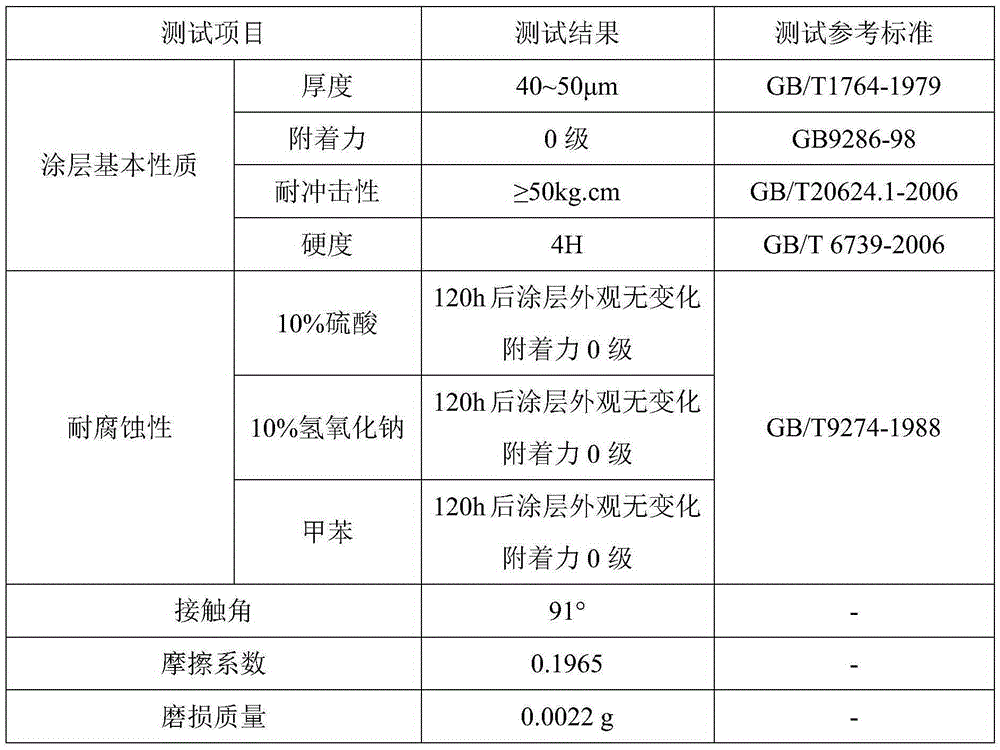

[0031] Coating perf...

Embodiment 3

[0034] Mix 25 grams of N-methylpyrrolidone, 25 grams of N,N-dimethylacetamide, 14 grams of toluene, and 6 grams of butanone to form a composite solvent, and dissolve 19 grams of polyethersulfone resin in Composite solvent, adding 6 grams of polytetrafluoroethylene resin micropowder and 9 grams of silicon carbide micropowder with a particle size of 5 microns to the solution of polyethersulfone, stirred for 20 minutes at a linear speed of 15 m / s, and then sanded for 4 hours to obtain Polyethersulfone wear-resistant and anti-corrosion coating. The logarithmic reduced viscosity of the polyethersulfone resin is between 0.31 and 0.37; the particle diameter of the polytetrafluoroethylene resin powder is within 10 microns.

[0035] The polyethersulfone wear-resistant and anti-corrosion coating was applied to the sandblasted steel plate by air spraying method, baked at 110°C for 40 minutes, cured at 380°C for 13 minutes and cooled to room temperature for testing.

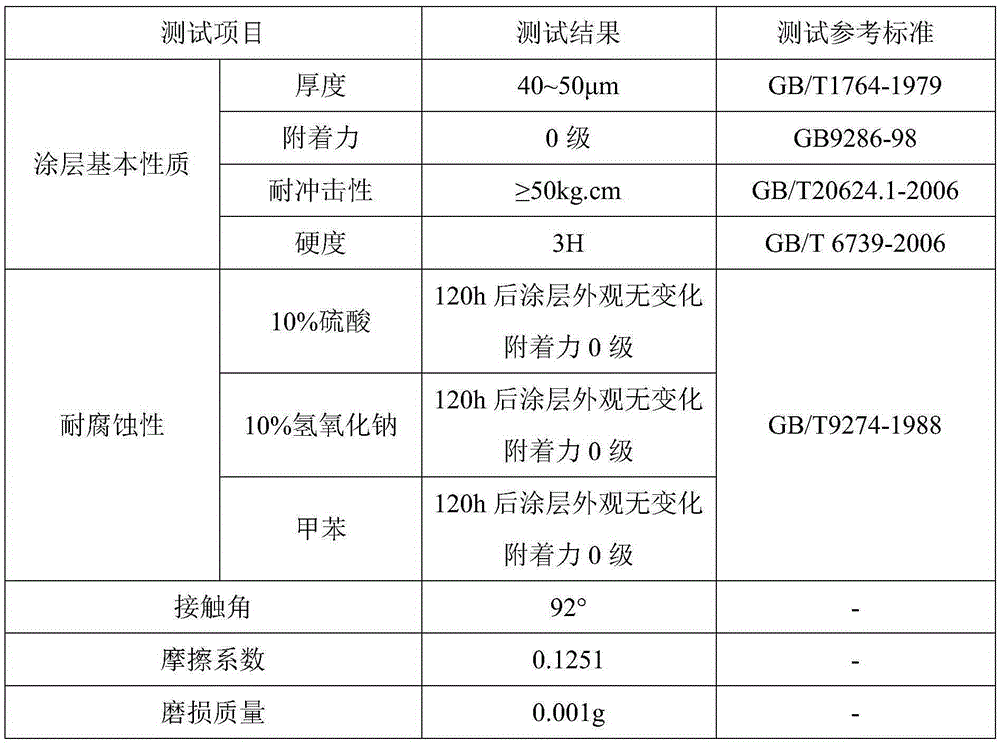

[0036] Coating perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com