Composite fiber material for FDM technology and preparation method of composite fiber material

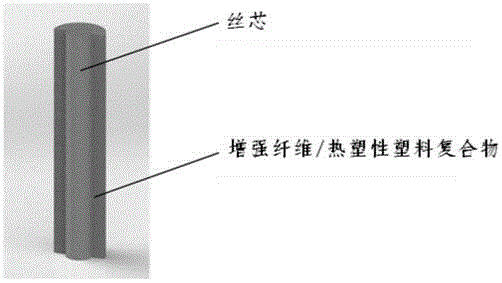

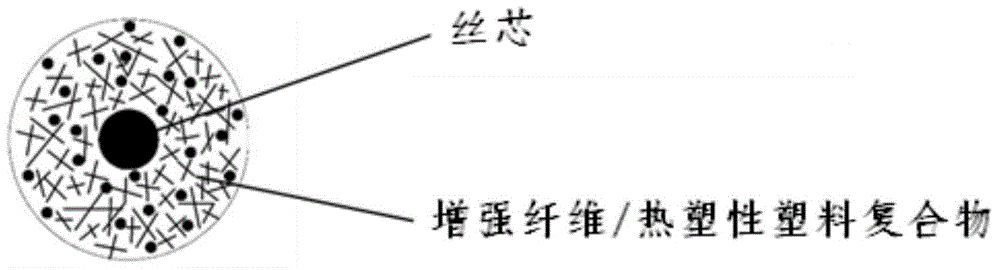

A composite fiber and wire technology, applied in the field of additive manufacturing, can solve the problems of low product strength and difficult to use directly, and achieve the effects of improving shear modulus, strengthening axial connection strength, and improving radial tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment prepares the method for the composite fiber filament material of FDM technology, comprises the following steps:

[0030] Stp1: Take 90 parts of polystyrene, 10 parts of reinforced short carbon fiber filaments and a long carbon fiber filament core with a diameter of 10 μm;

[0031] Stp2: heating polystyrene to molten state;

[0032] Stp3: Add short carbon fiber filaments to molten polystyrene and mix well;

[0033] Stp4: Through the wire feeding mechanism, the long carbon fiber core passes through the mixed melt obtained in Stp3 at a constant speed of 0.5m / min, so that the mixed melt is evenly attached to the surface of the core;

[0034] Stp5: Control the hole diameter of the wire extrusion port, and finally obtain a composite wire with a diameter of 35-45 microns.

[0035] In this embodiment, the short reinforcing carbon fibers have a diameter of 0.3-0.8 μm and a length of ≤1 mm.

[0036] When the composite fiber filament prepared in this embo...

Embodiment 2

[0038] The present embodiment prepares the method for the composite fiber filament material of FDM technology, comprises the following steps:

[0039] Stp1: Take 80 parts of polypropylene, 20 parts of reinforced glass fiber and a wire core with a diameter of 18 μm;

[0040] Stp2: heating polypropylene to molten state;

[0041] Stp3: Add reinforced glass fiber to molten polypropylene and mix well;

[0042] Stp4: Through the wire feeding mechanism, the metal wire core passes through the mixed melt obtained in Stp3 at a constant speed of 0.8m / min, so that the mixed melt is evenly attached to the surface of the metal wire core;

[0043] Stp5: Control the hole diameter of the wire extrusion port, and finally obtain a composite wire with a diameter of 20-35 microns.

[0044] In this embodiment, the reinforced glass fiber has a diameter of 0.5-0.9 μm and a length of ≤1 mm.

Embodiment 3

[0046] The present embodiment prepares the method for the composite fiber filament material of FDM technology, comprises the following steps:

[0047] Stp1: Take 75 parts of polycarbonate, 25 parts of reinforced carbon nanotubes and a glass fiber core with a diameter of 6 μm;

[0048] Stp2: heating polycarbonate to molten state;

[0049] Stp3: Add reinforced carbon nanotubes to molten polycarbonate and mix well;

[0050] Stp4: Through the wire feeding mechanism, the glass fiber core passes through the mixed melt obtained from Stp3 at a constant speed of 0.3m / min, so that the mixed melt is evenly attached to the surface of the glass fiber core;

[0051] Stp5: Control the hole diameter of the wire extrusion port, and finally obtain a composite wire with a diameter of 30-45 microns.

[0052] In this embodiment, the reinforced carbon nanotubes have a diameter of 0.2-0.6 μm and a length of ≤1 mm.

[0053] The composite fiber filament of the present invention adds short fibers to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com