High-content glass fibre-enhanced nylon 66 composite material and preparation method thereof

A high-content glass fiber and composite material technology, applied in the field of polymer materials, can solve problems such as difficult wetting, difficult fiber chemical bonding, and weak interface bonding of composite materials, so as to achieve good aging protection, improve thermal oxygen aging performance, The effect of improving the interfacial adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

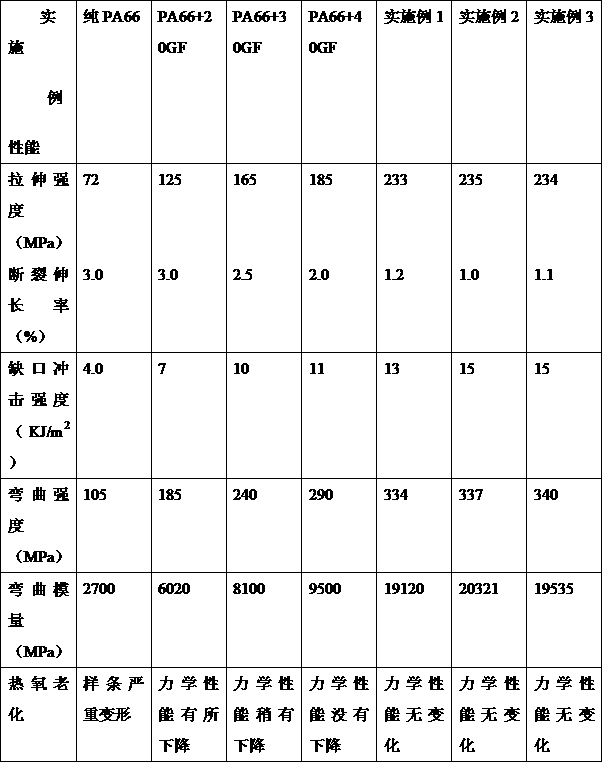

Embodiment 1

[0024] The high content glass fiber reinforced nylon 66 composite material in the present embodiment comprises the component of following mass percent content, nylon 66: 31.9%, non-alkali glass fiber: 62%, compatibilizer: 5%, primary antioxidant 1076: 0.3%, auxiliary antioxidant 168: 0.3%, lubricant calcium stearate: 0.5%, among them, the surface of the alkali-free glass fiber is coated with 0.3% carbon nanotube reinforcement layer, and the length of the alkali-free glass fiber is 1.5 -2.0mm, the diameter is 9-11μm, the molecular weight of nylon 66 is 17000-17500;

[0025] Add the above nylon 66, compatibilizer, main antioxidant, auxiliary antioxidant and lubricant into the high-speed mixer and mix evenly. The speed of the high-speed mixer is 350rpm / min. After mixing for 5 minutes, add the materials to the The main feeding hopper of the screw extruder, and the alkali-free glass fiber is added to the side feeding hopper of the twin-screw extruder at the same time, extruded and ...

Embodiment 2

[0027]The high content glass fiber reinforced nylon 66 composite material in the present embodiment comprises the component of following mass percentage content, nylon 66: 32%, alkali-free glass fiber: 61.5%, compatibilizer: 4.8%, main antioxidant 1098: 0.4%, auxiliary antioxidant 168: 0.4%, lubricant silicone: 0.9%, among them, the surface of alkali-free glass fiber is covered with 1.0% carbon nanotube reinforcement layer, and the length of alkali-free glass fiber is 2-2.5 mm, the diameter is 10-11μm, and the molecular weight of nylon 66 is 17300-17700;

[0028] Add the above-mentioned nylon 66, compatibilizer, main antioxidant, auxiliary antioxidant and lubricant into the high-speed mixer and mix evenly. The speed of the high-speed mixer is 320rpm / min. After mixing for 6 minutes, add the materials The main feeding hopper of the screw extruder, and the alkali-free glass fiber is added to the side feeding hopper of the twin-screw extruder at the same time, extruded and granula...

Embodiment 3

[0030] The high-content glass fiber reinforced nylon 66 composite material in the present embodiment comprises the component of following mass percent content, nylon 66: 33%, alkali-free glass fiber: 61%, compatibilizer: 4.5%, main antioxidant 1010: 0.3%, auxiliary antioxidant 168: 0.4%, lubricant TAF: 0.8%, among them, the surface of alkali-free glass fiber is covered with 2% carbon nanotube reinforcement layer, and the length of alkali-free glass fiber is 2.5-3.0mm , with a diameter of 10-12 μm and a molecular weight of nylon 66 of 17500-18000;

[0031] Add the above nylon 66, compatibilizer, main antioxidant, auxiliary antioxidant and lubricant into the high-speed mixer and mix evenly. The speed of the high-speed mixer is 360rpm / min. After mixing for 7 minutes, add the materials to the The main feeding hopper of the screw extruder, and the alkali-free glass fiber is added to the side feeding hopper of the twin-screw extruder at the same time, extruded and granulated, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com