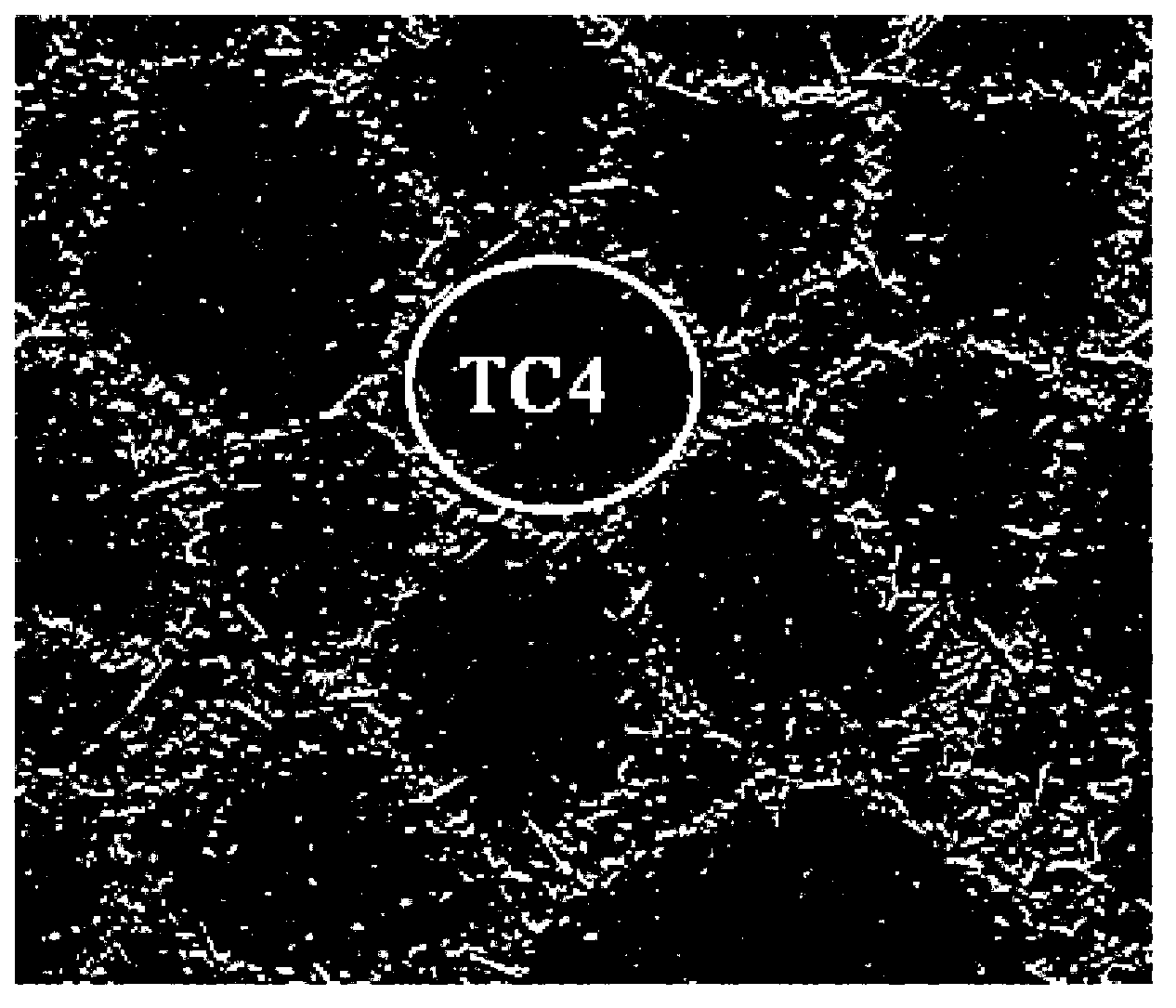

Composite soldering material, preparation method thereof and method of using composite soldering material to solder TiBw/TC4 titanium-based composite material

A technology of titanium-based composite materials and composite solders, applied in the direction of welding/cutting media/materials, welding media, manufacturing tools, etc., to achieve high-temperature strength and stiffness, high-temperature strength, and reduce the effect of compound content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

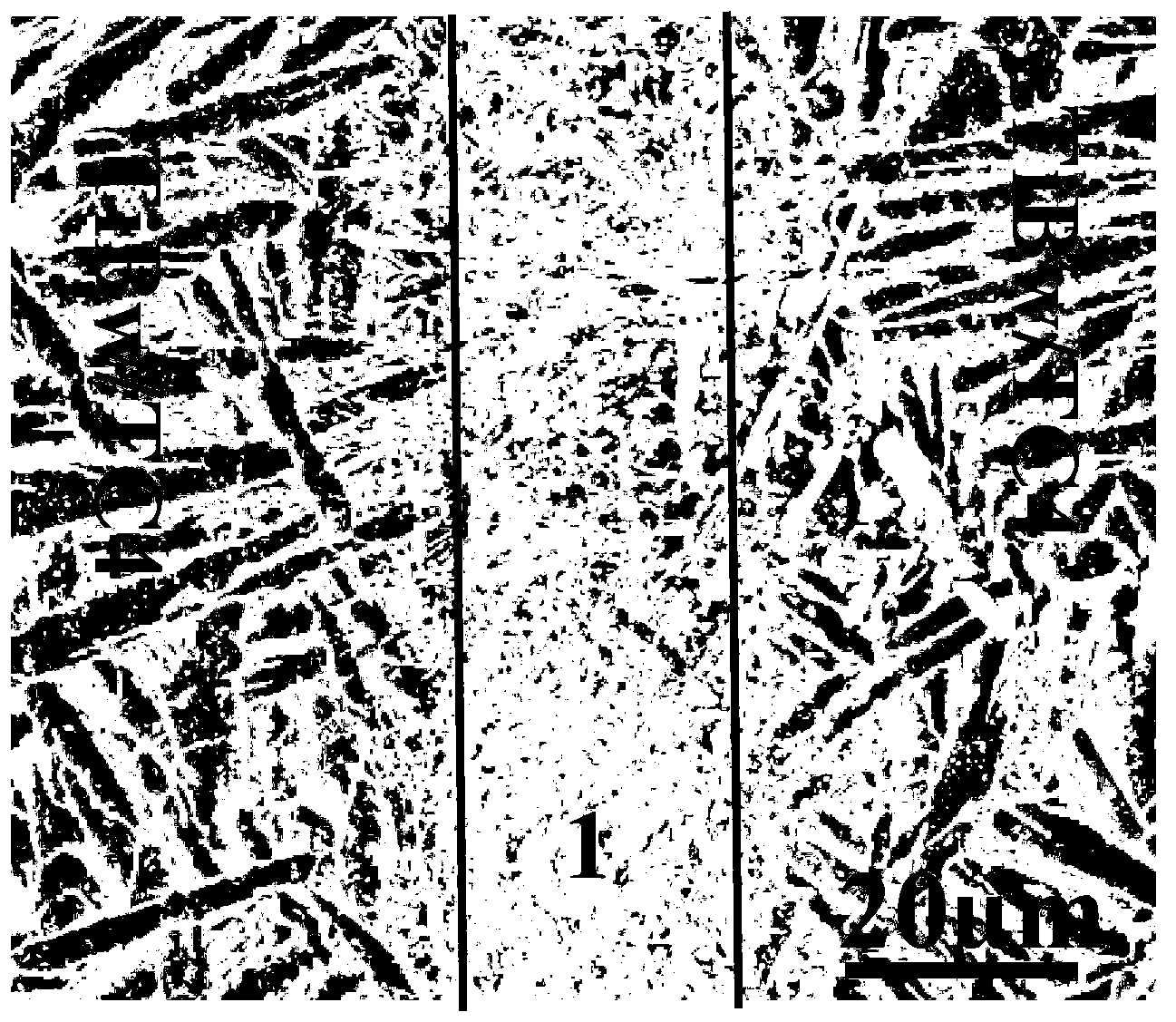

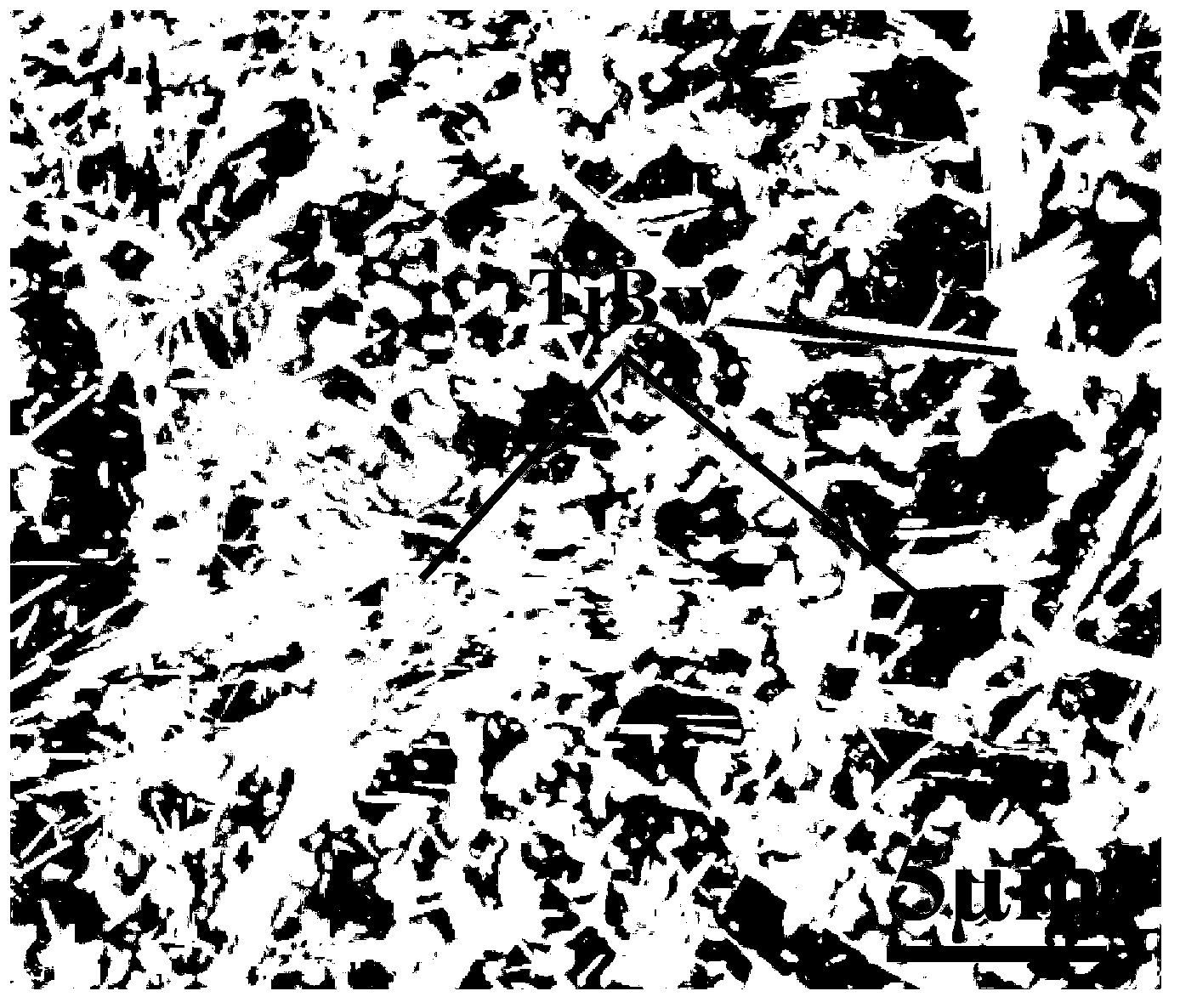

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: TiB in the composite solder 2 The volume percentage of the particles is 3% to 20%.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: TiB in the composite solder 2 The volume percentage of particles is 5% to 10%.

specific Embodiment approach 4

[0025] Specific embodiment four: prepare the method for a kind of composite solder described in embodiment one, specifically prepare according to the following steps:

[0026] TiB 2 The particles are evenly coated on the surface of the TiZrCuNi amorphous foil to complete the preparation method of the composite solder, wherein the binder is composed of hydroxyethyl cellulose and distilled water, and the mass ratio of hydroxyethyl cellulose to distilled water is 1:98~ 99.

[0027] Specific embodiment five: utilize the method for brazing TiBw / TC4 titanium-based composite material of composite brazing filler metal described in embodiment one, specifically complete according to the following steps:

[0028] 1. Use 400#, 600#, and 800# metallographic sandpaper to polish the TiBw / TC4 titanium-based composite material until the surface is bright to obtain the base material;

[0029] 2. Immerse the base metal obtained in step 1 in acetone, ultrasonically clean it for 10 minutes to 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com